Feasibility of Using Combustion-Based Methods to Quantify Saline-Based Anti-Stripping Agent in Modified Asphalt Binders

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Asphalt

2.1.2. Zychotherm

2.1.3. Mixing Process of Zycotherm in Asphalt Binder

2.2. Test Methods

2.2.1. Oxygen Bomb Calorimeter

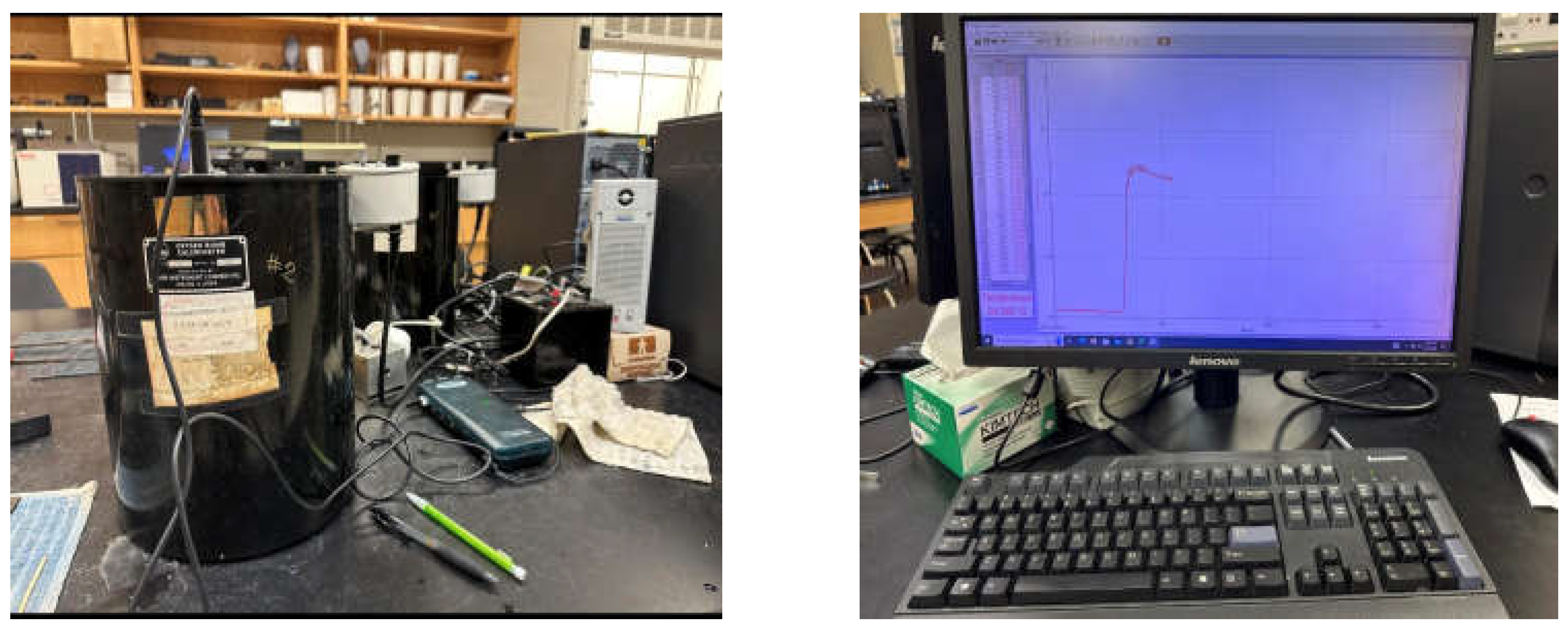

Experimental Apparatus

