A Simulation Study on the Smoke Control Effect with Different Smoke Exhaust Patterns and Longitudinal Air Supply for Ultra-Wide Tunnels

Abstract

:1. Introduction

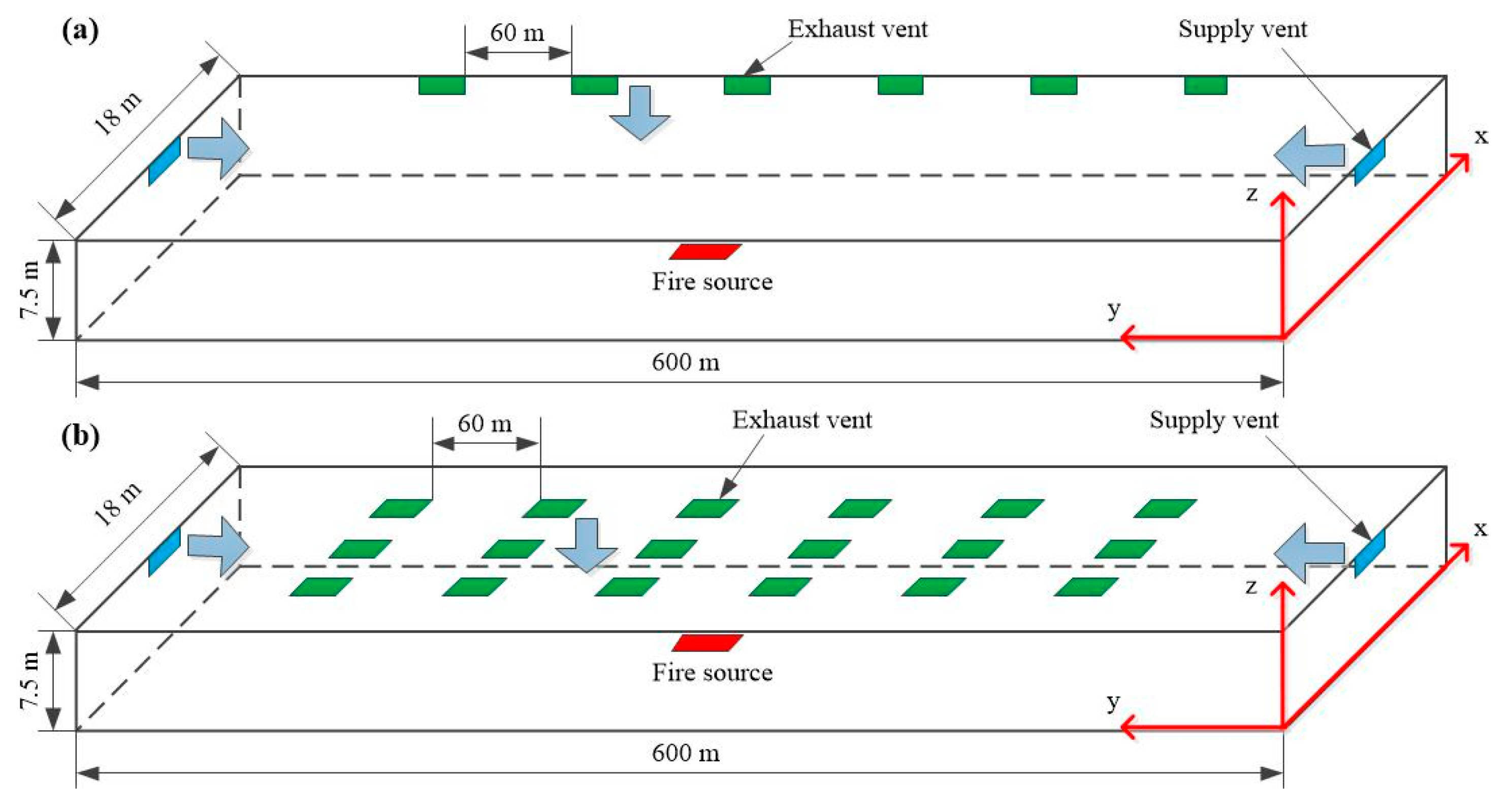

2. Numerical Simulation

2.1. Model Tunnel

- (1)

- Layer zoning device: 61 Layer zoning devices were set in the longitudinal centerline of the tunnel with an interval at 10 m to monitor the smoke layer height.

