A Laboratory-Scale Study of Selected Chinese Typical Flammable Wildland Timbers Ignition Formation Mechanism

Abstract

:1. Introduction

1.1. Background of Chinese Forest Fire and Firebrand Simulation

1.2. Experiments and Literature Review

2. Experiment Design and Method

2.1. Timber Species Selection

2.2. Experiment Design

- Select appropriate representative flammable wildland fuels in typical waste types in China as specimens for this study;

- Conduct an experimental study to measure and control the moisture content of selected agricultural fuels at the project MC level;

- Carry out TGA experiment and follow-up data analysis to obtain three preset MC levels and choose off-road fuel at the three preset levels. The main parameter of thermal decomposition rate is set below the heating rate;

- Conduct cone calorimeter experiments and subsequent data analysis in order to obtain basic flammability properties of the selected wildland fuels at the three predetermined MC levels and three pre-determined heat-flux levels.

2.3. Experiment Method

- (1)

- Thermal property (TP) as a function of fuel type (FT), wildland property (SP), and MC, represented as ;

- (2)

- Flammability property (FP) as a function of FT, SP, and MC, represented as ;

- (3)

- The relationship between functions and .

3. Results and Discussions

3.1. Data Analysis

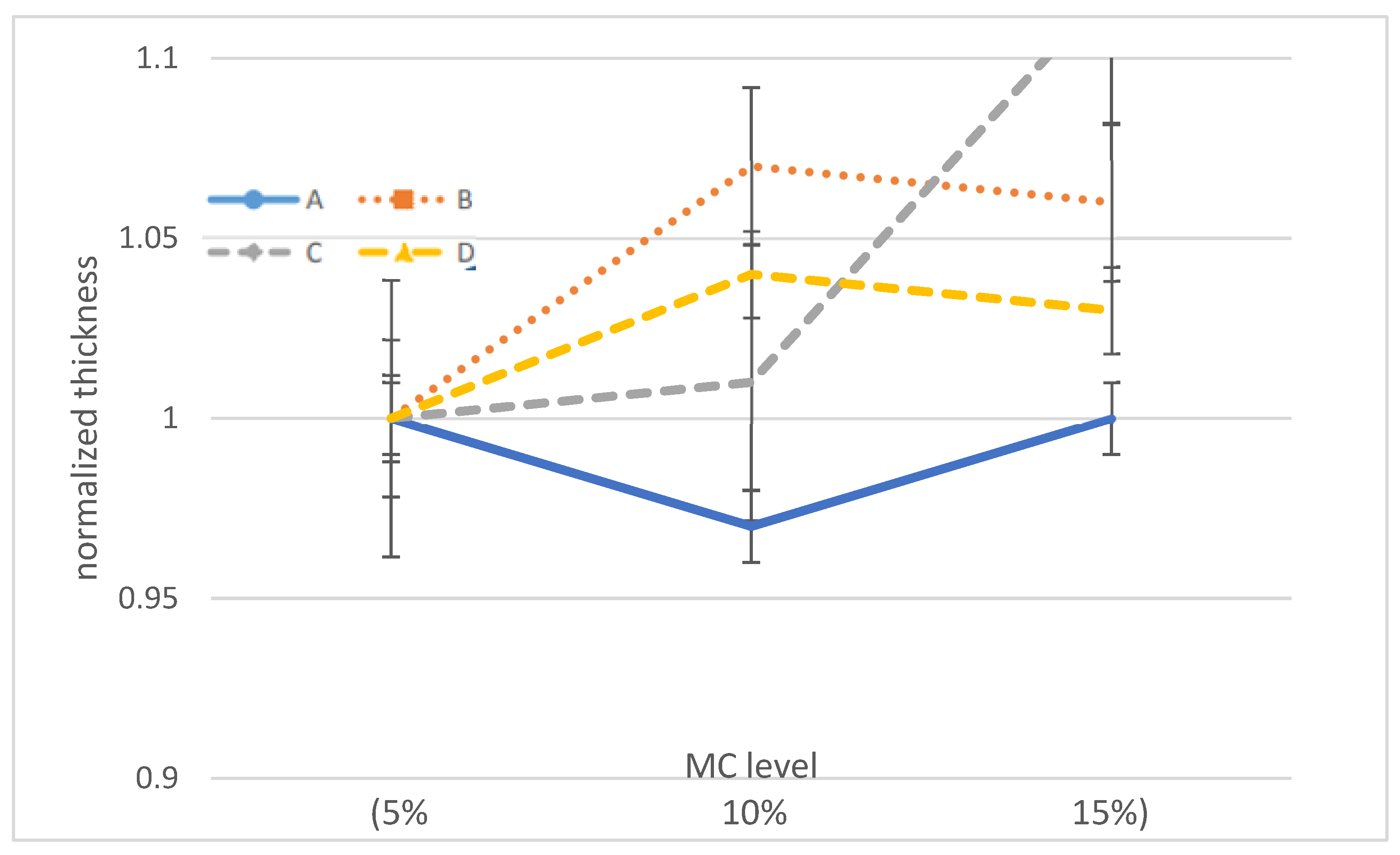

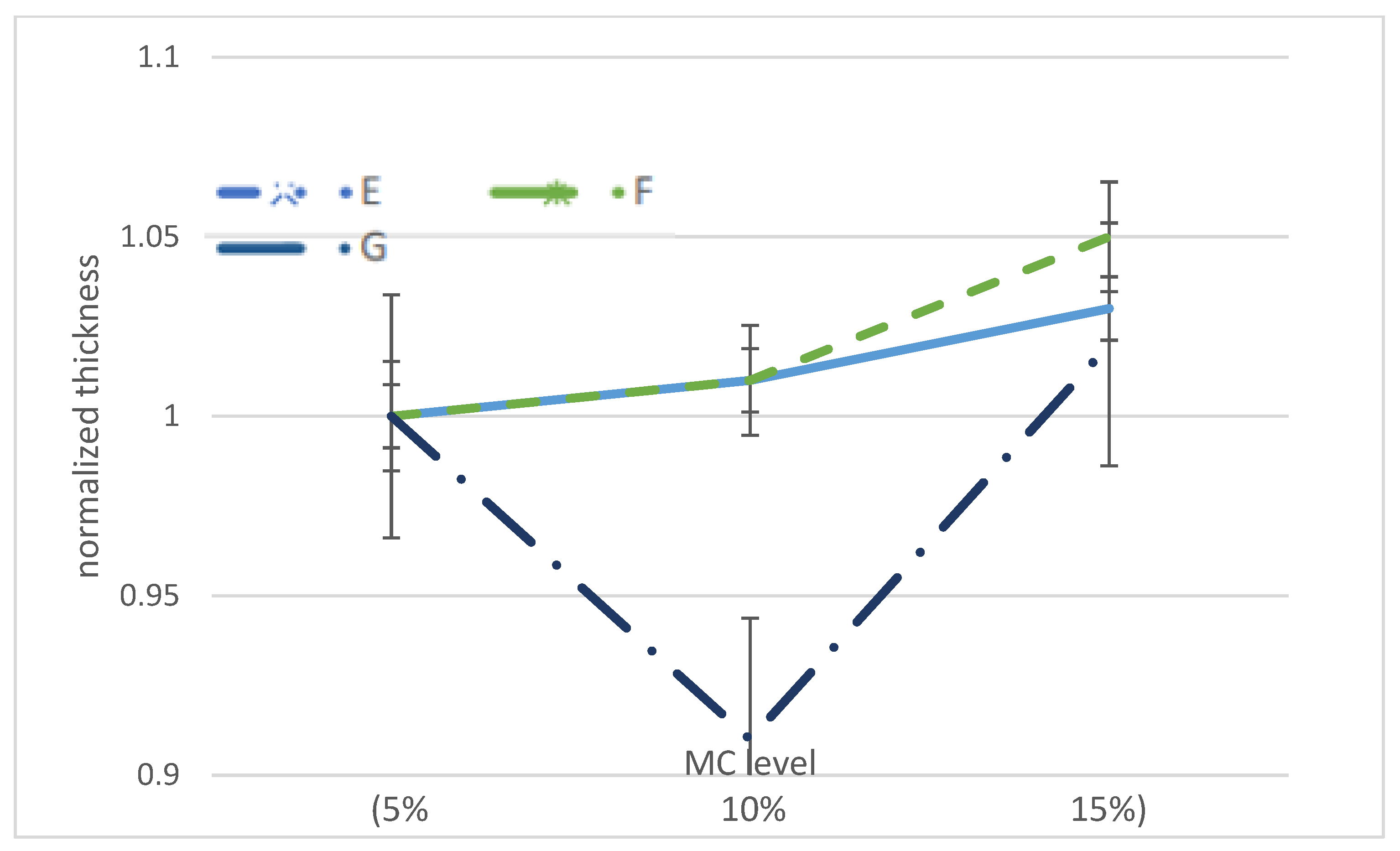

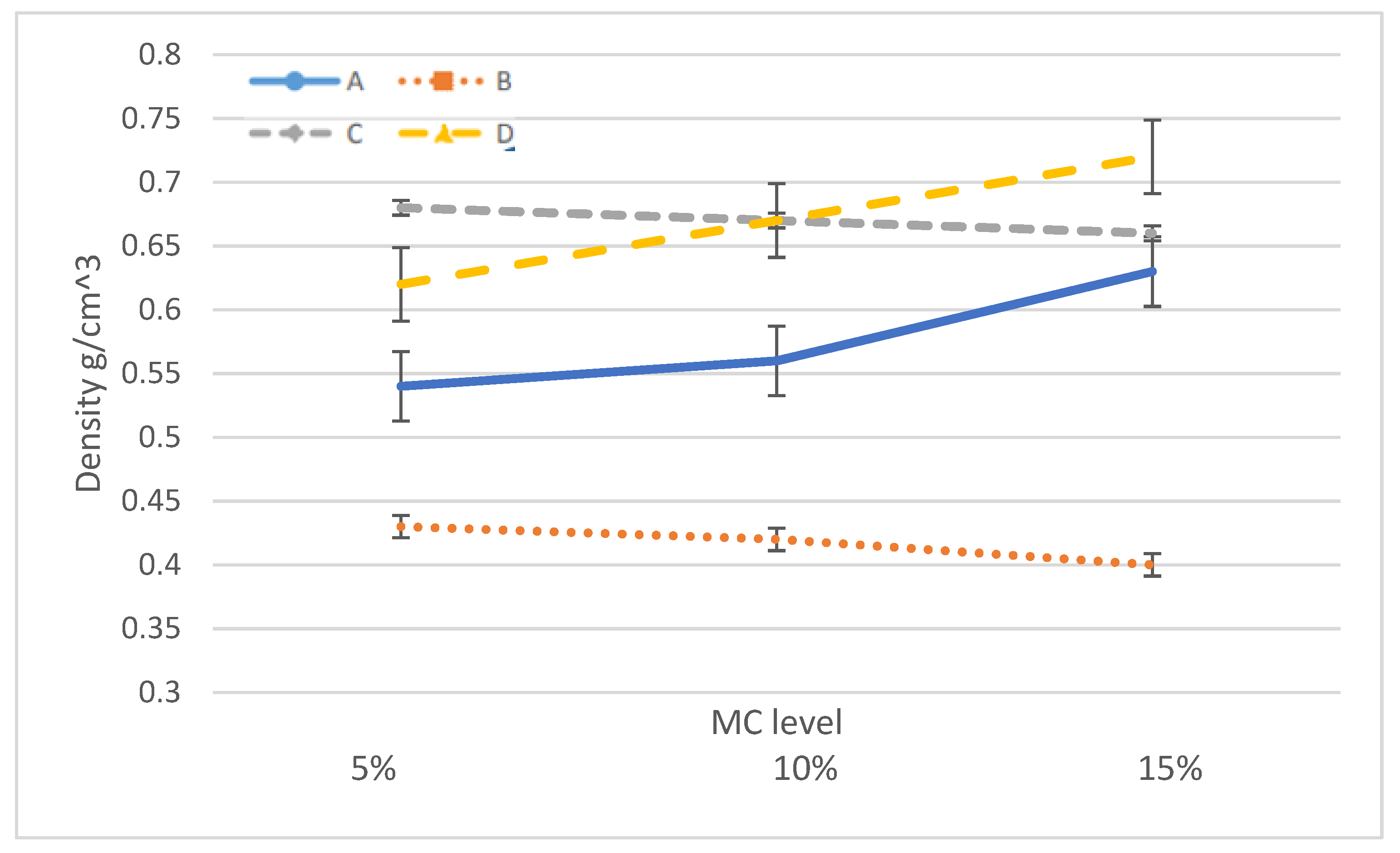

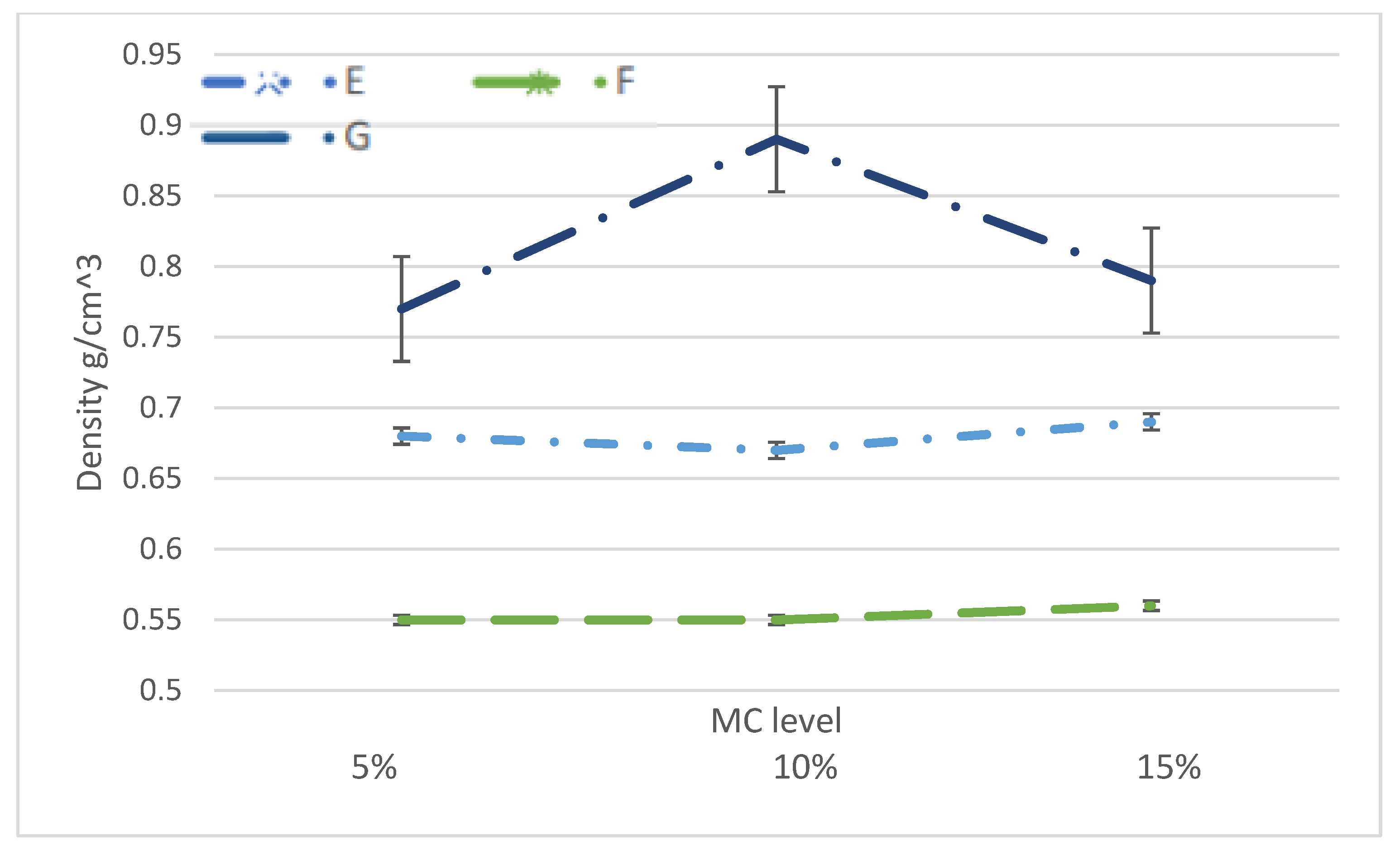

3.1.1. Fuel Properties

3.1.2. Pyrolysis Properties

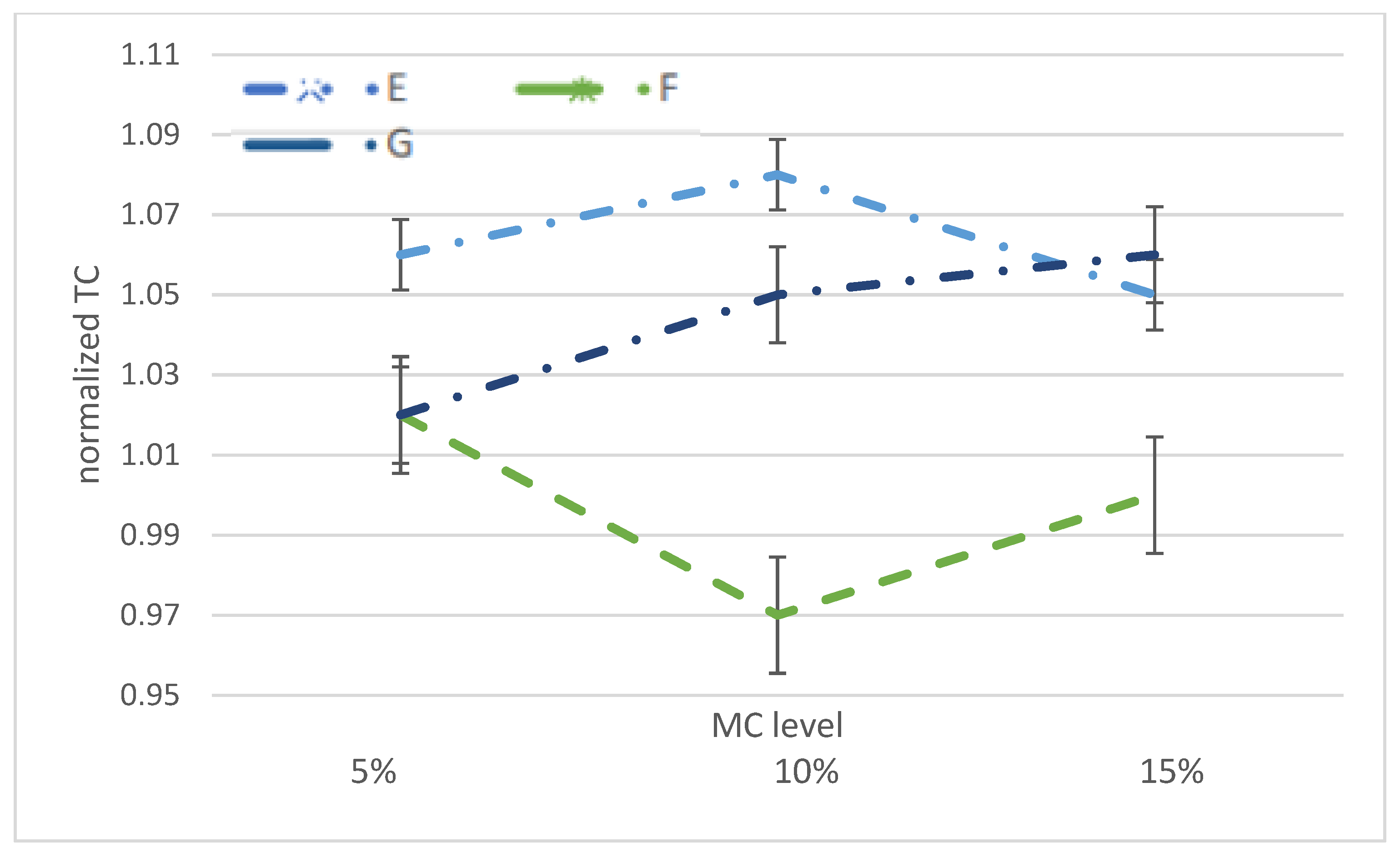

Thermal Conductivity

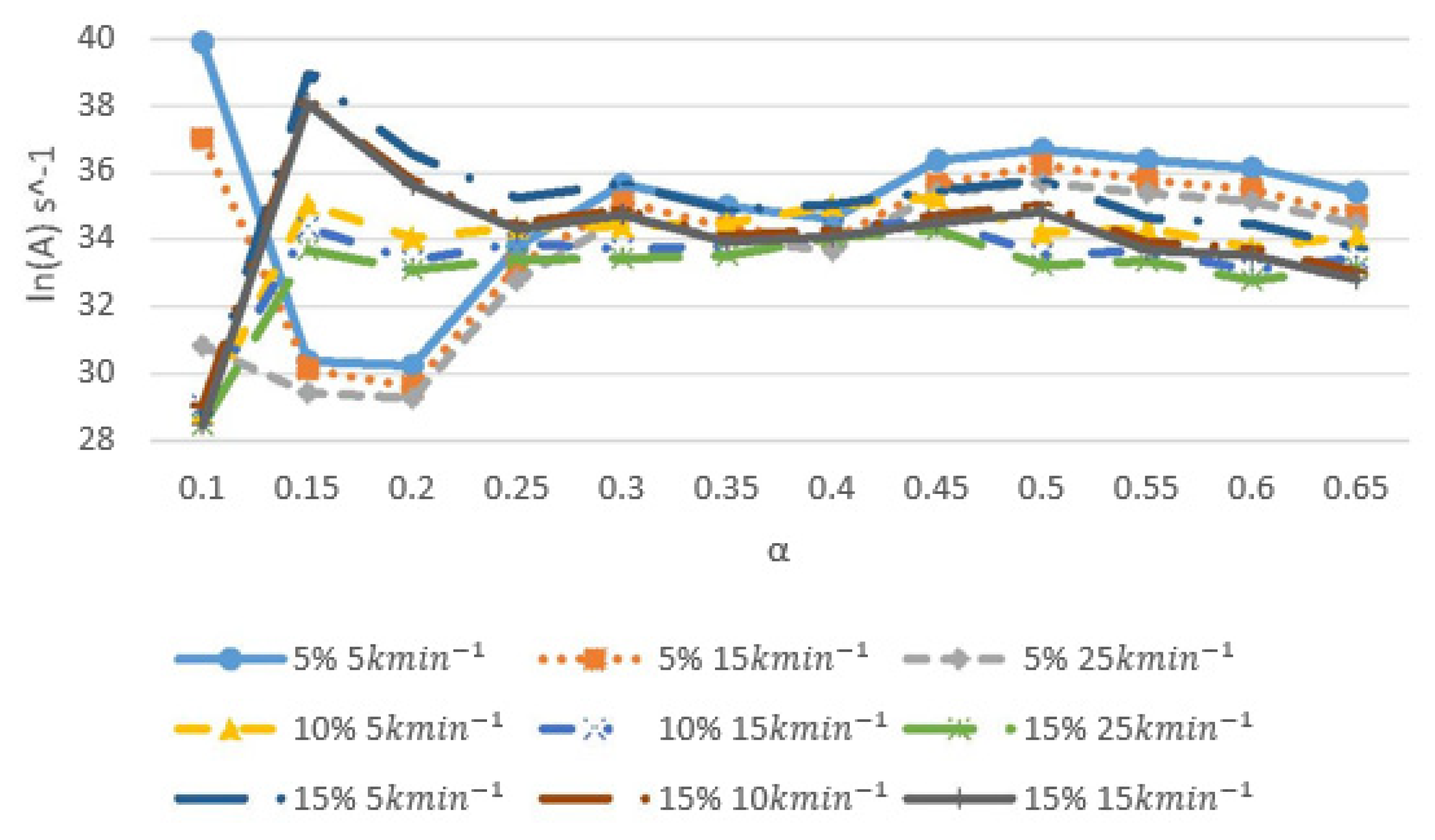

Pre-Exponential Factor (A)