Experimental Procedure

2.2.2. Ignition Oven

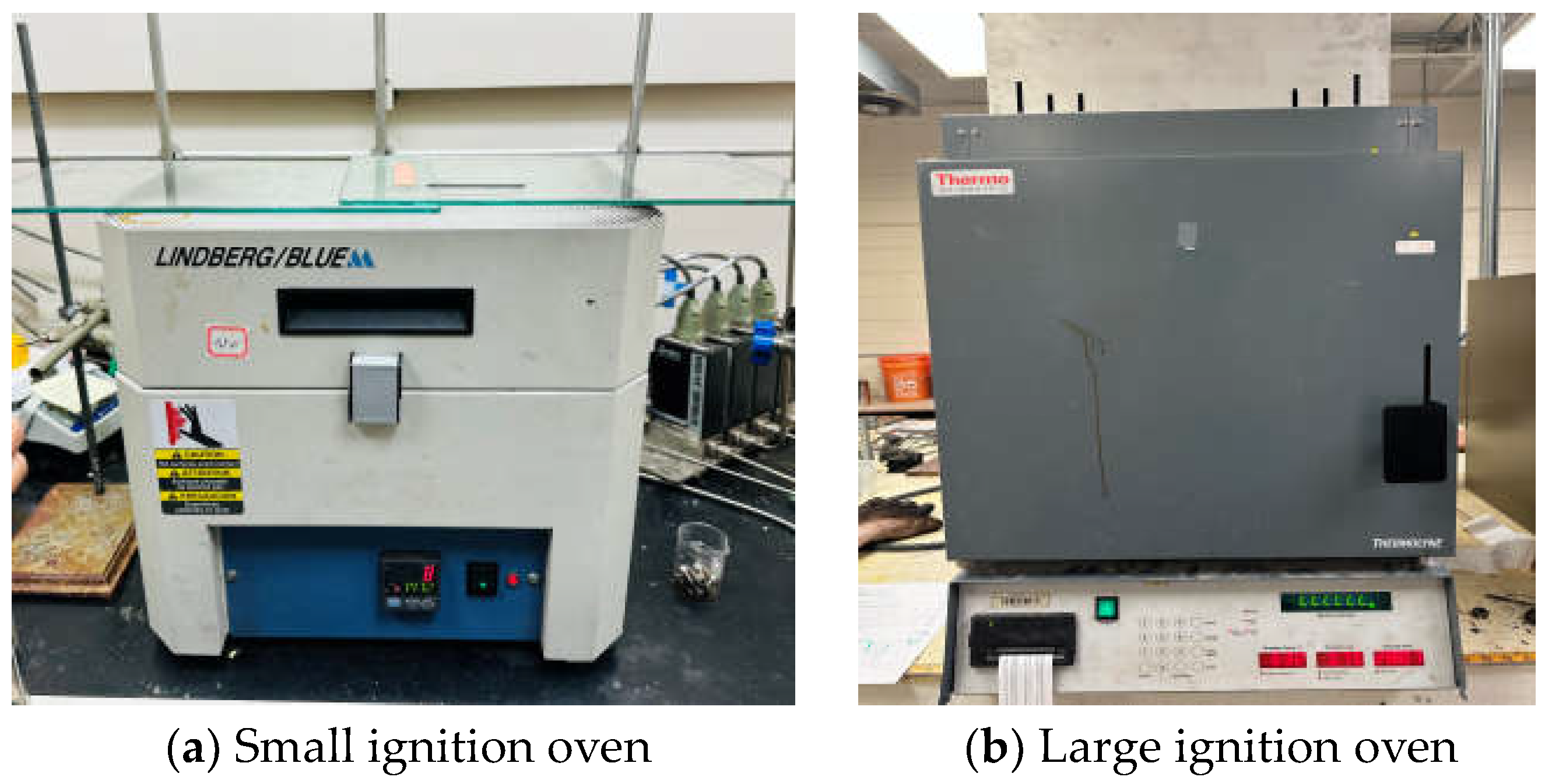

Experimental Apparatus

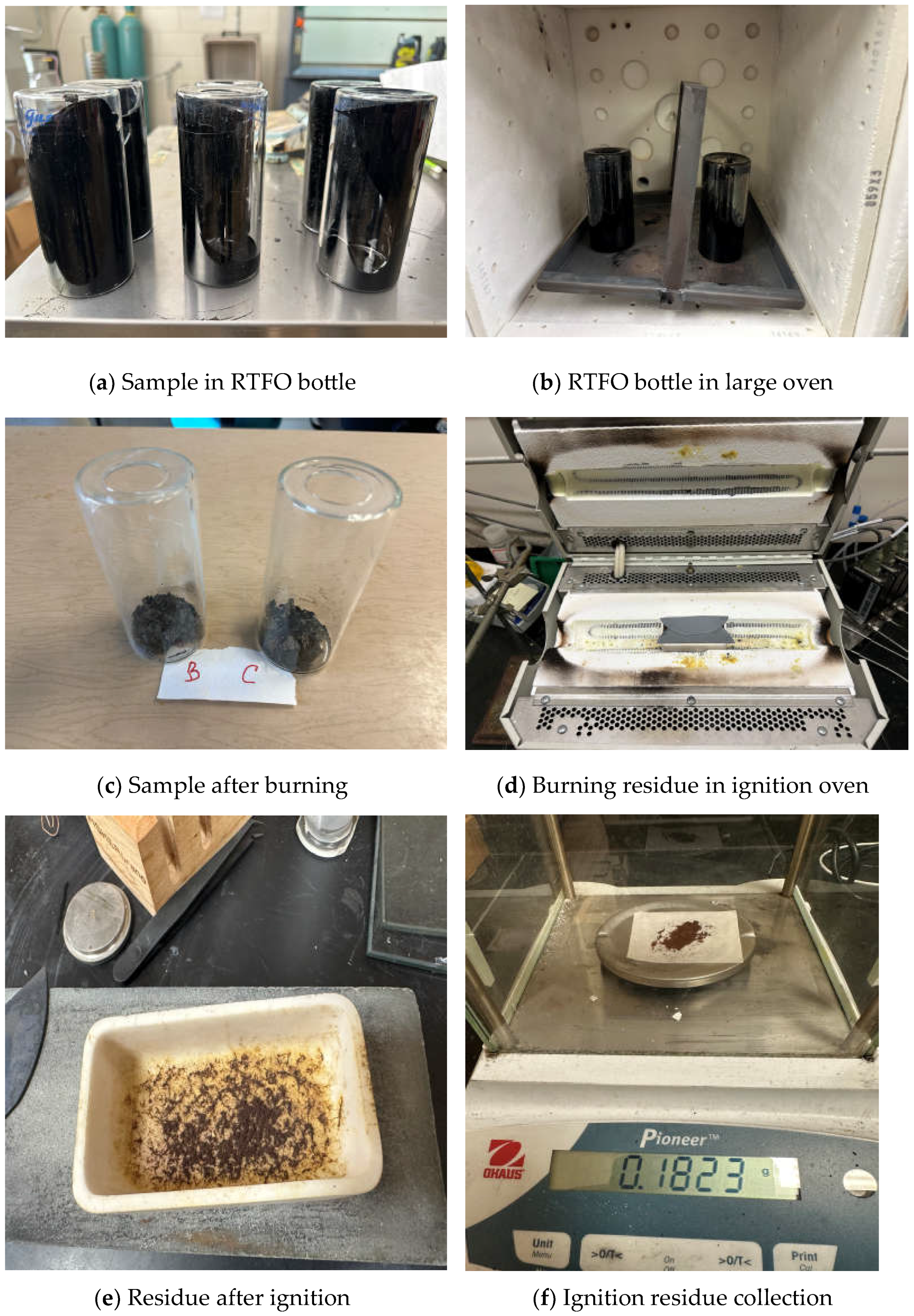

Experimental Procedure

2.2.3. Scanning Electron Microscopy (SEM)

2.2.4. Energy-Dispersive X-ray Spectroscopy (EDX)

3. Results

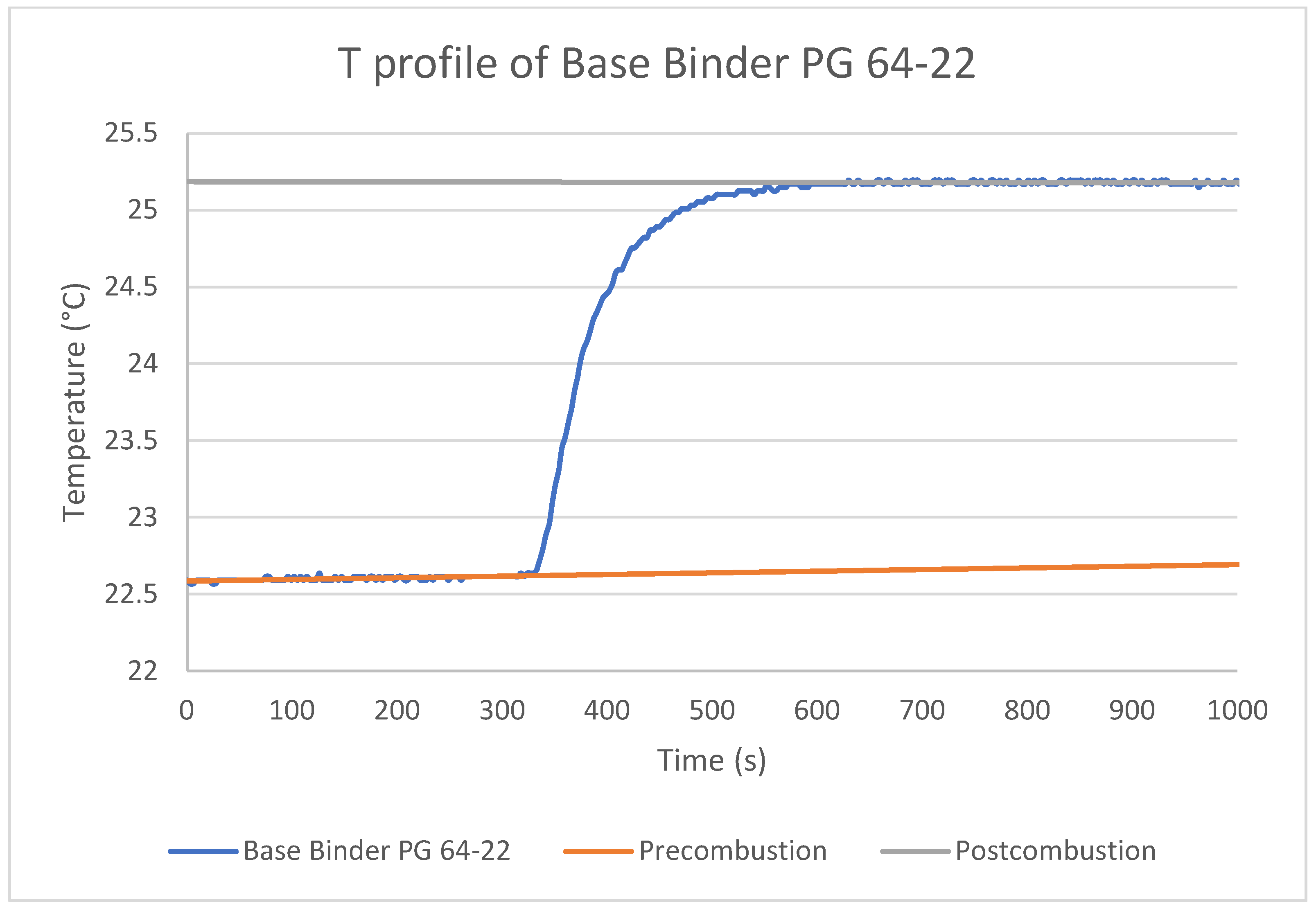

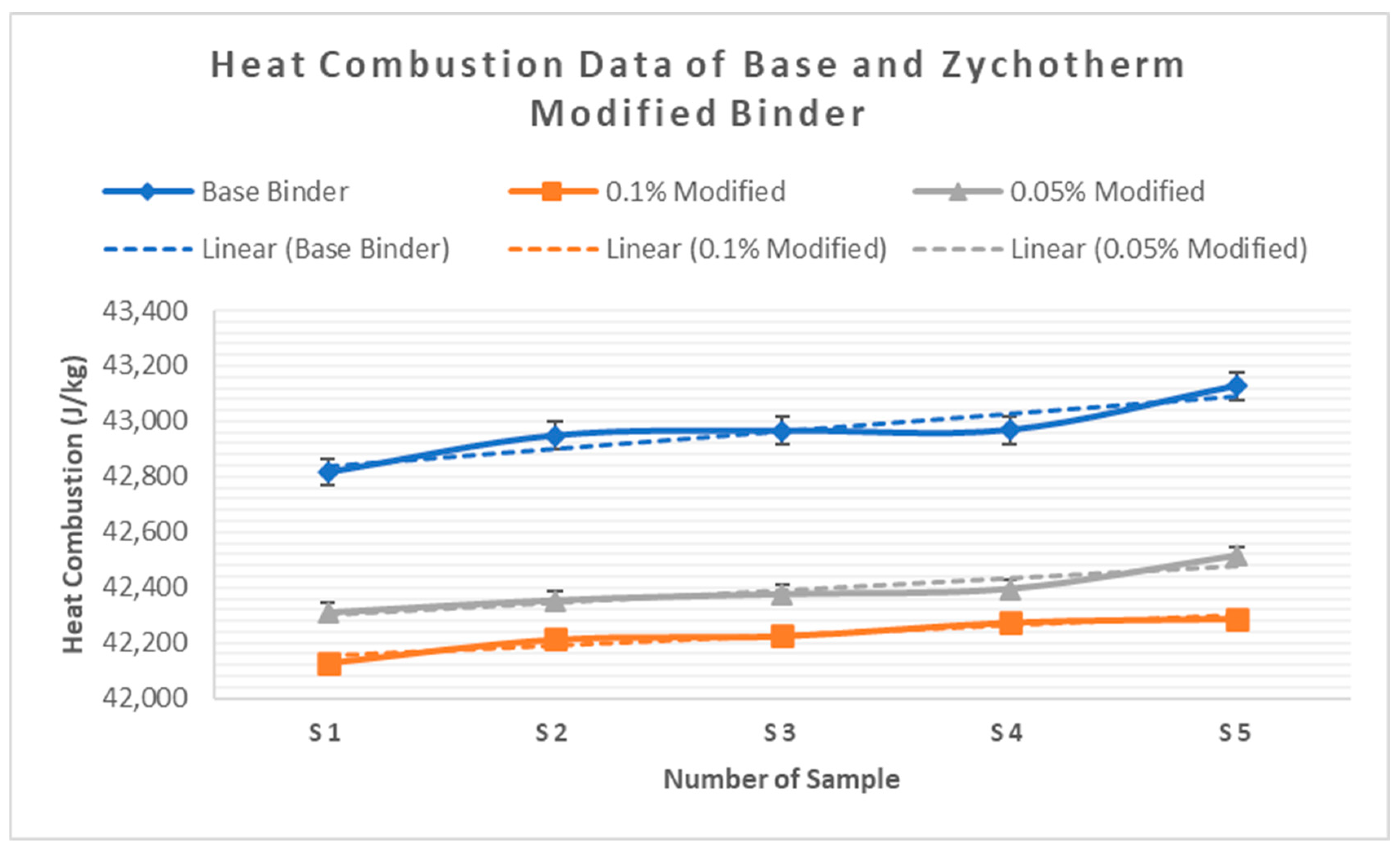

3.1. Oxygen Bomb Calorimeter Test

- Tc = temperature at the very highest point after combustion;

- Ta = temperature at the very lowest point before combustion;

- Spre = slope indicating leakage of heat “before” combustion;

- Spost = slope indicating leakage of heat “after” combustion;

- a = time at the lowest temperature;

- c = time at the highest temperature;

- b = time when 60% combustion completed.

