Investigating Intumescent Flame-Retardant Additives in Polyurethane Foam to Improve the Flame Resistance and Sustainability of Aircraft Cabin Materials

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Sample Preparation

2.2. Sample Characterisation

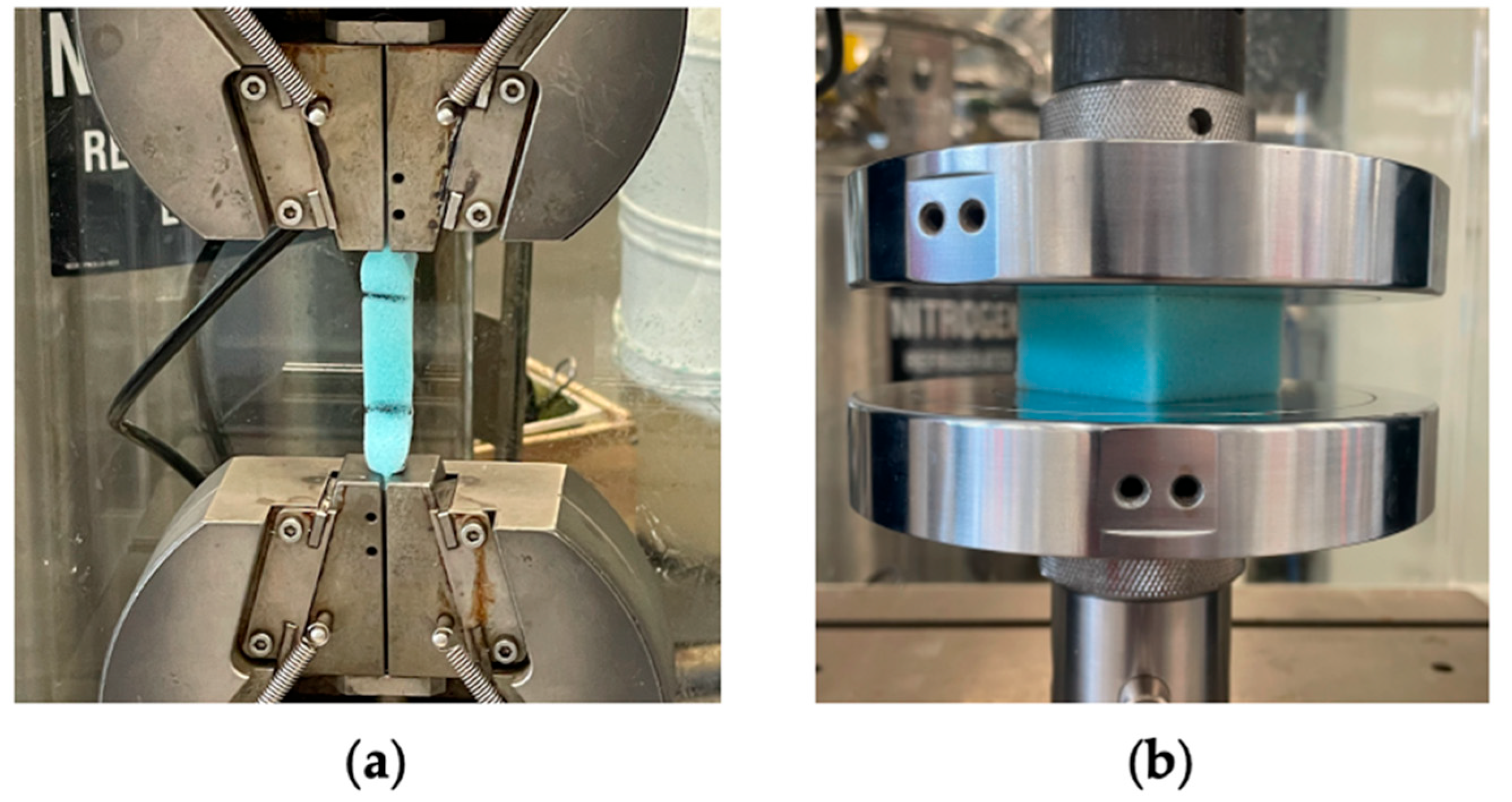

2.2.1. Mechanical Testing

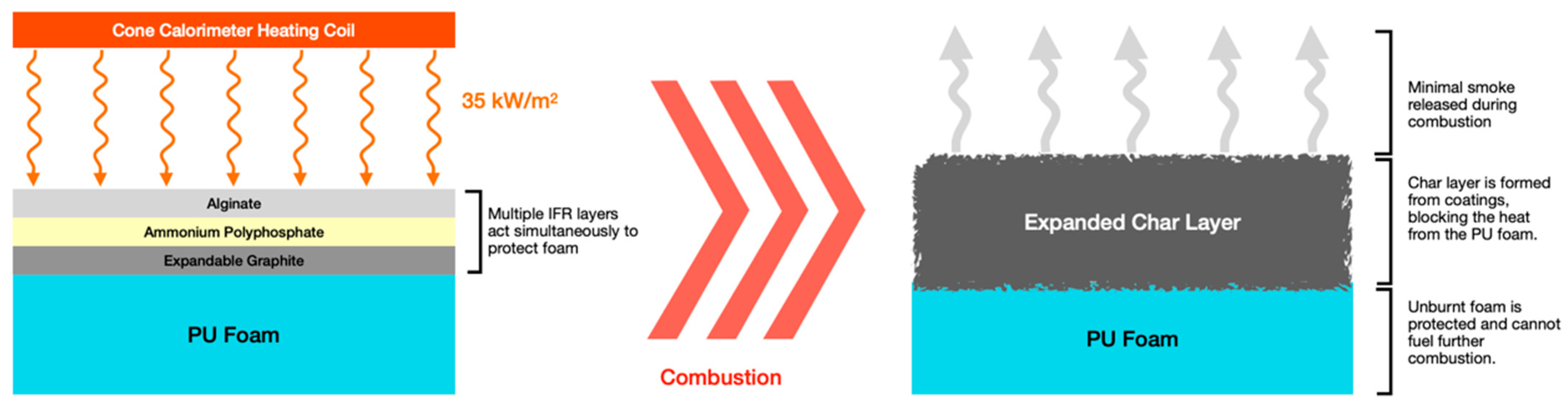

2.2.2. Cone Testing

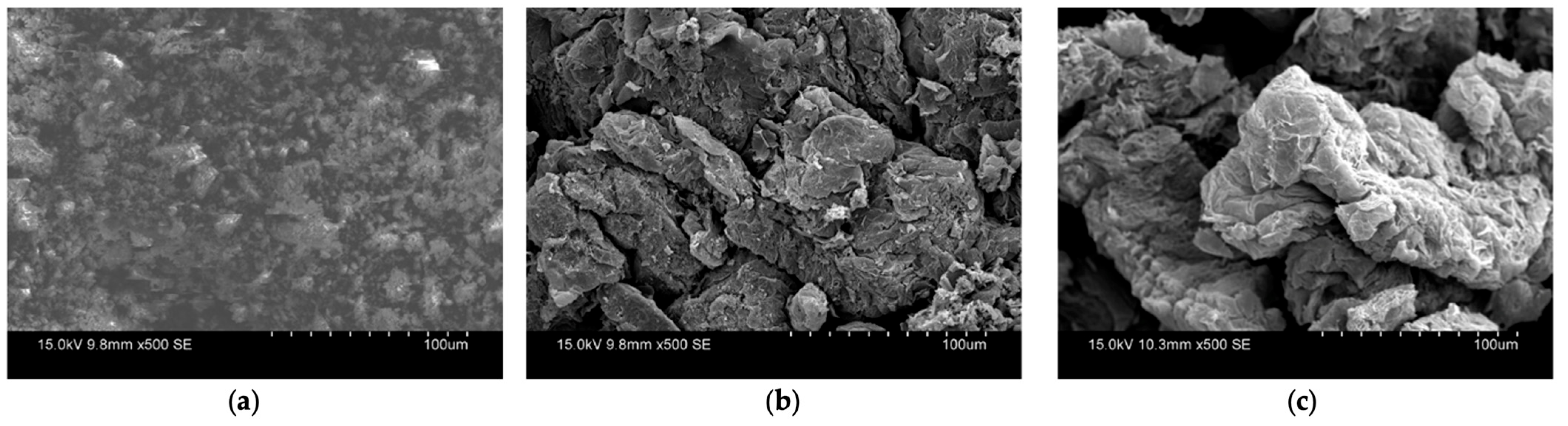

2.2.3. SEM Imaging

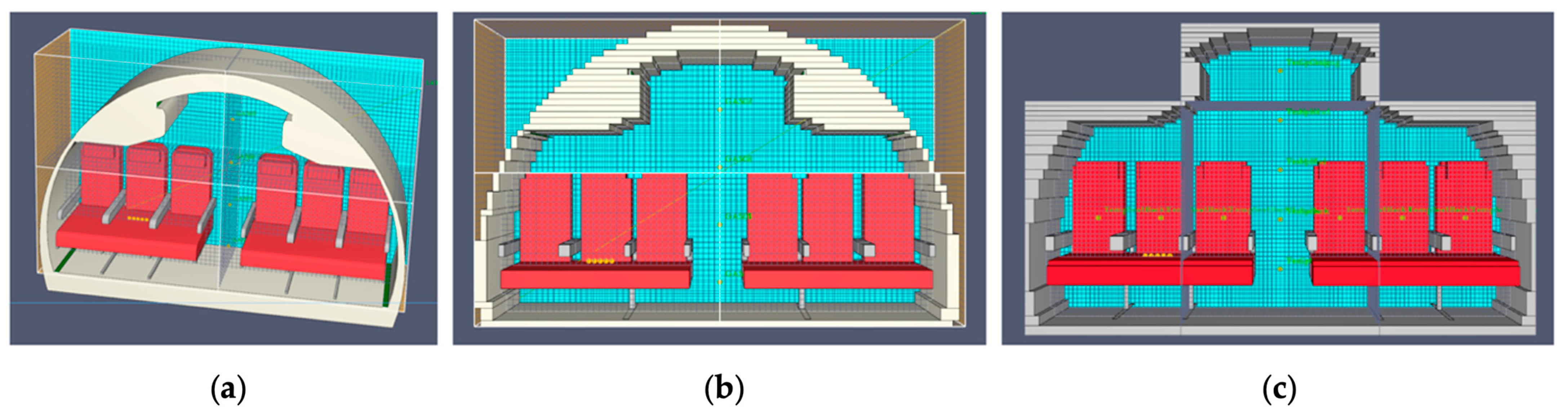

2.3. Numerical Modelling

3. Results and Discussion

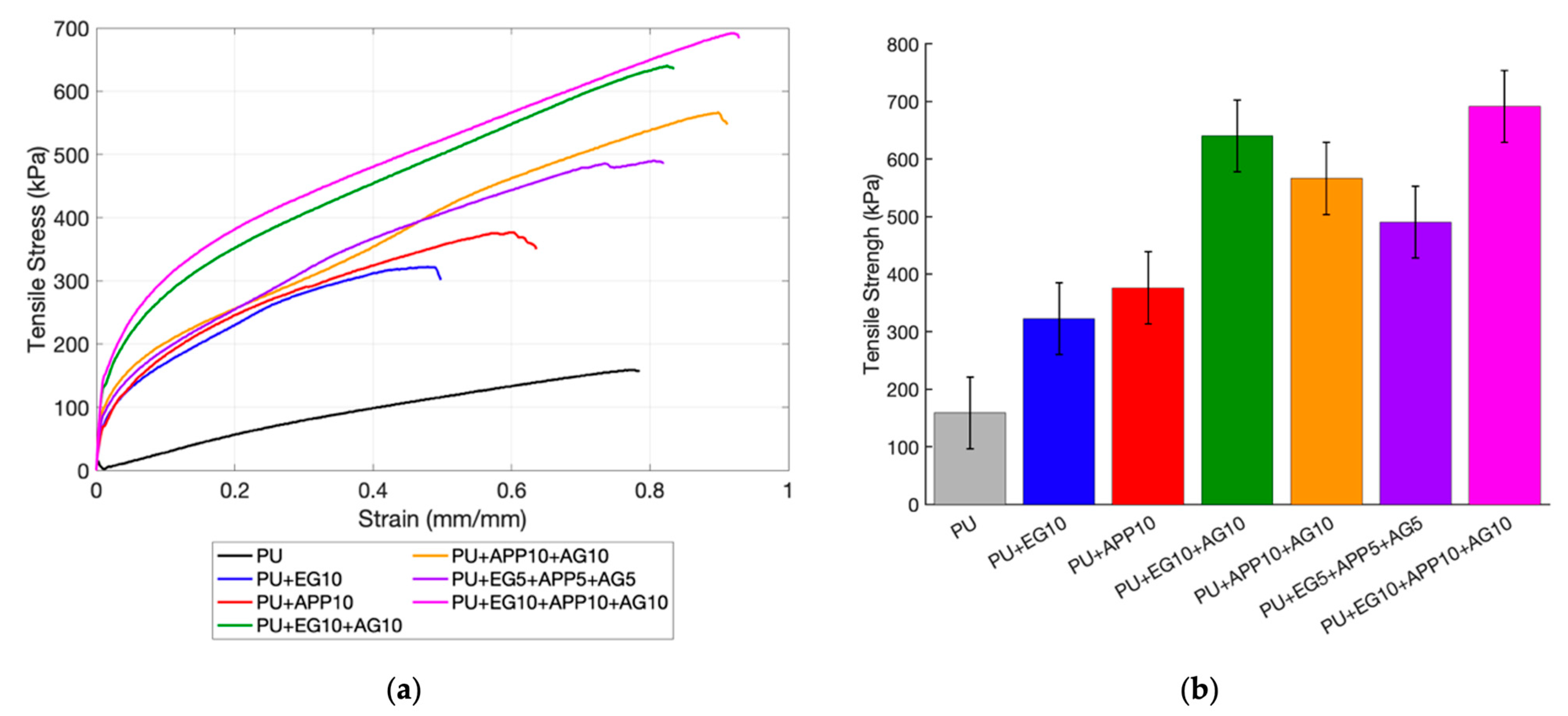

3.1. Mechanical Testing

3.2. Combustion Testing

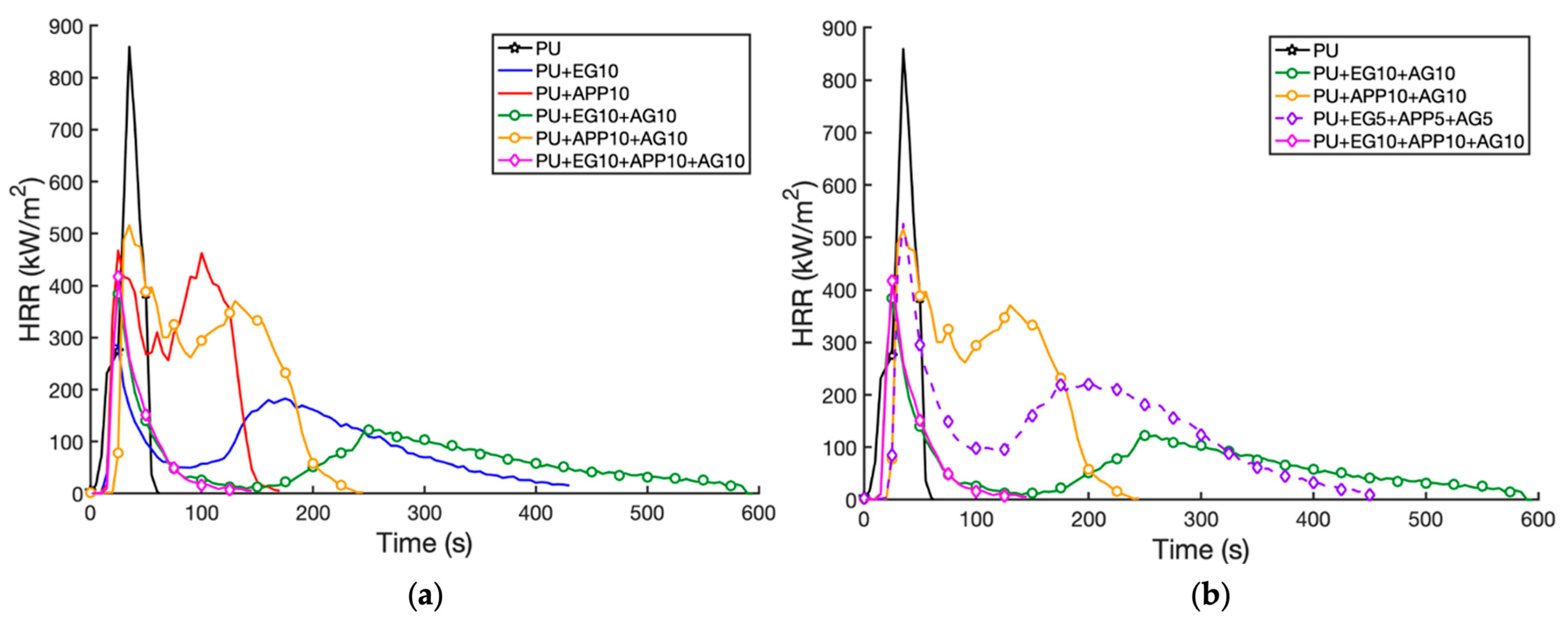

3.2.1. Heat Release Rate

3.2.2. Total Heat Release

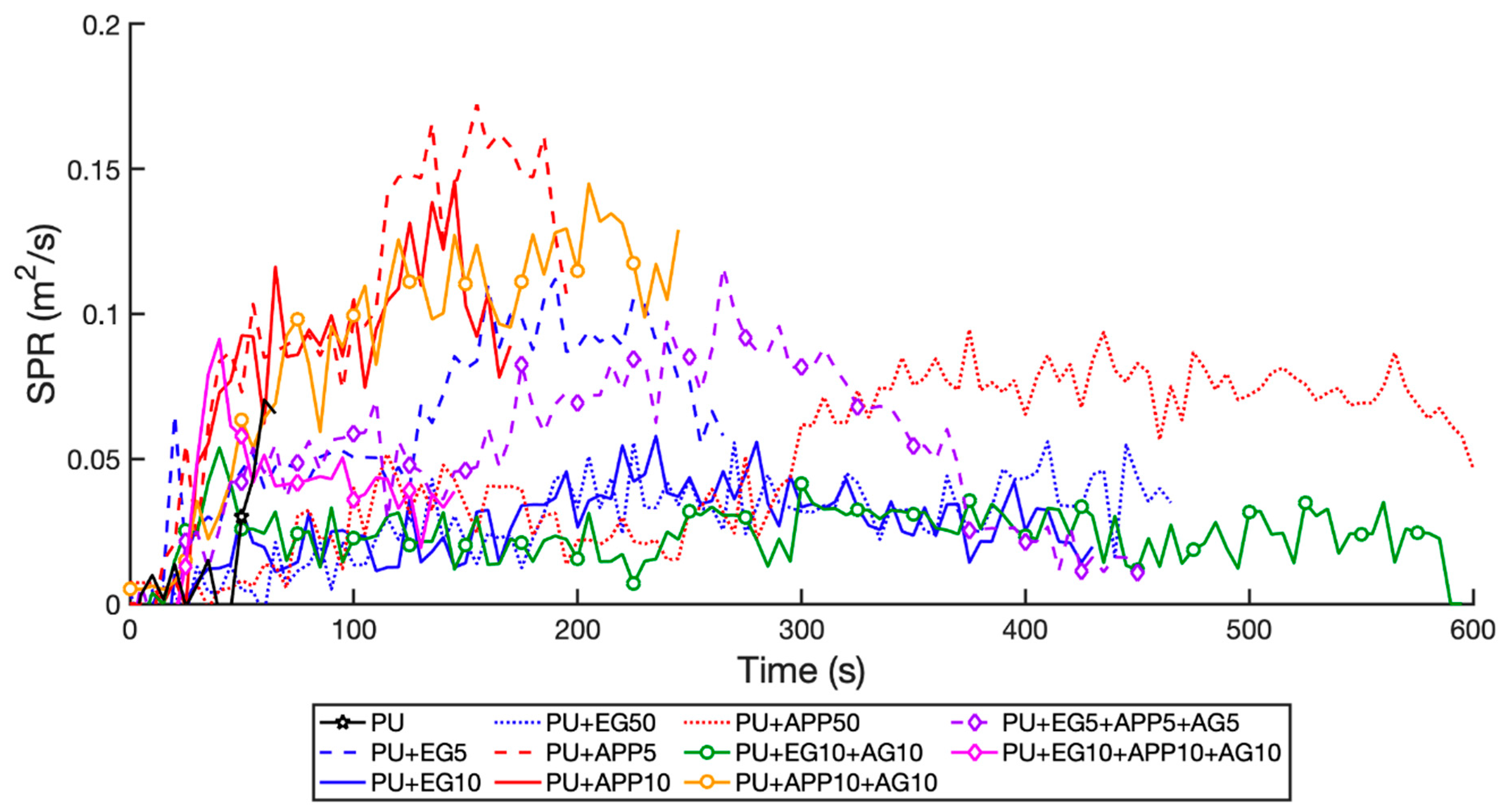

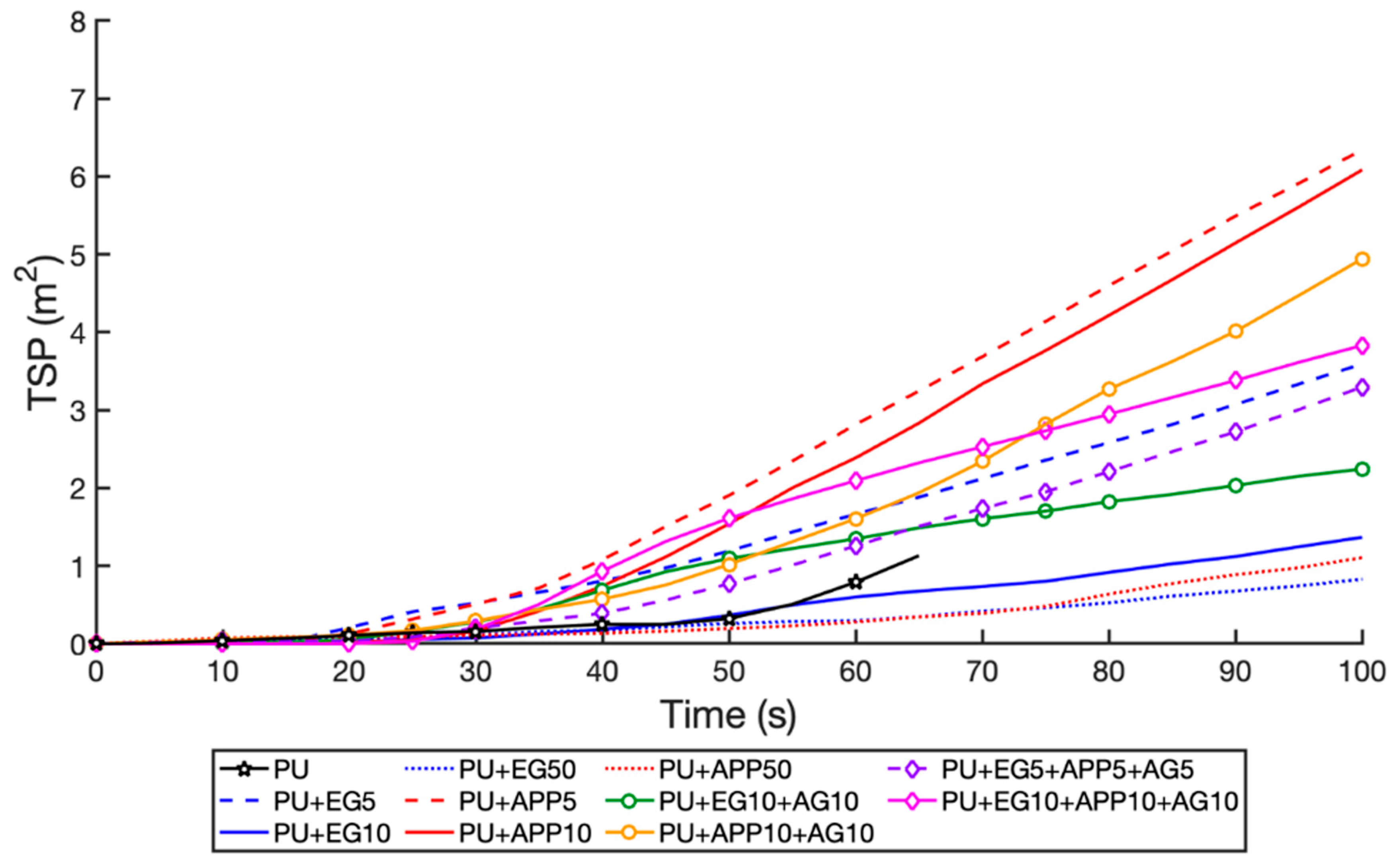

3.2.3. Smoke Production

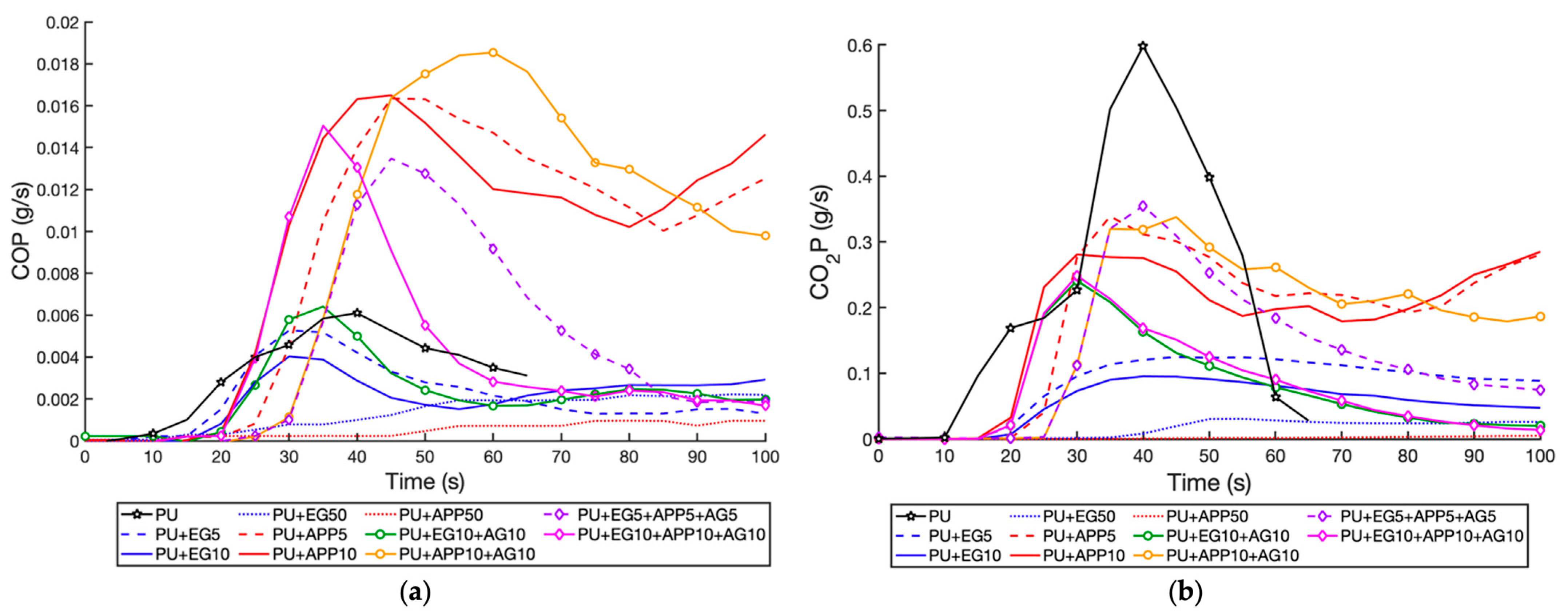

