FE Parametric Study of Composite Cold-Formed Steel Beams Under Positive and Negative Loadings

Abstract

1. Introduction

2. Finite Element Modeling

2.1. Material Properties

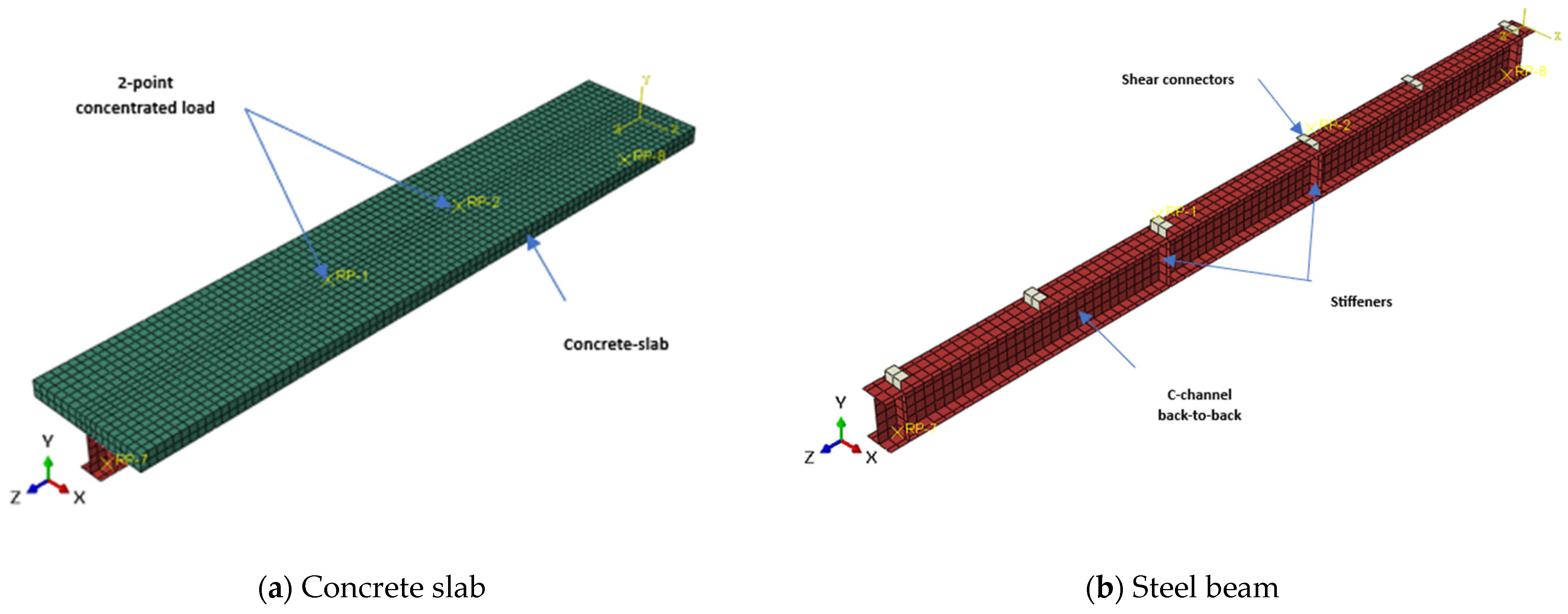

2.2. Elements, Loading, and Boundary Conditions

