Effective CdS:(Ce, Ga) Nanoparticles for Photocatalytic H2 Production Under Artificial Solar Light Exposer

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Characterizations

3. Results and Discussion

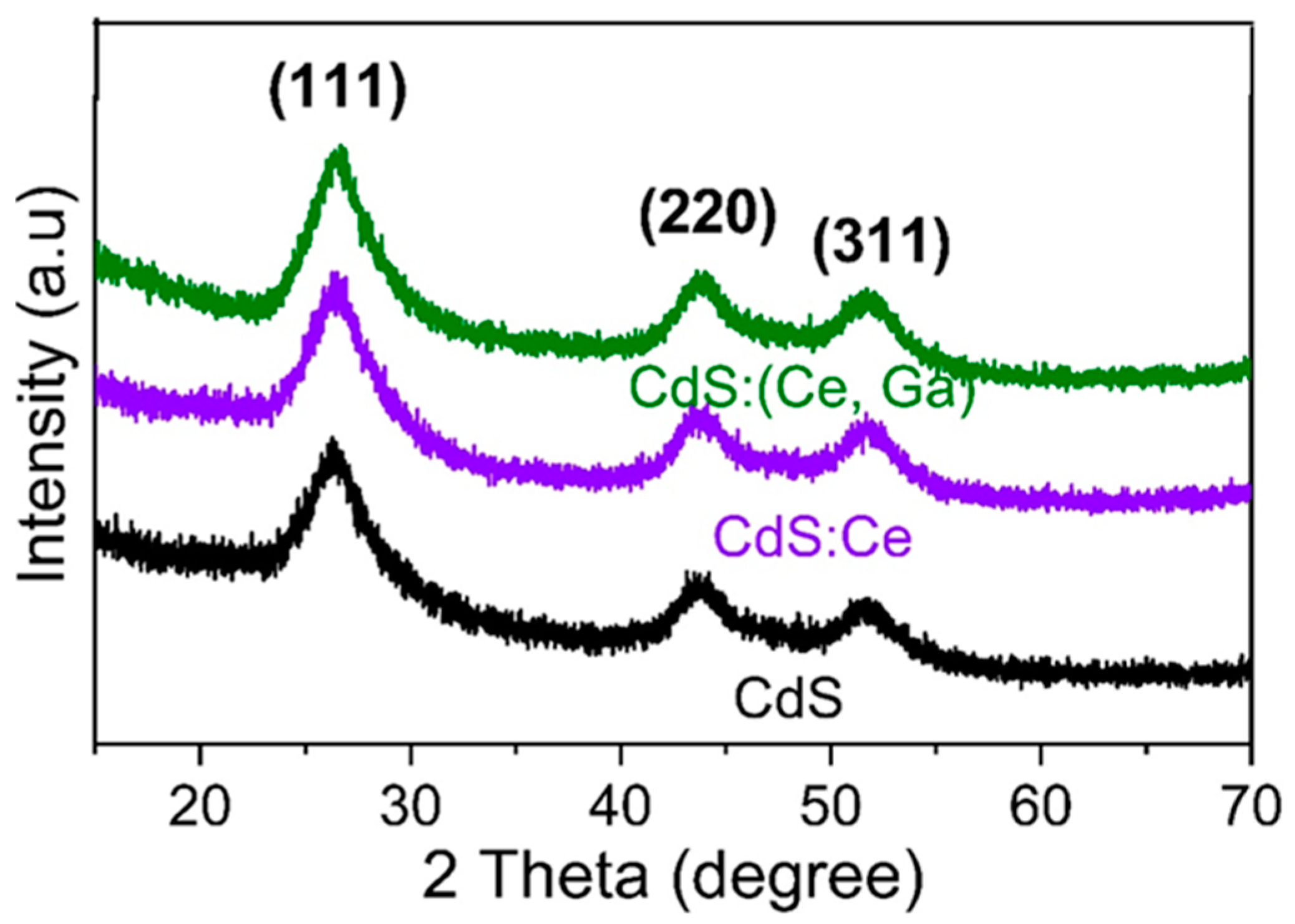

