Numerical Study of the Effects of Surface Tension and Initial Volume Fraction on Gas-Liquid-Foam Three-Phase Flow Separation Process

Abstract

:1. Introduction

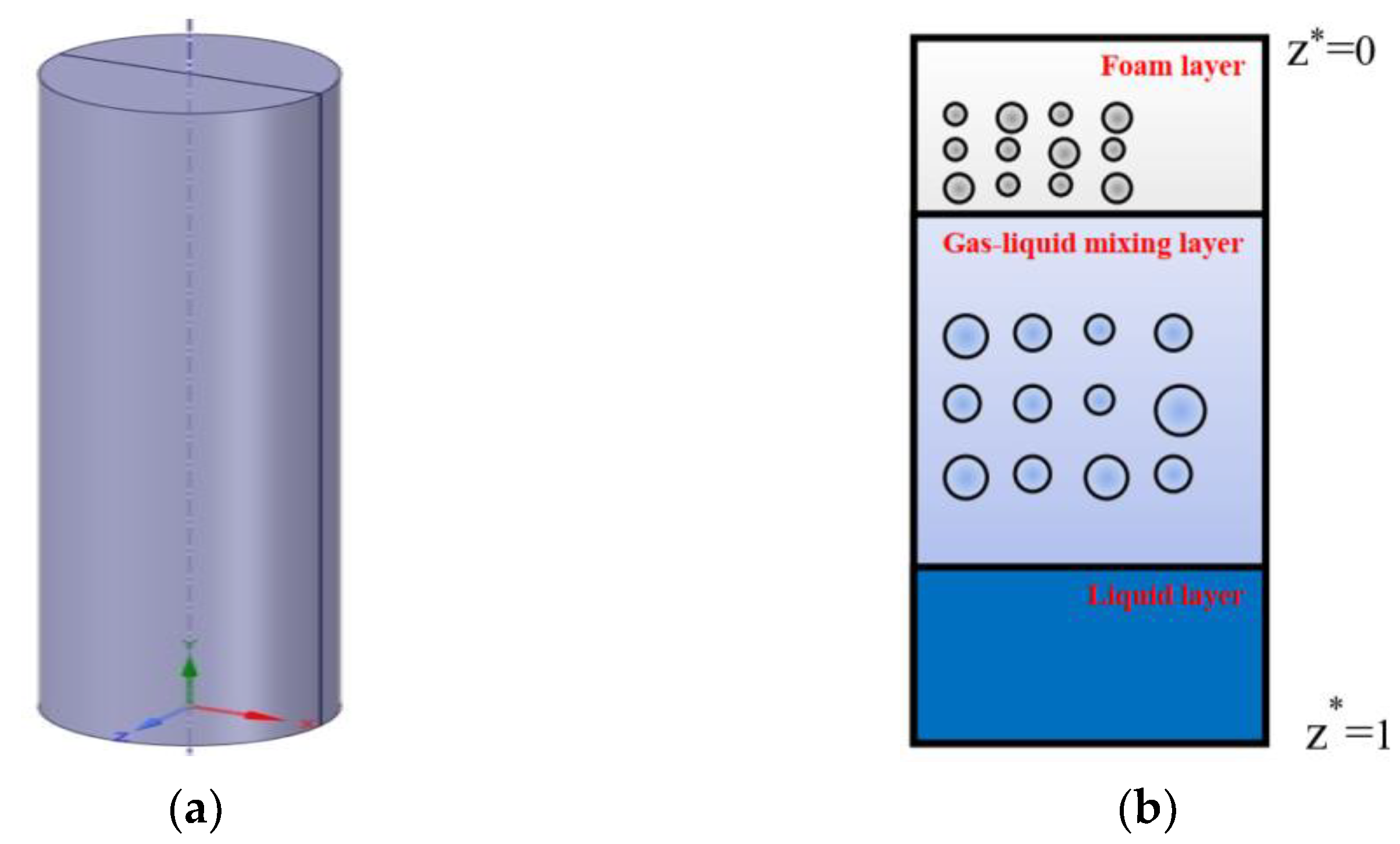

2. Numerical Modelling Setup

2.1. Numerical Scenarios

2.2. Governing Equations

2.3. Grid Sensitivity Analysis and Model Verification

3. Results and Discussion

3.1. Effect of Surface Tension on Liquid Separation

3.2. Effect of Initial Volume Fraction on Liquid Separation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhou, F.; Ren, W.; Wang, D.; Song, T.; Li, X.; Zhang, Y. Application of three-phase foam to fight an extraordinarily serious coal mine fire. Int. J. Coal Geol. 2006, 67, 95–100. [Google Scholar] [CrossRef]

- Choi, J.H.; Chae, S.U.; Hwang, E.H.; Choi, D.M. Fire Propagation Characteristics and Fire Risks of Polyurethanes: Effects of Material Type (Foam & Board) and Added Flame Retardant. Fire 2022, 5, 105. [Google Scholar] [CrossRef]