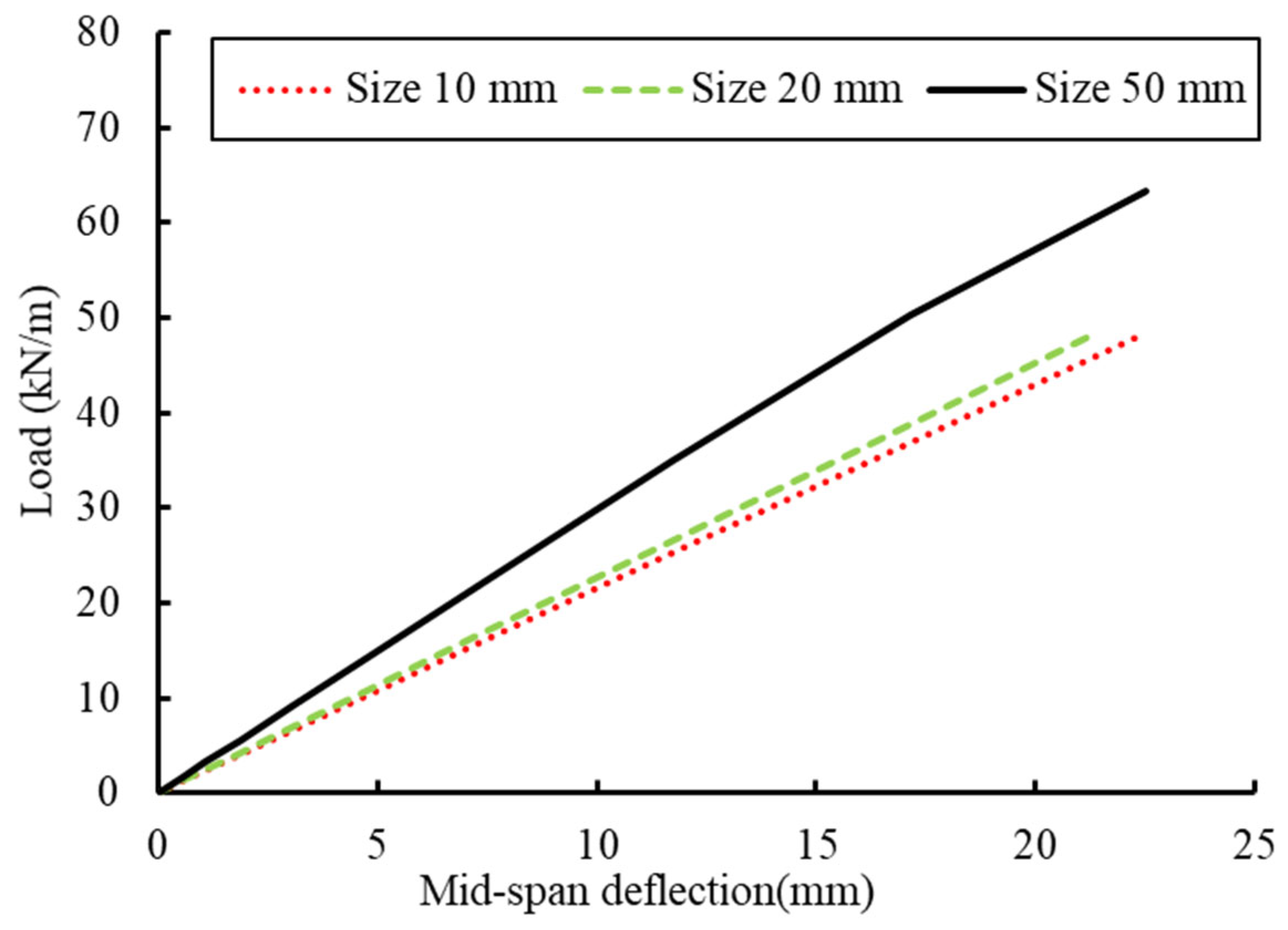

2.3. FE Meshing, Interaction, and Analysis Method

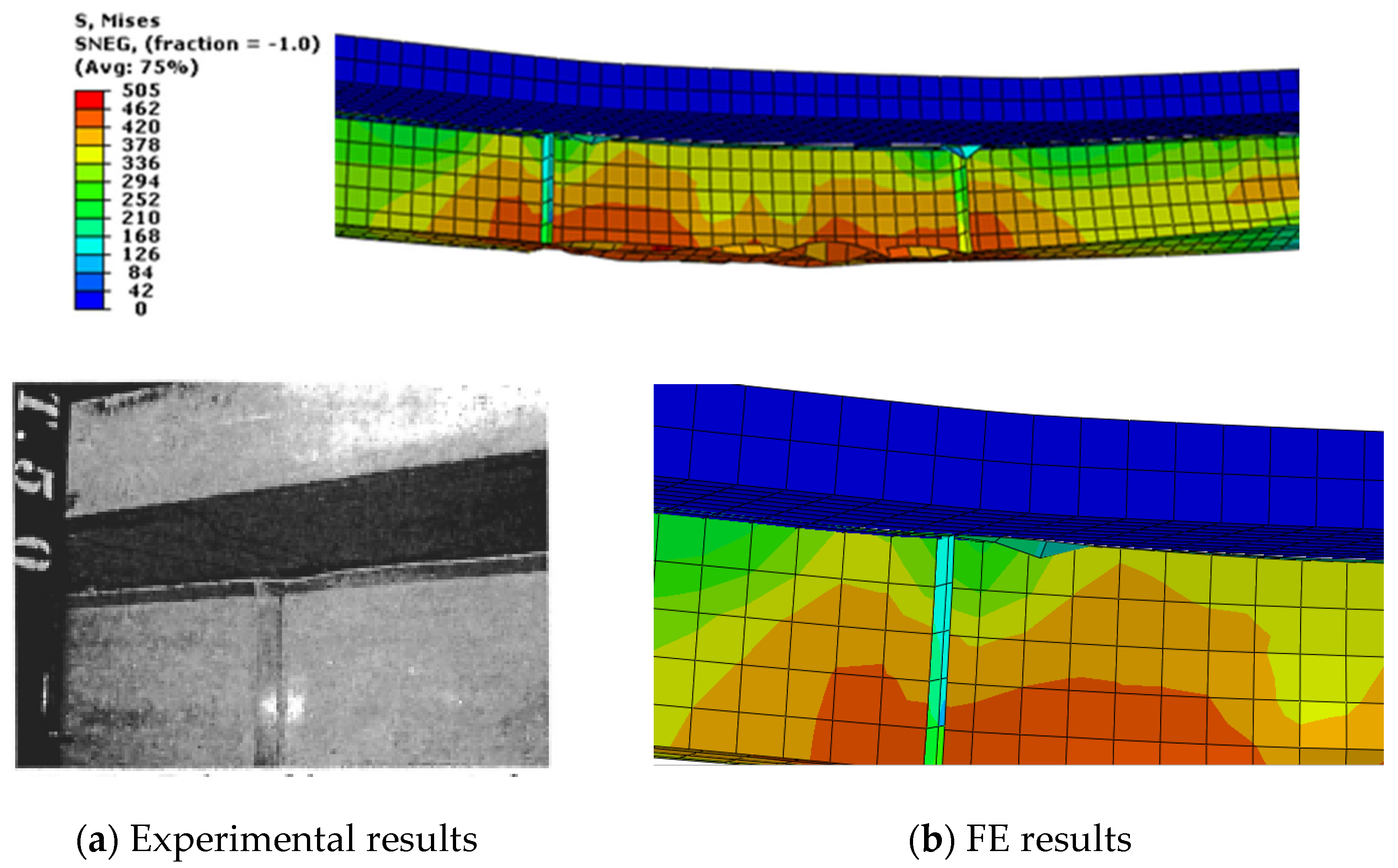

2.4. FE Verifications

3. Parametric Study

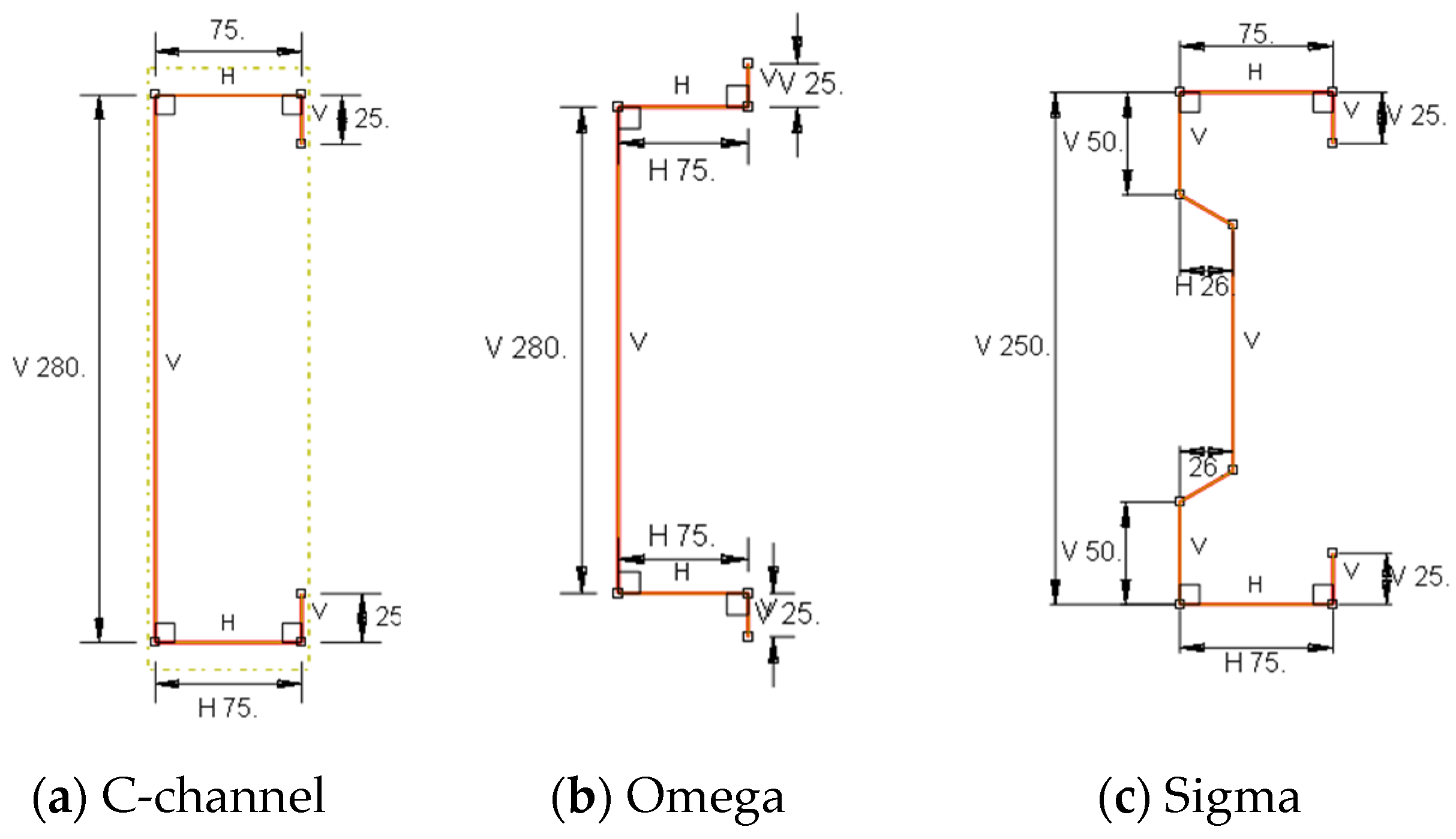