3.2.4. Carbon Monoxide and Carbon Dioxide Production

3.2.5. Mass Loss Profile

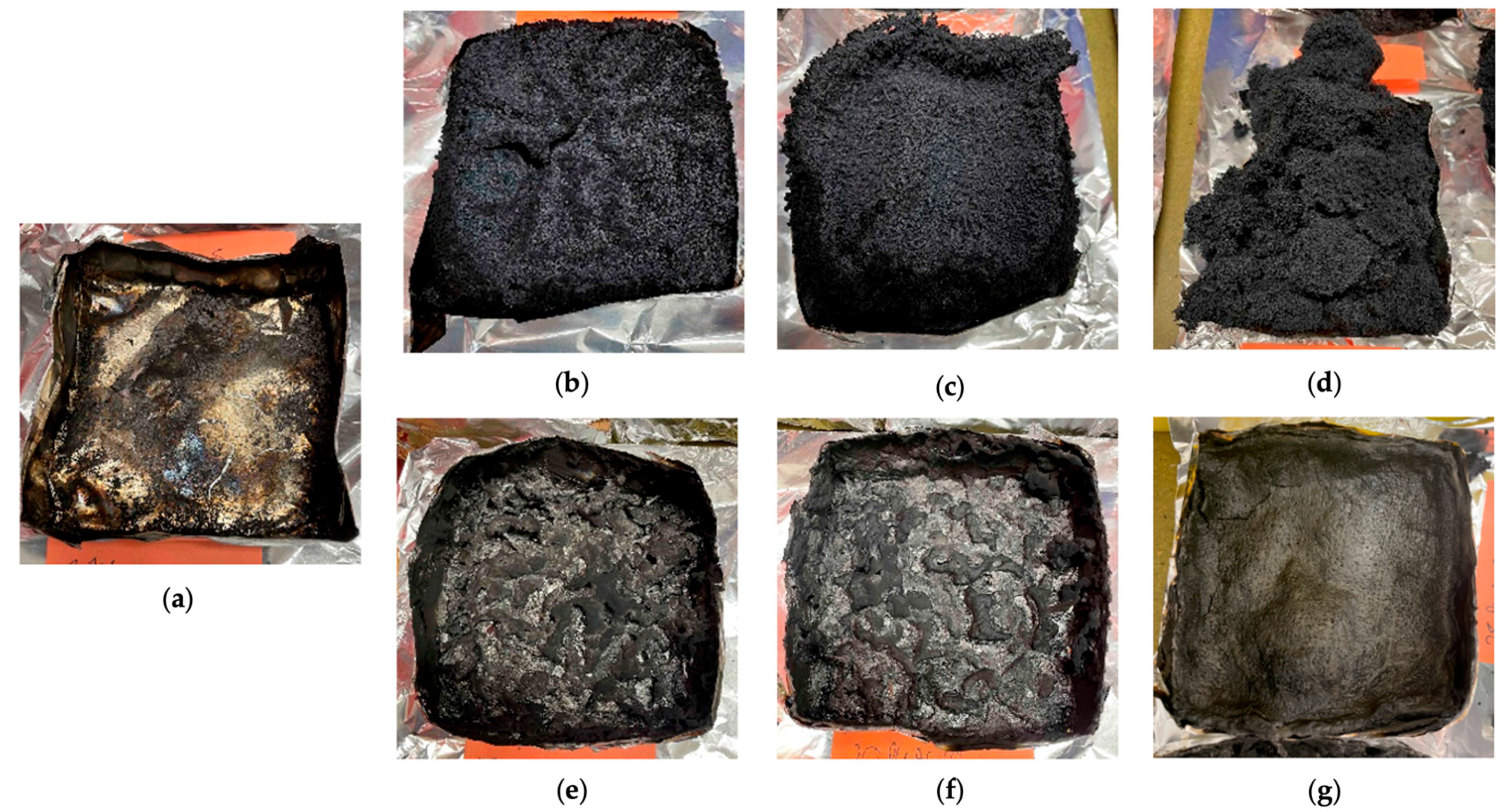

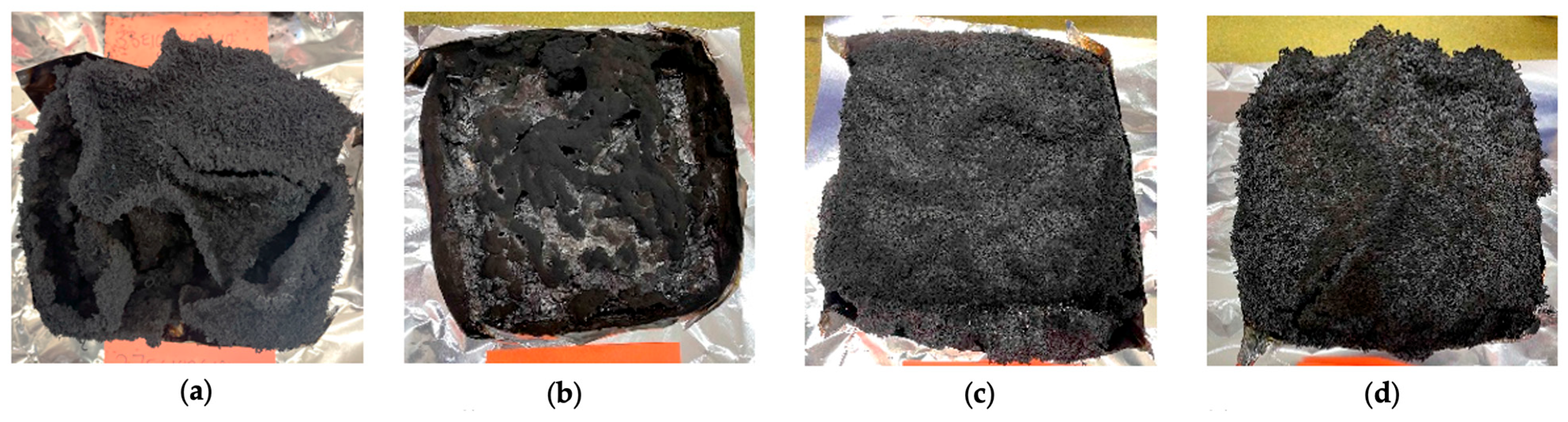

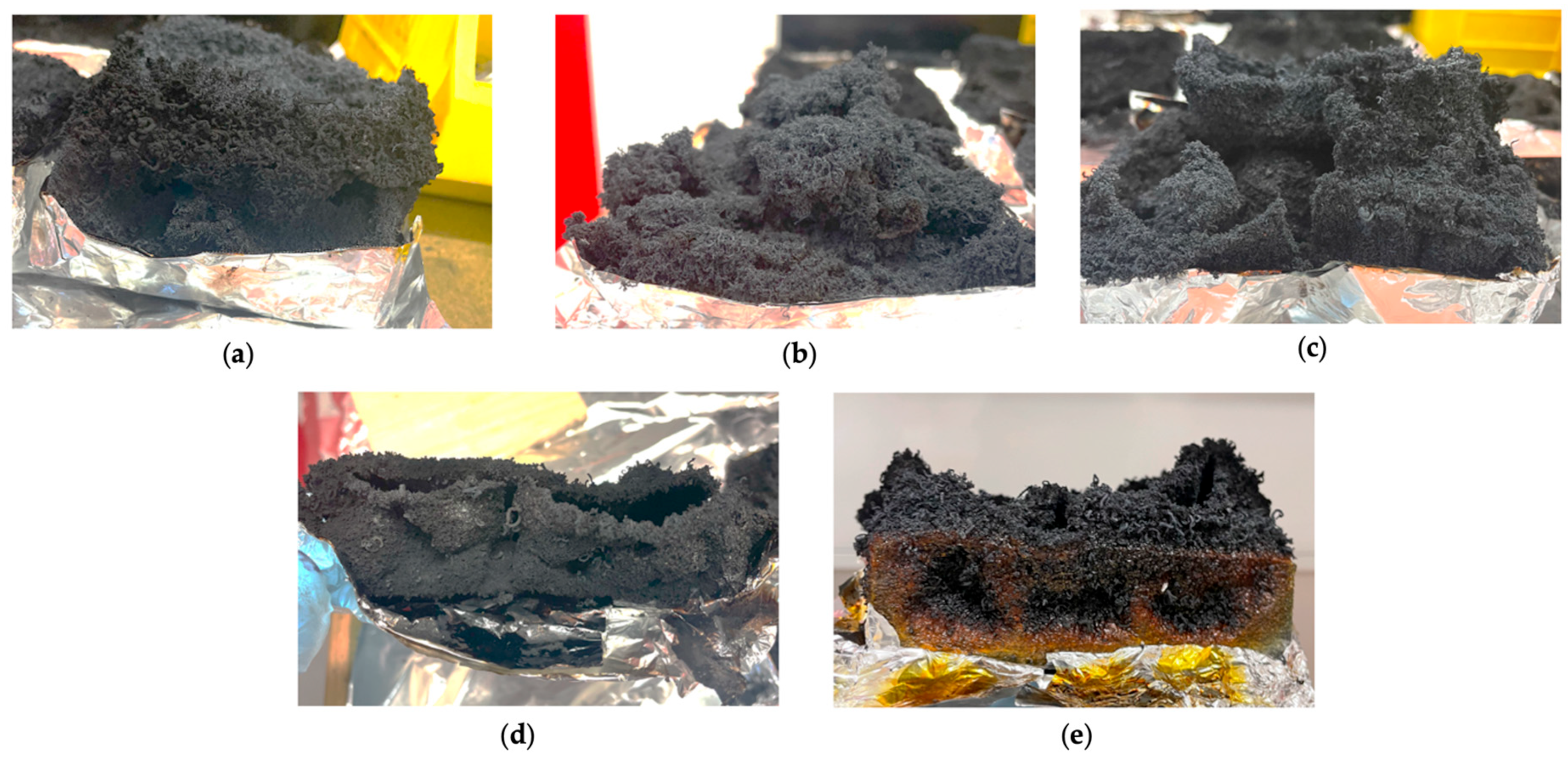

3.2.6. Char Residue Analysis

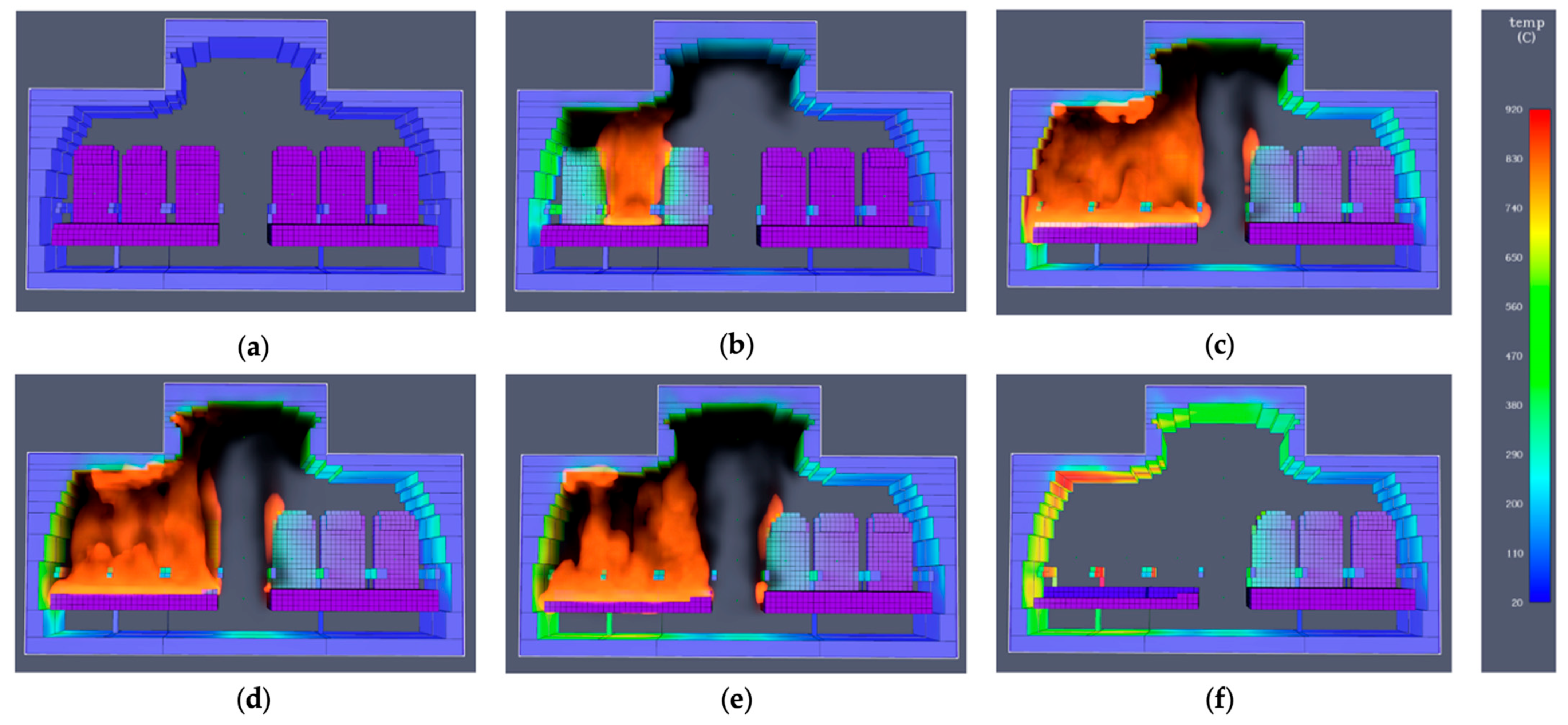

3.3. Numerical Modelling

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| AG | Alginate |

| APP | Ammonium polyphosphate |

| CFD | Computational fluid dynamics |

| CO2P | Carbon dioxide production |

| COP | Carbon monoxide production |

| DSC | Differential scanning calorimetry |

| EG | Expandable graphite |

| FDS | Fire dynamics simulator |

| HRR | Heat release rate |

| IFR | Intumescent flame retardant |

| LOI | Limiting oxygen index |

| pHRR | Peak heat release rate |

| PU | Polyurethane |

| SEM | Scanning electron microscope |

| SPR | Smoke production rate |

| TGA | Thermogravimetric analysis |

