Bushfire-Resistant Lightweight Masonry Blocks with Expanded Perlite Aggregate

Abstract

:1. Introduction

2. Experimental Program

2.1. Materials

2.1.1. Cement

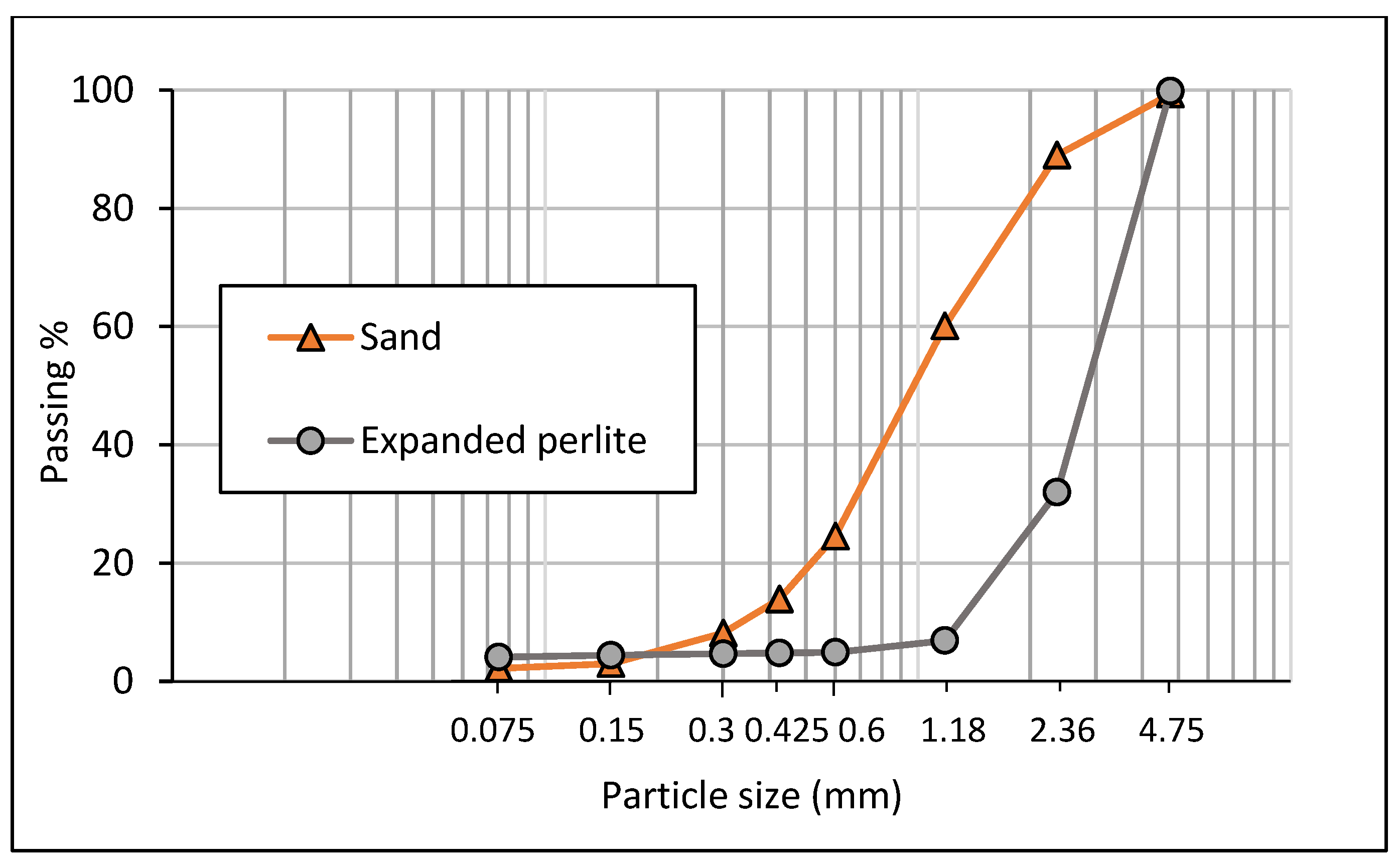

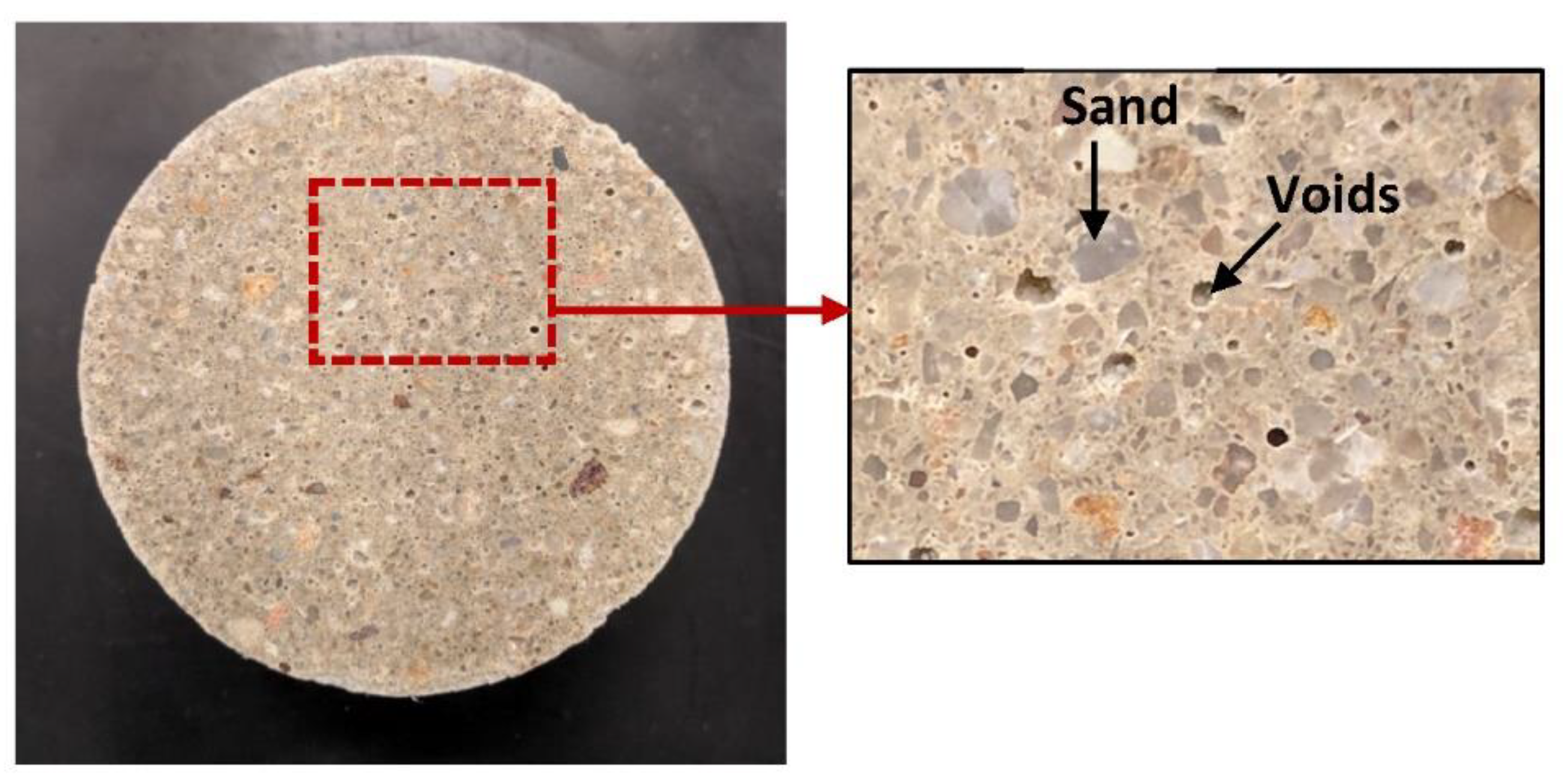

2.1.2. Sand

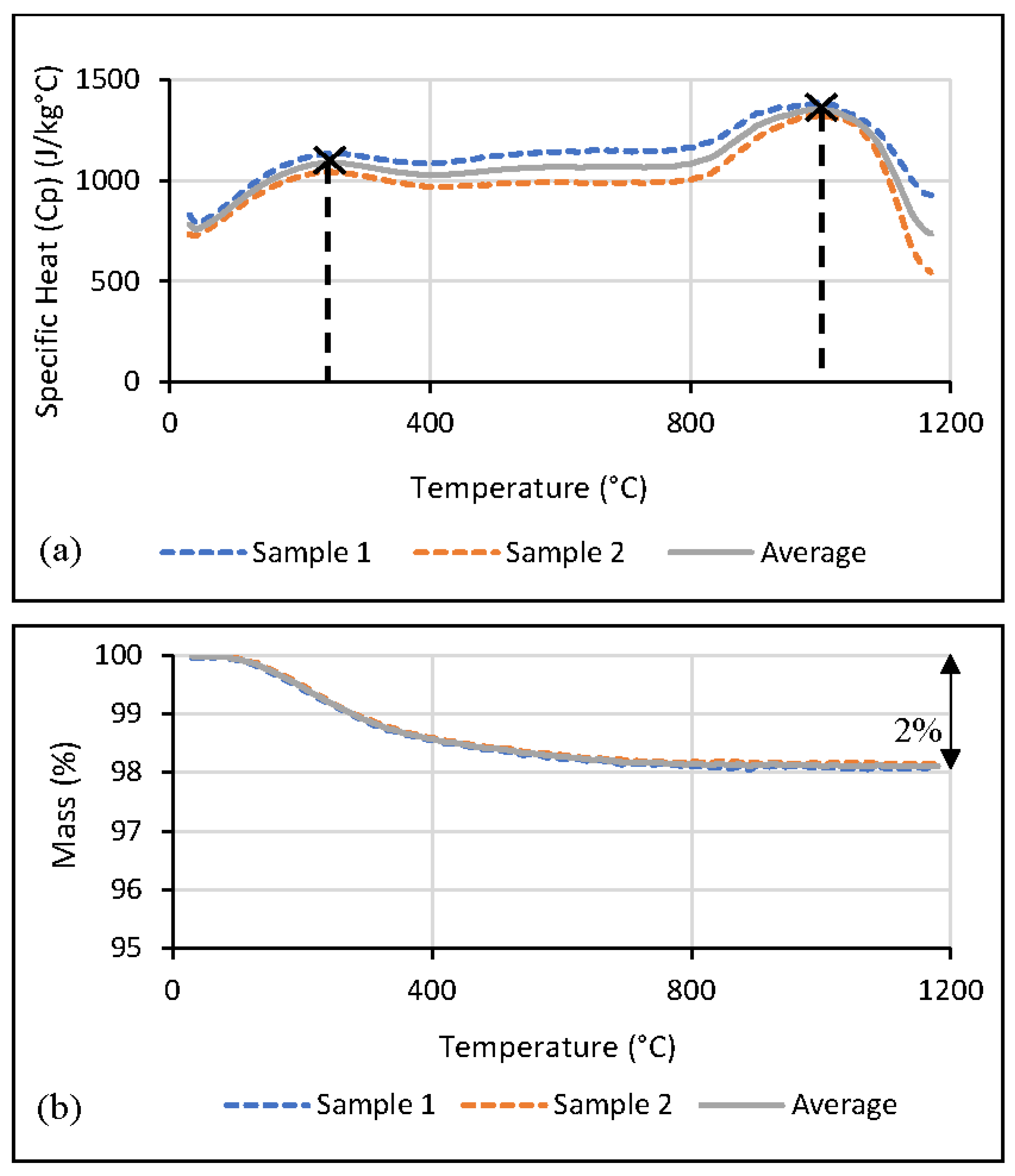

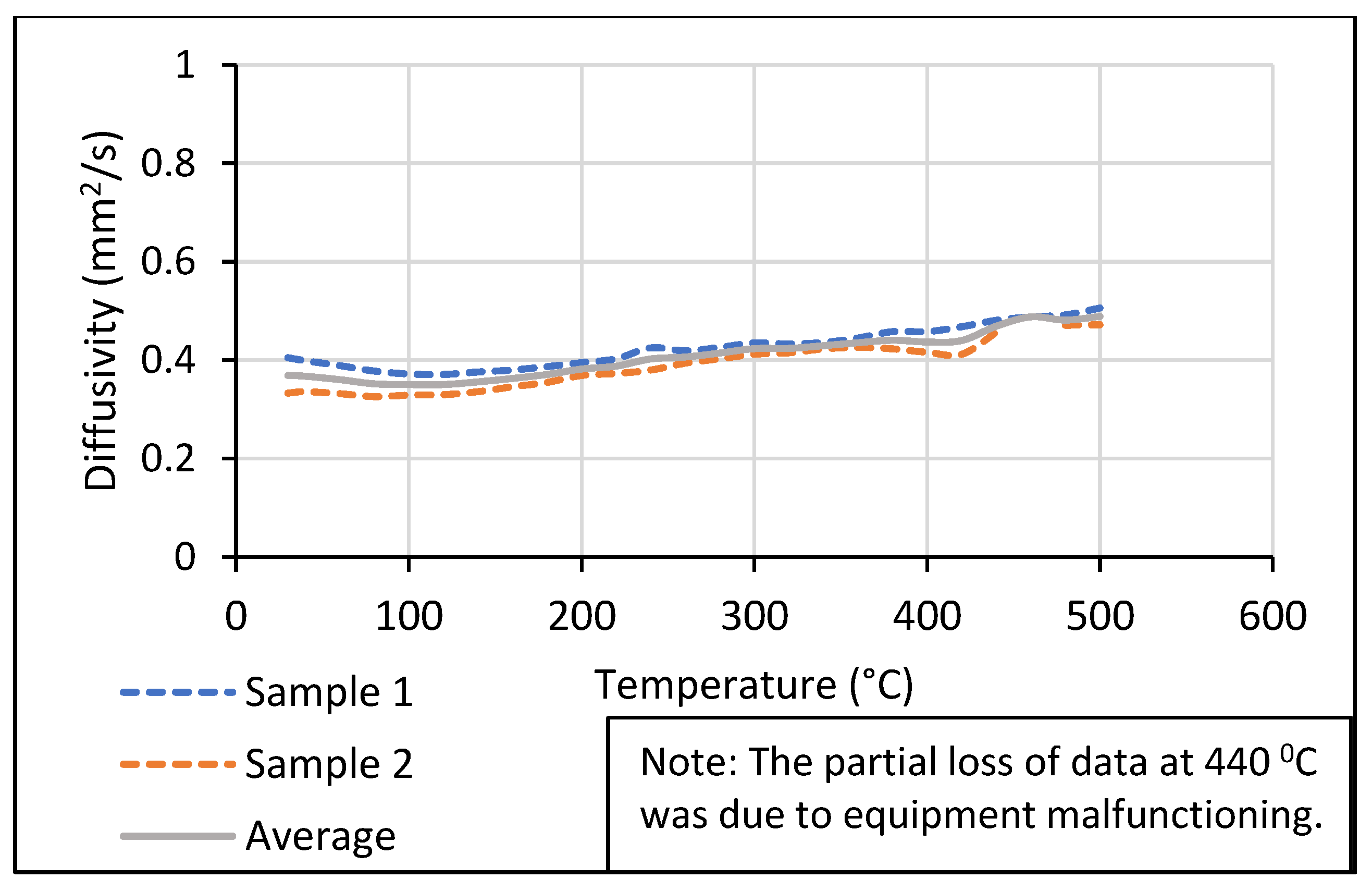

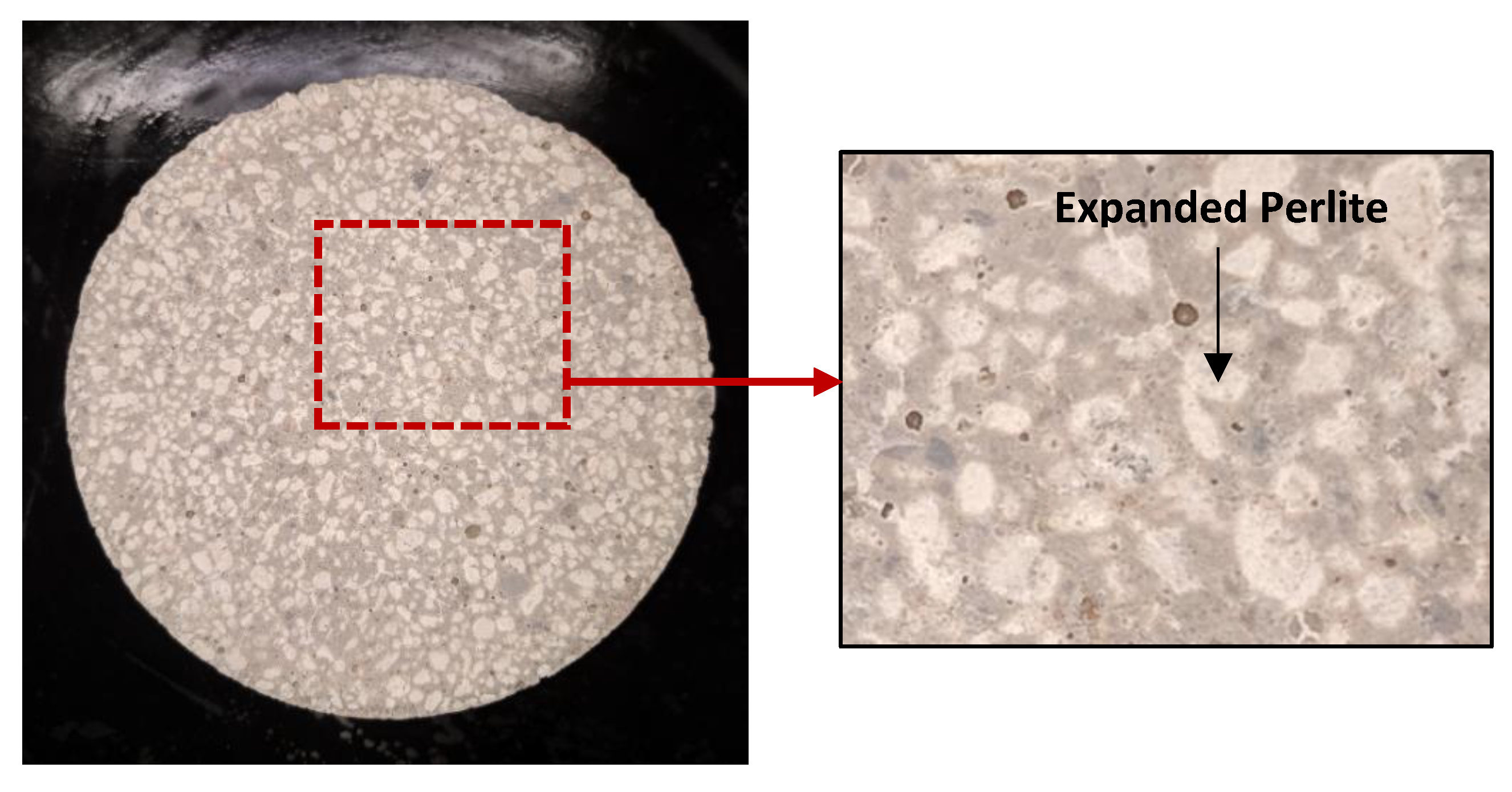

2.1.3. Expanded Perlite

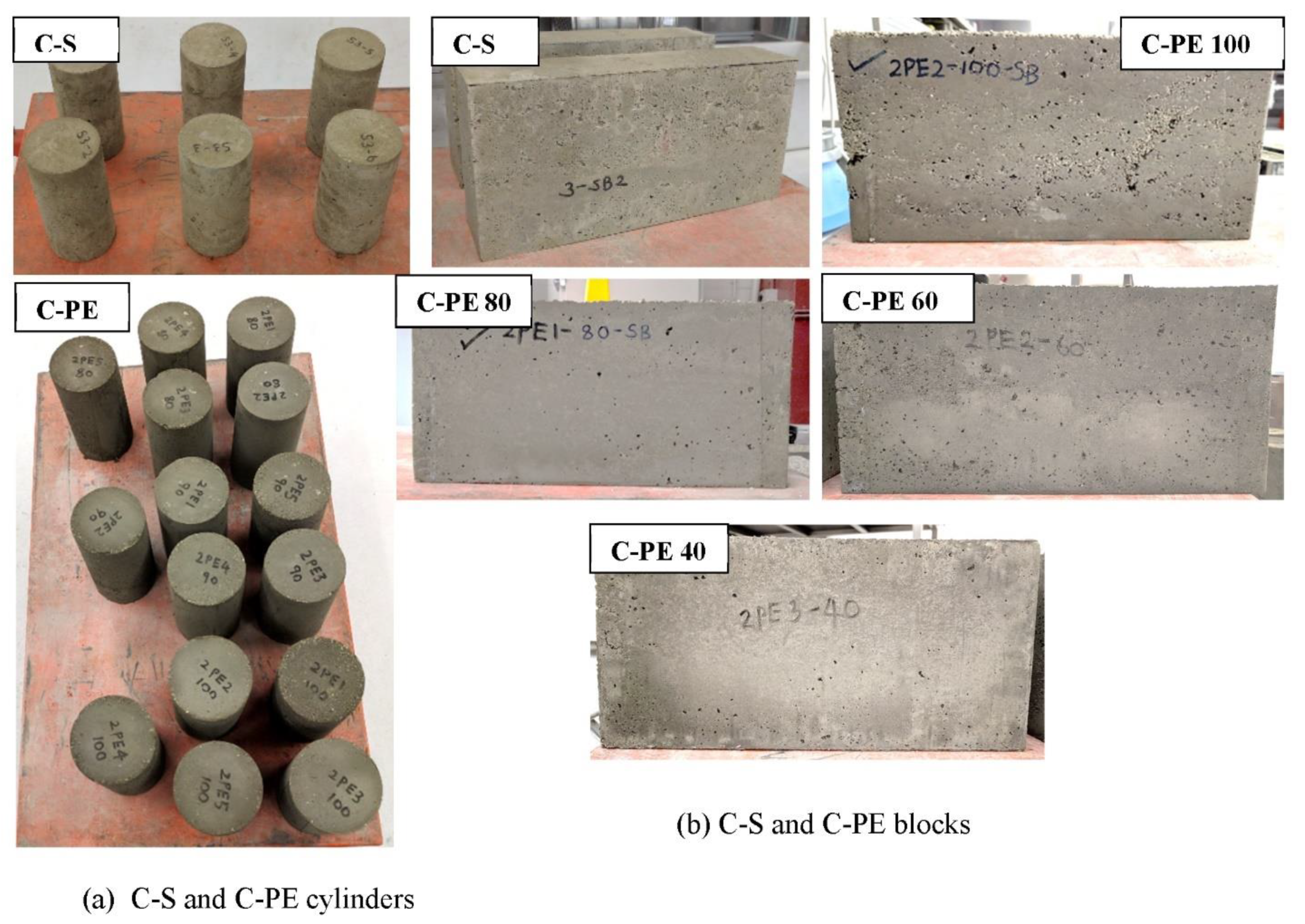

2.2. Mix Design

