Synergistic Effects of Titanium-Based MOFs MIL-125 with Intumescent Flame Retardants in ABS Polymer Composites on Flame Retardancy Study

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

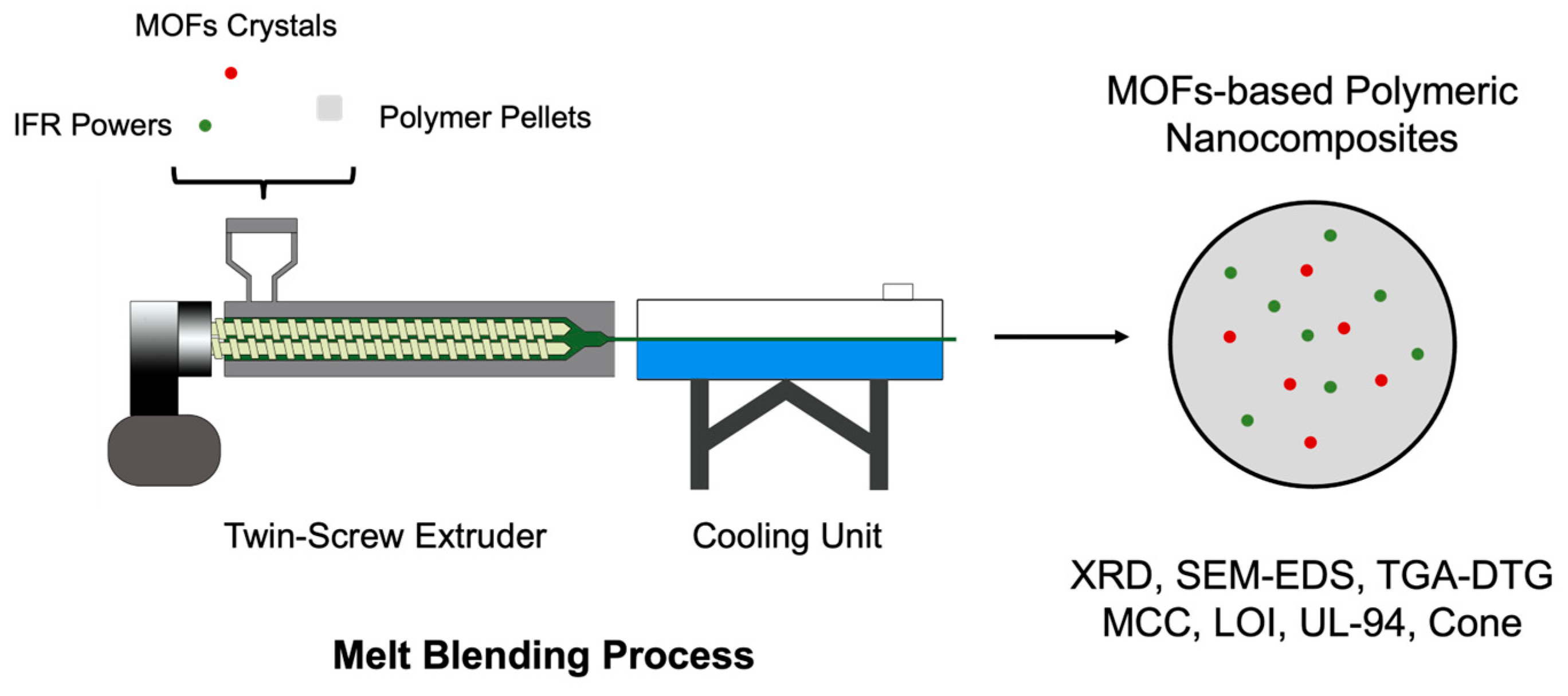

2.2. Preparation of ABS/MIL-125 Nanocomposites

2.3. Preparation of ABS/IFR/MIL-125 Composites

2.4. Characterizations

2.5. Fire Testing

3. Results and Discussion

3.1. Preliminary Thermal Stability and Flammability Studies of ABS/MIL-125

