Abstract

In this work, the impact resistance of three zirconia ceramics was investigated: two yttria-stabilized zirconia (3Y-TZP and 1.5Y-TZP) and a ceria-stabilized-zirconia (Ce-TZP) composite. The impact resistance was evaluated through drop-ball impact tests on disk-shaped samples. The results are discussed in terms of the materials’ transformability, which was correlated to the size of tetragonal-to-monoclinic (t-m) transformation zones observed after the impact tests and to the volume fraction of the monoclinic content on fractured surfaces. The findings show that impact resistance increases with the ability of the material to undergo t-m transformation. The Ce-TZP composite exhibited the highest transformability and consequently the highest impact resistance, followed by 1.5Y-TZP, and then 3Y-TZP.

1. Introduction

Zirconia ceramics are widely used in various industrial and biomedical applications due to their remarkable mechanical properties, biocompatibility, and wear resistance. The high toughness of zirconia, when compared to other oxide ceramics, is largely attributed to its stress-induced phase transformation from the tetragonal (t) to monoclinic (m) phase. This t-m phase transformation is accompanied by a volume expansion (~5%), resulting in compressive stresses, which lead to crack shielding from applied tensile stresses. Consequently, this contributes to the toughening of zirconia ceramics by increasing their toughness or crack propagation resistance [1,2,3].

Ce-TZP and Y-TZP are zirconia ceramics stabilized in the tetragonal phase by the addition of CeO2 and Y2O3, respectively. In the biomedical field, Y-TZP is favored for its aesthetic qualities and high mechanical strength, which may exceed 1 GPa, typically for ceramics containing 3 mol.% of yttria. However, this material exhibits moderate fracture toughness, ranging from 4 to 6 MPa [4,5,6]. In contrast, Ce-TZP ceramics offer higher toughness but lower strength (~500 MPa for zirconia stabilized with 12 mol.% ceria) [7,8,9,10] due to grain coarsening during sintering.

Numerous studies have explored strategies to achieve a better balance between strength and toughness in TZP ceramics [3,6,10,11,12,13,14,15,16,17,18,19,20,21,22,23,24,25]. Certain approaches involve the development of finer-grained Ce-TZP composites to enhance strength [3,6,9,15,19,21,26]. Another approach focuses on reducing Y2O3 content in Y-TZP ceramics to increase the material’s ability to undergo t-m transformation, thereby improving toughness without significantly compromising strength [27,28,29,30,31,32].

While the strength-toughness relationship in zirconia ceramics is well documented, less emphasis has been placed on impact resistance and energy absorption capacity. These properties, which are important for ballistic or shock-resistance applications, have been understudied and most previous investigations were focused on resistance to impact at very high speeds, known as ballistic impact loading [33,34,35,36,37,38,39,40]. In this study, we present a comparative analysis of the impact resistance of three TZP-based zirconia ceramics with increasing degrees of transformability: a standard 3Y-TZP zirconia, which exhibits transformation toughening but a quite modest crack-tip transformation zone size; a newly developed yttria-doped zirconia with less yttria content (1.5Y-TZP, doped with 1.5 mol.% yttria), which offers an attractive combination of toughness and strength [41]; and a Ce-TZP composite, showing a high transformation ability, a large transformation zone size, and, to a certain extent, some transformation-induced plasticity and ductility [9]. The aim of this work was also to clarify the question: ‘Is strength or toughness the most relevant figure of merit when designing a shock-resistant ceramic?’.

2. Materials and Methods

Three zirconia-based ceramic materials were used in this study: 1.5 mol.% and 3 mol.% yttria-stabilized zirconia, denoted by 1.5Y-TZP and 3Y-TZP, respectively, and a Ce-TZP composite consisting of 84 vol.% 11Ce-TZP, 8 vol.% Al2O3, and 8 vol.% SrAl12O19 aluminate platelets. The 1.5Y-TZP material was supplied by TOSOH (Zgaia 1.5Y-HT, Tokyo, Japan) and contained 0.25 wt.% Al2O3; the two other materials were provided by DOCERAM (Dortmund, Germany). All the samples were received in the shape of sintered disks with a diameter of 20 mm and a thickness of 1 mm. They were mirror-polished using diamond pastes (in the following order of grades: 6, 3, and 1 μm) and a colloidal silica suspension (0.03 μm). Density was measured using the Archimedes method in water [42] and the percentage of theoretical density (TD, from rule of mixture) was reported. The microstructure of the studied ceramics was investigated using Scanning Electron Microscopy (SEM; Zeiss SUPRA VP55, Oberkochen, Germany) at 1 kV on fractured surfaces. The zirconia grain size was estimated from the SEM micrographs from a minimum of 150 grains using ImageJ software (Version 1.54). Vickers hardness was measured by Vickers indentation (FV-700 tester, Future-Tech, Kanagawa, Japan) on mirror-polished samples with a load of 1 kgf applied for 10s (Hv1).

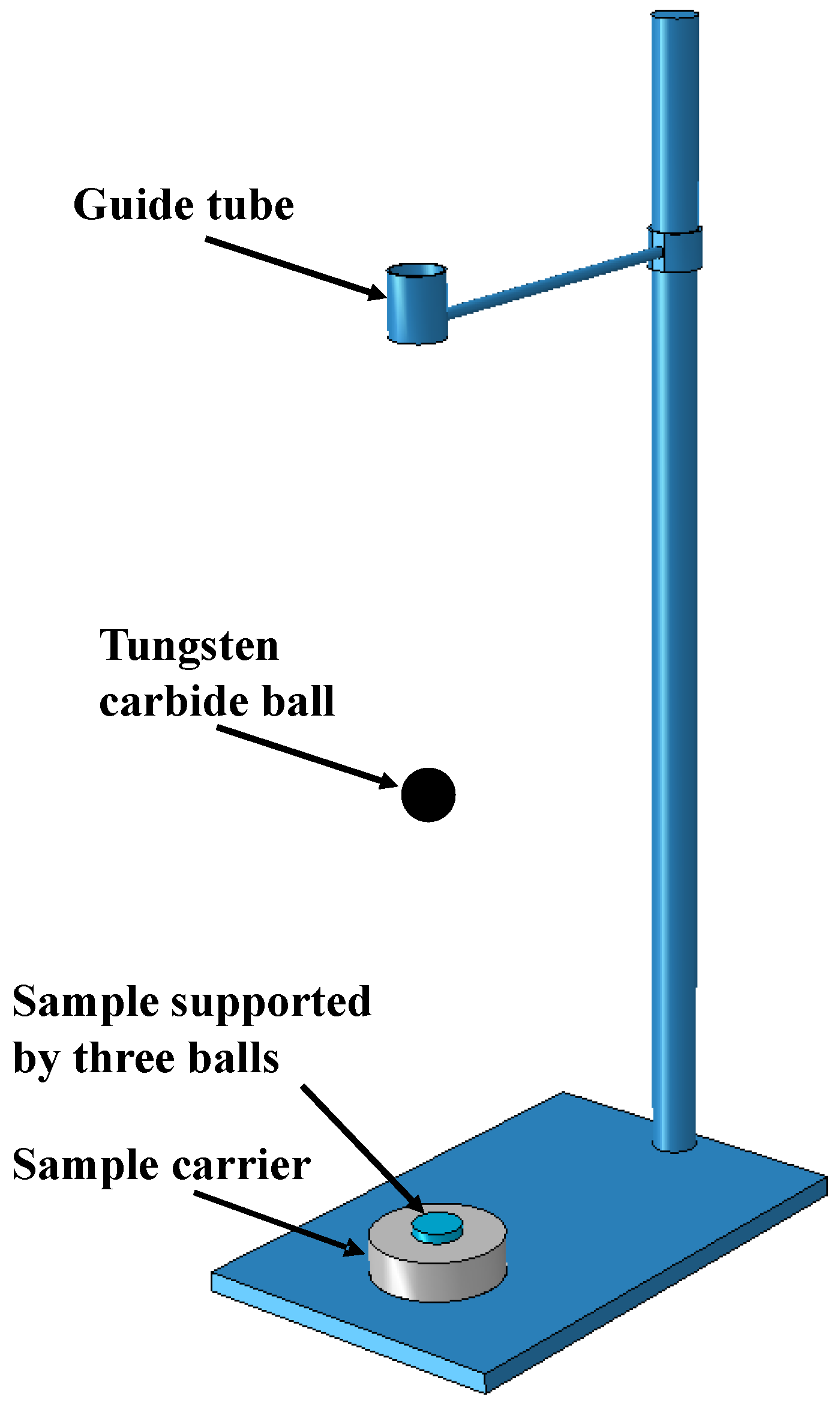

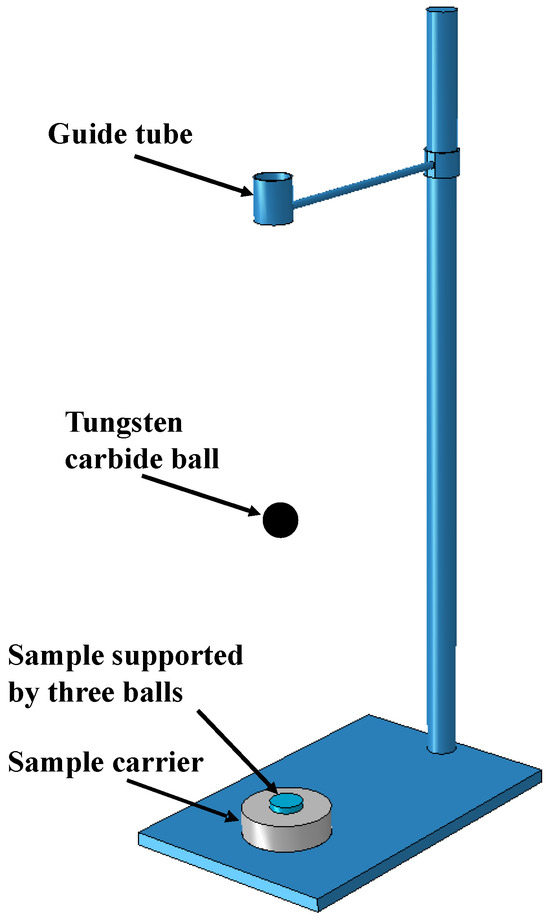

To evaluate the impact resistance of the studied materials, drop-ball impact tests were performed using a device developed in a laboratory, a schematic representation of which is shown in Figure 1. The mirror-polished surface of the disk-shape samples was placed on three balls equidistant from its center, arranged in a circle of 16 mm in diameter (as would be the case in biaxial bending tests). A tungsten carbide ball of 26.5 g weight and 15 mm in diameter was then dropped onto the center of the disk. The drop heights were chosen between 10 cm and 40 cm (with increments of 5 cm or 2.5 cm for more precision) to include, for all three ceramics, heights where no failure was observed towards heights for which all samples broke. For each material, six samples were tested at each drop height. The results were then analyzed in terms of failure probability, calculated as the ratio of the number of fractured samples to the number of tested samples under the same conditions (i.e., six samples), versus height. For each material, a critical height (HC)—corresponding to the drop height at which at least one sample among the six fractured (non-null failure probability)—was determined.

