1. Introduction

Wildfires pose a threat to communities located in or near wildland, Wildland Urban Interface, or Intermix (WUI) areas. Home and business losses during these fires have demonstrated the need for more effective building codes and standard test methods to evaluate products and, ultimately, reduce building ignitions during wildfires. Since building codes address new construction, policies that facilitate retrofit of existing buildings would also be needed.

Codes and standards are comprehensive sets of requirements and design procedures created by a consensus standards development organization, or by state or national authorities [

1]. The Australian Bushfire Code (ABC) and the California Fire Hazard Severity Zones are examples of a national and state-wide government developing and enforcing a WUI code. Because California has had a building code specifically related to wildfire longer than other states, and it provided a path to compliance for nominally combustible deck board products, details of this will be more fully discussed in this manuscript. In 2008, the Department of Forestry and Fire Protection (CAL FIRE) introduced new fire hazard severity maps with three fire hazard severity zones across the State of California, namely, medium, high, and very high. The state mandates specific material and design requirements for structures in all hazard zones in State Responsibility Areas (SRA). These requirements are listed in California Building Code, Chapter 7A [

2]. Revised hazard zone maps will be released in 2023.

Attached decks can be a vulnerable component of a building if they ignite and the resulting fire spreads to and into the occupied space.

Figure 1 shows the cascade of damage from burning decks to the main buildings during the Glass Fire. Spread into the building could occur if the building cladding was combustible (such as a wood or plastic siding product), or if the radiant heat or flame-impingement exposure was sufficient to break glass in a window or door. If the ignition occurred at the deck-to-wall intersection, spread into the building would be more likely. If ignition occurred at a location away from the building, flame spread to the building would have to occur, or sufficient fire growth would have to develop to ignite combustible cladding or break glass.

Post-wildfire investigations and lab studies have shown that decks can initially be ignited on either top or bottom surfaces [

3,

4,

5,

6]. Quarles et al. [

7] reported that flames from burning trees impinging on the underside of attached decks resulted in deck ignitions and subsequent loss of homes during the Waldo Canyon Fire in Colorado Springs, Colorado. Manzello and Suzuki [

8] reported ignition of solid wood decks subjected to ember exposures. The deck-to-wall intersection in a re-entrant (interior corner) was reported to be a vulnerable location, not specifically the gaps between deck boards. Maranghides et al. [

6] identified three locations of deck ignitions: (1) near the footers, (2) on the top surface, and (3) on the ground where combustible material had accumulated and ignited. Similar observations were made during the 2018 Camp Fire [

9]. IBHS’s post Glass Fire investigations 2022,

Figure 2, also confirmed similar deck vulnerabilities for decks.

The most recent version of Chapter 7A in the California Building Code requires the walking surface of decks to be constructed with materials that comply with one of seven options. Combustible materials can comply with Chapter 7A provisions using the sixth option, which states:

This standard evaluates the performance of decking material to an under-deck exposure. The acceptance criteria specifies that the peak heat-release rate does not exceed 269 kw/m2. This provision allows many combustible deck board products, including non-fire-retardant-treated redwood and many plastic composite decking products, to comply with the provisions of Chapter 7A. The exception regarding Class B flame spread index included in the code language allows these compliant decking products to be used adjacent to any siding product that otherwise complies with the provisions of Chapter 7A, if the deck board has a Class B or Class A flame spread index. In other words, the state of California only requires testing against an under-deck flame impingement, the provisions of which are provided in SFM 12-7A-4A and ASTM E2632. One could argue that this test method does not realistically evaluate the performance of deck assemblies, since (1) the size of the testing specimen is too small (2 ft × 2.4 ft or 0.70 m × 0.73 m) and, given the current use of an under-deck flaming exposure, could result in premature self-extinguishment of the deck assembly, (2) the test is performed at no-wind condition, and (3) the substructure (i.e., structural support system) is not an adjustable variable, although it has been found to contribute to the fire intensity of the decks in a consistent manner. Compliance with the provisions of this test method for nominally combustible decking products are applicable in areas where Chapter 7A has been adopted.

Given the fact that post-fire investigations identified an above-deck ember exposure as an ignition mechanism, the reliability of a test method that only evaluates products against an under-deck exposure should be assessed. To evaluate overall vulnerability of decks, a series of experiments that included top-of-deck ember exposures and under-deck flame-impingement exposures were conducted. The objectives for these experiments were to evaluate:

The ability of an ember exposure to directly ignite combustible decking without any under-deck flame exposure;

The effectiveness of the standard under-deck flame-impingement exposure test to predict the performance of decking to an ember exposure;

The effects of the three mentioned simplifications in under-deck flame-impingement test in SFM 12-7A-4A and ASTM E2632 on the fire performance of decks;

Fire propagation and growth on ignited decks in various conditions and the thermal attack on the building cladding.

In this paper, we investigated the above-mentioned issues. First, the validity of an under-deck exposure to evaluate decking material exposed to above-deck embers was investigated. Then, the three simplifications in the current standard test method, SFM 12-7A-4A and ASTM E2632, were challenged. Lastly, recommendations for changing the standard test method and end-users are proposed.

2. Experimental Procedure

All the experiments were conducted in the test chamber at the Insurance Institute for Business & Home Safety (IBHS) Research Center located in Richburg, SC, USA. The ember exposure tests were conducted in 2015–2016 and based on initial observations, the under-deck experiments were planned in 2018–2019 and performed in 2020–2021.

2.1. Test Facility

The IBHS Research Center test chamber can hold a full-scale, one- or two-story residential or small commercial building. The test chamber consists of a wind tunnel, powered by a 105-fan array (

Figure 3a). Each fan is 5.5 ft (1.68 m) in diameter and can create a time history of wind speeds from 12 to 120 mph [

10,

11]. The deck experiments were conducted at the center circle of the chamber against a building with dimensions of 145 ft × 145 ft (44.2 m × 44.2 m).

