1. Introduction

The process of liquid material extrusion, also called liquid deposition modeling (LDM), is currently being investigated in several engineering applications [

1,

2]. Although LDM is comparatively fast, cost-effective, and versatile [

3], material-related shrinkage and inaccuracies in material deposition have to be considered [

4] in the initial design. Problematic issues include perforations and material overhangs, which can only be addressed by a high amount of support structures that have to be painstakingly removed afterwards [

5]. Current approaches attempt to minimize the complex deformation behavior of liquid masses by utilizing materials that solidify quickly after deposition [

6]. Thus, a technically orientated approach is pursued, in which the material deposition follows the highly accurate instructions generated based on digital design. Pérez-Gomez described the influence of the tool or machine on the process and concluded, “tools are never neutral” [

7]. The potential for digital fabrication to overcome machine limitations in design processes is recognized and encouraged in various approaches [

8]. In this context, hardware, software, and material need to be more interconnected in order to complement each other [

8].

Contactless forming using electromagnetic fields is well-known from sheet metal forming. In this process, an inductor generates a pulsating electromagnetic field and changes the shape of the workpiece by means of opposing eddy currents [

9]. The forming of ceramic liquids by magnetic fields is not yet known. In fused deposition modeling, the effects of electromagnetic force on thermoplastic materials have already been demonstrated [

10]. The “magnetic force control device” developed for this purpose deforms the heated thermoplastic material via planar “arranged 3 × 3 actuators”. As the material cools and solidifies in the shape defined by the magnetic field. In a similar way, electromagnetic fields at the nozzle outlet of a filament extruder are also used to align soft and hard magnetic particles in the plastic filament and thus produce cost-effective complex-shaped permanent magnets [

11].

The electromagnetic forming of ceramic liquids becomes possible when soft magnetic particles are integrated. This fundamentally changes the material properties. Today, ceramics and metals are combined in industrial engineering to form composites with advantageous thermophysical and mechanical properties. Ceramic-particle-reinforced MMCs (metal matrix composites) or metal–ceramic composites with percolating structures are well-established. For this purpose, ceramic particles are, for example, alloyed into steels (e.g., ODS steels) to increase strength or wear resistance, or open-porous ceramics are pressure-infiltrated with copper, for example, to increase the fracture toughness and thermal conductivity of the monolithic ceramic. MMCs can also be produced by molding plastic masses and sintering. In the field of CMCs (ceramic matrix composites), ceramic fibers are incorporated into plastics or a ceramic matrix itself to achieve, for example, higher fracture elongation and crack resistance or thermal shock resistance for space, energy, and lightweight applications. Integrating ductile metal particles into a ceramic matrix can increase crack toughness by bridging cracks [

12]. Depending on the thermal expansion coefficient, microresidual stresses can be exploited for crack deflection. Despite this, metal-particle-reinforced CMCs are still considered scientific curiosities rather than established engineering materials [

13]. Ductile iron particles in an Al

2O

3 matrix have been investigated with different particle sizes and distributions as well as fabrication methods in terms of thermal shock resistance and residual strength or cracking behavior [

14,

15,

16,

17]. The typical sintering atmosphere is argon to avoid the (partial) oxidation of the metallic particles.

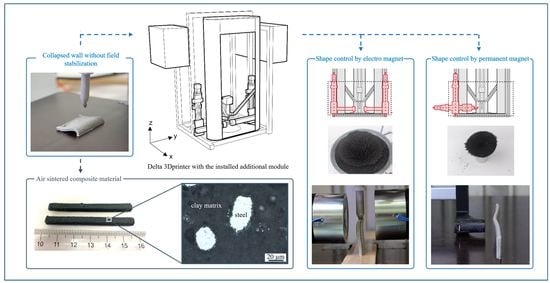

The aim of the present study was to compare the basic types and arrangements of magnets and the resulting ability to deform a green body in a controlled manner. Consequently, a composite material with a sufficient amount of metal particles must be developed to enable electromagnetic forming. At the same time, however, the proportion of metal particles must be low enough to avoid the high residual stresses and damage induced by the high thermal expansion of the added particles. In addition to pure iron particles, soft magnetic particles made of martensitic and ferritic corrosion-resistant steel were also tested. In order to produce cost-effective composites in the future, sintering should take place in air atmosphere. Two case studies were conducted to investigate how the still-soft composite material could be reshaped during or immediately after the printing process into a new geometry that deviates from the printing parameters. The magnetic fields required for deformation were created either by an electromagnet at a fixed position (case study 1) or by a movable permanent magnet (case study 2). To avoid the collision of the permanent magnet and printed part, the distance between the printed part and the magnet was monitored by an optical sensor.The described exploratory approach aims to investigate the design potential of liquid masses for an integrated, design-oriented approach and to unlock and harness the malleability of the material postdeposition as part of the design and manufacturing process.

