3D Printing Ceramics—Materials for Direct Extrusion Process

Abstract

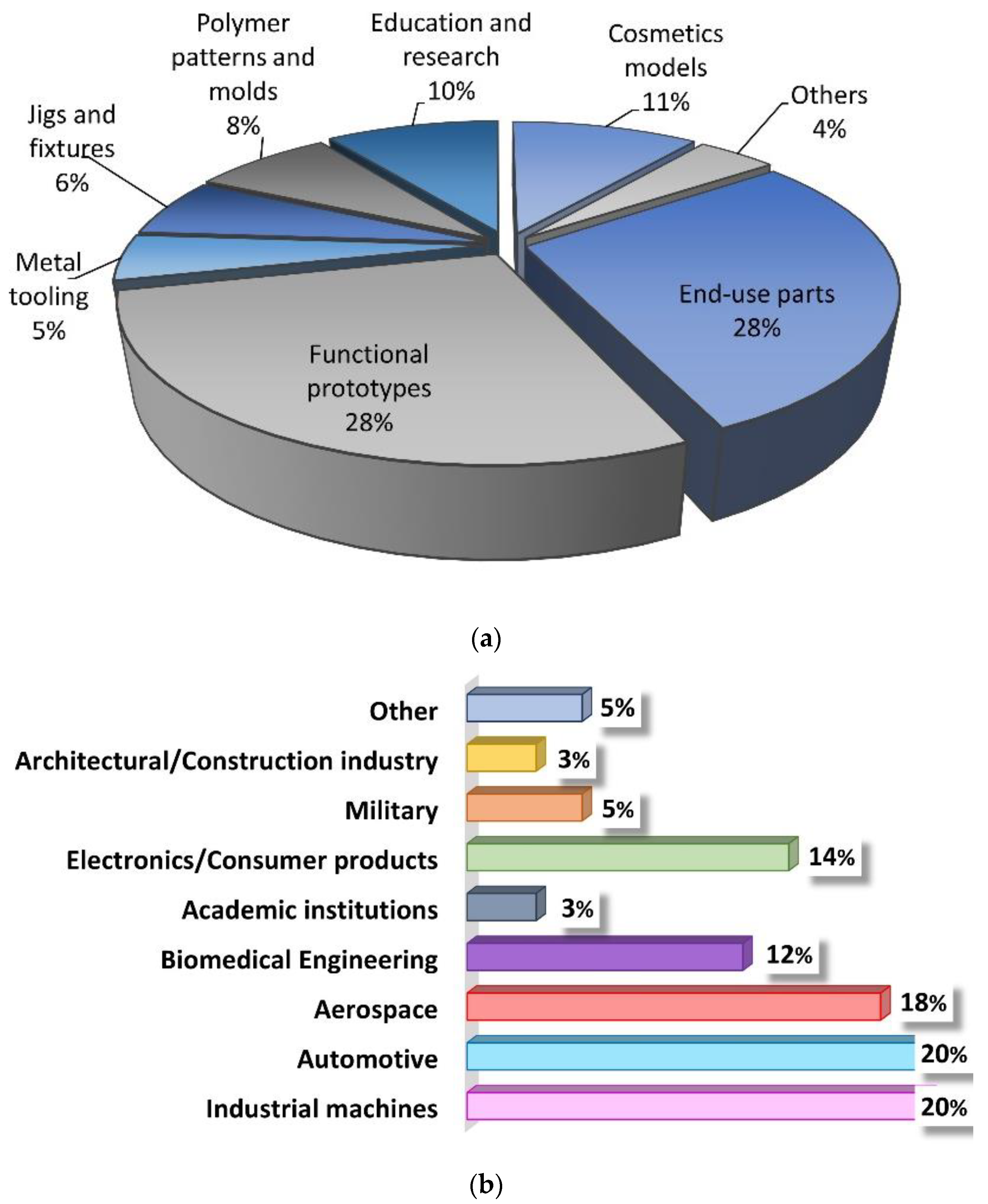

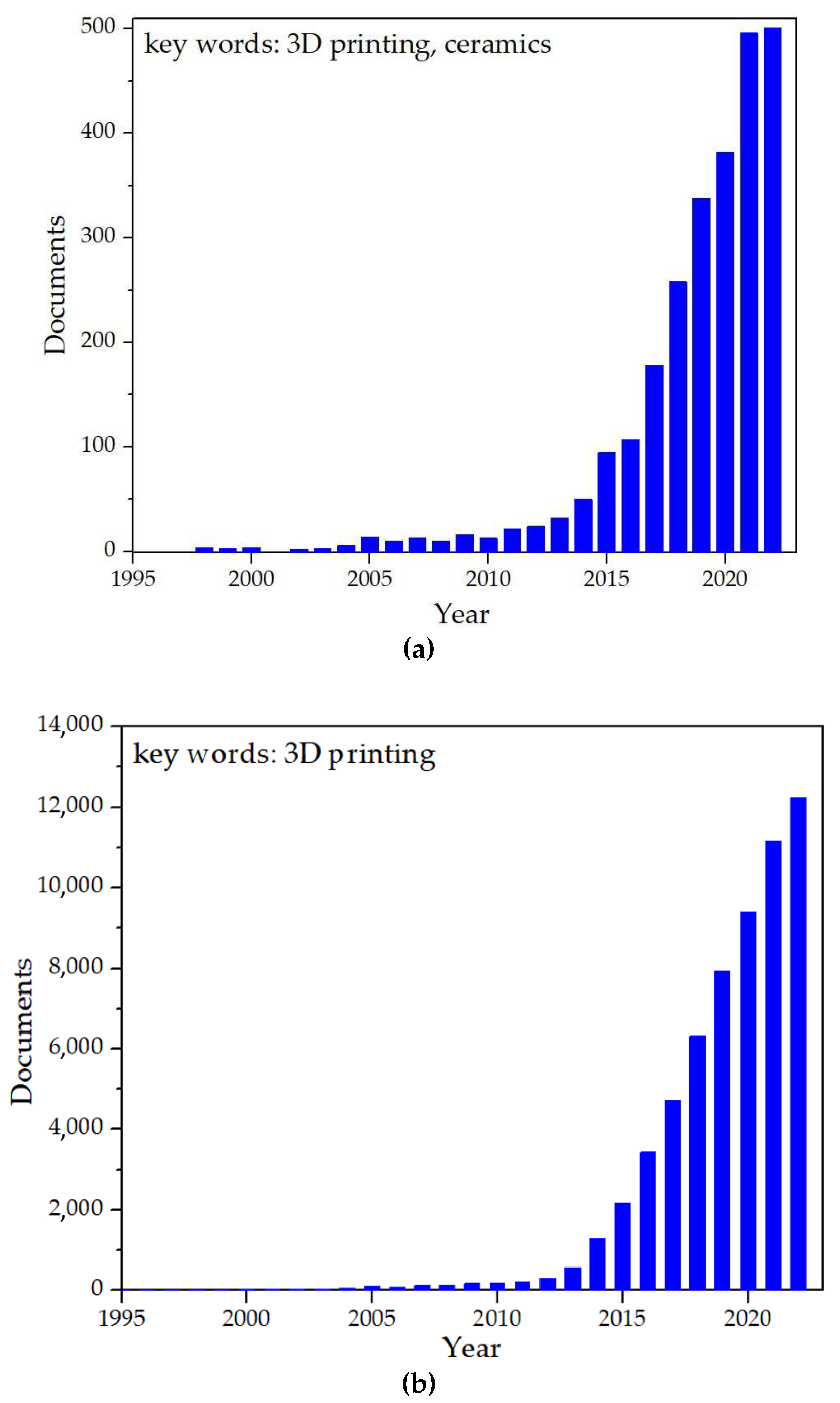

:1. Introduction

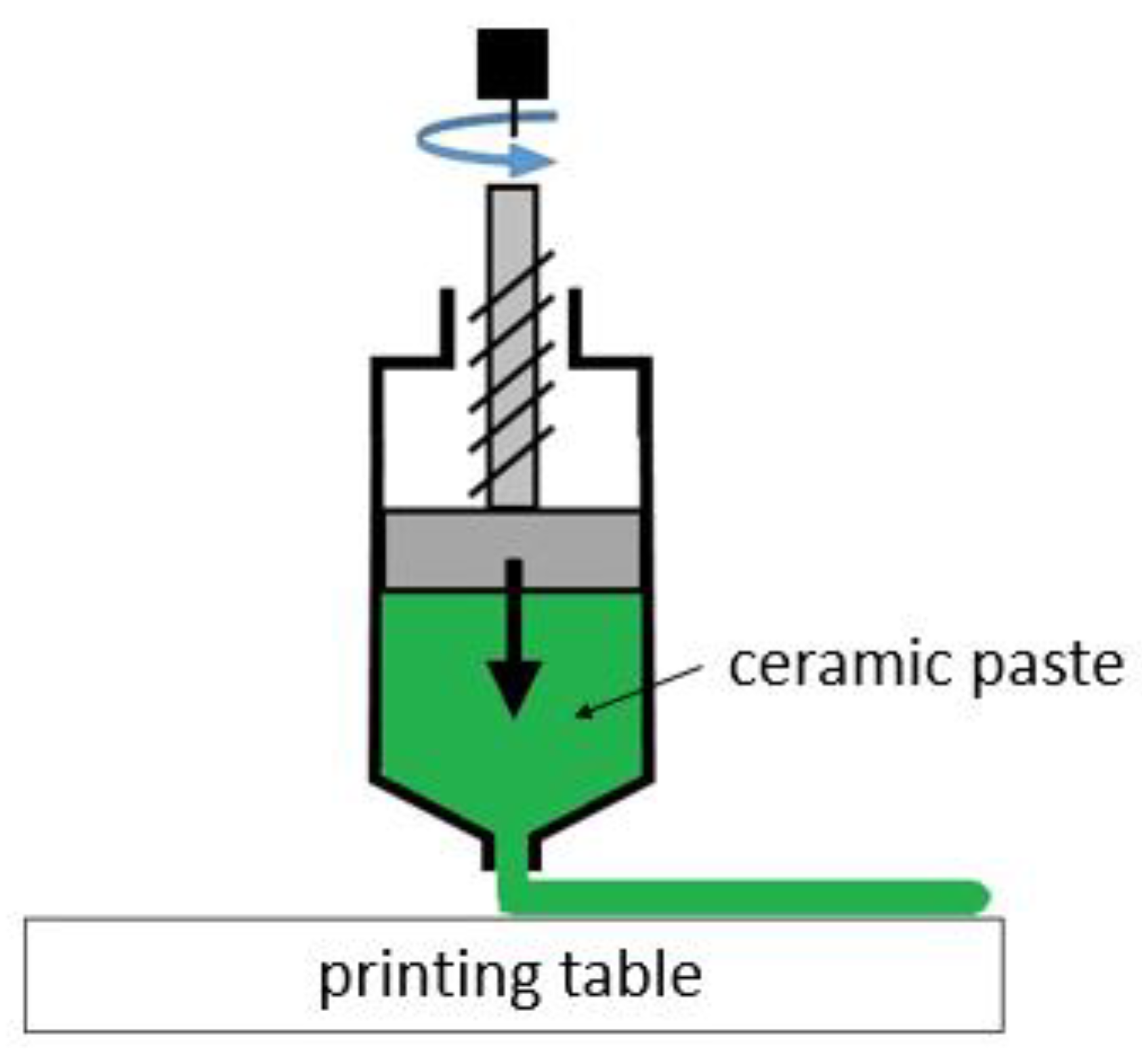

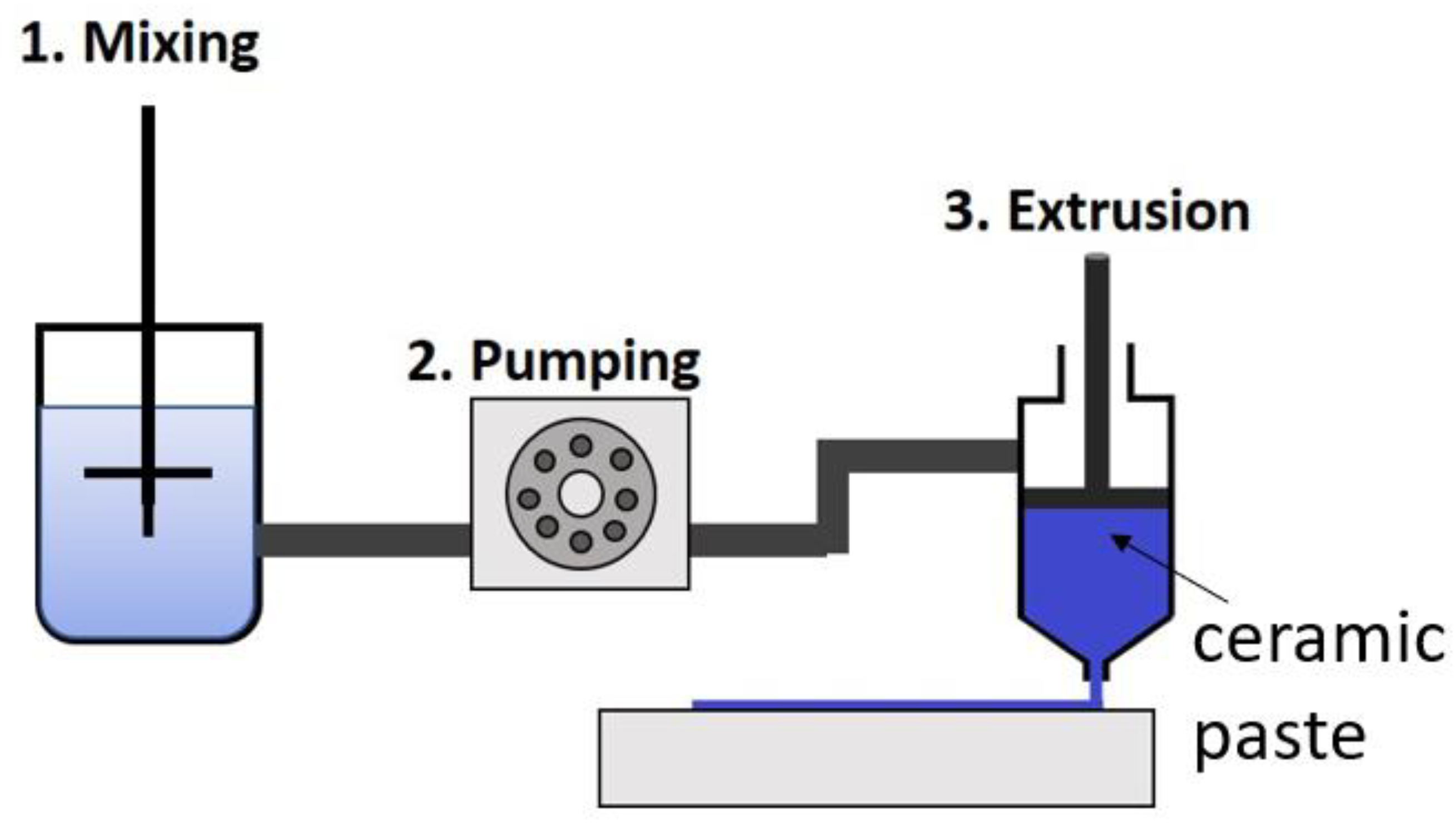

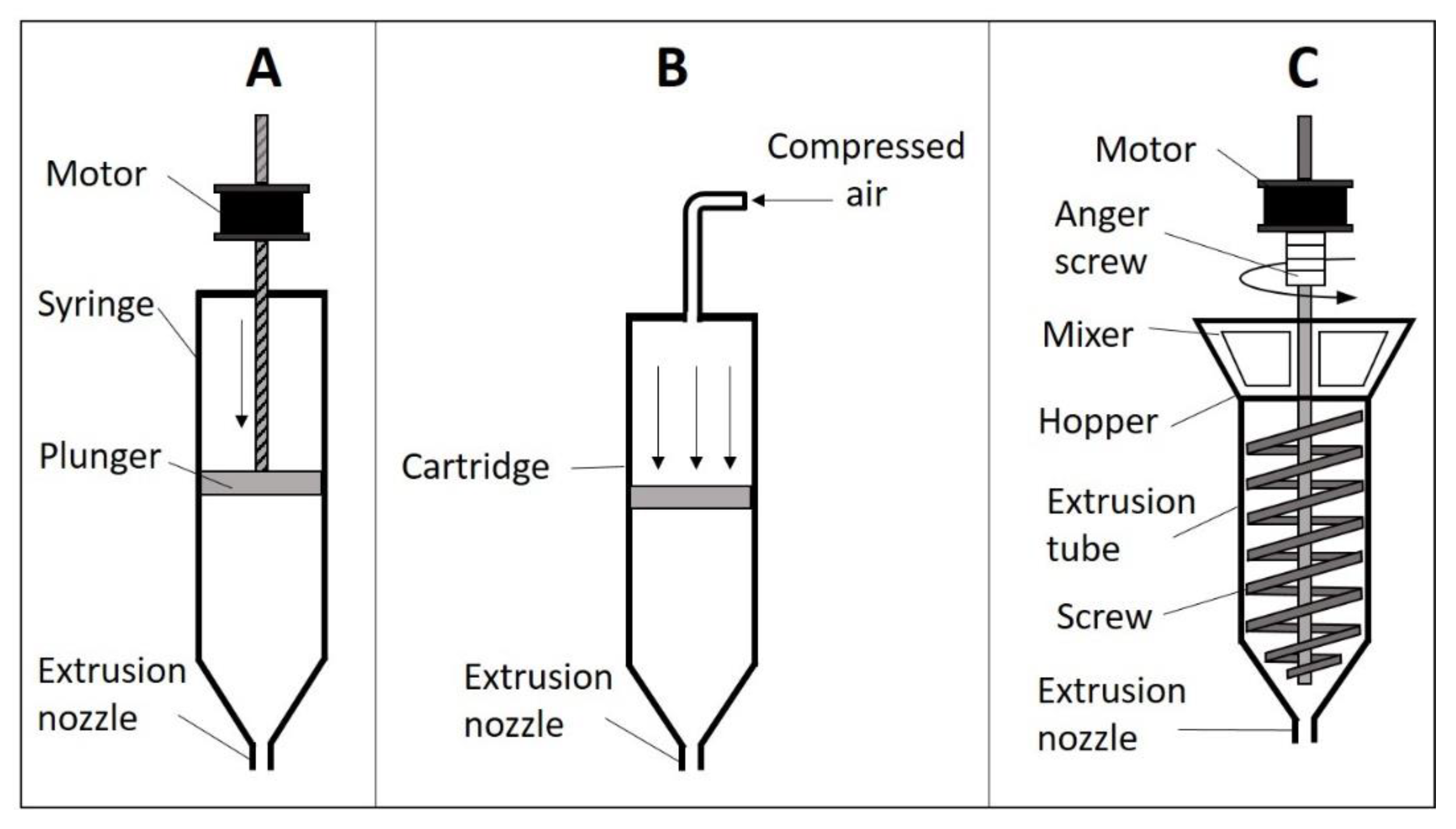

2. Fused Deposition of Ceramics

3. Ceramic Pastes Used in the FDC Method

3.1. General Properties of Ceramic Pastes

3.2. Classification of Ceramic Pastes

3.2.1. Oxides

Aluminum Oxide

Titanium Oxide

Zirconium Oxide

3.2.2. Mixed Oxides

Lead Zirconate Titanate

Barium Titanate

3.2.3. Non-Oxides

Zirconium Diboride

Silicon Carbide

3.2.4. Bioceramics

3.2.5. Clays

3.2.6. Cementitious Materials

3.2.7. Ceramic-Based Composite

4. Comparison of Conventional Production and 3D Printing

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chaudhary, R.; Parameswaran, C.; Idrees, M.; Rasaki, A.; Liu, C.; Chen, Z.; Colombo, P. Additive Manufacturing of Polymer-Derived Ceramics: Materials, Technologies, Properties and Potential Applications. Prog. Mater. Sci. 2022, 128, 100969. [Google Scholar]