3.1. X-Ray Diffraction Studies

3.2. Micro-Raman Studies

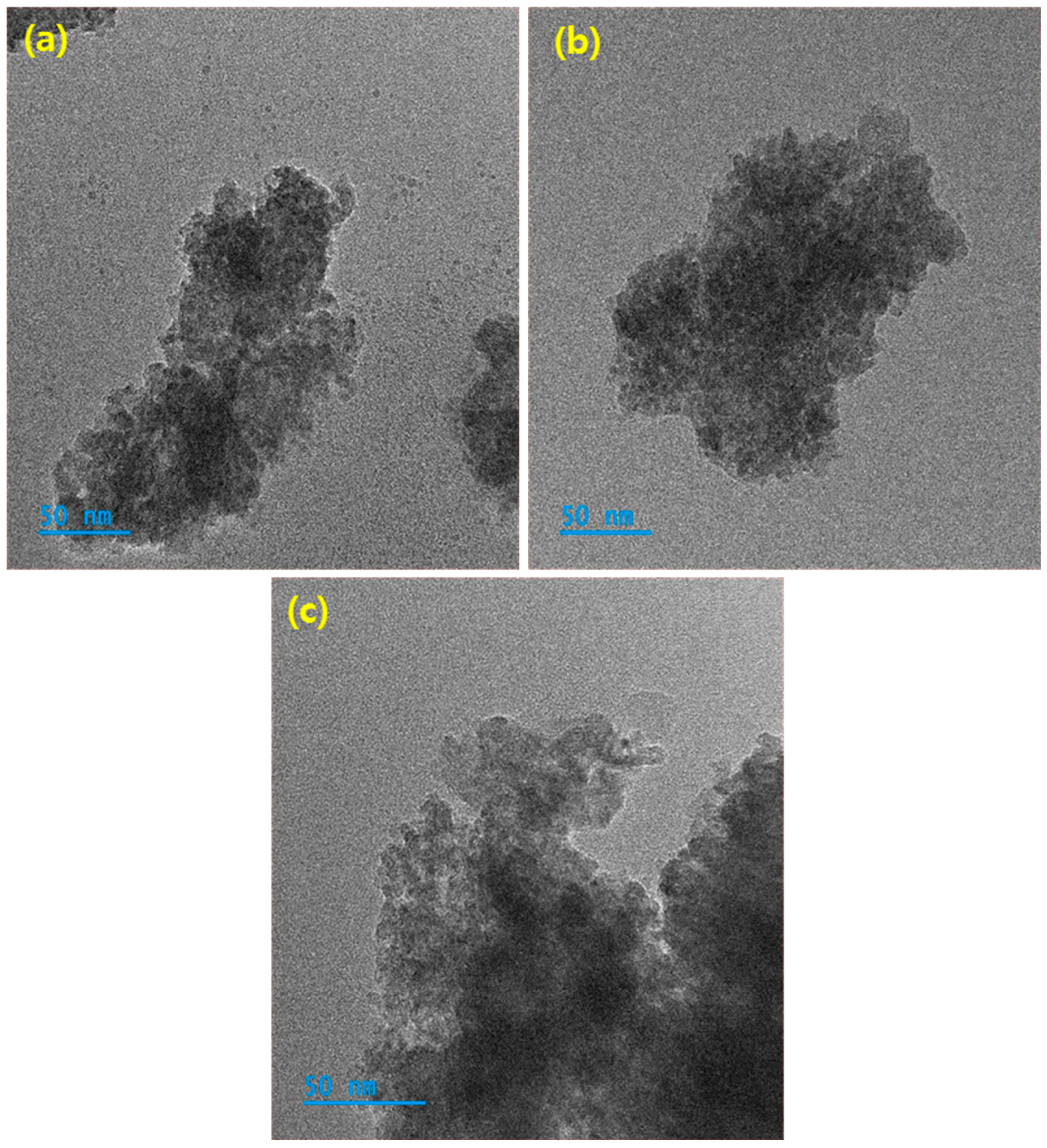

3.3. Morphology Studies

3.4. Chemical Studies

3.5. Optical and Photoluminescence Studies

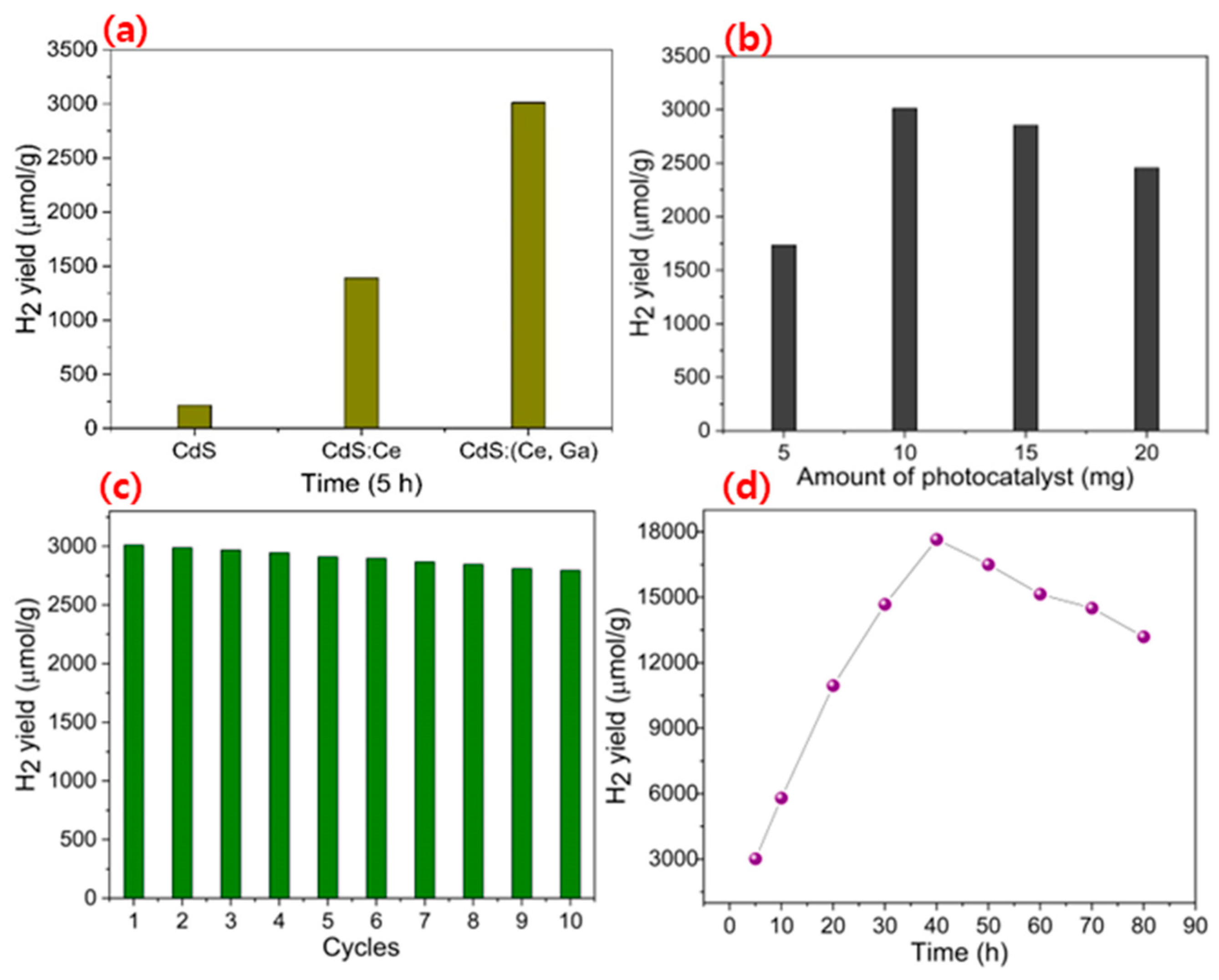

3.6. Photocatalytic H2 Production Studies

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kazemi, A.; Manteghi, F.; Tehrani, Z. Metal Electrocatalysts for Hydrogen Production in Water Splitting. ACS Omega 2024, 9, 7310–7335. [Google Scholar] [CrossRef] [PubMed]

