Effect of Printing Parameters on Mechanical Properties and Warpage of 3D-Printed PEEK/CF-PEEK Composites Using Multi-Objective Optimization Technique

Abstract

:1. Introduction

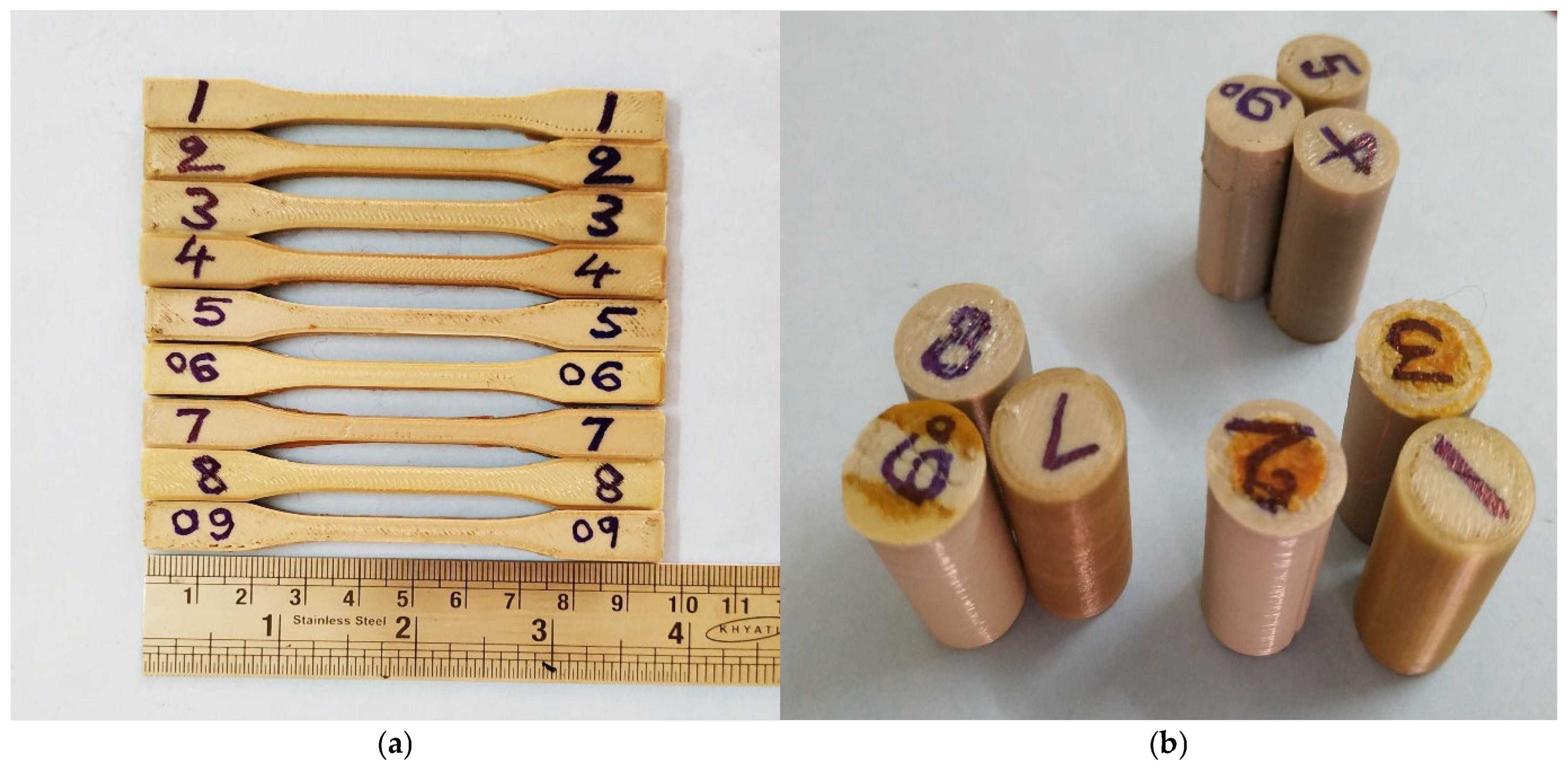

2. Materials and Methods

2.1. Materials

2.2. Processing of Samples

3. Results and Discussion

3.1. Tensile Properties