Figure 1.

Schematic representation of the impact resistance testing device.

The impact energy, Eimp, was calculated considering only the potential energy, i.e., ignoring the loss due to air resistance, as follows:

where m is the mass of the tungsten carbide drop ball (26.5 g), g is the gravitational acceleration (9.8 m/s2), and H is the drop height.

Eimp = mgH

The absorbed energy, Ea, during impact tests was calculated, as follows:

where HB is the bounce height, which was measured using a high-speed camera.

Ea = mg(H − HB)

To determine the phase composition and assess the transformability of the studied materials, X-ray Diffraction (XRD) analysis was conducted on mirror-polished and fractured surfaces using CuKα radiation (1.5418Å) in the angular domain 2θ ranging from 27 to 33° (D8 Advance Bruker AXS diffractometer, Billerica, MA, USA). The mass fraction of the monoclinic phase (Xm) was calculated according to the following expression [43]:

where Im (hkl) denotes the area of the peak generated by the hkl plane in the monoclinic (m) or the tetragonal (t) phase.

The volume fraction of the monoclinic phase (Vm) was then calculated according to [44]:

The bottom (tensile) side of the samples was observed for signs of t-m phase transformation zones induced by impact tests using optical microscopy (ZEISS Axiophot, Oberkochen, Germany) as well as 3D confocal microscopy, employing a S-Neox (Sensofar, Barcelona, Spain) 3D non-contact optical profiler machine. which combines confocal and interferometry techniques with a lateral resolution of 0.26 μm. The acquired data were processed using Mountains Map Universal software® (Digital Surf, Besançon, France).

3. Results

3.1. Microstructure and Properties

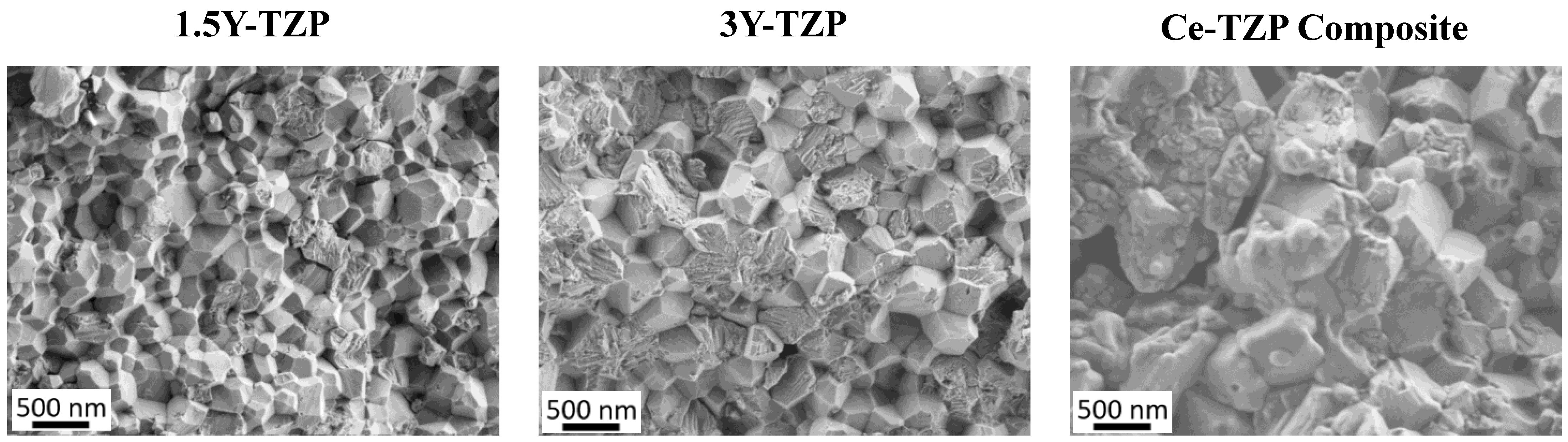

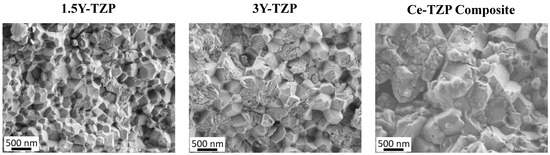

The density, Vickers hardness, and the zirconia grain size are presented in Table 1. SEM micrographs of fractured surfaces are show in Figure 2. All materials exceeded 99% of the theoretical density, indicating almost full densification. The Vickers hardness falls within the typical range for Y-TZP and Ce-TZP composites [45,46,47], with a lower value for the latter. The initial monoclinic phase content on polished surfaces was less than 5 vol.% for all studied materials.

Table 1.

Summary of density, hardness, and zirconia grain size of sintered disks.

Figure 2.

SEM micrographs of fractured surfaces of tested samples for each material.

