The Optimization of a Ternary Blend Using Grey Relation Analysis with the Taguchi Method for the Improved Performance and Reduction of Exhaust Emissions

Abstract

:1. Introduction

2. Materials and Methods

2.1. Feedstock Selection

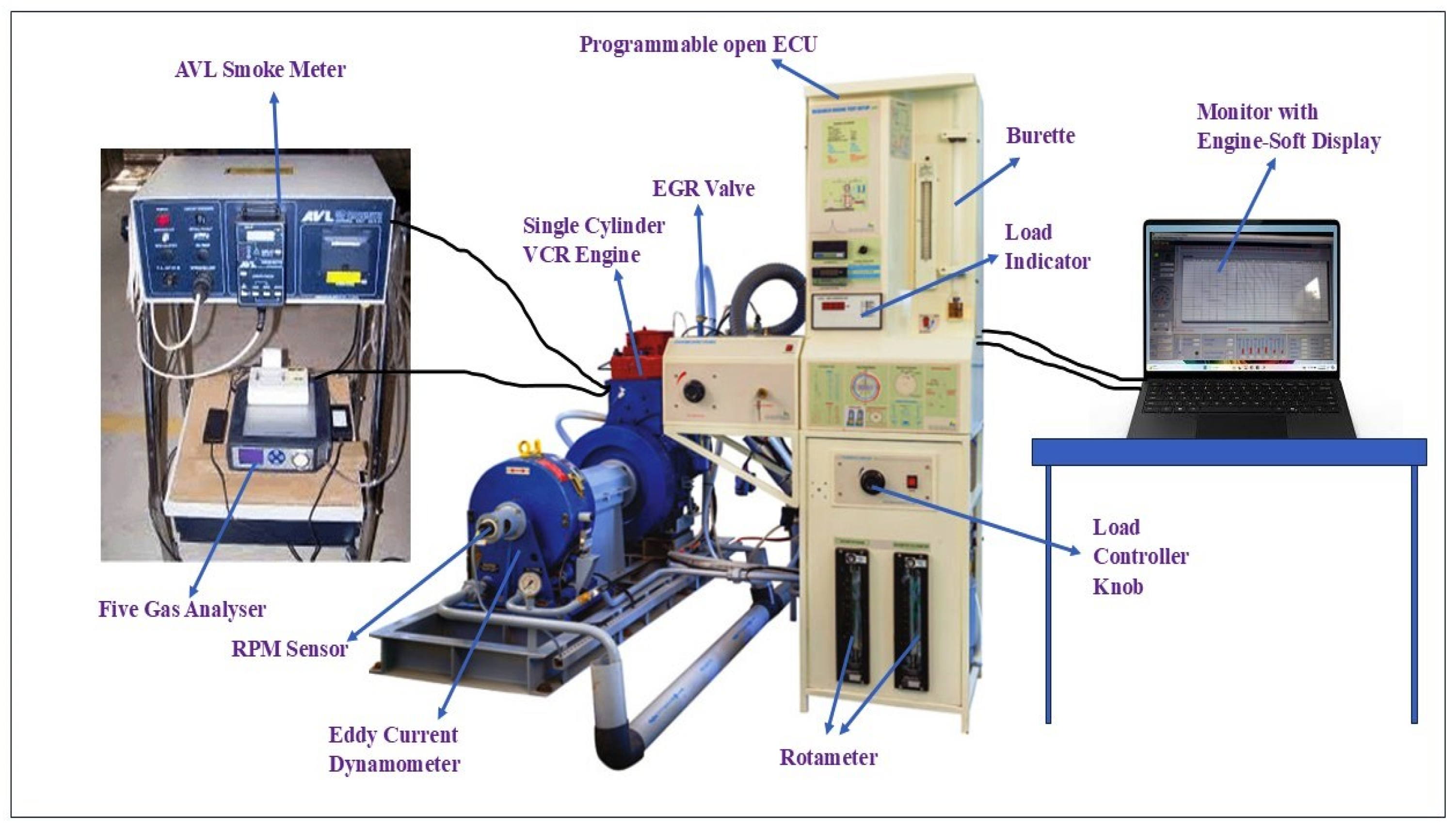

2.2. Experimental Setup and Measurements

