Investigating the Effects of H2 Additions to Helium and Argon Shielding Gases on TIG-Welded AISI 316L Stainless Steel

Abstract

:1. Introduction

2. Experiment Setup

2.1. Welding Machine

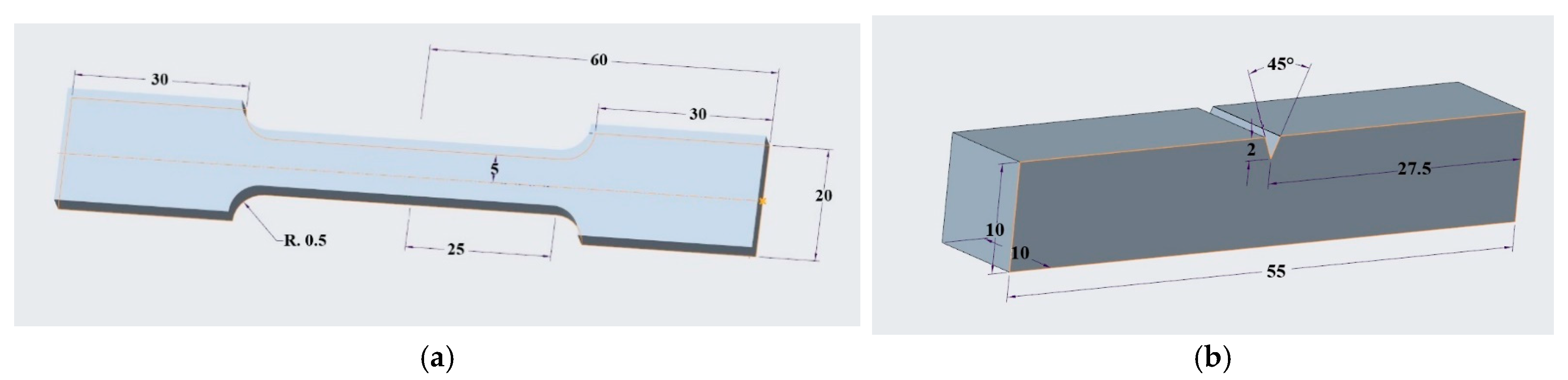

2.2. Preparation of AISI 316L Specimen

2.3. Filler Material

2.4. Shielding Gas Composition for L-27 Orthogonal Array Experimental Design

2.5. Experiment Procedure

2.6. Material Characterization

3. Results and Discussion

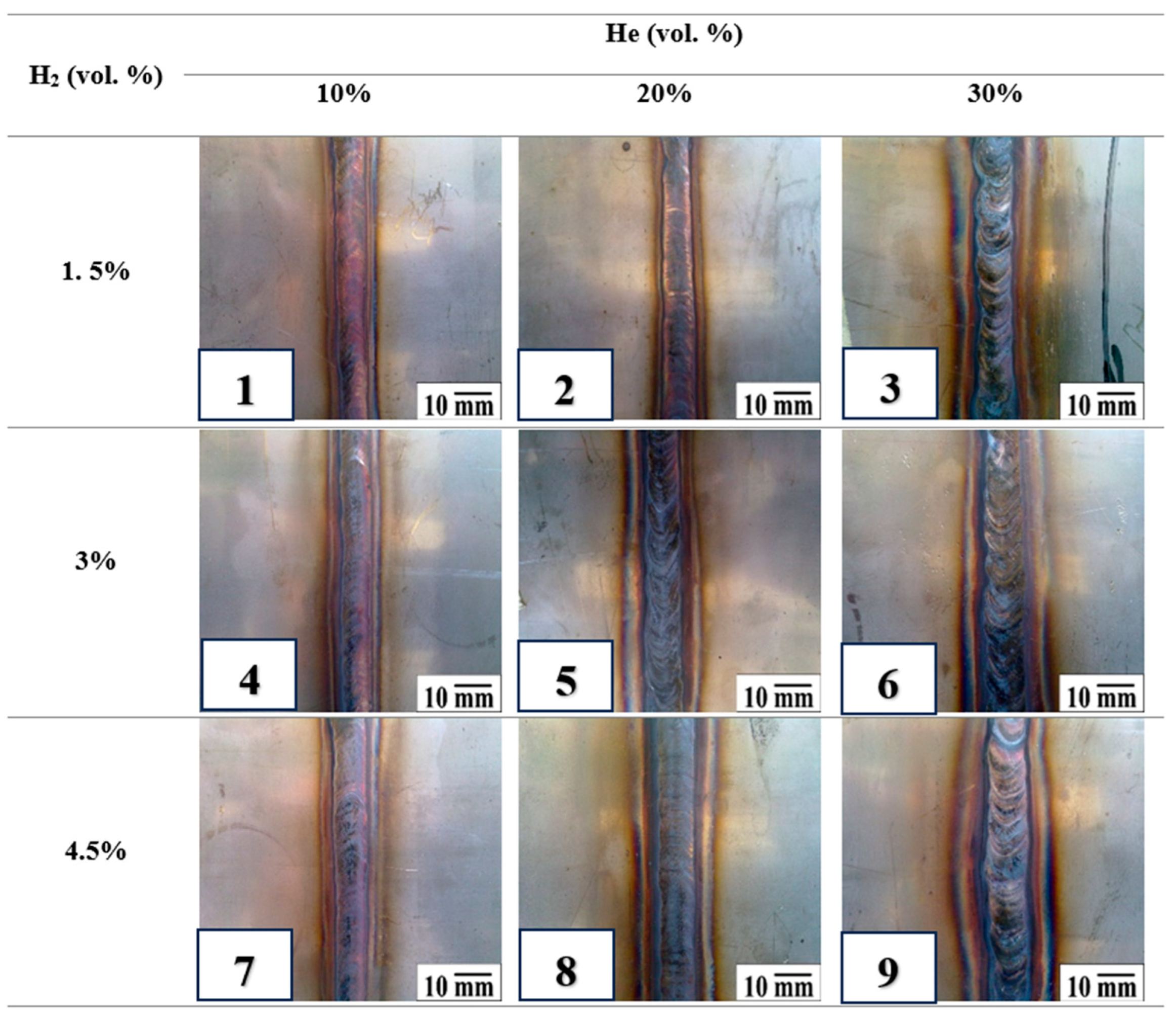

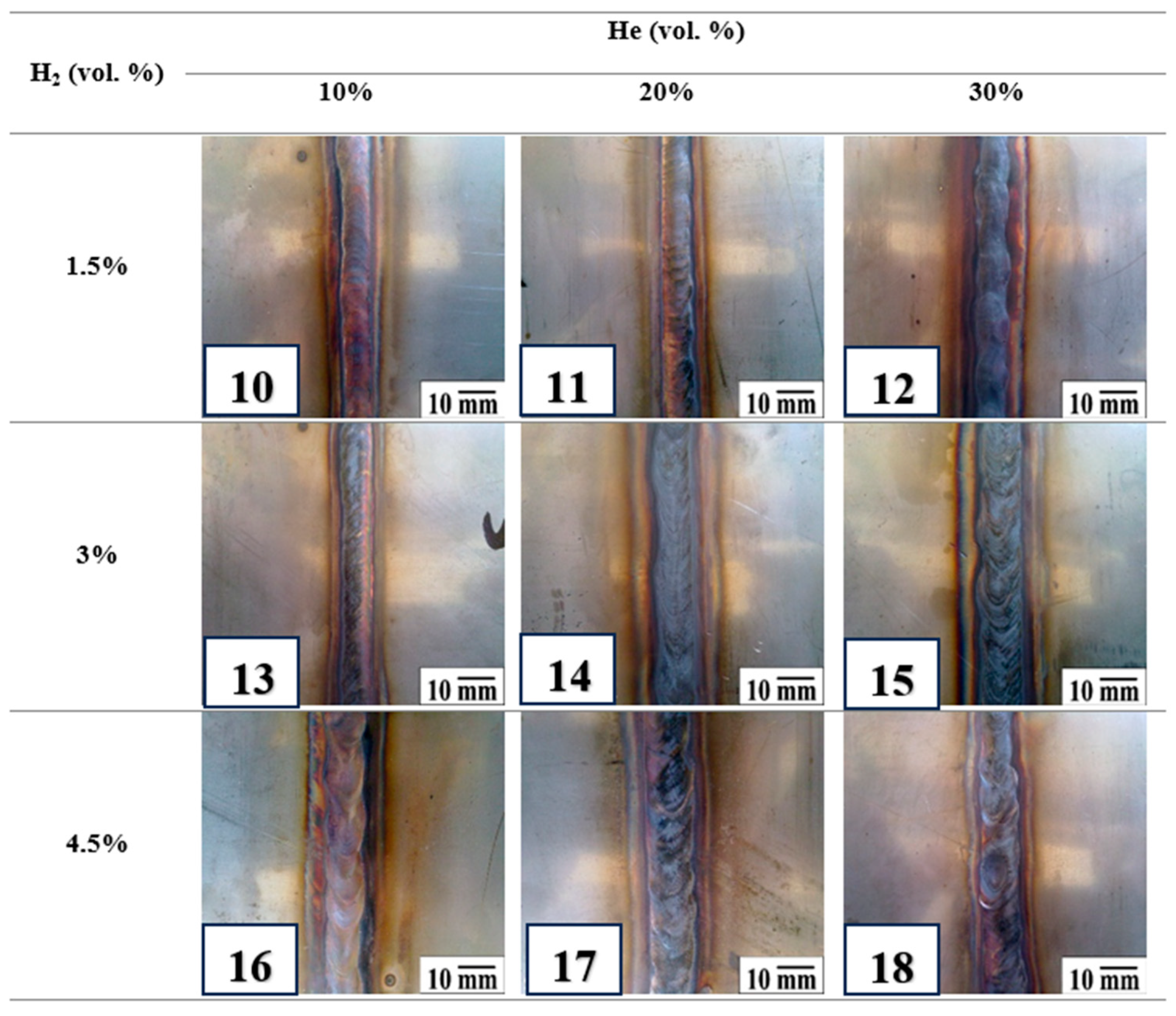

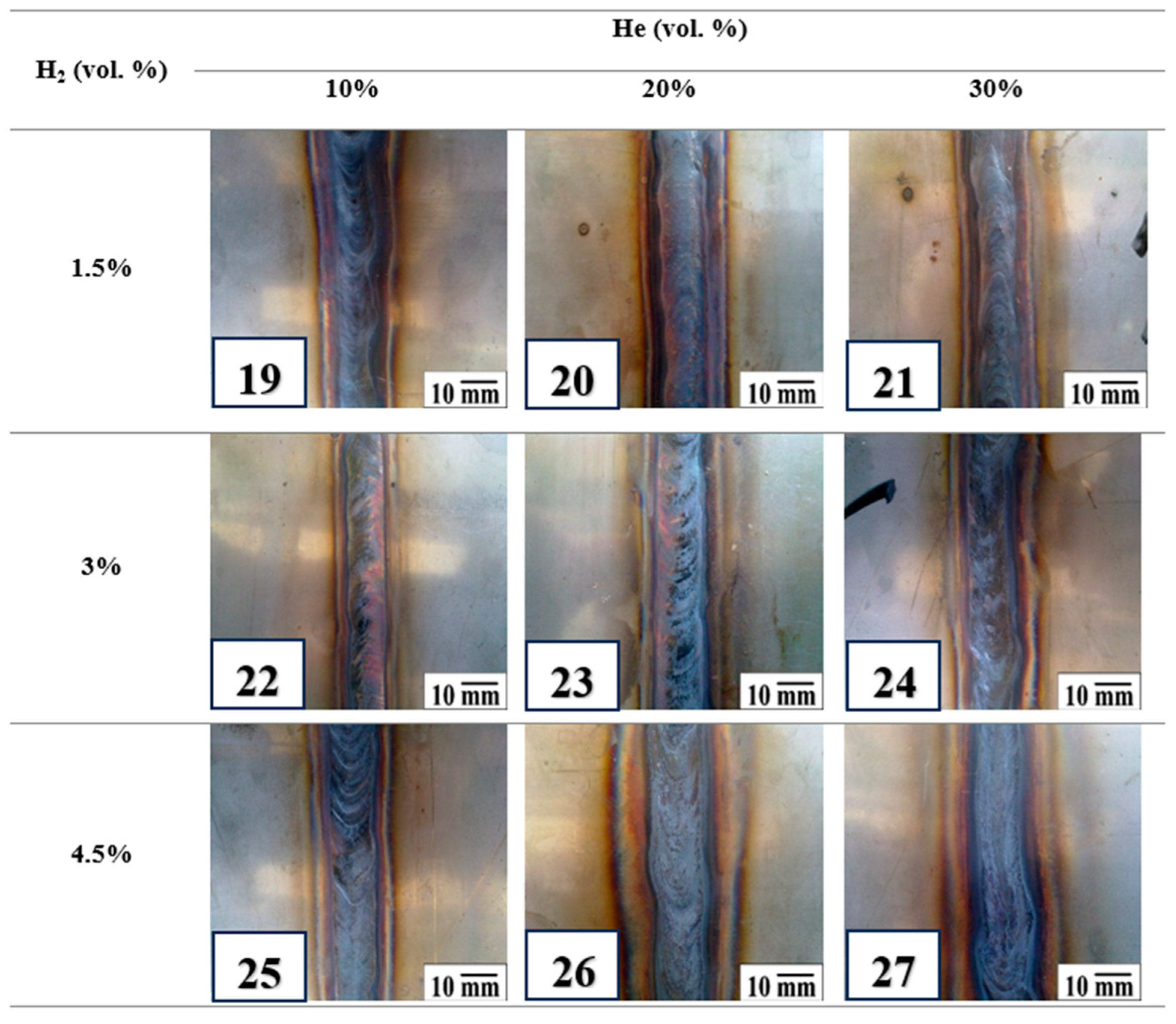

3.1. Bead Geometry Appearance

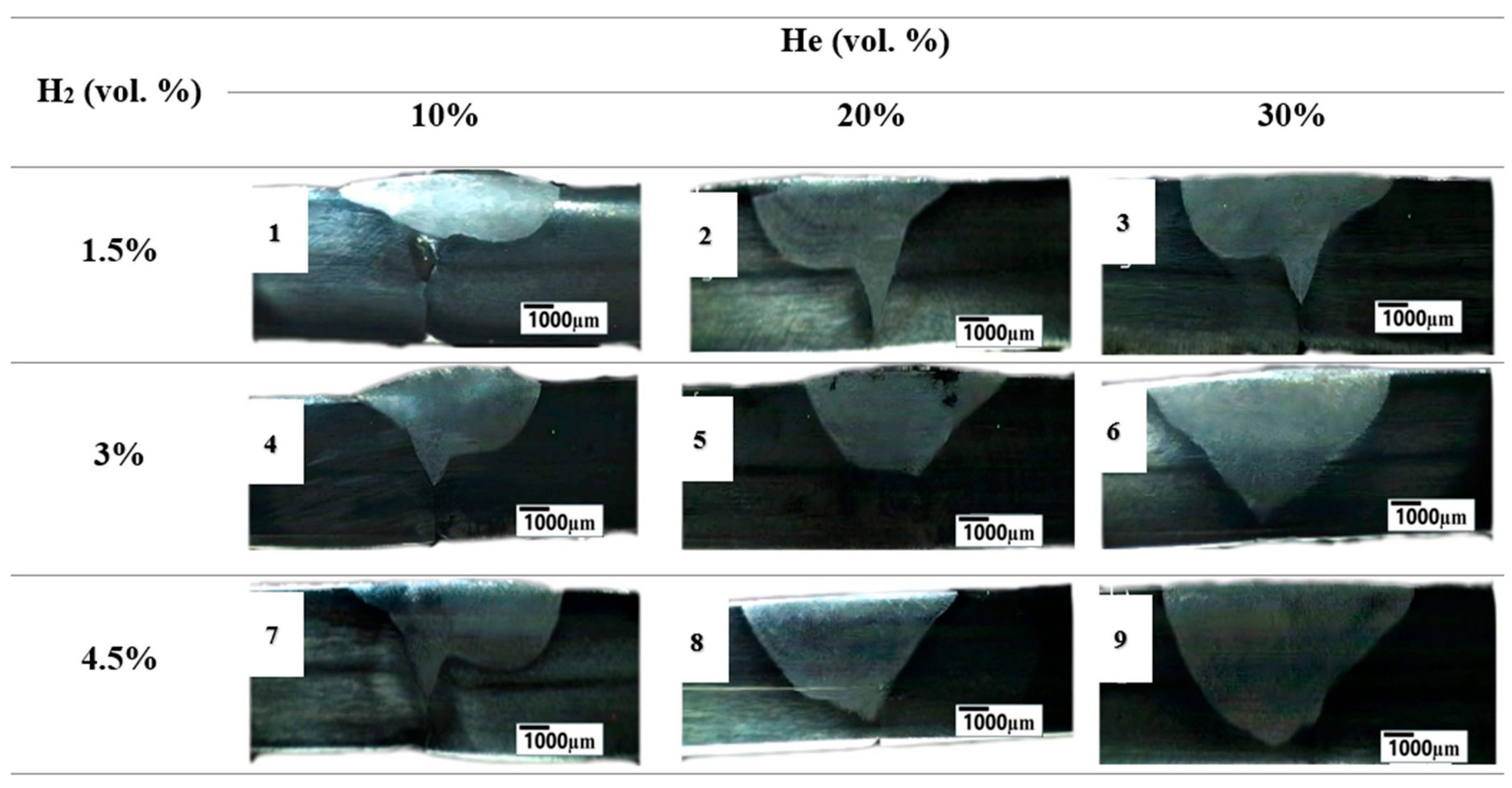

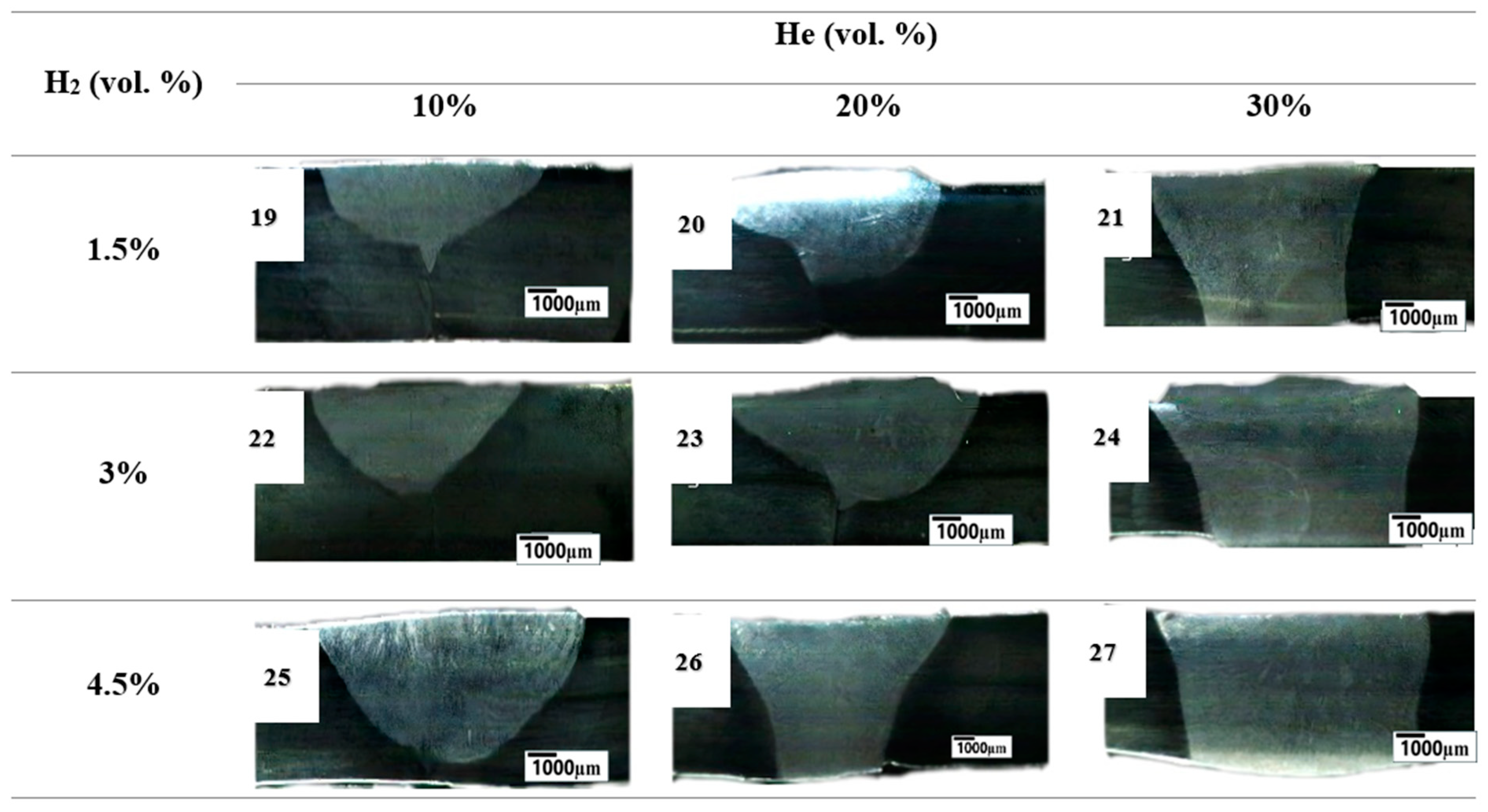

3.2. Cross-Sectional View

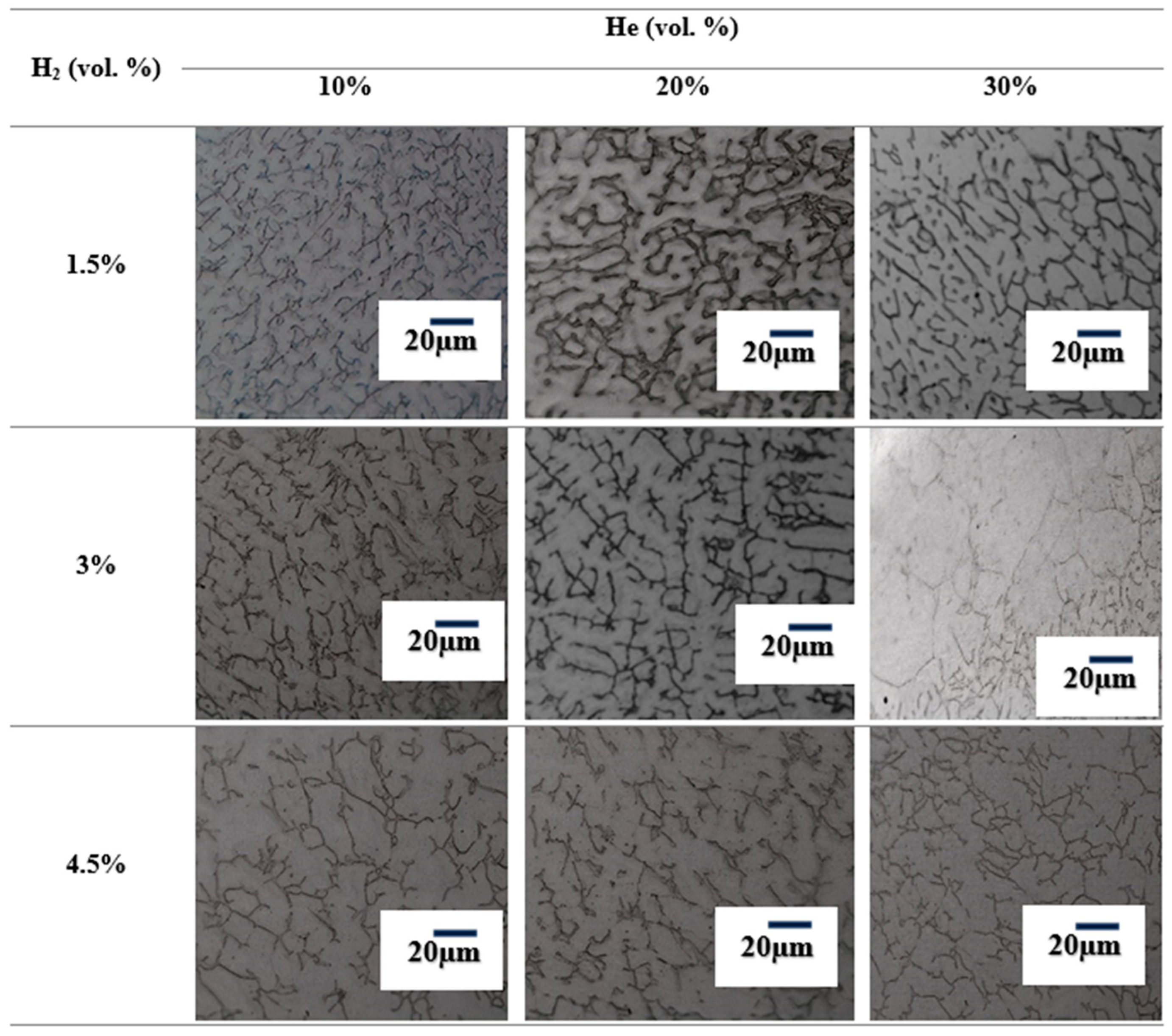

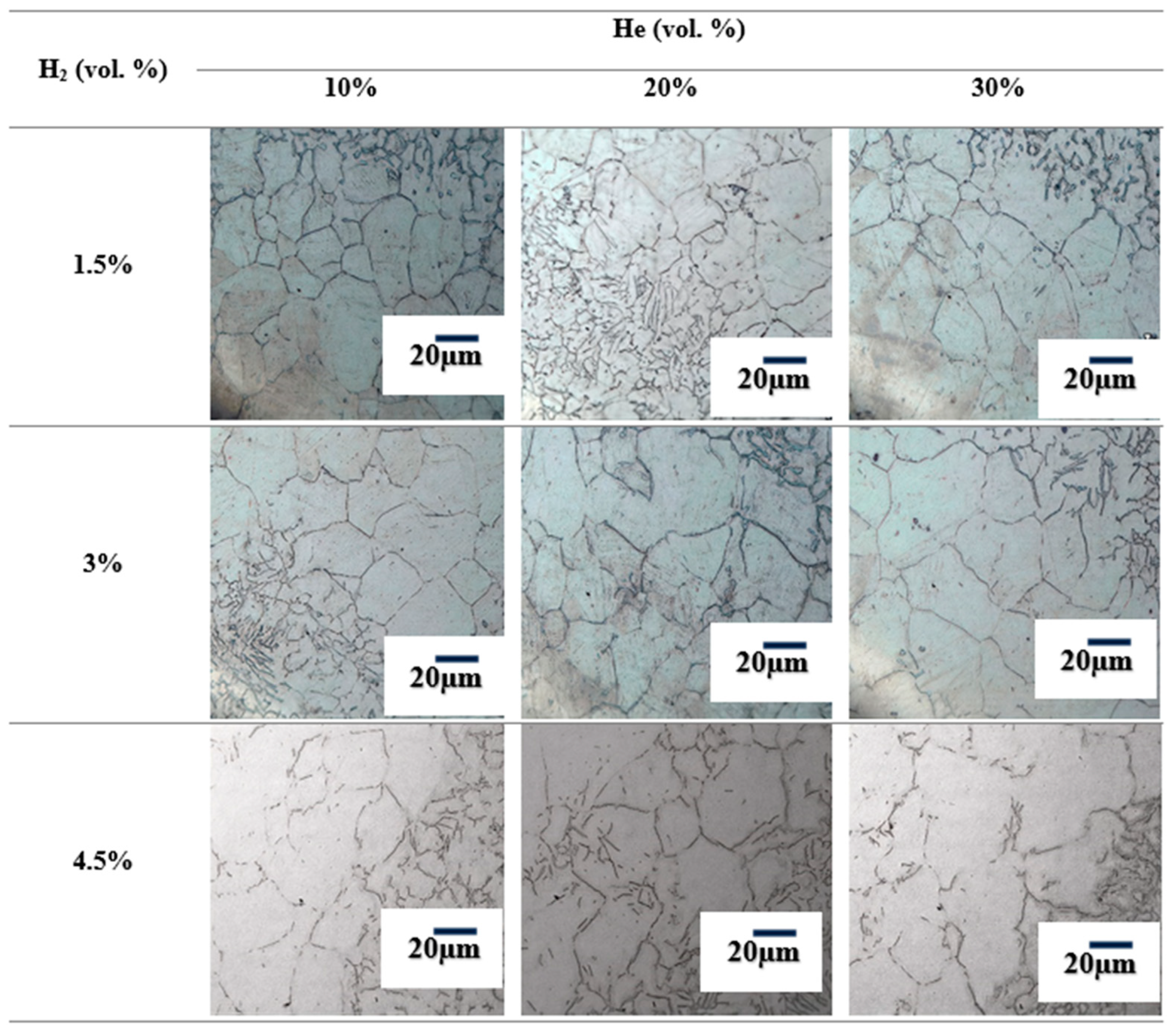

3.3. Microstructure Analysis

3.4. EDX- Analysis

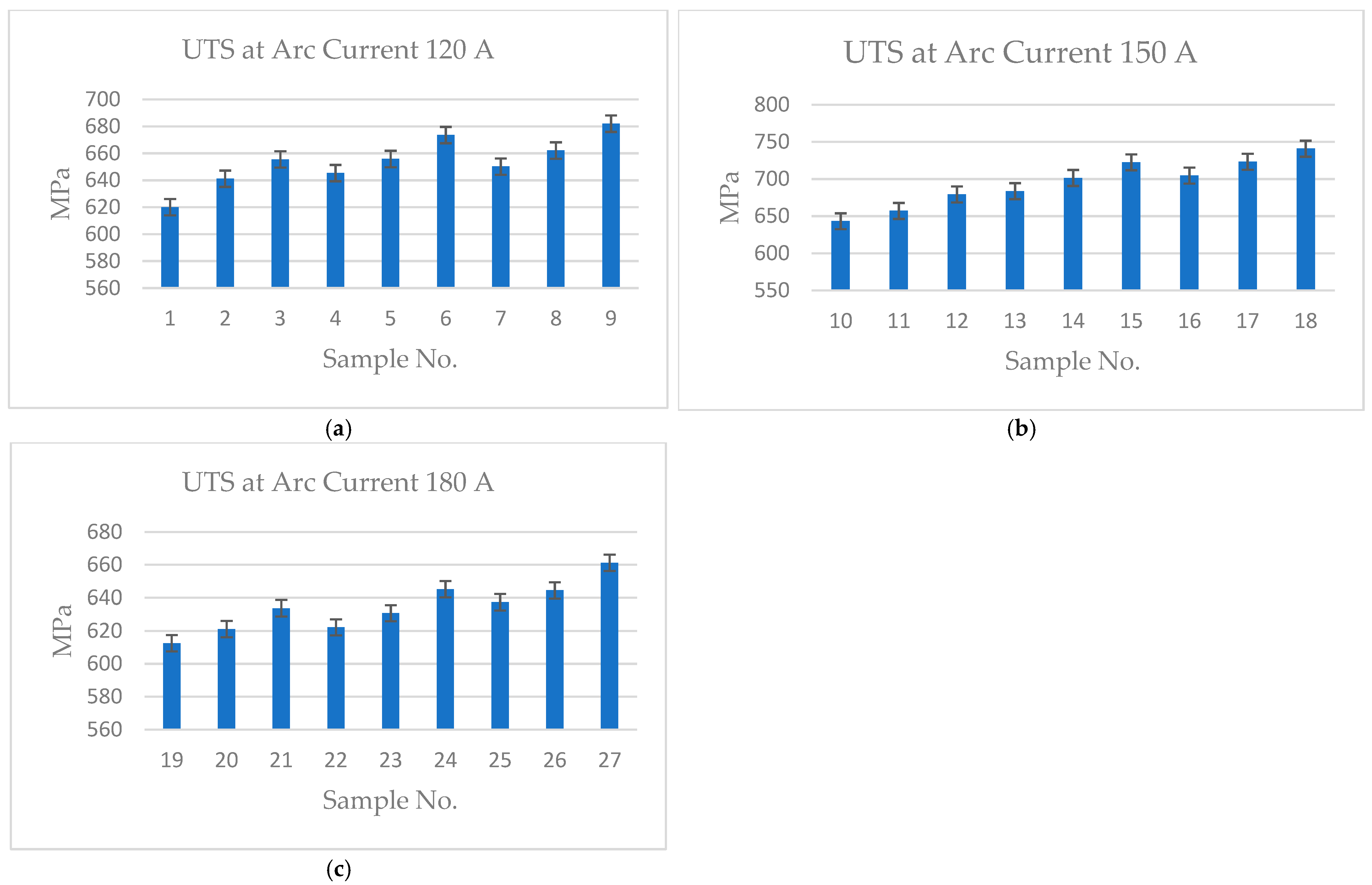

3.5. Tensile Strength and Yield Strength Analysis

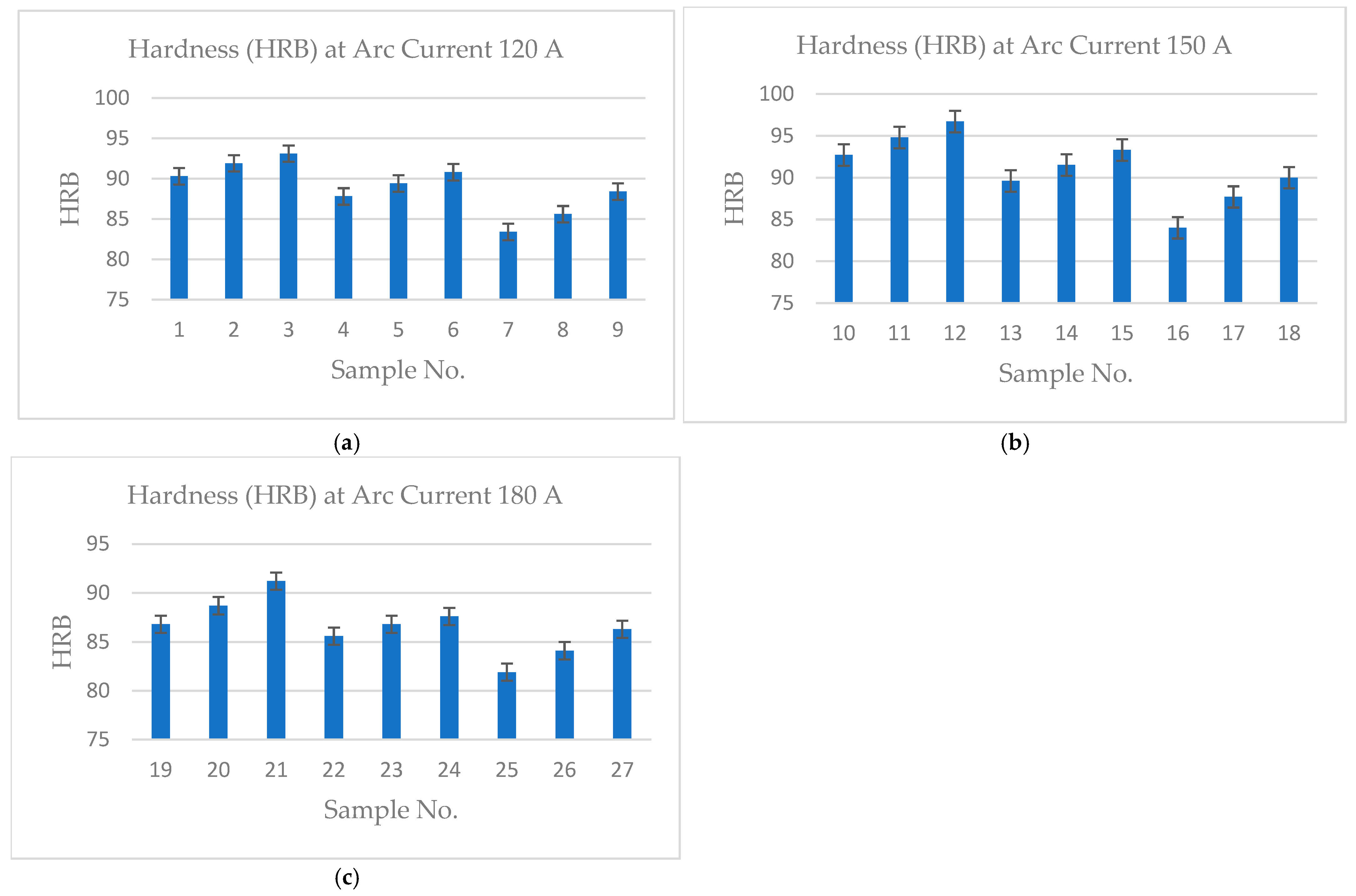

3.6. Rockwell Hardness (HRB) Analysis

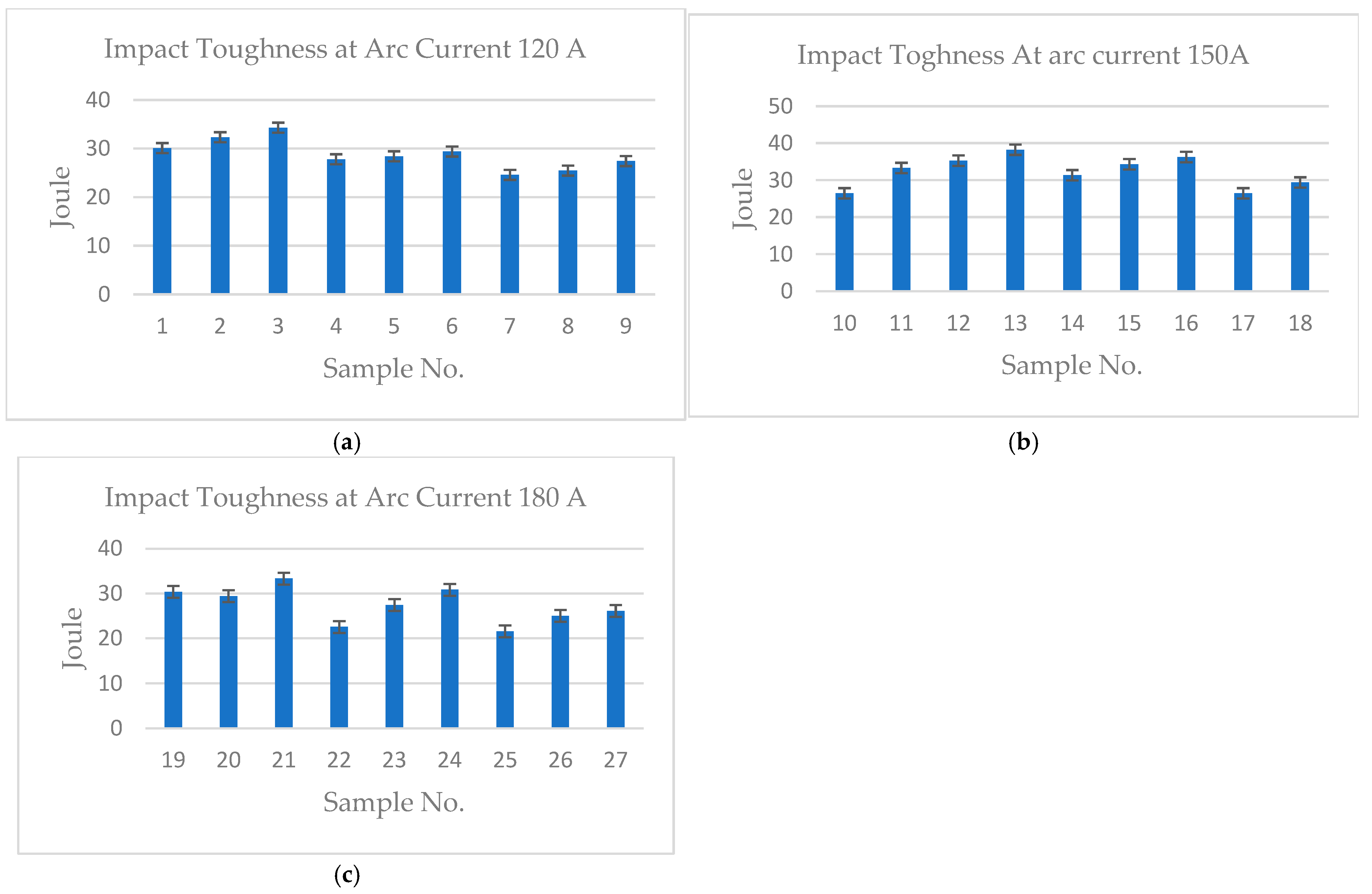

3.7. Impact Toughness Analysis

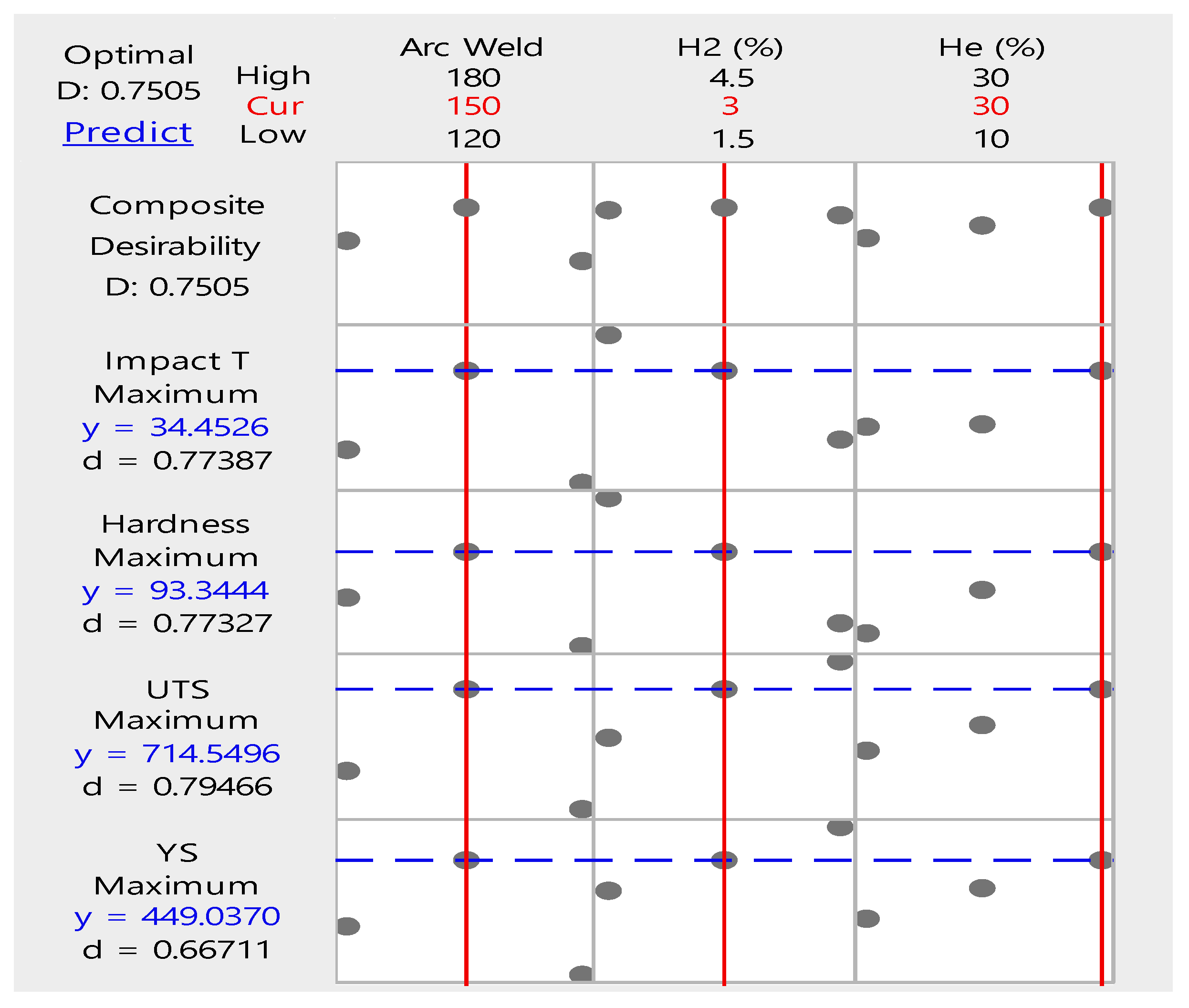

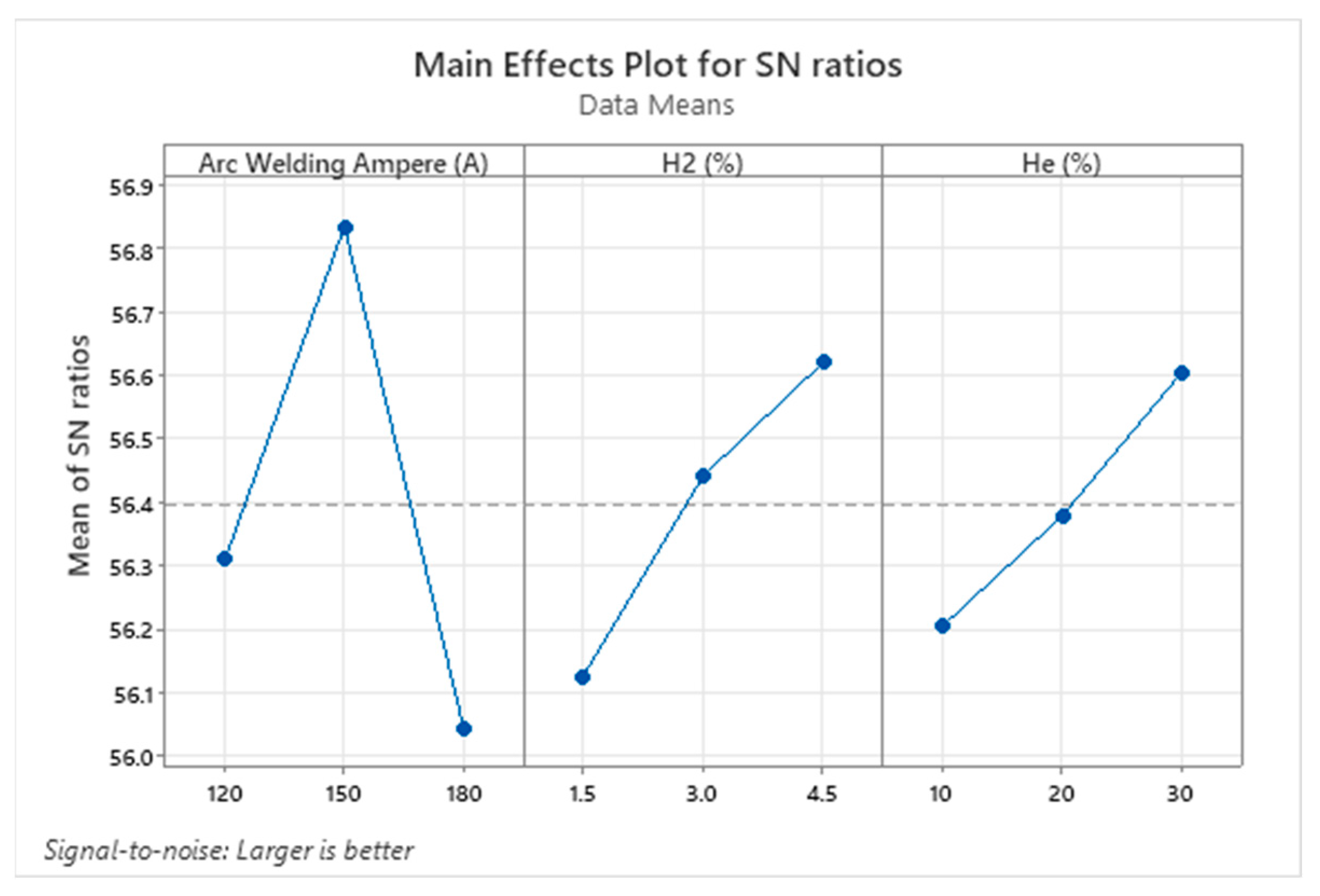

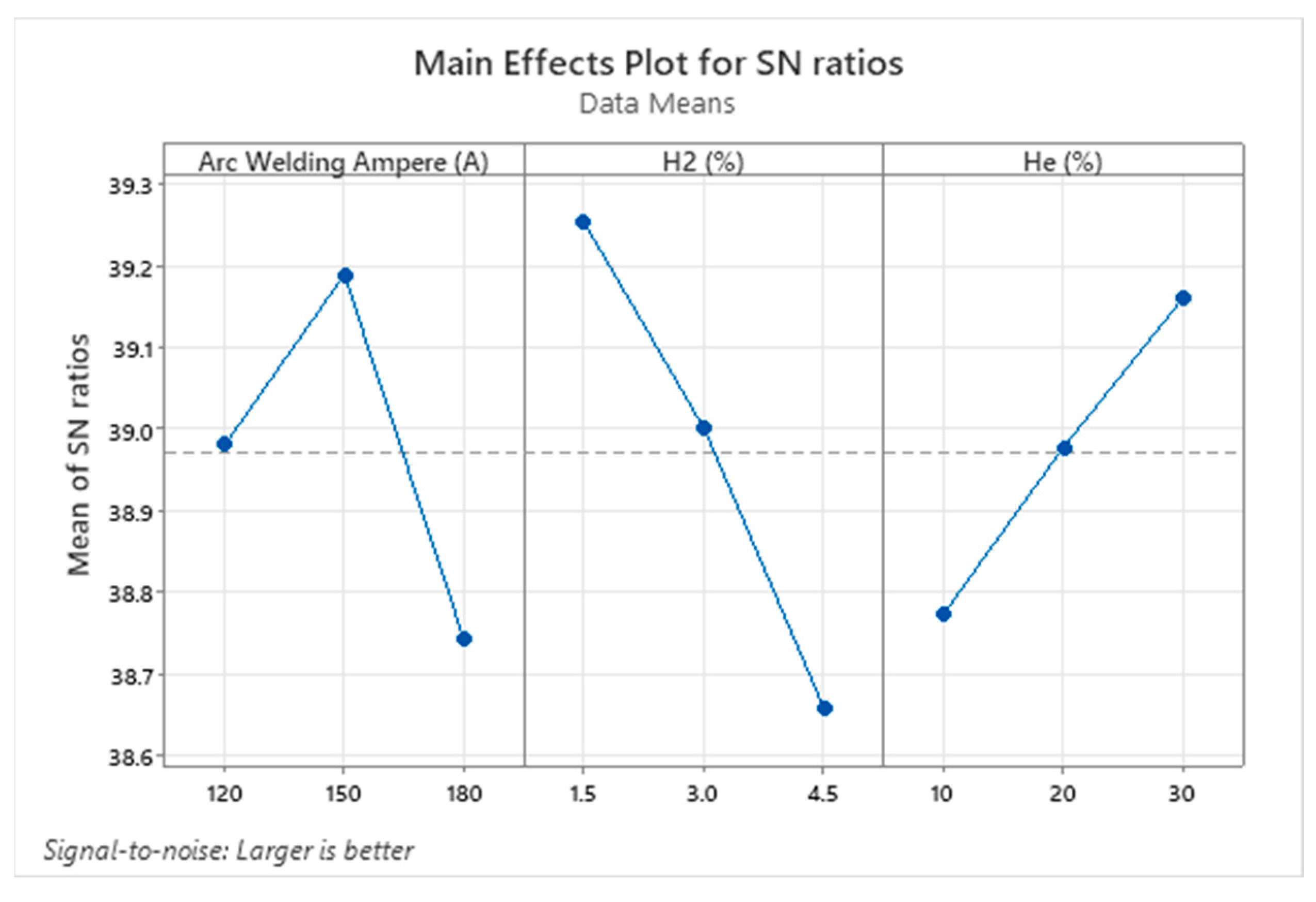