- (2)

- Thermocouples: To monitor the temperature variation at a safe height (2 m), a series of thermocouples were installed every 10 m along the longitudinal centerline of the tunnel, 2 m above the ground. In addition, near the fire source within 10 m, the thermocouples were arranged at a longitudinal interval of 1 m.

- (3)

- CO2: The mass flux of CO2 around each exhaust vent was monitored using the parameter “MASS FLUX Z”, SPEC-ID = “carbon dioxide”. Coordinate parameters were equal to those of the exhaust vents.

2.2. Mesh Size

3. Results and Discussion

3.1. Smoke Spread

3.2. Smoke Layer Height

3.3. Temperature at Safe Height

3.4. Smoke Exhaust Efficiency

4. Conclusions

- (1)

- As a result of the increase in the longitudinal air supply ratio, the smoke spread distance is shortened. The smoke spread distance for the top exhaust pattern is generally shorter than that for the sidewall exhaust pattern, except for the air supply ratio of 70%;

- (2)

- The height of the smoke layer is higher than the safe height of 2 m for the top exhaust pattern, but for the sidewall exhaust pattern, the height is lower than 2 m when the longitudinal air supply volume is less than 50% of the smoke exhaust volume.

- (3)

- The smoke exhaust pattern has a great impact on the temperature near the fire source, which reaches 250 °C for the top exhaust pattern and 120 °C for the sidewall exhaust pattern. In addition, the longitudinal air supply volume has no influence on the temperature, and its distribution is almost consistent.

- (4)

- The exhaust efficiency of the top exhaust pattern (~70%) is significantly higher than that of the sidewall exhaust pattern (~55%). The best air supply ratios are 30% for the top exhaust pattern and 50% for the sidewall exhaust pattern, respectively, taking the economic cost into account.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Taillefer, N.; Carlotti, P.; Larive, C.; Lemerle, C.; Avenel, R.; Pimienta, P. Ten years of increased hydrocarbon temperature curves in French tunnels. Fire Technol. 2013, 49, 531–549. [Google Scholar] [CrossRef]

- Vauquelin, O.; Mégret, O. Smoke extraction experiments in case of fire in a tunnel. Fire Saf. J. 2002, 37, 525–533. [Google Scholar] [CrossRef]

- Lee, S.R.; Ryou, H.S. A numerical study on smoke movement in longitudinal ventilation tunnel fires for different aspect ratio. Build. Environ. 2006, 41, 719–725. [Google Scholar] [CrossRef]

- Vauquelin, O.; Wu, Y. Influence of tunnel width on longitudinal smoke control. Fire Saf. J. 2006, 41, 420–426. [Google Scholar] [CrossRef]

- Nordmark, A. Fire and life safety for underground facilities: Present status of fire and life safety principles related to underground facilities: ITA working group 4, “subsurface planning”. Tunn. Undergr. Space Technol. 1998, 13, 217–269. [Google Scholar] [CrossRef]

- Ingason, H.; Li, Y.Z. Model scale tunnel fire tests with longitudinal ventilation. Fire Saf. J. 2010, 45, 371–384. [Google Scholar] [CrossRef]

- Chow, W.K.; Gao, Y.; Zhao, J.H.; Dang, J.F.; Chow, N.C.L. A study on tilted tunnel fire under natural ventilation. Fire Saf. J. 2016, 81, 44–57. [Google Scholar] [CrossRef]

- Yoon, S.-W.; Rie, D.H.; Kim, H.Y. Smoke control of a fire in a tunnel with vertical shaft. J. Loss Prev. Process Ind. 2009, 22, 954–957. [Google Scholar] [CrossRef]

- Yi, L.; Wei, R.; Peng, J.; Ni, T.; Xu, Z.; Wu, D. Experimental study on heat exhaust coefficient of transversal smoke extraction system in tunnel under fire. Tunn. Undergr. Space Technol. 2015, 49, 268–278. [Google Scholar] [CrossRef]