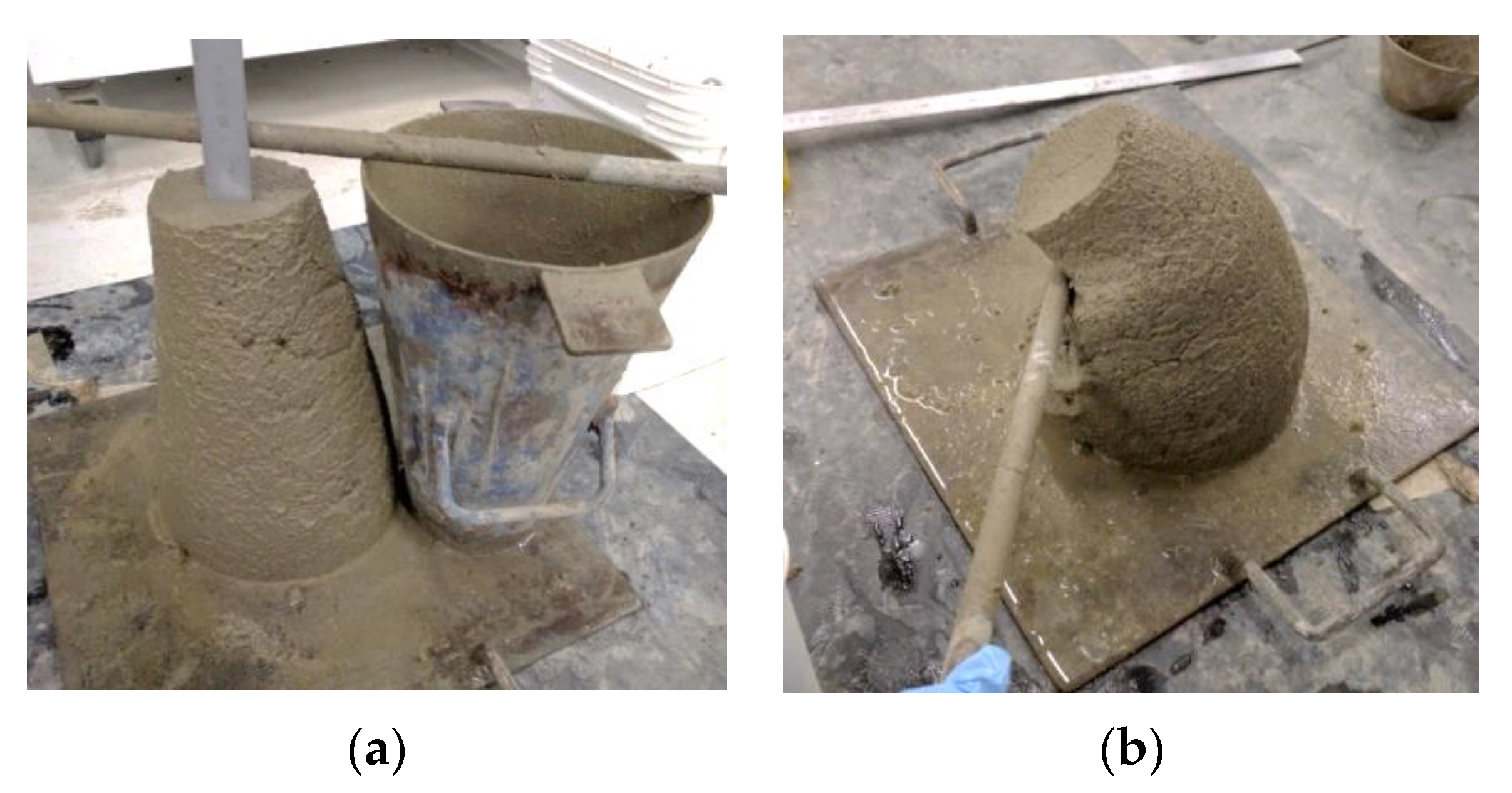

2.3. Details of Mixing

- (a)

- Fine aggregates were added to the mixer and mixed for ½ min;

- (b)

- Cement was added and covered with aggregates to minimize the loss of cement powder during mixing;

- (c)

- After 1 min of mixing, the effective water quantity was added and mixing was continued for another 1 min;

- (d)

- The mix was kept at rest for 2 min, then mixing was started again for another 2 min.