2.3. Plan of Investigation

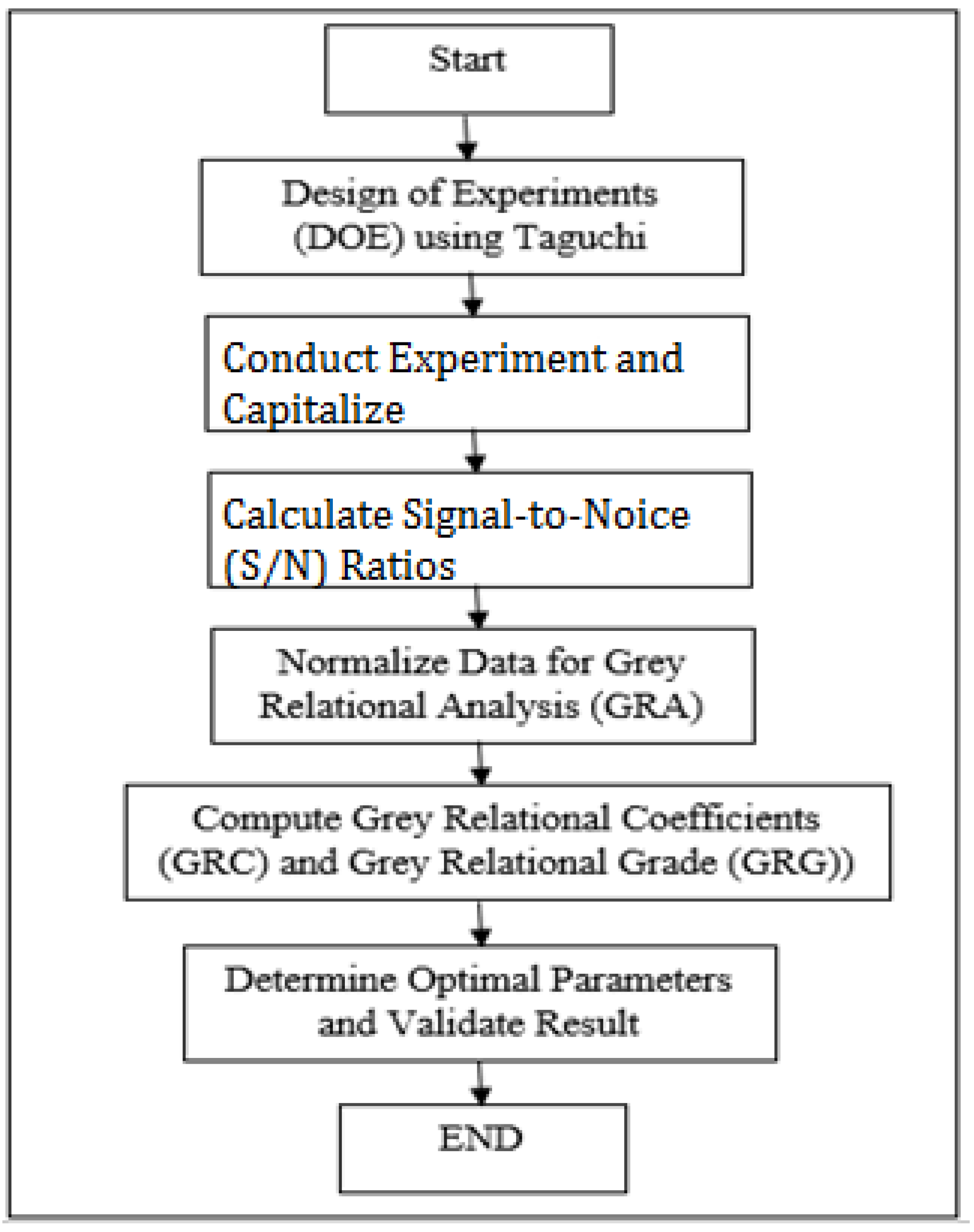

Grey Relation Analysis with Taguchi Method

3. Optimization Methodology

Optimization Steps Using Grey Relational Analysis

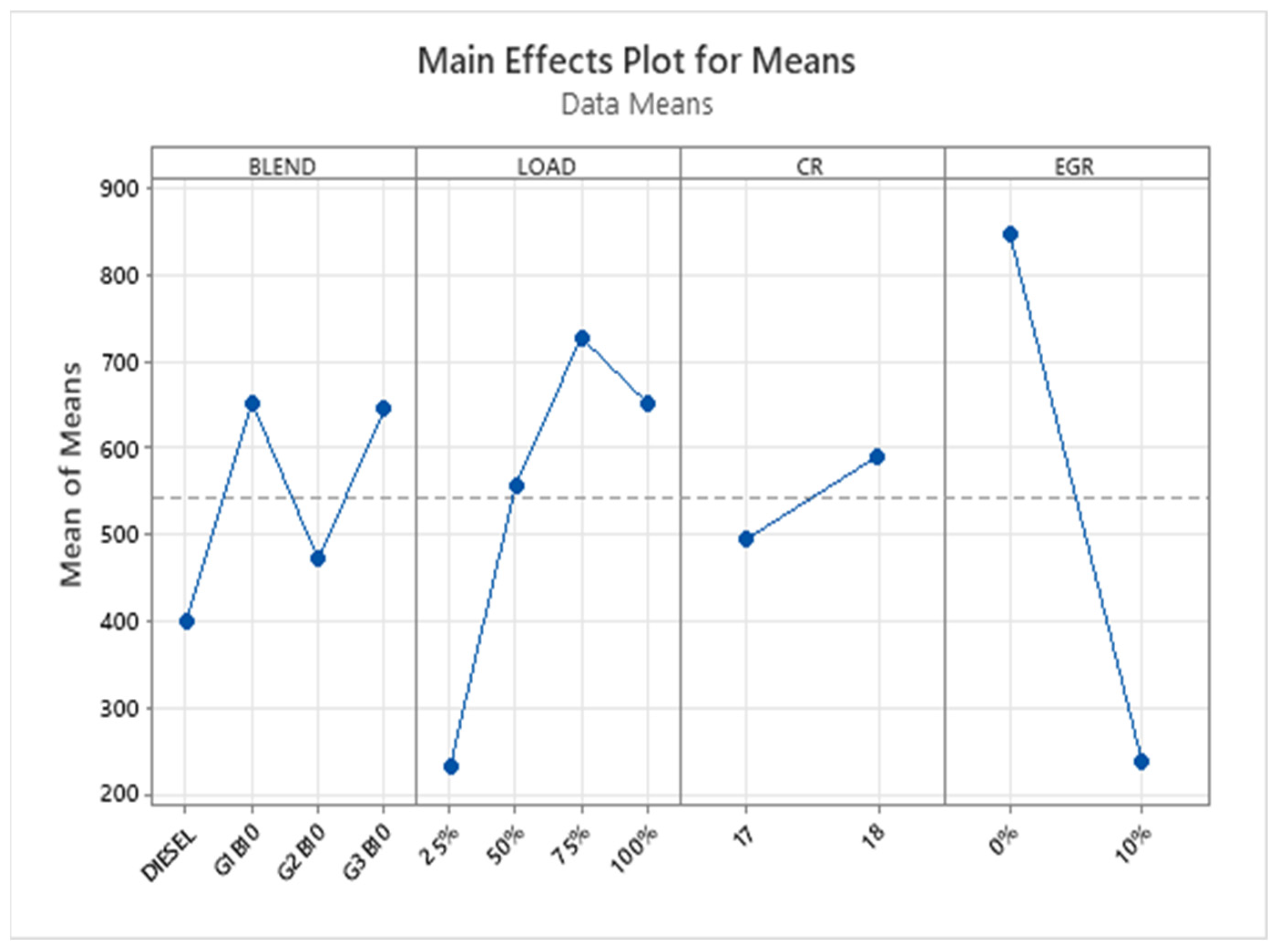

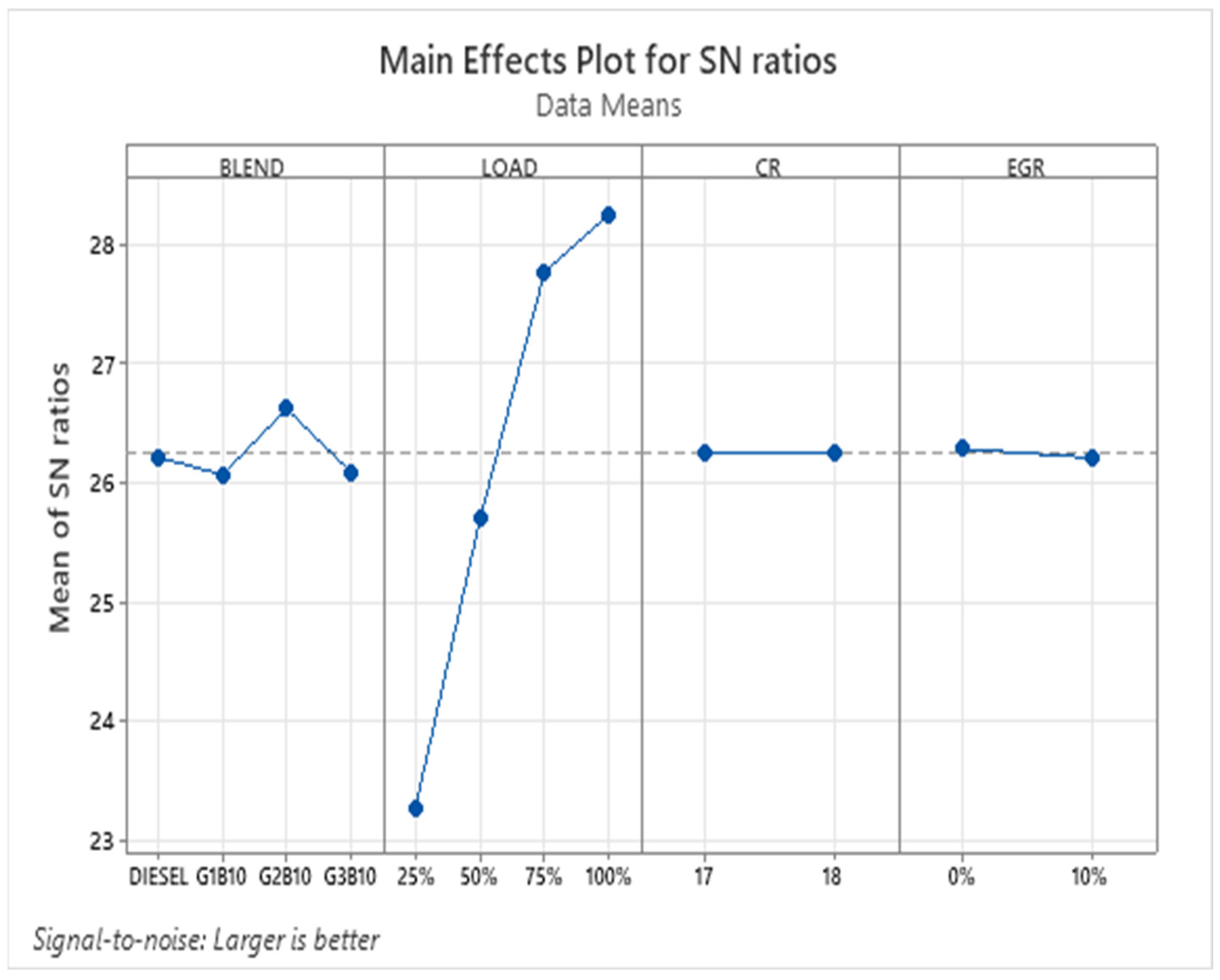

4. Implementation of Methodology