- Tanaka, F.; Majima, S.; Kato, M.; Kawabata, N. Performance validation of a hybrid ventilation strategy comprising longitudinal and point ventilation by a fire experiment using a model-scale tunnel. Fire Saf. J. 2015, 71, 287–298. [Google Scholar] [CrossRef]

- Gao, P.Z.; Liu, S.L.; Chow, W.K.; Fong, N.K. Large eddy simulations for studying tunnel smoke ventilation. Tunn. Undergr. Space Technol. 2004, 19, 577–586. [Google Scholar] [CrossRef]

- Li, Y.F.; Li, Y.F.; Feng, X.; Huang, Y.B. Influence of Arrangement of Jet Fans on Smoke Exhaust Effect in a Tunnel with Longitudinal Ventilation System. Procedia Eng. 2018, 211, 421–426. [Google Scholar] [CrossRef]

- Wang, Q.; Tang, F.; Li, L.; Zhang, X.; Fan, C. Large Eddy Simulation on the Effect of Smoke Exhaust Openings Arrangement on the Smoke Spread in Tunnel Fires. Procedia Eng. 2016, 135, 309–315. [Google Scholar] [CrossRef] [Green Version]

- Tao, L.; Zeng, Y. Effect of Different Smoke Vent Layouts on Smoke and Temperature Distribution in Single-Side Multi-Point Exhaust Tunnel Fires: A Case Study. Fire 2022, 5, 28. [Google Scholar] [CrossRef]

- Ribot, B. Modélisation Numérique d’un Système de Ventilation d’un Tunnel Routier par Une Trappe de Désenfumage Dans le Cas d’un Incendie. Ph.D. Thesis, Université Claude Bernar Lyon 1, Villeurbanne, France, 1999. [Google Scholar]

- Oucherfi, M.; Gay, B.; Mos, A.; Carlotti, P. Definition and Optimization of the Efficiency of Smoke Extraction in a Road Tunnel; ISAVVT 13, BHRG: Dundee, Scotland, 2009. [Google Scholar]

- Lovas, L.; Carlotti, P.; Desanghere, S.; Mos, A. Optimizing the Repartition of Extraction Vents in Transverse Ventilation; ISAVT 14, BHRG: Dundee, Scotland, 2011. [Google Scholar]

- Chaabat, F.; Salizzoni, P.; Creyssels, M.; Mos, A.; Wingrave, J.; Correia, H.; Marro, M. Smoke control in tunnel with a transverse ventilation system: An experimental study. Build. Environ. 2019, 167, 106480. [Google Scholar] [CrossRef]

- Xu, Q.Q.; Yi, L.; Xu, Z.S.; Wu, D.X. Preliminary Study on Exhaust Efficiency of Smoke Management System in Tunnel Fires. Procedia Eng. 2013, 52, 514–519. [Google Scholar] [CrossRef] [Green Version]

- Zhu, H.; Shen, Y.; Yan, Z.; Guo, Q.; Guo, Q. A numerical study on the feasibility and efficiency of point smoke extraction strategies in large cross-section shield tunnel fires using CFD modeling. J. Loss Prev. Process Ind. 2016, 44, 158–170. [Google Scholar] [CrossRef]

- Liu, S.; Jiang, Y.; Chen, J.; Li, K. Full-scale Experimental Research on the effect of Smoke Exhaust Strategies on Efficiency of Point Extraction System in an Underwater Tunnel. Procedia Eng. 2016, 166, 362–372. [Google Scholar] [CrossRef]

- Buchanan, A.H. Implementation of performance-based fire codes. Fire Saf. J. 1999, 32, 377–383. [Google Scholar] [CrossRef]

- Chen, J.J.; Fang, Z.; Yuan, J.P. Numerical Simulation about Smoke Vent Arrangement Influence on Smoke Control in Double-decked Tunnel. Procedia Eng. 2013, 52, 48–55. [Google Scholar] [CrossRef] [Green Version]

- Blanchard, E.; Boulet, P.; Desanghere, S.; Cesmat, E.; Meyrand, R.; Garo, J.P.; Vantelon, J.P. Experimental and numerical study of fire in a midscale test tunnel. Fire Saf. J. 2012, 47, 18–31. [Google Scholar] [CrossRef]