2.4. Details of Tests

2.4.1. Workability of Fresh Cement Mix

2.4.2. Fresh Density

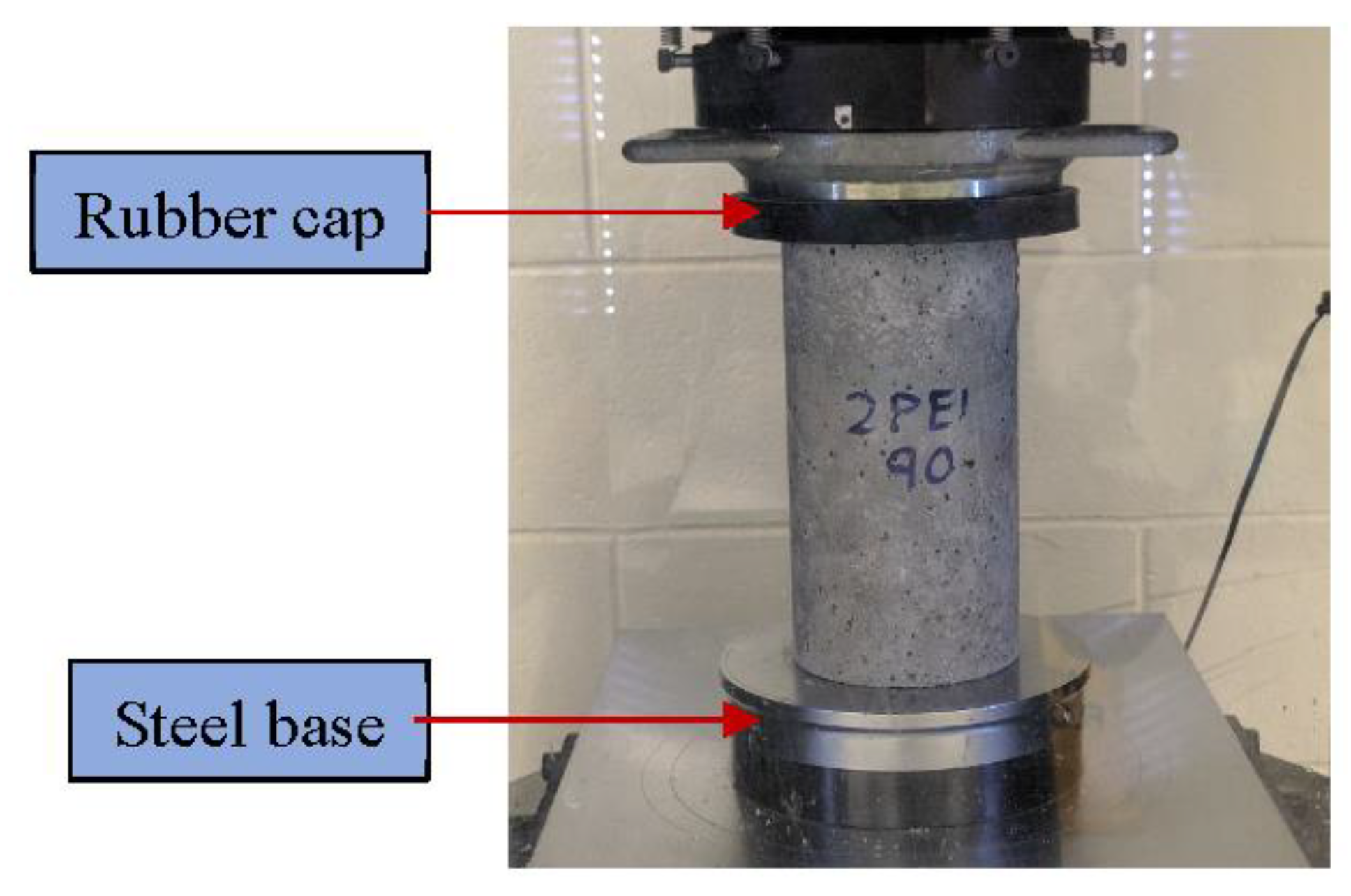

2.4.3. Compressive Strength

2.4.4. Hardened Density

2.4.5. Water Absorption

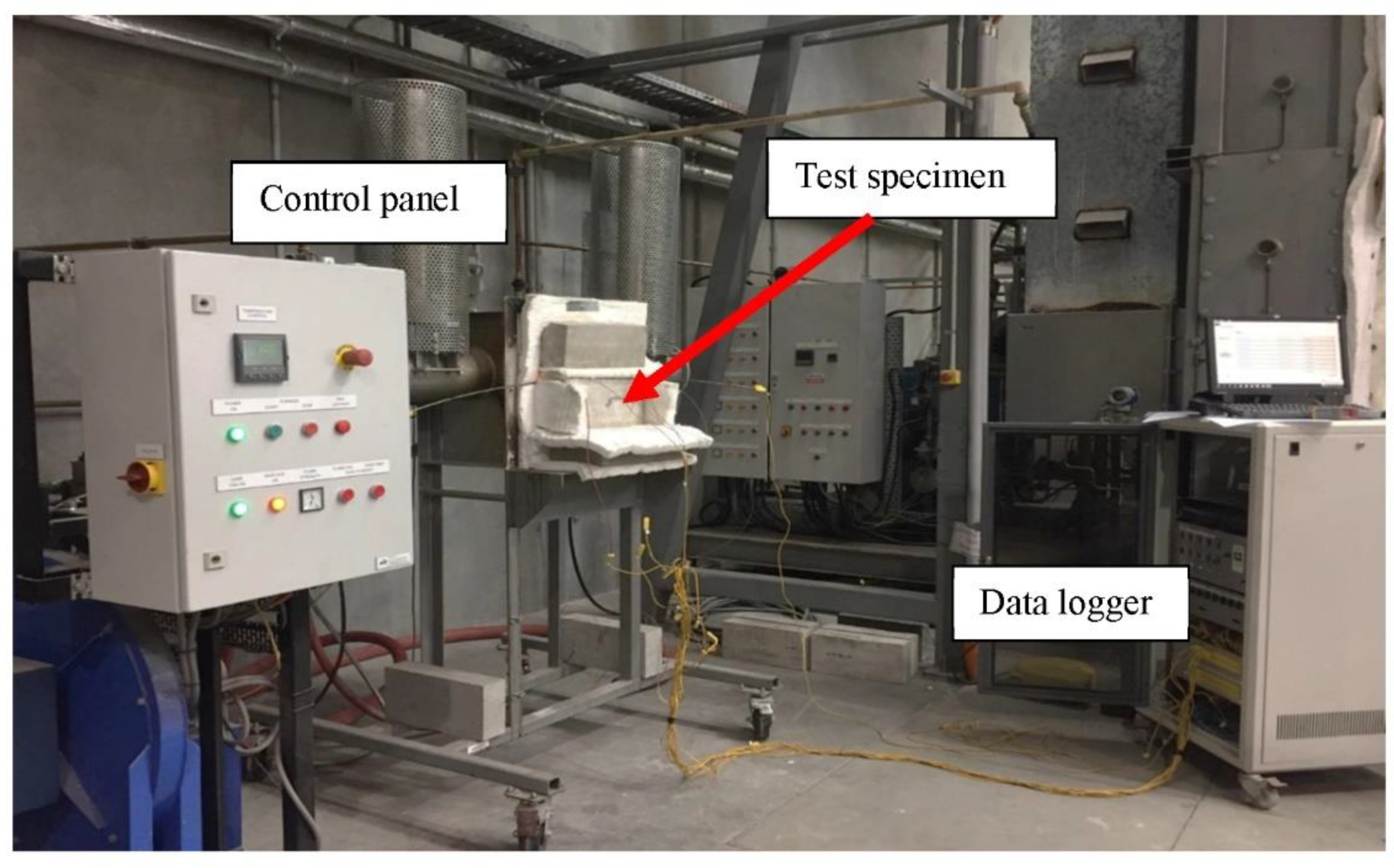

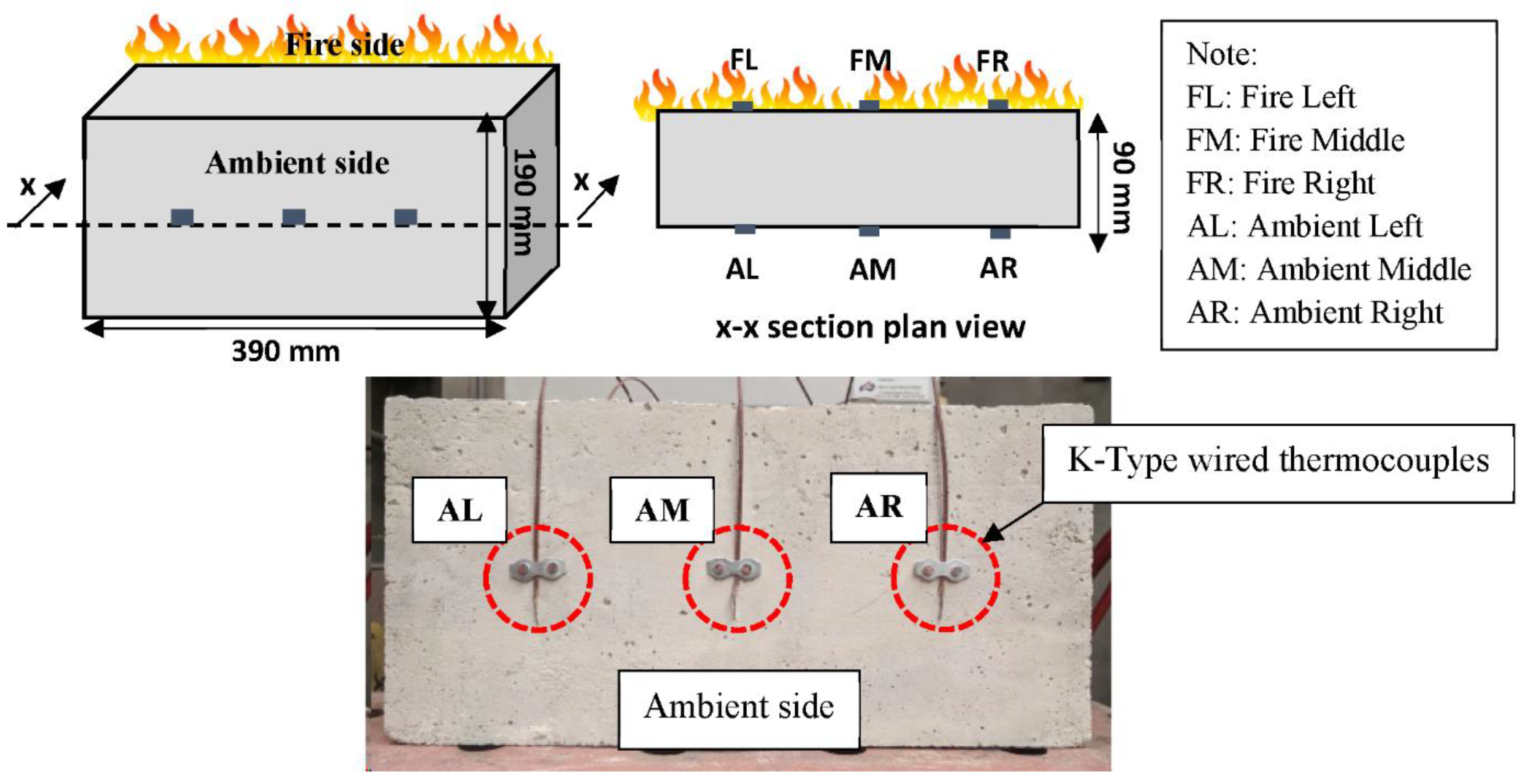

2.4.6. Fire Resistance of Masonry Blocks

3. Results

3.1. Standard Cement–Sand (C-S) mix

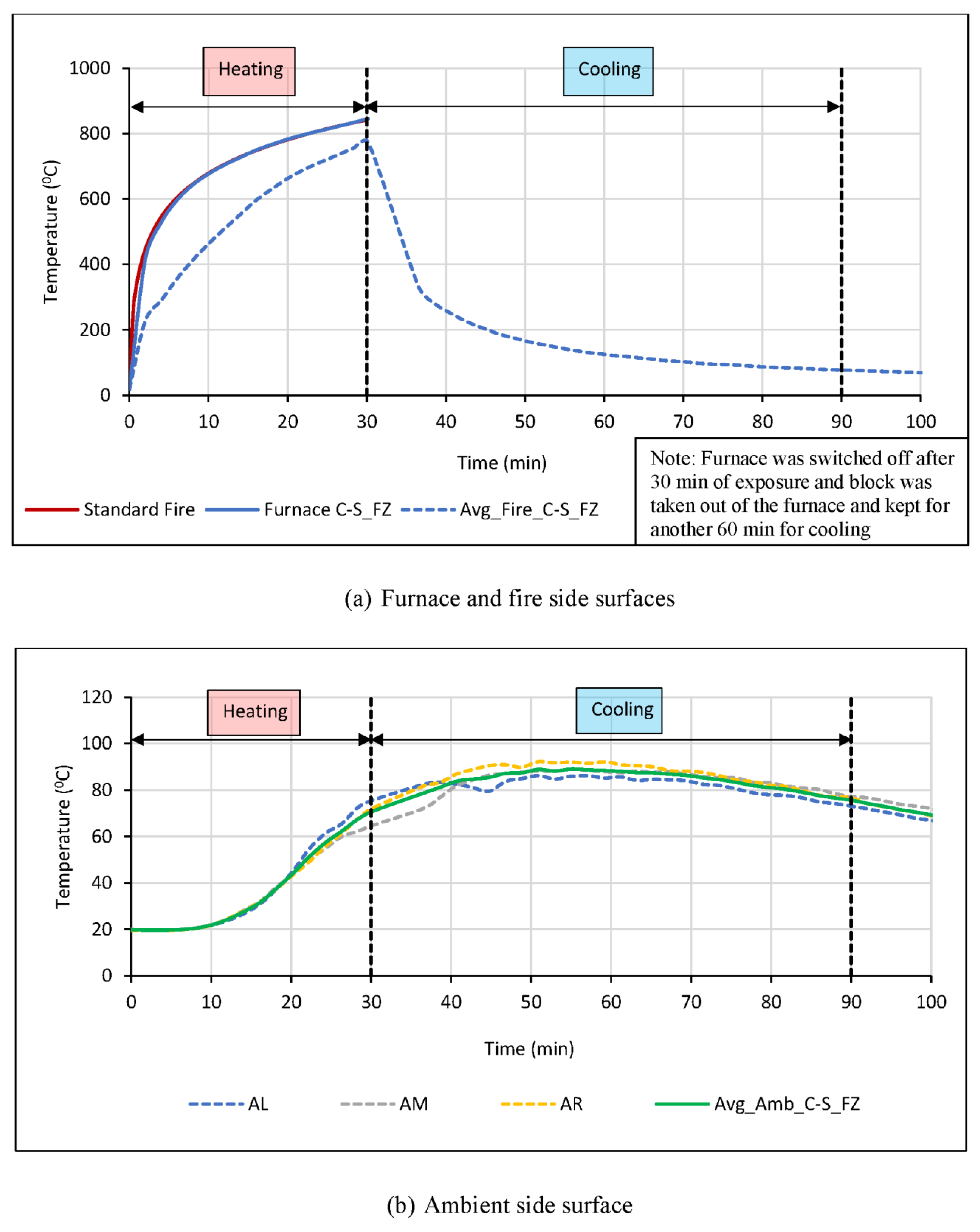

3.1.1. Bushfire Test of C-S Block

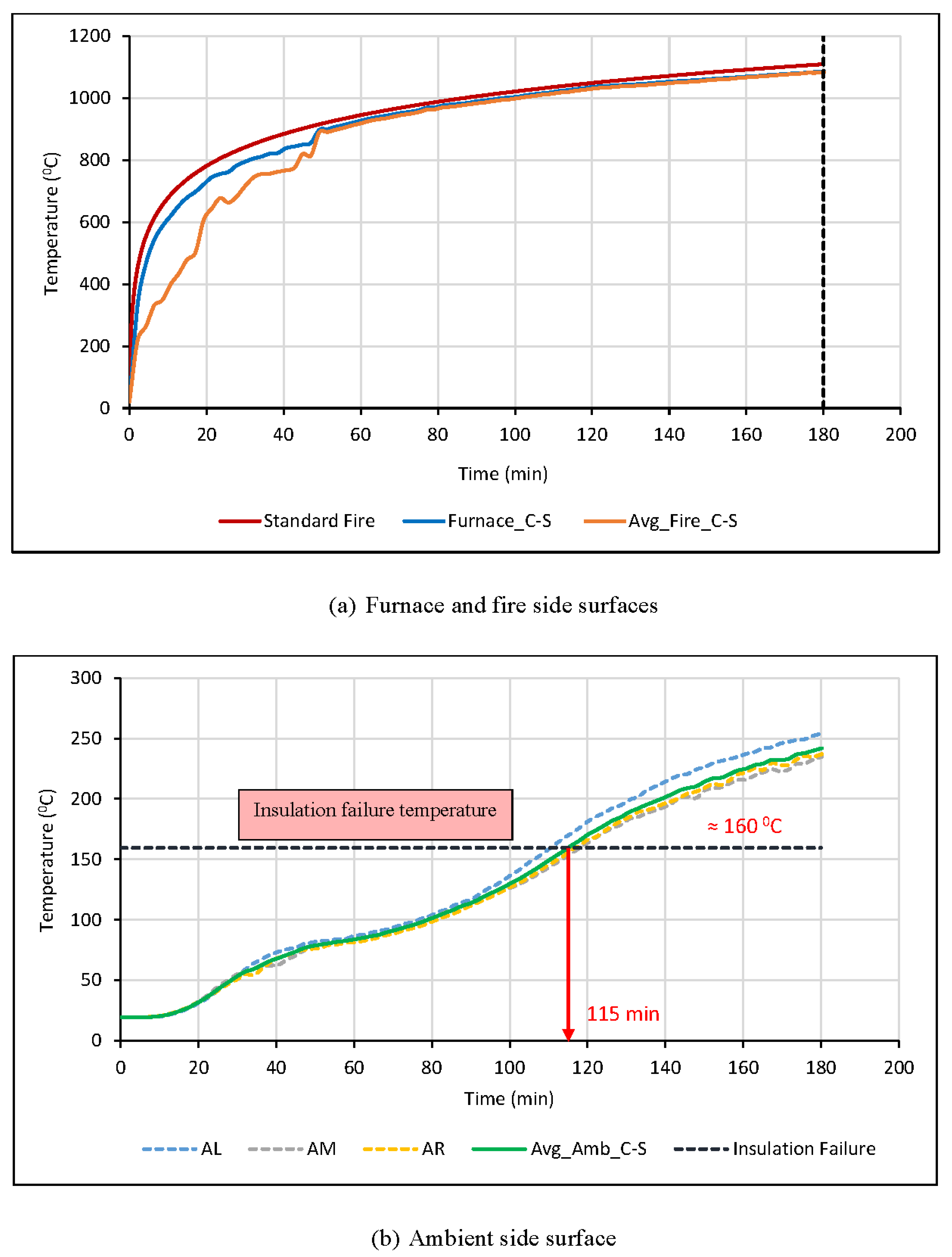

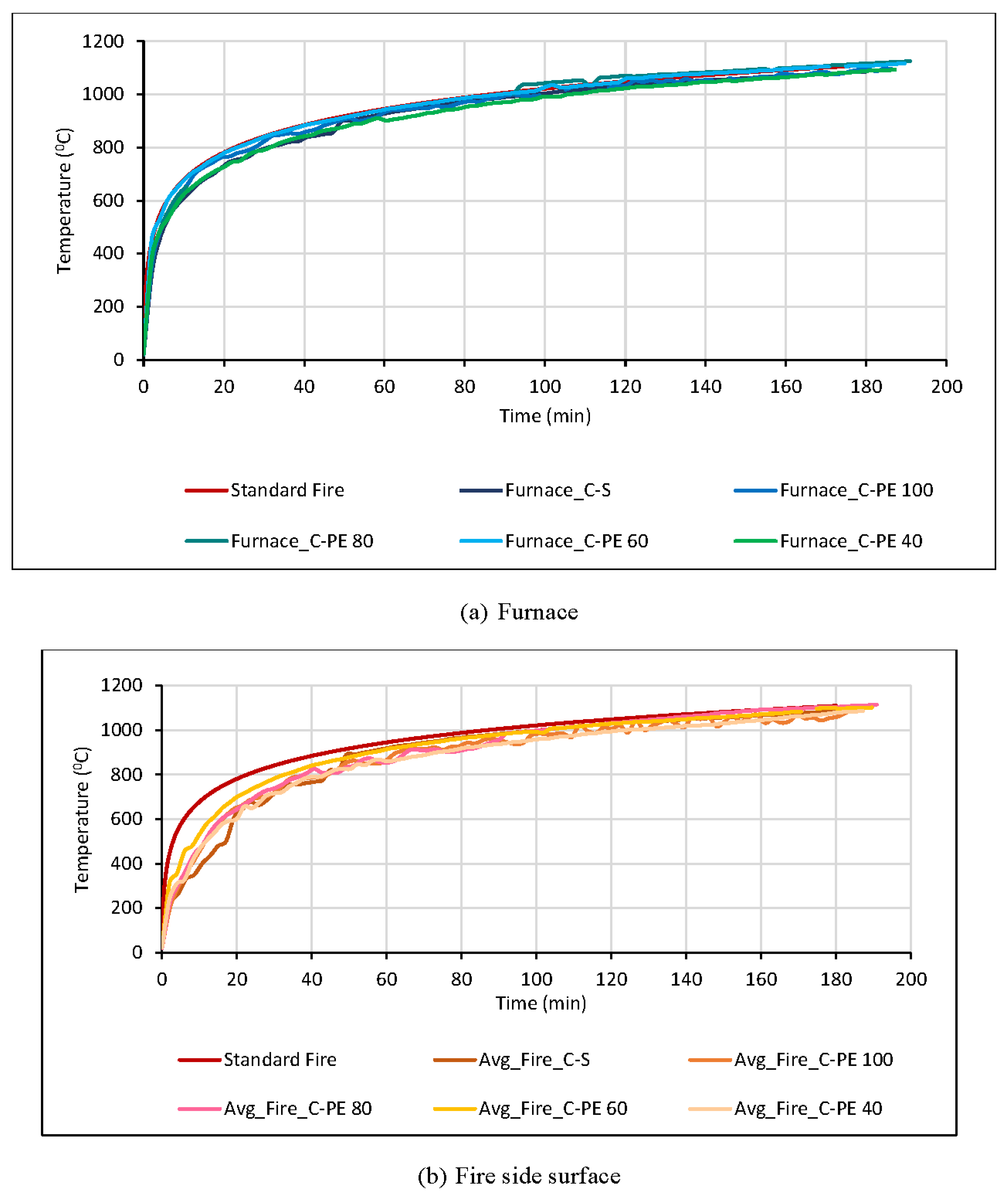

3.1.2. Building Fire Test of C-S Block

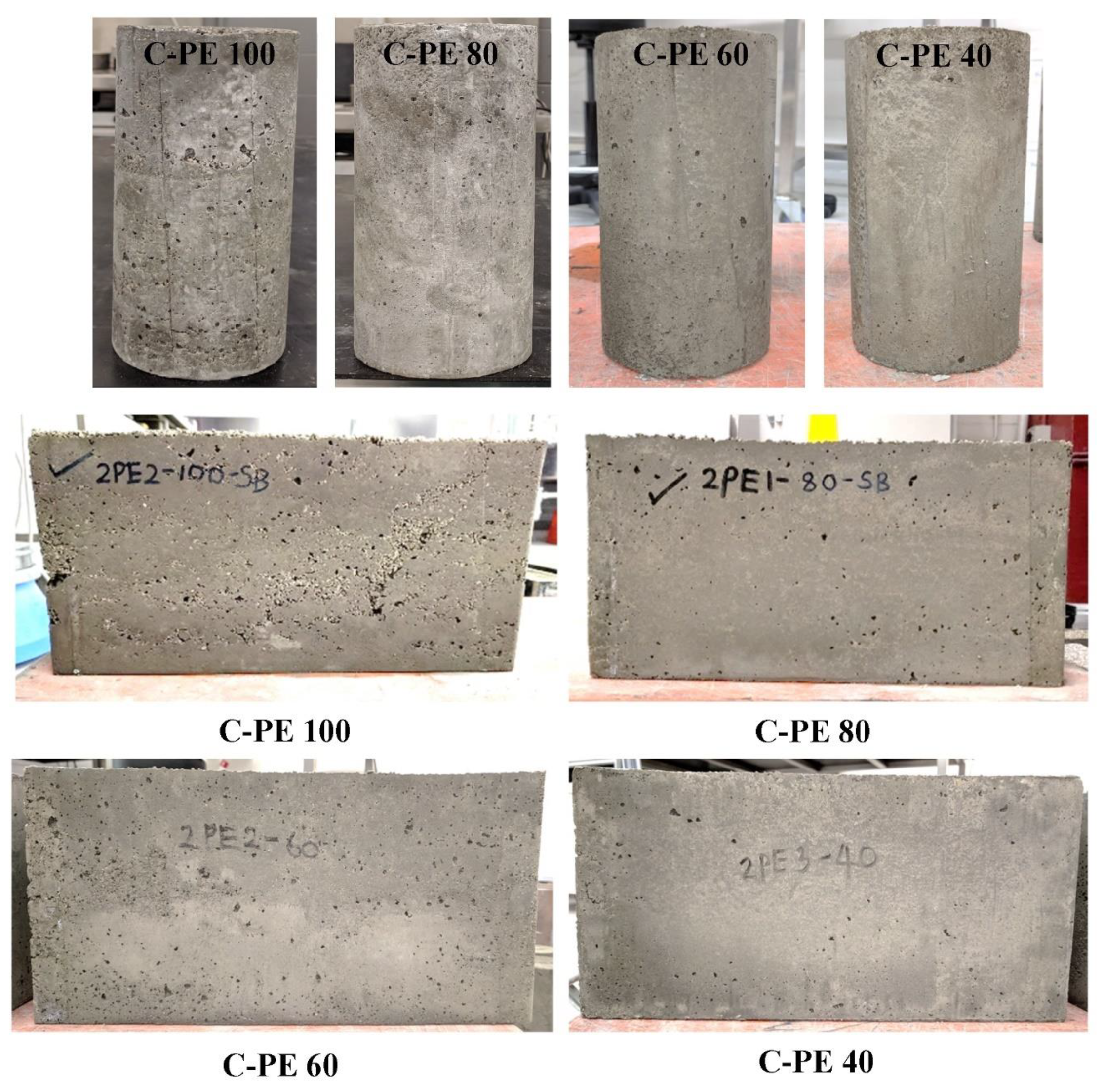

3.2. Cement–Expanded Perlite (C-PE) Mixes

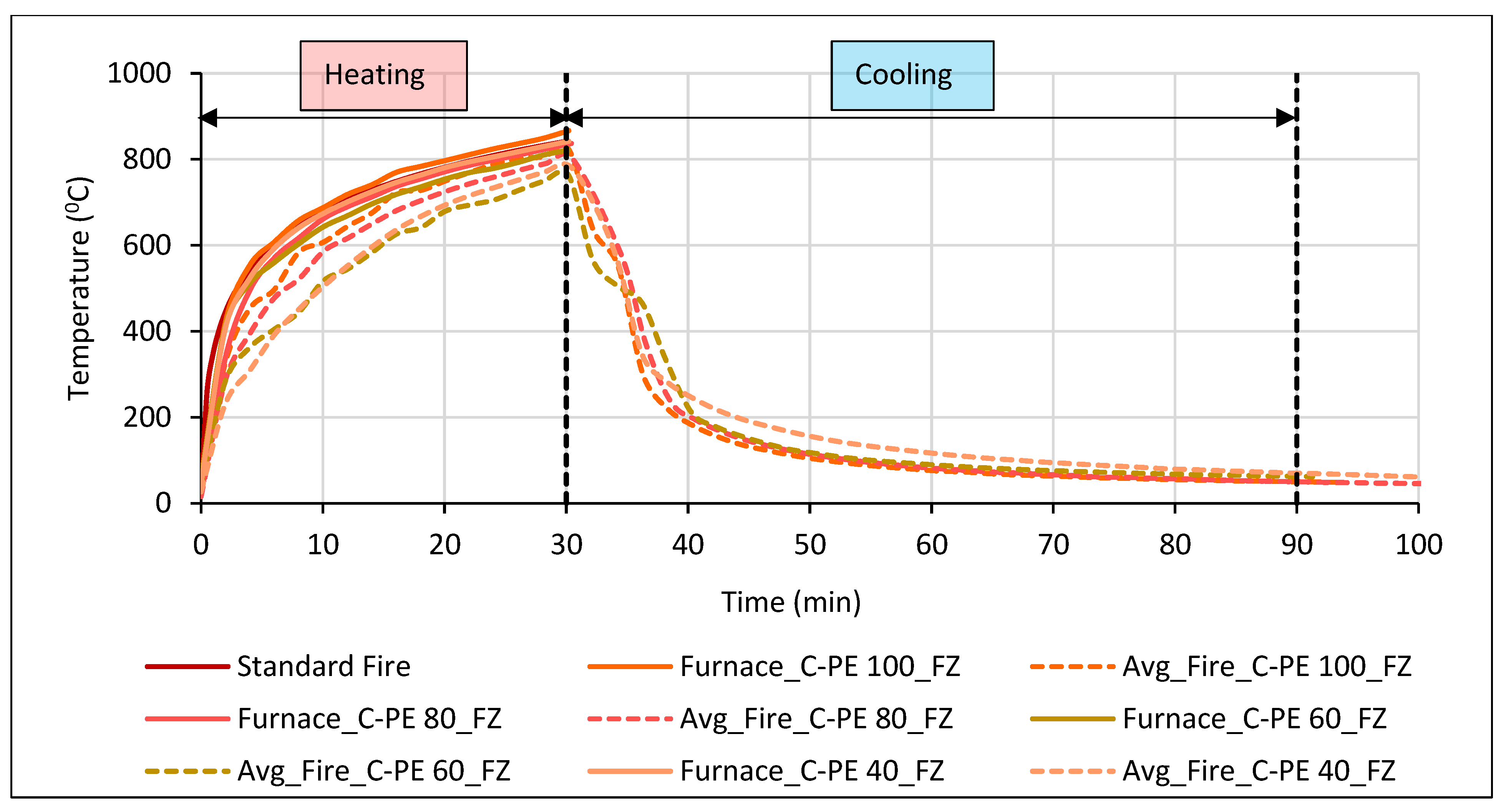

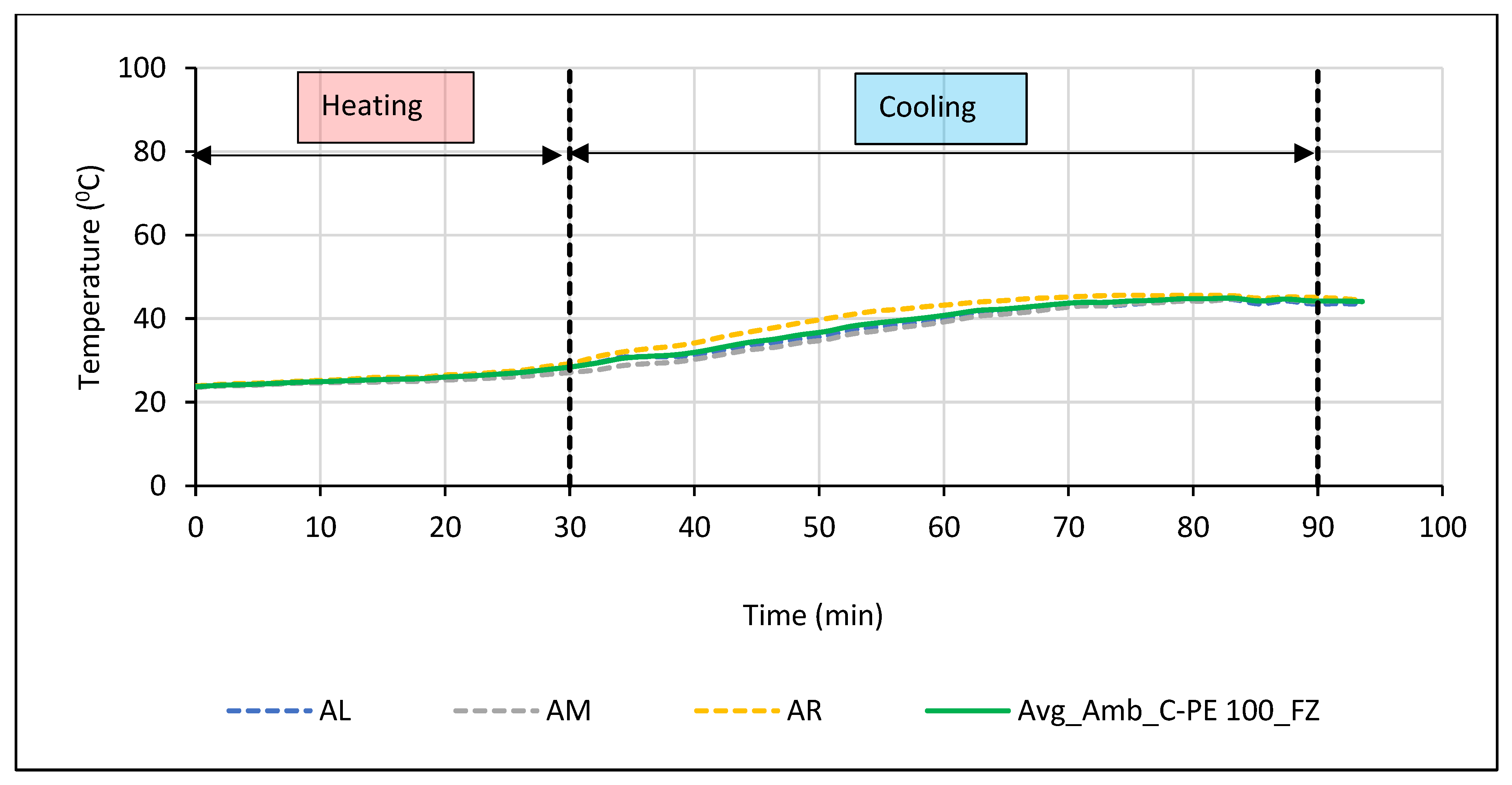

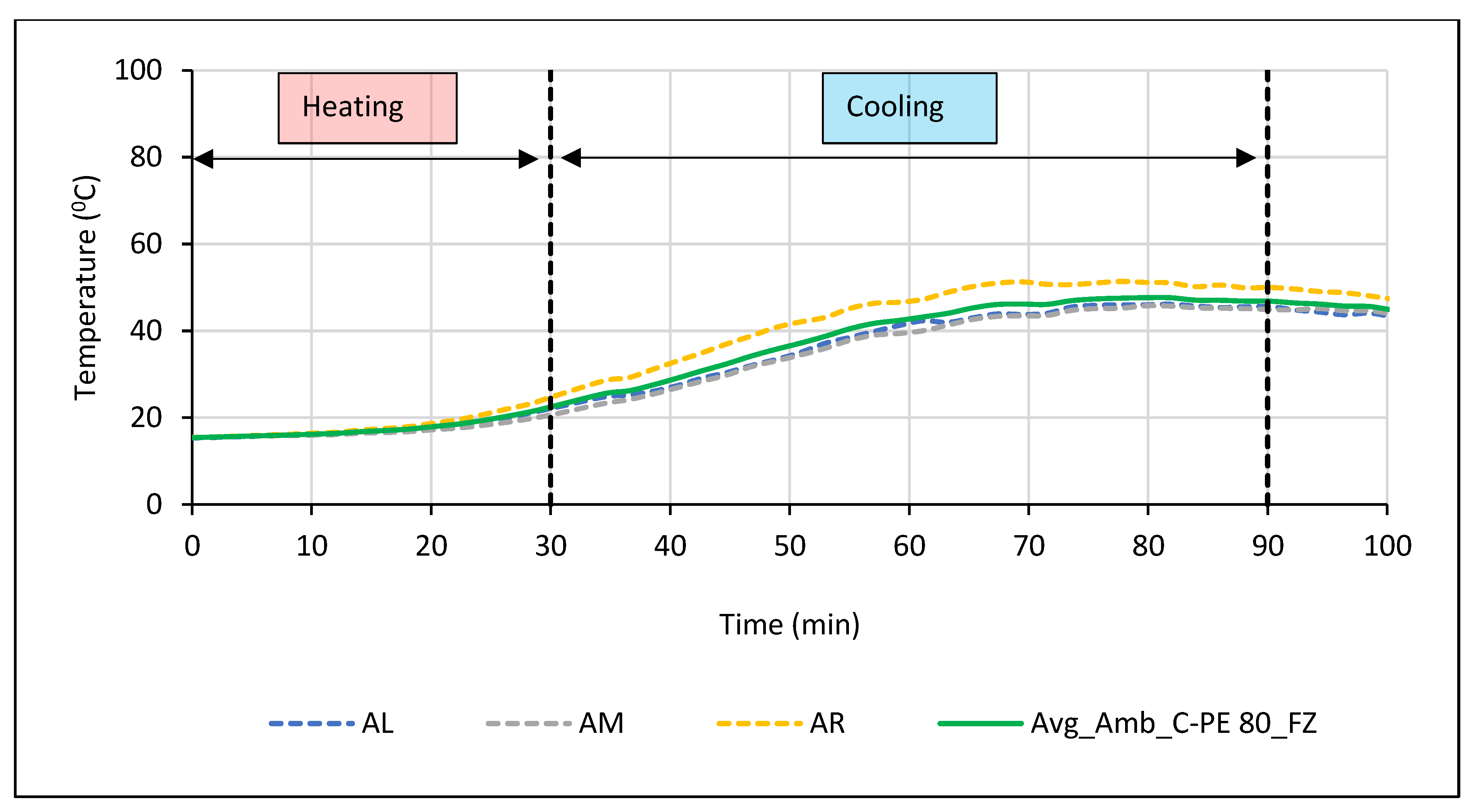

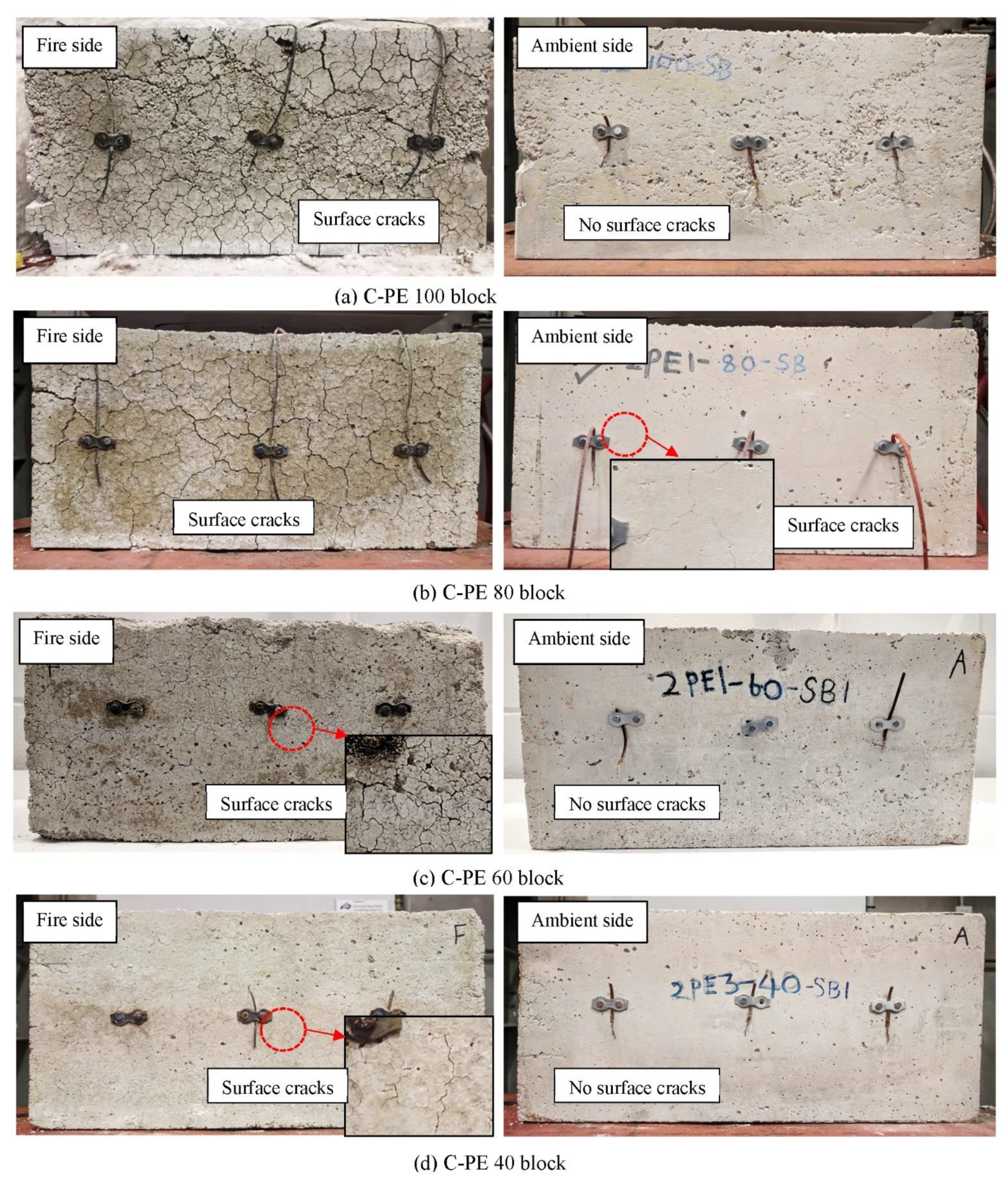

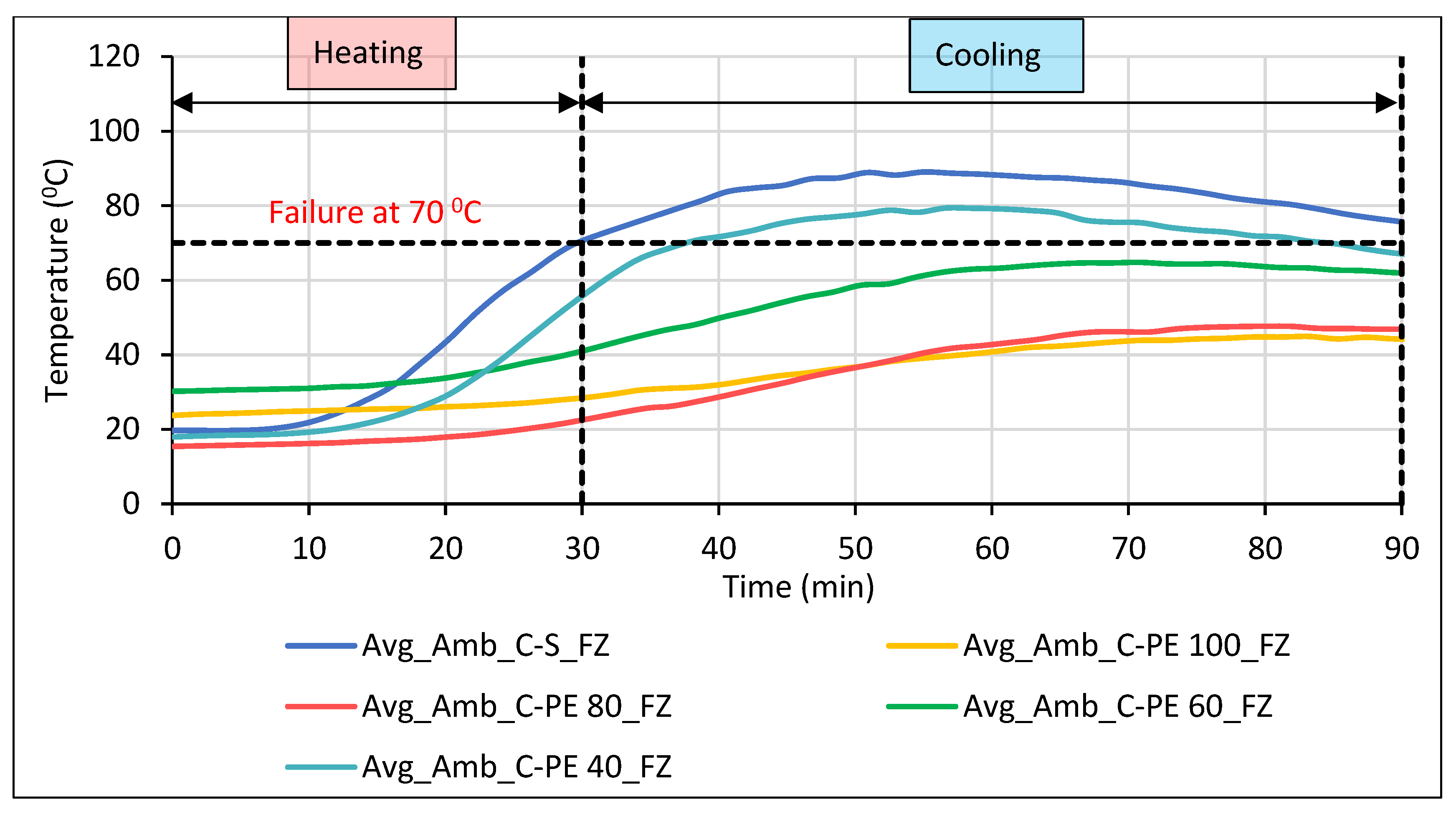

3.2.1. Bushfire Test of C-PE Blocks