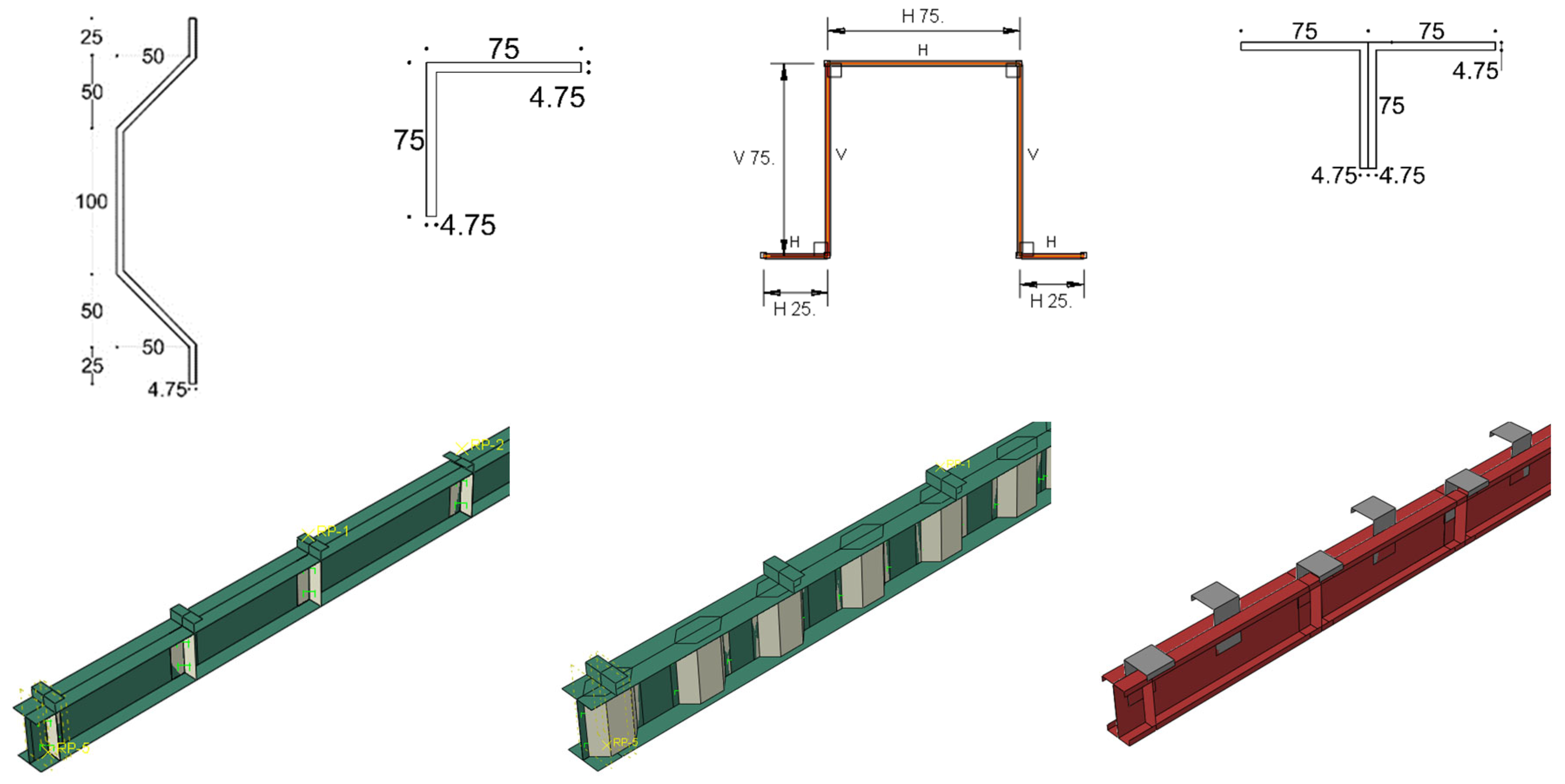

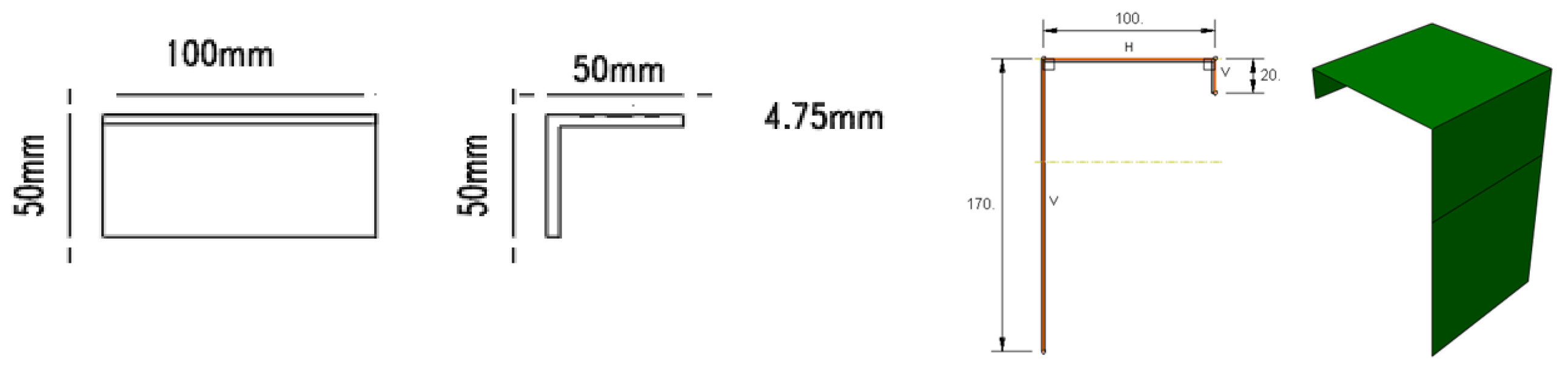

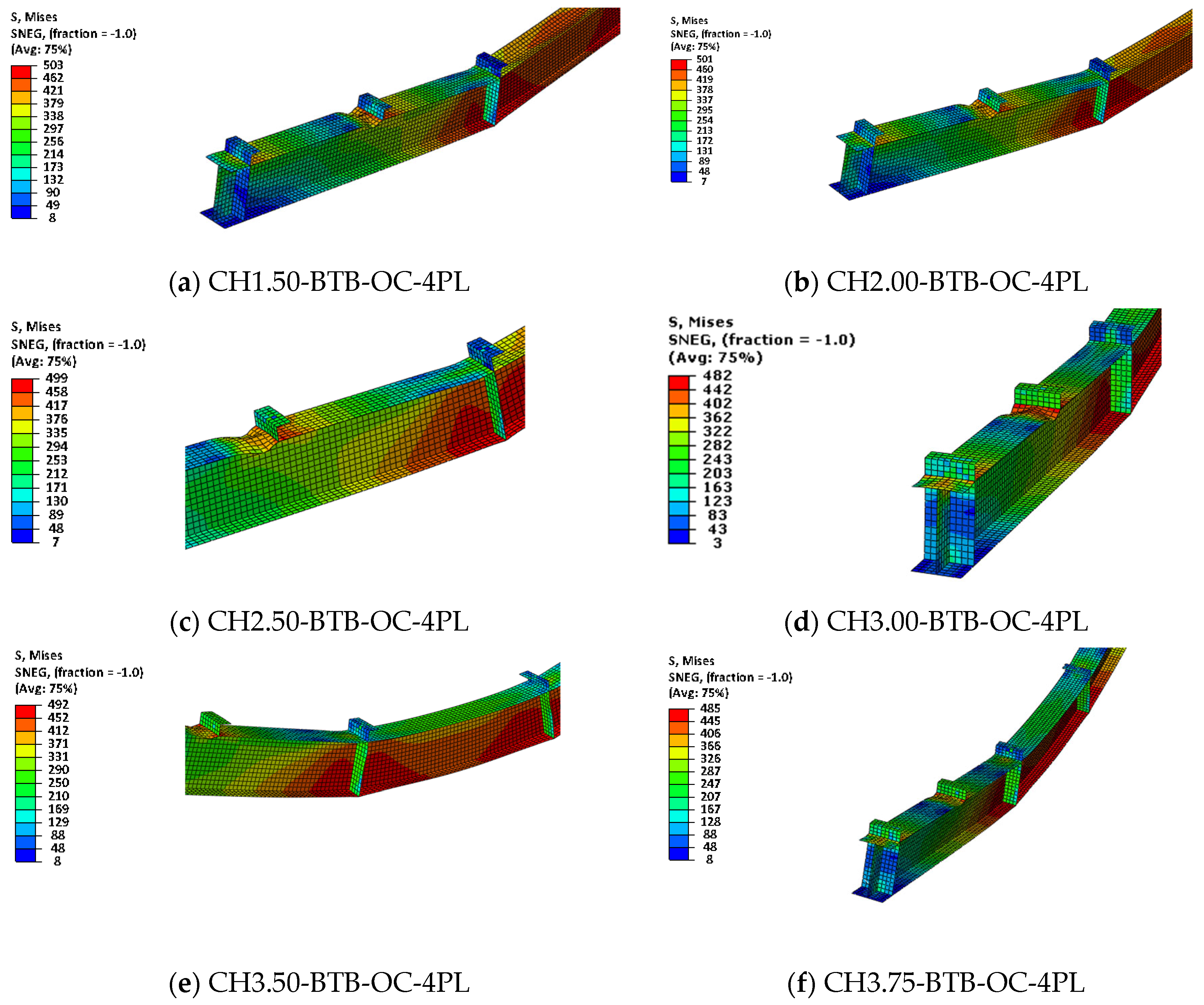

3.1. Section Geometry

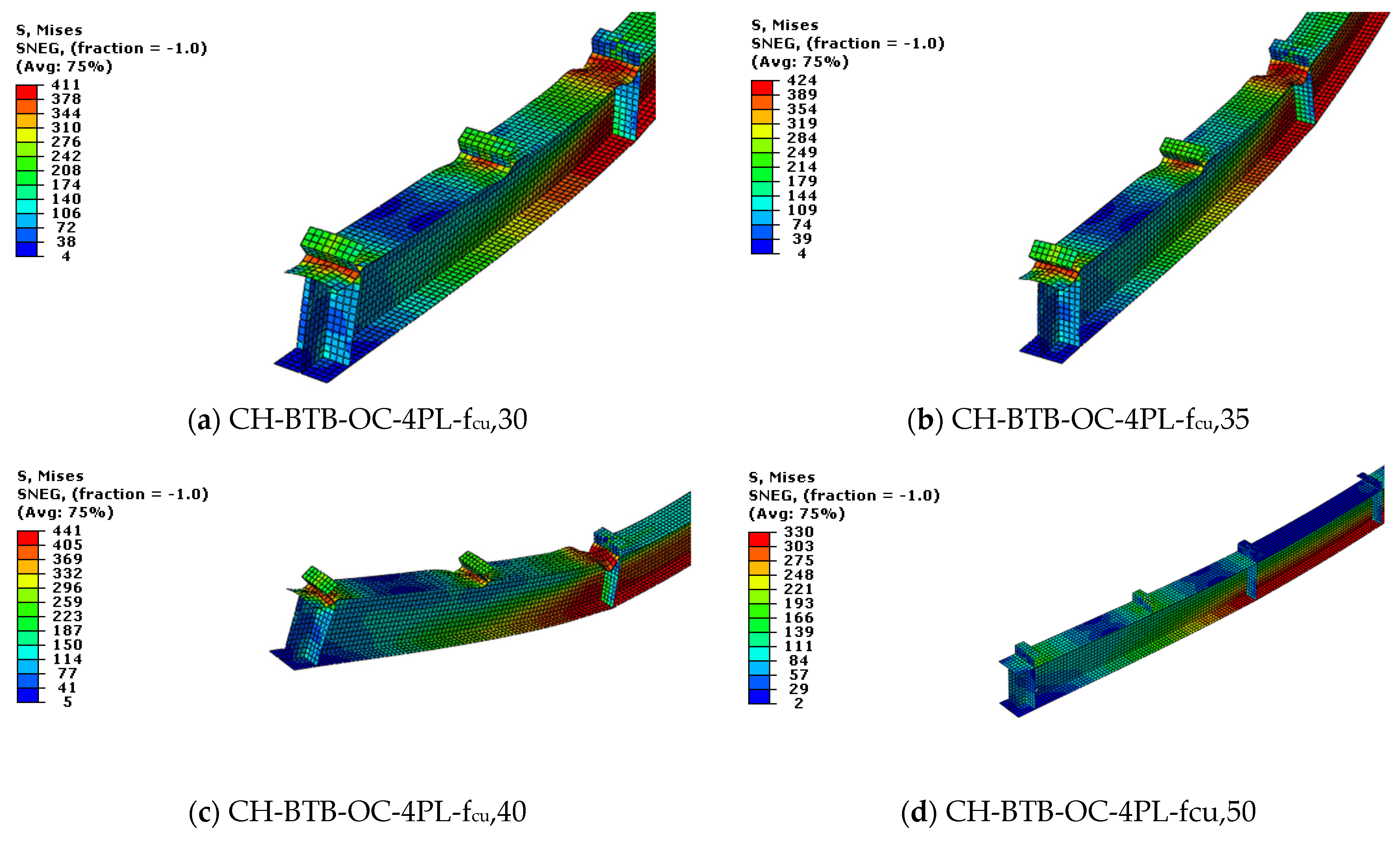

3.2. Concrete Compressive Strength