3.8. Taguchi Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Durgutlu, A. Experimental investigation of the effect of hydrogen in argon as a shielding gas on TIG welding of austenitic stainless steel. Mater. Des. 2004, 25, 19–23. [Google Scholar] [CrossRef]

- Gülenç, B.; Develi, K.; Kahraman, N.; Durgutlu, A. Experimental study of the effect of hydrogen in argon as a shielding gas in MIG welding of austenitic stainless steel. Int. J. Hydrogen Energy 2005, 30, 1475–1481. [Google Scholar] [CrossRef]

- Chuaiphan, W.; Srijaroenpramong, L. Effect of hydrogen in argon shielding gas for welding stainless steel grade SUS 201 by GTA welding process. J. Adv. Join. Process. 2020, 1, 100016. [Google Scholar] [CrossRef]

- Kah, P.; Martikainen, J. Influence of shielding gases in the welding of metals. Int. J. Adv. Manuf. Technol. 2013, 64, 1411–1421. [Google Scholar] [CrossRef]

- Huang, H.-Y. Argon-hydrogen shielding gas mixtures for activating flux-assisted gas tungsten arc welding. Metall. Mater. Trans. A 2010, 41, 2829–2835. [Google Scholar] [CrossRef]

- Eliezer, D.; Nissim, Y.; Kannengießer, T. Effects of shielding with various hydrogen-argon mixtures on supermartensitic stainless steel TIG welds. Mater. Test. 2010, 52, 306–315. [Google Scholar] [CrossRef]

