A Tale of Two Legacies: Byzantine and Egyptian Influences in the Manufacture and Supply of Glass Tesserae under the Umayyad Caliphate (661–750 AD)

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

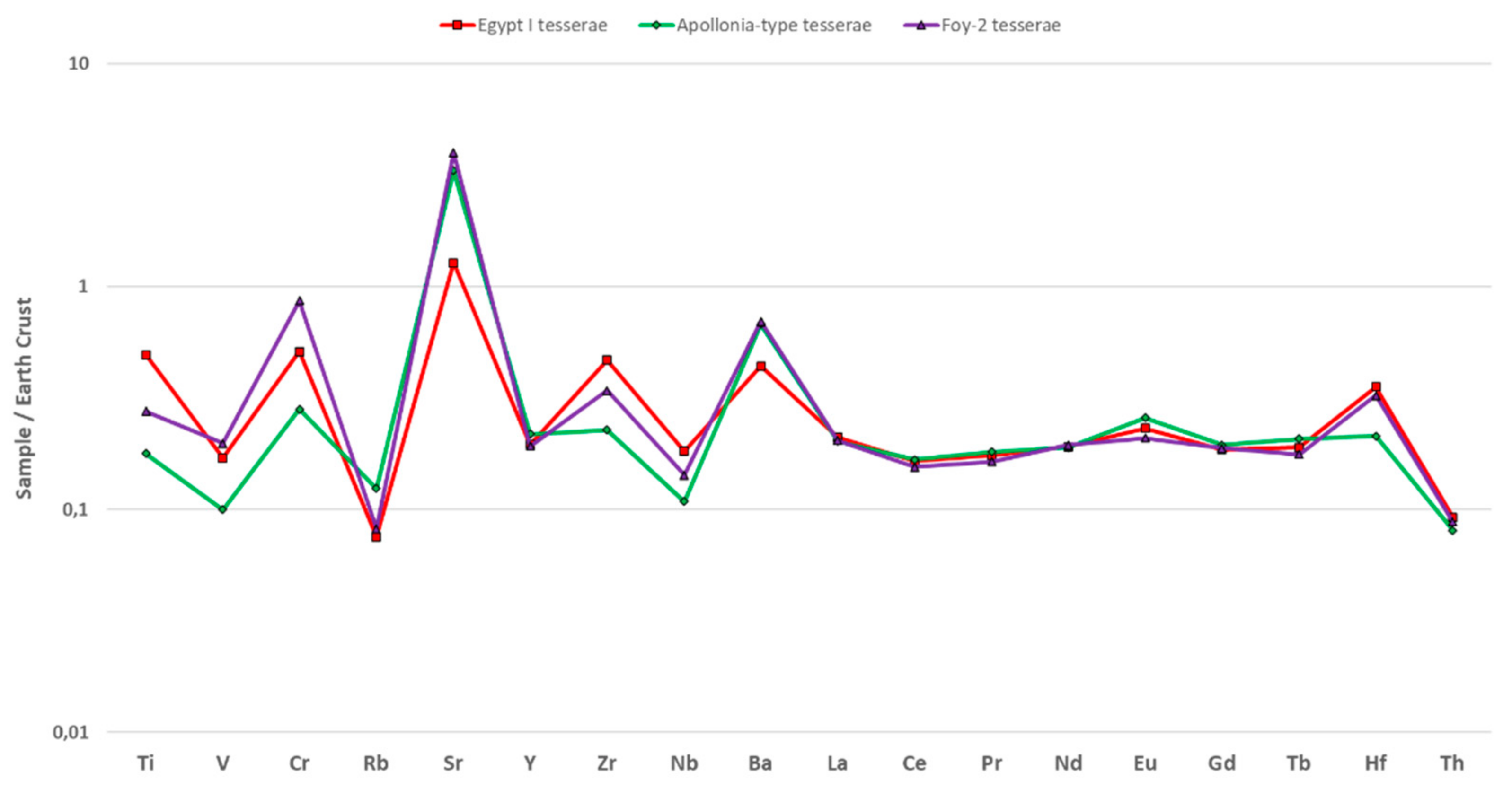

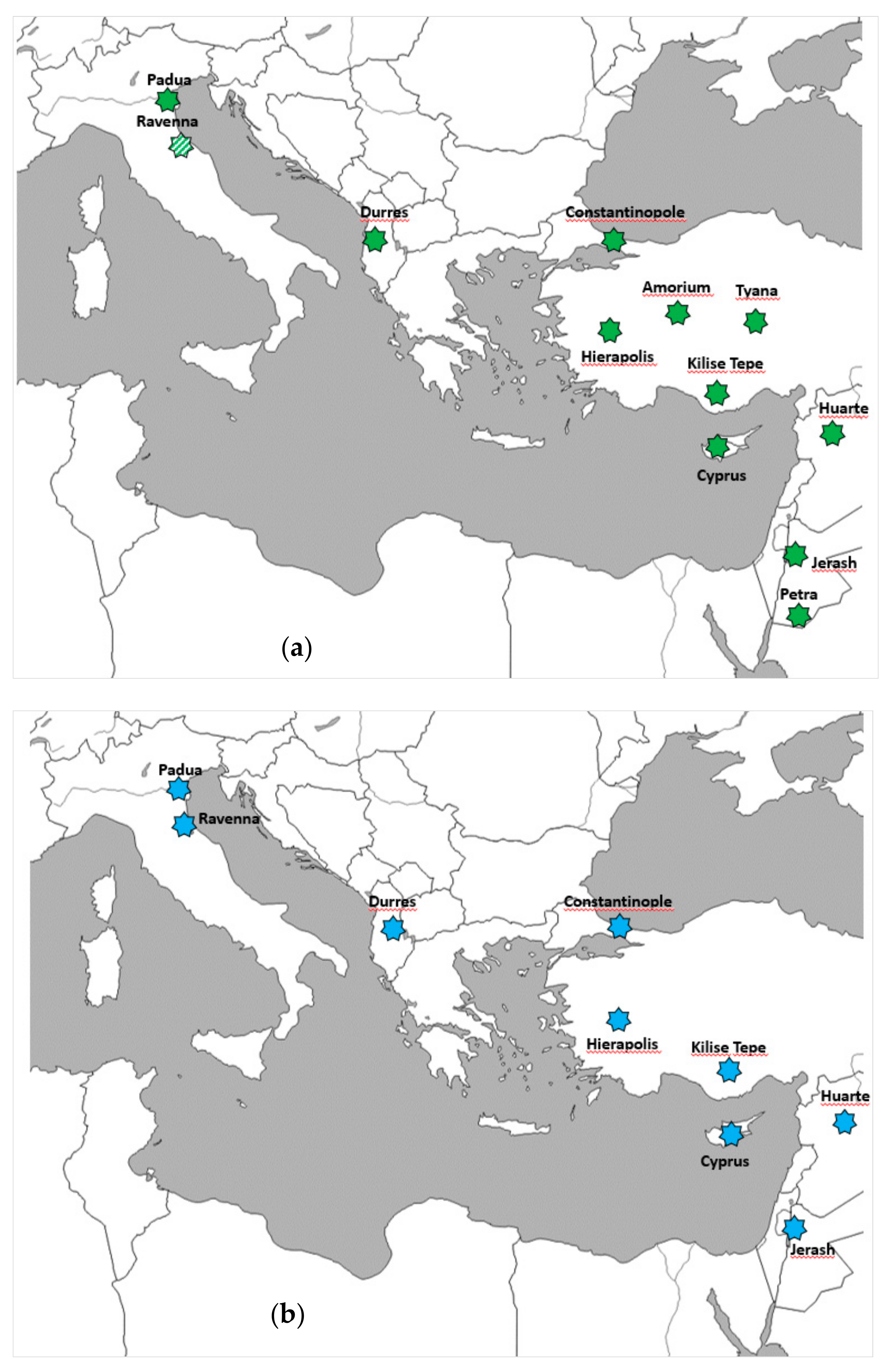

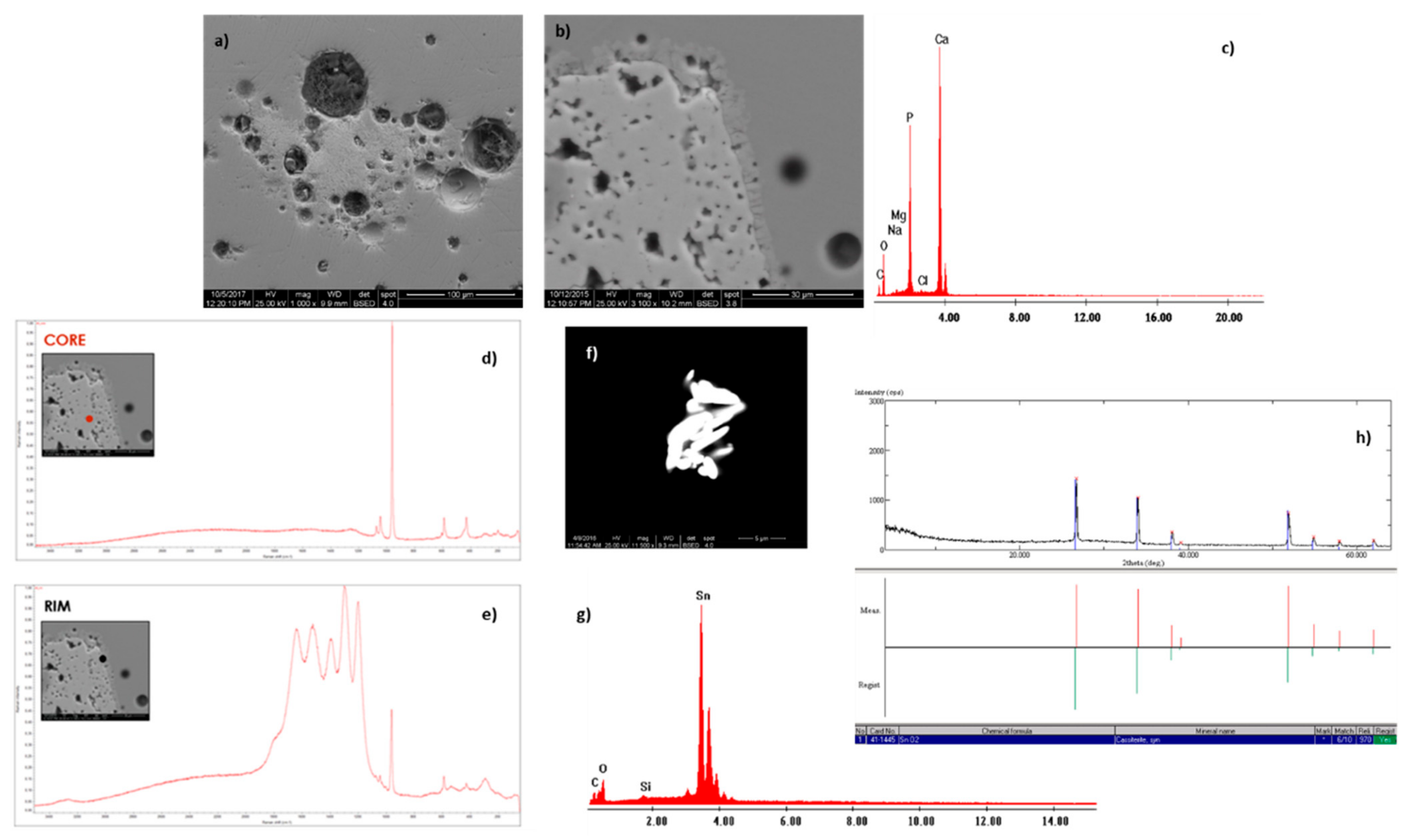

3.1. The Base Glass

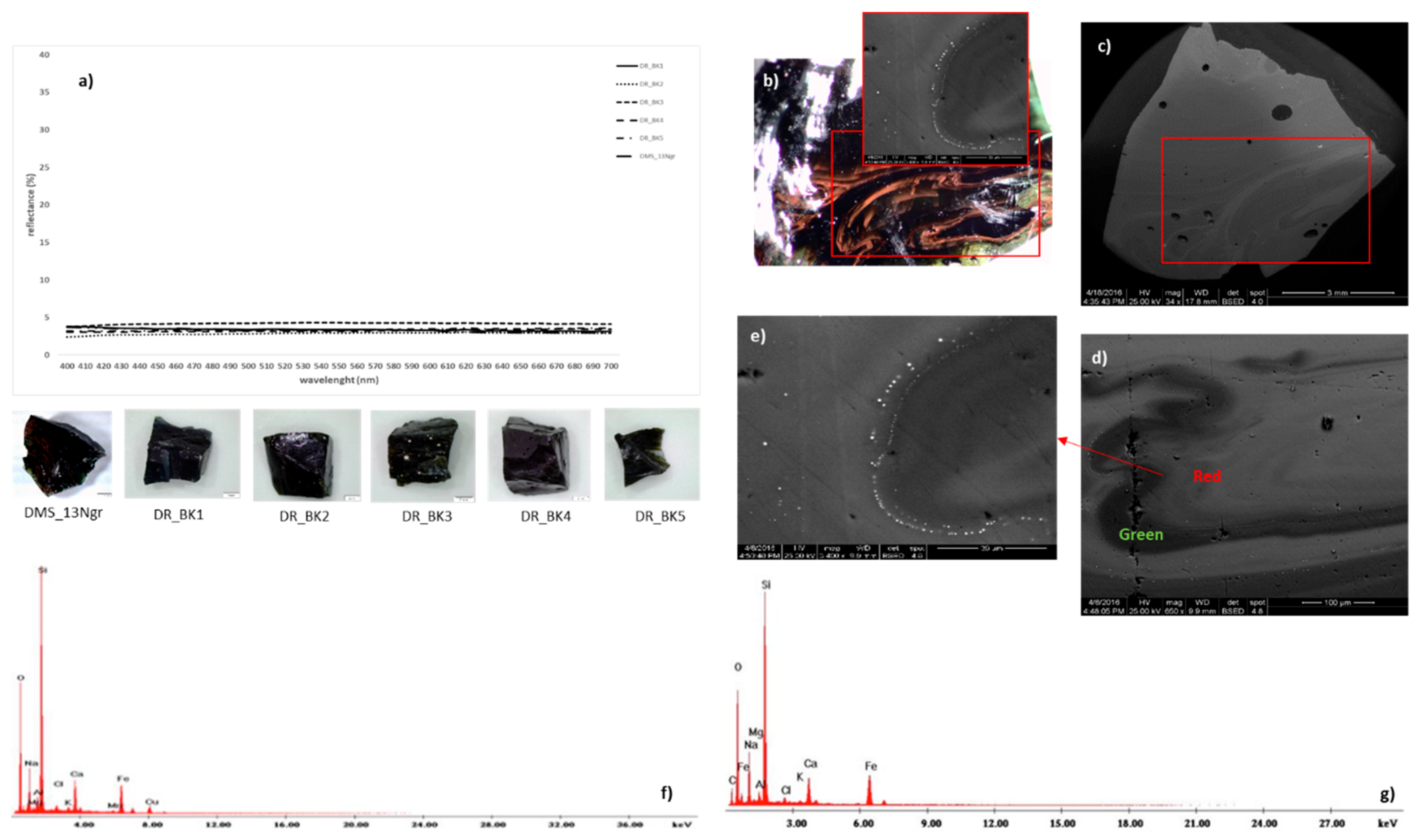

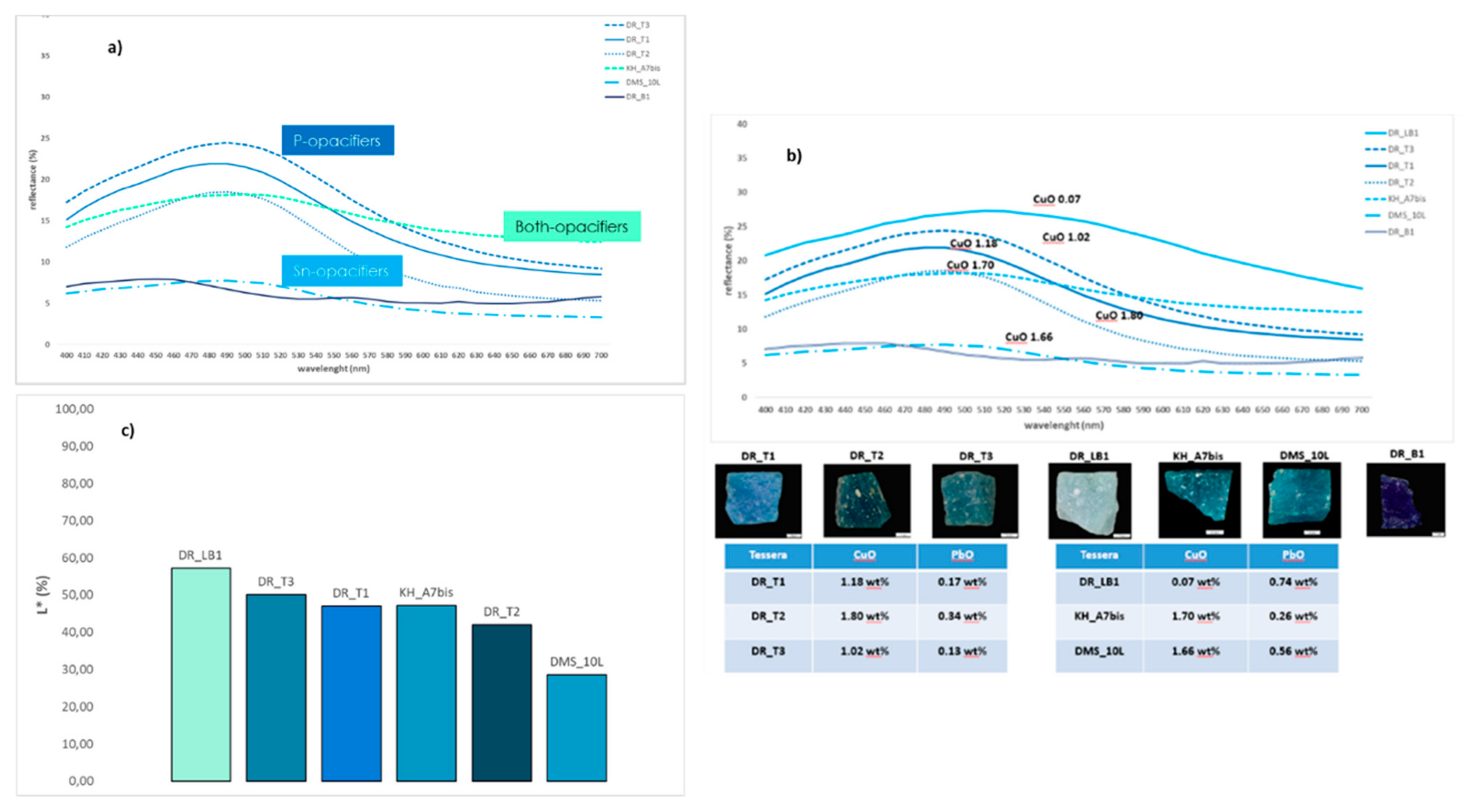

3.2. Colouring and Opacifying Agents

