Validation of a FEM-Based Method to Predict Crack Initiation from Arbitrary-Shaped Notches

Abstract

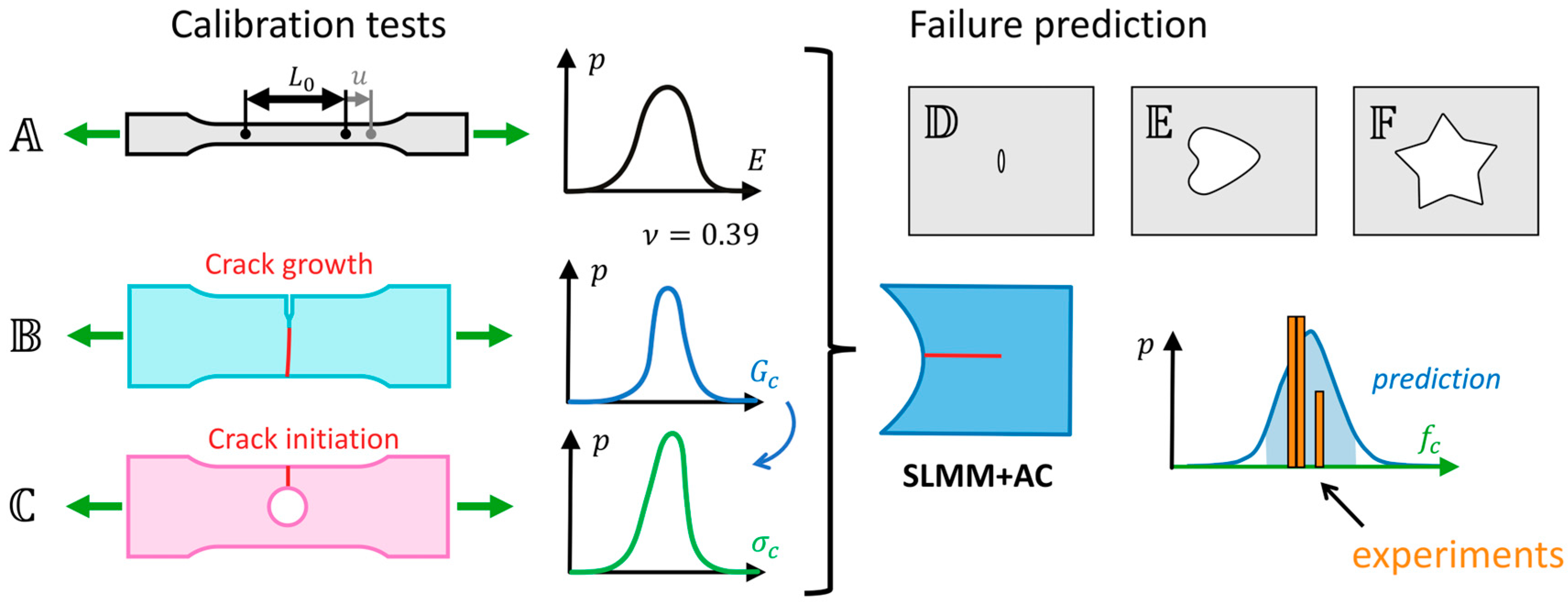

1. Introduction

2. Materials and Methods

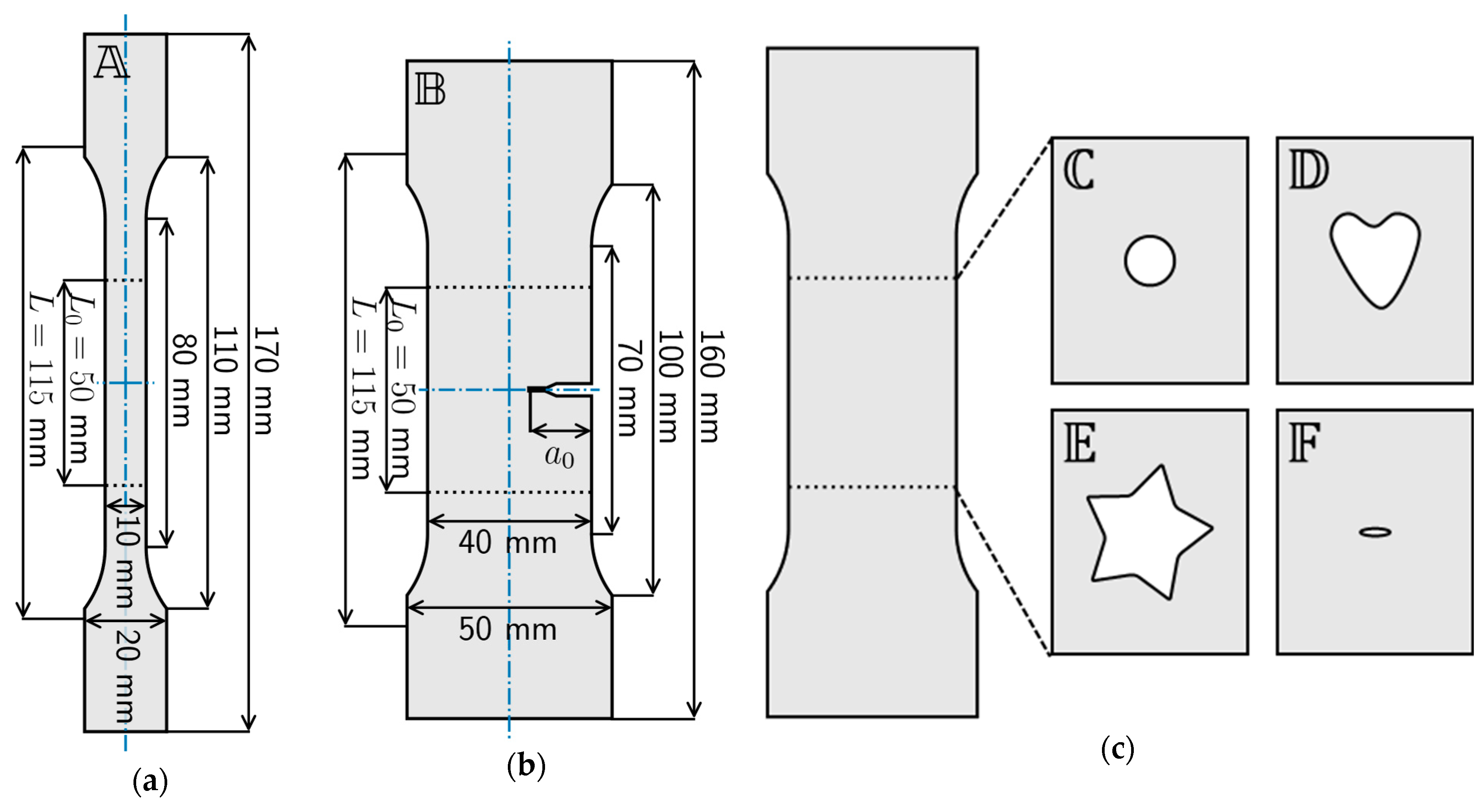

2.1. Specimen Shapes

- contains a circular cavity at the center of the specimen with a radius .

- contains a heart-shaped cavity with a width of and a height of , see Figure 2c.

- contains a star-shaped cavity whose corners are blunted by a radius .

- contains an elliptical cavity with a width of and a height of .