- Gao, H.; Zhang, M.; Xia, J.-J.; Song, B.; Wang, Y.-K. Time and surfactant types dependent model of foams based on the Herschel–Bulkley model. Colloids Surfaces A Physicochem. Eng. Asp. 2016, 509, 203–213. [Google Scholar] [CrossRef]

- Zhao, M.; Ni, X.; Zhang, S.; Cao, W.; Guan, Y.; Liang, C.; Wang, X.; Zhang, H. Improving the performance of fluoroprotein foam in extinguishing gasoline pool fires with addition of bromofluoropropene. Fire Mater. 2016, 40, 261–272. [Google Scholar] [CrossRef]

- Zhou, R.; Dou, X.; Lang, X.; He, L.; Liu, J.; Mu, S. Foaming ability and stability of silica nanoparticle-based triple-phase foam for oil fire extinguishing: Experimental. Soft Mater. 2018, 16, 327–338. [Google Scholar] [CrossRef]

- Szurgacz, D.; Tutak, M.; Brodny, J.; Sobik, L.; Zhironkina, O. The Method of Combating Coal Spontaneous Combustion Hazard in Goafs—A Case Study. Energies 2020, 13, 4538. [Google Scholar] [CrossRef]

- Ding, F.; Kang, W.; Yan, L.; Xu, Z.; Guo, X. Influence of gas—Liquid ratio on the fire-extinguishing efficiency of compressed gas protein foam in diesel pool fire. J. Therm. Anal. Calorim. 2021, 146, 1465–1472. [Google Scholar] [CrossRef]

- Tao, Y.; Lu, K.; Chen, X.; Mao, S.; Ding, Y.; Zhao, Y. Experimental investigation on the temperature profile of large scale RP—5 aviation kerosene pool fire in an open space. Fuel 2020, 264, 116852. [Google Scholar] [CrossRef]

- Chang, S.; Grigg, R. Effects of foam quality and flow rate on CO2-foam behavior at reservoir temperature and pressure. SPE Reserv. Eval. Eng. 1999, 2, 248–254. [Google Scholar] [CrossRef]

- Dziubinski, M.; Fidos, H.; Sosno, M. The flow pattern map of a two-phase non-Newtonian liquid–gas flow in the vertical pipe. Int. J. Multiph. Flow 2004, 30, 551–563. [Google Scholar] [CrossRef]

- Kruglyakov, P.; Elaneva, S.; Vilkova, N.; Karakashev, S. Investigation of foam drainage using foam pressure drop technique. Colloids Surfaces A Physicochem. Eng. Asp. 2010, 354, 291–297. [Google Scholar] [CrossRef]

- Risal, A.R.; Manan, M.A.; Yekeen, N.; Azli, N.B.; Samin, A.M.; Tan, X.K. Experimental investigation of enhancement of carbon dioxide foam stability, pore plugging, and oil recovery in the presence of silica nanoparticles. Pet. Sci. 2019, 16, 344–356. [Google Scholar] [CrossRef] [Green Version]

- Fan, Y.; Pereyra, E.; Sarica, C.; Schleicher, E.; Hampel, U. Analysis of flow pattern transition from segregated to slug flow in upward inclined pipes. Int. J. Multiph. Flow 2019, 115, 19–39. [Google Scholar] [CrossRef]

- Govindu, A.; Ahmed, R.; Shah, S.; Amani, M. Stability of foams in pipe and annulus. J. Pet. Sci. Eng. 2019, 180, 594–604. [Google Scholar] [CrossRef]

- Katsiavria, A.; Bontozoglou, V. Stability of liquid film flow laden with the soluble surfactant sodium dodecyl sulphate: Predictions versus experimental data. J. Fluid Mech. 2020, 894, A18. [Google Scholar] [CrossRef]

- Govindu, A.; Ahmed, R.; Shah, S.; Amani, M. The Effect of Inclination on the Stability of Foam Systems in Drilling and Well Operations. SPE Drill. Complet. 2021, 36, 263–280. [Google Scholar] [CrossRef]

- Zhang, P.; Guo, D.; Cao, X.; Li, X.; Xia, W.; Peng, W.; Bian, J. Foam stability: The key to inhibiting slug generation in gas–liquid flow. J. Pet. Sci. Eng. 2022, 218, 110969. [Google Scholar] [CrossRef]

- Bashir, A.; Haddad, A.; Rafati, R. An experimental investigation of dynamic viscosity of foam at different temperatures. Chem. Eng. Sci. 2022, 248, 117262. [Google Scholar] [CrossRef]

- Vardar-Sukan, F. Foaming: Consequences, prevention and destruction. Biotechnol. Adv. 1998, 16, 913–948. [Google Scholar] [CrossRef]

- Buwa, V.V.; Ranade, V. Dynamics of gas–liquid flow in a rectangular bubble column: Experiments and single/multi-group CFD simulations. Chem. Eng. Sci. 2002, 57, 4715–4736. [Google Scholar] [CrossRef]