- Xue, J.; Wu, H.; Zhou, C.; Zhang, Y.; He, M.; Yan, X.; Xie, H.; Yan, R.; Yin, Y. Effect of heat input on hydrogen embrittlement of TIG welded 304 austenitic stainless steel. Metals 2022, 12, 1943. [Google Scholar] [CrossRef]

- Mahajan, A.; Singh, H.; Kumar, S.; Kumar, S. Mechanical properties assessment of TIG welded SS 304 joints. Mater. Today Proc. 2022, 56, 3073–3077. [Google Scholar] [CrossRef]

- Sakthivel, P.; Sivakumar, P. Effect of vibration in Tig and arc welding using AISI 316 stainless steel. Int. J. Eng. Res. Sci. Technol. 2014, 3, 116–130. [Google Scholar]

- Pandya, D.; Badgujar, A.; Ghetiya, N. A novel perception toward welding of stainless steel by activated TIG welding: A review. Mater. Manuf. Process. 2021, 36, 877–903. [Google Scholar] [CrossRef]

- Ramachandran, R. Analysis and experimental investigations of weld characteristics for a TIG welding with SS316l. Int. J. Adv. Eng. Res. 2015, 10, 1–6. [Google Scholar]

- Olden, V.; Aune, R.; Ro̸rvik, G.; Akselsen, O.M. Hydrogen Pick Up and Diffusion in TIG Welding of Super martensitic 13% Cr Stainless Steel With Superduplex Wire. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Halkidiki, Greece, 12–17 June 2005; Volume 41979, pp. 269–274. [Google Scholar]