3.3. Hypotheses for Plausible Manufacture and Supply Models

4. Conclusions

Supplementary Materials

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gibb, H.A.R. Arab-Byzantine relations under the Umayyad caliphate. Dumbart. Oaks Pap. 1958, 12, 219–233. [Google Scholar] [CrossRef]

- Gautier-van Berchem, M. The mosaics of the Dome of the Rock in Jerusalem and of the Great Mosque in Damascus. In Earyl Muslim Architecture; Creswell, K.A.C., Ed.; Claredon Press: Oxford, UK, 1969; Volume 1, pp. 211–327. [Google Scholar]

- Cutler, A. Gifts and Gift Exchange as Aspects of the Byzantine, Arab, and Related Economies. Dumbart. Oaks Pap. 2001, 55, 247–278. [Google Scholar] [CrossRef]

- James, J. Byzantine glass mosaic tesserae: Some material considerations. Byz. Mod. Greek Stud. 2006, 30, 29–47. [Google Scholar] [CrossRef]

- Creswell, K.A.C. Early Muslim Architecture, 1st ed.; Claredon Press: Oxford, UK, 1932. [Google Scholar]

- Sauvaget, J. La Mosquée Omeyyade de Médine; VANOEST: Paris, France, 1974. [Google Scholar]

- Hillenbrand, R. Islamic Art and Architecture; Thames and Hudson: London, UK, 1999. [Google Scholar]

- Rosen-Ayalon, M. The Early Islamic Monument of al-Haram al-Sharif: An Iconographic Study (Qedem 28); Hebrew University, Institute of Archaeology: Jerusalem, Israel, 1989. [Google Scholar]

- Allan, J.W. A Short Account on Early Muslim Architecture; Revised Edition; Aldershot: London, UK, 1989. [Google Scholar]