BLEND_G3B10 + 0.0117 LOAD_25% − 0.0235 LOAD_50% + 0.0129 LOAD_75% − 0.0011 LOAD_100% +

0.0048 CR_17 − 0.0048 CR_18 − 0.0653 EGR_0% + 0.0653 EGR_10%

5. Confirmation Experiment

6. Conclusions

- Grey Relational Analysis is a highly helpful tool for estimating the NOx, HC, smoke, SFC, and BTE with many objectives in the Taguchi approach for optimizing the multi-response issues.

- Because it does not require complex mathematical theory or calculation, engineers without solid experience in statistics can use it.

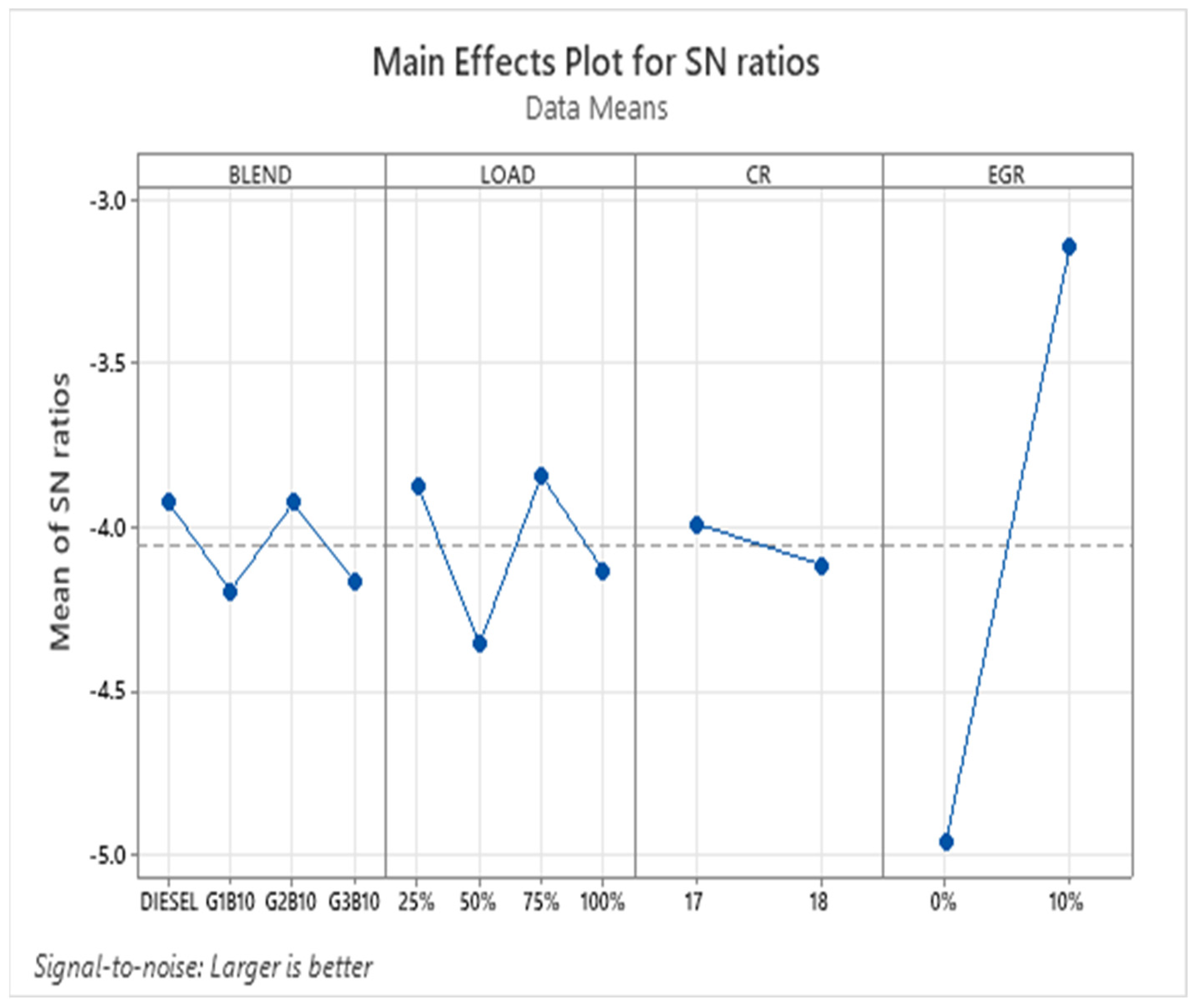

- Load (62.53%) influences more on engine performance and emissions followed by the EGR (33.92%), blend (0.59%) and CR (0.02%).