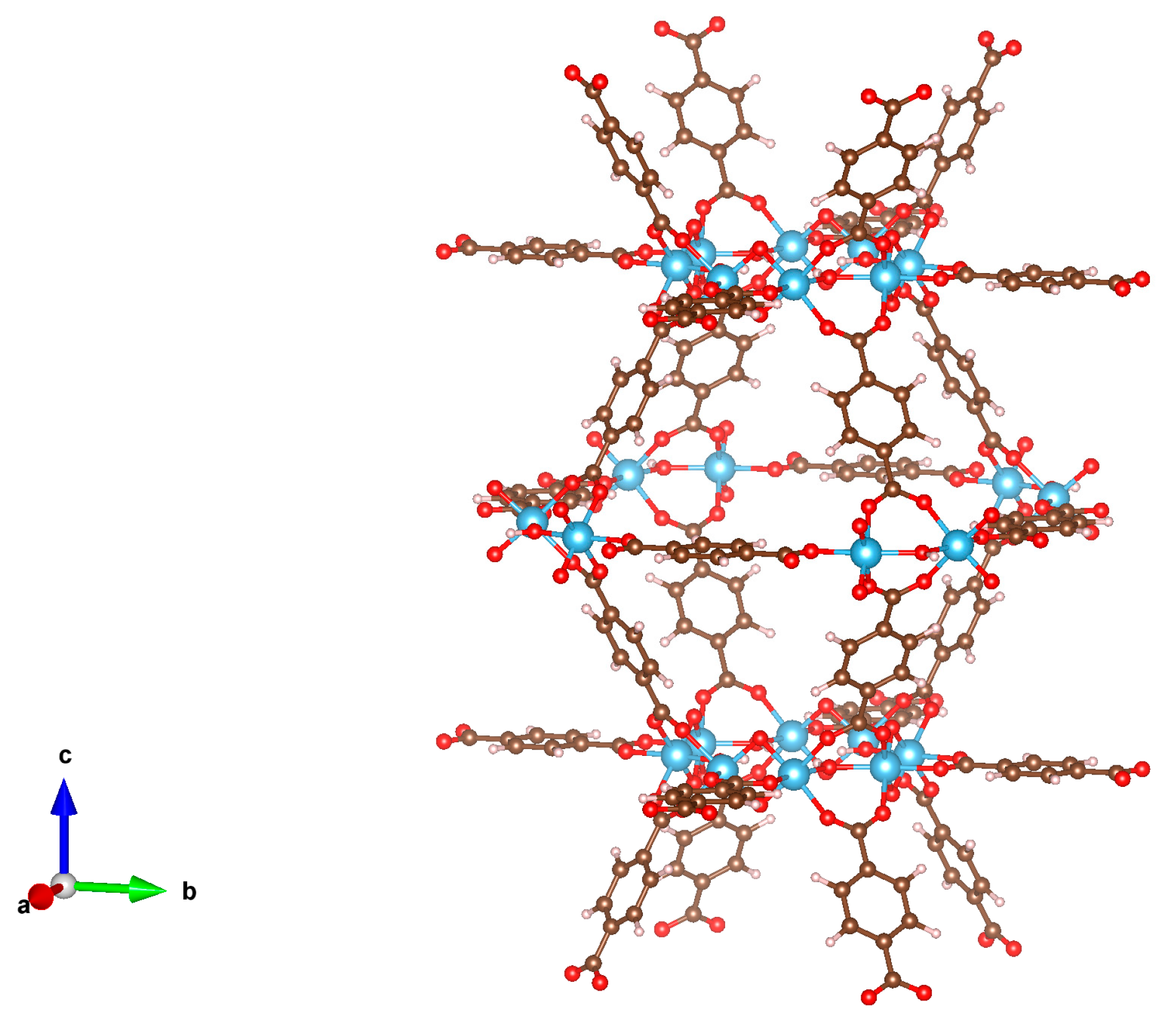

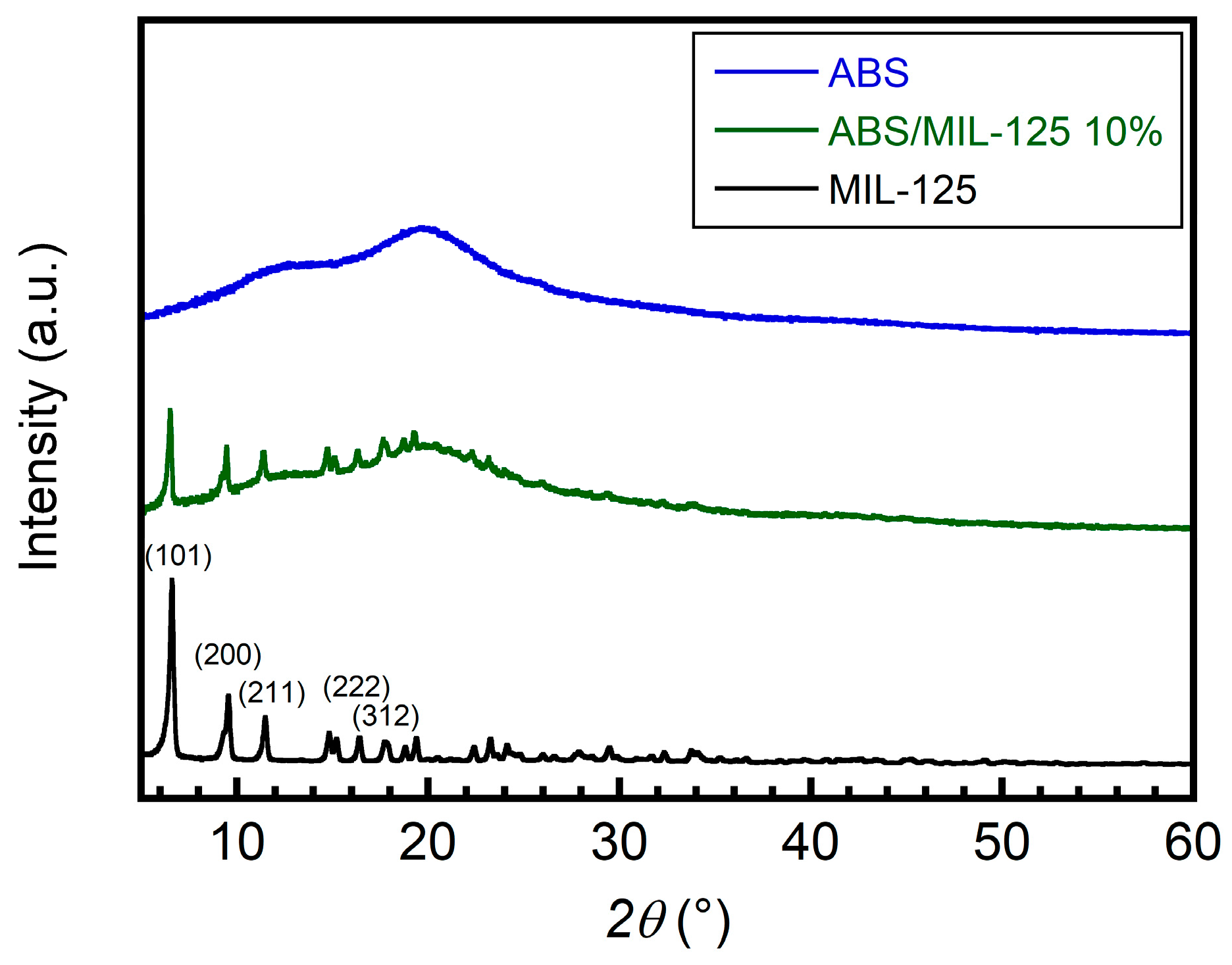

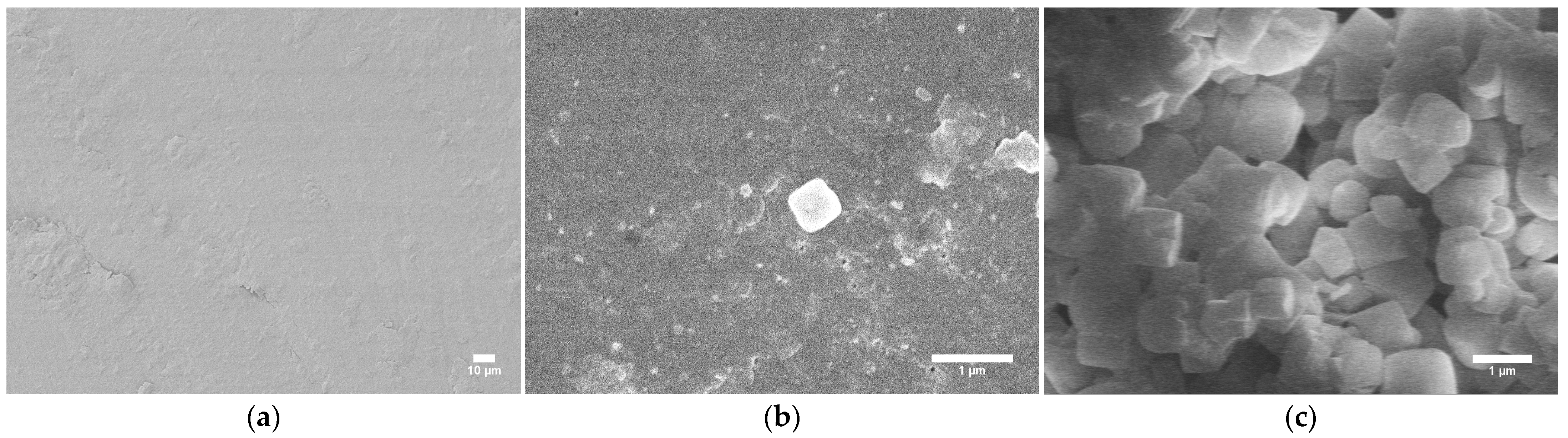

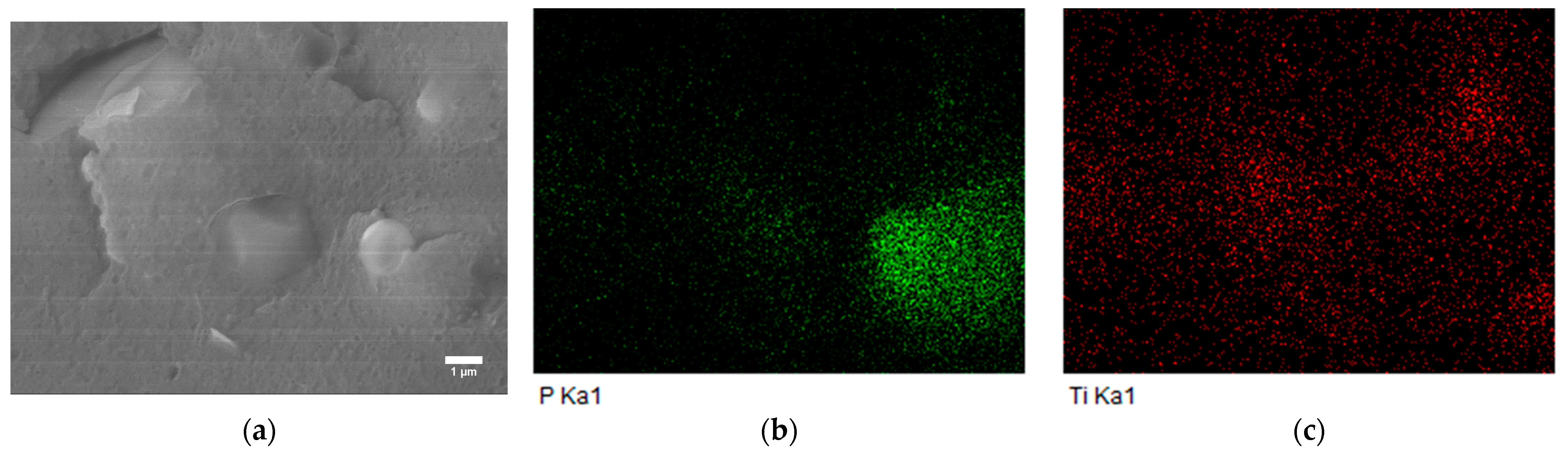

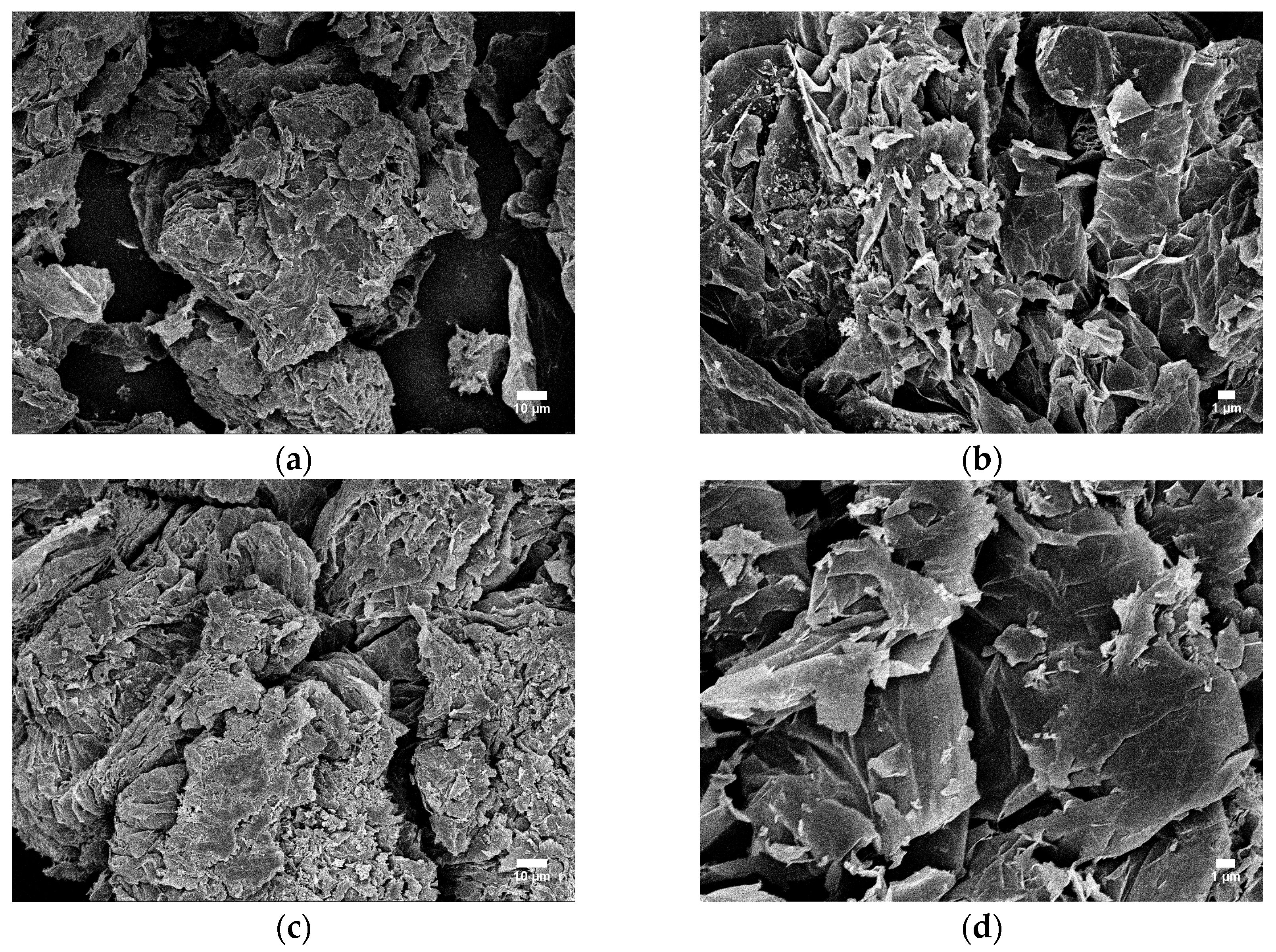

3.1.1. Characterizations of ABS/MIL-125

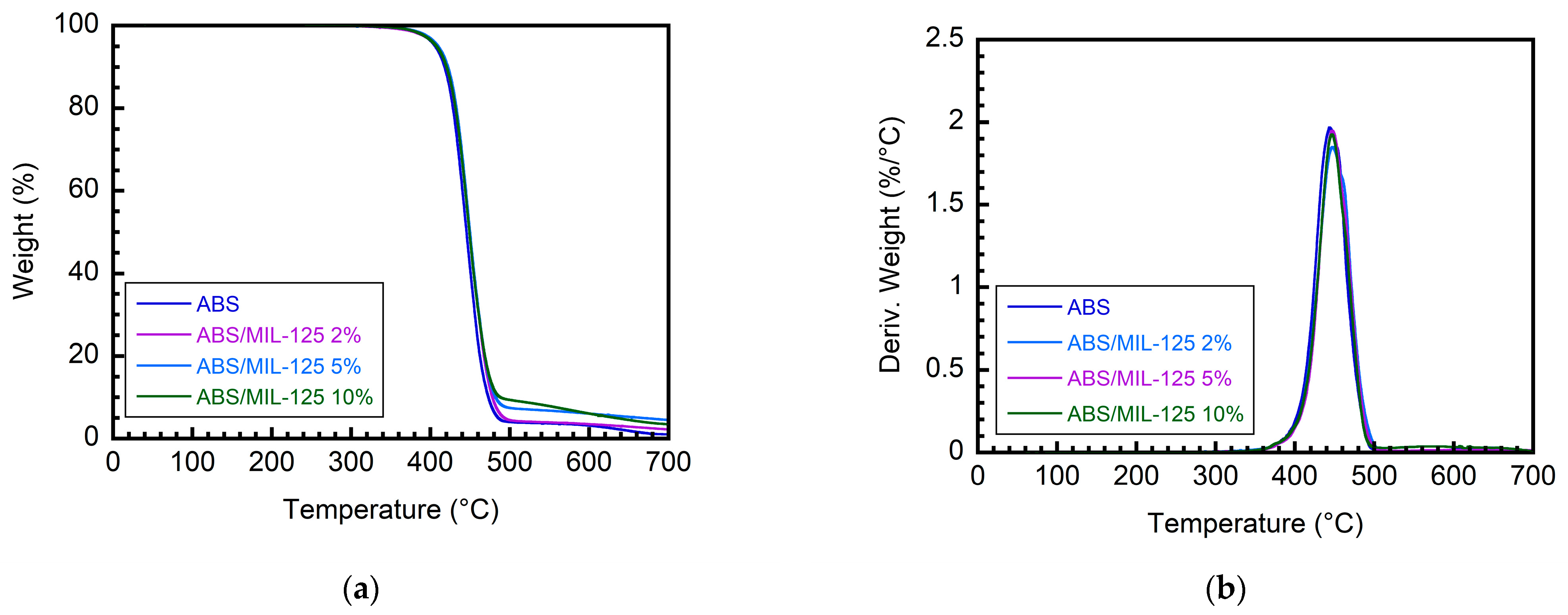

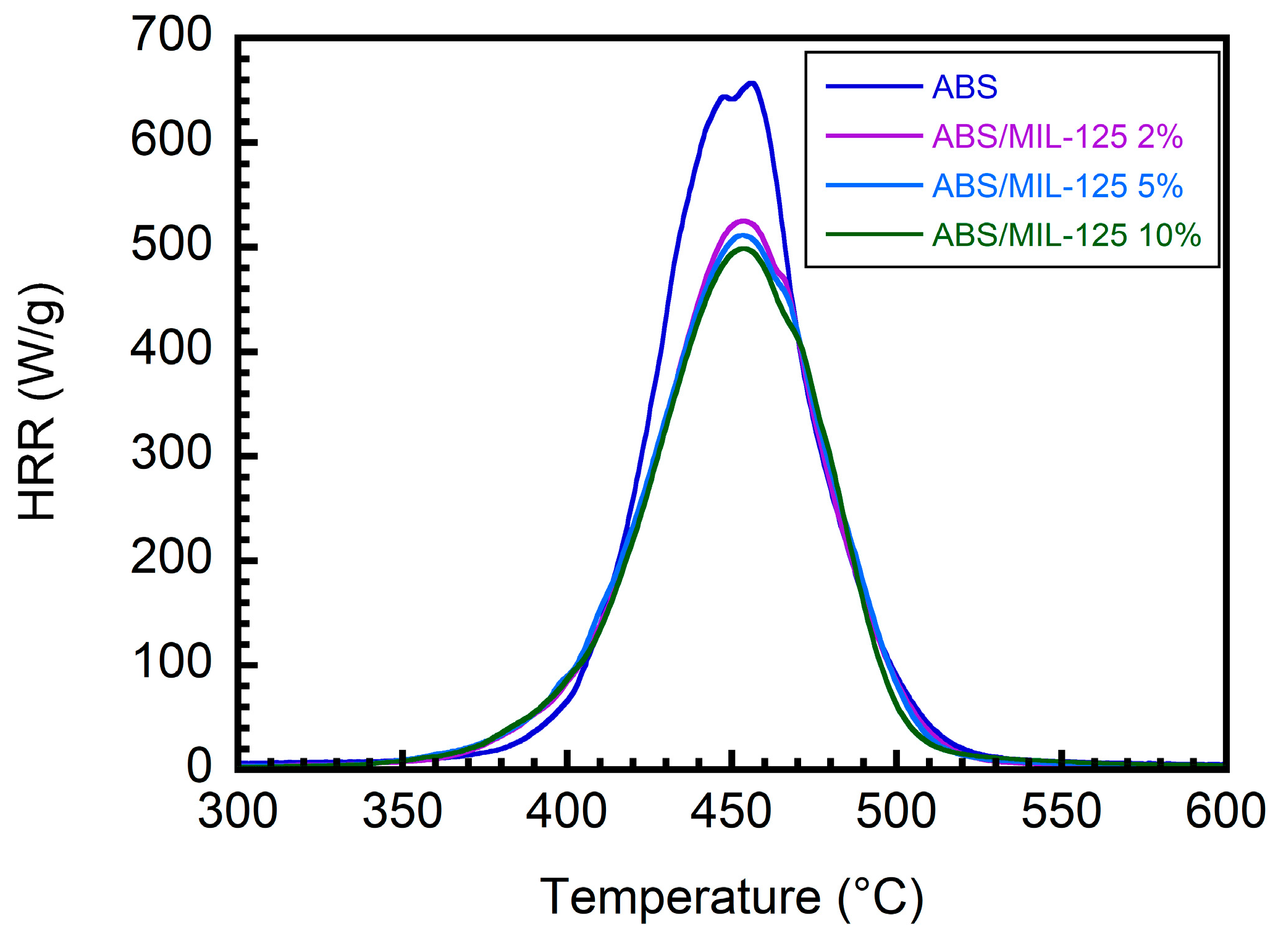

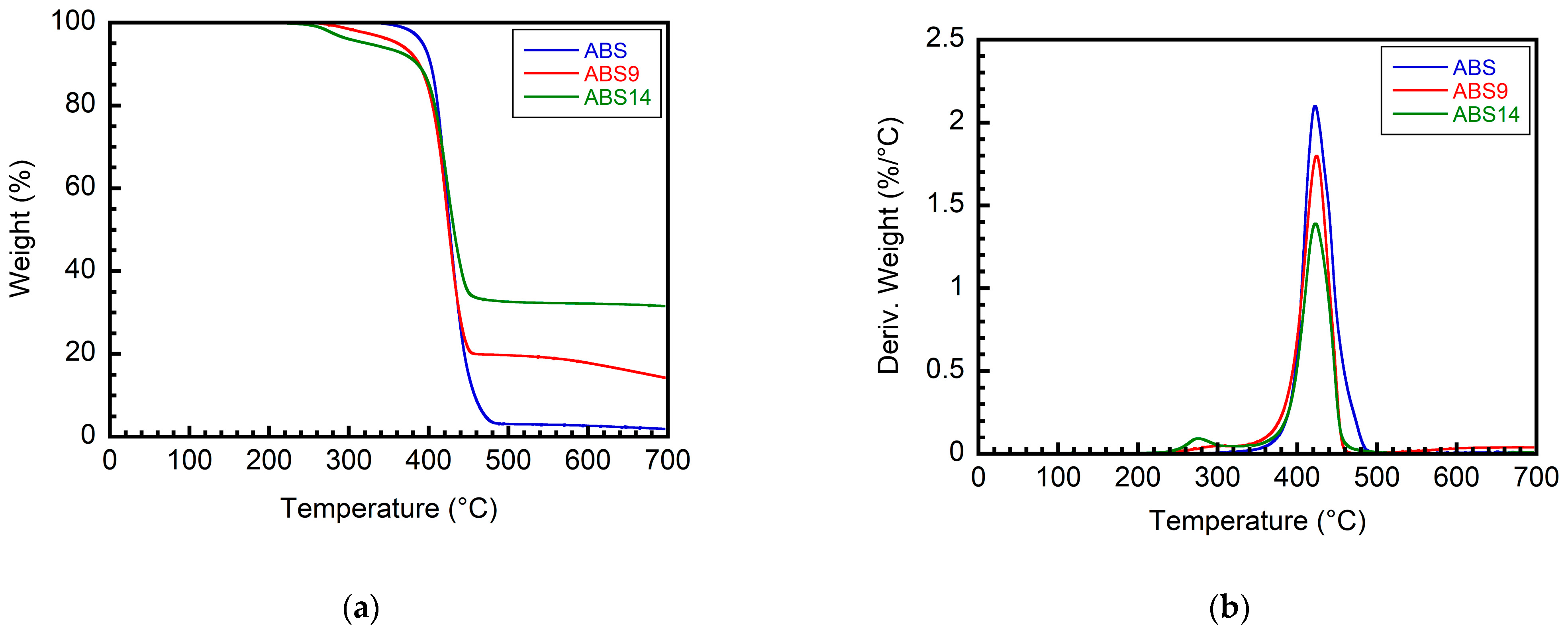

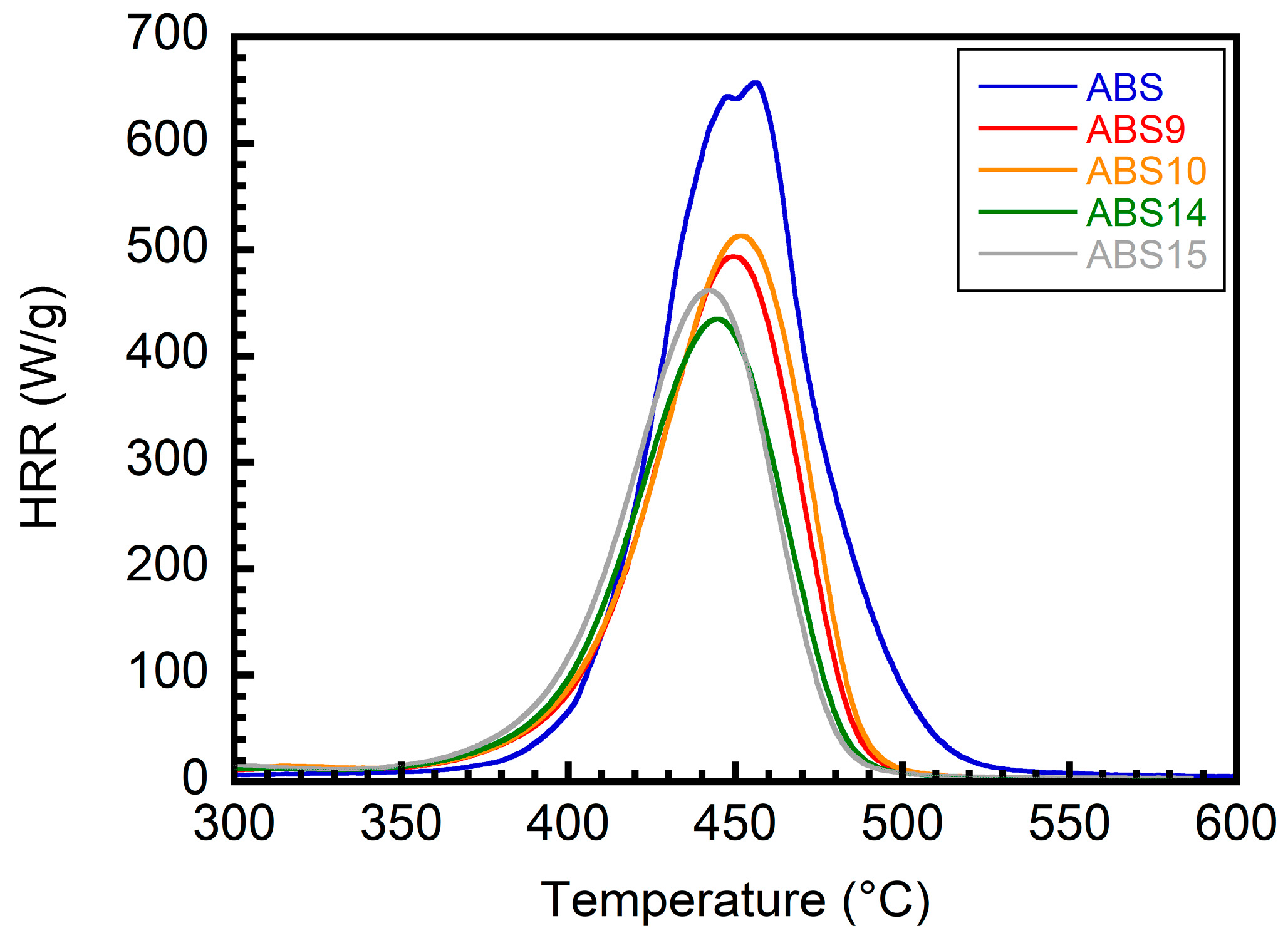

