- Article

Calcium Effect in PLR–PCR Geopolymers: Peak Compressive Strength at 30% PCR and Evidence of C-A-S-H/N-A-S-H Synergy

- Oscar Graos-Alva,

- Aldo Castillo-Chung and

- Alexander Vega-Anticona

- + 2 authors

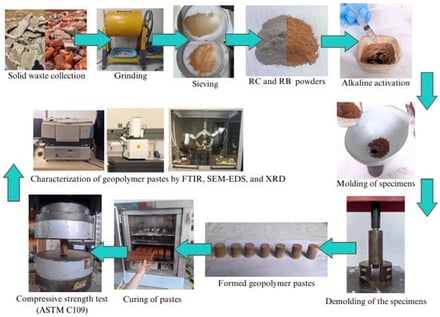

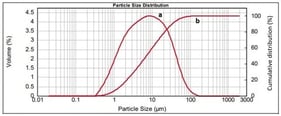

Valorizing construction and demolition waste (CDW) via alkaline activation enables low-carbon binders. This study assesses binary geopolymers formulated with recycled brick powder (PLR) and recycled concrete powder (PCR) in seven precursor ratios (0–100% PCR), activated with a ternary NaOH/Na2SiO3/KOH solution (silicate modulus Ms ≈ 3.2) at L/B = 0.15, and cured for 7, 14, and 28 days. Compressive strength (fc), X-ray diffraction (XRD), Fourier transform infrared spectroscopy (FTIR), and scanning electron microscopy with energy-dispersive X-ray spectroscopy (SEM-EDS) were used to link microstructure–phases–properties. A local maximum in fc at ~30% PCR (16.2 MPa at 28 d) was observed versus 0% PCR (14.2 MPa) and ≥50% PCR (13.8 → 10.1 MPa at 28 d). XRD indicated a reduction in inherited crystalline phases and an increased amorphous fraction at ~30% PCR; FTIR (normalized peak position and FWHM of the T–O–Si band, not absolute intensity) suggested higher network extension; SEM-EDS (local/semiquantitative) showed a moderate rise in Ca that supports C-A-S-H domains bridging the N-A-S-H network. At a high PCR, excess Ca simplified mineralogy (quartz/portlandite dominance), promoted competitive routes (C-S-H/carbonation), reintroduced microdefects, and reduced fc. A theoretical oxide balance per mix identified a compositional window where Ca/(Si + Al) ≈ 0.35–0.45 coincides with the mechanical optimum and with XRD/FTIR tracers. Overall, a ~30% PCR window maximizes co-reticulation of N-A-S-H/C-A-S-H and densification without compromising aluminosilicate continuity, providing transferrable design and process-control criteria for CDW-based geopolymer binders.

5 February 2026