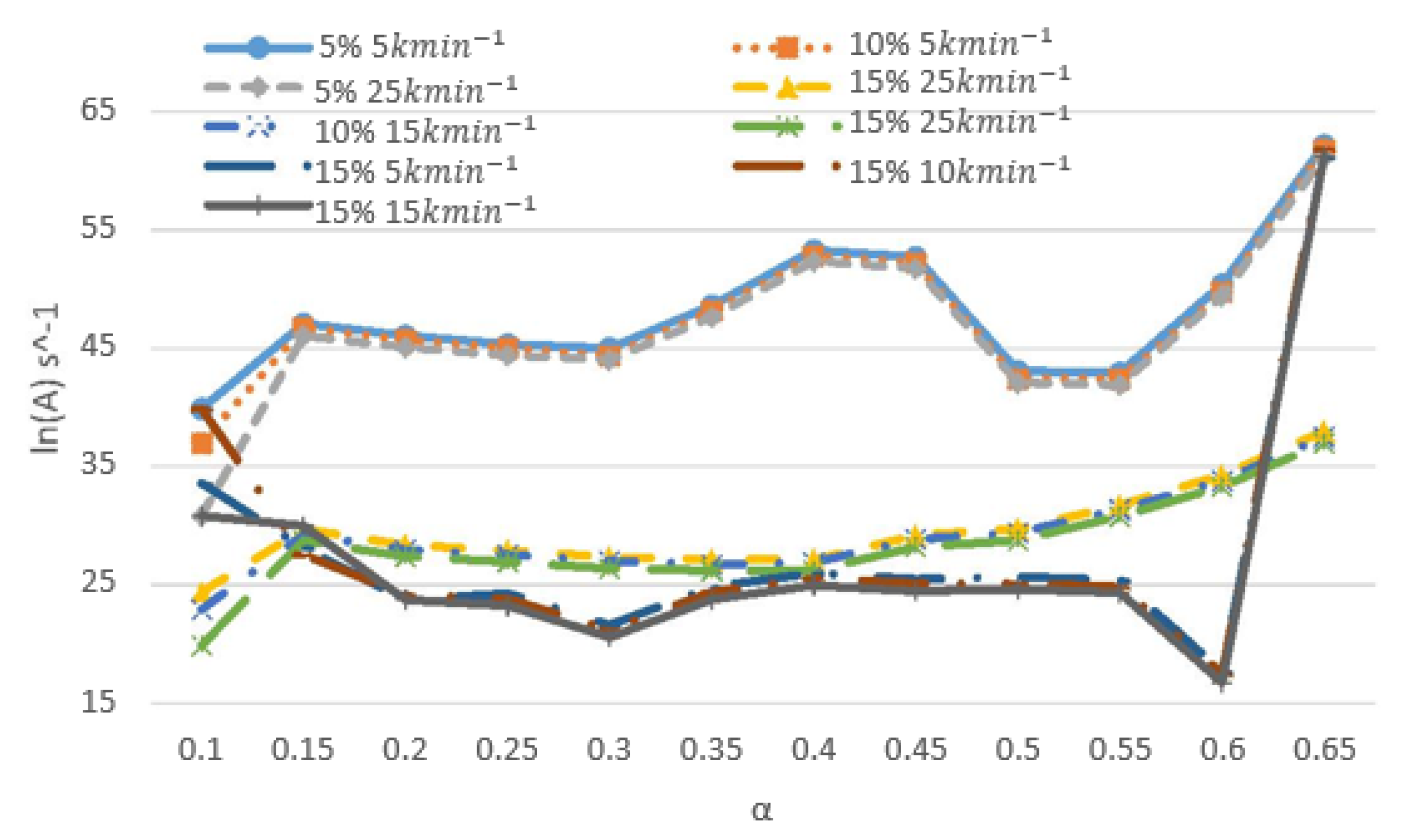

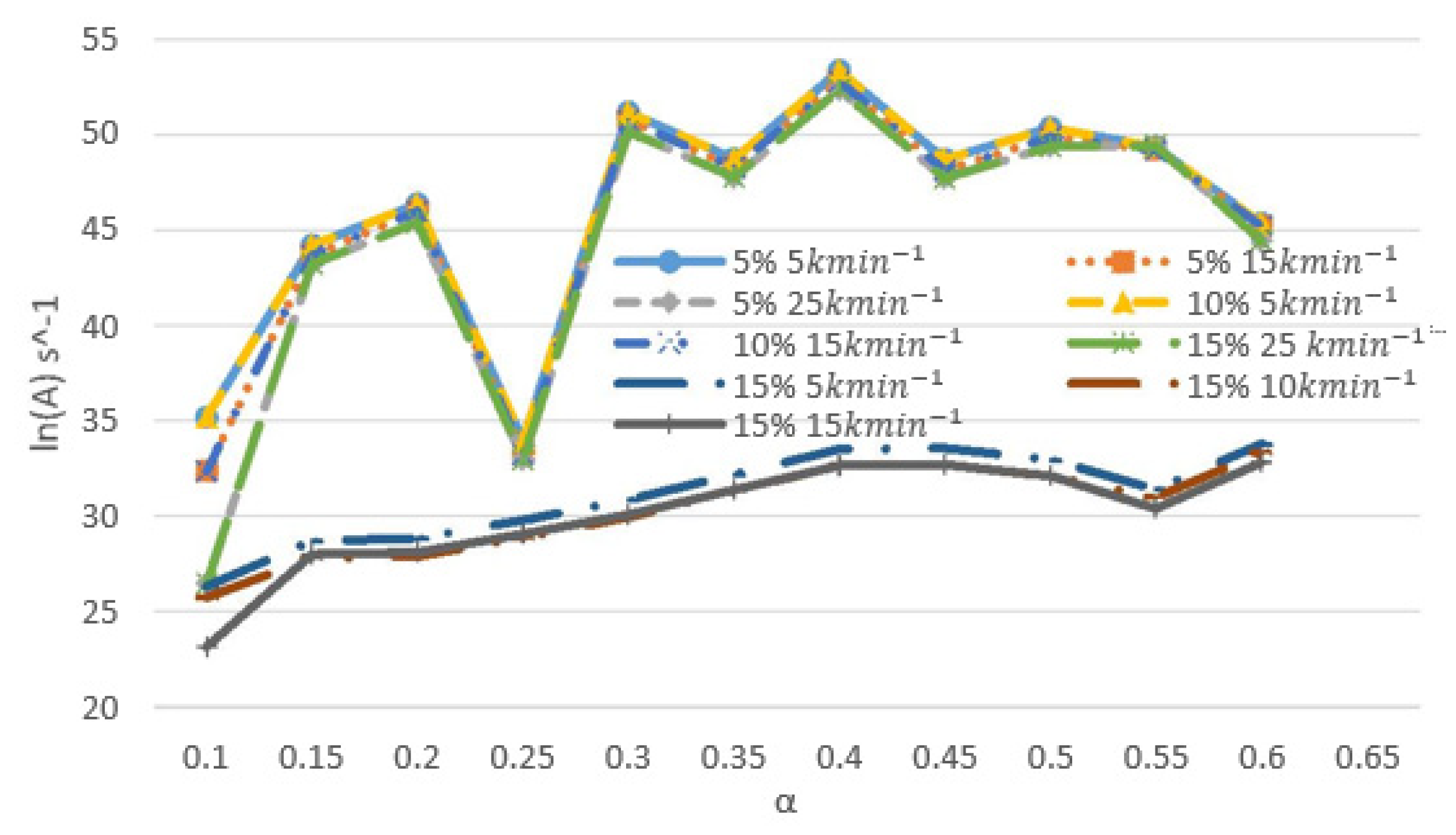

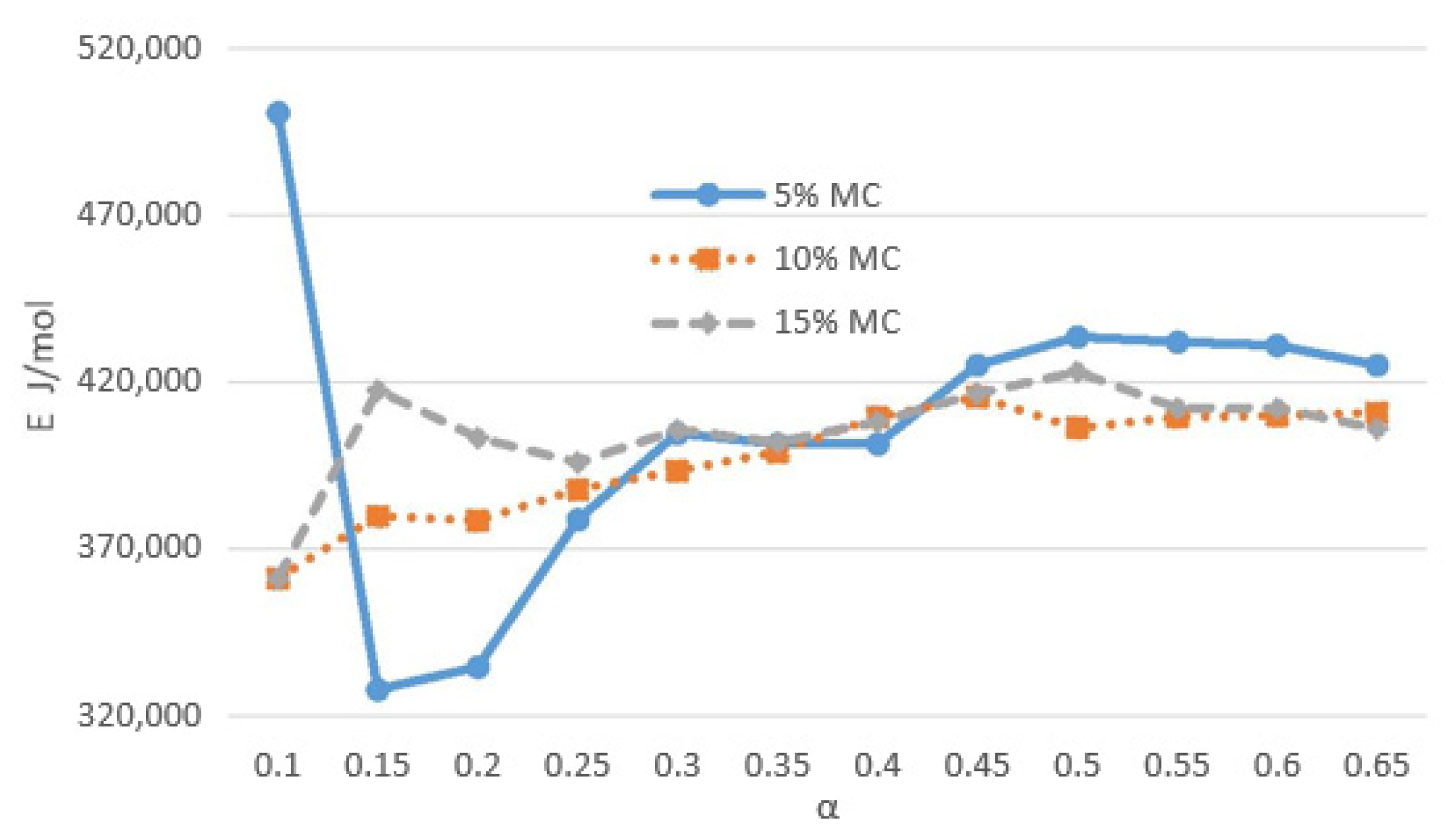