3.1.2. Thermal Stability and Flammability Studies of ABS/MIL-125

3.2. Flame Retardancy Studies of ABS/IFR/MIL-125

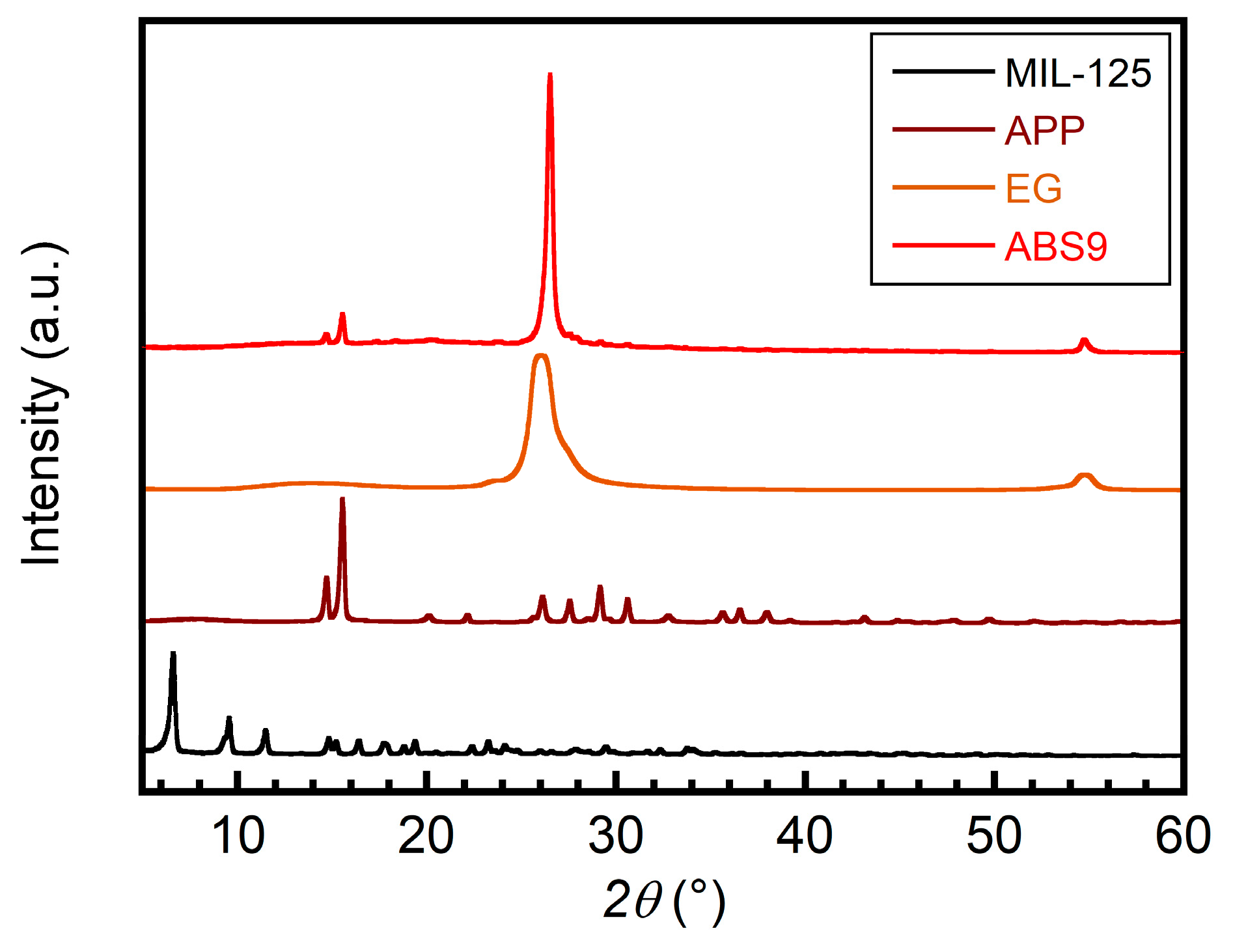

3.2.1. Characterizations of ABS/IFR/MIL-125

3.2.2. Thermal Stability and Flammability Studies of ABS/IFR/MIL-125

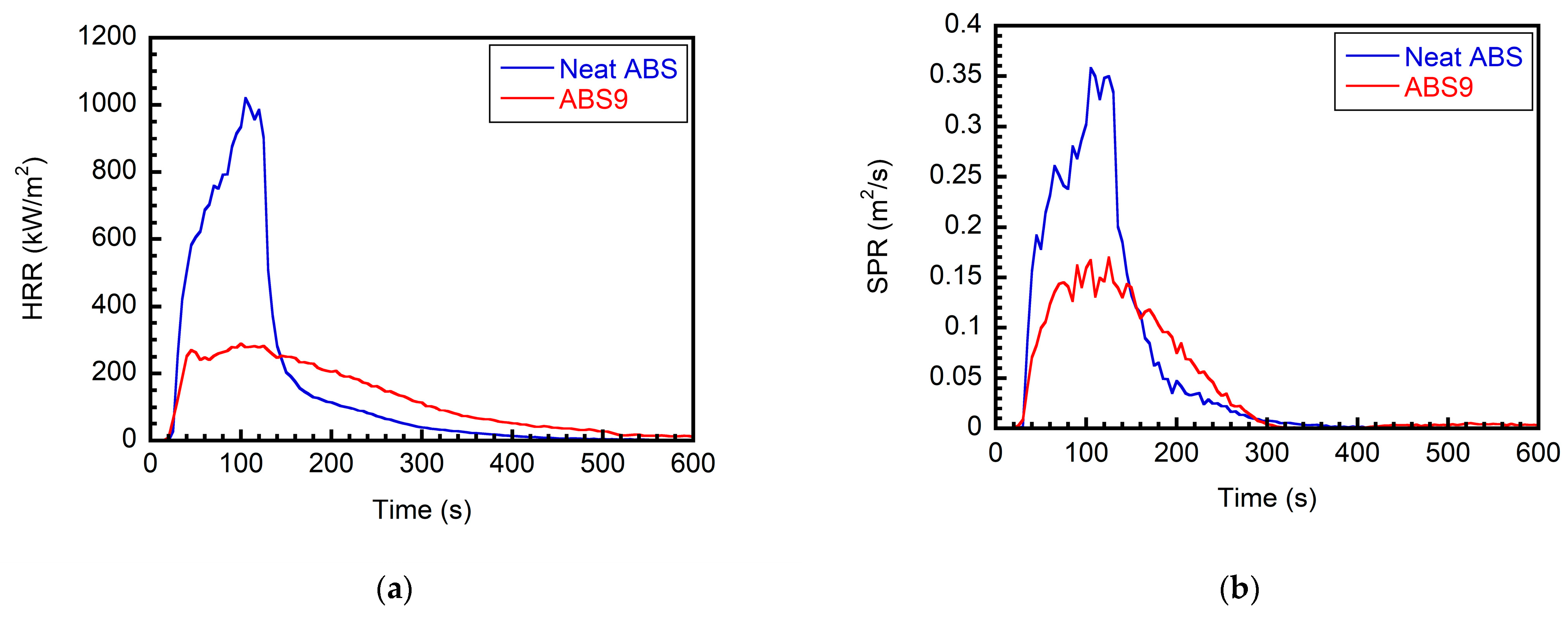

3.2.3. Flame Retardancy Studies

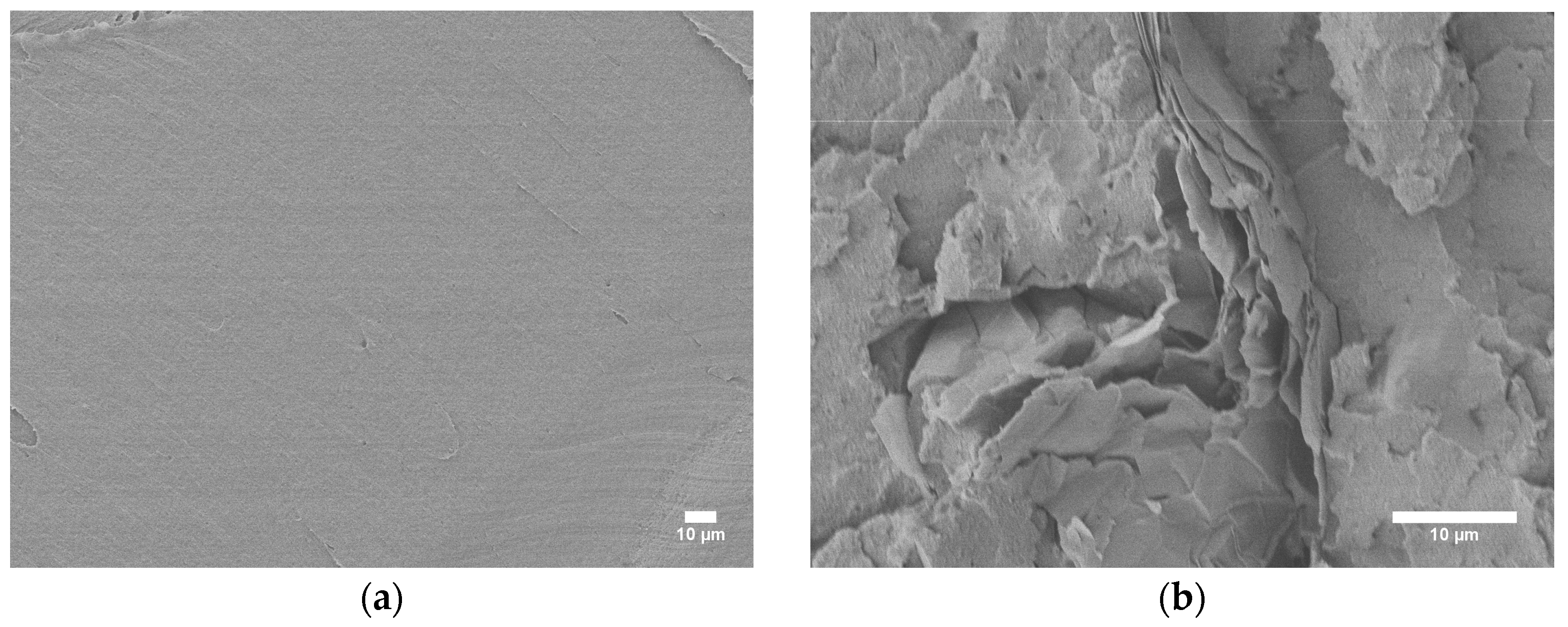

3.2.4. Carbonaceous Residue Analysis

3.2.5. Proposed Mechanism