- Stern, H. Notes sur les mosaïques du Dôme du Rocher et de la Mosquér de Damas. Cah. Archeol. 1972, 22, 201–217. [Google Scholar]

- McKenzie, J. The Architecture of Alexandria and Egypt: 300 BC—AD 700; Yale University Press: New Haven, CT, USA, 2007. [Google Scholar]

- Bell, H. Greek Papyri in the British Museum IV The Aphrodito Papyri; The British Museum: London, UK, 1910. [Google Scholar]

- Bell, H. Translation of the Greek Aphrodito Papyri. Der Islam 1911, 2, 269–283. [Google Scholar] [CrossRef]

- Creswell, K.A.C. Early Muslim Architecture, 2nd ed.; Claredon Press: Oxford, UK, 1969. [Google Scholar]

- McKenzie, J. Alexandria on the Barada. The Mosaics of the Great Mosque in Damascus. In New Light on Old Glass: Recent Research on Byzantine Mosaics and Glass; Entwistle, C., James, L., Eds.; The British Museum Press: London, UK, 2013; pp. 291–309. [Google Scholar]

- van Lohuizen-Mulder, M. The mosaics in the Great Mosque in Damascus: A Vision of Beauty. BA Besch 1995, 70, 193–213. [Google Scholar]

- Fiorentino, S.; Vandini, M.; Chinni, T.; Caccia, M.; Martini, M.; Galli, A. Colourants and opacifiers of mosaic glass tesserae from Khirbet al-Mafjar (Jericho, Palestine): Addressing technological issues by a multi-analytical approach and evaluating the potentialities of thermoluminescence and optically stimulated luminescence da. Archaeol. Anthropol. Sci. 2019, 11, 337–359. [Google Scholar] [CrossRef]

- Fiorentino, S.; Chinni, T.; Cirelli, E.; Arletti, R.; Conte, S.; Vandini, M. Considering the effects of the Byzantine–Islamic transition: Umayyad glass tesserae and vessels from the qasr of Khirbet al-Mafjar (Jericho, Palestine). Archaeol. Anthropol. Sci. 2018, 10, 223–245. [Google Scholar] [CrossRef]

- Whitcomb, D. Jericho Mafjar Project; Annual Report for the Oriental Institute: Chicago, IL, USA, 2013. [Google Scholar]

- de Lorey, E. Les Mosaïques de la Mosquéè des Omeyyades à Damas. Syria 1931, 12, 326–349. [Google Scholar] [CrossRef]

- Johnston-Feller, R. Color Science in the Examination of Museum Objects: Nondestructive Procedures; The Getty Conservation Institute: Los Angeles, CA, USA, 2001. [Google Scholar]

- Jarosewich, E. Smithsonian microbeam standards. J. Res. NIST 2002, 107, 681–685. [Google Scholar] [CrossRef]

- Pouchou, J.; Pichoir, F. Determination of mass absorption coefficients for soft X-rays by use of the electron microprobe. In Proceedings of the 23rd Annual Conference of the Microbeam Analysis Society, Milwaukee, WI, USA, 8–12 August 1988; Newbury, D.E., Ed.; San Francisco Press: San Francisco, CA, USA, 1988; pp. 319–324. [Google Scholar]

- Brill, R.H. Chemical Analyses of Early Glass; Corning Museum of Glass: New York, NY, USA, 1999. [Google Scholar]

- Pearce, J.G.; Perkins, W.T.; Westagate, J.A.; Gorton, M.P.; Jackson, S.E.; Neal, C.R.; Chenery, S.P. A compilation of new and published major and trace element data for NIST SRM 610 and NIST SRM 612 glass reference materials. Geostand. Newsl. 1997, 21, 115–144. [Google Scholar] [CrossRef]

- Longerich, H.P.; Jackson, S.E.; Gunther, D. Inter-laboratory note. Laser ablation inductively coupled plasma mass spectrometric transient signal data acquisition and analyte concentration calculation. J. Anal. At. Spectrom. 1996, 11, 899–904. [Google Scholar] [CrossRef]

- Kamber, B.S.; Greig, A.; Collerson, K.D. A new estimate for the composition of weathered young upper continental crust from alluvial sediments, Queensland, Australia. Geochim. Cosmochim. Acta 2005, 69, 1041–1058. [Google Scholar] [CrossRef]

- Lyliquist, C.; Brill, R. Studies in Early Egyptian Glass; Metropolitan Museum of Art: New York, NY, USA, 1993. [Google Scholar]

- Paynter, S. Experiments in the Reconstruction of Roman Wood-Fired Glassworking Furnaces: Waste Products and Their Formation Processes. J. Glass Stud. 2008, 50, 271–290. [Google Scholar]

- Henderson, J.; McLoughlin, S.D.; McPhail, D.S. Radical changes in Islamic glass technology: Evidence for conservatism and experimentation with new glass recipes from early and middle Islamic Raqqa, Syria. Archaeometry 2004, 46, 439–468. [Google Scholar] [CrossRef]

- Andreescu-Treadgold, I.; Henderson, J.; Roe, M. Glass from the Mosaics on the West Wall of Torcello’s Basilica. Arte Mediev. 2002, 5, 87–141. [Google Scholar]

- Freestone, I.; Jackson-tal, R.; Tal, O. Raw Glass and the Production of Glass Vessels at Late Byzantine Apollonia-Arsuf, Israel. J. Glass Stud. 2008, 50, 67–80. [Google Scholar]