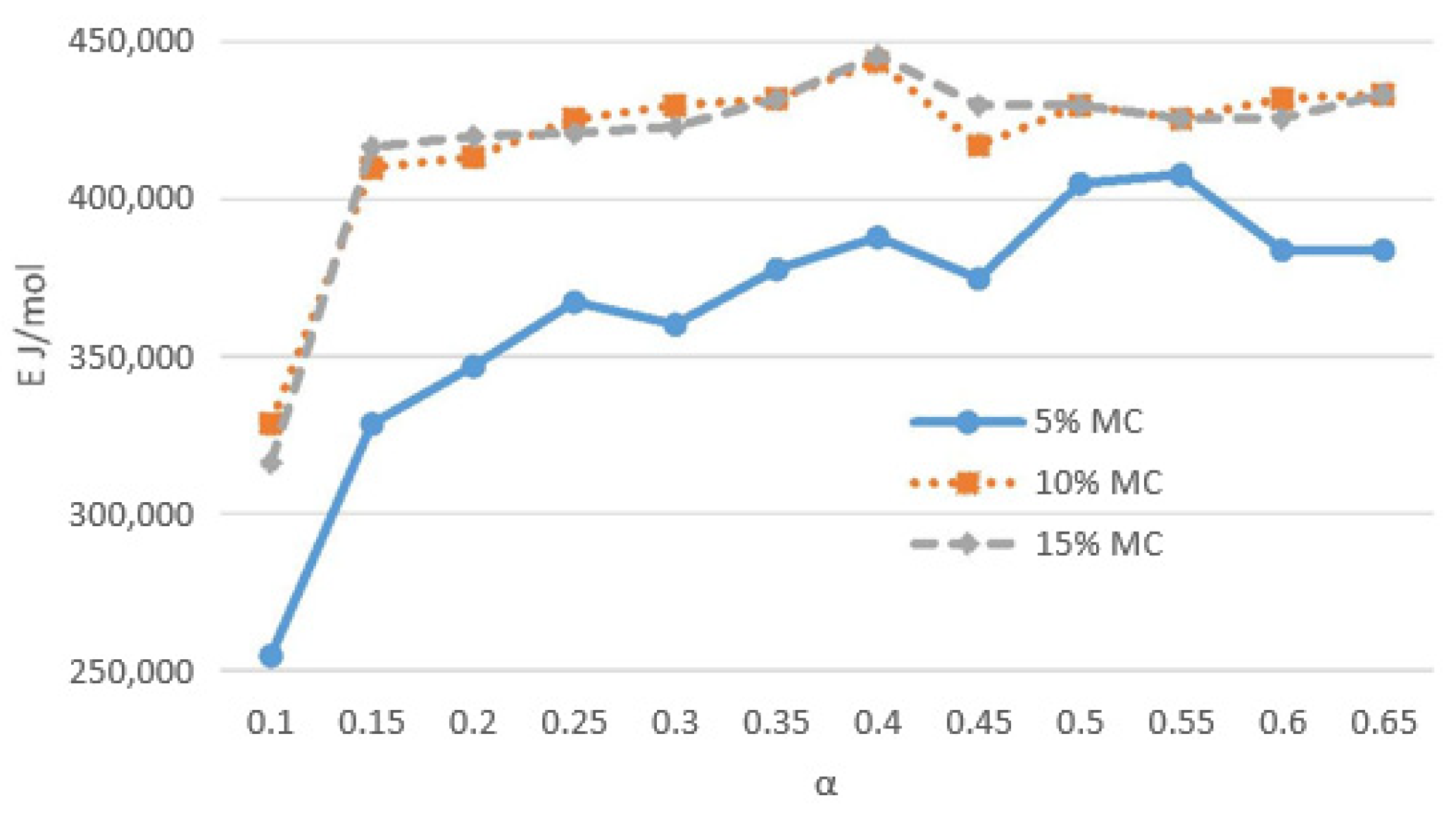

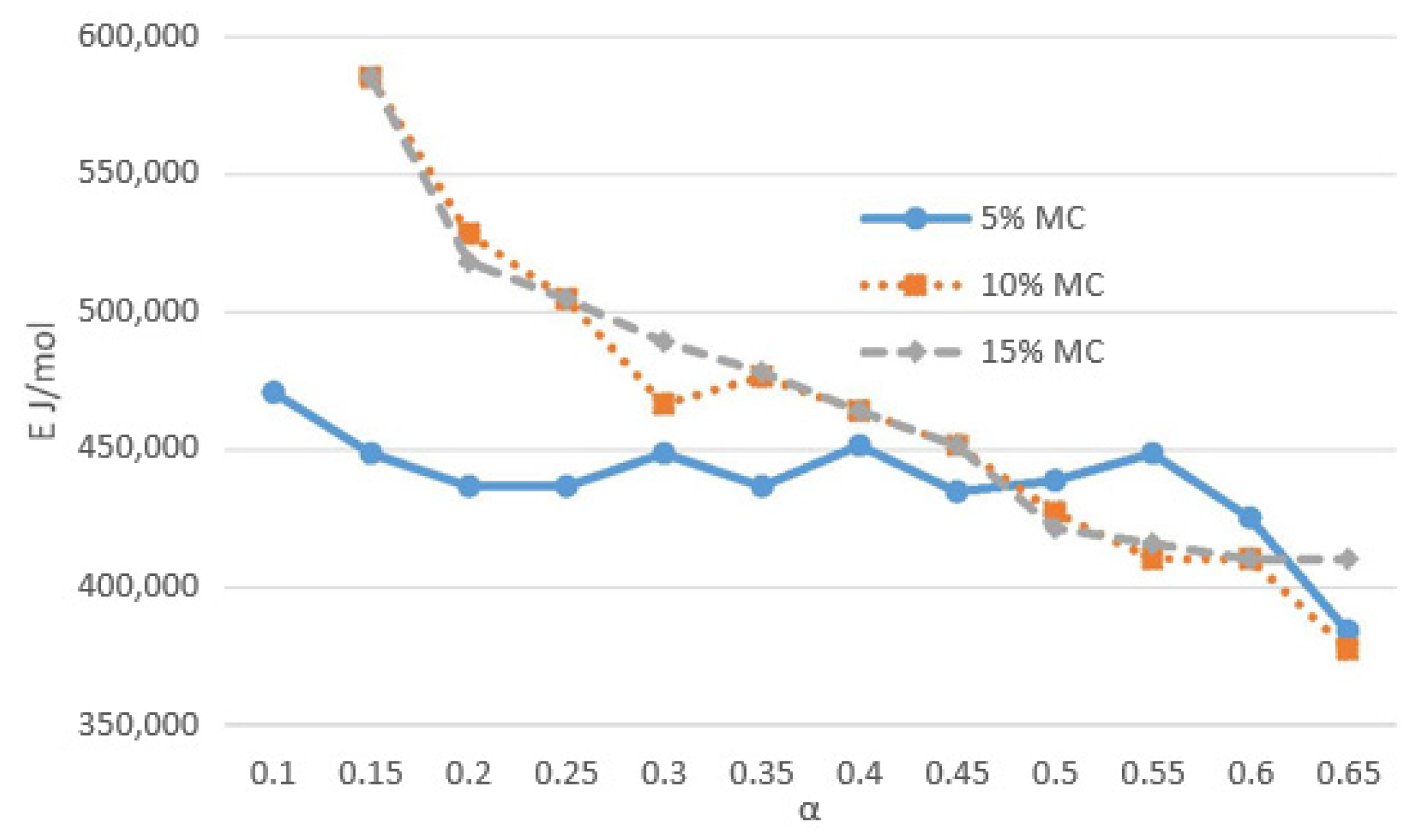

Activation Energy (E)

3.1.3. Flammability Properties

Time to Ignition (TTI)