- Optimum parameter settings from GRA and ANOVA is found to be G2B10, 100%Load, 17CR, 10%EGR and optimum values of NOx = 266 ppm, HC = 18 ppm, smoke = 15.7% Vol, SFC = 0.31 g/kWh, and BTE = 27.27%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Knothe, G.; Razon, L.F. Biodiesel fuels. Prog. Energy Combust. Sci. 2017, 58, 36–59. [Google Scholar] [CrossRef]

- Ramadhas, A.S.; Jayaraj, S.; Muraleedharan, C. Use of vegetable oils as I.C. engine fuels—A review. Renew. Energy 2004, 29, 727–742. [Google Scholar] [CrossRef]

- Kalam, M.A.; Masjuki, H.H. Biodiesel from palmoil—An analysis of its properties and potential. Biomass Bioenergy 2002, 23, 471–479. [Google Scholar] [CrossRef]

- Çiftçi, B.; Karagöz, M.; Aydin, M.; Çelik, M.B. The effect of fusel oil and waste biodiesel fuel blends on a CI engine performance, emissions, and combustion characteristics. J. Therm. Anal. Calorim. 2024, 149, 7783–7796. [Google Scholar] [CrossRef]

- Chauhan, B.S.; Kumar, N.; Jun, Y.D.; Lee, K.B. Performance and emission study of preheated Jatropha oil on medium capacity diesel engine. Energy 2010, 35, 2484–2492. [Google Scholar] [CrossRef]

- Jain, S.; Sharma, M.P. Prospects of biodiesel from Jatropha in India: A review. Renew. Sustain. Energy Rev. 2010, 14, 763–771. [Google Scholar] [CrossRef]

- Bhale, P.V.; Deshpande, N.V.; Thombre, S.B. Improving the low temperature properties of biodiesel fuel. Renew. Energy 2009, 34, 794–800. [Google Scholar] [CrossRef]

- Ramachandra, R.; Pandurangadu, V.; Raju KA, K. Comparison and Evaluation of Performance and Emission Characteristics of Four Stroke Diesel Engine with Neem and Cotton Seed Bio Diesels. Int. J. Eng. Technol. Res. 2014, 2, 282–285. [Google Scholar]

- Dhamodaran, G.; Krishnan, R.; Pochareddy, Y.K.; Pyarelal, H.M.; Sivasubramanian, H.; Ganeshram, A.K. A comparative study of combustion, emission, and performance characteristics of rice-bran-, neem-, and cottonseed-oil biodiesels with varying degree of unsaturation. Fuel 2017, 187, 296–305. [Google Scholar] [CrossRef]

- Gad, M.S.; El-Shafay, A.S.; Alqsair, U.F.; Ağbulut, Ü.; Attia, E.A. Multi-objective optimization based grey relational analysis and investigation of using the waste animal fat biodiesel on the engine characteristics. Fuel 2023, 343, 127950. [Google Scholar] [CrossRef]

- Karnwal, A.; Hasan, M.M.; Kumar, N.; Siddiquee, A.N.; Khan, Z.A. Multi-response optimization of diesel engine performance parameters using thumba biodiesel-diesel blends by applying the Taguchi method and grey relational analysis. Int. J. Automot. Technol. 2011, 12, 599–610. [Google Scholar] [CrossRef]

- Muqeem, M.; Sherwani, A.F.; Ahmad, M.; Khan, Z.A. Taguchi based grey relational analysis for multi response optimisation of diesel engine performance and emission parameters. Int. J. Heavy Veh. Syst. 2020, 27, 441–460. [Google Scholar] [CrossRef]

- Asokan, M.A.; Prabu, S.S.; Prathiba, S.; Sukhadia, D.S.; Jain, V.; Sarwate, S.M. Emission and performance behavior of Orange peel oil/diesel blends in di diesel engine. Mater. Today Proc. 2021, 46, 8114–8118. [Google Scholar] [CrossRef]

- Indian Council of Agricultural Research. Annual Report 2023–2024. 2016, pp. 1–23. Available online: https://icar.org.in/sites/default/files/2024-09/ICAREngAR_2023-24forweb.pdf (accessed on 1 September 2024).

- Gopidesi, R.K.; Reddy, V.R.K.; Kumar, V.S.S.; Vardhan, T.V.; Reddy, V.J. Effect of cotton seed oil in diesel engine performance emission and combustion characteristics. Int. J. Innov. Technol. Explor. Eng. 2019, 8, 2602–2605. [Google Scholar]

- Ranjith, V.V.; Thanikaikarasan, S. Prediction of Exhaust Gas Emission characteristics using Neem oil blended bio-diesel in diesel engine. Mater. Today Proc. 2020, 21, 870–875. [Google Scholar] [CrossRef]

- Ashok, B.; Nanthagopal, K.; Perumal, D.A.; Babu, J.M.; Tiwari, A.; Sharma, A. An investigation on CRDi engine characteristic using renewable orange-peel oil. Energy Convers. Manag. 2018, 180, 1026–1038. [Google Scholar] [CrossRef]

- Mourshed, M.; Ghosh, S.K.; Islam, M.W. Experimental investigation of cotton (Gossypium hirsutum) seed oil and neem (Azadirachta indica) seed oil methyl esters as biodiesel on DI (Direct Injection) engine. Int. J. Ambient Energy 2022, 43, 1772–1782. [Google Scholar] [CrossRef]