- Chen, P.; Sanyal, J.; Duducovic, M. Numerical simulation of bubble columns flows: Effect of different breakup and coalescence closures. Chem. Eng. Sci. 2005, 60, 1085–1101. [Google Scholar] [CrossRef]

- Bannari, R.; Kerdouss, F.; Selma, B.; Bannari, A.; Proulx, P. Three-dimensional mathematical modeling of dispersed two-phase flow using class method of population balance in bubble columns. Comput. Chem. Eng. 2008, 32, 3224–3237. [Google Scholar] [CrossRef]

- Bhole, M.; Joshi, J.B.; Ramkrishna, D. CFD simulation of bubble columns incorporating population balance modeling. Chem. Eng. Sci. 2008, 63, 2267–2282. [Google Scholar] [CrossRef]

- Díaz, M.E.; Iranzo, A.; Cuadra, D.; Barbero, R.; Montes, F.J.; Galán, M.A. Numerical simulation of the gas–liquid flow in a laboratory scale bubble column: Influence of bubble size distribution and non-drag forces. Chem. Eng. J. 2008, 139, 363–379. [Google Scholar] [CrossRef]

- Liao, Y.; Lucas, D. A literature review on mechanisms and models for the coalescence process of flu-id particles. Chem. Eng. Sci. 2010, 65, 2851–2864. [Google Scholar] [CrossRef]

- Tong, M.; Kole, K.; Neethling, S. Drainage and stability of 2D foams: Foam behavior in vertical Hele-Shaw cells. Colloids Surf. A Physicochem. Eng. Asp. 2011, 382, 42–49. [Google Scholar] [CrossRef]

- Ma, T.; Ziegenhein, T.; Lucas, D.; Krepper, E.; Fröhlich, J. Euler–Euler large eddy simulations for dispersed turbulent bubbly flows. Int. J. Heat Fluid Flow 2015, 56, 51–59. [Google Scholar] [CrossRef]

- Montoya, G.; Sanyal, J.; Braun, M. On the assessment, implementation, validation, and verification of drag and lift forces in gas-liquid applications for the CFD codes FLUENT and CFX. Exp. Comput. Multiph. Flow 2019, 1, 255–270. [Google Scholar] [CrossRef] [Green Version]

- Diba, F.; Karim, R.; Naser, J. Fluidized bed CFD using simplified solid-phase coupling. Powder Technol. 2020, 375, 161–173. [Google Scholar] [CrossRef]

- Shu, S.; Yang, N.; Bertrand, F.; Chaouki, J. High-resolution simulation of oscillating bubble plumes in a square cross-sectioned bubble column with an unsteady k-ε model. Chem. Eng. Sci. 2021, 231, 116321. [Google Scholar] [CrossRef]

- Agarwal, N.; Bhutani, G. LES modelling of multiphase turbulent flows in bubble columns using an adaptive-mesh finite element method. Chem. Eng. Res. Des. 2022, 180, 90–108. [Google Scholar] [CrossRef]

- Sattar, M.; Naser, J.; Brooks, G. Numerical simulation of creaming and foam formation in aerated liquid with population balance modeling. Chem. Eng. Sci. 2013, 94, 69–78. [Google Scholar] [CrossRef]

- Sarhan, A.; Naser, J.; Brooks, G. CFD modeling of bubble column: Influence of physico-chemical properties of the gas/liquid phases properties on bubble formation. Sep. Purif. Technol. 2018, 201, 130–138. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tan, T.; Zhang, J.; Hu, J.; Zhang, J.; Sun, G.; Li, B.; Guo, Y. Numerical Study of the Effects of Surface Tension and Initial Volume Fraction on Gas-Liquid-Foam Three-Phase Flow Separation Process. Fire 2023, 6, 117. https://doi.org/10.3390/fire6030117

Tan T, Zhang J, Hu J, Zhang J, Sun G, Li B, Guo Y. Numerical Study of the Effects of Surface Tension and Initial Volume Fraction on Gas-Liquid-Foam Three-Phase Flow Separation Process. Fire. 2023; 6(3):117. https://doi.org/10.3390/fire6030117

Chicago/Turabian StyleTan, TianTian, Jiaqing Zhang, Junjie Hu, Jianghong Zhang, Gang Sun, Bo Li, and Yi Guo. 2023. "Numerical Study of the Effects of Surface Tension and Initial Volume Fraction on Gas-Liquid-Foam Three-Phase Flow Separation Process" Fire 6, no. 3: 117. https://doi.org/10.3390/fire6030117

APA StyleTan, T., Zhang, J., Hu, J., Zhang, J., Sun, G., Li, B., & Guo, Y. (2023). Numerical Study of the Effects of Surface Tension and Initial Volume Fraction on Gas-Liquid-Foam Three-Phase Flow Separation Process. Fire, 6(3), 117. https://doi.org/10.3390/fire6030117