- Khrais, S.; Mohammed, A.; Al, A.A.; Darabseh, T. Effect of TIG welding parameters on 316 L stainless steel joints using taguchi L27 approach. Mater. Res. Express 2024, 11, 016512. [Google Scholar] [CrossRef]

- Khrais, S.; Al Hmoud, H.; Al, A.A.; Darabseh, T. Experimental investigation of the impact of GMAW welding parameters on the mechanical properties of AISI 316L/ER 316L using quaternary shielding gas. Mater. Res. Express 2024, 11, 046501. [Google Scholar] [CrossRef]

- Lippold, J.C.; Kotecki, D.J. Welding Metallurgy and Weldability of Stainless Steels; Wiley: Hoboken, NJ, USA, 2005. [Google Scholar]

- Zhang, H.; Shen, M.; Tian, X.; Zhang, Q.; Chen, Z.; Yao, J. Investigating the Influence Mechanism of Different Shielding Gas Types on Arc Characteristics and Weld Quality in TA2 Laser–Arc Hybrid Welding. Metals 2024, 14, 946. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, W.; Li, W.; Su, X.; Zhao, W.; Xu, G.; Zhu, J. Effects of He-Ar shielding gas compositions on arc plasma physical properties in rotating laser+ GMAW hybrid fillet welding: Numerical simulation. Opt. Laser Technol. 2024, 178, 111231. [Google Scholar] [CrossRef]