- Rastogi, A.; Shaban, M.; Saxena, S.; Singh, T.P. Neem Biodiesel: An Alternative Fuel. Innovare J. Eng. Technol. 2021, 9, 18–21. [Google Scholar] [CrossRef]

- Mishra, D.; Kumar, N.; Chaudhary, R. Effect of orange peel oil on the performance and emission characteristics of diesel engine fueled with quaternary blends. Energy Sources Part A Recovery Util. Environ. Eff. 2022, 45, 650–660. [Google Scholar] [CrossRef]

- Abifarin, J.; Ofodu, J. Modeling and Grey Relational Multi-response Optimization of Chemical Additives and Engine Parameters on Performance Efficiency of Diesel Engine. Int. J. Grey Syst. 2022, 2, 16–26. [Google Scholar] [CrossRef]

- Gul, M.; Shah, A.N.; Jamal, Y.; Masood, I. Multi-variable optimization of diesel engine fuelled with biodiesel using grey-Taguchi method. J. Braz. Soc. Mech. Sci. Eng. 2016, 38, 621–632. [Google Scholar] [CrossRef]

- Brijesh, P.; Chowdhury, A.; Sreedhara, S. The simultaneous reduction of NO x and PM using ultra-cooled EGR and retarded injection timing in a diesel engine. Int. J. Green Energy 2015, 12, 347–358. [Google Scholar] [CrossRef]

| Sr. No | Test Description | Ref Std ASTM 6751 | Reference | Testing Fuel | ||||

|---|---|---|---|---|---|---|---|---|

| Unit | Limit | B00 | G1B10 | G2B10 | G3B10 | |||

| 1 | Density | D1448 | gm/cc | 0.800–0.900 | 0.832 | 0.835 | 0.836 | 0.836 |

| 2 | Calorific Value | D6751 | MJ/Kg | 34–45 | 42.7 | 42.11 | 42 | 42.26 |

| 3 | Cetane Number | D613 | NA | 41–55 | 49 | 49.6 | 49.55 | 49.6 |

| 4 | Viscosity | D445 | mm2/s | 3–6 | 2.7 | 4.65 | 4.87 | 3.98 |

| 5 | Flash Point | D93 | °C | - | 64 | 160 | 149 | 83 |

| 6 | Fire Point | D93 | °C | - | 72 | 160 | 170 | 140 |

| 7 | Moisture | D2709 | % | 0.05% | Nil | Nil | Nil | Nil |

| Emission Parameter | Instrument Used | Measurement Principle | Calibration Method | Measurement Range | Resolution |

|---|---|---|---|---|---|

| Nitrogen Oxides (NOxs) | Chemiluminescence NOx Analyzer (Horiba PG-250) | Chemiluminescence Detection (CLD) | Zero calibration (N2), span calibration (NO2 in N2) | 0–5000 ppm | ±1 ppm |

| Hydrocarbons (HCs) | Flame Ionization Detector (FID) Gas Analyzer (AVL 444) | Flame Ionization Detection | Propane gas in balance air | 0–10,000 ppm | ±0.1 ppm |

| Carbon Monoxide (CO) | Non-Dispersive Infrared (NDIR) Gas Analyzer (Testo 350) | Infrared Absorption | Zero calibration (N2), span calibration (CO in N2) | 0–10% | ±0.01% |

| Carbon Dioxide (CO2) | Non-Dispersive Infrared (NDIR) Gas Analyzer (Testo 350) | Infrared Absorption | Zero calibration (N2), span calibration (CO2 in N2) | 0–20% | ±0.1% |

| Smoke Opacity | AVL 437 Smoke Meter | Light Extinction Method | Zero calibration (filtered air), span calibration | 0–100% opacity | ±0.1% |

| Parameters | Unit | Level | |||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | ||

| Blend Ratio | % | 0 | G1B10 | G2B10 | G3B10 |

| Load | % | 25% | 50% | 75% | 100% |

| CR | -- | 17 | 18 | ||

| EGR | % | 0 | 10 | ||

| Trial | Blend (%) | Load (%) | CR | EGR (0%) | NOx (ppm) | HC (ppm) | SMOKE (% Vol) | SFC (g/kWh) | BTE (%) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | DIESEL | 25% | 17 | 0% | 189 | 17 | 0.6 | 0.6 | 14.23 |