2. Materials and Methods

This study was based on the following assumptions: (1) The developed composite material has deformation, drying, and sintering behaviors similar to pure clay bodies, whose behaviors in LDM have been described in previous publications [

18]. (2) The additive build-up process of clay bodies by the LDM system, Delta WASP2040 Clay Printer, through G-code instructions is well-known. (3) The investigation on the control of the liquid composite material and its molding behavior was carried out using a self-developed autonomous add-on module made for the dimensions of the Delta WASP2040 Clay Printer. (4) A digital model in the form of a wall was adopted for the comparability of the test results. The wall produced in the LDM was only conditionally stable without a support structure.

2.1. Composite Material

The liquid material was created by adding ferromagnetic steel particles to kaolinitic clay powder (see

Table 1), homogenizing the blend with a roller mixer, and adding water.

To prevent high frictional forces from affecting the nozzle during the printing process, fine, spherical steel particles were employed. To minimize corrosion in the water-based mixture at a pH of 7.1 and the high-temperature oxidation during sintering, the steel needed to form an external protective chromia layer. This demanded high chromium contents. In addition, a soft magnetic material that aligned with the external magnetic field was required. In this study, AISI 430L special atomized ferritic steel powder was available for preliminary material development tests. For the compression tests, AISI 630 martensitic steel, which is commercially available, was used. For comparison purposes, another mass was prepared using pure iron powder.

Table 2 summarizes the chemical compositions, particle sizes, and shapes of the powders used.

After air drying, green bodies were sintered with the typical sintering profile of clay (100 K/h to 600 °C, 300 K/h to 1200 °C (2 h), and 300 K/h to RT). Samples were embedded in epoxy resin, prepared, and examined under an optical microscope (Axiophot, Zeiss, Jena, Germany) and a scanning electron microscope (LSM 6400, Jeol, Freising, Germany) to evaluate particle attachment after cosintering and different standing times of the liquid mass. Possible reactions between steel and clay were observed during sintering in a differential scanning calorimeter (DSC 404, Netzsch, Selb, Germany) with increasing contents of AISI 630 particles. The flexural strength of the CMC composite was determined by a four-point bending test according to EN 843-1. All bending bars were printed with a fixed composition of 17.5 wt.% AISI 430L steel particles, 52.5 wt.% clay powder, and 30 wt.% water. The expansion behavior of such a bending bar during heating and sintering was investigated in a dilatometer (DIL 402C, Netzsch, Selb Germany).

2.2. LDM System

The clay printer used for the experiments corresponded to the configuration of a Delta printer with three double support rods moving in space, each driven by a vertical belt. An extruder with a material feed tube was mounted on a horizontal carriage supported by the rods. The liquid material used for the additive build process was supplied by an external cartridge using compressed air. The maximum print volume of the clay printer was a cylindrical shape with the measurements of d = 200 mm and h = 400 mm. To avoid collisions of the components with the additive module, a 50 mm-long extended nozzle with a circular outlet with d = 1 mm was designed for the Delta Clay Printer, which was manufactured by fused deposition modeling in nylon.

2.3. Additional module

The additional module by Zumolab GmbH was built around the LDM system using a frame structure made of aluminum profiles (

Figure 1). The additional module was autonomous and consisted of two components: motor control and a U remote for the collection of analog measurement data. The individual components were connected in a network and could be operated via controlling software. Two opposing vertically positioned linear travel units carried the magnets. In case study 4.1, electromagnets were applied. In case study 4.2, a permanent magnet with a modification of the linear travel units in the horizontal axis and a laser sensor were added.

2.4. Digital Model

The instructions for the print job were generated using the visual programming environment Grasshopper. This program allows the generation of detailed specifications of path geometry, print direction, build-up speed, layer height, and extrusion rate as well as conversion to G-code (see

Table 3). The 3D printing parameters and path instructions influence the printing result. In preliminary tests, it was possible to develop a wall system that achieved a consistently stable print height of ~30 mm (

Figure 2c). This value was adopted for all further tests as a reference for the maximum print height and stability of the wall system without external manipulation.

3. Material Engineering

Processing a liquid CMC mass by LMD extrusion requires constant rheological properties. In particular, the time- and pH-dependent reaction of iron to form iron hydroxide around the steel particles in the liquid mass or drying green body can be critical.

Figure 3a shows how this corrosive attack led to high porosity in the air-sintered composite when particles of pure iron were used. The former iron hydroxide was converted to iron oxide fringes during sintering, and metallic bright iron was very rarely visible. If the 430L steel particles with a chromium content of 17 wt.% were used, the Cr

2O

3 passivation layer was effectively able to prevent the formation of hydroxides. The micrograph shows brightly shining metallic particles surrounded by a very fine seam (

Figure 3b). The seam thickness was unchanged when the mass was processed after 3 days and subsequently sintered.

In the scanning electron micrograph of the sample that was dried and sintered after 3 days, some pores were visible in the secondary electron contrast (

Figure 4a). However, these were predominantly found in the clay matrix and did not affect particle attachment. In the backscattered electron contrast (

Figure 4b and especially in the enlarged detail in

Figure 4c), the sharply defined seam around the steel particles was very clear. The EDS point analyses (

Figure 4d) revealed pure metallic iron–chromium steel at spot 1, an Al-Si-Cr oxide in the seam (spot 2) and in the clay matrix as Si-Al oxide with traces of K, Ti, Fe, and Cr.