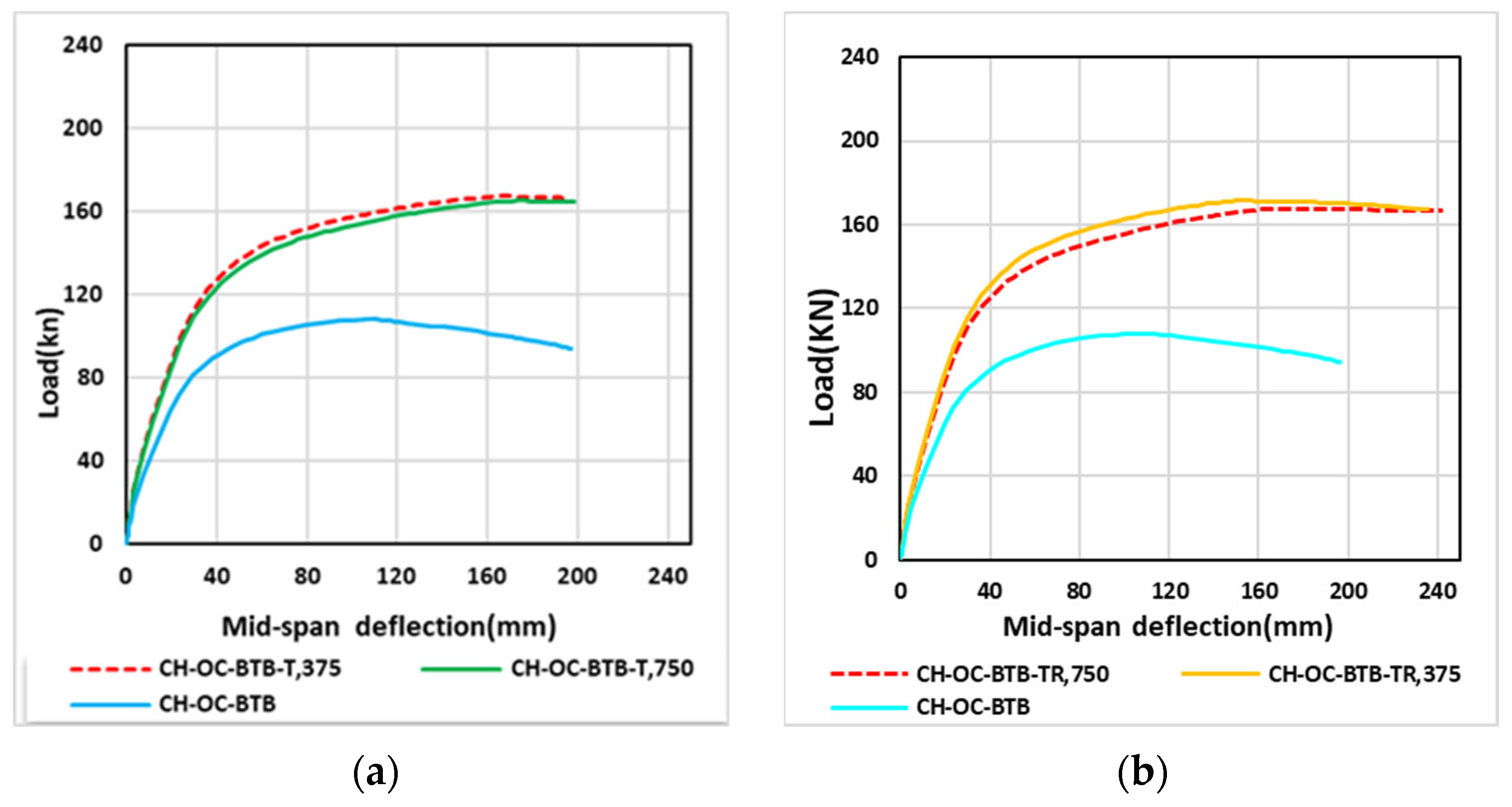

3.3. Type and Configurations of Proposed Stiffeners

3.4. Shear Connectors

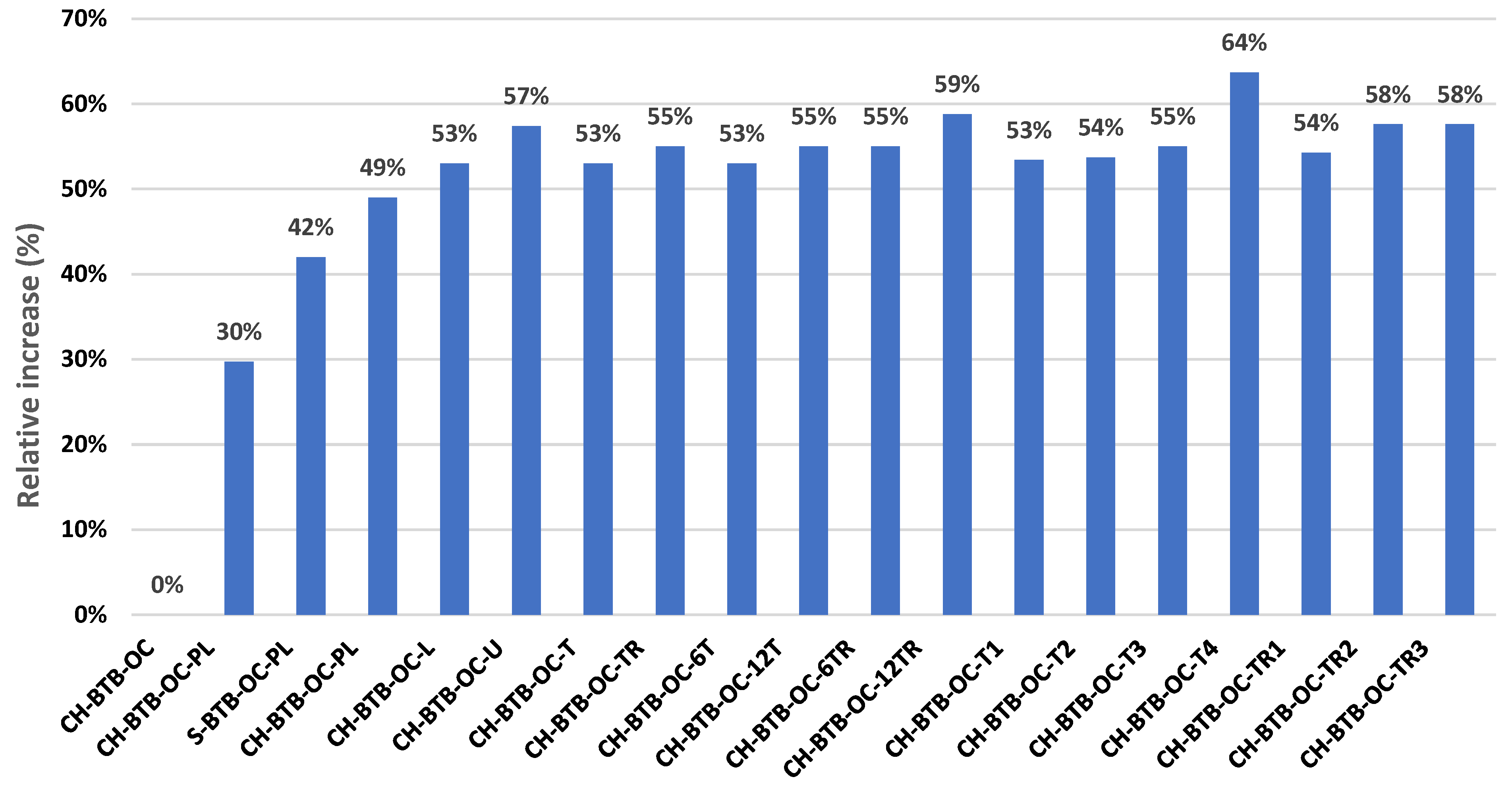

4. FE Results and Discussions

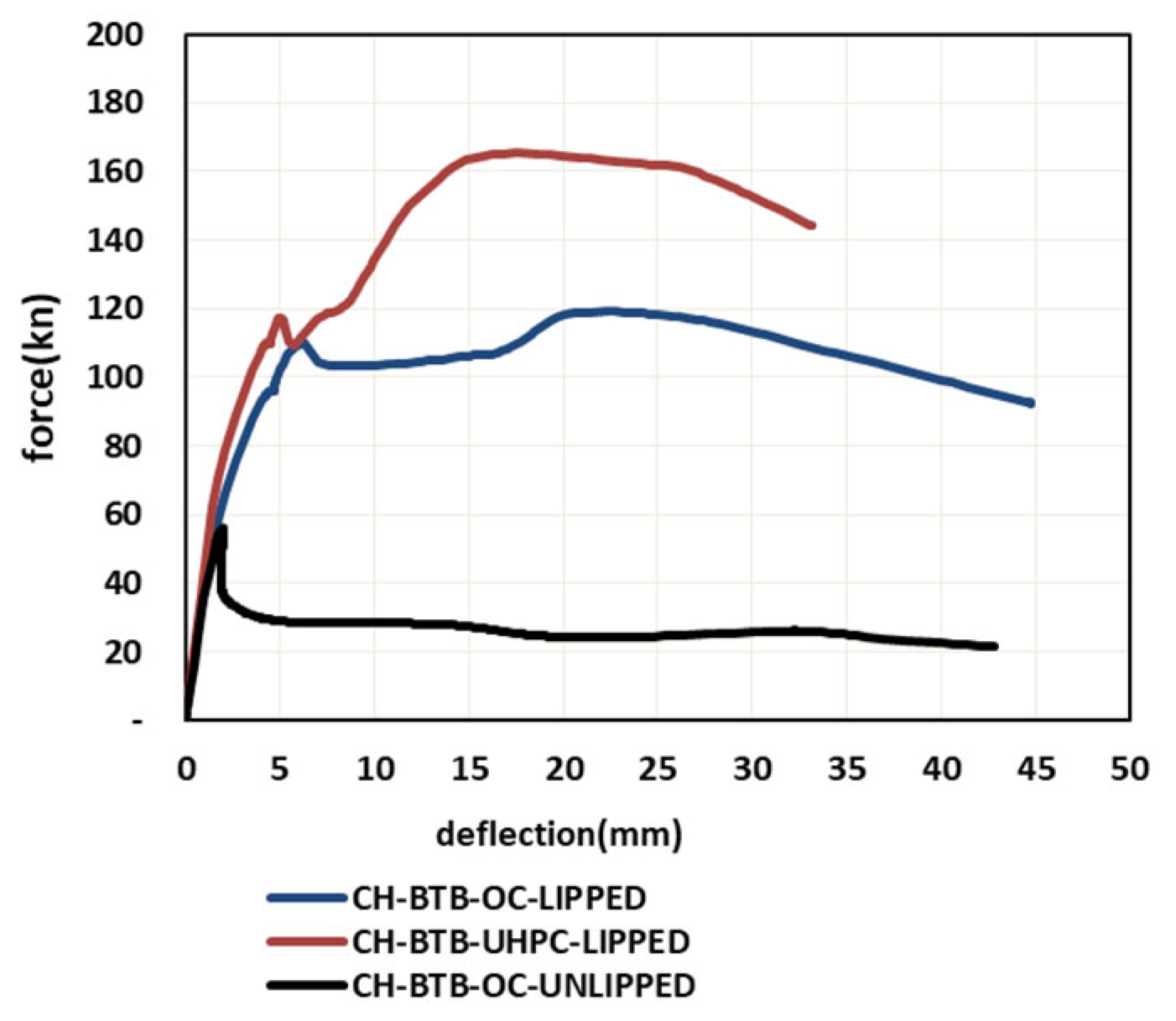

4.1. Load–Deflection Relationships

4.2. Modes of Failure

5. Conclusions

- The efficiency of the CSF with UHPC in negative loading enhances load capacity compared to CFS with ordinary concrete, achieving the highest first peak loads of 165.3 kN and 116.5 kN, respectively.