3.2. Critical Drop Height

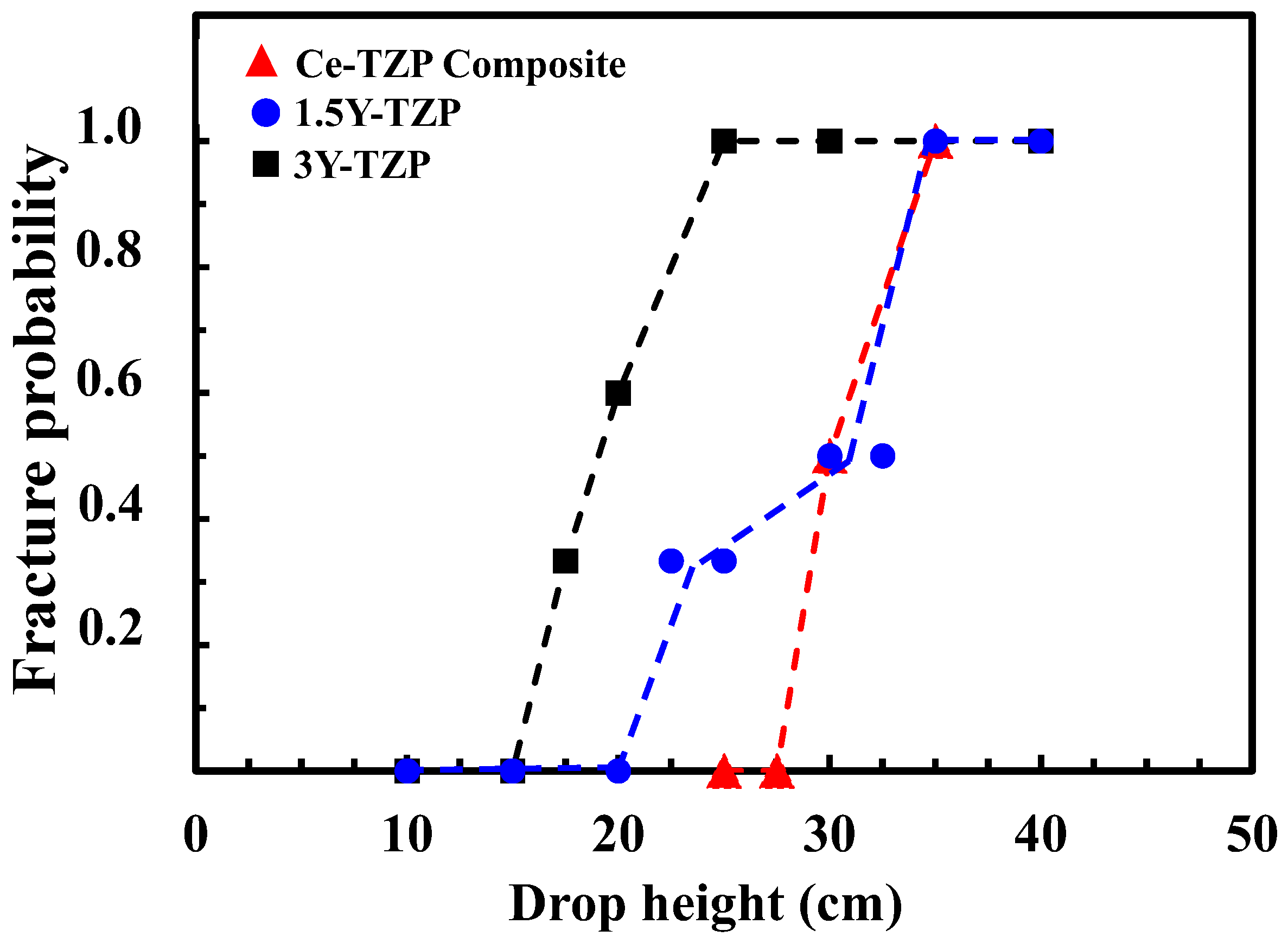

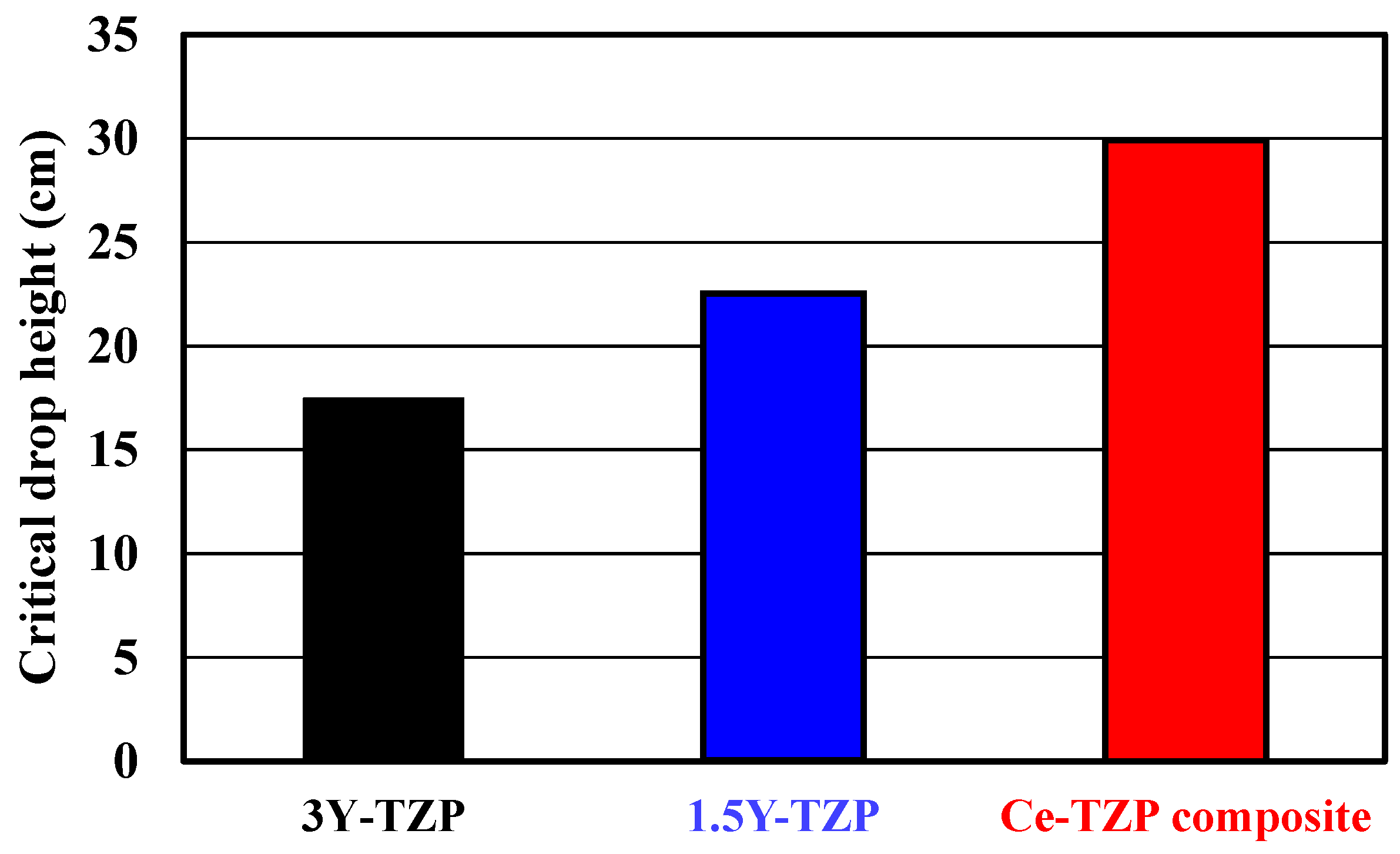

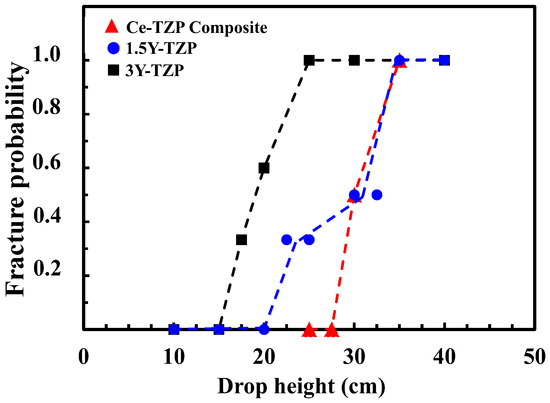

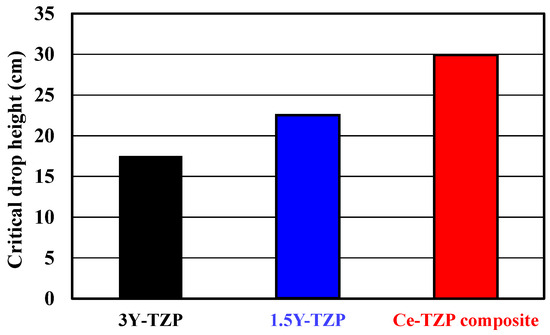

Figure 3 summarizes the results of the impact tests in terms of failure probability as a function of drop height. It can be observed that the range of drop heights over which the risk of fracture under impact is 100% is higher for 1.5Y-TZP and Ce-TZP composite (35 cm) compared to 3Y-TZP (25 cm). Both 1.5Y-TZP and Ce-TZP composite show similar drop heights for failure probabilities of 0.5 (30 cm), whereas this height is significantly lower for 3Y-TZP (~17.5 cm). Figure 4 shows the critical drop heights, HC, determined for the studied materials. The Ce-TZP composite exhibited the highest HC value of 30 cm. An intermediate value of 22.5 cm was observed for the 1.5Y-TZP zirconia, whereas the lowest value of 17.5 cm was observed for the 3Y-TZP zirconia.

Figure 3.

Fracture probability versus drop height for the three materials.

Figure 4.

Critical drop heights (HC) for the three materials.

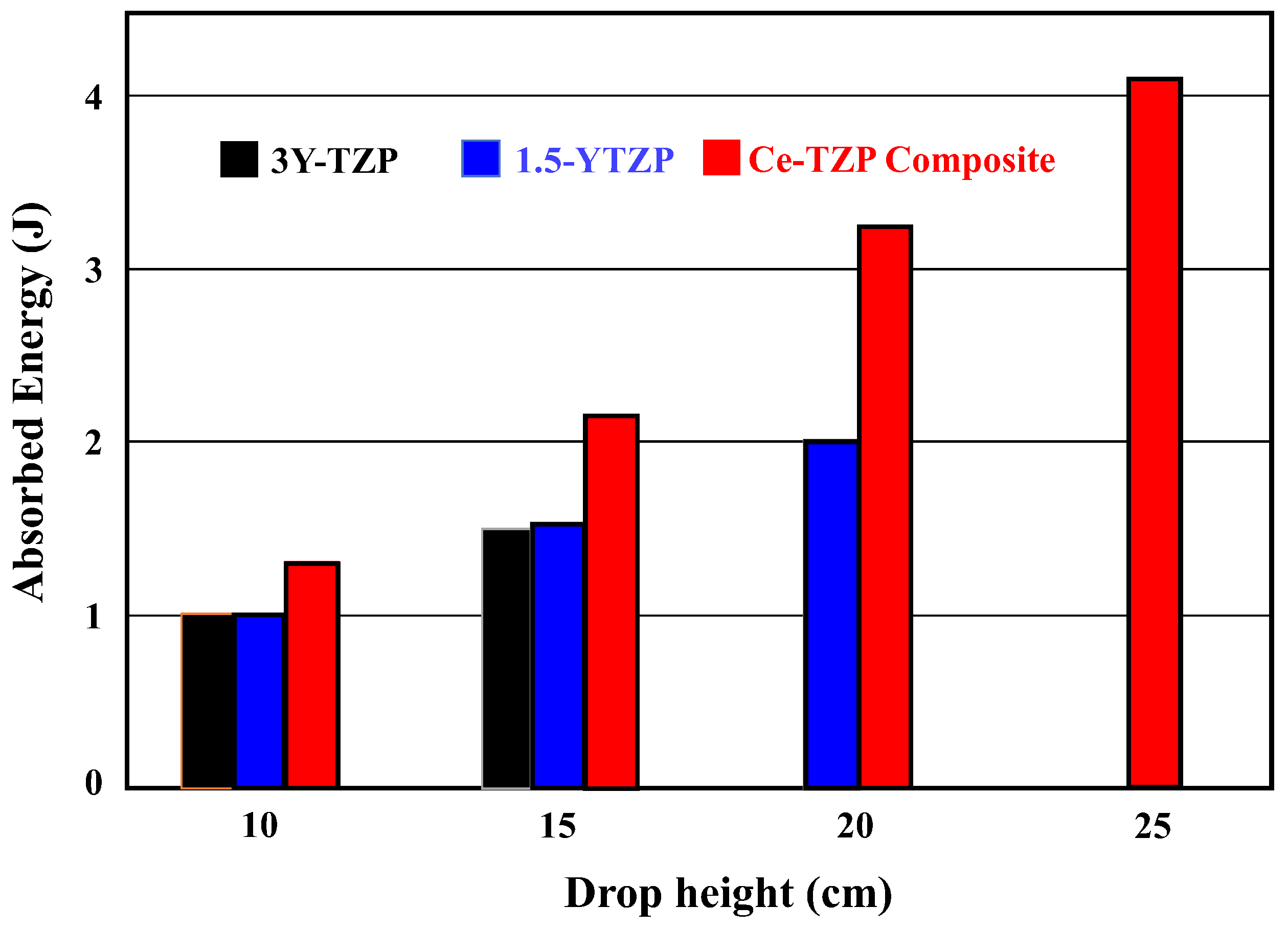

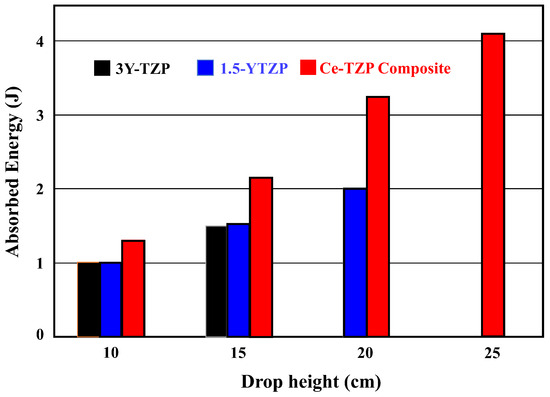

3.3. Absorbed Energy

Figure 5 shows the absorbed energy, Ea, during impact testing at drop heights of 10, 15, 20, and 25 cm. For the 1.5Y-TZP and 3Y-TZP materials, only rebound measurements performed below their respective critical drop heights were considered for Ea calculations. For all the materials, the absorbed energy increased as drop height increased. At the smaller drop heights of 10 cm and 15 cm, 1.5Y-TZP and 3Y-TZP absorbed roughly the same amount of energy, whereas the Ce-TZP composite absorbed significantly more energy at all drop heights.