Figure 5 shows the changes in exothermic or endothermic reactions with increasing weights of steel particles. It should be noted that no background correction was made, and thus only the upward (endothermic) and downward (exothermic) deviations from the smooth curve are to be evaluated. The addition of steel particles did not introduce new peaks, which confirms that no relevant reactions between steel and clay occurred. After the evaporation of the water (peak 1), dehydration occurred at about 500 °C (peak 2) [

19]. The small exothermic reaction (peak 3) probably corresponded to the formation of gamma-Al

2O

3 in kaolinite [

19]. The green body expanded due to thermal lattice expansion until the curve flattened at 800 °C (peak 4), marking the beginning of sintering activity. At 1000 °C, the composite material shrank very quickly (peak 5) by a total of 6.7% until the beginning of the isothermal holding phase.

Sintered composite bars, approximately 4.3 × 4.3 × 48 mm

3 in size, were tested by means of the standardized four-point bending test in accordance with EN 843-1. In order to investigate the influence of a possible notch effect, due to different pressure layouts, on the strength, the three different print patterns in

Figure 6a were tested. The determined fracture forces were converted into fracture stresses, as described in EN 843-5, and a fracture probability, P

f, was assigned to each specimen. In the Weibull diagram of

Figure 6b and c, data points on the right indicate high strength. The slope, m, of the regression line describes the scatter of the strength by the Weibull modulus. The higher the Weibull modulus, m, the lower the strength scatter. At a fracture probability of 63%, the ordinate value becomes 0, and the associated strength is called the characteristic strength, σ

0. Printing pure clay in pattern 3 resulted in a poor characteristic strength of 50.6 MPa. However, the corresponding Weibull modulus of 13.6 was high, indicating that the stress concentration always initiated failure of the same defect type. With pattern 2, the characteristic strength was increased since notches were removed. Pattern 1 was exactly between patterns 2 and 3 in terms of the Weibull modulus and characteristic strength, as the layered structure also suggested. Pattern 2 was selected as the print layout for the composite bars. As depicted in

Figure 6c, the strength of the composite material was comparably low. Despite the optically good particle bonding within the clay matrix, the characteristic strength was reduced significantly from 66 MPa to 7 MPa by the addition of steel particles. Increased toughness due to the addition of ductile particles could not be proven. Future investigations will have to clarify if the martensitic transformation of the AISI 630 leads to nonbeneficial microresidual stresses or damage.

5. Discussion

This study demonstrated that the electromagnetic forming of additively manufactured clay bodies is possible using the developed composite material. For technical applications, the comparably low fracture strength needs to be further increased. However, a clear effect of the print pattern on the strength of pure clay was observed, thus indicating promising approaches for improvements in the strength of the composite. If the inner notches of an LDM-processed material can be reduced by electromagnetic forming, the strength will be increased. For this approach, electromagnets would have to increase the connection of the extruded beads directly after depositing on the green component. Furthermore, sintering under atmospheres with lower or significantly lower oxygen contents than that of air will presumably also increase the strength.

A stabilizing effect of electromagnetic fields on the selected printing geometry could be observed since significantly higher walls were printed. The influence of the heat radiation of the electromagnets and the associated drying effects on the material could not be ruled out without further experiments. Although, in principle, an electromagnet promises better control of the deformation behavior due to the controllable magnetic field, this could not be confirmed in the present study. In the case of the selected electromagnet, despite a 10-fold higher holding force, this was due to the unfavorable, nonfocused course of the field lines, which ran predominantly in a radial direction between the iron core and the shell surface. As a result, the field decayed too quickly at a greater distance. The different magnitudes of the magnetic fields of the permanent magnet and electromagnet are clearly visualized in

Figure S1 at a distance of about 1 mm. A valid statement about the omission of

supporting material could not be further proven within the scope of this study. No visible changes could be observed on the surface of the additively manufactured wall due to the magnetic influence. The processes of the fatigue or saturation of the magnetizability of the liquid material affected control but were not detectable. In the future, it should be investigated whether the liquid composite material can be stabilized in the printing process until the onset of drying so that the need for support structures can be eliminated. Precise measurement and control technology is required for the accurate stabilization or forming of the material, and this needs to be further developed.

The digital design environment currently provides insufficient tools to adequately control a material’s parameters in relation to its physical properties and behavior during the build-up process. This raises the question of which design information must be retained in the digital model for the printing process and which forming parameters can be outsourced to the physical environment by controlling the additional module for electromagnetic deformation. Currently, the state of the physical rendering of digital designs through machine production proves to be an axiomatically simplified set of instructions for action that is not designed to control the production process, the material, and its complex behavior during assembly. The approach explored here was intended to broaden the range of possibilities for liquid material extrusion and make it useful for application in the design and technical fields. This study shows a perspective for a new field of additive manufacturing and for significant influence on classical LDM processes as well as metal-particle-reinforced ceramics in the fields of industrial development.