3.2. Compression Properties

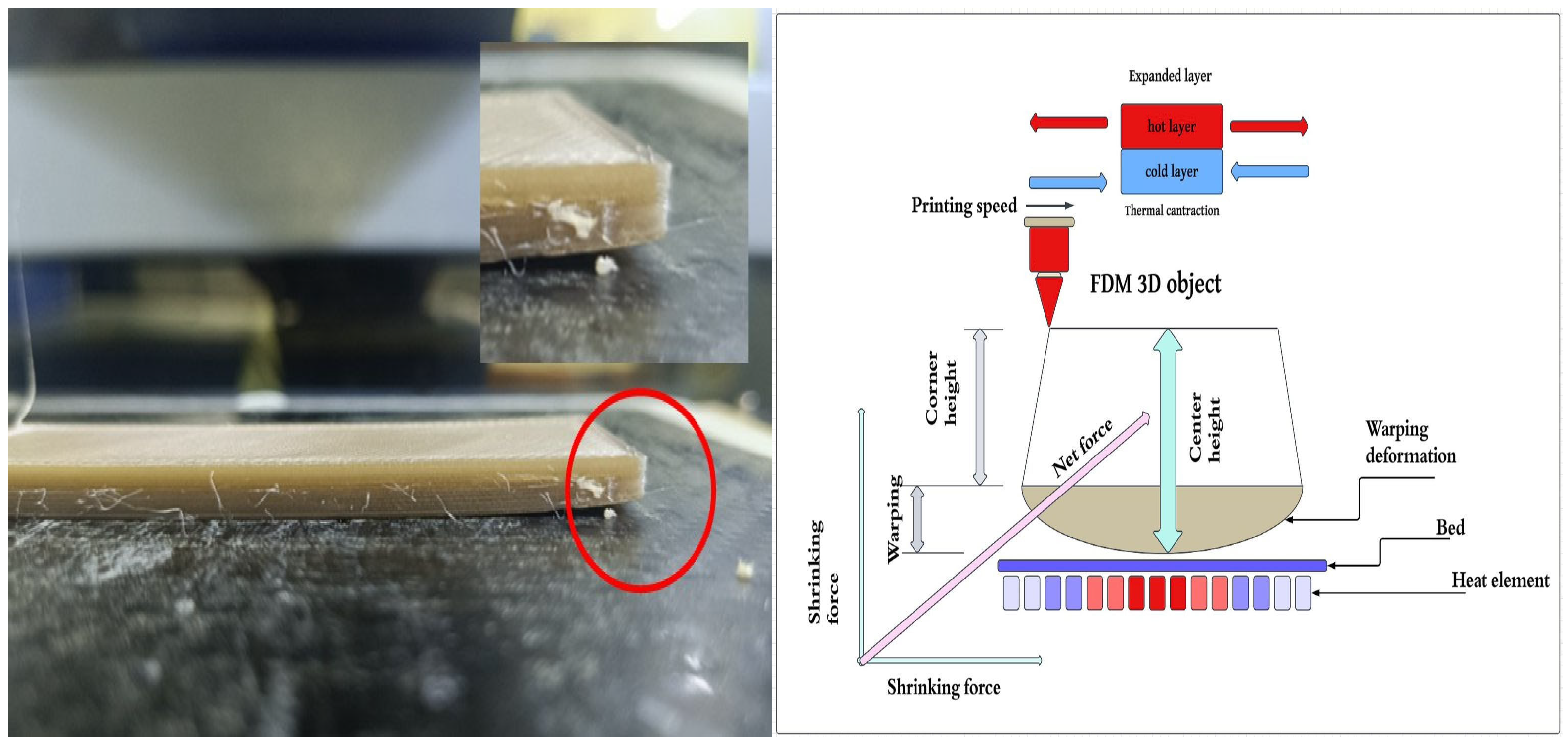

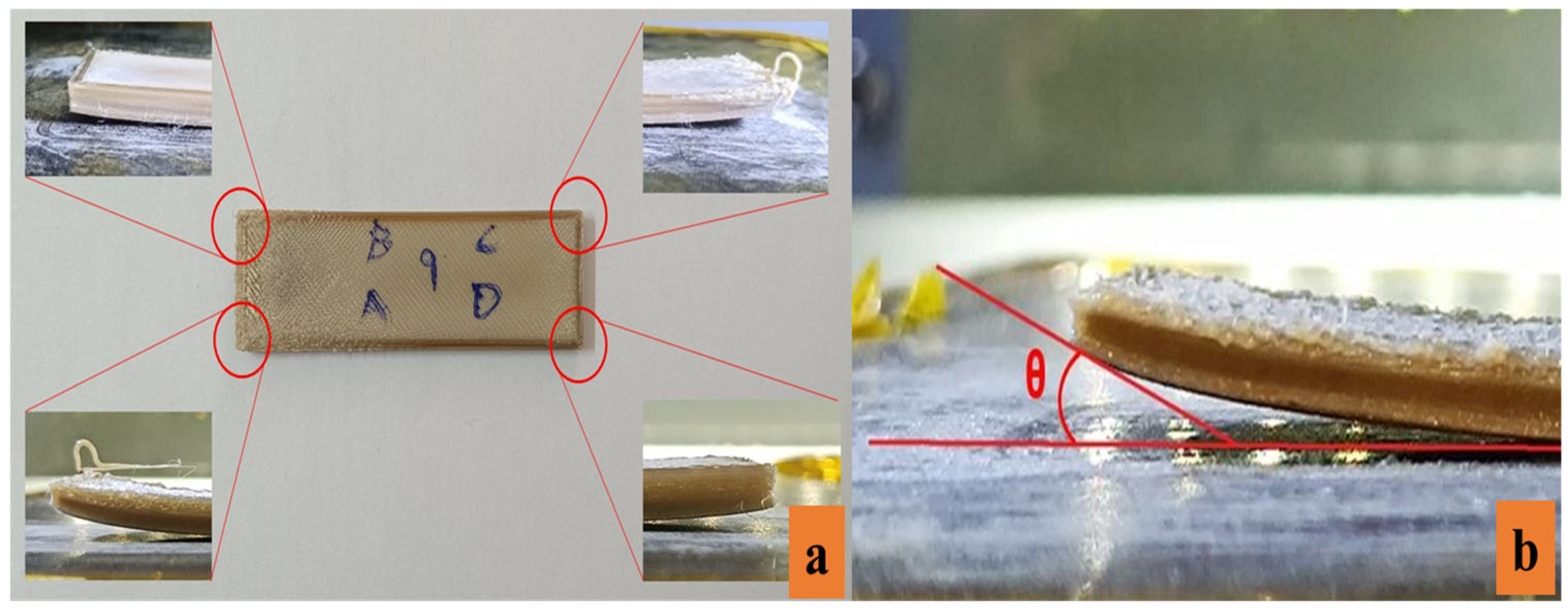

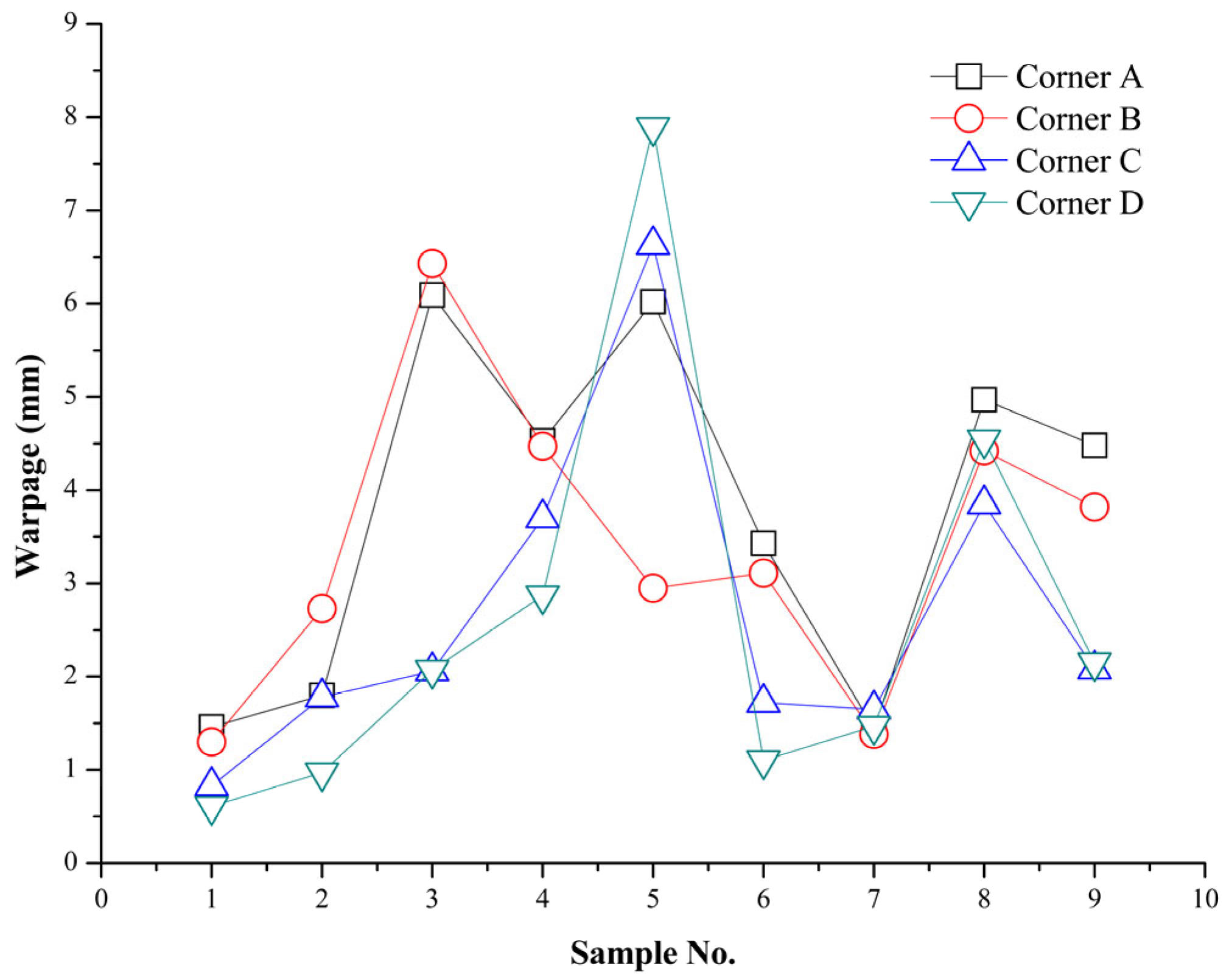

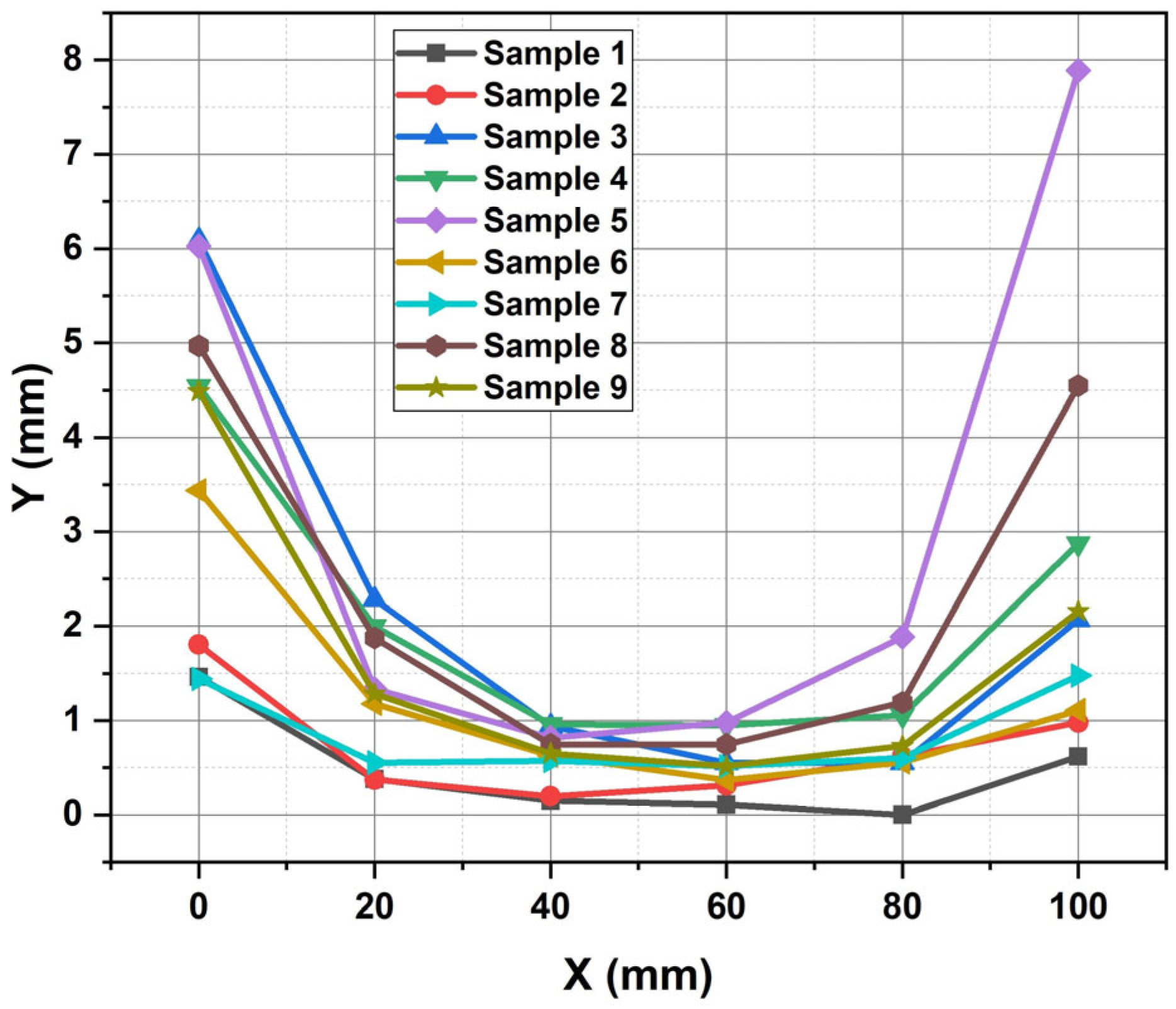

3.3. Warpage

3.4. Multi-Objective Optimization Technique

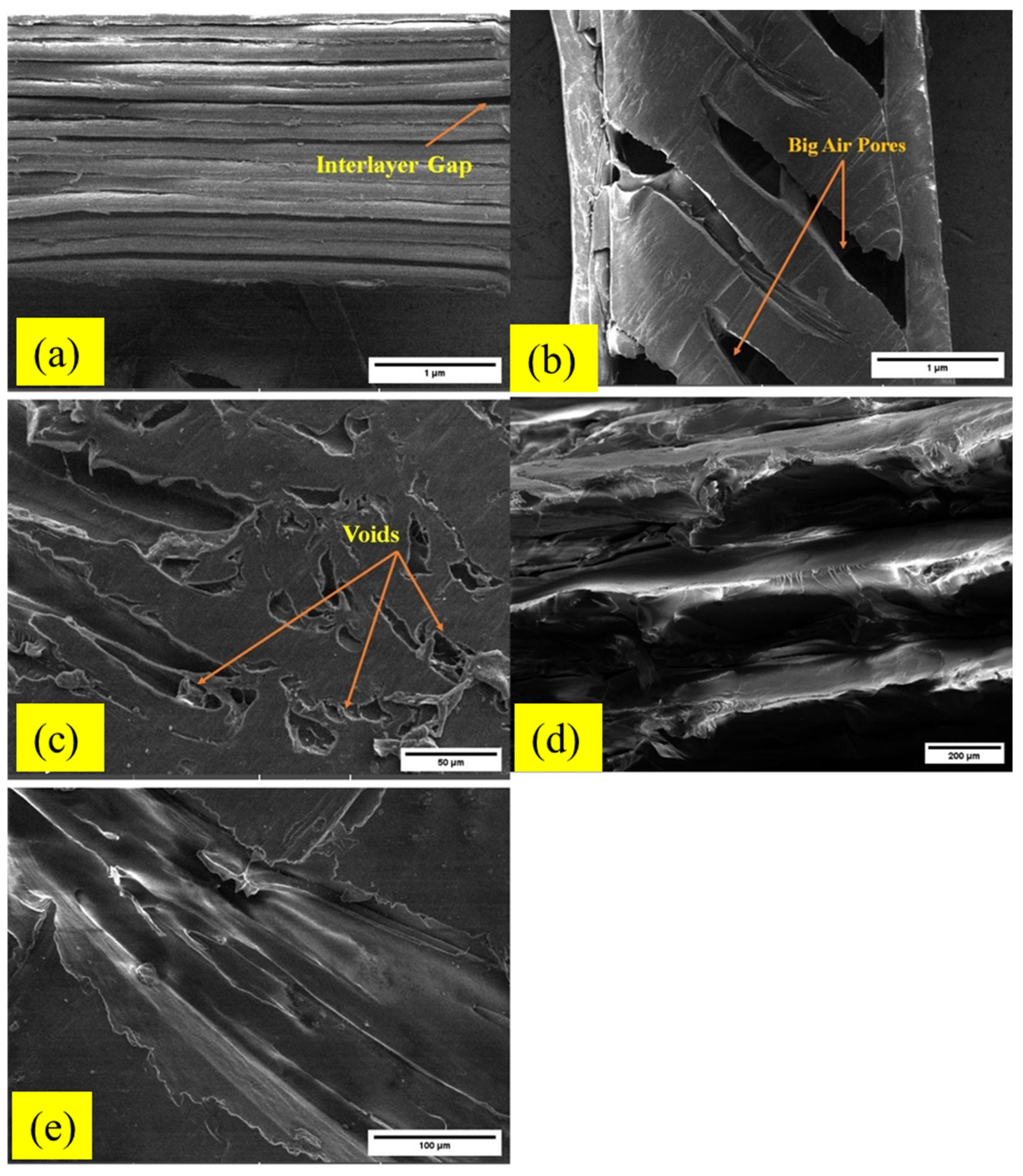

3.5. Scanning Electron Microscopy

4. Conclusions

- Optimal tensile performance was achieved with a nozzle temperature of 420 °C, a platform temperature of 130 °C, and an 80–100% infill rate, resulting in improved interlayer bonding and higher tensile strength (71.4 MPa). Compression strength was maximized at 167 MPa with higher nozzle temperatures, which facilitated better filament fusion. Warpage analysis revealed that dimensional stability was enhanced by optimizing temperature settings, with minimal distortion occurring at lower warpage values. Multi-objective optimization ranked Sample 1 as the best-performing specimen due to its balanced mechanical properties, minimal deformation, and enhanced fracture resistance.