The test chamber is equipped with custom-made ember generators. A diagram of the custom-made generators used to burn fuel and create embers is shown in

Figure 4. The fuel was delivered into the generator by a pneumatic feed line (A). The fuel drops on top of a metal grate immediately above a gas burner (not shown). A vertically oriented fan (B) under the burner pushes embers up and out of the exhaust duct (C). Eight generators were placed at equally spaced intervals in a trench in front of the fan array.

Figure 5 shows an overview of the feed system, ember generators, and test building. Prior to testing, fuel was placed in hoppers (A). Five augers (not shown) dropped fuel into the pneumatic feed lines. The feed rate was controlled by powering the augers on and off at defined intervals. The desired feed rate was obtained when individual augers were turned on for 3 to 5 s, and then off for 10 to 20 s. The on/off times for each individual auger were determined by visual inspection of ember output and evidence of elevated temperatures inside the ember generators (red color of the metal burn chambers). The goal of the intermittent fuel-delivery method was to ensure a consistent output of embers by all generators without damage to the generators from excessive heat.

The augers delivered fuel to the pneumatic feed lines (B). These feed lines delivered the fuel to the ember generators (C). As described previously, the ember generators burned the fuel and a fan pushed embers through the vertical exhaust duct. The fan array (D) created the desired wind flow in the test chamber. The test building (E) was then subjected to an ember exposure.

Figure 6b shows the ember-generating system operating.

2.2. Above-Deck Ember Exposure Tests

The main goal for the above-deck ember exposure experiment was to determine whether embers could ignite combustible wood and plastic composite decking without the contribution of other materials. To achieve this goal the decks were monitored using several cameras as well as observations made by individuals in the test chamber. Two replicates for each test configuration were performed. The decking assembly was attached to the test building and a wall positioned at 90-degrees to the building to recreate a re-entrant corner. The turntable was then rotated to determine the location of maximum ember accumulation. This location was visually observed and documented. Based on the results of these tests, the orientation and location of the test deck (within a larger deck structure) was determined. All ignition potential tests were conducted using this configuration (

Figure 6a).

2.3. Deck Specifications and Test Details

Based on results from the preliminary tests, experiments to evaluate the ignition potential of decking to an ember exposure were conducted with the 5 ft × 5 ft (1.5 × 1.5 m) test deck inserted into a larger deck that was 20 ft wide by 12 ft (6 × 3.5 m) deep. The larger deck surface was covered with a panelized, non-paper-faced gypsum product. A framed, movable wall was incorporated into the building design to create a re-entrant corner (

Figure 6a). To enhance visual abilities, the lights were turned off during the experiments (

Figure 6b).

Decking products were purchased from various commercial vendors. Prior to testing, the deck assembly was conditioned to a moisture content between 6 and 10 per cent (oven-dry basis) in a dehumidification lumber dry kiln. Decks consisted of nominal 6 in. wide (150 mm) deck boards supported by 2 × 6 joists spaced 16 in. (405 mm) on center. Joists were in the Spruce–Pine–Fir species group and obtained from a local building supply store. The 5 ft × 5 ft (1.5 × 1.5 m) test material was constructed with eight different walking surfaces (deck boards) attached to southern yellow pine joists. The detail of the deck material is provided in

Table 1.

The ember generators were on for 30 min and the wind speed was 17 mph (7.5 m/s) with a 3 s gust to 27 mph (12 m/s). After a 30 min ember exposure at gusty wind, (2) the fans were brought down to idle RPM to generate constant wind speed of 10 mph for 5 min. The idle wind speed allowed more embers to accumulate on the surface and potentially allowed for smoldering combustion to transition to flaming combustion. After this 5 min window, (3) the fans were brought up the original RPM time history to create the gusty wind for additional 30 min. (4) Then the ember generators then were turned off and the deck was exposed to a 15 min gusty wind to monitor for any smoldering and transitioning to flaming combustion, or to document any changes in flame behavior if the deck had already ignited. If flaming combustion occurred, the time was noted. If flaming occurred during the first 30 min interval, steps 2 through 4 were eliminated, but the 30 min wind trace was continued while the burning deck was monitored.

2.4. Under-Deck Flame-Impingement Tests

The main objective in this test series was to assess if the simplifications in SFM 12-7A-4A and ASTM E2632 are realistic. Hence, the assumptions mentioned in the introduction section were challenged separately.

2.5. Increasing Deck Size

As previously discussed, decks attached to homes or businesses would be substantially larger than the decks used in SFM-7A-4A. Testing a smaller deck is more efficient since it reduces the (cost) burden to the testing facility and manufacturer. However, the smaller size should not diminish the ability of the test to predict performance of a larger deck. Hence, the dimensions of the test deck were increased from 2 ft × 2.4 ft (0.70 m × 0.73 m) to 6.6 ft × 6.6 ft (2 m × 2 m). These dimensions were chosen to allow for more joist bays in the test deck and to allow the test to be conducted in this outflow area of the wind tunnel specified in ASTM E108. This standard test can be conducted at many commercial fire labs.

2.6. Adding Wind to the SFM-7A-4A Test Protocol

Most wildfires occur during red flag warning days [

12] which are always accompanied by elevated wind speeds (20 mph (9 m/s) or higher and/or gusts to 35 mph (15.5 m/s) or higher) and low relative humidity (minimum relative humidity 15% or less). Therefore, understanding the potential role of wind on the performance of decking material is a critical part of the assessment. In these tests, the samples were exposed to a gusty wind with mean of 19 mph (8.5 m/s) and 3 s gusts up to 27 mph (12 m/s).