| 2 | DIESEL | 50% | 17 | 0% | 856 | 26 | 4.1 | 0.43 | 19.72 |

| 3 | DIESEL | 75% | 18 | 10% | 281 | 15 | 14.6 | 0.37 | 22.88 |

| 4 | DIESEL | 100% | 18 | 10% | 282 | 25 | 23.7 | 0.31 | 27.29 |

| 5 | G1B10 | 25% | 17 | 10% | 90 | 8 | 0.9 | 0.57 | 15.01 |

| 6 | G1B10 | 50% | 17 | 10% | 191 | 12 | 5.2 | 0.48 | 17.88 |

| 7 | G1B10 | 75% | 18 | 0% | 1260 | 26 | 8.8 | 0.34 | 24.88 |

| 8 | G1B10 | 100% | 18 | 0% | 1069 | 50 | 18 | 0.35 | 24.52 |

| 9 | G2B10 | 25% | 18 | 0% | 435 | 19 | 3.1 | 0.61 | 14.12 |

| 10 | G2B10 | 50% | 18 | 0% | 894 | 29 | 8.1 | 0.39 | 21.93 |

| 11 | G2B10 | 75% | 17 | 10% | 294 | 16 | 7.1 | 0.34 | 25 |

| 12 | G2B10 | 100% | 17 | 10% | 266 | 18 | 15.7 | 0.31 | 27.27 |

| 13 | G3B10 | 25% | 18 | 10% | 221 | 1 | 0.8 | 0.57 | 15 |

| 14 | G3B10 | 50% | 18 | 10% | 288 | 3 | 2.7 | 0.48 | 17.83 |

| 15 | G3B10 | 75% | 17 | 0% | 1078 | 29 | 14.1 | 0.34 | 25.18 |

| 16 | G3B10 | 100% | 17 | 0% | 995 | 49 | 31.8 | 0.35 | 24.54 |

| Trial | S/N Ratio | Normalization Data | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| NOx (ppm) | HC (ppm) | SMOKE (% Vol) | SFC (g/kWh) | BTE (%) | NOx (ppm) | HC (ppm) | SMOKE (% Vol) | SFC (g/kWh) | BTE (%) | |

| 1 | −45.5 | −24.6 | 4.437 | 4.44 | 23.1 | 0.915 | 0.673 | 1.000 | 0.033 | 0.008 |

| 2 | −58.6 | −28.3 | −12.26 | 7.33 | 25.9 | 0.345 | 0.490 | 0.888 | 0.600 | 0.425 |

| 3 | −49 | −23.5 | −23.29 | 8.64 | 27.2 | 0.837 | 0.714 | 0.551 | 0.800 | 0.665 |

| 4 | −49 | −28 | −27.49 | 10.2 | 28.7 | 0.836 | 0.510 | 0.260 | 1.000 | 1.000 |

| 5 | −39.1 | −18.1 | 0.9151 | 4.88 | 23.5 | 1.000 | 0.857 | 0.990 | 0.133 | 0.068 |

| 6 | −45.6 | −21.6 | −14.32 | 6.38 | 25 | 0.914 | 0.776 | 0.853 | 0.433 | 0.285 |

| 7 | −62 | −28.3 | −18.89 | 9.37 | 27.9 | 0.000 | 0.490 | 0.737 | 0.900 | 0.817 |

| 8 | −60.6 | −34 | −25.11 | 9.12 | 27.8 | 0.163 | 0.000 | 0.442 | 0.867 | 0.790 |

| 9 | −52.8 | −25.6 | −9.827 | 4.29 | 23 | 0.705 | 0.633 | 0.920 | 0.000 | 0.000 |

| 10 | −59 | −29.2 | −18.17 | 8.18 | 26.8 | 0.313 | 0.429 | 0.760 | 0.733 | 0.593 |

| 11 | −49.4 | −24.1 | −17.03 | 9.37 | 28 | 0.826 | 0.694 | 0.792 | 0.900 | 0.826 |

| 12 | −48.5 | −30.1 | −23.92 | 10.2 | 28.7 | 0.850 | 0.367 | 0.516 | 1.000 | 0.998 |

| 13 | −46.9 | 0 | 1.9382 | 4.88 | 23.5 | 0.888 | 1.000 | 0.994 | 0.133 | 0.067 |

| 14 | −49.2 | −9.54 | −8.627 | 6.38 | 25 | 0.831 | 0.959 | 0.933 | 0.433 | 0.282 |

| 15 | −60.7 | −29.2 | −22.98 | 9.37 | 28 | 0.156 | 0.429 | 0.567 | 0.900 | 0.840 |

| 16 | −60 | −33.8 | −30.05 | 9.12 | 27.8 | 0.226 | 0.020 | 0.000 | 0.867 | 0.791 |

| Grey Relation Deviation | Grey Relation Coeff | Grade | Rank | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| NOx | HC | SMOKE | SFC | BTE | NOx | HC | SMOKE | SFC | BTE | ||

| 0.085 | 0.327 | 0.000 | 0.967 | 0.992 | 0.855 | 0.605 | 1.000 | 0.341 | 0.335 | 0.627 | 9 |

| 0.655 | 0.510 | 0.112 | 0.400 | 0.575 | 0.433 | 0.495 | 0.817 | 0.556 | 0.465 | 0.553 | 13 |

| 0.163 | 0.286 | 0.449 | 0.200 | 0.335 | 0.754 | 0.636 | 0.527 | 0.714 | 0.599 | 0.646 | 7 |

| 0.164 | 0.490 | 0.740 | 0.000 | 0.000 | 0.753 | 0.505 | 0.403 | 1.000 | 1.000 | 0.732 | 2 |

| 0.000 | 0.143 | 0.010 | 0.867 | 0.932 | 1.000 | 0.778 | 0.981 | 0.366 | 0.349 | 0.695 | 5 |

| 0.086 | 0.224 | 0.147 | 0.567 | 0.715 | 0.853 | 0.690 | 0.772 | 0.469 | 0.412 | 0.639 | 8 |