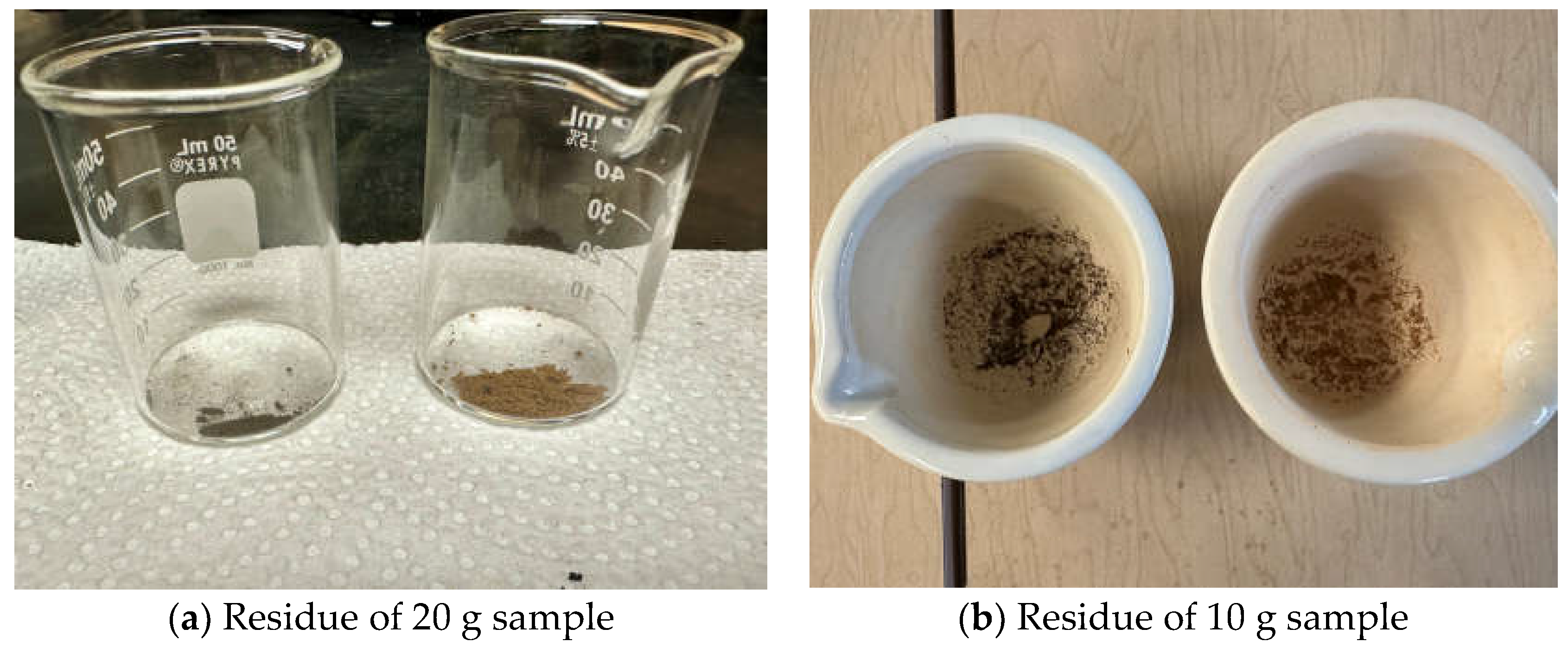

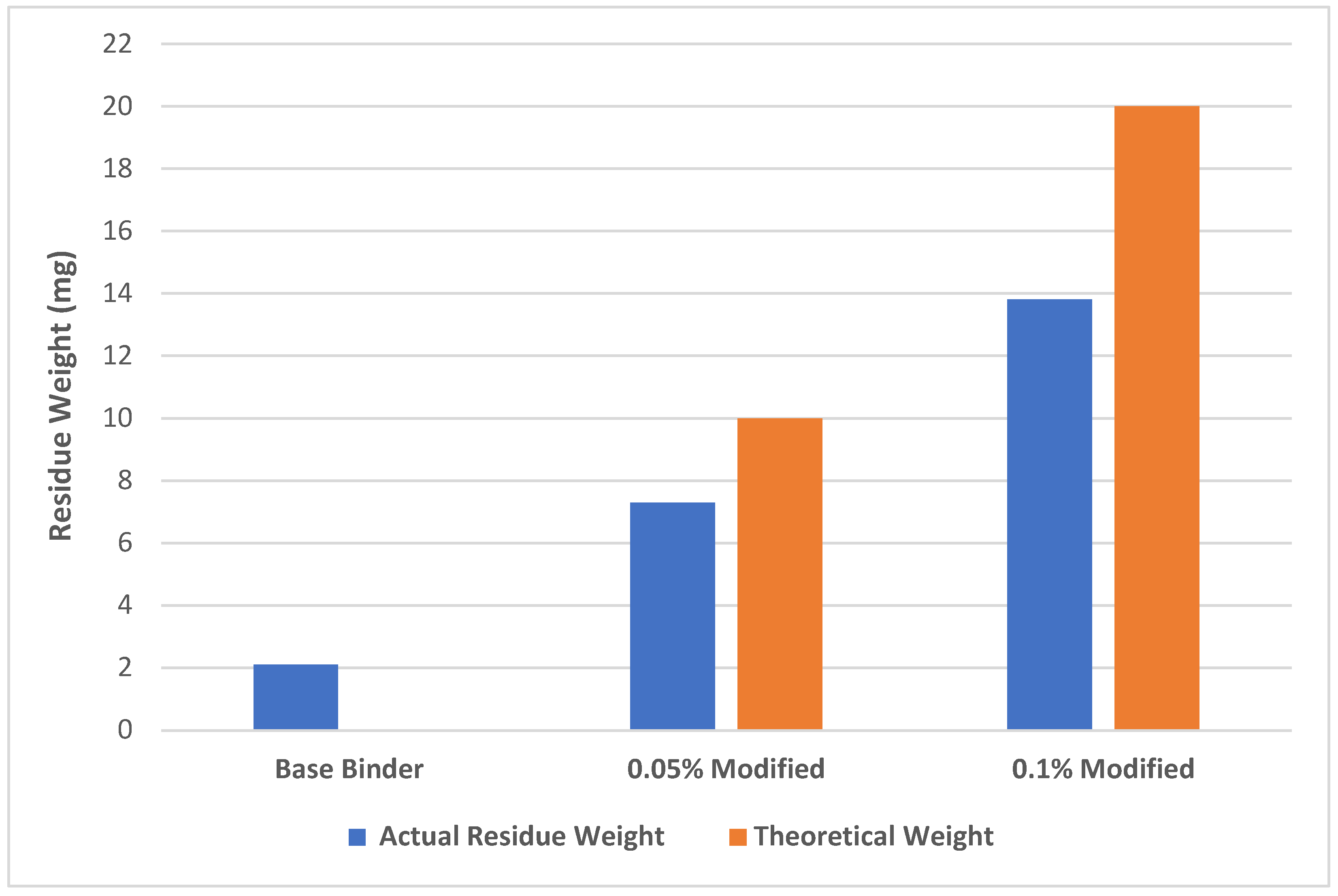

3.2. Detection by Residue Visualization

3.3. Scanning Electron Microscopy (SEM) Analysis

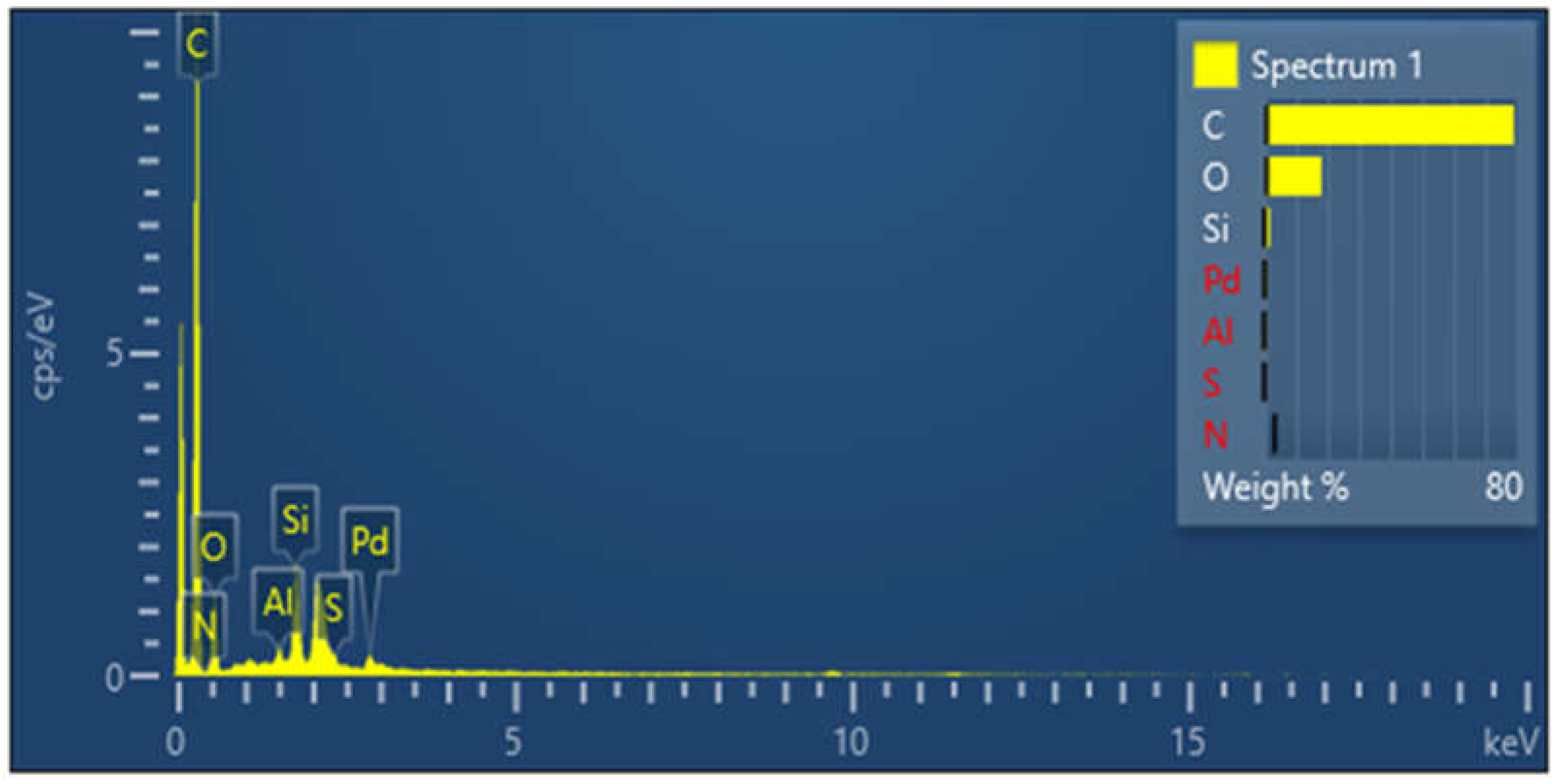

3.4. Energy-Dispersive X-ray Spectroscopy (EDX) Analysis

3.5. Sample Size Effect

4. Conclusions

- The study makes a feasible combustion-based detection method for quantifying siloxane-based