2.2. Experimental

2.2.1. Material and Sample Preparation

2.2.2. Testing

2.3. Evaluation

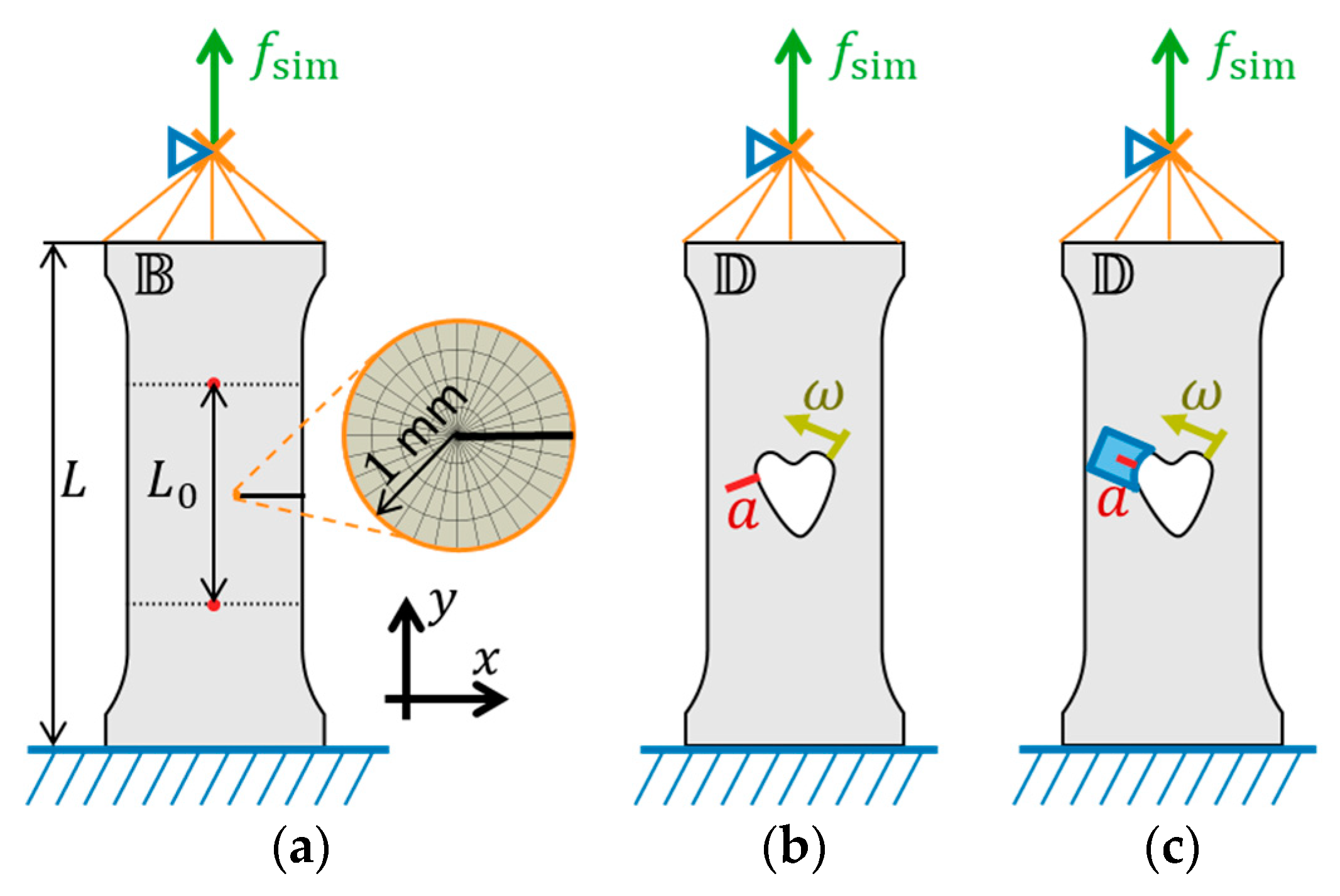

2.3.1. FEM Models

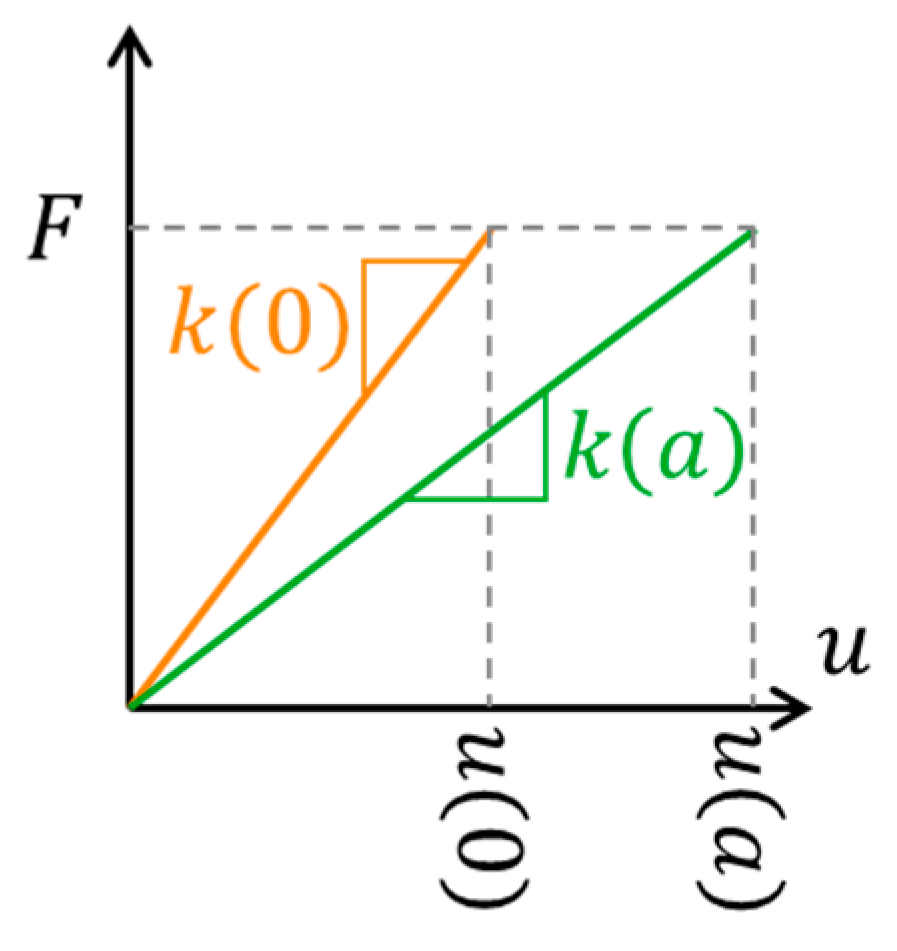

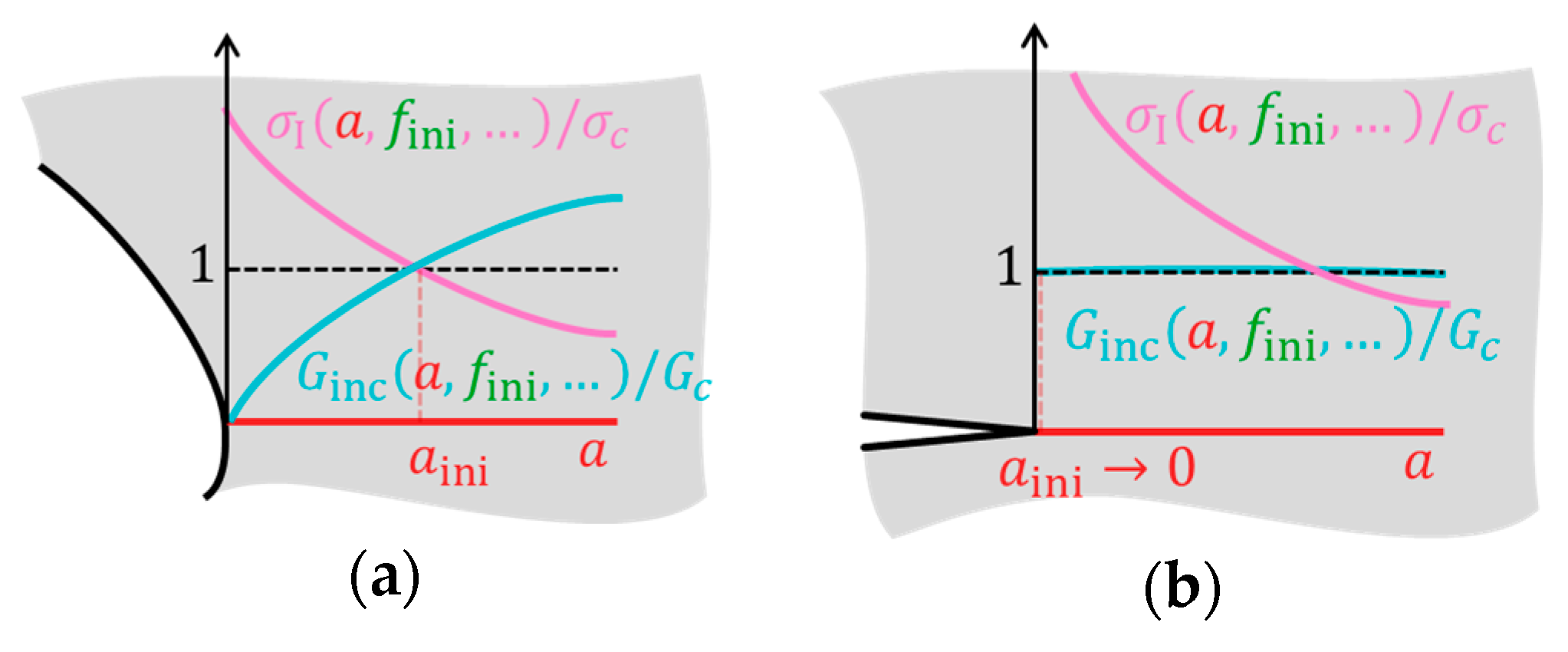

2.3.2. Coupled Criterion (CC)

2.3.3. Statistics

2.3.4. Parameter Calibration

2.3.5. Failure Prediction

2.3.6. Prediction Interval

3. Results and Discussion

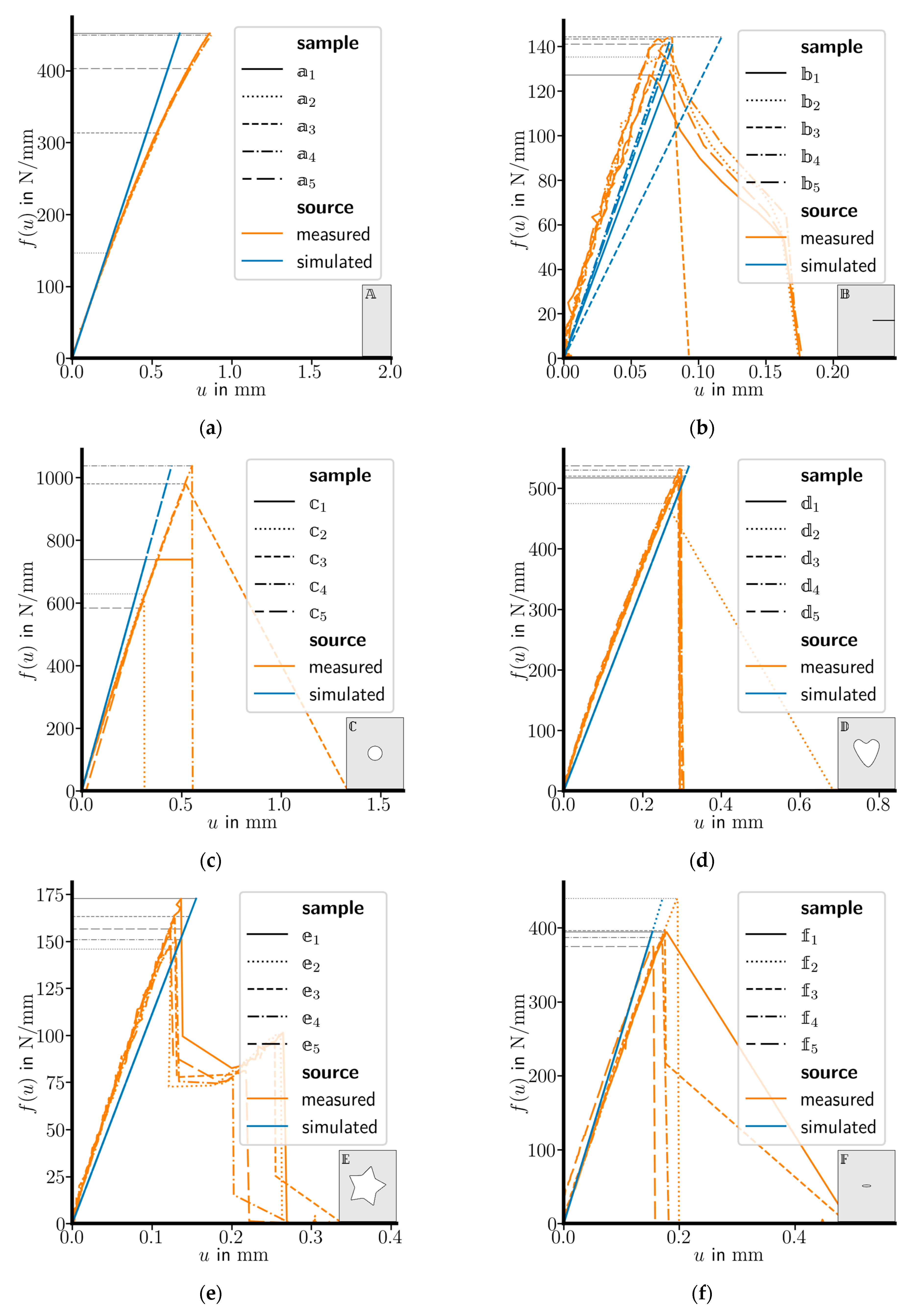

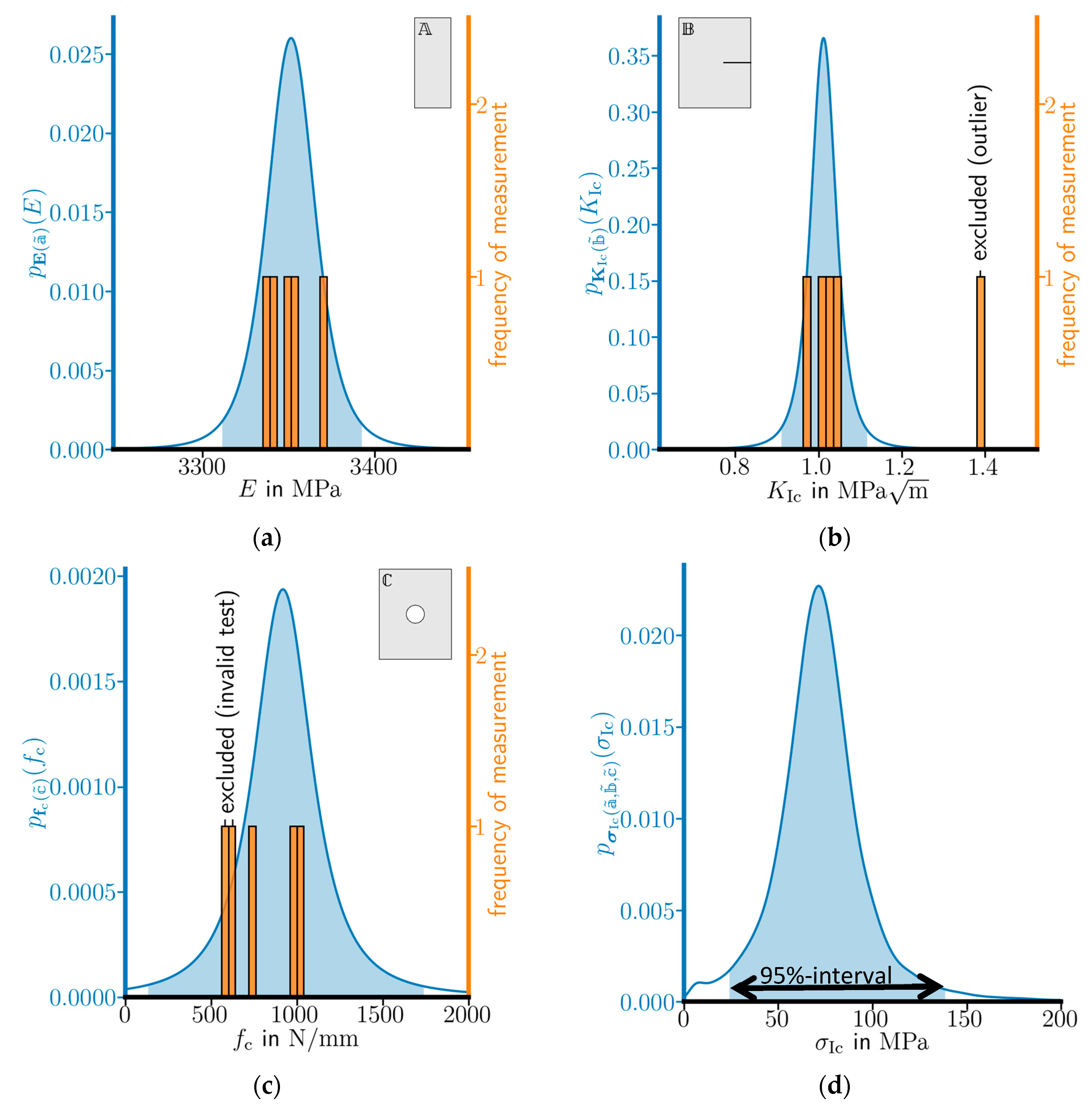

3.1. Calibration

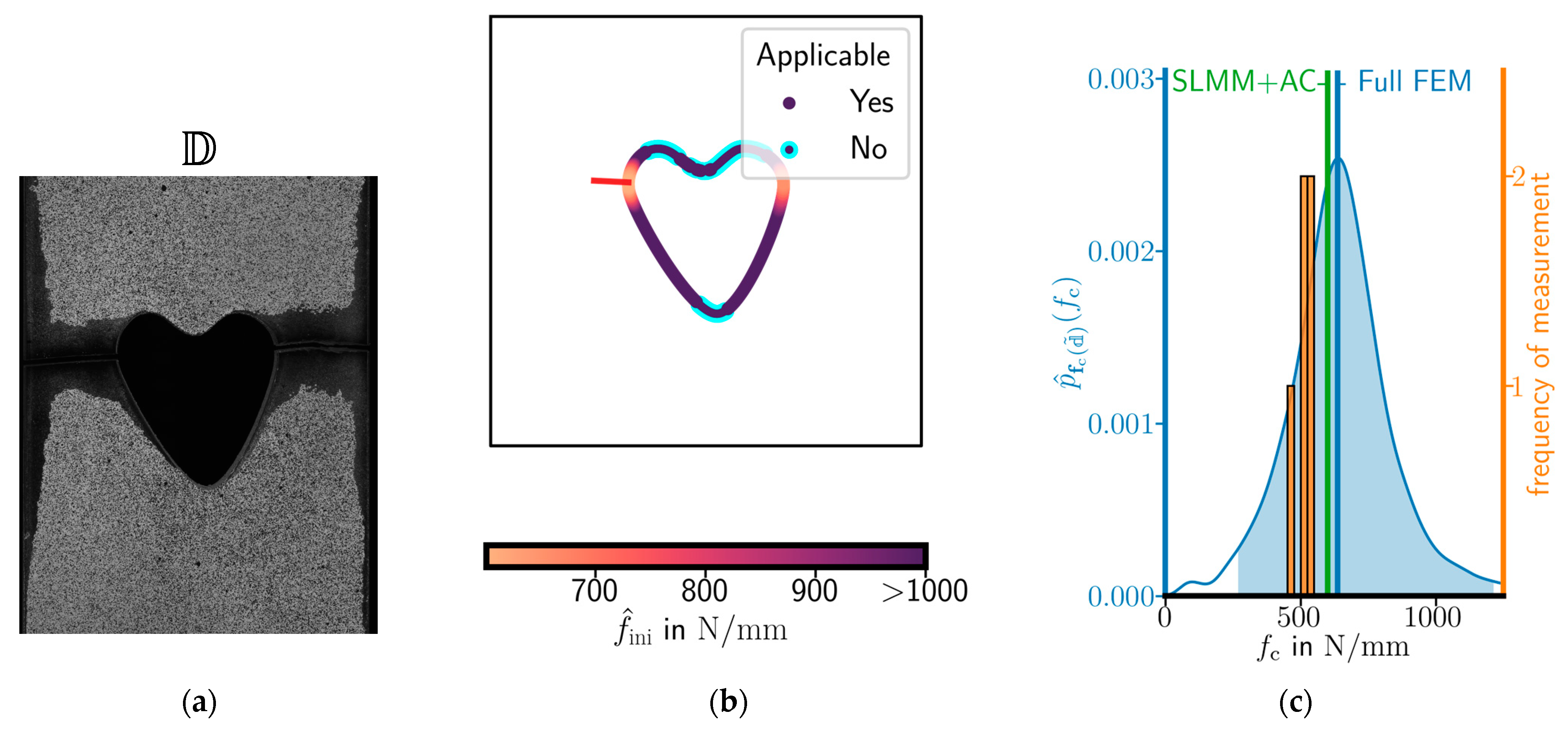

3.2. Validation

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| Geometrical quantities | Acronyms | ||