- Tal, O.; Jackson-Tal, R.; Freestone, I. New Evidence of the Production of Raw Glass at Late Byzantine Apollonia-Asurf, Israel. J. Glass Stud. 2004, 46, 51–66. [Google Scholar]

- Phelps, M.; Freestone, I.; Gorin-Rosen, Y.; Gratuze, B. Natron glass production and supply in the late antique and early medieval Near East: The effect of the Byzantine-Islamic transition. J. Archaeol. Sci. 2016, 75, 57–71. [Google Scholar] [CrossRef]

- Brill, R.H. Scientifc investigations of the Jalame glass and related finds. In Excavations at Jalame, Site of a Glass Factory in Late Roman Palestine; Weinberg, G.D., Ed.; University of Missouri Press: Columbia, MO, USA, 1988; pp. 257–293. [Google Scholar]

- Gratuze, B.; Barrandon, J. Islamic glass weights and stamps: Analysis using nuclear techniques. Archaeometry 1990, 32, 155–162. [Google Scholar] [CrossRef]

- Foy, D.; Picon, M.; Vichy, M. Verres omeyyades et abbasides d’origine egyptienne. In Proceedings of the Annales du 15e Congrès de l’Association Internationale pour l’Histoire du Verre (New York-Corning 2001), Corning, NY, USA, 15–20 October 2001; Association International pour l’Histoire du Verre: Nottingham, UK, 2003; pp. 138–143. [Google Scholar]

- Bonnerot, O.; Ceglia, A.; Michaelides, D. Technology and materials of Early Christian Cypriot wall mosaics. J. Archaeol. Sci. Rep. 2016, 7, 649–661. [Google Scholar] [CrossRef]

- Schibille, N.; Gratuze, B.; Ollivier, E.; Blondeau, É. Chronology of early Islamic glass compositions from Egypt. J. Archaeol. Sci. 2019, 104, 10–18. [Google Scholar] [CrossRef]

- Picon, M.; Thirion-merle, V.; Vichy, M. Les verres au natron et les verres aux cendres du Wadi Natrun (Egypte). Bull. l’Association Française pour l’Archéologie du Verre 2008, 22, 36–41. [Google Scholar]

- Foy, D.; Picon, M.; Vichy, M.; Thirion-Merle, V. Caracterisation des Verres de la Fin de L’antiquite En Mediterranee Occidentale: L’emergence De Nouveaux Courants Commerciaux. In Echanges et Commerce du Verre dans le Monde Antique: Actes du Colloque de l’Association Française Pour L’archéologie du verre Aix-en-Provence et Marseille 7–9 Juin 2001; Nenna, M.-D., Ed.; Moniqdue Mergoil: Montagnac, France, 2003; pp. 41–85. [Google Scholar]

- Conte, S.; Chinni, T.; Arletti, R.; Vandini, M. Butrint (Albania) between eastern and western Mediterranean glass production: EMPA and LA-ICP-MS of late antique and early medieval finds. J. Archaeol. Sci. 2014, 49, 6–20. [Google Scholar] [CrossRef]

- Neri, E.; Jackson, M.; O’Hea, M.; Gregory, T.; Blet-Lemarquand, M.; Schibille, N. Analyses of glass tesserae from Kilise Tepe: New insights into an early Byzantine production technology. J. Archaeol. Sci. Rep. 2017, 11, 600–612. [Google Scholar] [CrossRef]

- Neri, E.; Gratuze, B.; Schibille, N. Dating the mosaics of the Durres amphiteatre through interdisciplinary analysis. J. Cult. Herit. 2017, 28, 27–36. [Google Scholar] [CrossRef]

- Verità, M.; Santopadre, P.; De Palma, G. Scientific investigation of glass mosaic tesserae from the 8th century AD archaeological site of Qusayr’ Amra (Jordan). Boll. ICR 2017, 32, 7–18. [Google Scholar]

- Adlington, L.W.; Ritter, M.; Schibille, N. Production and provenance of architectural glass from the Umayyad period. PLoS ONE 2020, 15, e0239732. [Google Scholar] [CrossRef] [PubMed]

- Nenna, M.-D. Egyptian glass abroad: HIMT glass and its markets. In Neighbours and Successors of Rome: Traditions of Glass Production and Use in Europe and the Middle East in the Later 1st Millennium AD; Jackson, C., Keller, D., Price, J., Eds.; Oxbow Books: Oxford, UK, 2014; pp. 177–193. [Google Scholar]

- Nenna, M.-D. Primary glass workshops in Graeco-Roman Egypt: Preliminary report on the excavations of the site of Beni Salama, Wadi Natrun (2003, 2005–2009). In Glass of the Roman World; Bayley, J., Freestone, I., Jackson, C., Eds.; Oxbow Books: Oxford, UK, 2015; pp. 1–22. [Google Scholar]

- Kato, N.; Nakai, I.; Shindo, Y. Change in chemical composition of early Islamic glass excavated in Raya, Sinai Peninsula, Egypt: On-site analyses using a portable X-ray fluorescence spectrometer. J. Archaeol. Sci. 2009, 36, 1698–1707. [Google Scholar] [CrossRef]

- Ceglia, A.; Cosyns, P.; Nys, K.; Terryn, H.; Thienpont, H.; Meulebroeck, W. Late antique glass distribution and consumption in Cyprus: A chemical study. J. Archeol. Sci. 2015, 61, 213–222. [Google Scholar] [CrossRef]