Figure 5.

Absorbed energy (Ea) during impact testing at drop heights of 10, 15, 20, and 25 cm.

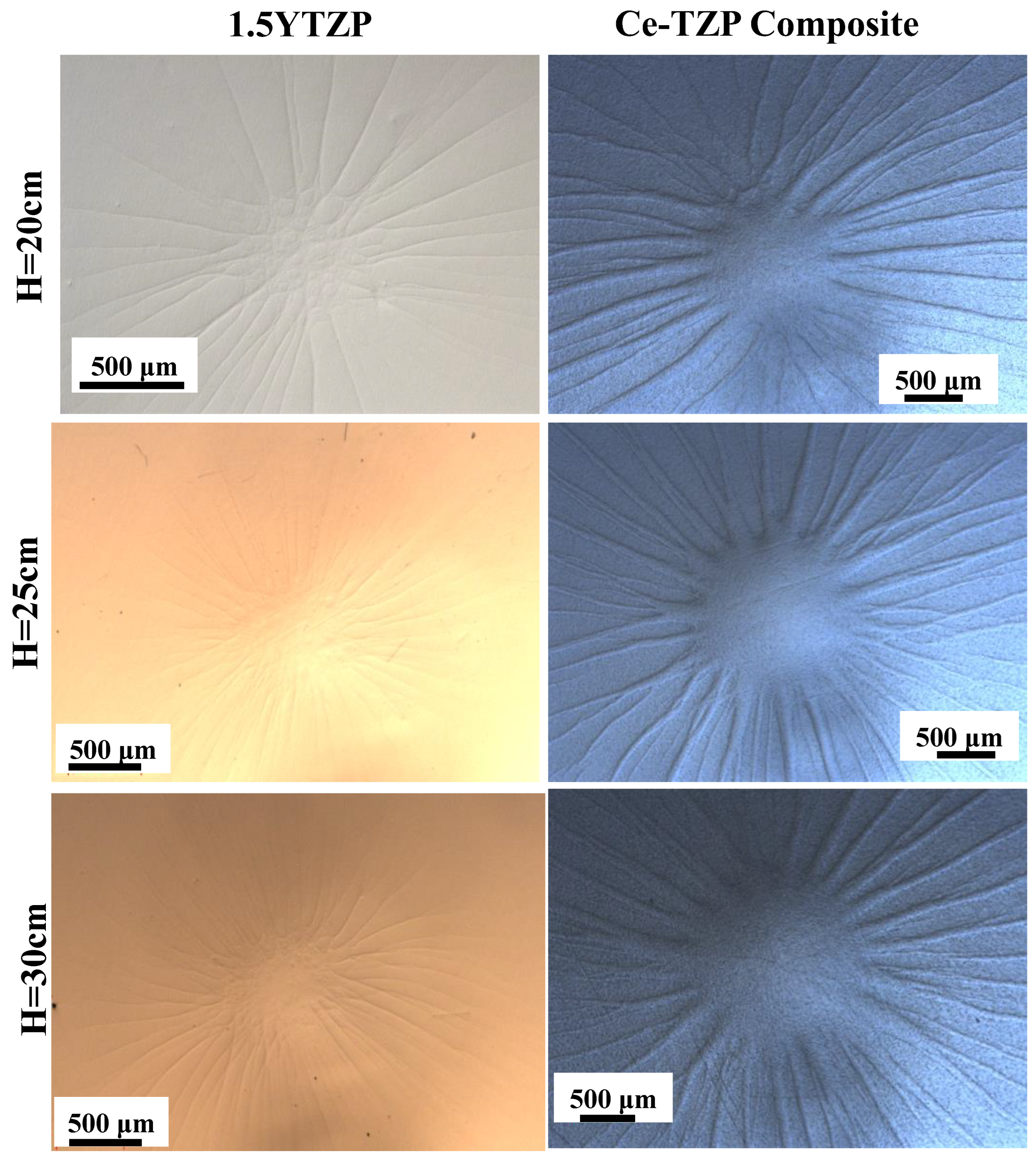

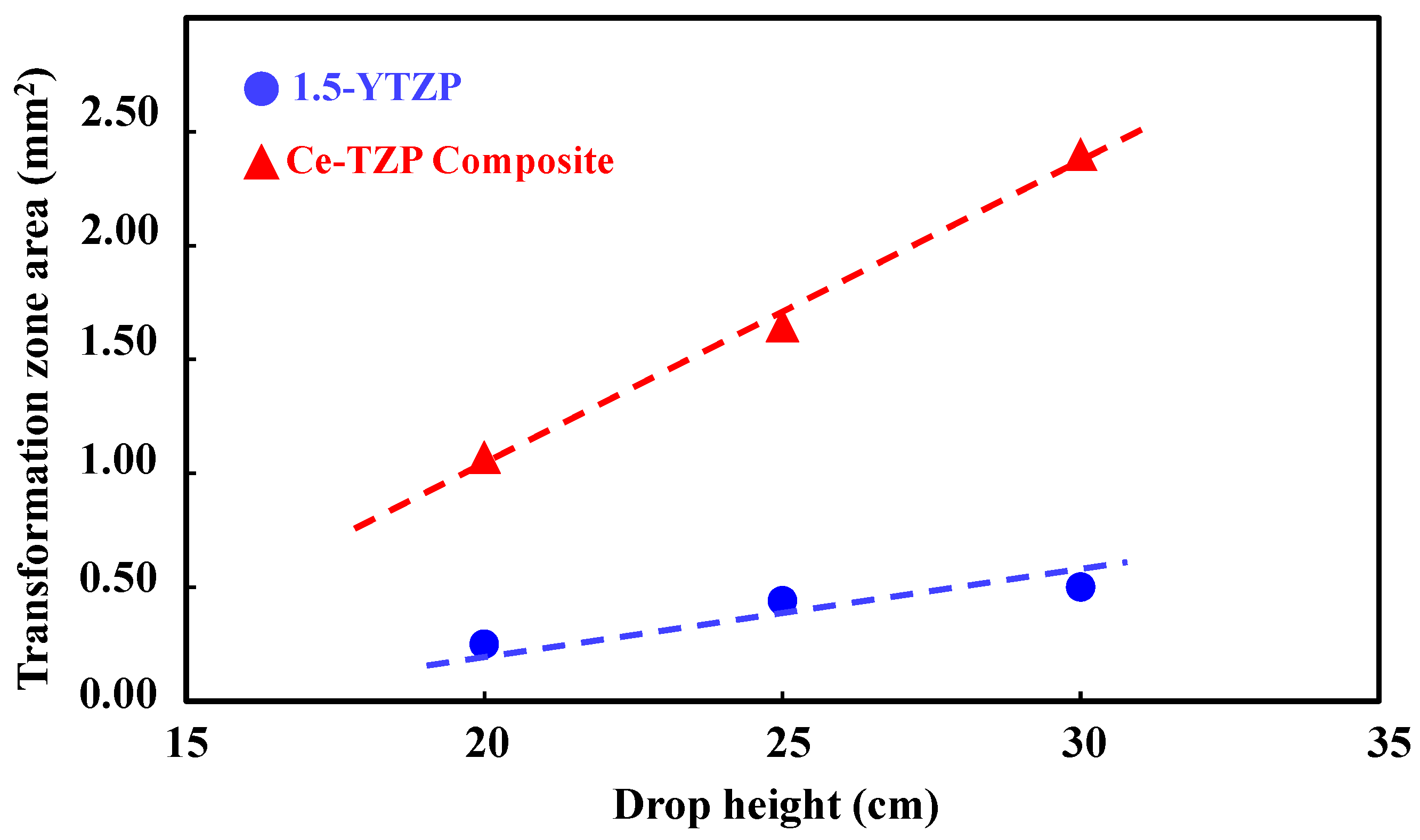

3.4. Impact-Induced Phase Transformation

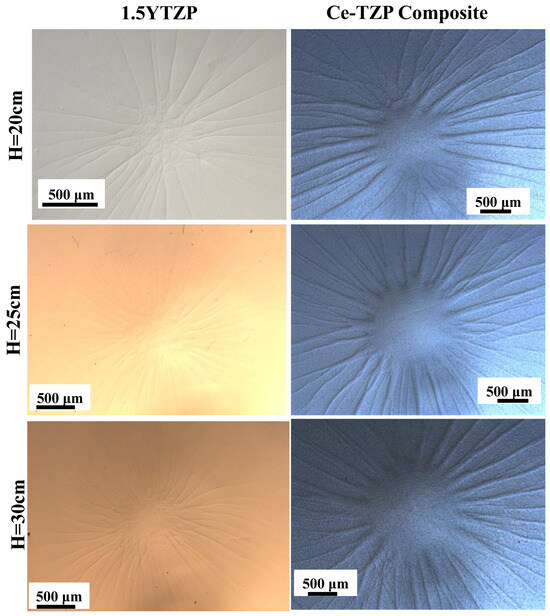

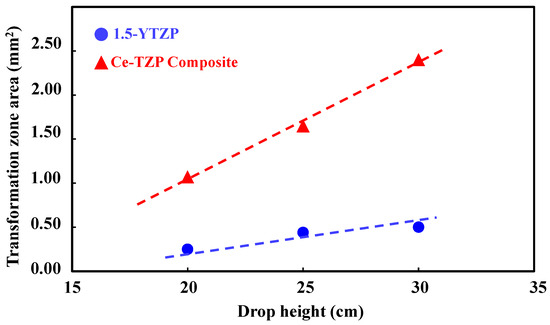

Optical observations of the tensile side of impacted and unbroken samples revealed the presence of t-m transformation zones in 1.5Y-TZP and the Ce-TZP composite, while no phase transformation was detected in the impacted 3Y-TZP zirconia. Figure 6 shows typical optical micrographs of the impact-induced t-m phase transformation zones for different drop heights. For heights above HC, only unbroken tested samples were observed. The transformation zones exhibited a star-shaped geometry, with a circular central transformed region from which radial bands extended towards the edge of the disk. The area of the transformation zone was evaluated by considering the transformed area within a circle corresponding to the effective surface in biaxial tests, as in [48]. Figure 7 shows the evolution of the impact-induced transformation zone area with drop height for the 1.5Y-TZP and the Ce-TZP composite. For both materials, the size of the transformation zone increases linearly with drop height (Figure 7), with consistently higher transformed areas for the Ce-TZP composite, which reached almost five times that of 1.5Y-TZP at a drop height of 30 cm (i.e., around 2.5 and 0.5 mm2, respectively).