| gauge length | CC | Coupled Criterion [6] | |

| clamping length | FEA (FEM) | Finite Element Analysis | |

| width | (Finite Element Method) | ||

| thickness | Full FEM | Full Finite Element Method approach [20] | |

| crack length | MA | Matched Asymptotic [11] | |

| initial crack length | MC | Monte Carlo [31] | |

| maximum applicable crack length for SLMM+AC | PMMA | Poly(methyl methacrylate) | |

| position on the notch surface | SLMM+AC | Scaling Law based Meta-Model [20] | |

| Quantities from tensile tests | SENT | Single Edge Notched Tensile [2] | |

| displacement | TCD | Theory of Critical Distances [3] | |

| force | Tensile tests () | ||

| load defined as | a specimen shape | ||

| Material quantities | an observed tensile test of the corresponding specimen shape | ||

| Young’s modulus | all observed tensile tests of the corresponding specimen shape | ||

| Poisson’s ratio | number of observed tests in | ||

| stiffness | an unobserved tensile test of the corresponding specimen shape | ||

| material toughness for mode I | Statistics | ||

| fracture energy | arbitrary quantity | ||

| critical stress | random quantity measured in the test | ||

| Irwin’s length | true mean value for tests of the specimen shape | ||

| Young’s modulus | true standard deviation for tests of the specimen shape | ||