4. Conclusions and Future Work

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Owen, S.R.; Harper, J.F. Mechanical, Microscopical and Fire Retardant Studies of ABS Polymers. Polym. Degrad. Stab. 1999, 64, 449–455. [Google Scholar] [CrossRef]

- Wilkie, C.A.; Morgan, A.B. Fire Retardancy of Polymeric Materials; CRC Press: Boca Raton, FL, USA, 2009; ISBN 1420084003. [Google Scholar]

- Rybiński, P.; Janowska, G. Influence Synergetic Effect of Halloysite Nanotubes and Halogen-Free Flame-Retardants on Properties Nitrile Rubber Composites. Thermochim. Acta 2013, 557, 24–30. [Google Scholar] [CrossRef]

- Vest, N.A.; Afonso, A.O.; Rodriguez-Melendez, D.; Ponis, J.; Smith, D.L.; Iverson, E.T.; Zhang, Z.; Marquez, J.A.D.; Banerjee, S.; Wang, Q.; et al. Polyelectrolyte Complex for Flame Retardant Silk. Polym. Degrad. Stab. 2023, 216, 110491. [Google Scholar] [CrossRef]

- Chen, Y.; Feng, Q.; Nie, Y.; Zhang, J.; Yang, L. A Review of Combustion and Flame Spread over Thermoplastic Materials: Research Advances and Prospects. Fire 2023, 6, 125. [Google Scholar] [CrossRef]

- Zhao, M.; Chen, H.; Zhu, Z.; Zhu, X.; Quan, Y.; Zhang, Z.; Wu, H.-M.; Wu, J.-L.; Kang, W.-H.; Wang, Q.; et al. Multifunctional Polyethylene Nanocomposites Based on Polyethylene-Grafted α-Zirconium Phosphate Nanoplatelets. Polymer 2022, 261, 125422. [Google Scholar] [CrossRef]