- The highest warpage was observed in Sample 5, which exhibited the highest linear warpage (7.89 mm at corner D) and angular warpage (23.2° at corner D), indicating strong sensitivity to high nozzle temperature (410 °C) and low infill rate (60%). Sample 1 showed the lowest warpage, with values as low as 0.61 mm (corner D) and 3.3° (corner A), demonstrating optimal dimensional stability under reduced temperature and thicker layers. Carbon fiber-reinforced PEEK reduced warpage significantly, with maximum values of 1.32 mm and 5.21°, confirming enhanced thermal stability over neat PEEK.

- Fracture image analysis confirmed that higher-strength specimens exhibited fewer voids, better fusion, and stronger bonding, while lower-strength specimens displayed interlayer separation and weak adhesion. Additionally, the inclusion of 10% carbon fiber reinforcement improved tensile properties and dimensional stability, while reducing ductility, with no significant effect on compression strength.

- These findings provide key insights into optimizing 3D printing parameters for PEEK and its composites, ensuring improved mechanical performance and structural integrity for advanced engineering applications.

5. Key Takeaways and Future Recommendations

- ○

- Higher nozzle temperatures improve interlayer bonding and reduce defects.

- ○

- Optimized cooling strategies can further enhance structural integrity.

- ○

- Post-processing treatments such as annealing may enhance mechanical properties.

- ○

- Future studies should explore hybrid infill patterns to balance strength and weight.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sapata, A.; Šinka, M.; Šahmenko, G.; Korat Bensa, L.; Hanžič, L.; Šter, K.; Ručevskis, S.; Bajāre, D.; Bos, F.P. Establishing Benchmark Properties for 3D-Printed Concrete: A Study of Printability, Strength, and Durability. J. Compos. Sci. 2025, 9, 74. [Google Scholar] [CrossRef]

- Indreș, A.I.; Constantinescu, D.M.; Mocian, O.A.; Sorohan, Ș. Particularities on the Low-Velocity Impact Be-havior of 3D-Printed Sandwich Panels with Re-Entrant and Honeycomb Core Topologies. J. Compos. Sci. 2024, 8, 426. [Google Scholar] [CrossRef]

- Anwajler, B.; Szulc, P. The Impact of 3D Printing Technology on the Improvement of External Wall Thermal Efficiency—An Experimental Study. J. Compos. Sci. 2024, 8, 389. [Google Scholar] [CrossRef]

- Ogaili, A.A.F.; Basem, A.; Kadhim, M.S.; Al-Sharify, Z.T.; Jaber, A.A.; Njim, E.K.; Al-Haddad, L.A.; Hamzah, M.N.; Al-Ameen, E.S. The Effect of Chopped Carbon Fibers on the Mechanical Properties and Fracture Tough-ness of 3D-Printed PLA Parts: An Experimental and Simulation Study. J. Compos. Sci. 2024, 8, 273. [Google Scholar] [CrossRef]

- Kyriakidis, I.F.; Kladovasilakis, N.; Pechlivani, E.M.; Tsongas, K. Mechanical Performance of Recycled 3D Printed Sustainable Polymer-Based Composites: A Literature Review. J. Compos. Sci. 2024, 8, 215. [Google Scholar] [CrossRef]

- Lecoublet, M.; Ragoubi, M.; Leblanc, N.; Koubaa, A. Investigation of Thermomechanical and Dielectric Prop-erties of PLA-CA 3D-Printed Biobased Materials. J. Compos. Sci. 2024, 8, 197. [Google Scholar] [CrossRef]

- Raziyan, M.S.; Palevicius, A.; Perkowski, D.; Urbaite, S.; Janusas, G. Development and Evaluation of 3D-Printed PLA/PHA/PHB/HA Composite Scaffolds for Enhanced Tissue-Engineering Applications. J. Compos. Sci. 2024, 8, 226. [Google Scholar] [CrossRef]

- Jawad, H.H.; Kordani, N.; Bagheri, A.; Derazkola, H.A. Optimization of 3D Printing Parameters for En-hanced Mechanical Strength: Effects of Glass Fiber Reinforcement and Fill Ratio Using RSM and ANOVA. J. Compos. Sci. 2025, 9, 63. [Google Scholar] [CrossRef]

- Papageorgiou, V.; Tsongas, K.; Mansour, M.T.; Tzetzis, D.; Mansour, G. Mechanical Properties and Vibra-tional Behavior of 3D-Printed Carbon Fiber-Reinforced Polyphenylene Sulfide and Polyamide-6 Composites with Different Infill Types. J. Compos. Sci. 2025, 9, 59. [Google Scholar] [CrossRef]

- Li, M.; Stokes-Griffin, C.; Compston, P. Post-Forming of Carbon Fibre-Reinforced PEEK Thermoplastic Tubu-lar Structures. J. Compos. Sci. 2024, 8, 335. [Google Scholar] [CrossRef]

- Ceddia, M.; Solarino, G.; Giannini, G.; De Giosa, G.; Tucci, M.; Trentadue, B. A Finite Element Analysis Study of Influence of Femoral Stem Material in Stress Shielding in a Model of Uncemented Total Hip Arthroplasty: Ti-6Al-4V versus Carbon Fibre-Reinforced PEEK Composite. J. Compos. Sci. 2024, 8, 254. [Google Scholar] [CrossRef]

- Campos, D.; Maimí, P.; Martín, A. Characterization of Interlaminar Friction during the Forming Processes of High-Performance Thermoplastic Composites. J. Compos. Sci. 2024, 8, 38. [Google Scholar] [CrossRef]

- Dederichs, M.; Lackner, O.; Kuepper, H.; Decker, M.; Viebranz, S.; Hennig, C.-L.; Guentsch, A.; Kuepper, C. An Explorative Evaluation on the Influence of Filler Content of Polyetheretherketone (PEEK) on Adhesive Bond to Different Luting Resin Cements. J. Compos. Sci. 2023, 7, 456. [Google Scholar] [CrossRef]

- Stawarczyk, B.; Beuer, F.; Wimmer, T.; Jahn, D.; Sener, B.; Roos, M.; Schmidlin, P.R. Polyetheretherketone—A suitable material for fixed dental prostheses? J. Biomed. Mater. Res.—Part B Appl. Biomater. 2013, 101, 1209–1216. [Google Scholar] [CrossRef]