2.7. Considering the Contribution of the Supporting Structure

Two different deck substructures were examined, namely, wood and metal joints, to evaluate their impact on deck board performance along with overall deck assembly performance.

2.8. Deck Specifications and Test Details

Similar to the specifications in the current test method, all experiments were planned to expose the samples to an 80 kW under-deck flame-impingement exposure for three minutes. However, it was observed that this fire exposure was too long, as will be discussed later. Hence, for some tests, the exposure time was reduced to two minutes. In these experiments five different deck board products (wood, two types of plastic composites, and two types of metal) were installed over two types of a structural support system, namely, wood and metal. The wooden joists (nominal 2 × 10) and posts (nominal 4 × 4) were Southern Yellow Pine. The metal joists were galvanized steel.

To replicate the moisture content of the decks similar to decks during red-flag warning events, the decks were placed in a kiln for about two days to reach the moisture content of 5–9%.

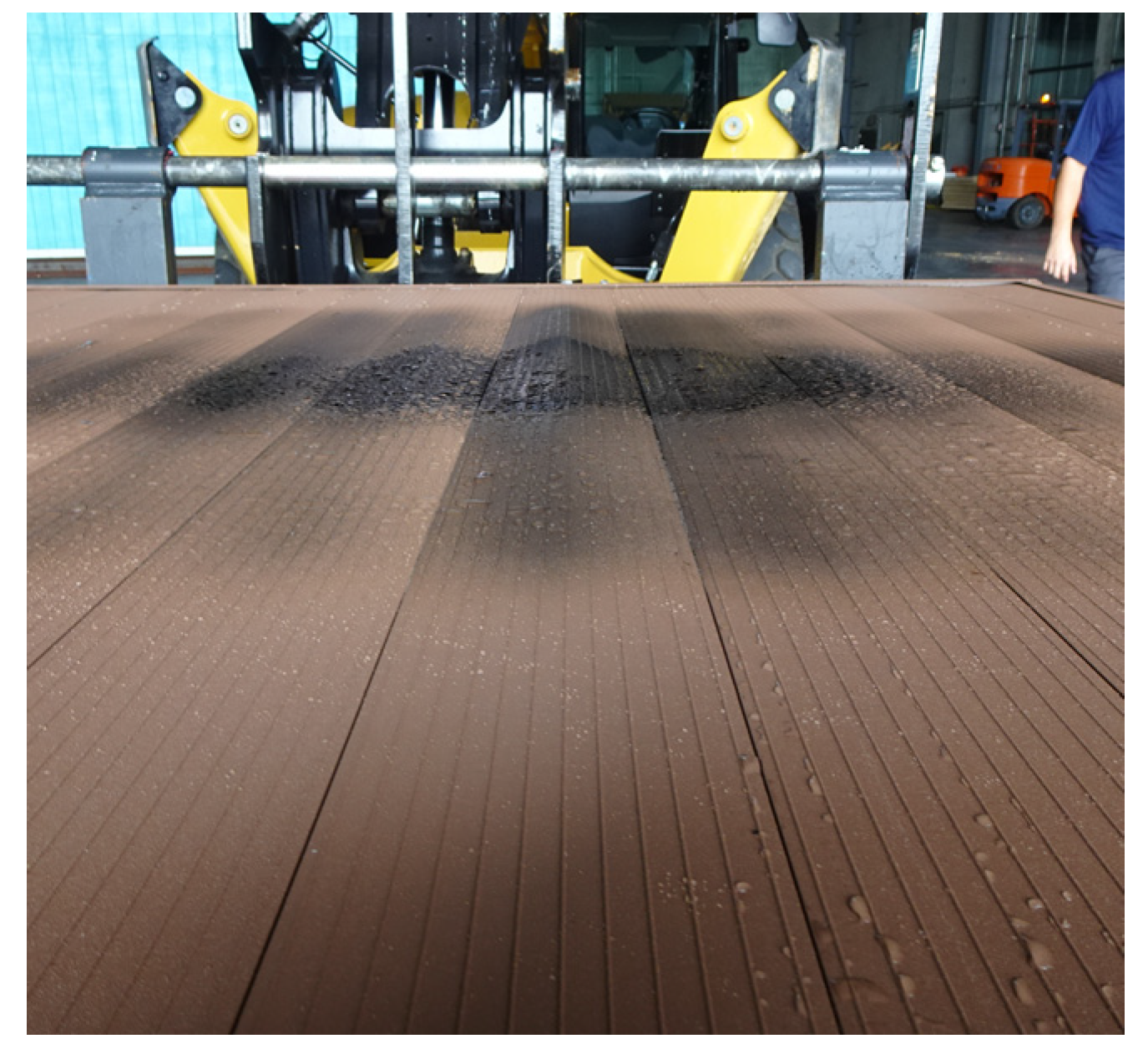

Figure 7a shows the decks in the kiln room to drive the moisture out, and

Figure 7b–d show the decks prior to ignition.

3. Results and Discussion

3.1. Above-Deck Ember Exposure Tests

Visual evidence of smoldering and flaming combustion were the principal indicators used to evaluate deck board performance.

Ember accumulation patterns and stagnation zones are shown in

Figure 8a. The circulation patterns on the deck resulted in embers dropping into gaps between deck boards. At joist locations, the embers accumulated in the gaps between deck boards on top of the joist (

Figure 8b).