- Nabipour, H.; Wang, X.; Song, L.; Hu, Y. Metal-Organic Frameworks for Flame Retardant Polymers Application: A Critical Review. Compos. Part. A Appl. Sci. Manuf. 2020, 139, 106113. [Google Scholar] [CrossRef]

- Quan, Y.; Shen, R.; Schweizer, C.; Parajuli, P.; Zhang, Z.; Kulatilaka, W.; Wang, Q. Synergistic Effects of Zeolitic Imidazolate Frameworks (ZIFs) with Different Transition Metals on Intumescent Flame-Retarded Polypropylene Composites: A Comparative Study. J. Mater. Sci. Technol. 2023, 155, 102–110. [Google Scholar] [CrossRef]

- Pan, Y.-T.; Zhang, Z.; Yang, R. The Rise of MOFs and Their Derivatives for Flame Retardant Polymeric Materials: A Critical Review. Compos. B Eng. 2020, 199, 108265. [Google Scholar] [CrossRef]

- Hou, Y.; Xu, Z.; Chu, F.; Gui, Z.; Song, L.; Hu, Y.; Hu, W. A Review on Metal-Organic Hybrids as Flame Retardants for Enhancing Fire Safety of Polymer Composites. Compos. B Eng. 2021, 221, 109014. [Google Scholar] [CrossRef]

- Kreider, M.C.; Sefa, M.; Fedchak, J.A.; Scherschligt, J.; Bible, M.; Natarajan, B.; Klimov, N.N.; Miller, A.E.; Ahmed, Z.; Hartings, M.R. Toward 3D Printed Hydrogen Storage Materials Made with ABS-MOF Composites. Polym. Adv. Technol. 2018, 29, 867–873. [Google Scholar] [CrossRef]

- Bible, M.; Sefa, M.; Fedchak, J.A.; Scherschligt, J.; Natarajan, B.; Ahmed, Z.; Hartings, M.R. 3D-Printed Acrylonitrile Butadiene Styrene-Metal Organic Framework Composite Materials and Their Gas Storage Properties. 3D Print. Addit. Manuf. 2018, 5, 63–72. [Google Scholar] [CrossRef]

- Kim, S.-N.; Kim, J.; Kim, H.-Y.; Cho, H.-Y.; Ahn, W.-S. Adsorption/Catalytic Properties of MIL-125 and NH2-MIL-125. Catal. Today 2013, 204, 85–93. [Google Scholar] [CrossRef]

- Yue, K.; Zhang, X.; Jiang, S.; Chen, J.; Yang, Y.; Bi, F.; Wang, Y. Recent Advances in Strategies to Modify MIL-125 (Ti) and Its Environmental Applications. J. Mol. Liq. 2021, 335, 116108. [Google Scholar] [CrossRef]

- Momma, K.; Izumi, F. VESTA 3 for Three-Dimensional Visualization of Crystal, Volumetric and Morphology Data. J. Appl. Crystallogr. 2011, 44, 1272–1276. [Google Scholar] [CrossRef]

- Shen, R.; Quan, Y.; Zhang, Z.; Ma, R.; Wang, Q. Metal–Organic Framework as an Efficient Synergist for Intumescent Flame Retardants against Highly Flammable Polypropylene. Ind. Eng. Chem. Res. 2022, 61, 7292–7302. [Google Scholar] [CrossRef]

- Morgan, A.B.; Gilman, J.W. An Overview of Flame Retardancy of Polymeric Materials: Application, Technology, and Future Directions. Fire Mater. 2013, 37, 259–279. [Google Scholar] [CrossRef]

- Xia, Y.; Liu, S.; Wang, X.; Han, Y.; Li, J.; Jian, X. The Analysis of Synergistic Effects of Zeolites Applied in Intumescent Halogen-Free Flame-Retardant ABS Composites. Polym. Plast. Technol. Eng. 2008, 47, 613–618. [Google Scholar] [CrossRef]

- Lim, K.-S.; Bee, S.-T.; Sin, L.T.; Tee, T.-T.; Ratnam, C.T.; Hui, D.; Rahmat, A.R. A Review of Application of Ammonium Polyphosphate as Intumescent Flame Retardant in Thermoplastic Composites. Compos. B Eng. 2016, 84, 155–174. [Google Scholar] [CrossRef]

- Sun, Y.; Yu, B.; Liu, Y.; Cheng, B.; Wang, J.; Yan, J.; Huang, F. Novel Bio-Based Nanosheets: Improving the Fire Safety, Electromagnetic Shielding and Mechanical Properties of Polylactic Acid. Compos. Part. A Appl. Sci. Manuf. 2024, 179, 108044. [Google Scholar] [CrossRef]

- Sun, Y.; Yuan, B.; Shang, S.; Zhang, H.; Shi, Y.; Yu, B.; Qi, C.; Dong, H.; Chen, X.; Yang, X. Surface Modification of Ammonium Polyphosphate by Supramolecular Assembly for Enhancing Fire Safety Properties of Polypropylene. Compos. B Eng. 2020, 181, 107588. [Google Scholar] [CrossRef]

- Duquesne, S.; Delobel, R.; Le Bras, M.; Camino, G. A Comparative Study of the Mechanism of Action of Ammonium Polyphosphate and Expandable Graphite in Polyurethane. Polym. Degrad. Stab. 2002, 77, 333–344. [Google Scholar] [CrossRef]

- Modesti, M.; Lorenzetti, A.; Simioni, F.; Camino, G. Expandable Graphite as an Intumescent Flame Retardant in Polyisocyanurate–Polyurethane Foams. Polym. Degrad. Stab. 2002, 77, 195–202. [Google Scholar] [CrossRef]

- Ge, L.-L.; Duan, H.-J.; Zhang, X.-G.; Chen, C.; Tang, J.-H.; Li, Z.-M. Synergistic Effect of Ammonium Polyphosphate and Expandable Graphite on Flame-Retardant Properties of Acrylonitrile-Butadiene-Styrene. J. Appl. Polym. Sci. 2012, 126, 1337–1343. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, X.; Fang, Z. Synergistic Effects of Expandable Graphite and Ammonium Polyphosphate with a New Carbon Source Derived from Biomass in Flame Retardant ABS. J. Appl. Polym. Sci. 2013, 128, 2424–2432. [Google Scholar] [CrossRef]

- Sun, R.; Elabd, Y.A. Synthesis and High Alkaline Chemical Stability of Polyionic Liquids with Methylpyrrolidinium, Methylpiperidinium, Methylazepanium, Methylazocanium, and Methylazonanium Cations. ACS Macro Lett. 2019, 8, 540–545. [Google Scholar] [CrossRef] [PubMed]

- Quan, Y.; Shen, R.; Ma, R.; Zhang, Z.; Wang, Q. Sustainable and Efficient Manufacturing of Metal-Organic Framework-Based Polymer Nanocomposites by Reactive Extrusion. ACS Sustain. Chem. Eng. 2022, 10, 7216–7222. [Google Scholar] [CrossRef]

- Quan, Y.; Tanchak, R.N.; Zhang, Z.; Wang, Q. Efficient and Sustainable Synthesis of ZIF-67 for Synergistically Improving Reaction-to-Fire Properties of Biomass-Based Polypropylene Composites. J. Therm. Anal. Calorim. 2024, 149, 2585–2592. [Google Scholar] [CrossRef]

- Zhang, Z.; Cao, H.; Quan, Y.; Ma, R.; Pentzer, E.B.; Green, M.J.; Wang, Q. Thermal Stability and Flammability Studies of MXene–Organic Hybrid Polystyrene Nanocomposites. Polymers 2022, 14, 1213. [Google Scholar] [CrossRef] [PubMed]

- Quan, Y.; Zhang, Z.; Tanchak, R.N.; Wang, Q. A Review on Cone Calorimeter for Assessment of Flame-Retarded Polymer Composites. J. Therm. Anal. Calorim. 2022, 147, 10209–10234. [Google Scholar] [CrossRef]

- ASTM E1354-23; Standard Test Method for Heat and Visible Smoke Release Rates for Materials and Products Using an Oxygen Consumption Calorimeter. American Society for Testing and Materials: West Conshohocken, PA, USA, 2023.