| Computed quantities | random quantity for the mean value measured in the tests | ||

| strain energy | random quantity for the standard deviation measured in the tests | ||

| J-Integral | Cumulative probability distribution of some random quantity | ||

| (in-plane) major principal stress | Probability density function of some random quantity | ||

| incremental energy release rate | Estimator for the random quantity | ||

| Sub- and superscripts | Student’s t-distribution with degrees of freedom [30] | ||

| arbitrary quantity | Normal distribution with mean and standard deviation [31] | ||

| corresponds to the Full FEM approach | |||

| corresponds to the SLMM+AC approach | |||

| corresponds to a position where SLMM+AC is applicable | |||

| corresponds to a position where SLMM+AC is not applicable | |||

| corresponds to a FEM simulation | |||

| corresponds to a crack initiation at a specific position | |||

| critical value | |||

| lower bound for a quantity | |||

Appendix A. Incremental Energy Release Rate

References

- Christensen, R.M. The Theory of Materials Failure, 1st ed.; Oxford University Press: Oxford, UK, 2013; ISBN 978-0-19-966211-1. [Google Scholar]

- Anderson, T.L. Fracture Mechanics: Fundamentals and Applications; CRC Press: Boca Raton, FL, USA, 1991; ISBN 978-0-8493-4277-6. [Google Scholar]