- Huang, S.; Ye, C.; Zhao, H.; Fan, Z. Additive manufacturing of thin alumina ceramic cores using binder-jetting. Addit. Manuf. 2019, 29, 100802. [Google Scholar] [CrossRef]

- Jinsong, C.; Enquan, B.; Dazhi, H.; Yunfei, D.; Xuhui, Q. Extrusion Freeforming-Based 3D Printing of Ceramic Materials. Mater. Trans. 2020, 6, 2236–2240. [Google Scholar] [CrossRef]

- Chen, Z.; Li, Z.; Li, J.; Liu, C.; Lao, C.; Fu, Y.; Liu, C.; Yang, L.; Wang, P.; Yi, H. 3D printing of ceramics: A review. J. Eur. Ceram. Soc. 2019, 39, 661–687. [Google Scholar]

- Bourell, D.; Kruth, J.; Leu, M.; Levy, G.; Rosen, D.; Beese, A.; Clare, A. Materials for additive manufacturing. CIRP Annals 2017, 66, 659–681. [Google Scholar]

- Vaezi, M.; Chianrabutra, S.; Mellor, B.; Yang, S. Multiple Material Additive Manufacturing—Part 1: A Review. Virtual Phys. Prototyp. 2013, 8, 19–50. [Google Scholar] [CrossRef]

- Zocca, A.; Colombo, P.; Gomes, C.; Günster, J. Additive Manufacturing of Ceramics: Issues, Potentialities, and Opportunities. J. Am. Ceram. Soc. 2015, 98, 1983–2001. [Google Scholar] [CrossRef]

- He, R.; Zhou, N.; Zhang, K.; Zhang, X.; Zhang, L.; Wang, W.; Fang, D. Progress and challenges towards additive manufacturing of SiC ceramic. J. Adv. Ceram. 2021, 10, 637–674. [Google Scholar]

- Vafadar, A.; Guzzomi, F.; Rassau, A.; Hayward, K. Advances in Metal Additive Manufacturing: A Review of Common Processes, Industrial Applications, and Current Challenges. Appl. Sci. 2021, 11, 1213. [Google Scholar] [CrossRef]

- Martin, V.; Witz, J.; Gillon, F.; Najjar, D.; Quaegebeur, P.; Benabou, A.; Hecquet, M.; Berté, E.; Lesaffre, F.; Meersdam, M.; et al. Low cost 3D printing of metals using filled polymer pellets. HardwareX 2022, 11, e00292. [Google Scholar] [CrossRef]

- Xiao, J.; Zhang, D.; Zheng, M.; Bai, Y.; Sun, Y.; Guo, Q.; Yang, J. 3D Printing of Metallic Structures using Dopamine-integrated Photopolymer. J. Mater. Res. Technol. 2022, 19, 1355–1366. [Google Scholar] [CrossRef]

- Zhang, K.; Xie, C.; Wang, G.; He, R.; Wang, M.; Dai, D.; Fang, D. High solid loading, low viscosity photosensitive Al2O3 slurry for stereolithography based additive manufacturing. Ceram. Int. 2019, 45, 203–208. [Google Scholar] [CrossRef]

- Xing, H.; Zou, B.; Li, S.; Fu, X. Study on surface quality, precision and mechanical properties of 3D printed ZrO2 ceramic components by laser scanning stereolithography. Ceram. Int. 2017, 43, 16340–16347. [Google Scholar] [CrossRef]

- Chang, C.; Lin, C.; Chang, C.; Liu, F.; Huang, Y.; Liao, Y. Enhanced biomedical applicability of ZrO2–SiO2 ceramic composites in 3D printed bone scaffolds. Sci. Rep. 2022, 12, 6845. [Google Scholar] [CrossRef]

- Li, W.; Leu, M. Material Extrusion Based Ceramic Additive Manufacturing. In Additive Manufacturing Processes; ASM International: Novelty, OH, USA, 2020. [Google Scholar]

- Gonzalez-Gutierrez, J.; Cano, S.; Schuschnigg, S.; Kukla, C.; Sapkota, J.; Holzer, C. Additive Manufacturing of Metallic and Ceramic Components by the Material Extrusion of Highly-Filled Polymers: A Review and Future Perspectives. Materials 2018, 11, 840. [Google Scholar] [CrossRef]

- Hu, F.; Mikolajczyk, T.; Pimenov, D.; Gupta, M. Extrusion-Based 3D Printing of Ceramic Pastes: Mathematical Modeling and In Situ Shaping Retention Approach. Materials 2021, 14, 1137. [Google Scholar] [CrossRef]

- Hu, F.; Cheng, J.; He, Y. Interactive design for additive manufacturing: A creative case of synchronous belt drive. Int. J. Interact.Des. Manuf. 2018, 12, 889–901. [Google Scholar]

- Bourell, D.; Beaman, J.; Wohlers, T. History of Additive Manufacturing. In Additive Manufacturing Processes; ASM International: Novelty, OH, USA, 2020. [Google Scholar]

- Wang, X.; Jiang, M.; Zhou, Z.; Gou, J.; Hui, D. 3D printing of polymer matrix composites: A review and prospective. Compos. Part B Eng. 2017, 110, 442–458. [Google Scholar]

- Wohlers, T.; Campbell, I.; Diegel, O.; Huff, R.; Kowen, J. Wohlers Report 2021: 3D Printing and Additive Manufacturing Global State of Theindustry; Wohlers Associates: Fort Collins, CO, USA, 2021. [Google Scholar]

- Additive Manufacturing Market Valued. Available online: https://additive-manufacturing-report.com/additive-manufacturing-market-2021/ (accessed on 15 January 2023).

- ISO/ASTM 52900; Additive Manufacturing, General Principles, Terminology. International Organization for Standardization: Geneva, Switzerland, 2015.