Flaming and smoldering ignitions consistently initiated in the gaps where deck boards crossed joists, or at the edge of the test decks where there was an underlying horizontal surface where embers could accumulate (

Figure 9). Accumulation at these locations occurred regardless of deck board type. Small piles of embers also accumulated at some locations on the deck board surfaces. This finding has been recently tested in a small-scale controlled environment by Richter et al. [

13] and it was confirmed that the re-radiation in crevices, between deck boards and the joist–deck board intersection creates a vulnerability for decks. Richter et al. [

13] concluded that crevice geometry significantly increases the likelihood for ignition, due to a higher heat flux from a smoldering pile than a flat plate under the same conditions. Manzello and Suzuki [

8] reported the deck-to-wall intersection in a re-entrant (interior corner) assembly as a vulnerable location, not specifically the gaps between deck boards.

Flame heights in the medium-density softwood decking were low, never more than a few inches (approximately 60 mm) high, as shown in

Figure 9a. Flaming continued until the distance between the deck boards and joists increased to the point where between-member radiant heat transfer decreased (

Figure 9b). The effects of wind in keeping the fire growing were predominant in these experiments.

Ignition results and density data for the decking products are summarized in

Table 1. With one exception, the plastic composite decking products initially exhibited smoldering combustion, but did not transition to flaming. During Replication 2 for the PE-1 decking product, sustained flaming occurred after an approximate 48 min ember exposure. The transitory flaming observed in the high-density, solid wood decking product (H) began approximately 47 min into the test. The medium-density, solid wood decking product (S) developed sustained flaming after an approximate 12 min ember exposure. The approximate 12 min time-to-ignition for the medium-density decking product was consistent for both replications.

The results reported in

Table 1 are in general agreement with Nagaoka et al. [

14] findings that the time-to-ignition for wood material increased with increasing density.

The PE-1 material had the lowest density of the polyethylene-based decking products included in these tests and did not comply with the California Building Code (Chapter 7A) performance requirements for decking. In addition to a slightly lower density, PE-1 may not have had the same amount of fire-retardant chemicals as the other complying products, including the PE-3 product, which had a density only slightly higher than PE-1. The chlorine content in the lower-density PVC product had a positive effect on the performance of that decking product. Similarly, the fire-retardant chemical in the FRT solid wood product improved its resistance to an ember exposure, as did the higher density of the non-FRT hardwood.

3.2. Contribution of Joists

Embers primarily accumulated either on the top of the joists in the gap between deck boards or at the gap between the deck and the wall. These areas are also prone to debris accumulation over time (

Figure 10). This can create a fuel ladder effect when exposed to embers.

These experiments demonstrated that when enough embers accumulate and generate a certain thermal energy, the deck boards and/or joists ignited. For decks where joists were installed perpendicular to the building, once ignition occurred the fire spread in a smoldering phase along the joist toward and away from the building under an average wind speed of 18 mph. At the deck board gaps, the smoldering combustion transitioned to flaming (

Figure 11a) due to the airflow between the deck boards. This allowed fire to continue to propagate all the way to the building. Similar burn pattern was seen during post-event investigations in Glass Fire (

Figure 11b).

Blanchi and Leonard [

15] conducted a post-fire study of the 2003 fires in the Australian Capital Territory (ACT) and reported that timber (wood) decks were vulnerable to multiple ignitions from ember attack. They also stated that, if left unattended, these small ignitions can grow to a point where the fire threatens components of the building envelope, including exterior walls, windows, and doors. The 2003 ACT post-fire findings generally agree with results of the experiments reported here. The flame heights were low when decks ignited, and flame height did not grow during the time the experiments were monitored.

In addition to the insights about vulnerability of different types of deck boards, these tests provided valuable information regarding the vulnerability of deck assemblies and how the supporting system can influence the fire dynamics. These experiments also raised the awareness of the limitation of the current standard test method to evaluate decks per the requirements of Chapter 7A (California Building Code).

3.3. Under-Deck Flame-Impingement Tests

During the above-deck ember tests, it was observed that embers that fell between the deck board gaps can ignite the debris (fine fuels) under the deck that can, subsequently, expose the deck to a flame-impingement exposure, as can be seen in

Figure 12. The ignition of the fine fuels from these embers provides additional supporting evidence that storage of combustible materials under the deck should be avoided.

As previously mentioned, deck walking surfaces can comply with the California Building Code Chapter 7A requirements by passing an under-deck flame-impingement test which has three major simplifying assumptions. In this section, the results of testing these assumptions are presented.

3.4. Current Test Method

Three replicas (Redwood deck boards and Southern Yellow Pine) were tested following the requirements of SFM 12-7A-4A.

Figure 13a shows a sample deck, tested under the current test method procedures, 15 min after the start of the test (12 min after the under-deck burner was extinguished). As shown, there is a thin char layer (

Figure 13b) on the boards. A visual observation confirmed that the Peak Heat Release Rate was below the maximum allowable 269 kW/m

2. The lower thermal conductivity of the char layer acts as an insulator that protects the inner portion of the deck board from thermal-related damage. In addition, the thin charred layer facilitates self-extinguishment of the flames on the surface as it limits the available fuel for the flame to move in any direction, which is one of the acceptance criteria in SFM 12-7A-4. In other words, this thin charred layer causes only a small amount of the material participates in the combustion process.

3.5. The Performance of a Large Deck Exposed to Wind

As previously discussed, decks attached to buildings would be substantially larger than the decks used in SFM-7A-4A. Increasing the deck size showed that the thermal attack from identical under-deck flame is distributed over a larger surface than would occur with a smaller deck.

Figure 14a,b show a comparison of the deck temperatures 90 s after burner ignition for the small and large decks, respectively. This distributed heat experienced by the larger deck resulted in a slower burning process and reduced the thickness of the char layer. Hence, eventually a large amount of the available fuel participated in the combustion and caused a more intense exposure from the burning deck to the siding on the building, as shown in

Figure 14c. Since this test was under no-wind condition, the smoke accumulated above the deck and limits the visibility of the intense flames behind it.