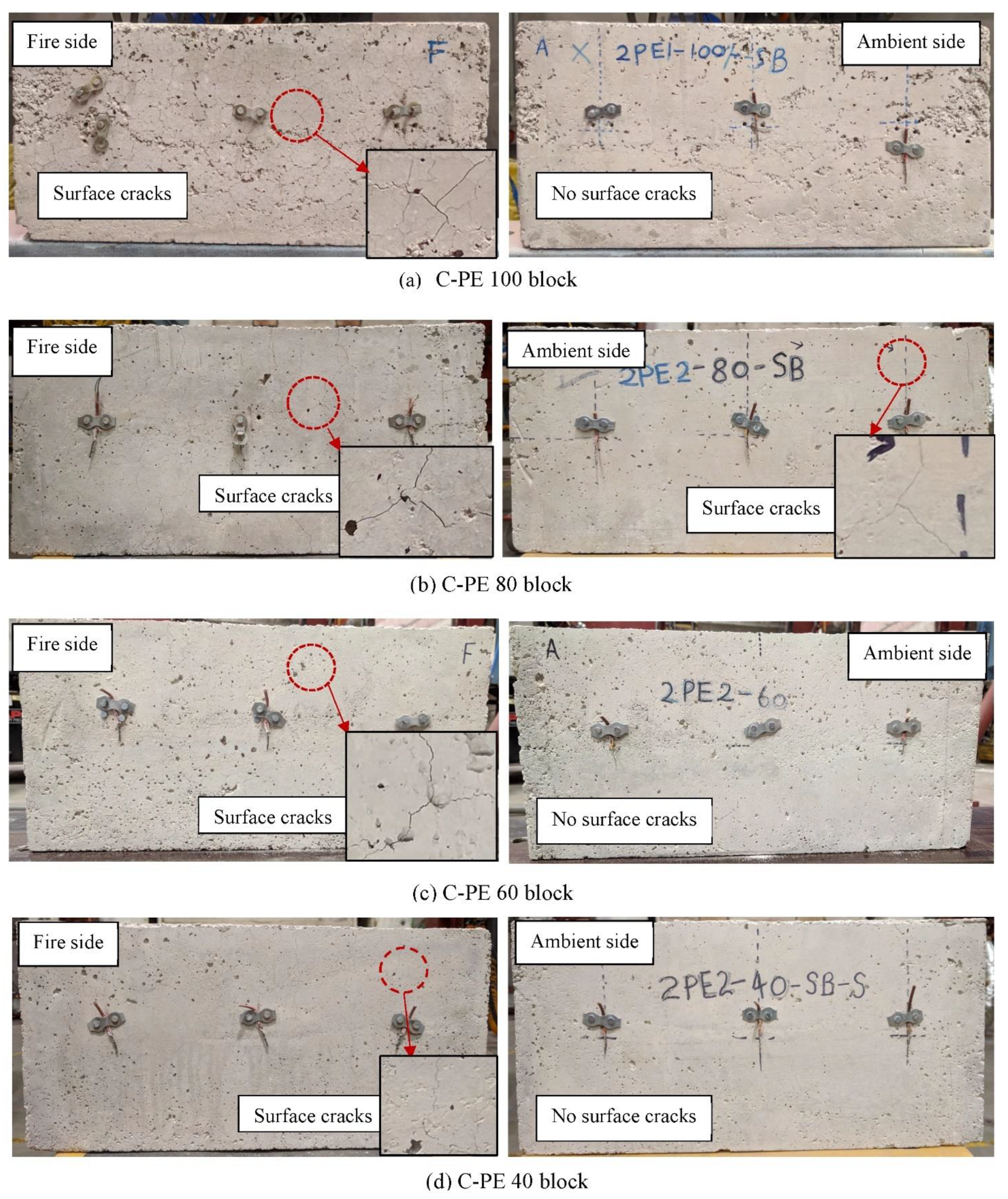

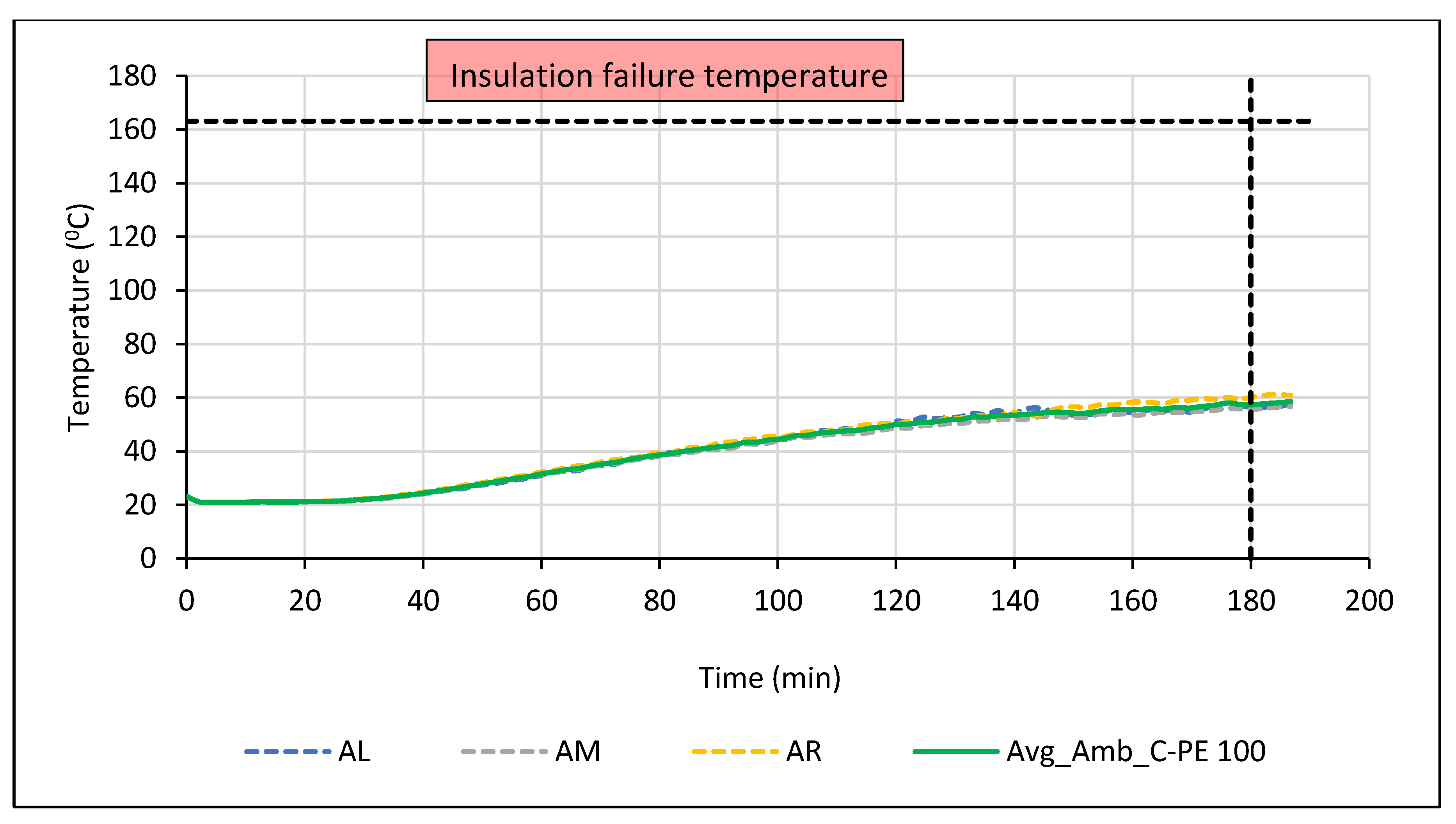

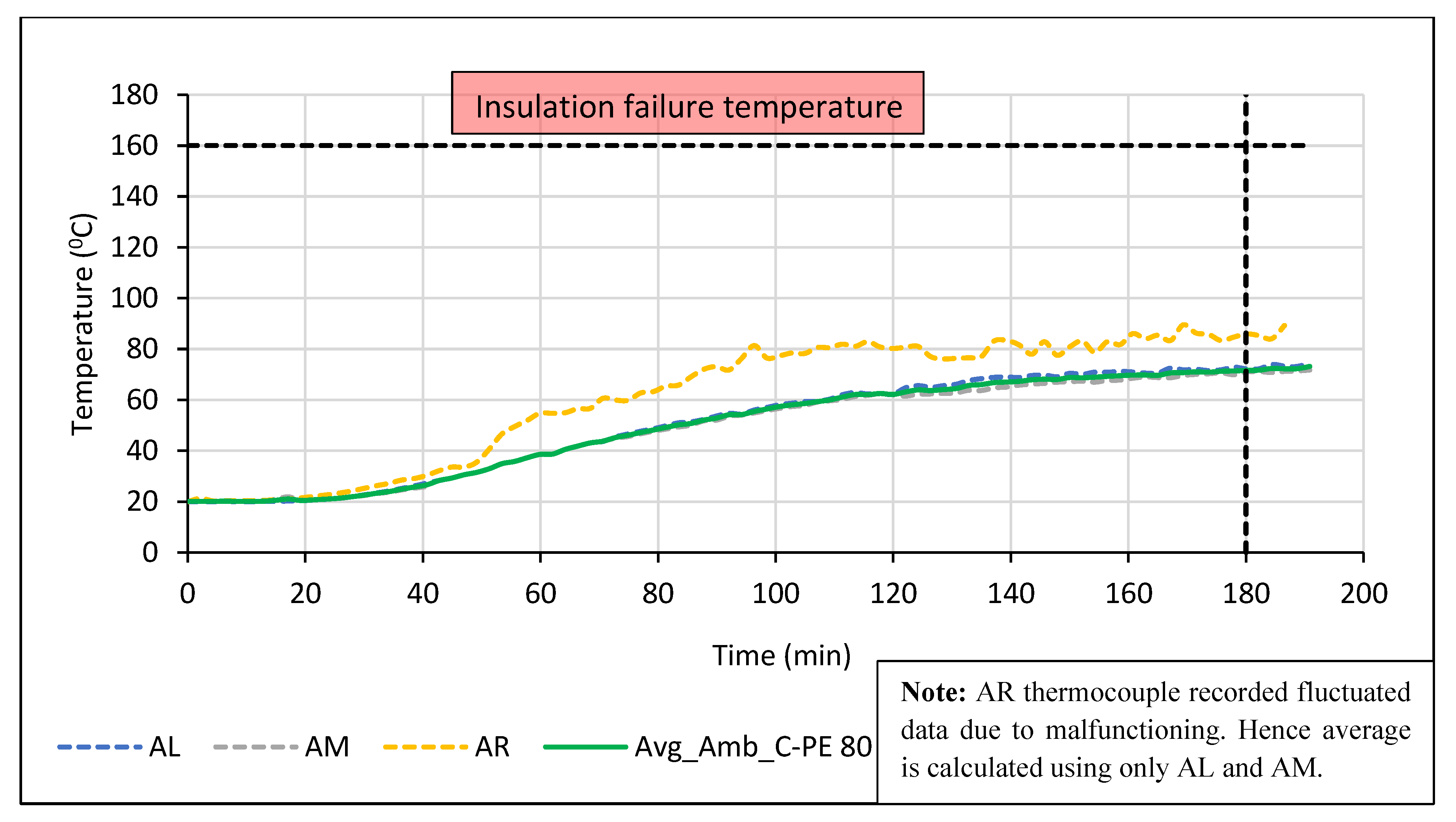

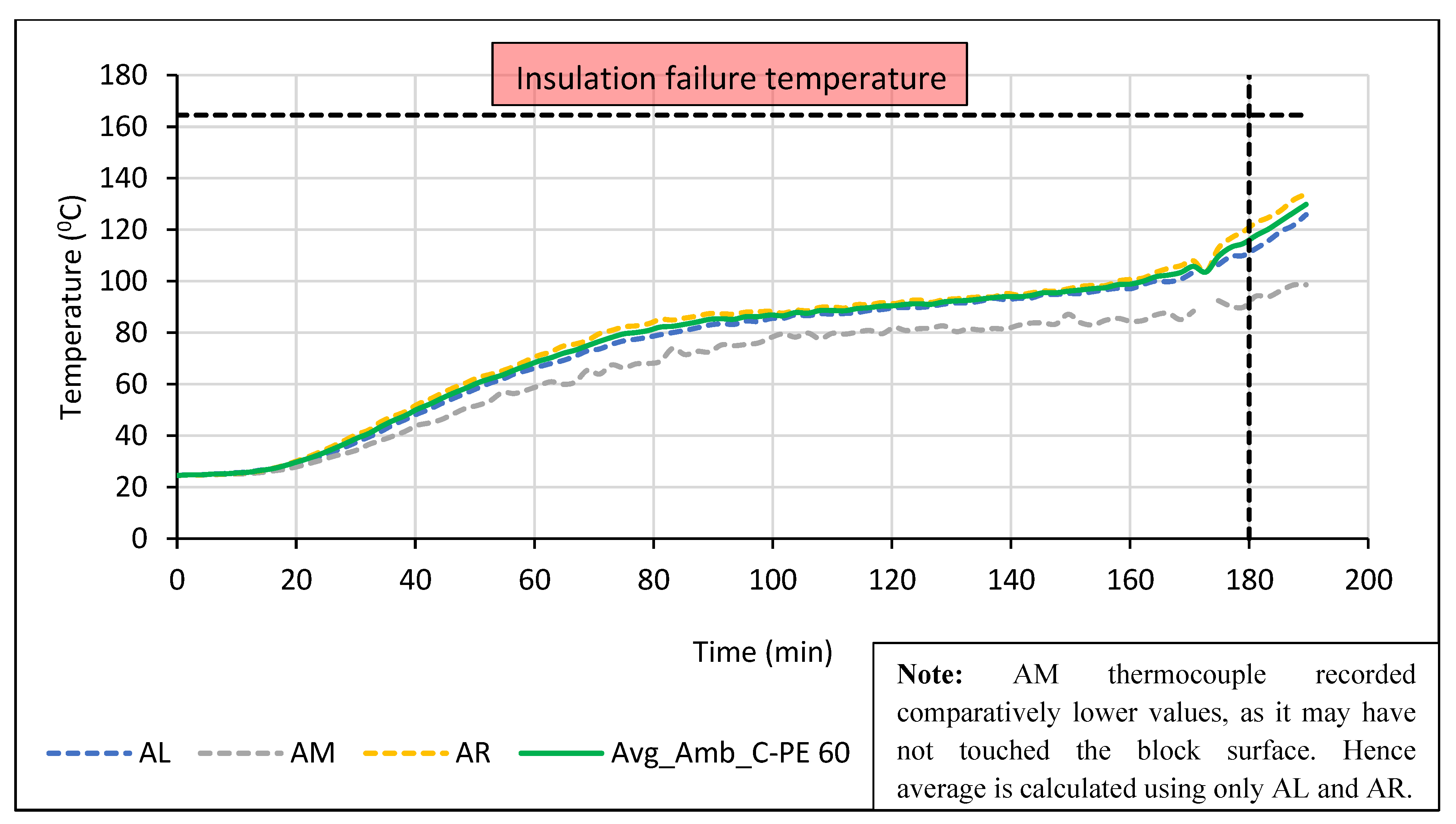

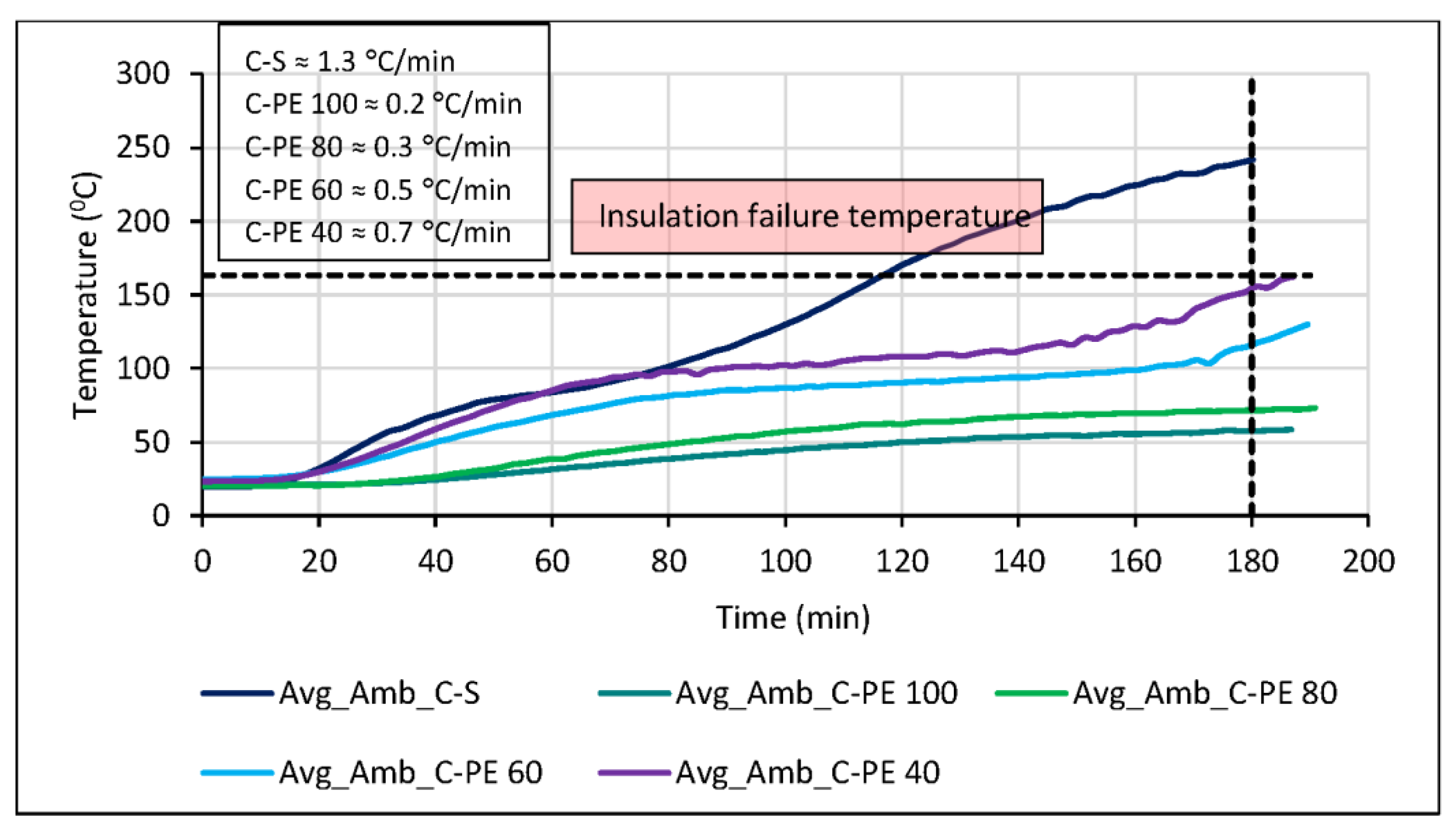

3.2.2. Building Fire Test of C-PE Blocks

4. Discussion

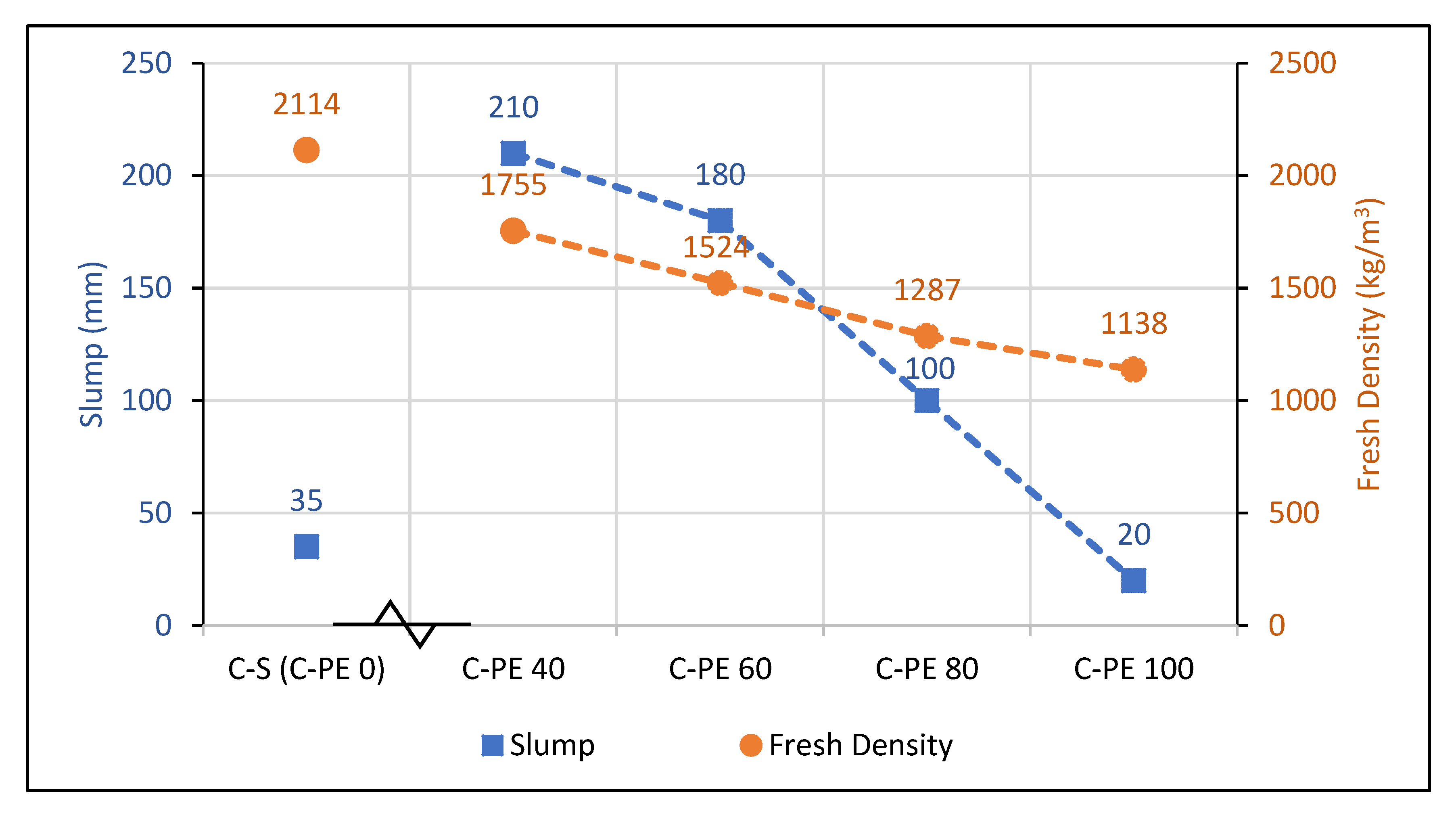

4.1. Properties of Fresh Cement Mixes

4.1.1. Workability

4.1.2. Fresh Density

4.2. Properties of Hardened Cement Mixes

4.2.1. Density

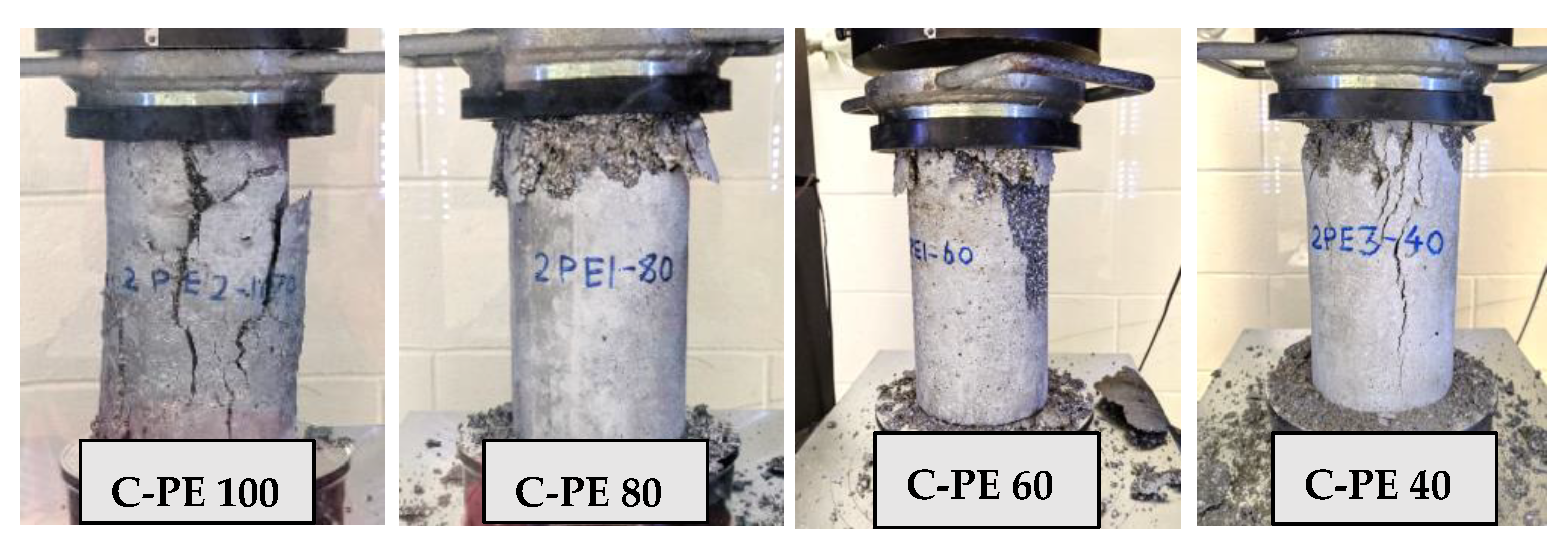

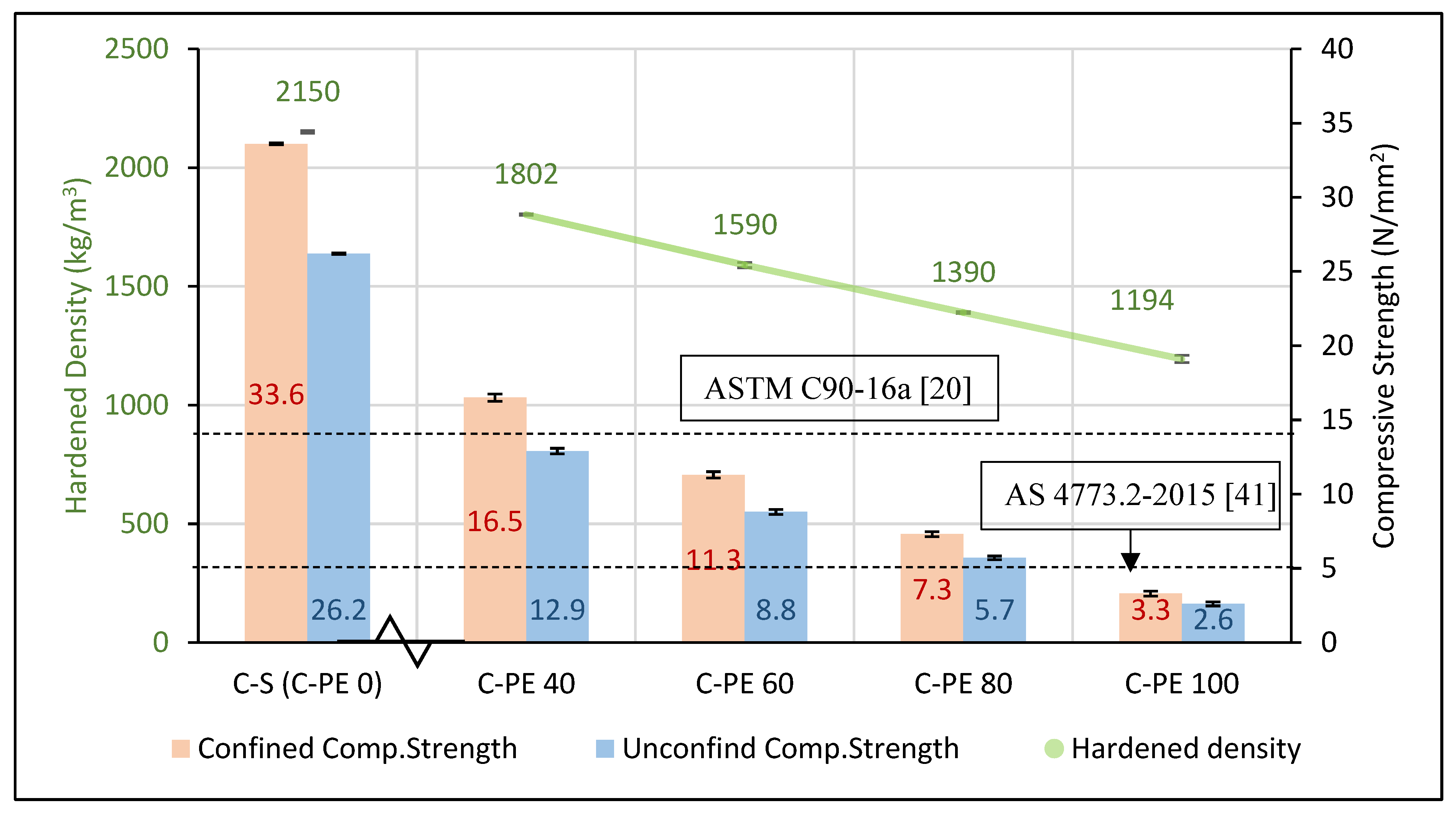

4.2.2. Compressive Strength

4.2.3. Water Absorption

4.2.4. Fire Resistance

Bushfire Resistance

Building Fire Resistance

5. Conclusions

- -

- The Cement–Sand (C-S) mix achieved the highest density and compressive strength and the lowest water absorption.

- -

- C-S masonry blocks reached the bushfire shelter interior surface temperature limit of 70 °C in 30 min and achieved only 90 min (-/90/90) of building fire resistance level.