- Mvola, B.; Kah, P. Effects of shielding gas control: Welded joint properties in GMAW process optimization. Int. J. Adv. Manuf. Technol. 2017, 88, 2369–2387. [Google Scholar] [CrossRef]

- Pandya, D.; Badgujar, A.; Ghetiya, N. Effect of hydrogen additions to shielding gas on activated TIG austenitic stainless steel weld. Mater. Today Proc. 2021, 47, 1025–1029. [Google Scholar] [CrossRef]

- Hosseini Farzaneh, S.; Belbasi, M. Effects of Shielding Gas on the Depth, Width and Hardness of 17-4PH Stainless Steel during TIG Welding. J. Environ. Friendly Mater. 2020, 4, 25–29. [Google Scholar]

- Aljufri, A.; Sofyan, S.; Rizki, M.N.; Putra, R.; Mawardi, I. Influence of shielding gas flow on the TIG welding process using stainless steel 304 material. J. Weld. Technol. 2024, 6, 38–45. [Google Scholar] [CrossRef]

- Abd Rahman, M.N.; Zulkipli, N.H.; Kasim, M.S.; Jamli, M.R.; Budi, E. Impact of argon gas shielding flow rate on the hardness of weld joint. J. Adv. Manuf. Technol. (JAMT) 2022, 16, 1–8. [Google Scholar]

- Mendoza, H. Effects of a Binary Argon-Helium Shielding Gas Mixture on Ultra-Thin Features Produced by Laser-Powder Bed Fusion Additive Manufacturing. Master’s Thesis, The Ohio State University, Columbus, OH, USA, 2021. [Google Scholar]