- Using a sigma CFS beam increased strength by 42% compared to a standard C-channel beam.

- Increasing the thickness of the C-channel as well as stiffener of CFS beam enhanced load-bearing capacity, likely due to improved flexural and buckling resistance.

- Local buckling became more pronounced in the cases of fcu = 400 and 500 MPa, indicating that increasing fcu led to a more brittle failure mode. The stress intensity in the flange and web increased.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Winter, G. Cold-formed light-gage steel construction. J. Struct. Div. 1959, 85, 151–173. [Google Scholar] [CrossRef]

- Yu, W.-W.; LaBoube, R.A.; Chen, H. Cold-Formed Steel Design; John Wiley & Sons: Hoboken, NJ, USA, 2019. [Google Scholar]

- Nguyen, R.P.; Yu, W.-W. Longitudinally reinforced cold-formed steel beam webs. J. Struct. Div. 1982, 108, 2423–2442. [Google Scholar] [CrossRef]

- Porter, M.L.; Ekberg, C.E., Jr. Design recommendations for steel deck floor slabs. J. Struct. Div. 1976, 102, 2121–2136. [Google Scholar] [CrossRef]

- Nguyen, R.P. Thin-walled, cold-formed steel composite beams. J. Struct. Eng. 1991, 117, 2936–2952. [Google Scholar] [CrossRef]

- Gotluru, B.P.; Schafer, B.W.; Peköz, T. Torsion in thin-walled cold-formed steel beams. Thin-Walled Struct. 2000, 37, 127–145. [Google Scholar] [CrossRef]

- Armo, A.A.S.; Saggaff, A.; Tahir, M.B.M. Push-out Test of Profiled Metal Decking Slabs with Cold-formed Steel Beams and Rebar Shear Connector. Walailak J. Sci. Technol. (WJST) 2021, 18, 19810–19825. [Google Scholar] [CrossRef]

- Al Zand, A.W.; Alghaaeb, M.F.; Liejy, M.C.; Mutalib, A.A.; Al-Ameri, R. Stiffening performance of cold-formed C-section beam filled with lightweight-recycled concrete mixture. Materials 2022, 15, 2982. [Google Scholar] [CrossRef]

- Majdub, M.S.; Baharom, S.; Al Zand, A.W.; Mutalib, A.A.; Hosseinpour, E. Innovation of Shear Connectors in Slim Floor Beam Construction. J. Eng. 2022, 2022, 2971811. [Google Scholar] [CrossRef]

- Nguyen, R.P. Strength of composite cold-formed steel-concrete beams. In Proceedings of the International Specialty Conference on Cold-Formed Steel Structures, St. Louis, MO, USA, 8–9 November 1988. [Google Scholar]

- Lakkavalli, B.S.; Liu, Y. Experimental study of composite cold-formed steel C-section floor joists. J. Constr. Steel Res. 2006, 62, 995–1006. [Google Scholar] [CrossRef]

- Hsiao, L.-E.; Yu, W.; Galambos, T.V. Load and Resistance Factor Design of Cold-Formed Steel Load and Resistance Factor Design Specification for Cold-Formed Steel Structural Members with Commentary; Cold-Formed Steel Library: Rolla, MO, USA, 1989. [Google Scholar]

- A Study on the Impact of Including Temporary Works in a BIM-Based Workflow for Cast-in-Place Concrete Construction—Theseus. Available online: https://www.theseus.fi/handle/10024/507892 (accessed on 21 February 2025).

- Simulation to Assess Cast-in-Place Concrete Construction Innovations. Available online: https://www.researchgate.net/publication/40868336_Simulation_to_assess_cast-in-place_concrete_construction_innovations (accessed on 21 February 2025).

- Alvarado, Y.; Gasch, I.; Calderón, P.; Torres, B. Study of Technical and Economical Alternatives of a Shoring and Striking Process during the Construction of a Building with Reinforced Concrete Slab Floors Estudio Técnico Económico de Alternativas del Proceso de Cimbrado y Descimbrado en la Construcción de un Edificio de Forjados de Losa Maciza de Hormigón Armado. Available online: www.ricuc.cl (accessed on 21 February 2025).

- Bamaga, S.O.; Tahir, M.M.; Tan, T.C.; Mohammad, S.; Yahya, N.; Saleh, A.L.; Mustaffar, M.; Osman, M.H.; Rahman, A.B.A. Feasibility of developing composite action between concrete and cold-formed steel beam. J. Central South Univ. 2013, 20, 3689–3696. [Google Scholar] [CrossRef]

- Wang, W.; Wang, J.; Zhao, P.; Ja, L.; Pan, G. Axial compressive experiments and structural behaviour estimation of CFS composite walls sprayed with LPM. J. Build. Eng. 2020, 30, 101305. [Google Scholar] [CrossRef]

- Franklin, N.P. Loadbearing Cold-Formed Steel for Mid-Rise Residential Buildings in Australia. November 2024. Available online: https://ro.uow.edu.au/articles/thesis/Loadbearing_Cold-Formed_Steel_for_Mid-Rise_Residential_Buildings_in_Australia/27668469?file=50390820 (accessed on 21 February 2025).

- Cross-Laminated Timber and Cold-Formed Steel Hybrid System: A New Approach. Available online: https://www.researchgate.net/publication/357605999_Cross-Laminated_Timber_and_Cold-Formed_Steel_Hybrid_System_A_New_Approach (accessed on 21 February 2025).

- Hussein, A.B.; Papp, F. State-of-the-Art: Integrating Fastener Technology and Design Guidelines for Enhanced Performance of Cold-Formed Steel Sections. Buildings 2023, 13, 2338. [Google Scholar] [CrossRef]

- Powell, E.; Mojtabaei, S.M.; Liew, A.; Hajirasouliha, I. Shear strength design of cold-formed steel channel sections with web openings. Eng. Struct. 2023, 291, 116426. [Google Scholar] [CrossRef]

- Siebers, R.; Fischer, D. Sustainable steel construction. Sustainable Steel Buildings: A Practical Guide for Structures and Envelopes; John Wiley & Sons: Hoboken, NJ, USA, 2016; p. 97. [Google Scholar]

- Laubscher, R.F.; van der Merwe, P. Structural design in hot rolled 3Cr12 sections. In Proceedings of the Stainless Steel Structures International Experts’ Seminar, Johannesburg, South Africa; 2003; pp. 93–100. [Google Scholar]

- Abdulrahman, A.S.; Kadir, M.R.A. Behavior and flexural strength of fire-damaged high-strength reinforced rectangular concrete beams with tension or compression zones exposed to fire repaired with CFRP sheets. Case Stud. Constr. Mater. 2021, 15, e00779. [Google Scholar] [CrossRef]

- Paik, J.K. Ultimate Limit State Analysis and Design of Plated Structures. In Ultimate Limit State Analysis and Design of Plated Structures; Wiley: Hoboken, NJ, USA, 2018. [Google Scholar] [CrossRef]

- Mohsan, N.M. Structural Behaviour of Concrete Filled Cold-Formed Steel Channel Wall Panel Under Axial Loading. 2020. Available online: http://openscience.utm.my/handle/123456789/689 (accessed on 21 February 2025).

- Agung, W.D. SNI 7971-2013 Struktur Baja Canai Dingin. Available online: https://www.academia.edu/14845422/SNI_7971_2013_Struktur_Baja_Canai_Dingin (accessed on 21 February 2025).