- Taylor, D. Predicting the Fracture Strength of Ceramic Materials Using the Theory of Critical Distances. Eng. Fract. Mech. 2004, 71, 2407–2416. [Google Scholar] [CrossRef]

- Taylor, D.; Cornetti, P.; Pugno, N. The Fracture Mechanics of Finite Crack Extension. Eng. Fract. Mech. 2005, 72, 1021–1038. [Google Scholar] [CrossRef]

- Cornetti, P.; Pugno, N.; Carpinteri, A.; Taylor, D. Finite Fracture Mechanics: A Coupled Stress and Energy Failure Criterion. Eng. Fract. Mech. 2006, 73, 2021–2033. [Google Scholar] [CrossRef]

- Leguillon, D. Strength or Toughness? A Criterion for Crack Onset at a Notch. Eur. J. Mech. A/Solids 2002, 21, 61–72. [Google Scholar] [CrossRef]

- Doitrand, A.; Duminy, T.; Girard, H.; Chen, X. A Review of the Coupled Criterion. J. Theor. Comput. Appl. Mech. 2024. [Google Scholar] [CrossRef]

- Leguillon, D.; Yosibash, Z. Crack Onset at a V-Notch. Influence of the Notch Tip Radius. Int. J. Fract. 2003, 122, 1–21. [Google Scholar] [CrossRef]

- Yosibash, Z.; Priel, E.; Leguillon, D. A Failure Criterion for Brittle Elastic Materials under Mixed-Mode Loading. Int. J. Fract. 2006, 141, 291–312. [Google Scholar] [CrossRef]

- Leguillon, D.; Quesada, D.; Putot, C.; Martin, E. Prediction of Crack Initiation at Blunt Notches and Cavities—Size Effects. Eng. Fract. Mech. 2007, 74, 2420–2436. [Google Scholar] [CrossRef]

- Doitrand, A.; Martin, E.; Leguillon, D. Numerical Implementation of the Coupled Criterion: Matched Asymptotic and Full Finite Element Approaches. Finite Elem. Anal. Des. 2020, 168, 103344. [Google Scholar] [CrossRef]

- Yosibash, Z.; Mendelovich, V.; Gilad, I.; Bussiba, A. Can the Finite Fracture Mechanics Coupled Criterion Be Applied to V-Notch Tips of a Quasi-Brittle Steel Alloy? Eng. Fract. Mech. 2022, 269, 108513. [Google Scholar] [CrossRef]

- Sapora, A.; Torabi, A.R.; Etesam, S.; Cornetti, P. Finite Fracture Mechanics Crack Initiation from a Circular Hole. Fatigue Fract. Eng. Mater. Struct. 2018, 41, 1627–1636. [Google Scholar] [CrossRef]

- Doitrand, A.; Sapora, A. Nonlinear Implementation of Finite Fracture Mechanics: A Case Study on Notched Brazilian Disk Samples. Int. J. Non-Linear Mech. 2020, 119, 103245. [Google Scholar] [CrossRef]

- Li, X.; Xie, Z.; Zhao, W.; Zhang, Y.; Gong, Y.; Hu, N. Failure Prediction of Irregular Arranged Multi-Bolt Composite Repair Based on Finite Fracture Mechanics Model. Eng. Fract. Mech. 2021, 242, 107456. [Google Scholar] [CrossRef]

- Ferrian, F.; Cornetti, P.; Marsavina, L.; Sapora, A. Finite Fracture Mechanics and Cohesive Crack Model: Size Effects through a Unified Formulation. Frat. Integrità Strutt. 2022, 16, 496–509. [Google Scholar] [CrossRef]

- Romani, R.; Bornert, M.; Leguillon, D.; Le Roy, R.; Sab, K. Detection of Crack Onset in Double Cleavage Drilled Specimens of Plaster under Compression by Digital Image Correlation—Theoretical Predictions Based on a Coupled Criterion. Eur. J. Mech. A/Solids 2015, 51, 172–182. [Google Scholar] [CrossRef]

- Li, J.; Leguillon, D. Finite Element Implementation of the Coupled Criterion for Numerical Simulations of Crack Initiation and Propagation in Brittle Materials. Theor. Appl. Fract. Mech. 2018, 93, 105–115. [Google Scholar] [CrossRef]

- Molnár, G.; Doitrand, A.; Estevez, R.; Gravouil, A. Toughness or Strength? Regularization in Phase-Field Fracture Explained by the Coupled Criterion. Theor. Appl. Fract. Mech. 2020, 109, 102736. [Google Scholar] [CrossRef]

- Rettl, M.; Pletz, M.; Schuecker, C. Efficient Prediction of Crack Initiation from Arbitrary 2D Notches. Theor. Appl. Fract. Mech. 2022, 119, 103376. [Google Scholar] [CrossRef]

- Bažant, Z.P. Size Effect in Blunt Fracture: Concrete, Rock, Metal. J. Eng. Mech. 1984, 110, 518–535. [Google Scholar] [CrossRef]

- DIN EN ISO 527-2:2012-06; Kunststoffe—Bestimmung Der Zugeigenschaften—Teil_2: Prüfbedingungen Für Form- Und Extrusionsmassen (ISO_527-2:2012); Deutsche Fassung EN_ISO_527-2:2012. Beuth Verlag GmbH: Berlin, Germany, 2012. [CrossRef]