| THR | Total heat release |

| TSP | Total smoke production |

References

- Lyon, R.E. Development of a Fire Test for Aircraft Seat Cusions. In Proceedings of the Consumer Product Safety Commission Meeting, Rockville, MD, USA, 25 April 2013. [Google Scholar]

- Cox, J.; Markey, A.; Kohn, R.; Butcher, N.J.; Moxon, M. Smoke, Fire and Fumes in Transport Aircraft; Past history, current risk and recommended mitigations. R. Aeronaut. Soc. 2013, 2, 4–70. [Google Scholar]

- Kausar, A. Polyurethane composite foams in high-performance applications. Polym.-Plast. Technol. Eng. 2017, 57, 346–369. [Google Scholar] [CrossRef]

- Vincent, T.; Vincent, C.; Dumazert, L.; Otazaghine, B.; Sonnier, R.; Guibal, E. Fire behavior of innovative alginate foams. Carbohydr. Polym. 2020, 250, 116910. [Google Scholar] [CrossRef]

- Cheong, J.Y.; Ahn, J.; Seo, M.; Nam, Y.S. Flame-retardant, flexible vermiculite-polymer hybrid film. RSC Adv. 2015, 5, 61768–61774. [Google Scholar] [CrossRef]

- Thirumal, M.; Kastgir, D.; Singha, N.K.; Manjunath, B.N.; Naik, Y.P. Effect of Expandable Graphite on the Properties of Intumescent Flame-Retardant Polyurethane Foam. J. Appl. Polym. Sci. 2008, 110, 2586–2594. [Google Scholar] [CrossRef]

- Guo, C.; Zhou, L.; Lv, J. Effects of Expandable Graphite and Modified Ammonium Polyphosphate on the Flame-Retardant and Mechanical Properties of Wood Flour-Polypropylene Composites. Polym. Polym. Compos. 2013, 21, 449–456. [Google Scholar] [CrossRef]

- Basnayake, A.P.; Hidalgo, J.P.; Heitzmann, M.T. A flammability study of aluminium hydroxide (ATH) and ammonium polyphosphate (APP) used with hemp/epoxy composites. Constr. Build. Mater. 2021, 304, 124540. [Google Scholar] [CrossRef]