Figure 6.

Optical micrographs (Nomarski contrast) of t-m transformation zones observed in 1.5Y-TZP and Ce-TZP composite after impact tests at drop heights of 20, 25, and 30 cm.

Figure 7.

Evolution of the impact-induced t-m transformation zone size with the drop height.

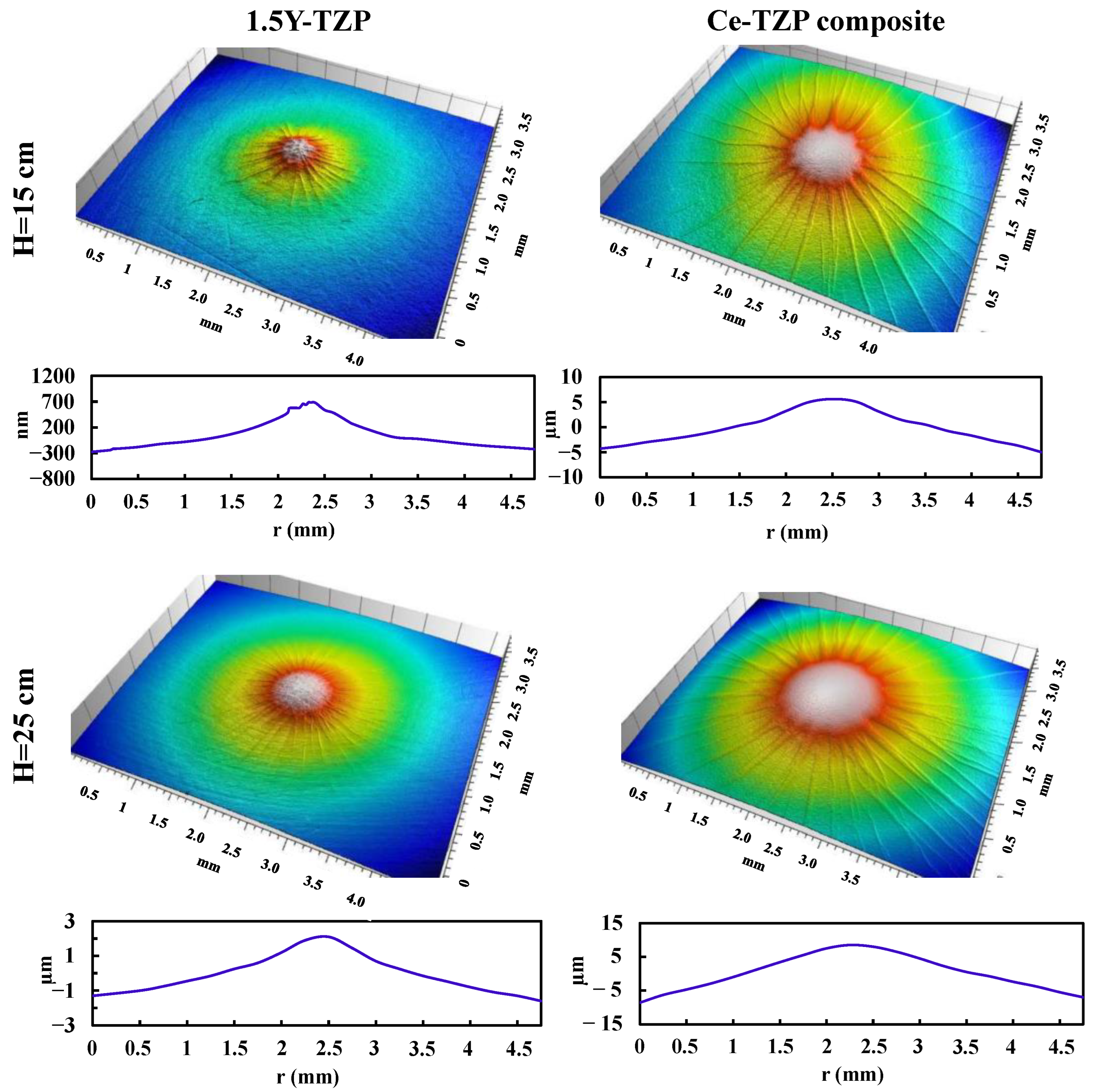

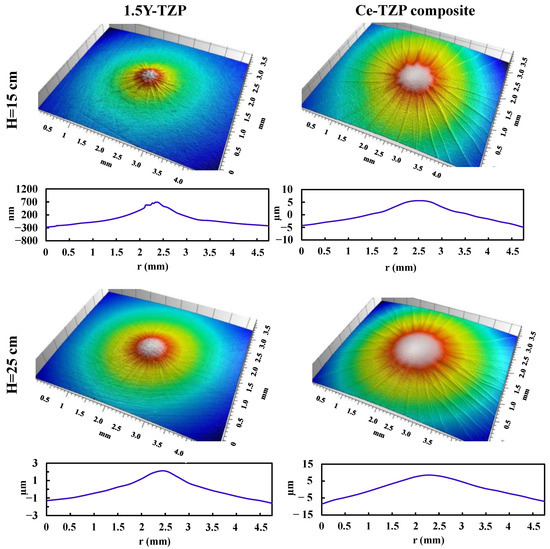

3D confocal microscopy observations confirmed the t-m phase transformation during impact testing and allowed quantitative analysis of the topography of impacted areas. Volume increase related to the t-m transformation (i.e., around 5 vol.%) was evidenced by circular dome-shaped zones, typical images of which are shown in Figure 8, where radial roughness profiles are also displayed. The effect of the impact on the t-m transformation extended over the sample (at least 5 mm in diameter around the impact point), as evidenced by the absence of a flat area in the 3D confocal images and analyses. For 1.5Y-TZP, roughness profiles revealed an increase of 2.4 µm in the maximum height of the transformation zone from 15 to 25 cm drop heights (1 and 3.4 µm, respectively). Similarly, for the Ce-TZP composite, the maximum height of the transformation zone increased by 9 µm over the same range of drop heights (i.e., from 9 µm at 15 cm to 18 µm at 25 cm).

Figure 8.

3D confocal images of the transformation zones developed under impact testing for 1.5Y-TZP and Ce-TZP composite samples with drop heights of 15 and 25 cm, along with their radial topography profile curves as a function of the distance, r.