- -

- All the Cement–Expanded Perlite (C-PE) mixes satisfied the oven dry density requirement for lightweight concrete masonry units, and all except the C-PE 100 mix can be used to produce load-bearing solid masonry units.

- -

- The workability, density, and compressive strength of all the expanded perlite mixes showed a negative correlation with the quantity of expanded perlite aggregate, while water absorption showed a positive correlation.

- -

- The bushfire and building fire resistance of masonry blocks made of cement mixes showed a positive correlation with the quantity of expanded perlite aggregate.

- -

- Considering the bushfire shelter interior surface temperature limit of 70 °C and the crack intensity on the fire and ambient side surfaces of the blocks after the bushfire test, the C-PE 60 block appears to be the most suitable for use in the external walls of bushfire shelters.

- -

- None of the expanded perlite blocks failed the insulation and integrity criteria during three hours of standard fire exposure, i.e., all the expanded perlite blocks had a minimum fire resistance level of three hours (-/180/180).

- -

- Considering its lightweight density, load-bearing strength requirements for solid masonry units, low water absorption level, low ambient side surface temperatures, and low crack intensity after bushfire and building fire exposure, the C-PE 60 block is recommended as the most suitable expanded perlite masonry unit for use in the external walls of bushfire shelters and other buildings in bushfire-prone areas.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| (C-S) | Cement–Sand |

| (C-PE) | Cement–Expanded Perlite |

| (SSD) | Saturated Surface Dry |

| (SEM) | Scanning Electron Microscope |

| (BAL-FZ) | Bushfire Attack Level Flame Zone |

| (FRL) | Fire Resistance Level |

| FL | Fire Left |

| FM | Fire Middle |

| FR | Fire Right |

| AL | Ambient Left |

| AM | Ambient Middle |

| AR | Ambient Right |

| (ABCB) | Australian Building Codes Board |

References

- McLennan, J.; Elliott, G.; Omodei, M.; Whittaker, J. Householders’ safety-related decisions, plans, actions and outcomes during the 7 February 2009 Victorian (Australia) wildfires. Fire Saf. J. 2013, 61, 175–184. [Google Scholar] [CrossRef]

- Stephenson, C. A Literature Review on the Economic, Social and Environmental Impacts of Severe Bushfires in South-Eastern Australia. 2010. Available online: https://www.ffm.vic.gov.au/__data/assets/pdf_file/0009/21114/Report-87-A-Lit.Rvw-On-The-Economic,-Social-and-Envtal-Impacts-of-Severe-Bushfires-In-SE-Aust.pdf (accessed on 22 April 2019).