anti-stripping agent (Zycotherm) concentrations in modified asphalt binders. This method, leveraging heat combustion and ignition processes, demonstrated the capability to closely measure low doses (0.05% and 0.1%) of Zycotherm, showcasing its potential for practical application in quality control and quality assurance processes in asphalt binder modification.

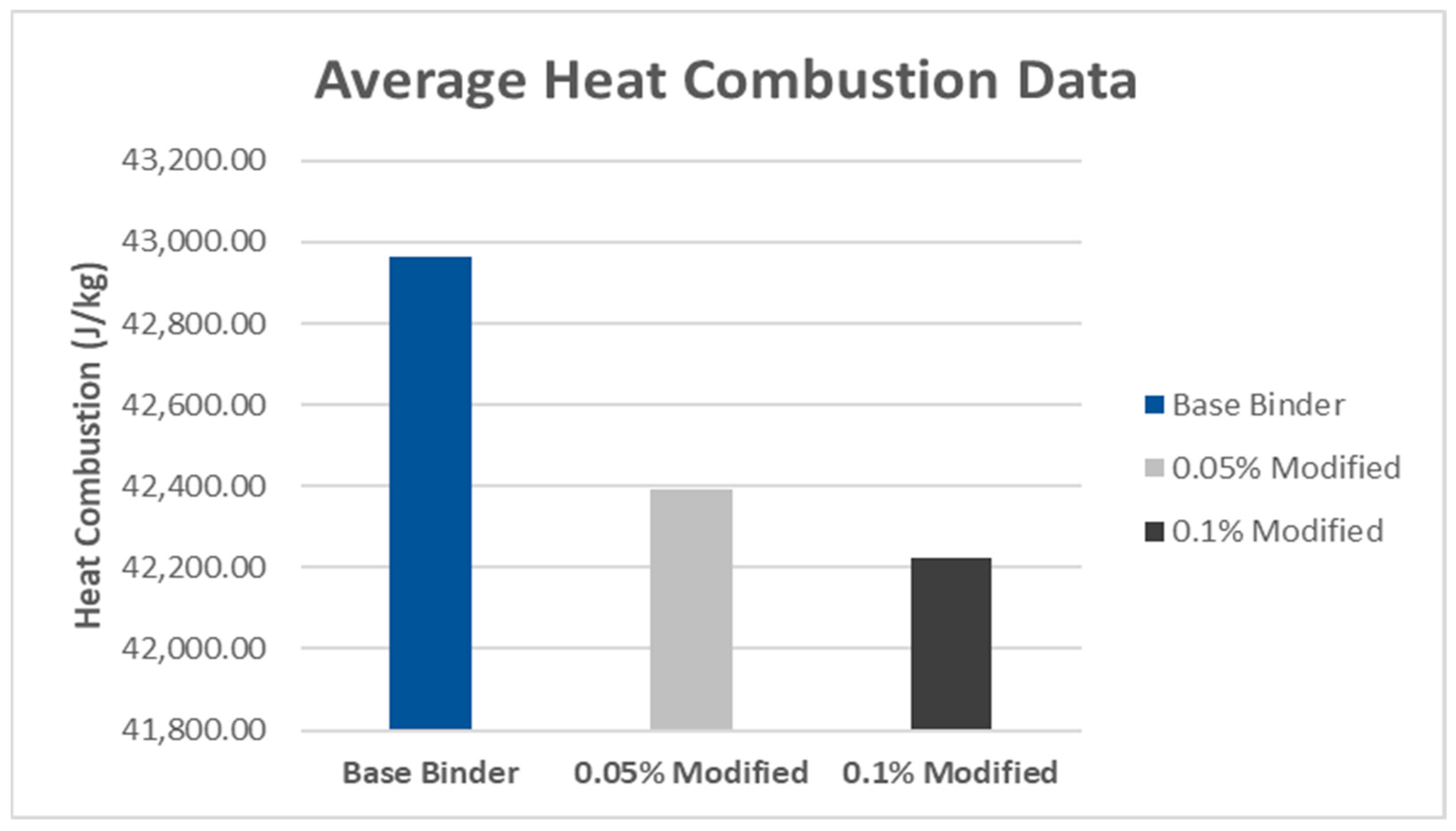

- Incorporation of Zycotherm into asphalt binders resulted in a measurable decrease in heat combustion values, with reductions of 1.34% and 1.72% for 0.05% and 0.1% Zycotherm-modified binders, respectively. This finding indicates that Zycotherm, even in minimal concentrations, can significantly affect the combustion characteristics of asphalt binders, suggesting a chemical interaction that alters the binder’s thermal properties.