- Xue, X.; Dong, W.; Luan, Q.; Gao, H.; Wang, G. Novel interfacial lateral electron migration pathway formed by constructing metallized CoP2/CdS interface for excellent photocatalytic hydrogen production. Appl. Catal. B Environ. 2023, 334, 122860. [Google Scholar] [CrossRef]

- Lalitha, K.; Sadanandam, G.; Kumari, V.D.; Subrahmanyam, M.; Sreedhar, B.; Hebalkar, N.Y. Highly stabilized and finely dispersed Cu2O/TiO2: A promising visible sensitive photocatalyst for continuous production of hydrogen from glycerol: Water mixtures. J. Phys. Chem. C 2010, 114, 22181–22189. [Google Scholar] [CrossRef]

- Bak, D.; Kim, J.H. Facile fabrication of pseudo-microspherical ZnO/CdS core-shell photocatalysts for solar hydrogen production by water splitting. Ceram. Int. 2017, 43, 13493–13499. [Google Scholar] [CrossRef]

- Dedong, H.; Kai, L.Y.; Yu, D.P. Multicolor photodetector of a single Er3+ doped CdS Nanoribbon. Nanoscale Res. Lett. 2015, 285, 1–10. [Google Scholar] [CrossRef]

- Zhai, J.; Wang, L.; Wang, D.; Li, H.; Zhang, Y.; He, D.Q.; Xie, T. Enhancement of gas sensing properties of CdS Nanowire/ZnO nanosphere composite materials at room temperature by visible-light activation. ACS Appl. Mater. Interfaces 2011, 3, 2253–2258. [Google Scholar] [CrossRef]

- Yuan, Y.J.; Chen, D.; Yu, Z.T.; Zou, Z.G. Cadmium sulfide-based nanomaterials for photocatalytic hydrogen production. J. Mater. Chem. A 2018, 6, 11606–11630. [Google Scholar] [CrossRef]

- Su, J.; Zhang, T.; Li, Y.; Chen, Y.; Liu, M. Photocatalytic activities of copper doped cadmium sulfide microspheres prepared by a facile ultrasonic spray-pyrolysis method. Molecules 2016, 21, 735. [Google Scholar] [CrossRef]

- Ma, Y.; Hai, G.; Liu, J.; Bao, J.; Li, Y.; Wang, G. Enhanced visible light photocatalytic hydrogen evolution by intimately contacted Ni2P decorated Ni-doped CdS nanospheres. Chem. Eng. J. 2022, 441, 136002. [Google Scholar] [CrossRef]

- Cheng, L.; Xiang, Q.; Liao, Y.; Zhang, H. CdS-Based photocatalysts. Energy Environ. Sci. 2018, 11, 1362–1391. [Google Scholar] [CrossRef]

- Chen, X.; Shangguan, W. Hydrogen production from water splitting on CdS-based photocatalysts using solar light. Front. Energy. 2013, 7, 111–118. [Google Scholar] [CrossRef]

- Fan, L.; Han, J.; Wei, K.; Ma, C.; Feng, S.; Zhou, Y.; Dai, X.; Ye, Z.; Wang, Y. Mn-doped CdS/Cu2O: An S-scheme heterojunction for photocatalytic hydrogen production. J. Alloys Compd. 2023, 960, 170382. [Google Scholar] [CrossRef]

- Chen, T.; Yang, C.; Rajendran, S.; Sawangphruk, M.; Zhang, X.; Qin, J. Utilizing the built-in electric field of p-n heterojunction to spatially separate the photogenerated charges in C, N co-doped Co3O4/CdS photocatalysts. Fuel 2023, 331, 125594–125604. [Google Scholar] [CrossRef]

- Poornaprakash, B.; Reddy, B.P.; Prasad, P.R.; Reddy, A.S.; Subramanyam, K.; Reddy, M.S.P.; Tighezza, A.M.; Sangaraju, S.; Park, S.H.; Kwon, M.W.; et al. Synthesis of highly efficient (Cr, Gd) co-doped CdS quantum dots for photocatalytic H2 evolution beneath artificial solar light irradiation. Ceram. Int. 2024, 50, 6120–6127. [Google Scholar] [CrossRef]