- Zafar, M.; Zhu, D.; Zhang, Z. 3D Printing of Bioceramics for Bone Tissue Engineering. Materials 2019, 12, 3361. [Google Scholar] [CrossRef]

- Deckers, J.; Vleugels, J.; Kruth, J. Additive Manufacturing of Ceramics: A Review. Ceram. Sci. Technol. 2014, 5, 245–260. [Google Scholar]

- Gmeiner, R.; Deisinger, U.; Schönherr, J.; Lechner, B.; Detsch, R.; Boccaccini, A.; Stampfl, J. Additive Manufacturing of Bioactive Glasses and Silicate Bioceramics. J. Ceram. Sci. Tech. 2015, 6, 75–86. [Google Scholar]

- Ruscitti, A.; Tapia, C.; Rendtorff, N. A review on additive manufacturing of ceramic materials based on extrusion processes of clay pastes. Ceramica 2020, 66, 354–366. [Google Scholar] [CrossRef]

- Muthukrishnan, S.; Ramakrishnan, S.; Sanjayan, J. Technologies for improving buildability in 3D concrete printing. Cem. Concr. Compos. 2021, 122, 104144. [Google Scholar] [CrossRef]

- Sun, J.; Zhou, W.; Yan, L.; Huang, D.; Lin, L. Extrusion-based food printing for digitalized food design and nutrition control. J. Food Eng. 2018, 220, 1–11. [Google Scholar] [CrossRef]

- Hussain, S.; Malakar, S.; Arora, V. Extrusion-Based 3D Food Printing: Technological Approaches, Material Characteristics, Printing Stability, and Post-processing. Food Eng. Rev. 2022, 14, 100–119. [Google Scholar] [CrossRef]

- Li, W.; Ghazanfari, A.; Leu, M.; Landers, R. Extrusion-on-demand methods for high solids loading ceramic paste in freeform extrusion fabrication. Virtual Phys. Prototyp. 2017, 12, 193–205. [Google Scholar] [CrossRef]

- Hinton, T.; Jallerat, Q.; Palchesko, R.; Park, J.; Grodzicki, M.; Shue, H.; Ramadan, M.; Hudson, A.; Feinberg, A. Three-dimensional printing of complex biological structures by freeform reversible embedding of suspended hydrogels. Sci. Adv. 2015, 1, e1500758. [Google Scholar] [CrossRef]

- Huang, C. Extrusion-Based 3D Printing and Characterization of Edible Materials. Ph.D. Thesis, University of Waterloo, Waterloo, ON, Canada, 2018. [Google Scholar]

- Wang, L.; Zhang, M.; Bhandari, B.; Yang, C. Investigation on fish surimi gel as promising food material for 3D printing. J. Food Eng. 2018, 220, 101–108. [Google Scholar] [CrossRef]

- Carter, C.; Norton, M. Ceramic Materials; Springer: New York, NY, USA, 2013. [Google Scholar]

- Lamnini, S.; Elsayed, H.; Lakhdar, Y.; Baino, F.; Smeacetto, F.; Bernardo, E. Robocasting of advanced ceramics: Ink optimization and protocol to predict the printing parameters—A review. Heliyon 2022, 8, e10651. [Google Scholar] [CrossRef]

- Ben-Arfa, B.; Pullar, R. Comparison of Bioactive Glass Scaffolds Fabricated by Robocasting from Powders Made by Sol–Gel and Melt-Quenching Methods. Processes 2020, 8, 615. [Google Scholar] [CrossRef]

- Del-Mazo-Barbara, L.; Ginebra, M. Rheological characterisation of ceramic inks for 3D direct ink writing: A review. J. Eur. Ceram. Soc. 2021, 41, 18–33. [Google Scholar] [CrossRef]

- Ana, B.; Isabel, S.; Salvado, M.; Pullar, R.; Ferreira, J. Robocasting: Prediction of Ink Printability in Solgel Bioactive Glass. J. Am. Ceram. Soc. 2019, 102, 1608–1618. [Google Scholar]

- Andrade, F.; Al-Qureshi, H.; Hotza, D. Measuring the plasticity of clays: A review. Appl. Clay Sci. 2011, 51, 1–7. [Google Scholar] [CrossRef]

- Álvarez, F.; Cifuentes, A.; Serrano, I.; Franco, L.; Fargas, G.; Fenollosa, F.; Uceda, R.; Llanes, L.; Tardivat, C.; Llorca, J.; et al. Optimization of the sintering thermal treatment and the ceramic ink used in direct ink writing of α-Al2O3: Characterization and catalytic application. J. Eur. Ceram. Soc. 2022, 42, 2921–2930. [Google Scholar] [CrossRef]

- Finke, B.; Hesselbach, J.; Schütt, A.; Tidau, M.; Hampel, B.; Schilling, M.; Kwade, A.; Schilde, C. Influence of formulation parameters on the freeform extrusion process of ceramic pastes and resulting product properties. Addit. Manuf. 2020, 32, 101005. [Google Scholar] [CrossRef]

- Xu, X.; Zhang, J.; Jiang, P.; Liu, D.; Jia, X.; Wang, X.; Zhou, F. Direct ink writing of aluminum-phosphate-bonded Al2O3 ceramic with ultra-low dimensional shrinkage. Ceram. Int. 2022, 48, 864–871. [Google Scholar] [CrossRef]

- Wang, R.; Zhu, P.; Yang, W.; Gao, S.; Li, B.; Li, Q. Direct-writing of 3D periodic TiO2 bio-ceramic scaffolds with a sol-gel ink for in vitro cell growth. Mater. Des. 2018, 144, 304–309. [Google Scholar] [CrossRef]

- Aleni, A.; Kretzschmar, N.; Jansson, A.; Ituarte, I.; St-Pierre, L. 3D printing of dense and porous TiO2 structures. Ceram. Int. 2020, 46, 16725–16732. [Google Scholar] [CrossRef]

- Arango, M.; Kwakye-Ackah, D.; Agarwal, S.; Gupta, R.; Sierros, K. Environmentally Friendly Engineering and Three-Dimensional Printing of TiO2 Hierarchical Mesoporous Cellular Architectures. ACS Sustain. Chem. Eng. 2017, 5, 10421–10429. [Google Scholar] [CrossRef]

- Xu, C.; Liu, T.; Guo, W.; Sun, Y.; Liang, C.; Cao, K.; Guan, T.; Liang, Z.; Jiang, L. D Printing of Powder-Based Inks into Functional Hierarchical Porous TiO2 Materials. Adv. Eng. Mater. 2019, 22, 1901088. [Google Scholar] [CrossRef]

- Jiaxiao, S.; Xie, B.; Zhu, Z. Extrusion-based 3D printing of fully dense zirconia ceramics for dental restorations. J. Eur. Ceram. Soc. 2022, in press. [Google Scholar] [CrossRef]

- Peng, E.; Wei, X.; Garbe, U.; Yu, D.; Edouard, B.; Liu, A.; Ding, J. Robocasting of dense yttria-stabilized zirconia structures. J. Mater. Nauka. 2018, 53, 247–273. [Google Scholar] [CrossRef]

- Mohammadi, M.; Becker, G.; Diener, S.; Tulliani, J.; Katsikis, N.; Palmero, P. Robocasting of dense zirconia parts using commercial yttria-stabilized zirconia granules and ultrafine particles. Paste preparation, printing, mechanical properties. Ceram. Int. 2022, 48, 1936–1946. [Google Scholar] [CrossRef]