- Lin, C.J.; Chuah, Y.K. A study on long tunnel smoke extraction strategies by numerical simulation. Tunn. Undergr. Space Technol. 2008, 23, 522–530. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, Z.; Tao, H. A numerical study on critical velocity and back-layering length with trains’ blockage in longitudinally ventilated tunnel fires. Tunn. Undergr. Space Technol. 2021, 116, 104093. [Google Scholar] [CrossRef]

- Hu, L.H.; Fong, N.K.; Yang, L.Z.; Chow, W.K.; Li, Y.Z.; Huo, R. Modeling fire-induced smoke spread and carbon monoxide transportation in a long channel: Fire Dynamics Simulator comparisons with measured data. J. Hazard. Mater. 2007, 140, 293–298. [Google Scholar] [CrossRef]

- Wang, F.; Wang, M. A computational study on effects of fire location on smoke movement in a road tunnel. Tunn. Undergr. Space Technol. 2017, 51, 405–413. [Google Scholar] [CrossRef]

- Baum, H.R.; Mccaffrey, B.J. Fire Induced Flow Field—Theory and Experiment. Fire Saf. Sci. Proceeding Second Int. Symp. 1989, 2, 129–148. [Google Scholar] [CrossRef] [Green Version]

- Heskestad, G. Fire plume air entrainment according to two competing assumptions. Symp. Int. Combust. 1988, 21, 111–120. [Google Scholar] [CrossRef]

- Drysdale, D. An Introduction to Fire Dynamics, 3rd ed.; John Wiley: New York, NY, USA, 2011; pp. 349–386. [Google Scholar]

- Ji, J.; Tan, T.; Gao, Z.; Wan, H.; Zhu, J.; Ding, L. Numerical Investigation on the Influence of Length–Width Ratio of Fire Source on the Smoke Movement and Temperature Distribution in Tunnel Fires. Fire Technol. 2019, 55, 963–979. [Google Scholar] [CrossRef]

- Kim, E.; Woycheese, J.P.; Dembsey, N.A. Fire Dynamics Simulator (Version 4.0) Simulation for Tunnel Fire Scenarios with Forced, Transient, Longitudinal Ventilation Flows. Fire Technol. 2008, 44, 137–166. [Google Scholar] [CrossRef]

- Ciga Da, A.; Ruggieri, D.; Zappa, E. Road and railway tunnel fire hazard: A new measurement method for risk assessment and improvement of transit safety. In Proceedings of the Measurement Systems for Homeland Security, Contraband Detection and Personal Safety Workshop, Orlando, FL, USA, 29–30 March 2005. [Google Scholar]

| Fire Power | 0.1 D* | Position | Mesh Size | Total Number of Mesh |

|---|---|---|---|---|

| 20 MW | 0.31 m | 0–275 m | 0.5 × 0.5 × 0.5 m | 1,227,400 |

| 275–325 m | 0.25 × 0.25 × 0.25 m | |||

| 325–600 m | 0.5 × 0.5 × 0.5 m |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Huang, F.; Ma, C.; Tang, K. A Simulation Study on the Smoke Control Effect with Different Smoke Exhaust Patterns and Longitudinal Air Supply for Ultra-Wide Tunnels. Fire 2022, 5, 72. https://doi.org/10.3390/fire5030072

Li Y, Huang F, Ma C, Tang K. A Simulation Study on the Smoke Control Effect with Different Smoke Exhaust Patterns and Longitudinal Air Supply for Ultra-Wide Tunnels. Fire. 2022; 5(3):72. https://doi.org/10.3390/fire5030072

Chicago/Turabian StyleLi, Ying, Fang Huang, Chuyuan Ma, and Kaixuan Tang. 2022. "A Simulation Study on the Smoke Control Effect with Different Smoke Exhaust Patterns and Longitudinal Air Supply for Ultra-Wide Tunnels" Fire 5, no. 3: 72. https://doi.org/10.3390/fire5030072

APA StyleLi, Y., Huang, F., Ma, C., & Tang, K. (2022). A Simulation Study on the Smoke Control Effect with Different Smoke Exhaust Patterns and Longitudinal Air Supply for Ultra-Wide Tunnels. Fire, 5(3), 72. https://doi.org/10.3390/fire5030072