- Kobayashi, T.; Shockey, D.A. Fracture Surface Topography Analysis (FRASTA)—Development, Accomplishments, and Future Applications. Eng. Fract. Mech. 2010, 77, 2370–2384. [Google Scholar] [CrossRef]

- Bura, E.; Seweryn, A. The Fracture Behaviour of Notched PMMA Specimens under Simple Loading Conditions—Tension and Torsion Experimental Tests. Eng. Fail. Anal. 2023, 148, 107199. [Google Scholar] [CrossRef]

- Barsoum, R.S. On the Use of Isoparametric Finite Elements in Linear Fracture Mechanics. Numer. Meth Eng. 1976, 10, 25–37. [Google Scholar] [CrossRef]

- Leguillon, D.; Martin, E.; Sevecek, O.; Bermejo, R. What Is the Tensile Strength of a Ceramic to Be Used in Numerical Models for Predicting Crack Initiation? Int. J. Fract. 2018, 212, 89–103. [Google Scholar] [CrossRef]

- Grubbs, F.E. Sample Criteria for Testing Outlying Observations. Ann. Math. Statist. 1950, 21, 27–58. [Google Scholar] [CrossRef]

- Rice, J.R. A Path Independent Integral and the Approximate Analysis of Strain Concentration by Notches and Cracks. J. Appl. Mech. 1968, 35, 379–386. [Google Scholar] [CrossRef]

- Geisser, S. Predictive Inference: An Introduction; Springer: Boston, MA, USA, 1993; ISBN 978-0-412-03471-8. [Google Scholar]

- Student The Probable Error of a Mean. Biometrika 1908, 6, 1. [CrossRef]

- Meeker, W.Q.; Hahn, G.J.; Escobar, L.A. Statistical Intervals: A Guide for Practitioners and Researchers, 2nd ed.; Wiley series in probability and statistics; Wiley: Hoboken, NJ, USA, 2017; ISBN 978-0-471-68717-7. [Google Scholar]

- Scott, D.W. Multivariate Density Estimation: Theory, Practice, and Visualization, 1st ed.; Wiley Series in Probability and Statistics; Wiley: Hoboken, NJ, USA, 1992; ISBN 978-0-471-54770-9. [Google Scholar]

- Atkins, A.G.; Lee, C.S.; Caddell, R.M. Time-Temperature Dependent Fracture Toughness of PMMA: Part 1. J. Mater. Sci. 1975, 10, 1381–1393. [Google Scholar] [CrossRef]

- Atkins, A.G.; Lee, C.S.; Caddell, R.M. Time-Temperature Dependent Fracture Toughness of PMMA: Part 2. J. Mater. Sci. 1975, 10, 1394–1404. [Google Scholar] [CrossRef]

| 1 | 3338 | 0.38 | 16.7 | 127 | 1.00 | 739 | 517 | 173 | 394 |

| 2 | 3372 | 0.38 | 14.9 | 135 | 0.98 | [b] 629 | 474 | 146 | 439 |

| 3 | 3355 | 0.39 | [a] 21 | [a] 144 | [a] 1.39 | 979 | 520 | 163 | 396 |

| 4 | 3343 | 0.40 | 14.7 | 143 | 1.02 | 1037 | 530 | 151 | 387 |

| 5 | 3349 | 0.40 | 15.4 | 141 | 1.04 | [b] 584 | 537 | 156 | 375 |

| 3351.4 | 0.39 | 15.4 | 136.5 | 1.01 | 918.3 | 515.6 | 157.8 | 398.2 | |

| 13.2 | 0.01 | 0.9 | 7.2 | 0.03 | 158.0 | 24.6 | 10.6 | 24.2 | |

| Quantiles | ||||

|---|---|---|---|---|

| 2.5% | 3311 | 0.91 | 324 | 24.1 |

| Median | 3351 | 1.01 | 398 | 71.9 |

| 97.5% | 3391 | 1.11 | 473 | 135.7 |

| Method | |||

|---|---|---|---|

| SLMM+AC | |||

| Mean | 601 | 156 | 532 |

| Full FEM | |||

| Mean | 669 | 175 | 518 |

| 2.5% | 269 | 120 | 394 |

| Median | 644 | 168 | 507 |

| 97.5% | 1215 | 271 | 712 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rettl, M.; Waly, C.; Pletz, M.; Schuecker, C. Validation of a FEM-Based Method to Predict Crack Initiation from Arbitrary-Shaped Notches. J. Compos. Sci. 2025, 9, 102. https://doi.org/10.3390/jcs9030102

Rettl M, Waly C, Pletz M, Schuecker C. Validation of a FEM-Based Method to Predict Crack Initiation from Arbitrary-Shaped Notches. Journal of Composites Science. 2025; 9(3):102. https://doi.org/10.3390/jcs9030102

Chicago/Turabian StyleRettl, Matthias, Christoph Waly, Martin Pletz, and Clara Schuecker. 2025. "Validation of a FEM-Based Method to Predict Crack Initiation from Arbitrary-Shaped Notches" Journal of Composites Science 9, no. 3: 102. https://doi.org/10.3390/jcs9030102

APA StyleRettl, M., Waly, C., Pletz, M., & Schuecker, C. (2025). Validation of a FEM-Based Method to Predict Crack Initiation from Arbitrary-Shaped Notches. Journal of Composites Science, 9(3), 102. https://doi.org/10.3390/jcs9030102