- Hall, S.; Regis, J.; Renteria, A.; Chavez, L.; Delfin, L.; Vargas, S.; Haberman, M.; Espalin, D.; Wicker, R.; Lin, Y. Paste extrusion 3D printing and characterization of lead zirconate titanate. Ceram. Int. 2021, 47, 22042–22048. [Google Scholar] [CrossRef]

- Liu, K.; Zhang, Q.; Zhou, C.; Shi, Y.; Sun, C.; Sun, H.; Yin, C.; Hu, J.; Zhou, S.; Zhang, Y.; et al. 4D Printing of Lead Zirconate Titanate Piezoelectric Composites Transducer Based on Direct Ink Writing. Front. Mater. 2021, 8, 659441. [Google Scholar] [CrossRef]

- Kim, H.; Renteria-Marquez, A.; Islam, M.; Chavez, L.; Garcia Rosales, C.; Ahsan, M.; Tseng, T.; Love, N.; Lin, Y. Fabrication of bulk piezoelectric and dielectric BaTiO3 ceramics using paste extrusion 3D printing technique. J. Am. Ceram. Soc. 2019, 102, 3685–3694. [Google Scholar] [CrossRef]

- Renteria, A.; Garcia, L.; Balcorta, V.; Ortiz, D.; Delfin, L.; Regis, J.; Marcos-Hernandez, M.; Espalin, D.; Tseng, T.; Lin, Y. Influence of bimodal particle distribution on material properties of BaTiO3 fabricated by paste extrusion 3D printing. Ceram. Int. 2021, 47, 18477–18486. [Google Scholar] [CrossRef]

- Renteria, A.; Diaz, J.; He, B.; Renteria-Marquez, I.; Chavez, L.; Regis, J.; Liu, Y.; Espalin, D.; Tseng, T.; Lin, Y. Particle size influence on material properties of BaTiO3 ceramics fabricated using freeze-form extrusion 3D printing. Mater. Res. Express 2019, 6, 115211. [Google Scholar] [CrossRef]

- Renteria, A.; Fontes, H.; Diaz, J.; Regis, J.; Chavez, L.; Tseng, T.; Liu, Y.; Lin, Y. Optimization of 3D printing parameters for BaTiO3 piezoelectric ceramics through design of experiments. Mater. Res. Express 2019, 6, 085706. [Google Scholar] [CrossRef] [Green Version]

- Sesso, M.; Slater, S.; Thornton, J.; Franks, G. Direct ink writing of hierarchical porous ultra-high temperature ceramics (ZrB2). J. Am. Ceram. Soc. 2021, 104, 4977–4990. [Google Scholar] [CrossRef]

- Eakins, E.; Jayaseelan, D.; Lee, W. Toward oxidation-resistant ZrB2-SiC ultra high temperature ceramics. Metall. Mater. Trans. 2011, 42, 878–887. [Google Scholar] [CrossRef]

- Aguirre, T.; Lamm, B.; Cramer, C.; Mitchell, D. Zirconium-diboride silicon-carbide composites: A review. Ceram. Int. 2022, 48, 7344–7361. [Google Scholar]

- Kemp, J.; Diaz, A.; Malek, E.; Croom, B.; Apostolov, Z.; Kalidindi, S.; Compton, B.; Rueschhoff, L. Direct ink writing of ZrB2-SiC chopped fiber ceramic composites. Addit. Manuf. 2021, 44, 102049. [Google Scholar] [CrossRef]

- Zhang, H.; Yang, Y.; Liu, B.; Huang, Z. The preparation of SiC-based ceramics by one novel strategy combined 3D printing technology and liquid silicon infiltration process. Ceram. Int. 2019, 45, 10800–10804. [Google Scholar] [CrossRef]

- Chen, H.; Wang, X.; Xue, F.; Huang, Y.; Zhou, K. 3D printing of SiC ceramic: Direct ink writing with a solution of preceramic polymers. J. Eur. Ceram. Soc. 2018, 38, 5294–5300. [Google Scholar] [CrossRef]

- Held, A.; Puchas, G.; Müller, F.; Krenkel, W. Direct ink writing of water-based C–SiC pastes for the manufacturing of SiC components. Open Ceram. 2021, 5, 100054. [Google Scholar] [CrossRef]

- He, X.; Guo, Y.; Yu, Z.; Zhou, Y.; Jia, J. Study on microstructures and mechanical properties of short-carbon-fiber-reinforced SiC composites prepared by hot-pressing. Mater. Sci. Eng. A 2009, 527, 334–338. [Google Scholar] [CrossRef]

- Liu, H.; Mei, D.; Yu, S.; Qian, S.; Wang, Y. Direct ink writing of chopped carbon fibers reinforced polymer-derived SiC composites with low shrinkage and high strength. J. Eur. Ceram. Soc. 2023, 43, 235–244. [Google Scholar] [CrossRef]

- Ly, M.; Spinelli, S.; Hay, S.; Zhu, D. 3D Printing of Ceramic Biomaterials. Eng. Regen. 2022, 3, 41–52. [Google Scholar] [CrossRef]

- Zhong, G.; Vaezi, M.; Liu, P.; Pan, L.; Yang, S. Characterization approach on the extrusion process of bioceramics for the 3D printing of bone tissue engineering scaffolds. Ceram. Int. 2017, 43, 13860–13868. [Google Scholar] [CrossRef]

- Roopavath, U.; Malferrari, S.; van Haver, A.; Verstreken, F.; Rath, S.; Kalaskar, D. Optimization of extrusion based ceramic 3D printing process for complex bony designs. Mater. Des. 2019, 162, 263–270. [Google Scholar] [CrossRef]

- Beniash, E.; Stifler, C.; Sun, C.; Jung, G.; Qin, Z.; Buehler, M.; Gilbert, P. The hidden structure of human enamel. Nat. Commun. 2019, 10, 4383. [Google Scholar] [CrossRef] [PubMed]

- Zhang, B.; Pei, X.; Zhou, C.; Fan, Y.; Jiang, Q.; D’Amora, U.; Chen, Y.; Li, H.; Sun, Y.; Zhang, X. The biomimetic design and 3D printing of customized mechanical properties porous Ti6Al4V scaffold for load-bearing bone reconstruction. Mater. Des. 2018, 152, 30–39. [Google Scholar] [CrossRef]

- Revelo, C.; Colorado, H. 3D printing of kaolinite clay ceramics using the Direct Ink Writing (DIW) technique. Ceram. Int. 2018, 44, 5673–5682. [Google Scholar] [CrossRef]

- Ordoñez, E.; Gallego, J.; Colorado, H. 3D printing via the direct ink writing technique of ceramic pastes from typical formulations used in traditional ceramics industry. Appl. Clay Sci. 2019, 182, 105285. [Google Scholar] [CrossRef]