As mentioned before, most wildfires occur during red flag warning days [

12] which are always accompanied by elevated wind speeds (20 mph or higher and/or gusts to 35 mph or higher) and low relative humidity (minimum relative humidity 15% or less). Therefore, understanding the potential role of wind on the performance of decking material is a critical part of the assessment.

Figure 15 depicts a time-lapse for a large redwood deck exposed to a gusty wind from two different angles; the first row is a corner view, and the second row is an under-deck view.

Columns a and b in

Figure 15 show the deck 5 s after igniting the burner and just before turning off the burner at 3 min, respectively. Column c shows the deck almost 7 min after ignition of the burner. During the test, the flame stayed underneath the deck boards for most of the time. The fire started consuming the edges of the combustible boards, widening the spacing between the boards, and, eventually, creating enough space between the boards to allow the flame to rise above the deck. This transition is shown in Column d. Column e shows the collapse of the deck after almost 10 min. Note that in

Figure 15e the change in the angle of the last photograph is because the below-deck camera was damaged by the intensity of the fire and an image from a different camera was used. Unlike the case for smaller deck, self-extinguishment did not happen here. To further explore the effects of wind on fire, see [

16].

After exposing a 6.6 ft × 6.6 ft deck to an 80 kW under-deck flame for 3 min (as indicated in

Figure 15) in the presence of wind, the entire assembly (joists, posts, redwood deck boards, and thermocouples on the deck) burned in less than 15 min. This intense exposure raised the temperature in the area underneath the deck beyond the tolerance of the high-temp thermocouples within minutes of starting the test. Consequently, without losing the generality, the exposure duration was reduced to 2 min in this research.

3.6. Contribution of Combustible Substructure

Another key observation in the under-deck flame exposure tests was the contribution of combustible joists in the fire dynamic. The contribution of a deck’s substructure to the initiation, intensity, and growth of fire has been observed in both post-event investigations [

1,

5] and lab experiments [

4].

Examining the fire dynamics under both the smaller and larger decks, with and without the presence of wind, the joists were found to be a major contributor to the fire dynamics of the burning deck. Joists are typically perpendicular to the building, which creates several bays at the bottom side of the deck boards and blowing wind can easily channel through these bays. Combustible joists, if ignited, can carry the fire toward the building in the presence of wind and expose the siding of the building to direct flame contact. In addition, the vortices created around the building can carry the flame in random directions and expose the entire field of the deck to the under-deck flame from burning joists. In other words, a 2 or 3 min exposure from the burner transforms to a much longer exposure to the decking material caused by the burning joists. If a joist was not engulfed in fire, the boards above it did not burn.

Figure 16 shows this phenomenon for redwood boards installed over a substructure made from Southern Yellow Pine.

Figure 16d1 to 16d4 shows the fire growth in one test in about 15 min. In this test, the gradual growth of fire on the joist caused the entire bay to be involved in the fire. A noncombustible joist in this case would limit, or even self-extinguish, the fire growth.

3.7. Evaluating Some Commercial Products under Realistic Conditions

Both the above-deck ember exposure and under-deck flame-impingement experiments show the importance of evaluating the entire deck assembly rather than just the walking surface. As previously mentioned, decks can comply with the requirements of Chapter 7A if they pass the requirements of an under-deck flame-impingement test.

Table 2 summarizes the different combinations that were tested along with information about their compliance status, time-lapse (in minutes) of the tests, and the temperature of the back wall. The back wall temperature was measured by seven high-temperature K-type thermocouples. Three of them were installed above the deck and four of them were at the under-deck area. The graphs in

Figure 17,

Figure 18,

Figure 19,

Figure 20,

Figure 21 and

Figure 22 show the temperature on the wall at the center bay, one foot below the joists. Since the walking surface is now being tested in the test method, the plots are grouped together. In each plot, the fire intensity at different times and the associating temperature on the wall are depicted.

The ignition temperature of wood depends on some samples’ thermophysical properties such as: moisture content, geometry, size, material, and some external parameters such as the test apparatus and piloted versus autoignition conditions. Since the 19th century, scientists have been reporting different ignition temperature for different types of wood under different conditions. Their results show a wide span of ignition temperatures of 210–497 C for piloted ignition and 200–510 C for autoignition. [

17]. From these observations, it can be concluded that “if a wood specimen is ignited under external heating barely sufficient to ignite it, it will ignite at approximately 250 C regardless of the type of heating arrangement [

17]”.

As discussed in

Figure 15, the redwood deck board over SYP structure burned intensely and caused elevated temperatures on the wall, above 800 C for about 400 s. In fact, the temperature is high enough to ignite most of cellulosic materials. When a steel supporting system was used, the elevated temperature on the wall is only associated with the burner and after its removal the temperature rapidly drops. Similar observations were made for composites A and B, but the fire growth happened at a slower rate. The plastic composite burned for a longer time compared to redwood.

Lastly, we tested two different metal walking surfaces installed over SYP supporting system. The time-lapse is shown in

Figure 20. The first two rows are associated with a metal board with gap in between the boards, similar to the traditional boards. The second two rows are associate with a metal board with no gap in between (the installation instructions for this product specified that there be no spacing between the boards). The graph below shows the variation of wall temperature as well as the fire behavior. Note that the last under-deck footage for the gapped deck is at t = 15 min. Beyond this point, the camera was overheated and removed.

In

Figure 20, the blue curve is associated with the no-gap metal boards. As can be seen, the temperature rapidly drops after turning off the burner. This is probably because of the limited oxygen for the fire.

Figure 21 is associated to the no-gap walking surface installed over SYP supporting structure after the test. As can be seen, the walking surface deformed because of exposure to the heat from the burner flames. Since the airflow between the deck boards is limited, the fire barely got into the flaming phase and, for the most part, the joist was being consumed by smoldering combustion.