- The study revealed that Zycotherm-modified asphalt binders leave a distinguishable yellowish residue after burning and ignition processes, contrasting with the dark black residue of unmodified binders. This observation not only supports the method’s effectiveness in detecting Zycotherm presence but also offers a simple, visual means of preliminary assessment before quantitative analysis.

- A direct, nearly proportional relationship was established between the amount of Zycotherm and the mass of silica residue. This correlation underscores the principle that the quantity of silica residue resulting from the combustion of siloxane-based additives can serve as a reliable indicator of the Zycotherm content in modified asphalt binders.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- 2018 Revision of World Urbanization Prospects|Multimedia Library-United Nations Department of Economic and Social Affairs. 2018. Available online: https://www.un.org/development/desa/publications/2018-revision-of-world-urbanizationprospects.html (accessed on 1 January 2024).

- Ma, B.; Chen, S.S.; Wei, K.; Liu, F.W.; Zhou, X.Y. Analysis of thermoregulation indices on microencapsulated phase change materials for asphalt pavement. Constr. Build. Mater. 2019, 208, 402–412. [Google Scholar] [CrossRef]

- Zheng, S.; Zhu, J.; Wu, Y.; He, J. Analysis of Asphalt Concrete Highway Construction Technology in Highway Engineering. J. Theory Pract. Eng. Sci. 2023, 3, 27–33. [Google Scholar] [CrossRef]

- Virginia Asphalt Association. 2020. Available online: https://vaasphalt.org/asphalt-facts/why-choose-asphalt-2/ (accessed on 11 March 2024).

- Kerh, T.; Wang, Y.-M.; Lin, Y. Experimental evaluation of anti-stripping additives mixing in road surface pavement materials. Am. J. Appl. Sci. 2005, 2, 1427–1433. [Google Scholar] [CrossRef]

- Anderson, D.A.; Dukatz, E.L.; Petersen, J.C. The effect of antistrip additives on the properties of asphalt cement. In Association of Asphalt Paving Technologists Proceedings; Transportation Research Board: Washington, DC, USA, 1982; Volume 51. [Google Scholar]

- Ford, M.C., Jr.; Manke, P.G.; O‘Bannon, C.E. Quantitative Evaluation of Stripping by the Surface Reaction Test (No. 517); Transportation Research Board: Washington, DC, USA, 1974. [Google Scholar]

- Mehrara, A.; Khodaii, A. A review of state of the art on stripping phenomenon in asphalt concrete. Constr. Build. Mater. 2013, 38, 423–442. [Google Scholar] [CrossRef]

- Chauhan, G.S.; Tripathy, S. Influence of Zycotherm on Properties of Bituminous Concrete Mix. J. Emerg. Technol. Innov. Res. 2019, 6. [Google Scholar]

- Xie, Z.; Shen, J. Fatigue performance of rubberized stone matrix asphalt by a simplified viscoelastic continuum damage model. J. Mater. Civ. Eng. 2016, 28, 04015162. [Google Scholar] [CrossRef]

- Ghabchi, R.; Rani, S.; Zaman, M.; Ali, S.A. Effect of WMA additive on properties of PPA-modified asphalt binders containing anti-stripping agent. Int. J. Pavement Eng. 2021, 22, 418–431. [Google Scholar] [CrossRef]

- Xie, Z.; Shen, J.; Fan, W.; Wang, L. Laboratory investigation of the effect of warm mix asphalt (WMA) additives on the properties of WMA used in China. J. Test. Eval. 2014, 42. [Google Scholar] [CrossRef]

- Xiao, F.; Amirkhanian, S.; Putman, B.; Shen, J. Laboratory investigation of engineering properties of rubberized asphalt mixtures containing reclaimed asphalt pavement. Can. J. Civil Eng. 2010, 37, 1414–1422. [Google Scholar] [CrossRef]

- Nazirizad, M.; Kavussi, A.; Abdi, A. Evaluation of the effects of anti-stripping agents on the performance of asphalt mixtures. Constr. Build. Mater. 2015, 84, 348–353. [Google Scholar] [CrossRef]

- Guha, S.; Kumar, A. A literature review on anti-strip additives in asphalt mixture. Int. J. Sci. Res. 2018, 2. [Google Scholar]

- Mirzababaei, P.; Moghadas Nejad, F.; Naderi, K. Effect of liquid silane-based anti-stripping additives on rheological properties of asphalt binder and hot mix asphalt moisture sensitivity. Road Mater. Pavement Des. 2020, 21, 570–585. [Google Scholar] [CrossRef]

- Fakhri, M.; Vanaei, V.; Rahi, M. “Rheological evaluation of the effect of nano-liquid additives on bitumen properties”. In Proceedings of the 8th National Congress on Civil Engineering, Babol, Iran, 7 May 2014; Nooshirvani Babol University of Technology: Babol, Iran, 2014. [Google Scholar]

- Xiao, F.; Zhao, W.; Gandhi, T.; Amirkhanian, S.N. Influence of antistripping additives on moisture susceptibility of warm mix asphalt mixtures. J. Mater. Civ. Eng. 2010, 22, 1047–1055. [Google Scholar] [CrossRef]