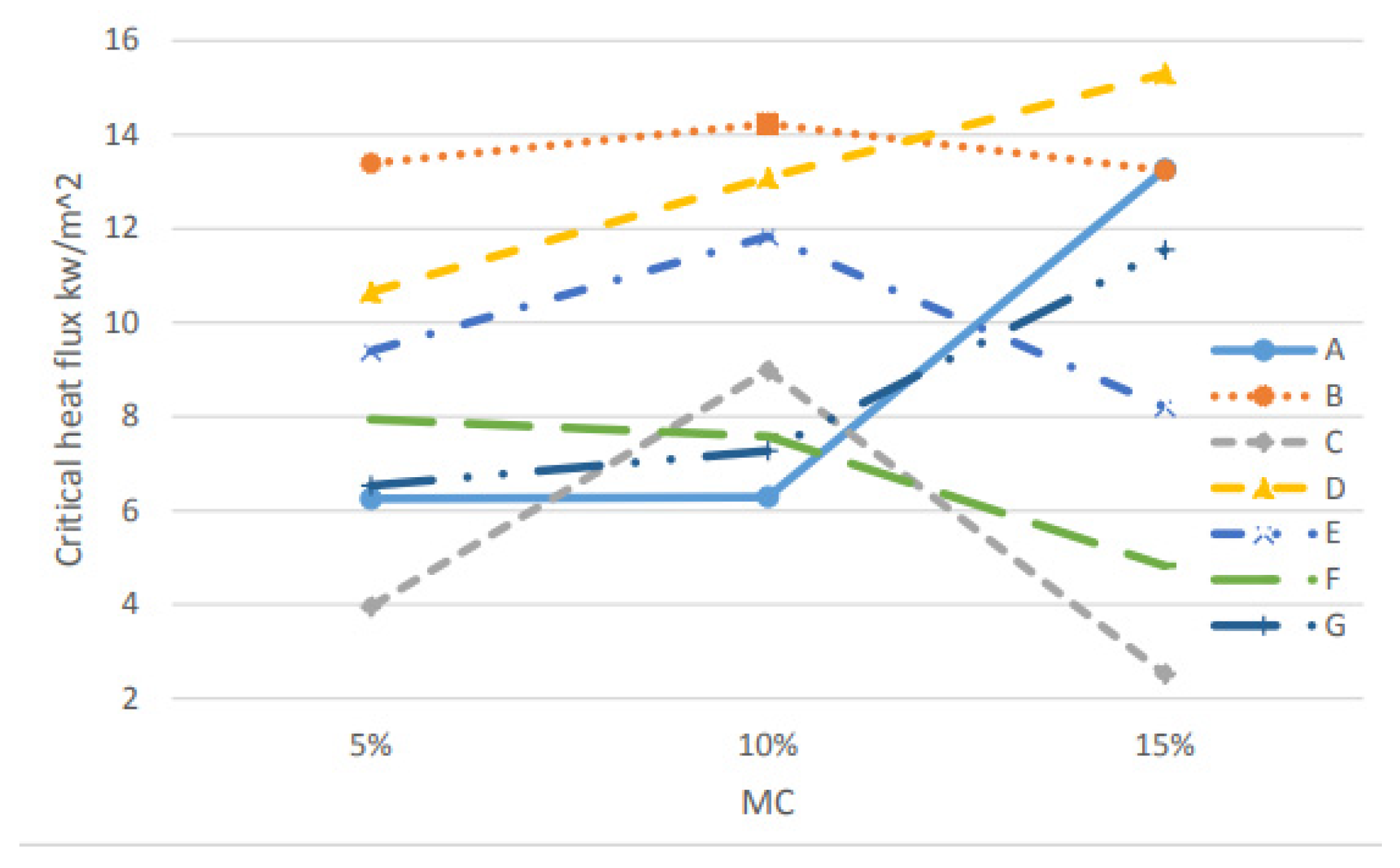

Critical Heat Flux (CHF)

Peak of Heat-Release Rate (pHRR)

Effective Heat of Combustion (EHC)

Mass Loss (ML)

Flameout Time (TTF)

- For TTI, material F has a shorter ignition time, and material D has a longer ignition time;

- A high value of thermal conductivity means a long ignition time, and material B and F have a shorter ignition time, and material D has a longer ignition time;

- Moreover, materials A, B, and G have the lowest peak HRR, whereas material D has the largest peak HRR;

- For MLR, materials B, E, and F have a higher MLR, and materials A and C have a lower MLR. A higher MLR indicates a higher pyrolysis rate with more flammable volatiles released, causing more heat release from their oxidation. Because the average charring rate is correlated to the MLR, materials B, E, and F have a higher charring rate.

4. Conclusions

- Forest fire barriers or fuel breaks should be used to separate Eucalyptus robusta Smith and Pinus massoniana before or in the fire due to their high risk for ignition and strong flammability; we recommend removing, controlling, and replacing high-risk flammable timbers with low-risk flammable timbers as a part of long-term wildland fire management strategies;

- The fire commander should use some research to test conclusions and make an accurate analysis and judgment: The TTI time indicates the ideal time for firefighters to put out fire (329 s as maximum time for firefighters to put out early-stage forest fire for the selected wildland fuels example, while Pinus massoniana only allows 191 s), the peak of heat-release time indicates a fully developed fire to suggest firefighters finish work before the forest fire spirals out of control, and the flameout time (1917 s as maximum time for the selected wildland firebrand flammability before the decay of fire, while Pinus massoniana allows 1168 s) represents the moment of low risk of fuel ignition, so firefighters could allow the fuel to burn out and change the extinguishing target to other regions of developing forest firebrands.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Brown, A.; Manzello, S.L.; Suzuki, J.; Hayashi, Y.; Suzuki, S. Firebrands generated from a full-scale structure burning under well-controlled laboratory conditions. Fire Saf. J. 2014, 63, 43–51. [Google Scholar]

- Park, W.C.; Atreya, A.; Baum, H.R. Experimental and theoretical investigation of heat and mass transfer processes during wood pyrolysis. Combust Flame 2010, 157, 481–494. [Google Scholar] [CrossRef]

- Cohen, J. The wildland-urban interface fire problem: A consequence of the fire exclusion paradigm. For. Hist Today Fall 2008, 20–26. [Google Scholar]

- Jin, W.; Singh, K.; Zondlo, J. Pyrolysis Kinetics of physical components of wood and wood-polymers using Iso-conversion method. Agriculture 2013, 3, 12–32. [Google Scholar] [CrossRef] [Green Version]

- Koo, E.; Pagni, P.J.; Weise, D.R.; Woycheese, J.P. Firebrands and spotting ignition in large-scale fires. Int. J. Wildland Fire 2010, 19, 818. [Google Scholar] [CrossRef] [Green Version]

- Manzello, S.L.; Park, S.; Cleary, T.G. Investigation on the ability of glowing firebrands deposited within crevices to ignite common building materials. Fire Saf. J. 2009, 44, 894–900. [Google Scholar] [CrossRef]

- Babrauskas, V. Development of the cone calorimeter–A bench-scale heat release rate apparatus based on oxygen consumption. Fire Mater. 1984, 8, 81–95. [Google Scholar] [CrossRef]

- Sornek, K.; Filipowicz, M.; Rzepka, K. Study of clean combustion of wood in a stove-fireplace with accumulation. J. Energy Inst. 2017, 90, 613–623. [Google Scholar] [CrossRef]

- Lea-Langton, A.R.; Spracklen, D.V.; Arnold, S.R.; Conibear, L.A.; Chan, J.; Mitchell, E.J.S.; Jones, J.M.; Williams, A. PAH emissions from an African cookstove. J. Energy Inst. 2019, 92, 587–593. [Google Scholar] [CrossRef]

- Chica, E.; Perez, J.F. Development and performance evaluation of an improved biomass cookstove for isolated communities from developing countries. Case Stud. Therm. Eng. 2019, 14, 100435. [Google Scholar] [CrossRef]

- Hafner, J.; Uckert, G.; Graef, F.; Hoffmann, H.; Sereya, O.; Sieber, S. A quantitative performance assessment of improved cooking stoves and traditional three-stone fire stoves using a two-pot test design in Chamwino, Dodoma, Tanzania. Environ. Res. Lett. 2018, 13, 025002. [Google Scholar] [CrossRef]

- Man, C.; Zhu, X.; Gao, X.; Che, D. Combustion and pollutant emission characteristics of lignite dried by low temperature air. Dry. Technol. 2015, 33, 616–631. [Google Scholar] [CrossRef]

- Possell, M.; Bell, T. The influence of fuel moisture content on the combustion of Eucalyptus foliage. Int. J. Wildland Fire 2013, 22, 343–352. [Google Scholar] [CrossRef]

- Yoshioka, H.; Hayashi, Y.; Masuda, H.; Noguchi, T. Real-Scale Fire Wind Tunnel Experiment on Generation of Firebrands from a House on Fire. Fire Sci. Technol. 2004, 23, 142–150. [Google Scholar] [CrossRef] [Green Version]

- Suzuki, S.; Manzello, S.L. Role of accumulation for ignition of fuel beds by firebrands. Appl. Energy Combust. Sci. 2020, 1–4, 100002. [Google Scholar] [CrossRef]

- Hudson, T.R.; Bray, R.B.; Blunck, D.L.; Page, W.; Butler, B. Effects of fuel morphology on ember generation characteristics at the tree scale. Int. J. Wildland Fire 2020, 29, 1042–1051. [Google Scholar] [CrossRef]

- Fang, W.; Peng, Z.; Chen, H. Ignition of pine needle fuel bed by the coupled effects of a hot metal particle and thermal radiation. Proc. Combust. Inst. 2021, 38, 5101–5108. [Google Scholar] [CrossRef]

- Rivera, J.; Hernández, N.; Consalvi, J.L.; Reszka, P.; Contreras, J.; Fuentes, A. Ignition of wildland fuels by idealized firebrands. Fire Saf. J. 2021, 120, 103036. [Google Scholar] [CrossRef]

- Stubbs, D.C.; Humphreys, L.H.; Goldman, A.A.M.; Kush, J.S.; Scarborough, D.E. An experimental investigation into the wildland fire burning characteristics of loblolly pine needles. Fire Saf. J. 2021, 126, 103471. [Google Scholar] [CrossRef]

- ASTM D4442; Standard Test Methods for Direct Moisture Content Measurement of Wood and Wood-Based Materials. ASTM: West Conshohocken, PA, USA, 2016.