| 1.000 | 0.510 | 0.263 | 0.100 | 0.183 | 0.333 | 0.495 | 0.655 | 0.833 | 0.732 | 0.610 | 10 |

| 0.837 | 1.000 | 0.558 | 0.133 | 0.210 | 0.374 | 0.333 | 0.473 | 0.789 | 0.704 | 0.535 | 15 |

| 0.295 | 0.367 | 0.080 | 1.000 | 1.000 | 0.629 | 0.576 | 0.862 | 0.333 | 0.333 | 0.547 | 14 |

| 0.687 | 0.571 | 0.240 | 0.267 | 0.407 | 0.421 | 0.467 | 0.675 | 0.652 | 0.551 | 0.553 | 12 |

| 0.174 | 0.306 | 0.208 | 0.100 | 0.174 | 0.741 | 0.620 | 0.706 | 0.833 | 0.742 | 0.729 | 3 |

| 0.150 | 0.633 | 0.484 | 0.000 | 0.002 | 0.769 | 0.441 | 0.508 | 1.000 | 0.997 | 0.743 | 1 |

| 0.112 | 0.000 | 0.006 | 0.867 | 0.933 | 0.817 | 1.000 | 0.987 | 0.366 | 0.349 | 0.704 | 4 |

| 0.169 | 0.041 | 0.067 | 0.567 | 0.718 | 0.747 | 0.925 | 0.881 | 0.469 | 0.410 | 0.686 | 6 |

| 0.844 | 0.571 | 0.433 | 0.100 | 0.160 | 0.372 | 0.467 | 0.536 | 0.833 | 0.757 | 0.593 | 11 |

| 0.774 | 0.980 | 1.000 | 0.133 | 0.209 | 0.393 | 0.338 | 0.333 | 0.789 | 0.705 | 0.512 | 16 |

| S | R-sq | R-sq(adj) | PRESS | R-sq(pred) | AICc | BIC |

|---|---|---|---|---|---|---|

| 0.047949 | 82.05% | 61.53% | 0.08408 | 6.21% | −1.02 | −37.3 |

| Level | BLEND | LOAD | CR | EGR |

|---|---|---|---|---|

| 1 | 0.6397 | 0.6432 | 0.6363 | 0.5662 |

| 2 | 0.6196 | 0.608 | 0.6267 | 0.6968 |

| 3 | 0.6429 | 0.6444 | ||

| 4 | 0.6238 | 0.6304 | ||

| Delta | 0.0233 | 0.0364 | 0.0097 | 0.1305 |

| Rank | 3 | 2 | 4 | 1 |

| Source | DF | Seq SS | Contribution | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|---|---|

| BLEND | 3 | 0.001596 | 1.78% | 0.001596 | 0.000532 | 0.23 | 0.872 |

| LOAD | 3 | 0.003424 | 3.82% | 0.003424 | 0.001141 | 0.5 | 0.696 |

| CR | 1 | 0.000375 | 0.42% | 0.000375 | 0.000375 | 0.16 | 0.698 |

| EGR | 2 | 0.068156 | 76.03% | 0.068156 | 0.068156 | 29.65 | 0.001 |

| Error | 7 | 0.016093 | 17.95% | 0.016093 | 0.002299 | ||

| Total | 15 | 0.089644 | 100.00% |

| Optimization | Blend | Load | CR | EGR | NOx (ppm) | HC (ppm) | SMOKE (% Vol) | SFC (g/kWh) | BTE (%) |

|---|---|---|---|---|---|---|---|---|---|

| GRA | G2B10 | 100% | 17 | 10% | 266 | 18 | 15.7 | 0.31 | 27.27 |

| Optimal parameter setting | G2B10 | 75% | 17 | 10% | 294 | 16 | 7.1 | 0.34 | 25 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Naik, G.G.; Dharmadhikari, H.M.; More, S.A.; Sarris, I.E. The Optimization of a Ternary Blend Using Grey Relation Analysis with the Taguchi Method for the Improved Performance and Reduction of Exhaust Emissions. Fire 2025, 8, 83. https://doi.org/10.3390/fire8020083

Naik GG, Dharmadhikari HM, More SA, Sarris IE. The Optimization of a Ternary Blend Using Grey Relation Analysis with the Taguchi Method for the Improved Performance and Reduction of Exhaust Emissions. Fire. 2025; 8(2):83. https://doi.org/10.3390/fire8020083

Chicago/Turabian StyleNaik, Ganesh G., Hanumant M. Dharmadhikari, Sunil A. More, and Ioannis E. Sarris. 2025. "The Optimization of a Ternary Blend Using Grey Relation Analysis with the Taguchi Method for the Improved Performance and Reduction of Exhaust Emissions" Fire 8, no. 2: 83. https://doi.org/10.3390/fire8020083

APA StyleNaik, G. G., Dharmadhikari, H. M., More, S. A., & Sarris, I. E. (2025). The Optimization of a Ternary Blend Using Grey Relation Analysis with the Taguchi Method for the Improved Performance and Reduction of Exhaust Emissions. Fire, 8(2), 83. https://doi.org/10.3390/fire8020083