- Shu, S.; Zhuang, C.; Ren, R.; Xing, B.; Chen, K.; Li, G. Effect of Different Anti-Stripping Agents on the Rheological Properties of Asphalt. Coatings 2022, 12, 1895. [Google Scholar] [CrossRef]

- Dai, Z.; Shen, J.; Shi, P.; Zhu, H.; Li, X. Nano-sized morphology of asphalt components separated from weathered asphalt binders. Constr. Build. Mater. 2018, 182, 588–596. [Google Scholar] [CrossRef]

- Shen, J.; Huang, B.; Shu, X.; Tang, B. Size effect of sub nano-scaled hydrated lime on selected properties of HMA. Int. J. Pavement Res. Technol. 2011, 4, 252. [Google Scholar]

- Arabani, M.; Hamedi, G.H. Using the surface free energy method to evaluate the effects of polymeric aggregate treatment on moisture damage in hot-mix asphalt. J. Mater. Civ. Eng. 2010, 23, 802–811. [Google Scholar] [CrossRef]

- Buechler, S.; Wistuba, M.P.; Falchetto, A.C. Mixing and compacting asphalt mixtures modified with silane molecules. In Proceedings of the 6th Eurasphalt & Eurobitume Congress, Prague, Czech Republic, 1–3 June 2016. [Google Scholar]

- Sybilski, D.; Wistuba, M.P.; Bankowski, W.; Buechler, S.; Heinrich, P. Investigation on binder-aggregate adhesivity using a nanotechnology chemically reactive silane additives based agent. In Bituminous Mixtures and Pavements VI; Talylor Francis Group: Abingdon, UK, 2015; Volume 447. [Google Scholar]

- Arabani, M.; Roshani, H.; Hamedi, G.H. Estimating moisture sensitivity of warm mix asphalt modified with zycosoil as an antistrip agent using surface free energy method. J. Mater. Civ. Eng. 2012, 24, 889–897. [Google Scholar] [CrossRef]

- Islam, T. Rheology and Surface Free Energy of Modified Asphalt Binder Containing Anti-Stripping Additives. Ph.D. Dissertation, Memorial University of Newfoundland, St. John’s, NL, Canada, 2022. [Google Scholar]

- Goldstein, J.I.; Newbury, D.E.; Michael, J.R.; Ritchie, N.W.; Scott JH, J.; Joy, D.C. Scanning Electron Microscopy and X-ray Microanalysis; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Hoy, M.; Horpibulsuk, S.; Rachan, R.; Chinkulkijniwat, A.; Arulrajah, A. Recycled asphalt pavement–fly ash geopolymers as a sustainable pavement base material: Strength and toxic leaching investigations. Sci. Total Environ. 2016, 573, 19–26. [Google Scholar] [CrossRef]

- Mazumder, M.; Ahmed, R.; Ali, A.W.; Lee, S.J. SEM and ESEM techniques used for analysis of asphalt binder and mixture: A state of the art review. Constr. Build. Mater. 2018, 186, 313–329. [Google Scholar] [CrossRef]

- Hainin, M.R.; Idham, M.K.; Yaro, N.S.A.; Hussein, S.O.A.E.; Warid, M.N.M.; Mohamed, A.; Naqibah, S.N.; Ramadhansyah, P.J. Performance of hot mix asphalt mixture incorporating kenaf fibre. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2018; Volume 140, p. 012092. [Google Scholar]

- Chagger, H.K.; Hainsworth, D.; Patterson, P.M.; Pourkashanian, M.; Williams, A. The formation of SiO2 from hexamethyldisiloxane combustion in counterflow methane-air flames. In Symposium (International) on Combustion; Elsevier: Amsterdam, The Netherlands, 1996; Volume 26, pp. 1859–1865. [Google Scholar]

- Panda, S.S.; Mishra, D.P.; Upadhyaya, A. Effect of varying gas-flow conditions on the characteristics of the diffusion flame and silica powders prepared using flame combustion synthesis. Powder Technol. 2009, 191, 164–169. [Google Scholar] [CrossRef]

| Aging Condition | Test Property | Standard | Value | Requirement |

|---|---|---|---|---|

| Unaged | Viscosity @ 135 °C (cP) | AASHTO PP6 | 535 | Maximum 3000 cP |

| G*/sin δ @ 64 °C (kPa) | AASHTO PP6 | 1.92 | Minimum 1.00 kPa | |

| RTFO Aged | G*/sin δ @ 64 °C (kPa) | AASHTO PP6 | 3.26 | Minimum 2.20 kPa |

| PAV Aged | G*/sin δ @ 25 °C (kPa) | AASHTO PP6 | 4695 | Maximum 5000 kPa |

| Stiffness @ −12 °C (MPa) | AASHTO PP6 | 255 | Maximum 300 MPa | |

| m-value @ −12 °C | AASHTO PP6 | 0.36 | Minimum 0.3 |

| Property | Zychotherm Value |

|---|---|

| Color | Pale Yellow |

| Form | Liquid |

| Viscosity @ 25 °C | <3000 cP |

| Freezing Point | 5–7 °C |

| Flash Point | >80 °C |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Riyad, R.H.; Wu, J.; Shen, J. Feasibility of Using Combustion-Based Methods to Quantify Saline-Based Anti-Stripping Agent in Modified Asphalt Binders. Fire 2024, 7, 138. https://doi.org/10.3390/fire7040138

Riyad RH, Wu J, Shen J. Feasibility of Using Combustion-Based Methods to Quantify Saline-Based Anti-Stripping Agent in Modified Asphalt Binders. Fire. 2024; 7(4):138. https://doi.org/10.3390/fire7040138

Chicago/Turabian StyleRiyad, Riyadul Hashem, Ji Wu, and Junan Shen. 2024. "Feasibility of Using Combustion-Based Methods to Quantify Saline-Based Anti-Stripping Agent in Modified Asphalt Binders" Fire 7, no. 4: 138. https://doi.org/10.3390/fire7040138