The metal walking surface and metal joist configuration is depicted in

Figure 22. Since none of the components in these tests where combustible, we only present the wall temperature here, representing a base line condition

The behavior of the wall temperature can be taken as an indicator of the deck assembly’s response to a thermal attack. Considering at the temperature behavior after shutting of the burner in these graphs, two patterns are recognizable: (1) the wall temperature maintains the elevated temperature and (2) the wall temperature exhibited a decreasing trend. The extreme case can be seen in

Figure 17 where a sudden drop happened after turning off the burner. As can be seen in

Figure 17,

Figure 18,

Figure 19,

Figure 20,

Figure 21 and

Figure 22, the contribution of joists to the fire performance of the deck assembly overpowered the effect of the walking surface. In other words, regardless of the walking-surface compliance status, the wall temperature can exhibit a decreasing or increasing trend after shutting off the gas burner.

4. Summary and Conclusions

Post-wildfire investigations and lab studies have identified combustible decks as a vulnerable component of a building located in wildfire-prone areas. Once ignited, decks can expose a building’s cladding (siding), wall components such as windows and doors, and the under-eave area to flames and radiant heat. Decks are typically exposed to under-deck flame impingement and/or an above-deck ember exposure. The former one can be effectively mitigated by managing the fuel in the under-deck area. The latter one, however, is almost certain.

The current WUI building code in California allows combustible materials such as certain types of wood and plastic composite deck boards to comply, if they pass an under-deck flame-impingement test. Hence, in this research the authors addressed the needs to evaluate the reliability of the current test method to meaningfully assess the vulnerability of different products.

Two series of tests were performed to understand the vulnerability of decks to above-deck ember exposure and under-deck flame impingement, respectively. The results of the above-deck ember exposure showed that embers primarily accumulate either on the top of the joists in the gap between deck boards or at the gap between the deck and the wall. Once ignition occurred between the deck boards, the fire spread in a smoldering phase along the joist toward and away from the test building. At the deck board gaps, the smoldering combustion transformed to flaming due to the airflow between the deck boards, which allowed fire to continue to propagate all the way to the building. This highlights a potential deficiency in the current test method that does not take the joist as a contributing element in the fire performance.

The under-deck flame impingements were performed similar to the specifications in SFM 12-7A-4A and ASTM E2632. However, based on the observations in above-deck ember exposure tests, and in order to making the testing condition closer to a real-world scenario, three parameters in these test methods were evaluated: (1) a larger deck size was tested, (2) the tests were performed with wind, and (3) the joists were considered as a contributor to the fire.

The results of the under-deck flame impingements highlighted the need to modify the current test method. It was observed that, currently, California’s Chapter 7A compliant materials expose the siding of the test building to extreme temperatures for a long duration which could ignite the combustible cladding or break the windows. This research shows that joists play a significant role in the compliance of different products. Once ignited, joists prolong the fire exposure duration the underside of the walking surfaces. Also, small details such as the gap between the deck boards can change the fire performance of different assemblies. In order to meaningfully assess the performance of different types of walking surfaces, one would need to test a larger deck assembly, i.e., joists and walking surfaces in the presence of wind.

While this research highlights the need to change the standard test method to evaluate decks in California’s building codes, this could be a time-consuming process to develop and enforce. To minimize the vulnerability of decks and potential fire spread from decks to the buildings, for new construction, the use of noncombustible materials, for both the walking surface and the supporting structure, is recommended. For retrofits, given that changing the supporting system could be cost-prohibitive, it is recommended to use the metal deck boards with no spacing between them. These deck boards are engineered to properly address water drainage and expansion due to heat.

Author Contributions

Conceptualization, S.L.Q.; methodology, F.H., S.L.Q. and C.S.-A.; formal analysis, F.H. and S.L.Q.; investigation, F.H., S.L.Q. and C.S.-A.; resources, S.L.Q.; data curation, C.S.-A.; writing—original draft preparation, F.H., S.L.Q. and C.S.-A.; writing—review and editing, F.H., S.L.Q. and C.S.-A.; project administration, F.H. and C.S.-A. All authors have read and agreed to the published version of the manuscript.

Funding

All the expenses in this research is funded by the Insurance Institute for Business & Home Safety, a nonprofit located in Richburg, SC, USA.

Data Availability Statement

The data in this study could be available to individuals upon request.

Acknowledgments

The authors appreciate the support of IBHS staff, research, instrumentation, communication, and operation teams.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Bryner, N.P. Building Codes and Standards for New Construction. In Encyclopedia of Wildfires and Wildland-Urban Interface (WUI) Fires; Manzello, S.L., Ed.; Springer International Publishing: Cham, Switzerland, 2018; pp. 1–9. [Google Scholar]

- SFM 12-7A-4; Materials and Construction Methods for Exterior Wildfire Exposure. California’s Office of Fire Marshals: York, PA, USA, 2019.

- Manzello, S.L.; Suzuki, S. Influence of Board Spacing on Mitigating Wood Decking Assembly Ignition. Fire Saf. J. 2019, 110, 102913. [Google Scholar] [CrossRef] [PubMed]

- Quarles, S.L.; Standohar-Alfano, C.D. Ignition Potential of Decks Subjected to an Ember Exposure; Insurance Institute for Business & Home Safety: Richburg, SC, USA, 2018. [Google Scholar]

- Hasburgh, L.E.; Stone, D.S.; Zelinka, S.L. Laboratory Investigation of Fire Transfer from Exterior Wood Decks to Buildings in the Wildland–Urban Interface. Fire Technol. 2017, 53, 517–534. [Google Scholar] [CrossRef]

- Maranghides, A.; McNamara, D.; Vihnanek, R.; Restaino, J.; Leland, C. A Case Study of a Community Affected by the Waldo Fire Event Timeline and Defensive Actions; NIST Pubs: Gaithersburg, MD, USA, 2015.