- Saravanan, L.; Pandurangan, A.; Jayavel, R. Synthesis and luminescence enhancement of Cerium doped CdS nanoparticles. Mater. Lett. 2012, 66, 343–345. [Google Scholar] [CrossRef]

- Giribabu, G.; Murali, G.; Reddy, D.A.; Liu, C.; Vijayalakshmi, R.P. Structural, optical and magnetic properties of Co doped CdS nanoparticles. J. Alloys Compd. 2013, 581, 363–368. [Google Scholar] [CrossRef]

- Poornaprakash, B.; Subramanyam, K.; Cheruku, R.; Kim, Y.L.; Reddy, M.S.P.; Reddy, V.R.M. Mn and Al co-doped CdS:Cr nanoparticles for spintronic applications. Mater. Sci. Semicond. Process. 2021, 134, 106055. [Google Scholar] [CrossRef]

- Beketov, I.V.; Safronov, A.P.; Medvedev, A.I.; Alonso, J.; Kurlyandskaya, G.V.; Bhagat, S.M. Iron oxide nanoparticles fabricated by electric explosion of wire: Focus on magnetic nanofluids. AIP Adv. 2012, 2, 022154. [Google Scholar] [CrossRef]

- Poornaprakash, B.; Poojitha, P.T.; Chalapathi, U.; Ramu, S.; Vijayalakshmi, R.P.; Park, S.H. Chemical synthesis, compositional, morphological, structural, optical and magnetic properties of Zn1−xDyxS nanoparticles. Ceram. Int. 2016, 42, 8092–8097. [Google Scholar] [CrossRef]

- Poornaprakash, B.; Chalapathi, U.; Vattikuti, S.V.P.; Sekhar, M.C.; Reddy, B.P.; Poojitha, P.T.; Reddy, M.S.P.; Suh, Y.; Park, S.H. Enhanced fluorescence efficiency and photocatalytic activity of ZnS quantum dots through Ga doping. Ceram. Int. 2019, 45, 2289–2294. [Google Scholar] [CrossRef]

- Poornaprakash, B.; Chalapathi, U.; Subramanyam, K.; Vattikuti, S.V.P.; Suh, Y.; Park, S.H. Effects of Ce incorporation on the structural, morphological, optical, magnetic, and photocatalytic characteristics of ZnO nanoparticles. Mater. Res. Express 2019, 6, 125075. [Google Scholar] [CrossRef]

- Giribabu, G.; Murali, G.; Reddy, D.A.; Sambasivam, S.; Vijayalakshmi, R.P. Structural, optical and magnetic properties of cobalt and aluminum codoped CdS nanoparticles. Mater. Lett. 2014, 126, 119–122. [Google Scholar] [CrossRef]

- Poornaprakash, B.; Chalapathi, U.; Kumar, M.; Subramanyam, K.; Vattikuti, S.V.P.; Reddy, M.S.P.; Park, S.H. Enhanced photocatalytic activity and hydrogen evolution of CdS nanoparticles through Er doping. Ceram. Int. 2020, 46, 21728–21735. [Google Scholar] [CrossRef]

- Giribabu, G.; Murali, G.; Vijayalakshmi, R.P. Structural, magnetic and optical properties of cobalt and manganese codoped CdS nanoparticles. Mater. Lett. 2014, 117, 298–301. [Google Scholar] [CrossRef]

- Liu, Y.; Ding, S.; Shi, Y.; Liu, X.; Wu, Z.; Jiang, Q.; Zhou, T.; Liu, N.; Hu, J. Construction of CdS/CoOx core-shell nanorods for efficient photocatalytic H2 evolution. Appl. Catal. B Environ. 2018, 234, 109–116. [Google Scholar] [CrossRef]

- Han, B.; Liu, S.; Zhang, N.; Xu, Y.Z.; Tang, Z.R. One-dimensional CdS@ MoS2 core-shell nanowires for boosted photocatalytic hydrogen evolution under visible light. Appl. Catal. B Environ. 2017, 202, 298–304. [Google Scholar] [CrossRef]