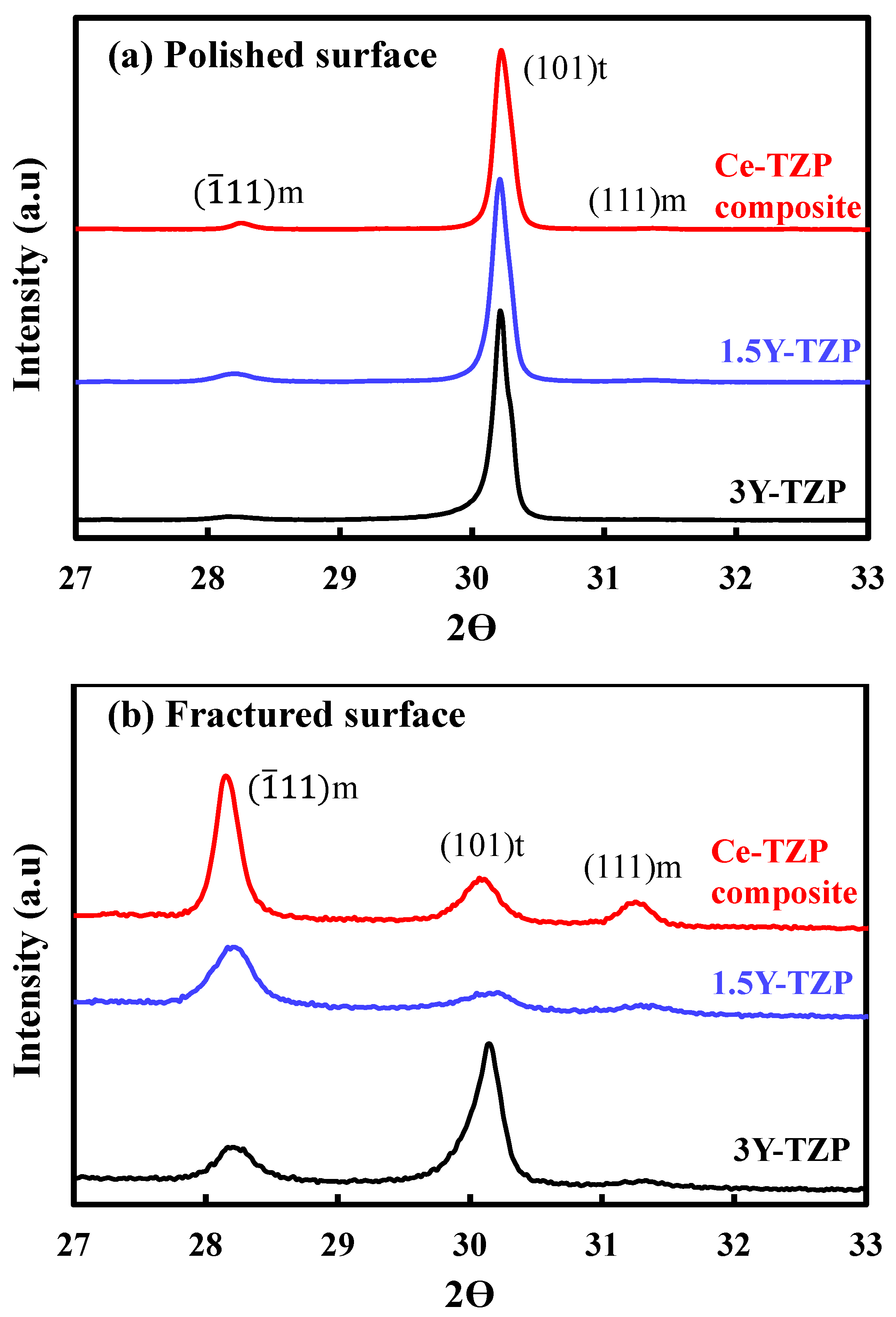

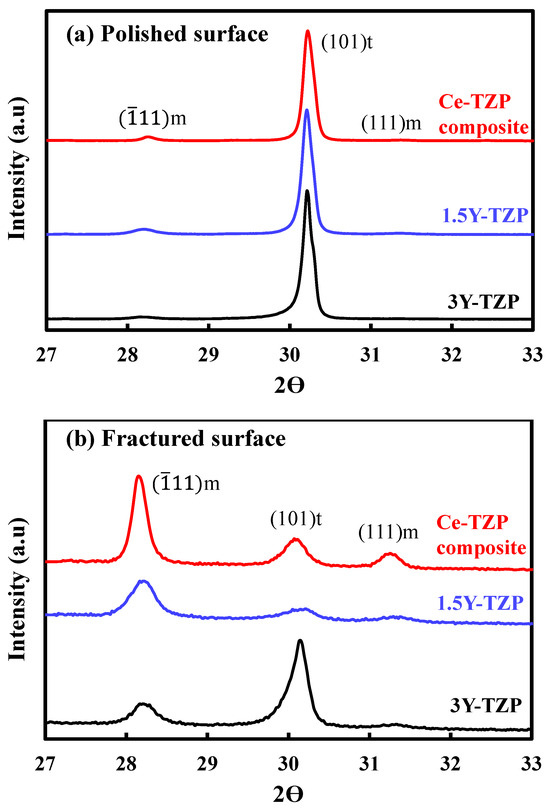

Evidence of t-m phase transformation in the studied materials during impact tests was also provided by XRD analysis of polished and fractured surfaces, as shown in Figure 9. The monoclinic phase content, (Vm), estimated on fractured surfaces after impact testing, was 80% for 1.5Y-TZP zirconia and the Ce-TZP composite, and 30% for 3Y-TZP zirconia.

Figure 9.

XRD patterns of polished (a) and fractured (b) surfaces of the studied materials.

4. Discussion

The phase transformation observed after impact testing of 1.5Y-TZP and Ce-TZP composite disks was induced by the stresses generated by the highly localized contact force between the ceramic surface and the WC drop ball, which is harder (Hv~2400) and stiffer (E = 500–700 MPa). The star-shaped transformation zones induced during impact tests (Figure 6) are similar to those previously observed for these materials on the tensile side of biaxial piston-on-three-ball test samples (i.e., in the center of the disk, over the piston, where the stresses are the highest) or three-ball-on-three-ball tests (i.e., under the three closest balls in contact with the surface under compression, but on the side under tension) [9,41,48,49].

The results revealed a strong correlation between impact resistance, expressed either by the critical drop height (HC) or the absorbed energy (Ea), and the stress-induced t-m phase transformation of the materials. The Ce-TZP composite, with the largest impact-induced transformation zones (Figure 6 and Figure 8), exhibited the highest critical drop height compared to the Y-TZP materials (Figure 4). Among the latter, the under-stabilized 1.5Y-TZP, for which impact-induced t-m phase transformation occurred, exhibited a higher critical drop height than 3Y-TZP, for which no transformation was observed on impacted surfaces.

The significantly high energy absorption of the Ce-TZP composite, even at low drop heights (Figure 5), can also be attributed to the high transformability of this material, which is known to provide a ductile-like behavior to these composite ceramics under quasi-static bending and tensile testing [48]. In previous works [10,48], it has been shown that this material and other similar composites [6,9,10,50] exhibited low critical t-m transformation stresses, σc(t-m), compared to their flexural strengths, allowing t-m phase transformation to occur at relatively low stresses (e.g., σc(t-m)~300–400 MPa) before any crack propagation, inducing nonlinear behavior (~0.4% plastic strain at failure) and high energy dissipation before fracture. The plasticity in these Ce-TZP composites is exclusively linked to the stress-induced t-m zirconia phase transformation, as no microcracking and/or damage occurred during plastic deformation under flexural loading [10]. At low drop heights (10–20 cm), no significant difference was observed between the energy absorption in 3Y-TZP and 1.5Y-TZP, as the t-m phase transformation zone was not sufficiently developed in the latter under such conditions. This agrees with the high critical t-m transformation stress of 1.5Y-TZP, which is of the same order as its flexural strength, σR (i.e., σc(t-m) = σR~1000 MPa), placing it at the transition between brittle and ductile behavior [41]. This characteristic also explains the wider range of drop heights over which the risk of fracture under impact increases from 0 to 100% for 1.5Y-TZP (Figure 3). At low drop heights, the transformation zones in this material were not sufficiently developed, and its behavior was close to that of 3Y-TZP (brittle-like). However, it then becomes similar to that of the Ce-TZP composite at high drop heights (ductile-like), at which its t-m transformation becomes important.

After sintering and polishing, mainly tetragonal zirconia was detected by XRD (Figure 9a). The volume fraction of the monoclinic phase was estimated to be 3% for 3Y-TZP and 5% for both 1.5Y-TZP and the Ce-TZP composite, related to transformation at the surface of the ceramics due to applied polishing stresses. The ability to undergo t-m phase transformation under stress, estimated from XRD performed on as-fractured surfaces (Figure 9b), was much higher for 1.5Y-TZP and the Ce-TZP composite (80 vol.% monoclinic phase) compared to the less impact-resistant material, 3Y-TZP (only 30 vol.%). It is worth noting, however, that the amount of monoclinic phase on fractured surfaces reached the same value for 1.5Y-TZP and Ce-TZP composite materials (80%), despite the higher impact resistance of the Ce-TZP composite. This is due to the limitations of XRD in assessing the extent of monoclinic phase transformation in zirconia, as X-rays only penetrate to a depth of ~5 µm [51]. Microstructural analysis of cross-sections should be carried out to better characterize the volume affected by t-m phase transformation under impact, but the transformability is already well described and quantified from topography analyses of the transformation areas.