- Schafer, B.W. Cold-formed steel structures around the world: A review of recent advances in applications, analysis and design. Steel Constr. 2011, 4, 141–149. [Google Scholar] [CrossRef]

- Newman, A. Metal Building Systems. Available online: https://www.google.com/search?q=NEWMAN+A.+METAL+BUILDING+SYSTEMS&oq=NEWMAN+A.+METAL+BUILDING+SYSTEMS&gs_lcrp=EgZjaHJvbWUyBggAEEUYOTIHCAEQIRigAdIBBzg4N2owajSoAgCwAgE&sourceid=chrome&ie=UTF-8 (accessed on 21 February 2025).

- Schafer, B.; Ayhan, D.; Leng, J.; Liu, P.; Padilla-Llano, D.; Peterman, K.; Stehman, M.; Buonopane, S.; Eatherton, M.; Madsen, R.; et al. Seismic response and engineering of cold-formed steel framed buildings. Structures 2016, 8, 197–212. [Google Scholar] [CrossRef]

- Schafer, B.W. 00.02: Developments in research and assessment of steel structures: Highlights from the perspective of an American researcher. ce/papers 2017, 1, 95–114. [Google Scholar] [CrossRef]

- Transforming Istanbul—Istanbul Technical University. Available online: https://research.itu.edu.tr/en/publications/transforming-istanbul (accessed on 21 February 2025).

- ANSYS BKA. Spravochnik Pol’zovatelya [ANSYS: User Reference]. 2005. Available online: https://www.ansys.com/ (accessed on 21 February 2025).

- Gama, B.A.; Bogetti, T.A.; Gillespie, J.W., Jr. Progressive damage modeling of plain-weave composites using LS-Dyna composite damage model MAT162. In Proceedings of the 7th European LS-DYNA Conference, Salzburg, Austria, 14–15 May 2009; pp. 14–15. [Google Scholar]

- Nawar, M.T.; Arafa, I.T.; Elhosseiny, O.M. Numerical damage evaluation of perforated steel columns subjected to blast loading. Def. Technol. 2022, 18, 735–746. [Google Scholar] [CrossRef]

- Abaqus Finite Element Analysis|SIMULIA—Dassault Systèmes. Available online: https://www.3ds.com/products/simulia/abaqus (accessed on 21 February 2025).

- Carreira, D.J.; Chu, K.H. Stress-strain relationship for plain concrete in compression. ACI J. Proc. 1985, 82, 797–804. [Google Scholar] [CrossRef]

- Jabbar, A.M.; Al-Zuheriy, A.S.J.; Hasan, Q.A. A numerical investigation of the structural behavior of reinforced concrete beams fully or partially encased with UHPC layers in flexure. Structures 2024, 70, 107706. [Google Scholar] [CrossRef]

- Nawar, M.T.; Silem, O.A.; Ibrahim, I.; Maaly, H.M.; Ibrahim, Y.E. Enhancing the Toughness of Composite Cold-Formed Steel Beams with ECC and Different Stiffener Arrangements and Shapes. J. Compos. Sci. 2025, 9, 24. [Google Scholar] [CrossRef]

- European Union. EN 1992-2: Eurocode 2: Design of Concrete Structures—Part 2: Concrete Bridges—Design and Detailing Rules; European Union: Brussels, Belgium, 1992. [Google Scholar]

- Lai, Z.; Weng, X.; Li, D.; Li, L. Shear behavior of high-strength tie bar connectors embedded in UHPC. Structures 2025, 72, 108200. [Google Scholar] [CrossRef]

- Lai, Z.; Wang, J.; Chen, X.; Li, D. Shear behavior of square ultra-high performance concrete-filled high-strength steel tube members. J. Constr. Steel Res. 2023, 212, 108330. [Google Scholar] [CrossRef]

- Malite, M.; Nimir, W.; de Sales, J.; Goncalves, R. On the Structural Behavior of Composite Beams Using Cold-formed Shapes. In Proceedings of the CCFSS International Specialty Conference on Cold-Formed Steel Structures (1971–2018), St. Louis, MO, USA, 19 October 2000; Available online: https://scholarsmine.mst.edu/isccss/15iccfss/15iccfss-session5/2 (accessed on 21 February 2025).

| Dilation Angle (Ψ) | Eccentricity (ε) | (σb0/σc0) | k | Parameter Viscosity μ |

|---|---|---|---|---|

| 56 | 0.1 | 1.16 | 0.667 | 0 |

| Specimen | Compressive Strength (MPa) | Modulus of Elasticity (MPa) |

|---|---|---|

| VA1 | 31.9 | 36,844 |

| VA2 | 29.6 | 33,467 |

| VA3 | 28.1 | 33,172 |

| Element | fy (MPa) | fu (MPa) | E (MPa) | A (%) |

|---|---|---|---|---|

| CFS beams | 377 | 543 | 203,000 | 29.2 |

| Shear connectors | 246 | 360 | 203,000 | 39.8 |

| Group | Loading | Parameter | Beam ID | Concrete | Stiffeners |

|---|---|---|---|---|---|

| 1 | Sagging moment loadings | Concrete strength | (CH-BTB-OC-fc,30) | fcu = 30 | 2pl |

| (CH-BTB-OC-fc,35) | fcu = 35 | 2pl | |||

| (CH-BTB-OC-fc,40) | fcu = 40 | 2pl | |||

| (CH-BTB-OC-fc,50) | fcu = 50 | 2pl | |||

| CFS beam dimensions | (CH1.5-BTB-OC) | OC | 2PL | ||

| (CH2.0-BTB-OC) | OC | 2PL | |||

| (CH3.0-BTB-OC) | OC | 2PL | |||

| (CH3.5-BTB-OC) | OC | 2PL | |||

| (CH3.75-BTB-OC) | OC | 2PL | |||

| With and without stiffeners | (CH-BTB-OC-SPL) | OC | 2PL | ||

| (CH- BTB-OC-NS) | OC | - | |||

| CFS beam type | (CH-BTB-OC-4PL) | OC | 4PL | ||

| (S-BTB-OC-4PL) | OC | 4PL | |||

| Stiffener type | (CH-BTB-OC-2PL) | OC | 2PL | ||

| (CH-BTB-OC-6L) | OC | 6L-stiffener | |||

| (CH-BTB-OC-6U) | OC | 6U-HAT | |||

| (CH-BTB-OC-6T) | OC | 6T-stiffener | |||

| (CH-BTB-OC-6TR) | OC | 6TR-stiffener | |||

| Stiffener spacing | (CH-BTB-OC-6T) | OC | 6T-stiffener | ||

| (CH-BTB-OC-12T) | OC | 12T-stiffener | |||

| (CH-BTB-OC-6TR) | OC | 6TR-stiffener | |||

| (CH-BTB-OC-12TR) | OC | 12TR-stiffener | |||

| Stiffener thickness | (CH-BTB-OC-T1) | OC | T-stiffener | ||

| (CH-BTB-OC-T2) | OC | T-stiffener | |||

| (CH-BTB-OC-T3) | OC | T-stiffener | |||

| (CH-BTB-OC-T4) | OC | T-stiffener | |||

| (CH-BTB-OC-TR1) | OC | TR-stiffener | |||

| (CH-BTB-OC-TR2) | OC | TR-stiffener | |||

| (CH-BTB-OC-TR3) | OC | TR-stiffener | |||

| (CH-BTB-OC-6TR) | OC | TR-stiffener | |||

| 2 | Hogging moment loadings | (CH- BTB-OC) | OC | TR-stiffener | |

| (CH-BTB-OC-4PL)-lipped | OC | 4PL | |||

| (CH-BTB-UHPC-4PL) unlipped | UHPC | 4PL | |||

| (CH-BTB-UHPC-4PL) lipped | UHPC | 4PL |

| Specimen ID | Length, L (mm) | CFS Flange Width, bf (mm) | CFS Web Depth, h (mm) | CFS Thickness, tc (mm) | Slab Width, b (mm) | Slab Thickness, ts (mm) | Type of Shear Connector | Stiffener Thickness (mm) | Stiffener Spacing (mm) |