- Guo, J.; Wang, F.; Zhou, L.; Zhao, Y.; Fu, J.; Chen, G.; Qin, Y. The Synergistic Enhancement Effect of H2 in the Shielding Gas on High Welding Efficiency and Corrosion Resistance in TIG Welding of Stainless Steel. Metall. Mater. Trans. B 2024, 56, 46–63. [Google Scholar] [CrossRef]

- Khrais, S.; Al Hmoud, H.; Al, A.A.; Darabseh, T. Impact of gas metal arc welding parameters on bead geometry and material distortion of AISI 316L. J. Manuf. Mater. Process. 2023, 7, 123. [Google Scholar] [CrossRef]

- Ghumman, K.Z.; Ali, S.; Khan, N.B.; Khan, M.I.; Ali, H.T.; Ashurov, M. Optimization of TIG welding parameters for enhanced mechanical properties in AISI 316L stainless steel welds. Int. J. Adv. Manuf. Technol. 2024, 136, 353–365. [Google Scholar] [CrossRef]

- Casanueva, R.; Brañas, C.; Diaz, F.J.; Azcondo, F.J.; Ferreño, D.; Setien, J. Characterization of an energy efficient pulsed current TIG welding process on AISI 316 and 304 stainless steels. Heliyon 2023, 9, e19819. [Google Scholar] [CrossRef]

- Tathgir, S.; Rathod, D.W.; Batish, A. Process enhancement using hydrogen-induced shielding: H2-induced A-TIG welding process. Mater. Manuf. Process. 2020, 35, 1084–1095. [Google Scholar] [CrossRef]