- Ordoñez, E.; Monteiro, S.; Colorado, H. Valorization of a hazardous waste with 3D-printing: Combination of kaolin clay and electric arc furnace dust from the steel making industry. Mater. Des. 2022, 217, 110617. [Google Scholar] [CrossRef]

- Faksawat, K.; Limsuwan, P.; Naemchanthara, K. 3D printing technique of specific bone shape based on raw clay using hydroxyapatite as an additive material. Appl. Clay Sci. 2021, 214, 10626. [Google Scholar] [CrossRef]

- Duan, Z.; Li, L.; Yao, Q.; Zou, S.; Singh, A.; Yang, H. Effect of metakaolin on the fresh and hardened properties of 3D printed cementitious composite. Constr. Build Mater. 2022, 350, 128808. [Google Scholar] [CrossRef]

- Kazemian, A.; Yuan, X.; Meier, R.; Khoshnevis, B. Performance-Based Testing of Portland Cement Concrete for Construction-Scale 3D Printing. 3D Concr. Print. Technol. 2019, 2019, 13–35. [Google Scholar]

- Sun, J.; Aslani, F.; Lu, J.; Wang, L.; Huang, Y.; Ma, G. Fibre-reinforced lightweight engineered cementitious composites for 3D concrete printing. Ceram. Int. 2021, 47, 27107–27121. [Google Scholar] [CrossRef]

- Endo-Kimura, M.; Janczarek, M.; Bielan, Z.; Zhang, D.; Wang, K.; Markowska-Szczupak, A.; Kowalska, E. Photocatalytic and Antimicrobial Properties of Ag2O/TiO2 Heterojunction. ChemEngineering 2019, 3, 3. [Google Scholar] [CrossRef] [Green Version]

- Chevalier, L.; Hammond, E.; Poitou, A. Extrusion of TiO2 ceramic powder paste. J. Mater. Process. Technol. 1997, 72, 243–248. [Google Scholar] [CrossRef]

- Kim, M.; Hong, M.; Min, B.; Kim, Y.; Shin, H.; Kwon, T. Microstructure, Flexural Strength, and Fracture Toughness Comparison between CAD/CAM Milled and 3D-Printed Zirconia Ceramics. Appl. Sci. 2022, 12, 9088. [Google Scholar] [CrossRef]

- Khanlar, L.; Salazar Rios, A.; Tahmaseb, A.; Zandinejad, A. Additive Manufacturing of Zirconia Ceramic and Its Application in Clinical Dentistry: A Review. Dent. J. 2021, 9, 104. [Google Scholar] [CrossRef]

- Zadeh, P.; Lumkemann, N.; Sener, B.; Eichberger, M.; Stawarczyk, B. Flexural strength, fracture toughness, and translucency of cubic/tetragonal zirconia materials. J. Prosthet. Dent. 2018, 120, 948–954. [Google Scholar] [CrossRef]

- Acosta, M.; Novak, N.; Rojas, V.; Patel, S.; Vaish, R.; Koruza, J.; Rossetti, G.; Rödel, J. BaTiO3-based piezoelectrics: Fundamentals, current status, and perspectives. Appl. Phys. Rev. 2017, 4, 041305. [Google Scholar] [CrossRef]

- Buscaglia, V.; Buscaglia, M.; Canu, G. BaTiO3-Based Ceramics: Fundamentals, Properties and Applications. Encycl. Mater. Tech. Ceram. Glasses 2021, 3, 311–344. [Google Scholar]

- Feilden, E.; Glymond, D.; Saiz, E.; Vandeperre, L. High temperature strength of an ultra high temperature ceramic produced by additive manufacturing. Ceram. Int. 2019, 45, 18210–18214. [Google Scholar] [CrossRef]

- Esslinger, S.; Gadow, R. Additive manufacturing of bioceramic scaffolds by combi- nation of FDM and slip casting. J. Eur. Ceram. Soc. 2020, 40, 3707–3713. [Google Scholar] [CrossRef]

- Dee, P.; Tan, S.; Le Ferrand, H. Fabrication of Microstructured Calcium Phosphate Ceramics Scaffolds by Material Extrusion-Based 3D Printing Approach. Int. J. Bioprint. 2022, 8, 551. [Google Scholar] [CrossRef]

- Ríos, C.; Williams, C.; Fullen, M. Hydrothermal Synthesis of Hydrogarnet and Tobermorite at 175 °C from kaolinite and metakaolinite in the CaO–Al2O3–SiO2–H2O system: A comparative study. Appl. Clay Sci. 2009, 43, 228–237. [Google Scholar] [CrossRef]

- Ma, G.; Wang, L.; Ju, Y. State-of-the-art of 3D printing technology of cementitious material—An emerging technique for construction. Sci. China Technol. Sci. 2018, 61, 475–495. [Google Scholar] [CrossRef]

- Chen, Y.; He, S.; Gan, Y.; Çopuroğlu, O.; Veer, F.; Schlangen, E. A review of printing strategies, sustainable cementitious materials and characterization methods in the context of extrusion-based 3D concrete printing. J. Build. Eng. 2022, 45, 103599. [Google Scholar] [CrossRef]

- Sun, J.; Ye, D.; Zou, J.; Chen, X.; Wang, Y.; Yuan, J.; Liang, H.; Qu, H.; Binner, J.; Bai, J. A review on additive manufacturing of ceramic matrix composites. J. Mater. Sci. Technol. 2023, 138, 1–16. [Google Scholar] [CrossRef]

- Shao, H.; Liu, A.; Ke, X.; Sun, M.; He, Y.; Yang, X.; Fu, J.; Zhang, L.; Yang, G.; Liu, Y.; et al. 3D robocasting magnesium-doped wollastonite/TCP bioceramic scaffolds with improved bone regeneration capacity in critical sized calvarial defects. J. Mater. Chem. B 2017, 5, 2941–2951. [Google Scholar] [CrossRef]

- Liu, C.; Ding, J. Carbon nanotubes reinforced alumina matrix nanocomposites for conductive ceramics by additive manufacturing. Procedia Manuf. 2020, 48, 763–769. [Google Scholar] [CrossRef]

- Zhang, D.; Kenel, C.; Caccia, M.; Sandhage, K.; Dunand, D. Complex-shaped, finely-featured ZrC/W composites via shape-preserving reactive melt infiltration of porous WC structures fabricated by 3D ink extrusion. Addit. Manuf. Lett. 2021, 1, 100018. [Google Scholar] [CrossRef]

- Li, A.; Thornton, A.; Deuser, B.; Watts, J.; Leu, M.; Hilmas, G.; Landers, R. Freezeform extrusion fabrication of functionally graded material composites using zirconium carbide and tungsten. In Proceedings of the 23rd Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 6–8 August 2012; pp. 467–479. [Google Scholar]