|---|---|---|---|---|---|---|---|---|---|

| CH-BTB-OC-4PL | 4200 | 75 | 250 | 3.75 | 800 | 100 | Angel-L | 4.75 | 1333 |

| CH-BTB-OC-2PL | 4200 | 75 | 250 | 3.75 | 800 | 100 | Angel-L | 4.75 | 4000 |

| S-BTB-OC-4PL | 4200 | 75 | 250 | 3.75 | 800 | 100 | Angel-L | 4.75 | 1333 |

| CH-BTB-OC-6L | 4200 | 75 | 250 | 3.75 | 800 | 100 | Angel-L | 4.75 | 750 |

| CH-BTB-OC-6U | 4200 | 75 | 250 | 3.75 | 800 | 100 | Angel-L | 4.75 | 750 |

| CH-BTB-OC-6T | 4200 | 75 | 250 | 3.75 | 800 | 100 | Angel-L | 4.75 | 750 |

| CH-BTB-OC-6TR | 4200 | 75 | 250 | 3.75 | 800 | 100 | Angel-L | 4.75 | 750 |

| CH-BTB-OC-12T | 4200 | 75 | 250 | 3.75 | 800 | 100 | Angel-L | 4.75 | 375 |

| CH-BTB-OC-12TR | 4200 | 75 | 250 | 3.75 | 800 | 100 | Angel-L | 4.75 | 375 |

| CH-BTB-OC-T1 | 4200 | 75 | 250 | 3.75 | 800 | 100 | Angel-L | 2.00 | 750 |

| CH-BTB-OC-T2 | 4200 | 75 | 250 | 3.75 | 800 | 100 | Angel-L | 3.00 | 750 |

| CH-BTB-OC-T3 | 4200 | 75 | 250 | 3.75 | 800 | 100 | Angel-L | 4.75 | 750 |

| CH-BTB-OC-TR1 | 4200 | 75 | 250 | 3.75 | 800 | 100 | Angel-L | 2.00 | 750 |

| CH-BTB-OC-TR2 | 4200 | 75 | 250 | 3.75 | 800 | 100 | Angel-L | 3.00 | 750 |

| CH-BTB-OC-TR3 | 4200 | 75 | 250 | 3.75 | 800 | 100 | Angel-L | 4.75 | 750 |

| CH-BTB-OC-PL)-lipped | 2200 | 50 | 200 | 3.75 | 500 | 100 | Angel-L | 2.00 | 665 |

| CH-BTB-OC-PL)-unlipped | 2200 | 50 | 200 | 3.75 | 500 | 100 | Angel-L | 2.00 | 665 |

| CH-BTB-UHPC-PL)-lipped | 2200 | 50 | 200 | 3.75 | 500 | 100 | Angel-L | 2.00 | 665 |

| Group | Sample | No. of Stiffener | Stiffener Spacing (mm) | Stiffener Thickness (mm) | First Peak Load (kn) | Deflection–Peak (mm) | Failure Load (kn) | Max–Deflection (mm) | Increasing Strengthen |

|---|---|---|---|---|---|---|---|---|---|

| G-1 | CH-BTB-OC | 2 | - | 4.7 | 108.088 | 107.01 | 94.07 | 197.33 | NS |

| CH-BTB-OC-PL | 4 | 1333 | 4.75 | 153.3 | 235.67 | 153.3 | 235.67 | 29.7% | |

| CH-BTB-OC-PL | 6 | 750 | 4.75 | 153.37 | 103.5 | 139.43 | 139.98 | NS | |

| S-BTB-OC-PL | 6 | 750 | 4.75 | 146.65 | 97.1844 | 146.65 | 97.1844 | 42% | |

| CH-BTB-OC-PL | 6 | 750 | 4.75 | 161 | 176.9 | 49% | |||

| CH-BTB-OC-L | 6 | 750 | 4.75 | 165.323 | 174.559 | 164.69 | 198.277 | 53% | |

| CH-BTB-OC-U | 6 | 750 | 4.75 | 158.60 | 169.9 | 153.7 | 231.36 | 57.4% | |

| CH-BTB-OC-T | 6 | 750 | 4.75 | 165.3 | 173.24 | 164.7 | 198.27 | 53% | |

| CH-BTB-OC-TR | 6 | 750 | 4.75 | 167.60 | 165.26 | 166.36 | 242.36 | 55% | |

| CH-BTB-OC-6T | 6 | 750 | 4.75 | 165.323 | 174.5 | 165 | 198.27 | 53% | |

| CH-BTB-OC-12T | 12 | 375 mm | 4.75 | 167.56 | 168.1 | 166.5 | 194.342 | 55% | |

| CH-BTB-OC-6TR | 6 | 750 mm | 4.75 | 167.60 | 162.25 | 166.36 | 242.36 | 55% | |

| CH-BTB-OC-12TR | 12 | 375 mm | 4.75 | 171.679 | 154.17 | 167.1 | 236.4 | 58.8% | |

| CH-BTB-OC-T1 | 12 | 375 mm | 2.00 | 165.7 | 177 | 165.6 | 178.6 | 53.4% | |

| CH-BTB-OC-T2 | 12 | 375 mm | 3.00 | 166.8 | 174.8 | 166.6 | 176.62 | 53.7% | |

| CH-BTB-OC-T3 | 12 | 375 mm | 4.75 | 167.562 | 168 | 166.5 | 194.34 | 55% | |

| CH-BTB-OC-T4 | 12 | 375 mm | 7.5 | 176.841 | 147.7 | 167.75 | 236.5 | 63.7% | |

| CH-BTB-OC-TR1 | 12 | 375 mm | 2.00 | 155.4 | 166.6 | 155.46 | 166.6 | 54.25% | |

| CH-BTB-OC-TR2 | 12 | 375 mm | 3.00 | 170.2 | 161.5 | 165.9 | 234.3 | 57.6% | |

| CH-BTB-OC-TR3 | 12 | 375 mm | 4.75 | 171.6 | 154.1 | 167.1 | 236.4 | 58.8% | |

| G-2 | CH-BTB-OC-2PL-lipped | 2 | 666.6 | 2.00 | 94 | 3.49 | 64 | 3.39 | NS |

| CH-BTB-OC-4PL-lipped | 4 | 666.6 | 2.00 | 119 | 24.24 | 92 | 44.7 | 26.5% | |

| CH-BTB-OC-4PLunlipped | 4 | 666.6 | 2.00 | 56 | 1.998 | 21 | 42.7 | 40.4% Decrease | |

| CH-BTB-UHPC-4PL lipped | 4 | 666.6 | 2.00 | 165 | 19.96 | 144 | 33.2 | 75.5% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nawar, M.T.; El-Zohairy, A.; Eisa, A.S.; Mohammed, A.; Gomaa, S. FE Parametric Study of Composite Cold-Formed Steel Beams Under Positive and Negative Loadings. J. Compos. Sci. 2025, 9, 209. https://doi.org/10.3390/jcs9050209

Nawar MT, El-Zohairy A, Eisa AS, Mohammed A, Gomaa S. FE Parametric Study of Composite Cold-Formed Steel Beams Under Positive and Negative Loadings. Journal of Composites Science. 2025; 9(5):209. https://doi.org/10.3390/jcs9050209

Chicago/Turabian StyleNawar, Mahmoud T., Ayman El-Zohairy, Ahmed S. Eisa, Amal Mohammed, and Shady Gomaa. 2025. "FE Parametric Study of Composite Cold-Formed Steel Beams Under Positive and Negative Loadings" Journal of Composites Science 9, no. 5: 209. https://doi.org/10.3390/jcs9050209

APA StyleNawar, M. T., El-Zohairy, A., Eisa, A. S., Mohammed, A., & Gomaa, S. (2025). FE Parametric Study of Composite Cold-Formed Steel Beams Under Positive and Negative Loadings. Journal of Composites Science, 9(5), 209. https://doi.org/10.3390/jcs9050209