- Huangfu, Y.; Li, H.; Chen, X.; Xue, C.; Chen, C.; Liu, G. Effects of moisture content in fuel on thermal performance and emission of biomass semi-gasified cookstove. Energy Sustain. Dev. 2014, 21, 60–65. [Google Scholar] [CrossRef]

- Grandesso, E. Effect of moisture, charge size, and chlorine concentration on PCDD/F emissions from simulated open burning of forest biomass. Environ. Sci. Technol. 2011, 45, 3887–3894. [Google Scholar] [CrossRef]

- Schartel, B.; Pawlowski, K.H.; Lyon, R.E. Pyrolysis combustion flow calorimeter: A tool to assess flame retarded PC/ABS materials? Thermochim. Acta 2007, 462, 1–14. [Google Scholar] [CrossRef]

- Jomaa, G.; Goblet, P.; Coquelet, C.; Morlot, V. Kinetic modeling of polyurethane pyrolysis using non-isothermal thermogravimetric analysis. Thermochim. Acta 2015, 612, 10–18. [Google Scholar] [CrossRef] [Green Version]

- ASTMC518; Standard Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus. ASTM: West Conshohocken, PA, USA, 2017.

- Somorin, T.; Parker, A.; McAdam, E.; Williams, L.; Tyrrel, S. Pyrolysis characteristics and kinetics of human faeces, simulant faeces and wood biomass by thermogravimetry–gas chromatography–mass spectrometry methods. Energy Rep. 2020, 6, 3230–3239. [Google Scholar] [CrossRef]

- Xu, Q.; Chen, L.; Zhang, F. Combustion and charring properties of five common constructional wood species from cone calorimeter tests. Constr. Build. Mater. 2015, 96, 416–427. [Google Scholar] [CrossRef]

- Britton, C.; Lynch, C.F.; Torner, J.; Peek-Asa, C. Fire characteristics associated with firefighter injury on large federal wildland fires. Ann. Epidemiol. 2013, 23, 37–42. [Google Scholar] [CrossRef] [PubMed]

- Crowl, D.A.; Louvar, J.F. Chemical Process Safety Fundamentals with Application, 3rd ed.; The Prentice Hall International Series in The Physical and Chemical Engineering Sciences; Prentice Hall: Hoboken, NJ, USA, 2011. [Google Scholar]

- Rossi, R. Fire fighting and its influence on the body. Ergonomics 2003, 46, 1017–1033. [Google Scholar] [CrossRef] [PubMed]

- Kinsman, P. Major Hazard Assessment: Survey of Current Methodologies and Information Sources; Specialist Inspector Reports No 29; Health and Safety Executive: London, UK, 1991. [Google Scholar]

| Southern Region | Northern Region | ||

|---|---|---|---|

| Schima superba | Michelia macclurei | Fraxinus mandshurica | Ulmus propinqua |

| Schima argentea | Acaci auriculaeformis | Phellodendron amureense | Ulmus laciniata |

| Schima wallichiii | Acacia confuse | Acer spp. | Juglans mandshurica |

| Acaciamangium | Myrica rubra | Salix sp. | Larix gemelininii |

| Alnuscremastogyne | Vernicia fordii | Populus sp. | Larix spp. |

| Castanopsis | Quercus glauca | Malus baccata | Larix kaempferi |

| Myricarubra | Alnus cremastogyne | Tilia amurense | |

| Species | MC Level | Wood Oil Content | Dry Weight (g) | Surface Flammable Coverage % | Hardness |

|---|---|---|---|---|---|

| Poplars | Medium | Low | 1280 | 92 | Soft |

| Birch | Medium | Low | 2320 | 91 | Hard |

| Scotch pine | Medium | High | 2670 | 95 | Soft |

| Korean pine | Medium | High | 3875 | 96 | Soft |

| Ash tree | Medium | Low | 527 | 56 | Soft |

| Walnut | High | Low | 627 | 48 | Soft |

| Phellodendron | High | Low | 725 | 58 | Hard |

| Lime tree | Medium | Low | 1050 | 72 | Soft |

| Larch | Medium | Medium | 4250 | 85 | Soft |

| Designation | Description | Source Place | Hardness |

|---|---|---|---|

| A | Pinus sylvestris var.—hard pines | Inner Mongolia | Very hard |

| B | Eucalyptus robusta Smith | Guangdong | Very hard |

| C | Cupressus funebris Endl | Guangdong | Medium |

| D | Betula platyphylla Suk | Dongbei | Medium |

| E | Larix mastersiana Rehder—larch | Sichuan | Soft |

| F | Pinus massoniana Lamb | Guangxi | Soft |

| G | Pinus bungeana | Shuangxi | Soft |

| Properties | Controlling Factor | Relationship | Parameters |

|---|---|---|---|

| Fuel | MC level | Increase/decrease/ non-influence | Thickness, area, and density |

| Pyrolysis | MC level Temperature Heating rate | Pre-exponential factor (ln(A)), activation energy (E), and thermal conductivity | |

| Flammability | MC level | Time to ignition (TTI), critical heat flux (CHF), peak of heat-release rate (PHRR), mass-loss rate, effective heat of flammability (EHC), and time to flameout |

| Specimen and MC Level Per ASTM D4442-15 (%) (Seven Replicates for Each Material) | ||||||||