- Kardak, A.A.; Sinclair, G.B. Stress concentration factors for ASTM E8/E8M-16a standard round specimens for tension testing. J. Test. Eval. 2020, 48, 711–719. [Google Scholar] [CrossRef]

- Baghel, P.K. Effect of SMAW process parameters on similar and dissimilar metal welds: An overview. Heliyon 2022, 8, e12161. [Google Scholar] [CrossRef]

- Aegerter, J.; Kühn, H.J.; Frenz, H.; Weißmüller, C. EN ISO 6892-1: 2009 tensile testing: Initial experience from the practical implementation of the new standard. Mater. Test. 2011, 53, 595–603. [Google Scholar] [CrossRef]

- Mupoperi, T.; Pita, M. An investigation of the effect of welding current on the mechanical properties of mild steel joints when using arc welding. In Proceedings of the 2022 IEEE 13th International Conference on Mechanical and Intelligent Manufacturing Technologies (ICMIMT), Cape Town, South Africa, 25–27 May 2022; IEEE: Piscataway, NJ, USA, 2022. [Google Scholar]

- Chowdhury, S.; Nirsanametla, Y.; Muralidhar, M.; Bag, S.; Paul, C.; Bindra, K. Identification of modes of welding using parametric studies during ytterbium fiber laser welding. J. Manuf. Process. 2020, 57, 748–761. [Google Scholar] [CrossRef]

- Pavan, A.; Chandrasekar, N.; Arivazhagan, B.; Kumar, S.; Vasudevan, M. Study of arc characteristics using varying shielding gas and optimization of activated-tig welding technique for thick AISI 316L (N) plates. CIRP J. Manuf. Sci. Technol. 2021, 35, 675–690. [Google Scholar] [CrossRef]

- Ghumman, K.Z.; Ali, S.; Din, E.U.; Mubashar, A.; Khan, N.B.; Ahmed, S.W. Experimental investigation of effect of welding parameters on surface roughness, micro-hardness and tensile strength of AISI 316L stainless steel welded joints using 308L filler material by TIG welding. J. Mater. Res. Technol. 2022, 21, 220–236. [Google Scholar] [CrossRef]

- Lowke, J.J.; Tanaka, M.; Ushio, M. Mechanisms giving increased weld depth due to a flux. J. Phys. D Appl. Phys. 2005, 38, 3438. [Google Scholar] [CrossRef]

- Chuaiphan, W.; Srijaroenpramong, L. Heat input and shielding gas effects on the microstructure, mechanical properties and pitting corrosion of alternative low cost stainless steel grade 202. Results Mater. 2020, 7, 100111. [Google Scholar] [CrossRef]

- Gao, S.; Geng, S.; Jiang, P.; Mi, G.; Han, C.; Ren, L. Numerical analysis of the deformation behavior of 2205 duplex stainless steel TIG weld joint based on the microstructure and micro-mechanical properties. Mater. Sci. Eng. A 2021, 815, 141303. [Google Scholar] [CrossRef]

- Yu, W.X.; Liu, B.X.; Chen, C.X.; Liu, M.Y.; Zhang, X.; Fang, W.; Ji, P.G.; He, J.N.; Yin, F.X. Microstructure and mechanical properties of stainless steel clad plate welding joints by different welding processes. Sci. Technol. Weld. Join. 2020, 25, 571–580. [Google Scholar] [CrossRef]

- Katherasan, D.; Sathiya, P.; Raja, A. Shielding gas effects on flux cored arc welding of AISI 316L (N) austenitic stainless steel joints. Mater. Des. 2013, 45, 43–51. [Google Scholar] [CrossRef]

- Phakpeetinan, P.; Chianpairot, A.; Viyanit, E.; Hartung, F.; Lothongkum, G. Effects of nitrogen and hydrogen in argon shielding gas on bead profile, delta-ferrite and nitrogen contents of the pulsed GTAW welds of AISI 316L stainless steel. Mater. Test. 2016, 58, 489–494. [Google Scholar] [CrossRef]

- Chuaiphan, W.; Srijaroenpramong, L. Microstructure, mechanical properties and pitting corrosion of TIG weld joints alternative low-cost austenitic stainless steel grade 216. J. Adv. Join. Process. 2020, 2, 100027. [Google Scholar] [CrossRef]

- Nedjad, S.H.; Yildiz, M.; Saboori, A. Solidification behaviour of austenitic stainless steels during welding and directed energy deposition. Sci. Technol. Weld. Join. 2023, 28, 1–17. [Google Scholar] [CrossRef]

- Bansod, A.V.; Patil, A.P.; Moon, A.P.; Shukla, S. Microstructural and electrochemical evaluation of fusion welded low-nickel and 304 SS at different heat input. J. Mater. Eng. Perform. 2017, 26, 5847–5863. [Google Scholar] [CrossRef]

- Sathiya, P.; Jaleel, M.A. Measurement of the bead profile and microstructural characterization of a CO2 laser welded AISI 904 L super austenitic stainless steel. Opt. Laser Technol. 2010, 42, 960–968. [Google Scholar] [CrossRef]

- Xu, K. Silicon electro-optic micro-modulator fabricated in standard CMOS technology as components for all silicon monolithic integrated optoelectronic systems. J. Micromech. Microeng. 2021, 31, 054001. [Google Scholar] [CrossRef]

- Hu, Y.; Shi, Y.; Wang, K.; Huang, J. Effect of heat input on the microstructure and mechanical properties of local dry underwater welded duplex stainless steel. Materials 2023, 16, 2289. [Google Scholar] [CrossRef] [PubMed]

- Açar, I.; Gülenç, B. Effect of shielding gas combination on microstructure and mechanical properties of MIG welded stainless steel 316. Mater. Test. 2021, 63, 97–101. [Google Scholar] [CrossRef]

- Kotecki, D.; Siewert, T. WRC-1992 constitution diagram for stainless steel weld metals: A modification of the WRC-1988 diagram. Weld. J. 1992, 71, 171–178. [Google Scholar]

- Kshirsagar, R.; Jones, S.; Lawrence, J.; Tabor, J. Measurement of ferrite content of stainless-steel sheet welds using a new Ferrite Density Number scale. J. Mater. Process. Technol. 2019, 274, 116278. [Google Scholar] [CrossRef]

- Zainon, F.; Ahmad, K.R.; Daud, R. Review on the tribology and hardness of aluminum AA332: Matrix composites reinforced with Mg2Si. Adv. Mater. Res. 2016, 5, 55–66. [Google Scholar] [CrossRef]

- LLuglla, A.I.; Martínez-Gómez, J.; Bustamante, V.D. QA/QC Validation of the GMAW Welding Process, Used in the Construction of Body Bodies in the Ecuadorian Industry. In Innovation and Research: A Driving Force for Socio-Econo-Technological Development 1st 2021; Springer International Publishing: Cham, Switzerland, 2021; pp. 416–427. [Google Scholar]

| Element | C | Mn | Si | Cr | Ni | Mo | P | S | N | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| Wt.% | 0.03 | 2.0 | 1.0 | 16.5–18.5 | 8–13 | 2–2.25 | 0.04 | 0.001 | 0.11 | Balance |

| Element | C | Mn | Si | Cr | Ni | Mo | P | S | N | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| Wt.% | 0.03 | 2 | 0.75 | 16–18 | 10–14 | 2–3 | 0.045 | 0.03 | 0.1 | Balance |

| Sample No. | Arc Welding Ampere (A) | H2 (%) | He (%) | Ar (%) | Heat Input (J/mm) |

|---|---|---|---|---|---|

| 1 | 120 | 1.5 | 10 | 88.5 | 76.19 |

| 2 | 120 | 1.5 | 20 | 78.5 | 76.19 |

| 3 | 120 | 1.5 | 30 | 68.5 | 76.19 |

| 4 | 120 | 3 | 10 | 87 | 76.19 |

| 5 | 120 | 3 | 20 | 77 | 76.19 |

| 6 | 120 | 3 | 30 | 67 | 76.19 |

| 7 | 120 | 4.5 | 10 | 85.5 | 76.19 |

| 8 | 120 | 4.5 | 20 | 75.5 | 76.19 |

| 9 | 120 | 4.5 | 30 | 65.5 | 76.19 |

| 10 | 150 | 1.5 | 10 | 88.5 | 95.24 |

| 11 | 150 | 1.5 | 20 | 78.5 | 95.24 |

| 12 | 150 | 1.5 | 30 | 68.5 | 95.24 |

| 13 | 150 | 3 | 10 | 87 | 95.24 |

| 14 | 150 | 3 | 20 | 77 | 95.24 |

| 15 | 150 | 3 | 30 | 67 | 95.24 |

| 16 | 150 | 4.5 | 10 | 85.5 | 95.24 |

| 17 | 150 | 4.5 | 20 | 75.5 | 95.24 |

| 18 | 150 | 4.5 | 30 | 65.5 | 95.24 |

| 19 | 180 | 1.5 | 10 | 88.5 | 114.29 |

| 20 | 180 | 1.5 | 20 | 78.5 | 114.29 |

| 21 | 180 | 1.5 | 30 | 68.5 | 114.29 |

| 22 | 180 | 3 | 10 | 87 | 114.29 |

| 23 | 180 | 3 | 20 | 77 | 114.29 |

| 24 | 180 | 3 | 30 | 67 | 114.29 |

| 25 | 180 | 4.5 | 10 | 85.5 | 114.29 |

| 26 | 180 | 4.5 | 20 | 75.5 | 114.29 |

| 27 | 180 | 4.5 | 30 | 65.5 | 114.29 |

| Sample | C (%) | N (%) | Si (%) | Cr (%) | Mn (%) | Ni (%) | Mo (%) | Fe (%) | Creq. | Nieq. | Creq./Nieq. | FN |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 0.03 | 0.04 | 0.4 | 18 | 1.8 | 11 | 2.1 | 66.63 | 20.2 | 13.58 | 1.49 | 29.28 |

| 2 | 0.03 | 0.04 | 0.4 | 18.05 | 1.8 | 11.05 | 2.12 | 66.55 | 20.22 | 13.62 | 1.48 | 29.23 |