- Rodriguez-Melendez, D.; Vest, N.A.; Kolibaba, T.J.; Quan, Y.; Zhang, Z.; Iverson, E.T.; Wang, Q.; Grunlan, J.C. Boron-Based Polyelectrolyte Complex Nanocoating for Fire Protection of Engineered Wood. Cellulose 2024, 31, 3083–3094. [Google Scholar] [CrossRef]

- ASTM D3801–20a; Standard Test Method for Measuring the Comparative Burning Characteristics of Solid Plastics in a Vertical Position. American Society for Testing and Materials: West Conshohocken, PA, USA, 2020.

- Shen, R.; Fan, T.; Quan, Y.; Ma, R.; Zhang, Z.; Li, Y.; Wang, Q. Thermal Stability and Flammability of Cotton Fabric with TiO2 Coatings Based on Biomineralization. Mater. Chem. Phys. 2022, 282, 125986. [Google Scholar] [CrossRef]

- ASTM D2863-19; Standard Test Method for Measuring the Minimum Oxygen Concentration to Support Candle-Like Combustion of Plastics (Oxygen Index). American Society for Testing and Materials: West Conshohocken, PA, USA, 2019.

- Sun, Y.; Liu, Y.; Zou, Y.; Wang, J.; Bai, F.; Yan, J.; Huang, F. Poorly-/Well-Dispersed Fe3O4: Abnormal Influence on Electromagnetic Wave Absorption Behavior of High-Mechanical Performance Polyurea. Chem. Eng. J. 2024, 493, 152833. [Google Scholar] [CrossRef]

- Sun, Y.; Yu, B.; Liu, Y.; Yan, J.; Xu, Z.; Cheng, B.; Huang, F.; Wang, J. Bio-Inspired Surface Manipulation of Halloysite Nanotubes for High-Performance Flame Retardant Polylactic Acid Nanocomposites. Nano Res. 2024, 17, 1595–1606. [Google Scholar] [CrossRef]

- Andrade, P.H.M.; Dhainaut, J.; Volkringer, C.; Loiseau, T.; Moncomble, A.; Hureau, M.; Moissette, A. Stability of Iodine Species Trapped in Titanium-Based MOFs: MIL-125 and MIL-125_NH2. Small 2024. [Google Scholar] [CrossRef]

- Réti, C.; Casetta, M.; Duquesne, S.; Bourbigot, S.; Delobel, R. Flammability Properties of Intumescent PLA Including Starch and Lignin. Polym. Adv. Technol. 2008, 19, 628–635. [Google Scholar] [CrossRef]

| Sample | ABS (wt.%) | APP (wt.%) | EG (wt.%) | MIL-125 (wt.%) |

|---|---|---|---|---|

| ABS | 100 | 0 | 0 | 0 |

| ABS/MIL-125 2 wt.% | 98 | 0 | 0 | 2 |

| ABS/MIL-125 5 wt.% | 95 | 0 | 0 | 5 |

| ABS/MIL-125 10 wt.% | 90 | 0 | 0 | 10 |

| ABS15 | 70 | 15 | 15 | 0 |

| ABS14 | 70 | 14 | 14 | 2 |

| ABS10 | 80 | 10 | 10 | 0 |

| ABS9 | 80 | 9 | 9 | 2 |

| Sample Name | TGA Results | ||

|---|---|---|---|

| T10% (°C) | Tmax (°C) | Residues (wt.%) | |

| ABS | 418 | 444 | 1.1 |

| ABS/MIL-125 2 wt.% | 420 | 448 | 1.6 |

| ABS/MIL-125 5 wt.% | 422 | 447 | 3.3 |

| ABS/MIL-125 10 wt.% | 420 | 447 | 3.5 |

| Sample Name | MCC Results | |||

|---|---|---|---|---|

| THR (kJ/g) | HRC (J/g·K) | pHRR (W/g) | TpHRR (°C) | |

| ABS | 39.0 | 639 | 657 | 448 |

| ABS/MIL-125 2 wt.% | 36.5 | 569 | 526 | 456 |

| ABS/MIL-125 5 wt.% | 33.8 | 506 | 511 | 454 |

| ABS/MIL-125 10 wt.% | 32.7 | 494 | 499 | 454 |

| Sample Name | TGA Results | |||

|---|---|---|---|---|

| T5% (°C) | Tmax (°C) | Deriv. Weight (%/°C) | Residues (wt.%) | |

| ABS | 392 | 422 | 2.1 | 2.0 |

| ABS9 | 361 | 424 | 1.8 | 14.2 |

| ABS14 | 322 | 423 | 1.4 | 31.5 |

| Sample Name | MCC Results | |||

|---|---|---|---|---|

| THR (kJ/g) | HRC (J/g·K) | pHRR (W/g) | TpHRR (°C) | |

| ABS | 39.0 | 639 | 657 | 448 |

| ABS15 | 25.0 | 463 | 454 | 442 |

| ABS14 | 23.9 | 428 | 428 | 445 |

| ABS10 | 28.1 | 517 | 506 | 452 |

| ABS9 | 26.9 | 495 | 486 | 449 |

| Sample | Flame Retardancy | |

|---|---|---|

| LOI | UL-94 | |

| ABS | 17.9% ± 0.1% | - |

| ABS15 | 31.3% ± 0.1% | V0 |

| ABS14 | 31.5% ± 0.1% | V0 |

| ABS10 | 25.9% ± 0.1% | V1 |

| ABS9 | 27.0% ± 0.1% | V0 |

| Sample Name | Cone Results | |||||||

|---|---|---|---|---|---|---|---|---|

| TTI (s) | THRc (MJ/m2) | PHRR (kW/m2) | TSR (m2/m2) | pSPR (m2/s) | FPI (s·m2/kW) | MARHE (kW/m2) | FGI (kW/(m2·s)) | |

| ABS | 29 | 101.40 | 1020.41 | 4049.25 | 0.36 | 0.28 | 590.15 | 9.72 |

| ABS9 | 25 | 24.74 | 288.18 | 2877.70 | 0.17 | 0.09 | 215.88 | 2.88 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Quan, Y.; Shen, R.; Wang, K.-Y.; Zhou, H.-C.; Wang, Q. Synergistic Effects of Titanium-Based MOFs MIL-125 with Intumescent Flame Retardants in ABS Polymer Composites on Flame Retardancy Study. Fire 2024, 7, 284. https://doi.org/10.3390/fire7080284

Zhang Z, Quan Y, Shen R, Wang K-Y, Zhou H-C, Wang Q. Synergistic Effects of Titanium-Based MOFs MIL-125 with Intumescent Flame Retardants in ABS Polymer Composites on Flame Retardancy Study. Fire. 2024; 7(8):284. https://doi.org/10.3390/fire7080284

Chicago/Turabian StyleZhang, Zhuoran, Yufeng Quan, Ruiqing Shen, Kun-Yu Wang, Hong-Cai Zhou, and Qingsheng Wang. 2024. "Synergistic Effects of Titanium-Based MOFs MIL-125 with Intumescent Flame Retardants in ABS Polymer Composites on Flame Retardancy Study" Fire 7, no. 8: 284. https://doi.org/10.3390/fire7080284