- Margolis, J.M. Engineering Thermoplastics; Marcel Dekker, Inc.: New York, NY, USA, 2020. [Google Scholar]

- Kurtz, S.M.; Devine, J.N. PEEK biomaterials in trauma, orthopedic, and spinal implants. Biomaterials 2007, 28, 4845–4869. [Google Scholar] [CrossRef]

- Lee, W.T.; Koak, J.Y.; Lim, Y.J.; Kim, S.K.; Kwon, H.B.; Kim, M.J. Stress shielding and fatigue limits of poly-ether-ether-ketone dental implants. J. Biomed. Mater. Res.—Part B Appl. Biomater. 2012, 100, 1044–1052. [Google Scholar] [CrossRef]

- Di Maggio, B.; Sessa, P.; Mantelli, P.; Maniscalco, P.; Rivera, F.; Calori, G.M.; Bisogno, L.; Scaravilli, G.; Caforio, M. PEEK radiolucent plate for distal radius fractures: Multicentre clinical results at 12 months follow up. Injury 2017, 48, S34–S38. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.W.; Stucker, B. Additive Manufacturing Technologies: 3D Printing, Rapid Pro-Totyping, and Direct Digital Manufacturing; Springer: Berlin/Heidelberg, Germany, 2021. [Google Scholar]

- Turner, B.N.; Strong, R.; Gold, S.A. A review of melt extrusion additive manufacturing processes: I. Process design and modeling. Rapid Prototyp. J. 2015, 21, 250–261. [Google Scholar] [CrossRef]

- Mohamed, O.A.; Masood, S.H.; Bhowmik, J.L. Optimization of fused deposition modeling process parameters: A review of current research and future prospects. Adv. Manuf. 2016, 4, 42–53. [Google Scholar] [CrossRef]

- Wang, W.; Wang, T. Anisotropic shrinkage and warpage of polymer parts in fused deposition modeling. Mater. Des. 2017, 135, 350–360. [Google Scholar]

- Singh, R.; Sandhu, A.; Kumar, R. Moisture absorption effect on the mechanical performance of FDM-printed parts. J. Thermoplast. Compos. Mater. 2018, 31, 1678–1695. [Google Scholar]

- Zhao, Y.; Zhang, S.; Zhao, X. Influence of composite filament properties on FDM-printed part per-formance: A review. J. Manuf. Process. 2019, 42, 101–117. [Google Scholar]

- Li, X.; Zhang, Y.; Chou, Y.K. Effects of process parameters on warping deformation of FDM printed parts. Int. J. Adv. Manuf. Technol. 2020, 106, 3767–3779. [Google Scholar]

- Yap, Y.L.; Yeong, W.Y.; Tan, C.S. Investigating the effects of nozzle temperature on mechanical properties of 3D-printed PEEK using fused deposition modeling. Mater. Des. 2017, 130, 70–79. [Google Scholar]

- Kuznetsov, V.E.; Solonin, A.N.; Urzhumtsev, O.D.; Schilling, R.; Tavitov, A.G. Strength anisotropy of 3D-printed specimens: Experimental characterization and numerical modeling. Mater. Des. 2018, 160, 79–89. [Google Scholar]

- Chacón, J.M.; Caminero, M.A.; García-Plaza, E.; Núñez, P.J. Additive manufacturing of PLA structures using fused deposition modelling: Effect of process parameters on mechanical properties and their optimal selection. Mater. Des. 2017, 124, 143–157. [Google Scholar] [CrossRef]

- Lee, J.; An, J.; Chua, C.K. Fundamentals and applications of 3D printing for novel materials. Appl. Mater. Today 2019, 15, 100571. [Google Scholar] [CrossRef]

- Mendes, L.A.; Neto, R.J.; Alves, J.L. Annealing effect on 3D printed parts: An experimental and numerical investigation. Polym. Test. 2021, 100, 107278. [Google Scholar]

- Lan, H.; Ding, Y.; Hong, J. Adaptive slicing for fused deposition modeling based on part geometry and build orientation. J. Manuf. Process. 2020, 49, 151–163. [Google Scholar]

- Gao, W.; Zhang, Y.; Ramanujan, D.; Ramani, K.; Chen, Y.; Williams, C.B.; Wang, C.C.L.; Shin, Y.C.; Zhang, S.; Zavattieri, P.D. The status, challenges, and future of additive manufacturing in engineering. Comput.-Aided Des. 2018, 69, 65–89. [Google Scholar] [CrossRef]

- Mohan, N.; Senthil, P.; Vinodh, S.; Jayanth, N. A review on influence of process parameters in addi-tive manufacturing using fused filament fabrication. Mater. Today Proc. 2021, 45, 6518–6524. [Google Scholar]

- Hussain, S.; Shakor, P.; Safaei, B. Self-healing materials for additive manufacturing: A review of re-cent advancements and challenges. Mater. Today Commun. 2022, 31, 103573. [Google Scholar]

- Dey, A.; Ashok, A.; Bose, S. Hybrid additive manufacturing: Merging different fabrication tech-niques for enhanced properties. Addit. Manuf. 2023, 47, 101241. [Google Scholar]

- Zhang, J.; Li, Z.; Li, Y. AI-driven real-time monitoring and control of warping in fused deposition modeling. Addit. Manuf. 2023, 54, 102847. [Google Scholar]