- Wedepohl, K.; Simon, K.; Kronz, A. Data on 61 chemical elements for the characterization of three major glass compositions in late antiquity and the middle ages. Archaeometry 2011, 53, 81–102. [Google Scholar] [CrossRef]

- Freestone, I.; Leslie, K.; Thirlwall, M.; Gorin-Rosen, Y. Strontium isotopes in the investigation of early glass production: Byzantine and early islamic glass from the near East. Archaeometry 2003, 45, 19–32. [Google Scholar] [CrossRef]

- Freestone, I.; Gorin-Rosen, Y.; Hughes, M. Primary glass from Israel and the production of glass in Late Antiquity and the Early Islamic period. In Proceedings of the La Route du verre. Ateliers Primaires et Secondaires du Second Millénaire av. J.-C. au Moyen Age. Actes du Colloque Organisé en 1989 par l’Association Française pour l’Archéologie du Verre (AFAV); Nenna, M.-D., Ed.; La Maison de l’Orient et de la Méditerranéen: Lyon, France, 2000; pp. 65–83. [Google Scholar]

- Barfod, G.H.; Freestone, I.C.; Lichtenberger, A.; Raja, R.; Schwarzer, H. Geochemistry of Byzantine and Early Islamic glass from Jerash, Jordan: Typology, recycling, and provenance. Geoarchaeology 2018, 33, 623–640. [Google Scholar] [CrossRef] [Green Version]

- Silvestri, A.; Tonietto, S.; Molin, G.; Guerriero, P. The palaeo-Christian glass mosaic of St. Prosdocimus (Padova, Italy): Archaeometric characterisation of tesserae with antimony- or phosphorus-based opacifiers. J. Archaeol. Sci. 2012, 39, 2177–2190. [Google Scholar] [CrossRef]

- Silvestri, A.; Tonietto, S.; Molin, G.; Guerriero, P. The palaeo-Christian glass mosaic of St. Prosdocimus (Padova, Italy): Archaeometric characterisation of tesserae with copper- or tin-based opacifiers. J. Archaeol. Sci. 2014, 42, 51–67. [Google Scholar] [CrossRef]

- Fiorentino, S.; Chinni, T.; Vandini, M. Ravenna, its mosaics and the contribution of archaeometry. A systematic reassessment on literature data related to glass tesserae and new considerations. J. Cult. Herit. 2020, 46, 335–349. [Google Scholar] [CrossRef]

- Fiori, C. Vetro musivo del VI secolo dagli scavi della Basilica di San Severo a Classe (Ravenna). Riv. Stn. Sper. Vetro 2011, 1, 22–34. [Google Scholar]

- Fiori, C. Mosaic Tesserae from the Basilica of San Severo and Glass Production in Classe, Ravenna, Italy. In New Light on Old Glass: Recent Research on Byzantine Mosaics and Glass; Entwistle, C., James, L., Eds.; The British Museum: London, UK, 2013; pp. 33–41. [Google Scholar]

- Fiori, C.; Vandini, M.; Mazzotti, V. I Colori del vetro Antico. Il vetro Musivo Bizantino; Il Prato: Saonara, Italy, 2004. [Google Scholar]

- Vandini, M.; Arletti, R.; Cirelli, E. Five Centuries of Mosaic Glass at Saint Severus (Classe, Ravenna). OCNUS 2014, 22, 91–108. [Google Scholar]

- Verità, M. Tessere vitree del battistero Neoniano: Tecniche e provenienza. In Il Battistero Neoniano. Uno Sguardo Attraverso il Restauro; Muscolino, C., Ranaldi, A., Tedeschi, C., Eds.; Angelo Longo Editore: Ravenna, Italy, 2011; pp. 73–87. [Google Scholar]

- Verità, M. Indagini analitiche delle tessere vitree a foglia d’oro e d’argento dai mosaici teodoriciani e agnelliani di Sant’Apollinare Nuovo. In Sant’Apollinare Nuovo: Un Cantiere Esemplare; Muscolino, C., Ed.; Angelo Longo Editore: Ravenna, Italy, 2012; pp. 128–134. [Google Scholar]

- Schibille, N.; McKenzie, J. Glass tesserae from Hagios Polyeuktos, Costantinopole: Their early Bizantine affiliations. In Neighbours and Successors of Rome; Keller, D., Price, J., Jackson, C., Eds.; Oxbow Books: Oxford, UK, 2014; pp. 114–127. [Google Scholar]

- Wypyski, M.T. Technical Analysis of Glass Mosaic Tesserae from Amorium.pdf. Dumbart. Oaks Pap. 2005, 59, 183–192. [Google Scholar] [CrossRef]

- Serra, C.; Silvestri, A.; Molin, G. Archaeometric characterization of vitreous mosaic from Tyana (Cappadocia). In Proceedings of the Late Antique/Early Byzantine Glass in the Eastern Mediterranean. Colloquia Anatolica et Aegaea—Acta Congressus Communis Omnium Gentium Smyrnae II, Izmir, Turkey, 16–17 May 2009; pp. 171–183. [Google Scholar]

- Lahanier, C. Etudes des tesselles de mosaïques et de verre à vitre syriens. In Huarte, Sanctuaire Chrétien d’Apamène (IVe-VIe s.); Canivet, M., Canivet, P., Eds.; Institut Français d’Archéologie au Proche-Orient: Paris, France, 1987; pp. 331–346. [Google Scholar]