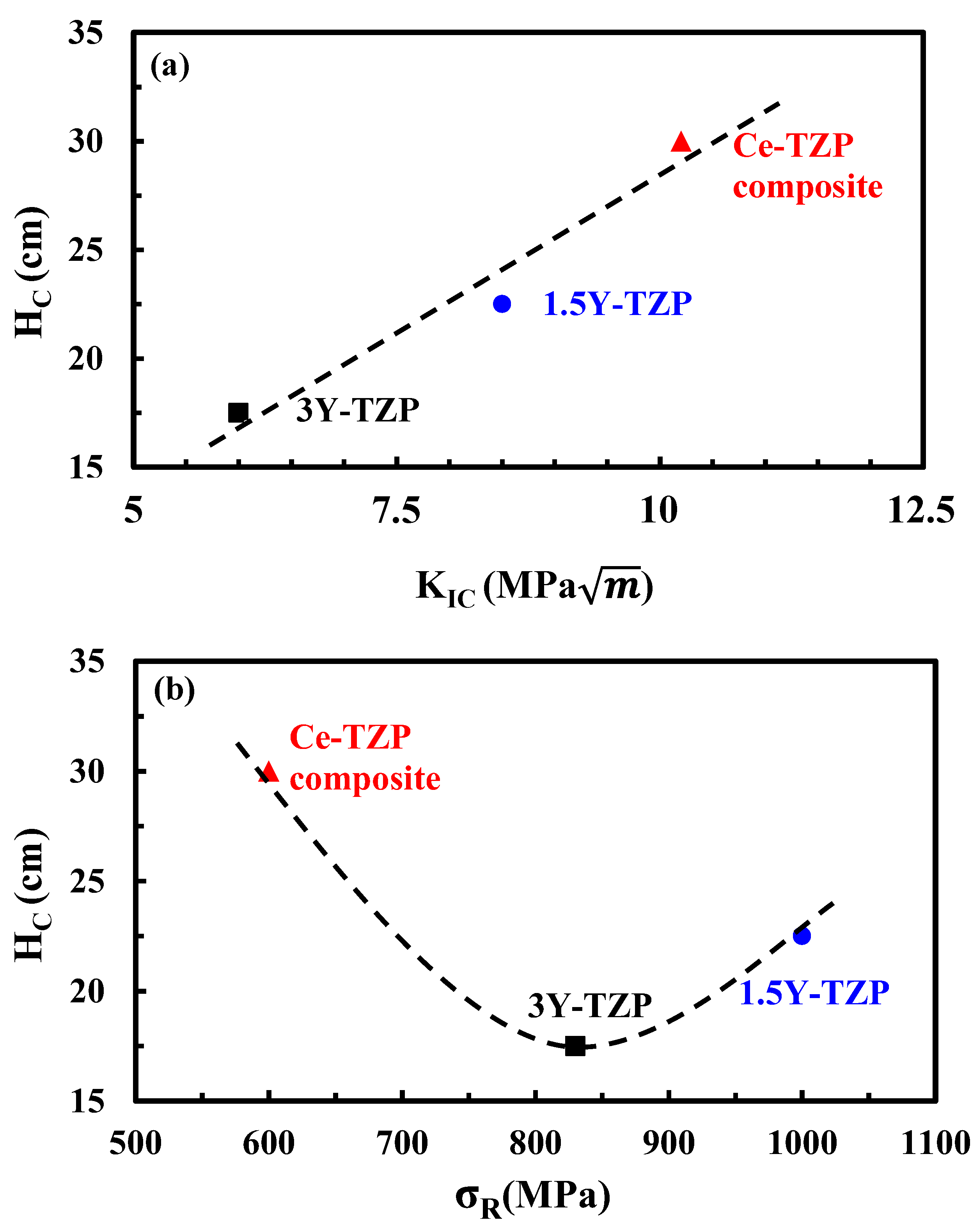

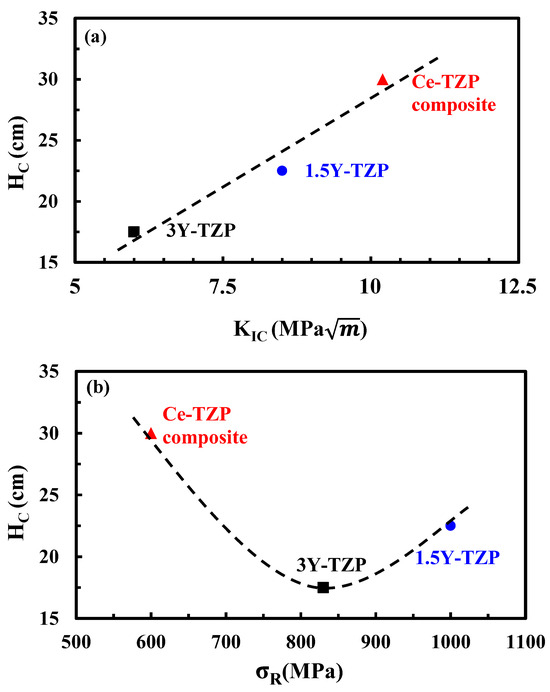

As outlined by several authors [52,53,54,55,56,57,58], the fracture toughness (KIC) is a key material parameter affecting the ballistic resistance of ceramic materials, as it measures the resistance to crack initiation. For the studied materials (Table 2), the higher the fracture toughness, the higher the impact resistance, following a linear trend, as shown in Figure 10a. In contrast, no direct relationship was observed between HC and strength, (σR), previously determined from four-point bending tests (Figure 10b) [41,48,59]. In particular, the material most resistant to impact (i.e., the Ce-TZP composite) displayed the lowest value of strength, indicating that strength has a weaker correlation with impact resistance than fracture toughness under the conditions of this study.

Table 2.

Impact resistance parameters (HC and absorbed energy at HC, Eac), strength (σR), and fracture toughness (KIC) of the studied materials.

Figure 10.

Variation of the critical drop high, HC, with toughness, KIC, (a), and with strength, σR, (b) for the studied materials.

The correlation between KIC and impact resistance can be understood by considering the positive influence of stress-induced t-m phase transformation on both properties. On one hand, crack shielding due to this transformation decreases the effective applied stress at the crack front, likely to propagate, which leads to improved fracture toughness. The size of the transformation zone around the crack (h) and the volume fraction of the monoclinic transformed phase are key parameters for transformation toughening, as previously verified for the studied materials during crack propagation under flexural loading [41,48]. It has been shown that h, typically about 5 µm for 3Y-TZP (known for its brittle behavior), reaches 20 µm for 1.5Y-TZP and 100 µm for the ductile Ce-TZP composite, which exhibited a significant crack growth resistance (rising R-curve behavior). On the other hand, the effect of t-m phase transformation on impact resistance can be attributed to the increased energy dissipation associated with the material’s ability to exhibit t-m phase transformation and ductile behavior. This finding is consistent with the impact-induced t-m phase transformation results, which highlight the intermediate behavior of 1.5Y-TZP, allowing it to perform relatively well in terms of impact resistance, though not as effectively as the ductile Ce-TZP composite. It would be interesting to better characterize the t-m transformed zones induced by impact to verify whether, as observed during biaxial flexural tests performed on Ce-TZP composites, the t-m transformation takes place without microcracking. If this is the case, strategies for “regenerating” impacted ceramics could be explored by inverse m-t phase transformation, which would be achieved by increasing the temperature of the material.

5. Conclusions

Our work clearly highlights the role of stress-induced t-m zirconia phase transformation in the impact resistance of zirconia ceramics. The higher the transformability, the higher the ability to absorb energy upon impact and the higher the critical height for failure. The highest transformability was observed in the Ce-TZP composite, which had the highest critical height (30 cm), followed by 1.5Y-TZP (22.5 cm) and 3Y-TZP (17.5 cm). A linear relationship between the fracture toughness and critical drop height was observed in these zirconia-transformable materials. However, further studies on other zirconia-based compositions and/or composites are needed to validate this dependence. Conversely, strength measured in bending is not a relevant figure of merit for shock resistance, at least under the conditions of this study. These findings show the positive influence of stress-induced t-m zirconia phase transformation on the impact resistance of zirconia materials, suggesting the potential use of highly transformable materials in applications where shock resistance is of prime importance.

Author Contributions

Conceptualization, M.I.; Validation, M.S. and H.R.; Investigation, M.I. and N.L.; Writing—original draft, M.I.; Writing—review & editing, M.S., H.R. and J.C.; Supervision, M.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Evans, A.G.; Heuer, A.H. Review-Transformation toughening in ceramics: Martensitic transformations in crack-tip stress fields. J. Am. Ceram. Soc. 1980, 63, 241–248. [Google Scholar] [CrossRef]

- Swain, M.V. Inelastic deformation of Mg-PSZ and its significance for the strength-toughness relationship of zirconia-toughened ceramics. Acta Metall. 1985, 33, 2083–2091. [Google Scholar] [CrossRef]

- Hannink, R.; Kelly, P.; Muddle, B. Transformation toughening in ZrO2-containing ceramics. J. Am. Ceram. Soc. 2000, 83, 461–487. [Google Scholar] [CrossRef]

- Al-Amleh, B.; Lyons, K.; Swain, M. Clinical trials in zirconia: A systematic review. J. Oral Rehabil. 2010, 37, 641–652. [Google Scholar] [CrossRef] [PubMed]

- Turon-Vinas, M.; Anglada, M. Fracture toughness of zirconia from a shallow notch produced by ultra-short pulsed laser ablation. J. Eur. Ceram. Soc. 2014, 34, 3865–3870. [Google Scholar] [CrossRef]

- Touaiher, I.; Saâdaoui, M.; Chevalier, J.; Preiss, L.; Reveron, H. Fracture behavior of Ce-TZP/alumina/aluminate composites with different amounts of transformation toughening: Influence of the testing methods. J. Eur. Ceram. Soc. 2018, 38, 1778–1789. [Google Scholar] [CrossRef]

- Tsukuma, K.; Shimada, M. Strength, fracture toughness, and Vickers hardness of CeO2-stabilized tetragonal ZrO2 polycrystals (Ce-TZP). J. Mater. Sci. 1985, 20, 1178–1184. [Google Scholar] [CrossRef]

- El Attaoui, H.; Saâdaoui, M.; Chevalier, J.; Fantozzi, G. Static and cyclic crack propagation in Ce-TZP ceramics with different amounts of transformation toughening. J. Eur. Ceram. Soc. 2007, 27, 483–486. [Google Scholar] [CrossRef]

- Chevalier, J.; Liens, A.; Reveron, H.; Zhang, F.; Reynaud, P.; Douillard, T.; Preiss, L.; Sergo, V.; Lughi, V.; Swain, M.; et al. Forty years after the promise of «ceramic steel?: Zirconia-based composites with a metal-like mechanical behavior. J. Am. Ceram. Soc. 2020, 103, 1482–1513. [Google Scholar] [CrossRef]

- Liens, A.; Reveron, H.; Douillard, T.; Blanchard, N.; Lughi, V.; Sergo, V.; Laquai, R.; Müller, B.R.; Bruno, G.; Schomer, S.; et al. Phase transformation induces plasticity with negligible damage in ceria-stabilized zirconia-based ceramics. Acta Mater. 2020, 183, 261–273. [Google Scholar] [CrossRef]

- Swain, V.; Rose, L. Strength limitations of transformation-toughened zirconia alloys. J. Am. Ceram. Soc. 1986, 69, 511–518. [Google Scholar] [CrossRef]

- Yu, C.S.; Shetty, D.K. Transformation zone shape, size, and crack-growth-resistance [R-curve] behavior of ceria-partially-stabilized zirconia polycrystals. J. Am. Ceram. Soc. 1989, 72, 921–928. [Google Scholar] [CrossRef]

- Sato, T.; Endo, T.; Shimada, M. Hot isostatic pressing of ceria-doped tetragonal zirconia/alumina composites in an argon-oxygen gas atmosphere. J. Am. Ceram. Soc. 1989, 72, 761–764. [Google Scholar] [CrossRef]

- Tsai, J.; Yu, C.; Shetty, D. Fatigue crack propagation in ceria-partially-stabilized zirconia (Ce-TZP)-alumina composites. J. Am. Ceram. Soc. 1990, 73, 2992–3001. [Google Scholar] [CrossRef]

- Yu, C.; Shetty, D. Transformation yielding, plasticity, and crack-growth-resistance (R-curve) behavior of CeO2-TZP. J. Mater. Sci. 1990, 25, 2025–2035. [Google Scholar] [CrossRef]

- Cutler, R.; Mayhew, R.; Prettyman, K.; Virkar, A. High-toughness Ce-TZP/Al2O3 ceramics with improved hardness and strength. J. Am. Ceram. Soc. 1991, 74, 179–186. [Google Scholar] [CrossRef]

- Tsai, J.; Chon, U.; Ramachandran, N.; Shetty, D. Transformation plasticity and toughening in CeO2-partially-stabilized zirconia–alumina (Ce-TZP/Al2O3) composites doped with MnO. J. Am. Ceram. Soc. 1992, 75, 1229–1238. [Google Scholar] [CrossRef]

- Ramachandran, N.; Chao, L.; Shetty, D. R-curve behavior and flaw insensitivity of Ce-TZP/Al2O3 composite. J. Am. Ceram. Soc. 1993, 76, 961–969. [Google Scholar] [CrossRef]

- Readey, M.; McCallen, C. Flaw tolerance and reliability of Ce-TZP and Y-TZP ceramics. J. Am. Ceram. Soc. 1995, 78, 2769–2776. [Google Scholar] [CrossRef]

- Nawa, M.; Nakamoto, S.; Sekino, T.; Niihara, K. Tough and strong Ce-TZP/alumina nanocomposites doped with titania. Ceram. Int. 1998, 24, 497–506. [Google Scholar] [CrossRef]

- Dietrich, M. What can we learn from R-curve measurements? J. Am. Ceram. Soc. 2007, 90, 1–15. [Google Scholar]

- Benzaid, R.; Chevalier, J.; Saâdaoui, M. Fracture toughness, strength, and slow crack growth in a ceria-stabilized zirconia-alumina nanocomposite for medical applications. Biomaterials 2008, 29, 3636–3641. [Google Scholar] [CrossRef] [PubMed]