- Yin, X.L.; Li, L.L.; Jiang, W.J.; Zhang, Y.; Zhang, X.; Wan, L.J.; Hu, J.S. MoS2/CdS nanosheets-on-nanorod heterostructure for highly efficient photocatalytic H2 generation under visible light irradiation. ACS Appl. Mater. Interfaces 2016, 8, 15258–15266. [Google Scholar] [CrossRef]

- Murish, M.A.; Autade, V.; Barimah, E.K.; Panmand, R.; Kale, B.; Jh, A. Engineering of Solar Energy Harvesting Tb3+-Ion-Doped CdS Quantum Dot Glasses for Photodissociation of Hydrogen Sulfide. ACS Appl. Energy Mater. 2023, 6, 8875–8888. [Google Scholar]

- Liu, M.H.; Takahashi, Y. Boosting photocatalytic hydrogen production of CdS/BiVO4 nanoplates by transferring in-plane plasmon resonant energy of gold nanoparticles. Catal. Sci. Technol. 2014, 14, 1756–1759. [Google Scholar] [CrossRef]

- Meena, B.; Subramanyam, P.; Suryakala, D.; Biju, V.; Subramanyam, C. Efficient solar water splitting using a CdS quantum dot decorated TiO2/Ag2Se photoanode. Int. J. Hydrogen Energy 2001, 46, 34079–34088. [Google Scholar] [CrossRef]

- Sun, B.; Vorontsov, A.V.; Smirniotis, P.G. Role of Platinum Deposited on TiO2 in Phenol Photocatalytic Oxidation. Langmuir 2003, 19, 3151–3156. [Google Scholar] [CrossRef]

- Sun, B.; Reddy, E.P.; Smirniotis, P.G. Visible Light Cr(VI) Reduction and Organic Chemical Oxidation by TiO2 Photocatalysis. Environ. Sci. Technol. 2005, 39, 6251–6259. [Google Scholar] [CrossRef] [PubMed]

- Reddy, E.P.; Sun, B.; Smirniotis, P.G. Transition Metal Modified TiO2-Loaded MCM-41 Catalysts for Visible- and UV-Light Driven Photodegradation of Aqueous Organic Pollutants. J. Phys. Chem. B 2004, 108, 17198–17205. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Poojitha, P.T.; Dhanalakshmi, R.; Karim, M.R.; An, S.J.; Madhusudana Rao, K.; Mallem, S.P.R.; Kim, Y.L. Effective CdS:(Ce, Ga) Nanoparticles for Photocatalytic H2 Production Under Artificial Solar Light Exposer. J. Compos. Sci. 2025, 9, 34. https://doi.org/10.3390/jcs9010034

Poojitha PT, Dhanalakshmi R, Karim MR, An SJ, Madhusudana Rao K, Mallem SPR, Kim YL. Effective CdS:(Ce, Ga) Nanoparticles for Photocatalytic H2 Production Under Artificial Solar Light Exposer. Journal of Composites Science. 2025; 9(1):34. https://doi.org/10.3390/jcs9010034

Chicago/Turabian StylePoojitha, Pedda Thimmula, Radhalayam Dhanalakshmi, Mohammad Rezaul Karim, Sung Jin An, Kummara Madhusudana Rao, Siva Pratap Reddy Mallem, and Young Lae Kim. 2025. "Effective CdS:(Ce, Ga) Nanoparticles for Photocatalytic H2 Production Under Artificial Solar Light Exposer" Journal of Composites Science 9, no. 1: 34. https://doi.org/10.3390/jcs9010034

APA StylePoojitha, P. T., Dhanalakshmi, R., Karim, M. R., An, S. J., Madhusudana Rao, K., Mallem, S. P. R., & Kim, Y. L. (2025). Effective CdS:(Ce, Ga) Nanoparticles for Photocatalytic H2 Production Under Artificial Solar Light Exposer. Journal of Composites Science, 9(1), 34. https://doi.org/10.3390/jcs9010034