- Olhero, S.; Torres, P.; Mesquita-Guimarães, J.; Baltazar, J.; Pinho-da-Cruz, J.; Gouveia, S. Conventional versus additive manufacturing in the structural performance of dense alumina-zirconia ceramics: 20 years of research, challenges and future perspectives. J. Manuf. Process. 2022, 77, 838–879. [Google Scholar] [CrossRef]

- Abyzov, A. Aluminum Oxide and Alumina Ceramics (Review). Part 2. Foreign Manufacturers of Alumina Ceramics. Technologies and Research in the Field of Alumina Ceramics. Refract. Ind. Ceram. 2019, 60, 33–42. [Google Scholar] [CrossRef]

- Klocke, F.; Iqbal, I.; Nath, R.; Bora, L.; Singh, B.; Mandal, N. Modern Approaches for the Production of Ceramic Components. J. Eur. Ceram. Soc. 1997, 17, 457–465. [Google Scholar] [CrossRef]

- Franks, G.; Tallon, C.; Studart, A.; Sesso, M. Colloidal processing: Enabling complex shaped ceramics with unique multiscale structures. J. Am. Ceram. Soc. 2017, 100, 458–490. [Google Scholar] [CrossRef]

- Zhang, F.; Li, Z.; Xu, M.; Wang, S.; Li, N.; Yang, J. A review of 3D printed porous ceramics. J. Eur. Ceram. Soc. 2022, 42, 3351–3373. [Google Scholar] [CrossRef]

- Ngo, T.; Kashani, A.; Imbalzano, G.; Nguyen, K.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Choppala, S.; Allam, A.; Fang, Z.; Armani, A. Next generation of advanced ceramic 3D printers. Future Technol. 2022, 2, 36–42. [Google Scholar] [CrossRef]

| Group of Materials | Material Used | Binder/ Additions | Application | Refs. |

|---|---|---|---|---|

| Oxides | Aluminum oxide (Al2O3) | glycerin, boehmite nanoparticles (AlO(OH)), aluminum dihydrogen phosphate (Al(H2PO4)3, AP), CuO and TiO2; | catalysts | [41,42,43] |

| Titanium oxide (TiO2) | modified titanium diisopropoxide bisacetylacetonate (TIA), polyvinyl alcohol (PVA), zinc, TALH (Ti(IV) bis (ammonium lactato) dihydroxide); | biomedical engineering, filtration, energy industry | [44,45,46,47] | |

| Zirconium oxide (ZrO2) | yttrium oxide stabilized zirconium powder (YZS), polyvinyl alcohol (PVA), polyethylene glycol (PEG-400), L-ascorbic acid (AA), citric acid (CA), Methocel, Darvan 821A, glycerol, Agitan 299 and polyethyleneimine; | biomedical engineering | [48,49,50] | |

| Mixed oxides | Lead zirconate titanate (PZT) | polyvinyl alcohol (PVA), ammonium polyacrylate; | piezoelectric transducers, acoustic sensors, energy harvesting | [51,52] |

| Barium titanate (BaTiO3—BT) | polyvinylidene fluoride (PVDF), N,N-dimethylformamide (DMF), polyvinyl alcohol (PVA); | capacitors, multilayer capacitors, sensors, and energy storage devices | [53,54,55,56] | |

| Non-oxides | Zirconium diboride (ZrB2) | polyvinyl alcohol (PVA), sodium 1-heptanesulfonsodium 1-heptanesulfonate (C7), sunflower oil; | ultra-high-temperature applications, aerospace, nuclear reactor | [57,58,59,60] |

| Silicon carbide (SiC) | liquid silicon, n-hexane mixed with polycarbosilane (PCS), distilled water, dispersing agent (Tamol NN 9401), glycerol, n-hexane (PCS solvent), and toluene; | aerospace and military industries, nuclear applications, sensors | [61,62,63,64,65] | |

| Bioceramics | Hydroxyapatite (HA) | polyvinyl butyral (PVB), polyethylene glycol (PEG), propan-2-ol, hydroxy propyl methyl cellulose (HPMC); | bone tissue engineering (scaffolds) | [66,67,68] |

| Calcium phosphate (CaP) | Dolapix CE 64 anionic surfactant, polyvinylpyrrolidone (PVP); | biomedical engineering | [67,68,69,70] | |

| Clays | Kaoline (2SiO2·Al2O3·2H2O) | sodium silicate, sodium polyacrylate; | pottery, catalysts | [71,72,73,74] |

| Cementitious materials | Ordinary Portland Cement | fly ash, blast furnace slag, silica fume, polyvinyl alcohol fiber (PVA), hollow glass microspheres (HGMs); | construction | [75,76,77] |

| Chemical Compound | SiO2 | Al2O3 | CaO | K2O | MgO | Na2O | TiO2 | Fe2O3 | P2O5 | Rb2O |

|---|---|---|---|---|---|---|---|---|---|---|

| Mass content [%] | 68.45 | 26.68 | 0.94 | 1.33 | 1.32 | 0.76 | 0.08 | 0.34 | 0.07 | 0.03 |

| Chemical Compound | SiO2 | Al2O3 | CaO | SO3 | Fe2O3 | K2O | TiO2 | LOI |

|---|---|---|---|---|---|---|---|---|

| Mass content [%] | 18.7 | 4.4 | 68.1 | 5.24 | 2.7 | 0.56 | 0.32 | 0.98 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Romanczuk-Ruszuk, E.; Sztorch, B.; Pakuła, D.; Gabriel, E.; Nowak, K.; Przekop, R.E. 3D Printing Ceramics—Materials for Direct Extrusion Process. Ceramics 2023, 6, 364-385. https://doi.org/10.3390/ceramics6010022

Romanczuk-Ruszuk E, Sztorch B, Pakuła D, Gabriel E, Nowak K, Przekop RE. 3D Printing Ceramics—Materials for Direct Extrusion Process. Ceramics. 2023; 6(1):364-385. https://doi.org/10.3390/ceramics6010022

Chicago/Turabian StyleRomanczuk-Ruszuk, Eliza, Bogna Sztorch, Daria Pakuła, Ewa Gabriel, Krzysztof Nowak, and Robert E. Przekop. 2023. "3D Printing Ceramics—Materials for Direct Extrusion Process" Ceramics 6, no. 1: 364-385. https://doi.org/10.3390/ceramics6010022

APA StyleRomanczuk-Ruszuk, E., Sztorch, B., Pakuła, D., Gabriel, E., Nowak, K., & Przekop, R. E. (2023). 3D Printing Ceramics—Materials for Direct Extrusion Process. Ceramics, 6(1), 364-385. https://doi.org/10.3390/ceramics6010022