- Quarles, S.; Leschak, P.; Cowger, C.R.; Worley, K.; Brown, R.; Iskowitz, C. Candace, Lessons Learned from Waldo Canyon—Fire Adapted Communities Mitigation Assessment Team Findings; U.S. Department of Agriculture: Washington, DC, USA, 2013.

- Manzello, S.L.; Suzuki, S. Experimental Investigation of Wood Decking Assemblies Exposed to Firebrand Showers. Fire Saf. J. 2017, 92, 122–131. [Google Scholar] [CrossRef] [PubMed]

- Maranghides, A.; Mell, W.E.; Hawks, S.; Wilson, M.; Brewer, W.; Link, E.; Brown, C.; Murrill, C.; Ashley, E. Preliminary Data Collected from the Camp Fire Reconnaissance; NIST: Gaithersburg, MD, USA, 2020.

- Standohar-Alfano, C.D.; Estes, H.; Johnston, T.; Morrison, M.J.; Brown-Giammanco, T.M. Reducing losses from wind-related natural perils: Research at the IBHS research center. Front. Built Environ. 2017, 3, 9. [Google Scholar] [CrossRef] [Green Version]

- Hedayati, F.; Bahrani, B.; Zhou, A.; Quarles, S.L.; Gorham, D.J. A Framework to Facilitate Firebrand Characterization. Front. Mech. Eng. 2019, 5, 43. [Google Scholar] [CrossRef] [Green Version]

- Keeley, J.E.; Safford, H.; Fotheringham, C.J.; Franklin, J.; Moritz, M. The 2007 southern California wildfires: Lessons in complexity. J. For. 2009, 107, 287–296. [Google Scholar]

- Richter, F.; Bathras, B.; Barbetta Duarte, J.; Gollner, M.J. The Propensity of Wooden Crevices to Smoldering Ignition by Firebrands. Fire Technol. 2022, 1–22. [Google Scholar] [CrossRef]

- Nagaoka, T.; Kodaira, A.; Uehara, S. Relationship between density and the ignitability and combustibility of wood. Fire Saf. Sci. 1988, 3, 197–208. [Google Scholar]

- Leonard, J.; Bowditch, P. Findings of studies of houses damaged by bushfire in Australia. In Proceedings of the 3rd International Wildland Fire Conference, Sydney, Australia, 3–6 October 2003. [Google Scholar]

- Ghodrat, M.; Shakeriaski, F.; Nelson, D.J.; Simeoni, A. Existing Improvements in Simulation of Fire–Wind Interaction and Its Effects on Structures. Fire 2021, 4, 27. [Google Scholar] [CrossRef]

- Babrauskas, V. Ignition of wood: A review of the state of the art. J. Fire Prot. Eng. 2002, 12, 163–189. [Google Scholar] [CrossRef] [Green Version]

Figure 1.

Examples of burning decks causing damage to the main structure of (a) a commercial wine-tasting room in Napa Valley and (b) a residential structure in Santa Rosa, California, during the 2020 Glass Fire. (Images taken during IBHS’s post-event investigation).

Figure 1.

Examples of burning decks causing damage to the main structure of (a) a commercial wine-tasting room in Napa Valley and (b) a residential structure in Santa Rosa, California, during the 2020 Glass Fire. (Images taken during IBHS’s post-event investigation).

Figure 2.

Examples of decks ignited at different locations in the 2020 Glass Fire, (a) ignition at the right footer (suppressed by first-responders during the event), (b) likely above-deck ignition because of uncharred joists, and (c) ignition of combustibles near/below the deck and fire spread to the deck. (Images taken during IBHS’s post-event investigation).

Figure 2.

Examples of decks ignited at different locations in the 2020 Glass Fire, (a) ignition at the right footer (suppressed by first-responders during the event), (b) likely above-deck ignition because of uncharred joists, and (c) ignition of combustibles near/below the deck and fire spread to the deck. (Images taken during IBHS’s post-event investigation).

Figure 3.

(a) The IBHS Research Center and (b) inside the test chamber.

Figure 3.

(a) The IBHS Research Center and (b) inside the test chamber.

Figure 4.

Diagram of an ember generator used in wildfire experiments, showing the pneumatic feed line (A) for feeding fuel to the generator; vertically oriented fan (B); and exhaust duct (C).

Figure 4.

Diagram of an ember generator used in wildfire experiments, showing the pneumatic feed line (A) for feeding fuel to the generator; vertically oriented fan (B); and exhaust duct (C).

Figure 5.

Auger feed and ember generation system, including left and right hoppers (A); auger feed lines (B) for delivery of fuel to generators (C); fan array (D); and test building (E).

Figure 5.

Auger feed and ember generation system, including left and right hoppers (A); auger feed lines (B) for delivery of fuel to generators (C); fan array (D); and test building (E).

Figure 6.

Test setup for ember exposure on decks. (a) test set up. (b) decks exposed to embers.

Figure 6.

Test setup for ember exposure on decks. (a) test set up. (b) decks exposed to embers.

Figure 7.

(a) Decks in the kiln. (b) Redwood. (c) Composite A. (d) Composite B.

Figure 7.

(a) Decks in the kiln. (b) Redwood. (c) Composite A. (d) Composite B.

Figure 8.

(a) The patterns on the deck resulted in embers dropping into gaps between deck boards. (b) The embers accumulated in the gaps between deck boards on top of the joist.

Figure 8.

(a) The patterns on the deck resulted in embers dropping into gaps between deck boards. (b) The embers accumulated in the gaps between deck boards on top of the joist.

Figure 9.

Flame height between the deck boards from (a) above and (b) below.

Figure 9.