- Nawa, M.; Kurizoe, N.; Okamoto, Y.; Ueno, A. Transformation-induced plastic deformation in Ce-TZP/alumina nanocomposite generated during fatigue tests at room temperature. J. Eur. Ceram. Soc. 2014, 34, 4337–4345. [Google Scholar] [CrossRef]

- Palmero, P.; Fornabaio, M.; Montanaro, L.; Reveron, H.; Esnouf, C.; Chevalier, J. Towards long-lasting zirconia-based composites for dental implants: Part I: Innovative synthesis, microstructural characterization, and in vitro stability. Biomaterials 2015, 50, 38–46. [Google Scholar] [CrossRef] [PubMed]

- Reveron, H.; Fornabaio, M.; Palmero, P.; Fürderer, T.; Adolfsson, E.; Lughi, V.; Bonifacio, A.; Sergo, V.; Montanaro, L.; Chevalier, J. Towards long-lasting zirconia-based composites for dental implants: Transformation-induced plasticity and its consequence on ceramic reliability. Acta Biomater. 2017, 48, 423–432. [Google Scholar] [CrossRef] [PubMed]

- Hannink, R.H.; Swain, M.V. Metastability of the martensitic transformation in a 12 mol% ceria-zirconia alloy: I, deformation and fracture observations. J. Am. Ceram. Soc. 1989, 72, 90–98. [Google Scholar] [CrossRef]

- Vasylkiv, O.S.; Sakka, Y.; Skorokhod, V.V. Low-temperature processing and mechanical properties of zirconia and zirconia–alumina nanoceramics. J. Am. Ceram. Soc. 2003, 86, 299–304. [Google Scholar] [CrossRef]

- Basu, B. Toughening of yttria-stabilised tetragonal zirconia ceramics. Int. Mater. Rev. 2005, 50, 239–256. [Google Scholar] [CrossRef]

- Trunec, M.; Chlup, Z. Higher fracture toughness of tetragonal zirconia ceramics through nanocrystalline structure. Scr. Mater. 2009, 61, 56–59. [Google Scholar] [CrossRef]

- Cui, J.; Gong, Z.; Lv, M.; Lv, M.; Rao, P. Determination of fracture toughness of Y-TZP ceramics. Ceram. Int. 2017, 43, 16319–16322. [Google Scholar] [CrossRef]

- Matsui, K.; Nakamura, K.; Saito, M.; Kuwabara, A.; Yoshida, H.; Ikuhara, Y. Low-temperature degradation in yttria-stabilized tetragonal zirconia polycrystal: Effect of Y3+ distribution in grain interiors. Acta Mater. 2022, 227, 117659. [Google Scholar] [CrossRef]

- Kern, F.; Osswald, B. Properties of a pressureless sintered 2Y-TZP material combining high strength and toughness. Ceramics 2024, 7, 893–905. [Google Scholar] [CrossRef]

- Zhang, X.F.; Li, Y.C. On the comparison of the ballistic performance of 10% zirconia toughened alumina and 95% alumina ceramic target. Mater. Des. 2010, 31, 1945–1952. [Google Scholar] [CrossRef]

- Savio, S.G.; Madhu, V.; Gogia, A.K. Ballistic performance of alumina and zirconia-toughened alumina against 7.62 armour piercing projectile. Def. Sci. J. 2014, 64, 477–483. [Google Scholar] [CrossRef]

- Huang, C.Y.; Chen, Y.L. Design and impact resistant analysis of functionally graded Al2O3–ZrO2 ceramic composite. Mater. Des. 2016, 91, 294–305. [Google Scholar] [CrossRef]

- Huang, C.Y.; Chen, Y.L. Effect of varied alumina/zirconia content on ballistic performance of a functionally graded material. Int. J. Refract. Met. Hard Mater. 2017, 67, 129–140. [Google Scholar] [CrossRef]

- Koch, B.M.; Jannotti, P.; Mallick, D.; Schuster, B.; Sano, T.; Hogan, J.D. Influence of microstructure on the impact failure of alumina. Mater. Sci. Eng. A 2020, 770, 138549. [Google Scholar] [CrossRef]

- Wade-Zhu, Y.; Wade-Zhu, J.; Wu, H.; Binner, J.; Vaidhyanathan, B. The ballistic impact performance of nanocrystalline zirconia-toughened alumina (nZTA) and alumina ceramics. J. Eur. Ceram. Soc. 2021, 41, 1427–1437. [Google Scholar] [CrossRef]

- Andraskar, N.D.; Tiwari, G.; Goel, M.D. Impact response of ceramic structures—A review. Ceram. Int. 2022, 48, 27262–27279. [Google Scholar] [CrossRef]

- Umbharatwala, M.D.; Goel, M.D. Experimental, numerical, and analytical prediction of ballistic resistance of indigenously developed zirconia-toughened alumina, Kevlar®, and CFRP composite. Compos. Part B Eng. 2024, 282, 111582. [Google Scholar] [CrossRef]

- Imariouane, M.; Saâdaoui, M.; Denis, G.; Reveron, H.; Chevalier, J. Low-yttria doped zirconia: Bridging the gap between strong and tough ceramics. J. Eur. Ceram. Soc. 2023, 43, 4906–4915. [Google Scholar] [CrossRef]

- ASTM C373-88; Standard Test Method for Water Absorption, Bulk Density, Apparent Porosity, and Apparent Specific Gravity of Fired Whiteware Products. ASTM International: West Conshohocken, PA, USA, 1988.

- Garvie, R.C.; Nicholson, P.S. Phase analysis in zirconia systems. J. Am. Ceram. Soc. 1972, 55, 303–305. [Google Scholar] [CrossRef]

- Toraya, H.; Yoshimura, M.; Somiya, S. Calibration curve for quantitative analysis of the monoclinic-tetragonal ZrO2 system by X-ray diffraction. J. Am. Ceram. Soc. 1984, 67, 1197–2121. [Google Scholar] [CrossRef]

- Lin, J.D.; Duh, J.G. Fracture toughness and hardness of ceria-and yttria-doped tetragonal zirconia ceramics. Mater. Chem. Phys. 2003, 78, 253–261. [Google Scholar] [CrossRef]

- Ćorić, D.; Ćurković, L.; Majić Renjo, M. Statistical analysis of Vickers indentation fracture toughness of Y-TZP ceramics. Trans. FAMENA 2017, 41, 1–16. [Google Scholar] [CrossRef]

- Freitas, B.X.; Duarte, E.T.; Vasconcelos, J.E.A.; Magnago, R.O.; Strecker, K.; Santos, C. Mechanical properties of Ce-TZP/Al2O3 ceramic composites as a function of sintering parameters. Ceramica 2024, 69, 305–311. [Google Scholar]

- Touaiher, I.; Saâdaoui, M.; Chevalier, J.; Reveron, H. Effect of loading configuration on strength values in a highly transformable zirconia-based composite. Dent. Mater. 2016, 32, e211–e219. [Google Scholar] [CrossRef]

- Liens, A. On the Potential of Ti-Based Bulk Metallic Glasses and Ce-TZP Zirconia Composites for the Development of Innovative Dental Implants. Ph.D. Thesis, Institut National des Sciences Appliquées de Lyon, Lyon, France, 2019. [Google Scholar]

- Chevalier, J.; Gremillard, L.; Virkar, A.V.; Clarke, D.R. The tetragonal—monoclinic transformation in zirconia: Lessons learned and future trends. J. Am. Ceram. Soc. 2009, 92, 1901–1920. [Google Scholar] [CrossRef]

- Valot, C.; Ciosmak, D.; Mesnier, M.T.; Lallemant, M. Phase analysis by variable-incidence X-ray diffraction: Application to zirconium oxidation. Oxid. Met. 1997, 48, 329–345. [Google Scholar] [CrossRef]

- Choi, S.R.; Pereira, J.M.; Janosik, L.A.; Bhatt, R.T. Foreign object damage in flexure bars of two gas-turbine grade silicon nitrides. Mater. Sci. Eng. A 2004, 379, 411–419. [Google Scholar] [CrossRef]

- Berthier da Cunha, T.; Wu, J.P.; Peitl, O.; Fokin, V.M.; Zanotto, E.D.; Iannucci, L.; Boccaccini, A.R. Mechanical properties and impact resistance of a new transparent glass-ceramic. Adv. Eng. Mater. 2007, 9, 191–196. [Google Scholar] [CrossRef]

- Guo, Y.N.; Sun, Q.; Wu, L. Study of dynamic impact behaviors and ballistic properties of ceramic/UHMWPE composite armor. Appl. Mech. Mater. 2012, 121, 397–400. [Google Scholar] [CrossRef]

- Huang, C.Y.; Chen, Y.L. Effect of mechanical properties on the ballistic resistance capability of Al2O3-ZrO2 functionally graded materials. Ceram. Int. 2016, 42, 12946–12955. [Google Scholar] [CrossRef]

- Hu, D.; Zhang, Y.; Shen, Z.; Cai, Q. Investigation on the ballistic behavior of mosaic SiC/UHMWPE composite armor systems. Ceram. Int. 2017, 43, 10368–10376. [Google Scholar] [CrossRef]

- Fabris, D.C.N.; Polla, M.B.; Acordi, J.; Luza, A.L.; Bernardin, A.M.; De Noni, A., Jr.; Montedo, O.R.K. Effect of MgO·Al2O3·SiO2 glass-ceramic as a sintering aid on properties of alumina armors. Mater. Sci. Eng. A 2020, 781, 139237. [Google Scholar] [CrossRef]

- Dresch, A.B.; Venturini, J.; Arcaro, S.; Montedo, O.R.; Bergmann, C.P. Ballistic ceramics and analysis of their mechanical properties for armour applications: A review. Ceram. Int. 2021, 47, 8743–8761. [Google Scholar] [CrossRef]

- Touaiher, I. Comportement à la Rupture de Nouveaux Composites Triphasiques à Base de Zircone Ce-TZP Hautement Transformables: Influence des Méthodes D’essais. Ph.D. Thesis, Ecole Mohammadia d’Ingénieurs, Rabat, Morocco, 2018. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).