- Ren, Y.; Sikder, P.; Lin, B.; Bhaduri, S.B. Microwave assisted coating of bioactive amorphous magnesium phosphate (AMP) on polyetheretherketone (PEEK). Mater. Sci. Eng. C 2018, 85, 107–113. [Google Scholar] [CrossRef] [PubMed]

| Parameter | Hydra 16 AS |

|---|---|

| Hot End Type | Bowden type and dual nozzle |

| Print Process | Fused filament fabrication or fused deposition modeling |

| Resolution | Along the XY platform (15 μm) and along the Z direction (5 μm) |

| Minimum Layer Thickness | 50 μm |

| Print Speed | 250 mm/s |

| Build Temperature Type | Temperature-monitored enclosed chamber |

| Maximum Chamber Temperature | 90 °C |

| Maximum Platform Temperature | 150 °C |

| Platform Leveling | Kinematic auto bed leveling |

| Maximum Extrusion Temperature | 450 °C |

| Build Platform | Ceramic glass |

| Filament Storage | Enclosed bay with moisture control |

| Air Filtration Unit | HEPA H13 and activated carbon filter |

| Print Material | PEEK, PLA, ABS, PETG |

| Bed Size | 600 × 400 × 250 mm3 |

| Parameter | FDM (Fused Deposition Modeling) |

|---|---|

| Filament Diameter | 1.75 mm |

| Nozzle Diameter | 0.4 mm |

| Material Type | PEEK |

| File Compatibility | STL and G-code |

| Print Speed | 20 mm/s |

| Raster Angle | ±45° |

| Chamber Temperature | 60 °C |

| Printing Size (l × b × h) | 100 × 30 × 5 mm |

| Internal (Infill) Structure | Rectilinear |

| Level Number | Nozzle Temperature (°C) | Layer Height (mm) | Platform Temperature (°C) | Infill Ratio (%) |

|---|---|---|---|---|

| 1 | 400 | 0.16 | 130 | 60 |

| 2 | 410 | 0.18 | 140 | 80 |

| 3 | 420 | 0.20 | 150 | 100 |

| Run/Sample Number | Nozzle Temperature (°C) | Layer Thickness (mm) | Platform Temperature (°C) | Infill Rate (%) |

|---|---|---|---|---|

| 1 | 400 | 0.16 | 130 | 60 |

| 2 | 400 | 0.18 | 140 | 80 |

| 3 | 400 | 0.2 | 150 | 100 |

| 4 | 410 | 0.16 | 140 | 100 |

| 5 | 410 | 0.18 | 150 | 60 |

| 6 | 410 | 0.2 | 130 | 80 |

| 7 | 420 | 0.16 | 150 | 80 |

| 8 | 420 | 0.18 | 130 | 100 |

| 9 | 420 | 0.2 | 140 | 60 |

| Run/Sample No. | Tensile Stress at Break (MPa) | Strain at Break (%) | ||||||

|---|---|---|---|---|---|---|---|---|

| Average | Minimum | Maximum | Standard Deviation | Average | Minimum | Maximum | Standard Deviation | |

| 1 | 45.36 | 47.2 | 43 | 1.701 | 29.4 | 34 | 25.5 | 3.343 |

| 2 | 63.2 | 64.5 | 61.5 | 1.358 | 8.26 | 10 | 6 | 1.545 |

| 3 | 68.2 | 70 | 66 | 1.605 | 7.4 | 10 | 5 | 1.935 |

| 4 | 66.04 | 67.2 | 64 | 1.316 | 11.7 | 15 | 9 | 2.387 |

| 5 | 54.5 | 56 | 53 | 1.202 | 8.54 | 11 | 6 | 2.170 |

| 6 | 59.46 | 61 | 58 | 1.248 | 7.1 | 9 | 4 | 1.981 |

| 7 | 52.24 | 54 | 50.5 | 1.383 | 8.5 | 11 | 6 | 1.904 |

| 8 | 71.4 | 73 | 70 | 1.294 | 8.24 | 10 | 5.5 | 1.799 |

| 9 | 50.4 | 52 | 49 | 1.294 | 27.5 | 35 | 20 | 5.590 |

| Run/ Sample No. | Compression Stress at Break (MPa) | Strain at Break (%) | ||||||

|---|---|---|---|---|---|---|---|---|

| Average | Minimum | Maximum | Standard Deviation | Average | Minimum | Maximum | Standard Deviation | |

| 1 | 104.2 | 108 | 100 | 3.094 | 21.7 | 30 | 15.5 | 5.805 |

| 2 | 116.2 | 119 | 113 | 2.564 | 34 | 41.5 | 27.5 | 6.548 |

| 3 | 120.6 | 123.5 | 118 | 2.162 | 32.1 | 39 | 22 | 7.215 |

| 4 | 167 | 173 | 160 | 4.950 | 78 | 90 | 65 | 10.368 |

| 5 | 113.4 | 116 | 111 | 1.981 | 44.4 | 55 | 35 | 8.112 |

| 6 | 116.1 | 118 | 114 | 1.517 | 43 | 55 | 30 | 9.906 |

| 7 | 115.8 | 118 | 113 | 2.080 | 28.2 | 38 | 18 | 8.438 |

| 8 | 164.4 | 168 | 160 | 3.453 | 73 | 85 | 60 | 10.368 |

| 9 | 72.5 | 75 | 70 | 2.062 | 25.8 | 35 | 18 | 6.723 |

| Groups | Count | Tensile Loading | Compressive Loading | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Stress (MPa) | Strain (%) | Stress (MPa) | Strain (%) | ||||||||||

| Sum | Average | Variance | Sum | Average | Variance | Sum | Average | Variance | Sum | Average | Variance | ||

| 1 | 5 | 226.8 | 45.36 | 2.893 | 147 | 29.4 | 11.175 | 521 | 104.2 | 9.575 | 108.5 | 21.7 | 33.7 |

| 2 | 5 | 316 | 63.2 | 1.845 | 41.3 | 8.26 | 2.388 | 581 | 116.2 | 6.575 | 170 | 34 | 42.875 |

| 3 | 5 | 341 | 68.2 | 2.575 | 37 | 7.4 | 3.745 | 603 | 120.6 | 4.675 | 160.5 | 32.1 | 52.05 |

| 4 | 5 | 330.2 | 66.04 | 1.733 | 58.5 | 11.7 | 5.7 | 835 | 167 | 24.5 | 390 | 78 | 107.5 |