- Arockiam, N.J.; Jawaid, M.; Saba, N. Sustainable Bio Composites for Aircraft Components. In Sustainable Composites for Aerospace Applications; Woodhead Publishing: Sawston, UK, 2018. [Google Scholar]

- Kabir, I.I.; Sorrell, C.C.; Mofarah, S.S.; Yang, W.; Yuen, A.C.Y.; Nazir, M.T.; Yeoh, G.H. Alginate/Polymer-Based Materials for Fire Retardancy: Synthesis, Structure, Properties, and Applications. Polym. Rev. 2021, 61, 357–414. [Google Scholar] [CrossRef]

- Chen, H.-B.; Shen, P.; Chen, M.-J.; Zhao, H.-B.S.D.A. Highly-efficient Flame Retardant Polyurethane Foam with Alginate/Clay Aerogel Coating. ACS Appl. Mater. Interfaces 2016, 8, 32557–32564. [Google Scholar] [CrossRef]

- Yew, M.C.; Sulong, N.H.; Yew, M.K.; Amalina, M.A.; Johan, M.R. Influences of flame-retardant fillers on fire protection and mechanical properties of intumescent coatings. Prog. Org. Coat. 2015, 78, 59–66. [Google Scholar] [CrossRef]

- Craig, M.; Asim, T. Numerical Investigations on the Propagation of Fire in a Railway Carriage. Energies 2020, 13, 4999. [Google Scholar] [CrossRef]

- Ng, Y.H.; Dasari, A.; Tan, K.H.; Qian, L. Intumescent fire-retardant acrylic coatings: Effects of additive loading ratio and scale of testing. Prog. Org. Coat. 2021, 150, 105985. [Google Scholar] [CrossRef]

- ATSM International. Standard Test Method for Heat and Visible Smoke Release Rates for Materials and Products Using an Oxygen Consumption Calorimeter; ASTM International: West Conshohocken, PA, USA, 8 August 2017; Available online: https://www.astm.org/e1354-17.html (accessed on 3 April 2022).

- Ugarte, L.; Saralegi, A.; Fernández, R.; Martín, L.; Corcuera, M.A.; Eceiza, A. Flexible polyurethane foams based on 100% renewably sourced polyols. Ind. Crops Prod. 2014, 62, 545–551. [Google Scholar] [CrossRef]

- ASTM D638-14; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2017.