Flame height between the deck boards from (a) above and (b) below.

Figure 10.

(

a) Deck to wall connection, with accumulation of vegetative debris in gap between deck and vertical wall. (

b) Debris accumulation in the gap between deck boards [

4].

Figure 10.

(

a) Deck to wall connection, with accumulation of vegetative debris in gap between deck and vertical wall. (

b) Debris accumulation in the gap between deck boards [

4].

Figure 11.

(a) Fire propagation along the joist towards the test building (b) Fire propagation along the joist towards the main building in a commercial wine-tasting room in Napa Valley, California, during the 2020 Glass Fire. (Images taken during IBHS’s post-event investigation).

Figure 11.

(a) Fire propagation along the joist towards the test building (b) Fire propagation along the joist towards the main building in a commercial wine-tasting room in Napa Valley, California, during the 2020 Glass Fire. (Images taken during IBHS’s post-event investigation).

Figure 12.

(a) Embers dropping between the boards gaps. (b) Embers igniting the pine needles and causing under-deck flame impingement.

Figure 12.

(a) Embers dropping between the boards gaps. (b) Embers igniting the pine needles and causing under-deck flame impingement.

Figure 13.

Replicating the current test method. (a) Fire intensity after 15 min (12 min after shutting off the gas burner). (b) Cross-section of the burned deck.

Figure 13.

Replicating the current test method. (a) Fire intensity after 15 min (12 min after shutting off the gas burner). (b) Cross-section of the burned deck.

Figure 14.

(a) Distribution of heat under a 2 ft × 2.4 ft deck 90 s after igniting the burner. (b) Distribution of heat under a 6.6 ft × 6.6 ft deck 90 s after igniting the burner. (c) Intensity of the fire for a 6.6 ft × 6.6 ft deck 40 min after turning off the burner at no-wind condition.

Figure 14.

(a) Distribution of heat under a 2 ft × 2.4 ft deck 90 s after igniting the burner. (b) Distribution of heat under a 6.6 ft × 6.6 ft deck 90 s after igniting the burner. (c) Intensity of the fire for a 6.6 ft × 6.6 ft deck 40 min after turning off the burner at no-wind condition.

Figure 15.

Time-lapse of a redwood deck with Southern Yellow Pine joists test from two angles. (a) After 5 s. (b) After 3 min. (c) After 5 min. (d) After 7 min. (e) After 10 min.

Figure 15.

Time-lapse of a redwood deck with Southern Yellow Pine joists test from two angles. (a) After 5 s. (b) After 3 min. (c) After 5 min. (d) After 7 min. (e) After 10 min.

Figure 16.

Combustible joists provide a constant heat source to the deck boards, (a–c) are from different experiments, (d1–d4) are taken in one experiment, d1 is taken 6 min after ignition, and (d2–d4) are about 4 min apart.

Figure 16.

Combustible joists provide a constant heat source to the deck boards, (a–c) are from different experiments, (d1–d4) are taken in one experiment, d1 is taken 6 min after ignition, and (d2–d4) are about 4 min apart.

Figure 17.

Time-lapse of redwood deck boards with (First Row) Southern Yellow Pine joists and (Second Row) metal supporting system, and the wall temperature.

Figure 17.

Time-lapse of redwood deck boards with (First Row) Southern Yellow Pine joists and (Second Row) metal supporting system, and the wall temperature.

Figure 18.

Time-lapse of Composite A deck boards with (First Row) Southern Yellow Pine joists and (Second Row) metal supporting system, and the wall temperature.

Figure 18.

Time-lapse of Composite A deck boards with (First Row) Southern Yellow Pine joists and (Second Row) metal supporting system, and the wall temperature.

Figure 19.

Time-lapse of Composite B deck boards with (First Row) Southern Yellow Pine joists and (Second Row) metal supporting system, and the wall temperature.

Figure 19.

Time-lapse of Composite B deck boards with (First Row) Southern Yellow Pine joists and (Second Row) metal supporting system, and the wall temperature.

Figure 20.

Time-lapse of two types of metal boards installed over SYP supporting system, (First Row) gapped metal boards, and (Second Row) no-gap metal boards, and the wall temperature.

Figure 20.

Time-lapse of two types of metal boards installed over SYP supporting system, (First Row) gapped metal boards, and (Second Row) no-gap metal boards, and the wall temperature.

Figure 21.

No-gap metal boards on SYP deck assembly after the test.

Figure 21.

No-gap metal boards on SYP deck assembly after the test.

Figure 22.

Wall temperature for gapped and no-gap metal boards over a metal substructure.

Figure 22.

Wall temperature for gapped and no-gap metal boards over a metal substructure.

Table 1.

Summary of the above-deck ember exposure tests.

Table 1.

Summary of the above-deck ember exposure tests.

Deck

Name | Chapter 7A Compliant | Density 1 (g/cm3) | Performance |

|---|

| Replication 1 | Replication 2 |

|---|

| PVC Composite | Yes | 0.68 | Smoldering | Smoldering |

| PE Composite 1 | No | 0.97 | Smoldering | Sustained

Flaming 2 |

| PE Composite 2 | Yes | 1.19 | Smoldering | Smoldering |

| PE Composite 3 | Yes | 1.03 | Smoldering | Smoldering |

| PE Composite 4 | No | 1.21 | Smoldering | Smoldering |

High-Density Tropical

Hardwood | Yes | 1.15 | Smoldering | Transitory

Flaming 3 |

| Medium-Density Softwood | Yes | 0.51 | Sustained

Flaming | Sustained

Flaming |

| FRT Wood | Yes | 0.50 | Smoldering | Smoldering |

Table 2.

Summary of the under-deck flame-impingement tests.

Table 2.

Summary of the under-deck flame-impingement tests.

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).