| 5 | 5 | 272.5 | 54.5 | 1.445 | 42.7 | 8.54 | 4.708 | 567 | 113.4 | 3.925 | 222 | 44.4 | 65.8 |

| 6 | 5 | 297.3 | 59.46 | 1.558 | 35.5 | 7.1 | 3.925 | 580.5 | 116.1 | 2.3 | 215 | 43 | 98.125 |

| 7 | 5 | 261.2 | 52.24 | 1.913 | 42.5 | 8.5 | 3.625 | 579 | 115.8 | 4.325 | 141 | 28.2 | 71.2 |

| 8 | 5 | 357 | 71.4 | 1.675 | 41.2 | 8.24 | 3.238 | 822 | 164.4 | 11.925 | 365 | 73 | 107.5 |

| 9 | 5 | 252 | 50.4 | 1.675 | 137.5 | 27.5 | 31.25 | 362.5 | 72.5 | 4.25 | 129 | 25.8 | 45.2 |

| Sample No. | Corner A | Corner B | Corner C | Corner D | Average |

|---|---|---|---|---|---|

| 1 | 1.46 | 1.30 | 0.83 | 0.61 | 1.05 |

| 2 | 1.80 | 2.73 | 1.78 | 0.97 | 1.82 |

| 3 | 6.09 | 6.43 | 2.06 | 2.07 | 4.16 |

| 4 | 4.53 | 4.47 | 3.70 | 2.87 | 3.89 |

| 5 | 6.02 | 2.95 | 6.63 | 7.89 | 5.87 |

| 6 | 3.43 | 3.11 | 1.72 | 1.10 | 2.34 |

| 7 | 1.44 | 1.38 | 1.65 | 1.47 | 1.49 |

| 8 | 4.97 | 4.42 | 3.85 | 4.54 | 4.45 |

| 9 | 4.48 | 3.82 | 2.08 | 2.15 | 3.13 |

| Average | 3.80 | 3.40 | 2.70 | 2.63 |

| Sample No. | Corner A | Corner B | Corner C | Corner D | Average |

|---|---|---|---|---|---|

| 1 | 3.3 | 6.3 | 1.6 | 2.2 | 3.35 |

| 2 | 4.9 | 7.5 | 4.4 | 2.1 | 4.72 |

| 3 | 20.7 | 13.4 | 8.8 | 5.5 | 12.10 |

| 4 | 19.6 | 15.5 | 11.2 | 11.5 | 14.45 |

| 5 | 17.2 | 12.8 | 21.6 | 23.2 | 18.70 |

| 6 | 10.8 | 10.6 | 7.6 | 5.9 | 8.72 |

| 7 | 6.0 | 5.7 | 6.4 | 5.5 | 5.90 |

| 8 | 21.9 | 12.0 | 13.5 | 21.1 | 17.12 |

| 9 | 22.0 | 11.7 | 9.6 | 11.4 | 13.67 |

| Average | 14.04 | 10.61 | 9.41 | 9.82 |

| Name | Cj | Weights | |

|---|---|---|---|

| Tensile | Stress | 2.573264 | 0.069236 |

| Strain | 3.498358 | 0.094127 | |

| Compression | Stress | 2.674397 | 0.071957 |

| Strain | 5.803776 | 0.156157 | |

| Warpage at each corner in mm | A | 2.630422 | 0.070774 |

| B | 2.269163 | 0.061054 | |

| C | 2.325958 | 0.062582 | |

| D | 2.474688 | 0.066584 | |

| Warpage at each corner in degrees | A | 2.906478 | 0.078202 |

| B | 2.354517 | 0.063351 | |

| C | 4.824957 | 0.129821 | |

| D | 2.830365 | 0.076154 | |

| Sum of weights | 1 | ||

| Run/Sample Number | Nozzle Temperature (°C) | Layer Thickness (mm) | Platform Temperature (°C) | Infill Rate (%) | Ranks |

|---|---|---|---|---|---|

| 1 | 400 | 0.16 | 130 | 60 | 1 |

| 2 | 400 | 0.18 | 140 | 80 | 3 |

| 3 | 400 | 0.2 | 150 | 100 | 5 |

| 4 | 410 | 0.16 | 140 | 100 | 7 |

| 5 | 410 | 0.18 | 150 | 60 | 8 |

| 6 | 410 | 0.2 | 130 | 80 | 4 |

| 7 | 420 | 0.16 | 150 | 80 | 2 |

| 8 | 420 | 0.18 | 130 | 100 | 6 |

| 9 | 420 | 0.2 | 140 | 60 | 9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Adarsh, S.H.; Nagamadhu, M. Effect of Printing Parameters on Mechanical Properties and Warpage of 3D-Printed PEEK/CF-PEEK Composites Using Multi-Objective Optimization Technique. J. Compos. Sci. 2025, 9, 208. https://doi.org/10.3390/jcs9050208

Adarsh SH, Nagamadhu M. Effect of Printing Parameters on Mechanical Properties and Warpage of 3D-Printed PEEK/CF-PEEK Composites Using Multi-Objective Optimization Technique. Journal of Composites Science. 2025; 9(5):208. https://doi.org/10.3390/jcs9050208

Chicago/Turabian StyleAdarsh, Sorekunte Huchappa, and Mahadevappa Nagamadhu. 2025. "Effect of Printing Parameters on Mechanical Properties and Warpage of 3D-Printed PEEK/CF-PEEK Composites Using Multi-Objective Optimization Technique" Journal of Composites Science 9, no. 5: 208. https://doi.org/10.3390/jcs9050208

APA StyleAdarsh, S. H., & Nagamadhu, M. (2025). Effect of Printing Parameters on Mechanical Properties and Warpage of 3D-Printed PEEK/CF-PEEK Composites Using Multi-Objective Optimization Technique. Journal of Composites Science, 9(5), 208. https://doi.org/10.3390/jcs9050208