- Witkiewicz, W.; Zieliński, A. Properties of the Polyurethane(PU) Light Foams. Adv. Mater. Sci. 2006, 6, 35–51. [Google Scholar]

- Leng, Y.; Xu, M.-J.; Sun, Y.; Han, R.-X.; Li, B. Simultaneous enhancement of thermal conductivity and flame retardancy for epoxy resin thermosets through self-assemble of ammonium polyphosphate surface with graphitic carbon nitride. Polym. Adv. Technol. 2019, 30, 2468–2479. [Google Scholar] [CrossRef]

- Yuen, A.C.Y.; Chen, T.; Yuan, B.; Yeoh, G.H.; Yang, W.; Cheung, S.C.-P.; Cook, M.; Yu, B.; Chan, Q.N.; Yip, H.L. Establishing pyrolysis kinetics for the modelling of the flammability and burning characteristics of solid combustible materials. J. Fire Sci. 2018, 36, 494–517. [Google Scholar] [CrossRef]

- Fehrm, B. Redefining the 757 replacement: Requirement for the 225/5000 Sector. Leeham News and Analysis, 25 February 2015; p. 1. [Google Scholar]

- Bich, C. Application of RAMSIS in Passenger Aircraft Seat Development at Recaro Aircraft Seating. In Proceedings of the RAMSIS User Conference 2018, Schwabisch Hall, Germany, 20 June 2018. [Google Scholar]

- McGrattan, K.; McDermott, R.; Weinschenk, C.; Forney, G. Fire Dynamics Simulator Users Guide, 6th ed.; National Institute of Standards and Technology (NIST): Gaithersburg, MD, USA, 2013. [Google Scholar]

- Wang, X. Fire Dynamics Simulator (FDS) Pyrolysis Model Analysis of Heavy Goods Vehicle Fires in Road Tunnels; University of Canterbury: Christchurch, New Zealand, 2017. [Google Scholar]

- National Research Council (US) Committee on Air Quality in Passenger Cabins of Commercial Aircraft. The Airliner Cabin Environment and the Health of Passengers and Crew; National Library of Medicine: Washington, DC, USA, 2002.

- ASTM D3574-17; Standard Test Methods for Flexible Cellular Materials—Slab, Bonded, and Molded Urethane Foams. ASTM International: West Conshohocken, PA, USA, 2017.

- Špirk, S.; Křížek, M.; Jeníček, Š. Polyurethane Foam Behaviour during Impact. In Proceedings of the MATEC Web of Conferences; EDP Sciences: Les Ulis, France,, 2018. [Google Scholar]

- Zeng, L.; Yang, L.; Ai, L.; Ye, Z.; Liu, P. Synergistic Flame Retardant Effect of Ammonium Polyphosphate and Aluminum Hydroxide on Polyurethane. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2022, 37, 533–539. [Google Scholar] [CrossRef]

- Wang, Z.; Han, E.; Ke, W. Influence of expandable graphite on fire resistance and water resistance of flame retardant coatins. Corros. Sci. 2007, 49, 2237–2253. [Google Scholar] [CrossRef]

- Wang, Y.; Zhao, J.; Meng, X. Effect of expandable graphite on polyester resin-based intumescent flame retardant coating. Prog. Org. Coat. 2019, 132, 178–183. [Google Scholar] [CrossRef]

- Morgan, A.; Wilkie, C. Non-Halogenated Flame Retardant Handbook; Scrivener Publishing LLC.: Beverly, MA, USA, 2014. [Google Scholar]

- Kabir, I.I.; Fu, Y.; De Souza, N.; Baena, J.C.; Yuen, A.C.Y.; Yang, W.; Mata, J.; Peng, Z.; Yeoh, G.H. PDMS/MWCNT nanocomposite films for underwater sound absorption applications. J. Mater. Sci. 2020, 55, 5048–5063. [Google Scholar] [CrossRef]

- Butcher, N.; Barnett, D.J.; Buckland, T. Emergency Evacuation of Commercial Passenger Aeroplanes. R. Aeronaut. Soc. 2022, 2, 33–34. [Google Scholar]

- Lohert, A.; Monreal, N.; Knaust, C.; Hofmann, A.; Krause, U. CFD Modelling approach of smoke toxiticy and opacity for flaming and non-flaming combustion processes. Fire Mater. 2015, 40, 759–772. [Google Scholar] [CrossRef]

- Amaral, C.; Vicente, R.; Eisenblätter, J.; Marques, P.A.A.P. Thermal characterization of polyurethane foams with phase change material. Ciência Tecnol. Dos Mater. 2017, 29, 1–7. [Google Scholar] [CrossRef]

| Sample Configuration | Composition | ||

|---|---|---|---|

| Layer 1 | Layer 2 | Layer 3 | |

| PU (Control) | - | - | - |

| PU + EG5 | EG 5 wt% | - | - |

| PU + EG10 | EG 10 wt% | - | - |

| PU + EG50 | EG 50 wt% | - | - |

| PU + APP5 | APP 5 wt% | - | - |

| PU + APP10 | APP 10 wt% | - | - |

| PU + APP50 | APP 50 wt% | - | - |

| PU + EG10 + APP10 | EG 10 wt% | AG 10 wt% | - |

| PU + APP10 + AG10 | APP 10 wt% | AG 10 wt% | - |

| PU + EG5 + APP5 + AG5 | EG 5 wt% | APP 5 wt% | AG 5 wt% |

| PU + EG10 + APP10 + AG10 | EG 10 wt% | APP 10 wt% | AG 10 wt% |

| Sample Configuration | Composition | ||

|---|---|---|---|

| Layer 1 | Layer 2 | Layer 3 | |

| PU (Control) | - | - | - |

| PU + EG10 | EG 10 wt% | - | - |

| PU + APP10 | APP 10 wt% | - | - |

| PU + EG10 + APP10 | EG 10 wt% | AG 10 wt% | - |

| PU + APP10 + AG10 | APP 10 wt% | AG 10 wt% | - |

| PU + EG5 + APP5 + AG5 | EG 5 wt% | APP 5 wt% | AG 5 wt% |

| PU + EG10 + APP10 + AG10 | EG 10 wt% | APP 10 wt% | AG 10 wt% |

| Sample | Tensile Strength (kPa) | %Δ from Control | Maximum Elongation (mm) | %Δ from Control |

|---|---|---|---|---|

| PU | 158.8 | - | 106.9 | - |

| PU + EG10 | 322.5 | 103.1% | 67.0 | −37.3% |

| PU + APP10 | 376.3 | 137.0% | 83.4 | −22.0% |

| PU + EG10 + AG10 | 640.0 | 303.1% | 115.4 | 8.0% |

| PU + APP10 + AG10 | 566.3 | 256.7% | 125.7 | 17.6% |

| PU + EG5 + APP5 + AG5 | 490.0 | 208.7% | 112.5 | 5.3% |

| PU + EG10 + APP10 + AG10 | 691.3 | 335.4% | 127.9 | 19.7% |

| Sample | Strength at 50% Compression (kPa) | %Δ from Control | Strength at 80% Compression (kPa) | %Δ from Control | % Difference in Final Thickness |

|---|---|---|---|---|---|

| PU | 3.4 | - | 19.8 | - | −4% |

| PU + EG10 | 15.3 | 355% | 270.0 | 1264% | −4% |

| PU + APP10 | 11.0 | 226% | 194.0 | 880% | −8% |

| PU + EG10 + AG10 | 14.8 | 342% | 299.9 | 1415% | −4% |

| PU + APP10 + AG10 | 21.8 | 550% | 420.5 | 2024% | 0% |

| PU + EG5 + APP5 + AG5 | 26.1 | 676% | 418.0 | 2011% | 0% |

| PU + EG10 + APP10 + AG10 | 55.0 | 1537% | 281.9 | 1324% | 0% |

| Sample | pHRR (kW/m2) | %Δ from Control | Average HRR (kW/m2) | %Δ from Control |