| 3 | 0.03 | 0.04 | 0.4 | 18.1 | 1.81 | 11.1 | 2.14 | 66.48 | 20.25 | 13.65 | 1.48 | 29.22 |

| 4 | 0.03 | 0.05 | 0.41 | 18.2 | 1.82 | 11.15 | 2.15 | 66.44 | 20.3 | 13.7 | 1.48 | 29.21 |

| 5 | 0.03 | 0.05 | 0.41 | 18.25 | 1.82 | 11.2 | 2.17 | 66.36 | 20.33 | 13.73 | 1.48 | 29.2 |

| 6 | 0.03 | 0.05 | 0.41 | 18.3 | 1.83 | 11.25 | 2.18 | 66.29 | 20.35 | 13.77 | 1.48 | 29.15 |

| 7 | 0.04 | 0.05 | 0.42 | 18.4 | 1.84 | 11.3 | 2.2 | 66.24 | 20.4 | 13.82 | 1.48 | 29.14 |

| 8 | 0.04 | 0.05 | 0.42 | 18.45 | 1.84 | 11.35 | 2.22 | 66.16 | 20.43 | 13.85 | 1.48 | 29.13 |

| 9 | 0.04 | 0.06 | 0.43 | 18.5 | 1.85 | 11.4 | 2.23 | 66.09 | 20.45 | 13.89 | 1.47 | 29.08 |

| 10 | 0.03 | 0.04 | 0.4 | 18 | 1.8 | 11.05 | 2.12 | 66.63 | 20.22 | 13.63 | 1.48 | 29.2 |

| 11 | 0.03 | 0.04 | 0.4 | 18.05 | 1.81 | 11.1 | 2.14 | 66.55 | 20.25 | 13.67 | 1.48 | 29.17 |

| 12 | 0.03 | 0.04 | 0.4 | 18.1 | 1.81 | 11.15 | 2.15 | 66.48 | 20.28 | 13.72 | 1.48 | 29.12 |

| 13 | 0.03 | 0.05 | 0.41 | 18.2 | 1.82 | 11.2 | 2.17 | 66.44 | 20.33 | 13.75 | 1.48 | 29.15 |

| 14 | 0.03 | 0.05 | 0.41 | 18.25 | 1.83 | 11.25 | 2.18 | 66.36 | 20.35 | 13.78 | 1.48 | 29.13 |

| 15 | 0.03 | 0.05 | 0.41 | 18.3 | 1.83 | 11.3 | 2.2 | 66.29 | 20.38 | 13.82 | 1.48 | 29.09 |

| 16 | 0.04 | 0.05 | 0.42 | 18.4 | 1.84 | 11.35 | 2.22 | 66.24 | 20.43 | 13.87 | 1.47 | 29.08 |

| 17 | 0.04 | 0.05 | 0.42 | 18.45 | 1.84 | 11.4 | 2.23 | 66.16 | 20.45 | 13.91 | 1.47 | 29.03 |

| 18 | 0.04 | 0.06 | 0.43 | 18.5 | 1.85 | 11.45 | 2.25 | 66.09 | 20.5 | 13.94 | 1.47 | 29.07 |

| 19 | 0.04 | 0.04 | 0.41 | 18.1 | 1.82 | 11.1 | 2.15 | 66.38 | 20.29 | 13.68 | 1.48 | 29.24 |

| 20 | 0.04 | 0.04 | 0.41 | 18.15 | 1.83 | 11.15 | 2.17 | 66.3 | 20.32 | 13.72 | 1.48 | 29.2 |

| 21 | 0.04 | 0.04 | 0.42 | 18.2 | 1.83 | 11.2 | 2.18 | 66.24 | 20.35 | 13.76 | 1.48 | 29.17 |

| 22 | 0.05 | 0.05 | 0.42 | 18.3 | 1.84 | 11.25 | 2.2 | 66.14 | 20.4 | 13.8 | 1.48 | 29.19 |

| 23 | 0.05 | 0.05 | 0.42 | 18.35 | 1.84 | 11.3 | 2.22 | 66.08 | 20.42 | 13.84 | 1.48 | 29.13 |

| 24 | 0.05 | 0.05 | 0.42 | 18.4 | 1.85 | 11.35 | 2.23 | 66 | 20.45 | 13.88 | 1.47 | 29.1 |

| 25 | 0.05 | 0.05 | 0.43 | 18.5 | 1.85 | 11.4 | 2.25 | 65.95 | 20.5 | 13.91 | 1.47 | 29.14 |

| 26 | 0.05 | 0.05 | 0.43 | 18.55 | 1.86 | 11.45 | 2.27 | 65.87 | 20.53 | 13.96 | 1.47 | 29.08 |

| 27 | 0.05 | 0.06 | 0.43 | 18.6 | 1.86 | 11.5 | 2.28 | 65.8 | 20.55 | 13.99 | 1.47 | 29.05 |

| Parameter | Condition | UTS (MPa) | YS (MPa) |

|---|---|---|---|

| H2 Content Increase and He Content Increase | 1.5% to 4.5% 10% to 30% | 620.1 → 740.92 | 401 → 477 |

| Arc Current—120 A | 3% H2, 30% He | 673.68 | 429 |

| Arc Current—150 A | 3% H2, 30% He | 722.6 | 451 |

| Arc Current—180 A | 3% H2, 30% He | 645.16 | 417 |

| Optimal Conditions | Sample No. 18 (150 A, 4.5% H2, 30% He) | ~740 | 477 |

| Parameter | Condition | Hardness (HRB) |

|---|---|---|

| H2 Content Increase and He Content Increase | 1.5% to 4.5%, 10% to 30% | 86.8 → 90.0 |

| Arc Current—120 A | 3% H2, 30% He | 90.8 |

| Arc Current—150 A | 3% H2, 30% He | 93.3 |

| Arc Current—180 A | 3% H2, 30% He | 87.6 |

| Optimal Conditions | Sample No. 18 (150 A, 4.5% H2, 30% He) | 90 |

| Parameter | Condition | Charpy Impact (J) |

|---|---|---|

| H2 Content Increase and He Content Increase | 1.5% to 4.5%, 10% to 30% | 21.56 → 35.28 |

| Arc Current—120 A | 3% H2, 30% He | 29.4 |

| Arc Current—150 A | 3% H2, 30% He | 34.3 |

| Arc Current—180 A | 3% H2, 30% He | 30.83 |

| Optimal Conditions | Sample No. 18 (150 A, 4.5% H2, 30% He) | 29.4 |

| Source | DF | Seq SS | Contribution | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|---|---|

| Arc Welding Ampere (A) | 2 | 17,384 | 57.77% | 17,384 | 8692.09 | 96.02 | 0.000 |

| H2 (%) | 2 | 6677 | 22.19% | 6677 | 3338.28 | 36.88 | 0.000 |

| He (%) | 2 | 4222 | 14.03% | 4222 | 2111.08 | 23.32 | 0.000 |

| Error | 20 | 1811 | 6.02% | 1811 | 90.53 | ||

| Total | 26 | 30,093 | 100.00% |

| Source | DF | Seq SS | Contribution | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|---|---|

| Arc Welding Ampere (A) | 2 | 2422.9 | 51.41% | 2422.9 | 1211.44 | 65.64 | 0.000 |

| H2 (%) | 2 | 1406.0 | 29.83% | 1406.0 | 703.00 | 38.09 | 0.000 |

| He (%) | 2 | 514.7 | 10.92% | 514.7 | 257.33 | 13.94 | 0.000 |

| Error | 20 | 369.1 | 7.83% | 369.1 | 18.46 | ||

| Total | 26 | 4712.7 | 100.00% |

| Source | DF | Seq SS | Contribution | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|---|---|

| Arc Welding Ampere (A) | 2 | 94.84 | 27.57% | 94.84 | 47.4211 | 78.77 | 0.000 |

| H2 (%) | 2 | 167.80 | 48.79% | 167.80 | 83.8978 | 139.37 | 0.000 |

| He (%) | 2 | 69.27 | 20.14% | 69.27 | 34.6344 | 57.53 | 0.000 |

| Error | 20 | 12.04 | 3.50% | 12.04 | 0.6020 | ||

| Total | 26 | 343.95 | 100.00% |

| Source | DF | Seq SS | Contribution | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|---|---|

| Arc Welding Ampere (A) | 2 | 122.73 | 37.58% | 122.73 | 61.365 | 42.16 | 0.000 |

| H2 (%) | 2 | 145.64 | 44.59% | 145.64 | 72.819 | 50.03 | 0.000 |

| He (%) | 2 | 29.15 | 8.92% | 29.15 | 14.574 | 10.01 | 0.001 |

| Error | 20 | 29.11 | 8.91% | 29.11 | 1.455 | ||

| Total | 26 | 326.62 | 100.00% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khrais, S.; Darabseh, T.; Mohammed, A.; Abdel Al, A. Investigating the Effects of H2 Additions to Helium and Argon Shielding Gases on TIG-Welded AISI 316L Stainless Steel. J. Compos. Sci. 2025, 9, 199. https://doi.org/10.3390/jcs9050199

Khrais S, Darabseh T, Mohammed A, Abdel Al A. Investigating the Effects of H2 Additions to Helium and Argon Shielding Gases on TIG-Welded AISI 316L Stainless Steel. Journal of Composites Science. 2025; 9(5):199. https://doi.org/10.3390/jcs9050199

Chicago/Turabian StyleKhrais, Samir, Tariq Darabseh, Awsan Mohammed, and Ahmad Abdel Al. 2025. "Investigating the Effects of H2 Additions to Helium and Argon Shielding Gases on TIG-Welded AISI 316L Stainless Steel" Journal of Composites Science 9, no. 5: 199. https://doi.org/10.3390/jcs9050199

APA StyleKhrais, S., Darabseh, T., Mohammed, A., & Abdel Al, A. (2025). Investigating the Effects of H2 Additions to Helium and Argon Shielding Gases on TIG-Welded AISI 316L Stainless Steel. Journal of Composites Science, 9(5), 199. https://doi.org/10.3390/jcs9050199