|---|---|---|---|---|---|---|---|---|

| Material/ Replicate | 1 | 2 | 3 | 4 | 5 | 6 | 7 | AVE (%) |

| A | 14.1 | 14 | 13.7 | 13.9 | 8.7 | 13.6 | 13.8 | 13.5 |

| B | 18 | 11 | 7.8 | 11 | 11.4 | 11 | 10.7 | 11.7 |

| C | 4.7 | 4 | 4.3 | 4.4 | 4 | 4.3 | 4.7 | 4.5 |

| D | 3.1 | 2.7 | 3 | 3.2 | 3.3 | 3 | 3.2 | 3.2 |

| E | 6 | 6.3 | 5.8 | 6.2 | 5.9 | 6 | 5.8 | 6 |

| F | 7 | 7.4 | 6.9 | 7.2 | 7.5 | 6.8 | 7 | 7.2 |

| G | 5.5 | 5.6 | 6 | 5.9 | 5.5 | 5.6 | 5.4 | 5.7 |

| Heat Flux (kW/m2) | Types of Human Injury |

|---|---|

| 37.5 | 100% of people die in 1 min, 1% in 10 s |

| 25.0 | 100% of people die within 1 min and are severely burned within 10 s |

| 12.5 | 1% of people die in 1 min and one-degree burns in 10 s |

| 4.0 | Causes pain for more than 20 s but does not blister |

| 1.6 | Long-term contact with no discomfort |

| TTI (s) | HF (kW/m2) | 20 | 30 | 50 |

|---|---|---|---|---|

| A | 5% | 192 | 34 | 24 |

| 10% | 357 | 71 | 25 | |

| 15% | 703 | 65 | 31 | |

| B | 5% | 233 | 32 | 10 |

| 10% | 307 | 56 | 15 | |

| 15% | 465 | 49 | 17 | |

| C | 5% | 192 | 70 | 24 |

| 10% | 258 | 85 | 25 | |

| 15% | 317 | 101 | 31 | |

| D | 5% | 329 | 65 | 21 |

| 10% | 406 | 142 | 31 | |

| 15% | 625 | 119 | 33 | |

| E | 5% | 301 | 56 | 20 |

| 10% | 343 | 98 | 29 | |

| 15% | 461 | 104 | 36 | |

| F | 5% | 191 | 32 | 13 |

| 10% | 210 | 77 | 22 | |

| 15% | 306 | 76 | 32 | |

| G | 5% | 206 | 63 | 20 |

| 10% | 206 | 97 | 26 | |

| 15% | 375 | 115 | 30 |

| pHRR (Kw/m2) | HF (kW/m2) | 20 | 30 | 50 |

|---|---|---|---|---|

| A | 5% | 160.21 | 182.8 | 176.68 |

| 10% | 162.36 | 169.59 | 190.81 | |

| 15% | 131.83 | 158.48 | 200.75 | |

| B | 5% | 174.88 | 192.64 | 230.36 |

| 10% | 152.63 | 204.33 | 185.08 | |

| 15% | 112.59 | 168.43 | 182.84 | |

| C | 5% | 193.95 | 206.76 | 303.76 |

| 10% | 164.41 | 221.63 | 290.35 | |

| 15% | 166.38 | 179.91 | 251.81 | |

| D | 5% | 255.25 | 242.35 | 339.85 |

| 10% | 252.94 | 226.96 | 269.19 | |

| 15% | 191.85 | 168.31 | 221.19 | |

| E | 5% | 301.01 | 192.61 | 289.66 |

| 10% | 208.26 | 217.15 | 249.94 | |

| 15% | 213.52 | 201.33 | 253.8 | |

| F | 5% | 162.09 | 188.32 | 319.2 |

| 10% | 143.78 | 201.87 | 281.91 | |

| 15% | 155.35 | 151.95 | 203.15 | |

| G | 5% | 170.17 | 217.05 | 370.89 |

| 10% | 170.17 | 215.27 | 321.74 | |

| 15% | 141.66 | 187.42 | 387 |

| EHC (MJ/kg) | HF (kW/m2) | 20 | 30 | 50 |

|---|---|---|---|---|

| A | 5% | 14.09 | 13.89 | 7.88 |

| 10% | 14.32 | 14.12 | 12.23 | |

| 15% | 14.83 | 13.62 | 13.97 | |

| B | 5% | 14.29 | 14.26 | 14.62 |

| 10% | 13.70 | 13.10 | 13.89 | |

| 15% | 10.99 | 12.80 | 13.39 | |

| C | 5% | 13.93 | 13.59 | 15.87 |

| 10% | 13.89 | 13.87 | 13.50 | |

| 15% | 9.88 | 12.85 | 10.42 | |

| D | 5% | 14.77 | 10.78 | 14.46 |

| 10% | 14.46 | 10.40 | 14.22 | |

| 15% | 14.31 | 12.70 | 10.34 | |

| E | 5% | 17.41 | 9.55 | 11.50 |

| 10% | 18.32 | 17.37 | 18.71 | |

| 15% | 26.83 | 18.50 | 18.94 | |

| F | 5% | 16.16 | 13.30 | 14.57 |

| 10% | 13.58 | 13.88 | 14.06 | |

| 15% | 13.40 | 7.54 | 10.05 | |

| G | 5% | 14.73 | 13.94 | 15.53 |

| 10% | 14.73 | 13.24 | 12.30 | |

| 15% | 13.28 | 13.24 | 14.33 |

| ML (Mass Loss) | HF (kW/m2) | 20 | 30 | 50 |

|---|---|---|---|---|

| A | 5% | 14.09 | 13.89 | 7.88 |

| 10% | 14.32 | 14.12 | 12.23 | |

| 15% | 14.83 | 13.62 | 13.97 | |

| B | 5% | 14.29 | 14.26 | 14.62 |

| 10% | 13.70 | 13.10 | 13.89 | |

| 15% | 10.99 | 12.80 | 13.39 | |

| C | 5% | 13.93 | 13.59 | 15.87 |

| 10% | 13.89 | 13.87 | 13.50 | |

| 15% | 9.88 | 12.85 | 10.42 | |

| D | 5% | 14.77 | 10.78 | 14.46 |

| 10% | 14.46 | 10.40 | 14.22 | |

| 15% | 14.31 | 12.70 | 10.34 | |

| E | 5% | 17.41 | 9.55 | 11.50 |

| 10% | 18.32 | 17.37 | 18.71 | |

| 15% | 26.83 | 18.50 | 18.94 | |

| F | 5% | 16.16 | 13.30 | 14.57 |

| 10% | 13.58 | 13.88 | 14.06 | |

| 15% | 13.40 | 7.54 | 10.05 | |

| G | 5% | 14.73 | 13.94 | 15.53 |

| 10% | 14.73 | 13.24 | 12.30 | |

| 15% | 13.28 | 13.24 | 14.33 |

| TTF(s) | HF (kW/m2) | 20 | 30 | 50 |

|---|---|---|---|---|

| A | 5% | 1443.3 | 1153 | 868.3 |

| 10% | 1616.7 | 1090 | 981.7 | |

| 15% | 1950 | 1406.3 | 1004.7 | |

| B | 5% | 1486 | 1228 | 844 |

| 10% | 1479 | 1304.7 | 1015.7 | |

| 15% | 1856 | 1346.7 | 1075.7 | |

| C | 5% | 1168 | 706 | 402 |

| 10% | 1159 | 751 | 746 | |

| 15% | 1423 | 992 | 802 | |

| D | 5% | 998 | 818.3 | 441.3 |

| 10% | 1109.7 | 876.3 | 597 | |

| 15% | 1363.7 | 953.7 | 691 | |

| E | 5% | 1917.7 | 1558.7 | 1197 |

| 10% | 1943.3 | 1713.3 | 1408 | |

| 15% | 1716 | 1764.3 | 1740.3 | |

| F | 5% | 1027 | 805 | 469 |

| 10% | 1217.3 | 822 | 566.3 | |

| 15% | 1112 | 441.7 | 1714.7 | |

| G | 5% | 1312 | 924.3 | 864.3 |

| 10% | 1347.2 | 932 | 715.7 | |

| 15% | 1620 | 1056 | 716.3 |

| Fuel Properties | Pyrolysis Properties | Flammability Properties |

|---|---|---|

| The densities of materials C, D, and E are close to each other. Material G has the highest density, and material B has the lowest density. As the MC level increased, the densities of materials A, D, E, and F increased slightly, while those of materials B and C decreased slightly. Material G has the highest density at 10% MC level. | The effect of temperature on thermal conductivity is less than that of MC level. As the temperature increases from 25 °C to 100 °C, the thermal conductivity increases in all except materials A, B, and F. The ln(A) values varied in the early stage of pyrolysis but appeared to be more stable when the conversion factor α was 0.25 or higher. Both MC level and heating rate had strong effect on the pre-exponential factor. E values varied in the early stage of pyrolysis but appeared to be more stable when the conversion factor α was 0.25 or higher. This is similar to pre-exponential factor. | Heat flux had significant effect on TTI; the higher the heat flux levels, the smaller the TTI values. MC levels had a significant effect at low heat-flux levels (20 or 30 kW/m2). The CHFs of A and B increased as the MC level increased. The CHFs of C and D decreased as the MC level increased. The CHFs of E, F, and G increased from MC 5% to MC 10% but decreased from MC 10% to MC 15%. The pHRR of all selected structural materials increased as the heat flux level increased and decreased as the MC level increased although with a few exceptions. The MC level had a strong effect on the EHC of selected wildland fuels. HF levels had less effect on the EHC values. The ML of the material increases with increasing HF levels. MC levels had little effect on ML. The TTFs of all materials increased with increasing MC levels and, with few exceptions, decreased with increasing heat flux. |

| Author/ Research Institute | Fuel and Findings |

|---|---|

| Pacific Southwest Forest and Range Experiment Station (1976) | The greater thermal conductivity and heat capacity of dense fuels acts to increase the amount of heat needed for ignition and the fuel ignition time. As the moisture content increases, the ignition time increases. |

| Building and Fire Research Laboratory (BFRL), Gaithersburg, USA (2020) | OSB and wood studs (re-entrant corner wall assemblies). Under the same windspeed, the slope of the relationship of the mass of flammable timbers fuel and the projected area turned out to be the same, which was affected by the wind speed within the setting’s experimental range. |

Oregon State University, USA (2020) | Douglas fir (Pseudotsuga menziesii), western juniper (Juniperus occidentalis), ponderosa pine (Pinus ponderosa), and grand fir (Abies grandis). Under different combinations of the species above and moisture content, the size of flammable wildland woods to ignite spot fires was explored. |

| State Key Laboratory of Fire Science, Hefei, China (2020) | 600–1100 °C: Pine needles, 6–14 mm steel spherical particle. (1) As particle temperature and radiant heat flux increase, the likelihood of ignition increases. (2) As particle size and temperature increase, the critical radiative heat flux required for ignition decreases. The ignition-delay time decreases with increasing radiative heat flux. |

| Auburn University, AL, USA (2020) | Pinus ponderosa and Pinus monticola needle fuel beds. Fuel charge has a strong positive effect on flame height, specific surface area, and flame depth. After adding fuel, the flame intensity and temperature do not change significantly. |

| Huali Hao (2020) Massachusetts Institute of Technology, USA | Dried oak, larch, and red cedar. The effect of heat flux on the fire performance of oak, larch. and red cedar is attenuated with its increment. An increased heat flux promotes heat release, charring rate. and CO2 production, while it has a negative effect on CO release. The peak CO production of oak is initially decreased and then increased with the rise of heat flux, whereas the peak CO production of larch is first increased and then decreased. |

| Material | TTI | pHRR | Flameout Time | ML (Mass Loss) | Fire Risk Classification |

|---|---|---|---|---|---|

| A | 192 | 160.21 | 1443.3 | 14.09 | High |

| B | 233 | 174.88 | 1486 | 14.29 | High |

| C | 192 | 193.95 | 1168 | 13.93 | Intermediate |

| D | 329 | 255.25 | 998 | 14.77 | Low |

| E | 301 | 208.26 | 1917.7 | 17.41 | Intermediate |

| F | 191 | 208.26 | 1027 | 16.16 | High |

| G | 206 | 170.17 | 1312 | 14.73 | Intermediate |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, W.; Bakar, B.H.A.; Mamat, H.; Gong, L.; Nursyamsi, N. A Laboratory-Scale Study of Selected Chinese Typical Flammable Wildland Timbers Ignition Formation Mechanism. Fire 2023, 6, 20. https://doi.org/10.3390/fire6010020

Yang W, Bakar BHA, Mamat H, Gong L, Nursyamsi N. A Laboratory-Scale Study of Selected Chinese Typical Flammable Wildland Timbers Ignition Formation Mechanism. Fire. 2023; 6(1):20. https://doi.org/10.3390/fire6010020

Chicago/Turabian StyleYang, Wenxu, B. H. Abu Bakar, Hussin Mamat, Liang Gong, and Nursyamsi Nursyamsi. 2023. "A Laboratory-Scale Study of Selected Chinese Typical Flammable Wildland Timbers Ignition Formation Mechanism" Fire 6, no. 1: 20. https://doi.org/10.3390/fire6010020

APA StyleYang, W., Bakar, B. H. A., Mamat, H., Gong, L., & Nursyamsi, N. (2023). A Laboratory-Scale Study of Selected Chinese Typical Flammable Wildland Timbers Ignition Formation Mechanism. Fire, 6(1), 20. https://doi.org/10.3390/fire6010020