|---|---|---|---|---|

| PU | 859.9 | - | 105.9 | - |

| PU + EG5 | 438.9 | −49.0% | 115.9 | 9.4% |

| PU + EG10 | 287.8 | −66.5% | 81.2 | −23.3% |

| PU + EG50 | 69.6 | −91.9% | 33.4 | −68.5% |

| PU + APP5 | 553.8 | −35.6% | 155.3 | 46.7% |

| PU + APP10 | 467.9 | −45.6% | 150.7 | 42.4% |

| PU + APP50 | 152.6 | −82.3% | 25.4 | −76.0% |

| PU + EG10 + AG10 | 384.0 | −55.3% | 63.4 | −40.1% |

| PU + APP10 + AG10 | 516.3 | −40.0% | 160.8 | 51.9% |

| PU + EG5 + APP5 + AG5 | 526.6 | −38.8% | 101.9 | −3.8% |

| PU + EG10 + APP10 + AG10 | 417.3 | −51.5% | 46.1 | −56.4% |

| Sample | THR (MJ/m2) | %Δ from Control |

|---|---|---|

| PU | 19.5 | - |

| PU + EG5 | 45.2 | 131.4% |

| PU + EG10 | 39.8 | 103.6% |

| PU + EG50 | 19.7 | 0.8% |

| PU + APP5 | 49.7 | 154.5% |

| PU + APP10 | 43.7 | 123.8% |

| PU + APP50 | 27.5 | 40.6% |

| PU + EG10 + AG10 | 37.4 | 91.4% |

| PU + APP10 + AG10 | 55.5 | 184.2% |

| PU + EG5 + APP5 + AG5 | 60.3 | 208.8% |

| PU + EG10 + APP10 + AG10 | 13.4 | −31.6% |

| Sample | pSPR (m2/s) × 10−2 | %Δ from Control | Average SPR (m2/s) × 10−2 | %Δ from Control | TSP (m2) | %Δ from Control |

|---|---|---|---|---|---|---|

| PU | 7.52 | - | 3.31 | - | 5.64 | - |

| PU + EG5 | 11.20 | 48.9% | 5.53 | 67% | 21.57 | 282.1% |

| PU + EG10 | 5.79 | −23.1% | 2.49 | −25% | 12.65 | 124.2% |

| PU + EG50 | 5.60 | −25.6% | 2.85 | −14% | 16.85 | 198.5% |

| PU + APP5 | 17.23 | 129.0% | 9.23 | 179% | 29.51 | 422.7% |

| PU + APP10 | 14.59 | 94.0% | 7.04 | 113% | 20.35 | 260.5% |

| PU + APP50 | 9.47 | 25.8% | 4.44 | 34% | 47.86 | 747.9% |

| PU + EG10 + AG10 | 5.39 | −28.4% | 2.39 | −28% | 14.14 | 150.5% |

| PU + APP10 + AG10 | 14.50 | 92.7% | 8.33 | 152% | 28.65 | 407.5% |

| PU + EG5 + APP5 + AG5 | 11.62 | 54.5% | 4.09 | 24% | 24.46 | 333.3% |

| PU + EG10 + APP10 + AG10 | 9.14 | 21.4% | 3.07 | −7% | 8.98 | 59.1% |

| Sample | pCOP (mg/s) | %Δ from Control | pCO2P (g/s) | %Δ from Control |

|---|---|---|---|---|

| PU | 6.10 | - | 0.60 | - |

| PU + EG5 | 5.27 | −13.6% | 0.18 | −70.6% |

| PU + EG10 | 4.22 | −30.8% | 0.11 | −80.8% |

| PU + EG50 | 3.75 | −38.5% | 0.05 | −92.2% |

| PU + APP5 | 16.35 | 168.1% | 0.34 | −43.3% |

| PU + APP10 | 17.51 | 187.2% | 0.30 | −50.3% |

| PU + APP50 | 2.50 | −59.0% | 0.06 | −89.7% |

| PU + EG10 + AG10 | 6.41 | 5.1% | 0.24 | −59.7% |

| PU + APP10 + AG10 | 18.54 | 204.1% | 0.34 | −43.5% |

| PU + EG5 + APP5 + AG5 | 13.48 | 121.1% | 0.35 | −40.6% |

| PU + EG10 + APP10 + AG10 | 15.05 | 146.9% | 0.25 | −58.4% |

| Sample | Initial Mass (g) | Final Mass (g) | % Remaining |

|---|---|---|---|

| PU | 9.94 | 1.59 | 16.0% |

| PU + EG5 | 21.16 | 3.20 | 15.1% |

| PU + EG10 | 21.15 | 4.48 | 21.2% |

| PU + EG50 | 20.07 | 9.53 | 47.5% |

| PU + APP5 | 25.86 | 3.77 | 14.6% |

| PU + APP10 | 23.96 | 4.24 | 17.7% |

| PU + APP50 | 33.37 | 18.81 | 56.4% |

| PU + EG10 + AG10 | 24.25 | 8.87 | 36.6% |

| PU + APP10 + AG10 | 29.83 | 4.95 | 16.6% |

| PU + EG5 + APP5 + AG5 | 29.31 | 4.43 | 15.1% |

| PU + EG10 + APP10 + AG10 | 29.77 | 21.74 | 73.0% |

| Mesh Size | Cell Width (cm) | N. of Cells | CPU Time |

|---|---|---|---|

| Coarse | 10 | 10,000 | 0:08:43 |

| Medium | 5 | 53,280 | 1:18:13 |

| Fine | 3.75 | 161,280 | 3:58:21 |

| Sensor | Ventilation OFF | Ventilation ON | ||

|---|---|---|---|---|

| Peak Temperature (°C) | Min Visibility (m) | Peak Temperature (°C) | Min Visibility (m) | |

| 1—Seat | 1126 | - | 1113 | - |

| 2—Seat | 1089 | - | 1078 | - |

| 3—Seat | 1060 | - | 1030 | - |

| 4—Seat | 111 | - | 104 | - |

| 5—Seat | 46 | - | 45 | - |

| 6—Seat | 37 | - | 35 | - |

| 7—Aisle—Ceiling Height | 497 | 0.19 | 401 | 0.21 |

| 8—Aisle—Standing Height | 101 | 1.52 | 100 | 1.44 |

| 9—Aisle—Crawl Height | 50 | 3.32 | 74 | 2.96 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Loewenthal, O.; Doley, P.; Wang, C.; Yeoh, G.H.; Kabir, I.I. Investigating Intumescent Flame-Retardant Additives in Polyurethane Foam to Improve the Flame Resistance and Sustainability of Aircraft Cabin Materials. Fire 2024, 7, 351. https://doi.org/10.3390/fire7100351

Loewenthal O, Doley P, Wang C, Yeoh GH, Kabir II. Investigating Intumescent Flame-Retardant Additives in Polyurethane Foam to Improve the Flame Resistance and Sustainability of Aircraft Cabin Materials. Fire. 2024; 7(10):351. https://doi.org/10.3390/fire7100351

Chicago/Turabian StyleLoewenthal, Oliver, Preety Doley, Cheng Wang, Guan Heng Yeoh, and Imrana I. Kabir. 2024. "Investigating Intumescent Flame-Retardant Additives in Polyurethane Foam to Improve the Flame Resistance and Sustainability of Aircraft Cabin Materials" Fire 7, no. 10: 351. https://doi.org/10.3390/fire7100351

APA StyleLoewenthal, O., Doley, P., Wang, C., Yeoh, G. H., & Kabir, I. I. (2024). Investigating Intumescent Flame-Retardant Additives in Polyurethane Foam to Improve the Flame Resistance and Sustainability of Aircraft Cabin Materials. Fire, 7(10), 351. https://doi.org/10.3390/fire7100351