- McLennan, J.; Paton, D.; Wright, L. At-risk householders’ responses to potential and actual bushfire threat: An analysis of findings from seven Australian post-bushfire interview studies 2009–2014. Int. J. Disaster Risk Reduct. 2015, 12, 319–327. [Google Scholar] [CrossRef]

- Posi, P.; Lertnimoolchai, S.; Sata, V.; Chindaprasirt, P. Pressed lightweight concrete containing calcined diatomite aggregate. Constr. Build. Mater. 2013, 47, 896–901. [Google Scholar] [CrossRef]

- ASTM C332-17; Standard Specification for Lightweight Aggregates for Insulating Concrete. ASTM International: West Conshohocken, PA, USA, 2017.

- Topçu, I.B.; Işikdağ, B. Manufacture of high heat conductivity resistant clay bricks containing perlite. Build. Environ. 2007, 42, 3540–3546. [Google Scholar] [CrossRef]

- Rashad, A.M. A synopsis about perlite as building material—A best practice guide for Civil Engineer. Constr. Build. Mater. 2016, 121, 338–353. [Google Scholar] [CrossRef]

- Demirboğa, R.; Gül, R. The effects of expanded perlite aggregate, silica fume and fly ash on the thermal conductivity of lightweight concrete. Cem. Concr. Res. 2003, 33, 723–727. [Google Scholar] [CrossRef]

- Al-Tamimi, A.S.; Al-Amoudi, O.S.B.; Al-Osta, M.A.; Ali, M.R.; Ahmad, A. Effect of insulation materials and cavity layout on heat transfer of concrete masonry hollow blocks. Constr. Build. Mater. 2020, 254, 119300. [Google Scholar] [CrossRef]

- Sharma, B. Properties of Light Weight Concrete Made with Expanded Perlite and Pumice. Master’s Thesis, Thapar Institute of Engineering & Technology, Punjab, Pakistan, 2019. [Google Scholar]

- Zukowski, M.; Haese, G. Experimental and numerical investigation of a hollow brick filled with perlite insulation. Energy Build. 2010, 42, 1402–1408. [Google Scholar] [CrossRef]

- Bakhtiyari, S.; Allahverdi, A.; Rais-Ghasemi, A.M. A case study on modifying the fire resistance of self-compacting concrete with expanded perlite aggregate and zeolite powder additives. Asian J. Civ. Eng. (BHRC) 2014, 15, 339–349. [Google Scholar]

- Rashad, A.M. Mitigating the Elevated Temperature Effects and Predicting the Residual Strength of Loaded RC Short Columns. Ph.D. Thesis, Structural Engineering, Faculty of Engineering, Cairo University, Cairo, Egypt, 2005. [Google Scholar]

- Hodhod, O.; Rashad, A.; Abdel-Razek, M.; Ragab, A. Coating protection of loaded RC columns to resist elevated temperature. Fire Saf. J. 2009, 44, 241–249. [Google Scholar] [CrossRef]

- Ariyaratne, I.E.; Ariyanayagam, A.D.; Mahendran, M. Lightweight Masonry Blocks with Expanded Perlite Aggregate for Bushfire Resistance. In Proceedings of the Australasian Structural Engineering Conference, Online, 11–13 November 2020. [Google Scholar]

- ASTM C188-17; Standard Test Method for Density of Hydraulic Cement. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM C109/C109M-16a; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens). ASTM International: West Conshohocken, PA, USA, 2016.

- AS 1141.5-2000; Method for Sampling and Testing Aggregates—Particle Density and Water Absorption of Fine Aggregate. Standards Australia Limited: Sydney, Australia, 2000.

- AS 1141.4-2000; Methods for Sampling and Testing Aggregates—Bulk Density of Aggregate. Standards Australia Limited: Sydney, Australia, 2000.

- ASTM C90-16a; Standard Specification for Loadbearing Concrete Masonry Units. ASTM International: West Conshohocken, PA, USA, 2016.

- AS 1012.2-2014; Methods of Testing Concrete—Preparing Concrete Mixes in the Laboratory. Standards Australia Limited: Sydney, Australia, 2014.

- AS 1012.8.1-2014; Methods of Testing Concrete—Method for Making and Curing Concrete—Compression and Indirect Tensile Test Specimens. Standards Australia Limited: Sydney, Australia, 2014.

- ASTM C192/C192M-18; Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory. ASTM International: West Conshohocken, PA, USA, 2018.

- AS 1012.3.1-2014; Methods of Testing Concrete—Determination of Properties Related to the Consistency of Concrete—Slump Test. Standards Australia Limited: Sydney, Australia, 2014.

- ASTM C143/C143M-15a; Standard Test Method for Slump of Hydraulic-Cement Concrete. ASTM International: West Conshohocken, PA, USA, 2015.

- AS 1012.5-2014; Methods of Testing Concrete—Determination of Mass per Unit Volume of Freshly Mixed Concrete. Standards Australia Limited: Sydney, Australia, 2014.

- ASTM C138/C138M-17a; Standard Test Method for Density (Unit Weight), Yield, and Air Content (Gravimetric) of Concrete. ASTM International: West Conshohocken, PA, USA, 2017.

- AS 1012.9-2014; Methods of Testing Concrete—Compressive Strength Tests—Concrete, Mortar and Grout Specimens. Standards Australia Limited: Sydney, Australia, 2014.

- ASTM C39/C39M-18; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM C617/C617M-15; Standard Practice for Capping Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2015.

- AS/NZS 4456.4-2003; Masonry Units, Segmental Pavers and Flags—Methods of Test—Determining Compressive Strength of Masonry Units. Standards Australia Limited: Sydney, Australia, 2003.

- ASTM C567/C567M-14; Standard Test Method for Determining Density of Structural Lightweight Concrete. ASTM International: West Conshohocken, PA, USA, 2014.

- AS 1012.12.1-1998; Methods of Testing Concrete—Determination of Mass per Unit Volume of Hardened Concrete—Rapid Measuring Method. Standards Australia Limited: Sydney, Australia, 1998.

- AS/NZS 4456.14-2003; Masonry Units, Segmental Pavers and Flags—Methods of Test—Determining Water Absorption Properties. Standards Australia Limited: Sydney, Australia, 2003.

- ASTM C140/C140M-18a; Standard Test Methods for Sampling and Testing Concrete Masonry Units and Related Units. ASTM International: West Conshohocken, PA, USA, 2018.

- AS 1530.8.2-2018; Methods for Fire Tests on Building Materials, Components and Structures: Tests on Elements of Construction for Buildings Exposed to Simulated Bushfire Attack—Large Flaming Sources. Standards Australia Limited: Sydney, Australia, 2018.

- AS 1530.4-2014; Methods for Fire Tests on Building Materials, Components and Structures: Fire Resistance Tests for Elements of Construction. Standards Australia Limited: Sydney, Australia, 2014.

- Hager, I. Colour Change in Heated Concrete. Fire Technol. 2014, 50, 945–958. [Google Scholar] [CrossRef] [Green Version]

- Ali, M.; Maslehuddin, M.; Shameem, M.; Barry, M. Thermal-resistant lightweight concrete with polyethylene beads as coarse aggregates. Constr. Build. Mater. 2018, 164, 739–749. [Google Scholar] [CrossRef]

- Yao, X.; Wang, W.; Liu, M.; Yao, Y.; Wu, S. Synergistic use of industrial solid waste mixtures to prepare ready-to-use lightweight porous concrete. J. Clean. Prod. 2018, 211, 1034–1043. [Google Scholar] [CrossRef]

- AS 4773.2-2015; Masonry in Small Buildings—Construction. Standards Australia Limited: Sydney, Australia, 2015.

- Bastos, A.M.; Sousa, H.; Melo, A.F. Methodology for the Design of Lightweight Concrete with Expanded Clay Aggregates. TMS J. 2005, 73–84. [Google Scholar]

- Canberra ACT 2601; The Design and Construction of Private Bushfire Shelters. Australian Building Codes Board: Canberra, Australia, 2014.

| Fe2O3 | Mn3O4 | TiO2 | CaO | K2O | SO3 | SiO2 | Al2O3 | MgO | Na2O | LOI | Others | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cement | 3.294 | 0.146 | 0.251 | 62.792 | 0.657 | 2.32 | 19.401 | 4.329 | 3.108 | 0.108 | 3.08 | 0.514 |

| Expanded perlite | 0.918 | 0.061 | 0.119 | 0.899 | 3.443 | 0.011 | 73.497 | 12.059 | 0.133 | 3.902 | 3.22 | 1.738 |

| Material | C-S (C-PE 0) | C-PE 100 | C-PE 80 | C-PE 60 | C-PE 40 |

|---|---|---|---|---|---|

| Cement (kg/m3) | 478.0 | 480.2 | 480.2 | 467.7 | 467.7 |

| Sand (kg/m3) | 1380.1 | 0 | 275.0 | 561.8 | 842.7 |

| Expanded Perlite (kg/m3) | 0 | 390.5 | 312.4 | 239.4 | 159.6 |

| Effective Water (kg/m3) | 286.8 | 288.1 | 288.1 | 280.6 | 280.6 |

| Fresh Density (kg/m3) | 2145 | 1159 | 1356 | 1550 | 1751 |

| Test | Specimen Dimensions |

|---|---|

| L: Length, W: Width, H: Height, Ø: Diameter | |

| Compressive strength | Cylinder (100 mm Ø × 200 mm H) |

| Hardened density | Cylinder (100 mm Ø × 200 mm H) |

| Oven dry density | Cylinder (150 mm Ø × 300 mm H) |

| Water absorption | Cylinder slices (100 mm Ø × 50 mm H) |

| Fire resistance | Solid block (390 mm L × 90 mm W × 190 mm H) |

| Mix | Slump (mm) | Fresh Density (kg/m3) | Compressive Strength (N/mm2) | Hardened Density (kg/m3) | Oven Dry Density (kg/m3) | Water Absorption % (kg/m3) | Insulation Failure Time (min) |

|---|---|---|---|---|---|---|---|

| C-S | 35 | 2114 Average | 33.5 33.7 33.7 33.6 | 2143 2161 2147 2150 | - | 9.3 (181) 8.6 (172) 9.1 (181) 9.0 (178) 9.0 (178) | 115 |

| C-PE 100 | 20 | 1138 | 3.3 3.0 3.6 | 1224 1187 1171 | Less than 1458 | 49.6 (403) 51.6 (414) 50.2 (400) 52.2 (407) | >180 |

| Average | 3.3 | 1194 | 50.9 (406) | ||||

| C-PE 80 | 100 | 1287 | 7.1 7.2 7.6 | 1384 1395 1392 | Less than 1458 | 34.4 (356) 32.4 (348) 30.3 (337) 35.5 (358) | >180 |

| Average | 7.3 | 1390 | 33.2 (350) | ||||

| C-PE 60 | 180 | 1524 | 11.2 11.0 11.7 | 1571 1591 1609 | Less than 1458 | 20.9 (280) 22.9 (295) 23.9 (301) 23.4 (298) | >180 |

| Average | 11.3 | 1590 | 22.8 (294) | ||||

| C-PE 40 | 210 | 1755 | 16.1 16.7 16.9 | 1802 1797 1808 | 1458 | 15.1 (236) 16.8 (256) 16.8 (257) 17.3 (262) | >180 |

| Average | 16.5 | 1802 | 16.5 (253) |

| Performance Criteria | C-S | C-PE 100 | C-PE 80 | C-PE 60 | C-PE 40 | |

|---|---|---|---|---|---|---|

| A crack from the fire side face to the ambient side face greater than 3 mm | No | No | No | No | No | |

| Combustibility | No | No | No | No | No | |

| Initial avg. ambient side temperature (°C) | 20 | 24 | 15 | 30 | 18 | |

| Initial avg. ambient side temperature at the end of heating phase (°C) [Rise in avg. ambient side temperature during the heating phase * (°C)] | 71 [51 *] | 29 [5 *] | 23 [8 *] | 41 [11 *] | 56 [38 *] | |

| Maximum of the avg. ambient side temperature for the duration of 90 min (°C) [Maximum rise of the avg. ambient side temperature for the duration of 90 min *(°C)] | 89 [69 *] | 45 [21 *] | 48 [33 *] | 65 [35 *] | 79 [61 *] | |

| Avg. ambient side temperature at the end of cooling phase (°C) | 76 | 44 | 47 | 62 | 67 | |

| Surface cracks on | Fire side | Yes | Yes | Yes | Yes | Yes |

| Ambient side | No | No | Yes | No | No | |

| Top | Yes | No | Yes | Yes | Yes | |

| Bottom | Yes | Yes | Yes | Yes | Yes | |

| Sides | Yes | Yes | Yes | Yes | Yes | |

| Surface discoloration | Yes | Yes | Yes | Yes | Yes | |

| Performance Criteria | C-S | C-PE 100 | C-PE 80 | C-PE 60 | C-PE 40 | |

|---|---|---|---|---|---|---|

| Any specific observations during the fire test | Spalling & moisture | No | No | No | No | |

| Avg. fire side temperature at the end of three hours of fire exposure (°C) [Rise in avg. fire side temperature * (°C)] | 1094 [1074 *] | 1061 [1038 *] | 1105 [1085 *] | 1098 [1074 *] | 1080 [1057 *] | |

| Avg. ambient side temperature at the end of three hours of fire exposure (°C) [Rise in avg. ambient side temperature * (°C)] | 242 [222 *] | 57 [34 *] | 72 [52 *] | 118 [93 *] | 156 [133 *] | |

| A crack from the fire side face to the ambient side face greater than 3 mm | No | No | No | No | No | |

| Insulation failure (min) | 115 | >180 | >180 | >180 | >180 | |

| Fire resistance level (FRL) | -/90/90 | -/180/180 | -/180/180 | -/180/180 | -/180/180 | |

| Surface cracks on | Fire side | Yes | Yes | Yes | Yes | Yes |

| Ambient side | Yes | No | Yes | No | No | |

| Top | Yes | Yes | Yes | Yes | Yes | |

| Bottom | Yes | Yes | Yes | Yes | Yes | |

| Sides | Yes | Yes | Yes | Yes | Yes | |

| Surface discolouration | Yes (whitish colour) | Yes (whitish colour) | Yes (whitish colour) | Yes (whitish colour) | Yes (whitish colour) | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ariyaratne, I.E.; Ariyanayagam, A.; Mahendran, M. Bushfire-Resistant Lightweight Masonry Blocks with Expanded Perlite Aggregate. Fire 2022, 5, 132. https://doi.org/10.3390/fire5050132

Ariyaratne IE, Ariyanayagam A, Mahendran M. Bushfire-Resistant Lightweight Masonry Blocks with Expanded Perlite Aggregate. Fire. 2022; 5(5):132. https://doi.org/10.3390/fire5050132

Chicago/Turabian StyleAriyaratne, Indunil Erandi, Anthony Ariyanayagam, and Mahen Mahendran. 2022. "Bushfire-Resistant Lightweight Masonry Blocks with Expanded Perlite Aggregate" Fire 5, no. 5: 132. https://doi.org/10.3390/fire5050132

APA StyleAriyaratne, I. E., Ariyanayagam, A., & Mahendran, M. (2022). Bushfire-Resistant Lightweight Masonry Blocks with Expanded Perlite Aggregate. Fire, 5(5), 132. https://doi.org/10.3390/fire5050132