- Marii, F. Glass Tesserae from the Petra Church. In New Light on Old Glass: Recent Research on Byzantine Mosaics and Glass; Entwistle, C., James, L., Eds.; The British Museum: London, UK, 2013; pp. 11–24. [Google Scholar]

- Marii, F.; Rehren, T. Archaeological coloured glass cakes and tesserae from the Petra Church. In Annales du 17e Congres del’Association Internationale pour l’Histoire du Verre; Janssens, K., Ed.; University Press Antwerp: Brussels, Belgium, 2009; pp. 295–300. [Google Scholar]

- Boschetti, C.; Lichtenberger, A.; Raja, R.; Wootton, W.; Schibille, N. Loose glass tesserae and lost decorations: Chronology and production of mosaics from Gerasa’s Northwest Quarter. Archaeometry 2021, 63, 960–974. [Google Scholar] [CrossRef]

- Vandini, M.; Fiorentino, S. From crystals to color: A compendium of multi-analytical data on mineralogical phases in opaque colored glass mosaic tesserae. Minerals 2020, 10, 609. [Google Scholar] [CrossRef]

- Fiorentino, S.; Chinni, T.; Vandini, M. Materials Inspiring Methodology: Reflecting on the Potential of Transdisciplinary Approaches to the Study of Archaeological Glass. Appl. Sci. 2021, 11, 8049. [Google Scholar] [CrossRef]

- Maltoni, S.; Silvestri, A. A mosaic of colors: Investigating production technologies of roman glass tesserae from Northeastern Italy. Minerals 2018, 8, 255. [Google Scholar] [CrossRef] [Green Version]

- Boschetti, C.; Henderson, J.; Evans, J.; Leonelli, C. Mosaic tesserae from Italy and the production of Mediterranean coloured glass (4rd century BCE–4th century CE). Part I: Chemical composition and technology. J. Archaeol. Sci. Rep. 2016, 7, 303–311. [Google Scholar] [CrossRef]

- Freestone, I.; Stapleton, C.; Rigby, V. The production of red glass and enamel in the Late Iron Age, Roman and Byzantine periods. In Through a Glass Brightly—Studies in Byzantine and Medieval Art and Archaeology Presented to David Buckton; Entwistle, C., Ed.; Oxbow Books: Oxford, UK, 2003; pp. 142–154. [Google Scholar]

- Arletti, R.; Dalconi, M.C.; Quartieri, S.; Triscari, M.; Vezzalini, G. Roman coloured and opaque glass: A chemical and spectroscopic study. Appl. Phys. A Mater. Sci. Process. 2006, 83, 239–245. [Google Scholar] [CrossRef]

- Maltoni, S.; Silvestri, A. Innovation and tradition in the fourth century mosaic of the Casa delle Bestie Ferite in Aquileia, Italy: Archaeometric characterisation of the glass tesserae. Archaeol. Anthropol. Sci. 2016. [Google Scholar] [CrossRef]

- Galli, A.; Poldi, G.; Martini, M.; Sibilia, E.; Montanari, C.; Panzeri, L. Study of blue colour in ancient mosaic tesserae by means of thermoluminescence and reflectance measurements. Appl. Phys. A Mater. Sci. Process. 2006, 83, 675–679. [Google Scholar] [CrossRef]

- Galli, A.; Poldi, G.; Martini, M.; Sibilia, E. Thermoluminescence and visible reflectance spectroscopy applied to the study of blue-green mosaic silica-glass tesserae. Phys. Status Solidi Curr. Top. Solid State Phys. 2007, 4, 950–953. [Google Scholar] [CrossRef]

- Silvestri, A.; Nestola, F.; Peruzzo, L. Multi-methodological characterisation of calcium phosphate in late-Antique glass mosaic tesserae. Microchem. J. 2016, 124, 811–818. [Google Scholar] [CrossRef]

- Penel, G.; Cau, E.; Delfosse, C.; Rey, C.; Hardouin, P.; Jeanfils, J.; Delecourt, C.; Lemaitre, J.; Leroy, G. Raman microspectrometry studies of calcified tissues and related biomaterials. Dent. Med. Probl. 2003, 40, 37–43. [Google Scholar]

- Maltoni, S.; Silvestri, A. Investigating a Byzantine technology: Experimental replicas of Ca-phosphate opacified glass. J. Cult. Herit. 2019. [Google Scholar] [CrossRef]

- Zhao, H.; Li, Q.; Liu, S.; Gan, F. Characterization of microcrystals in some ancient glass beads from china by means of confocal Raman microspectroscopy. J. Raman Spectrosc. 2013, 44, 643–649. [Google Scholar] [CrossRef]

- Šefců, R.; Chlumská, Š.; Hostašová, A. An investigation of the lead tin yellows type I and II and their use in Bohemian panel paintings from the Gothic period. Herit. Sci. 2015, 3, 16. [Google Scholar] [CrossRef] [Green Version]

- Welter, N.; Schüssler, U.; Kiefer, W. Characterisation of inorganic pigments in ancient glass beads by means of Raman microscpectroscopy, microprobe analysis and X-ray diffractometry. J. Raman Spectrosc. 2007, 38, 113–121. [Google Scholar] [CrossRef]

- Cloutis, E.; Norman, L.; Cuddy, M.; Mann, P. Spectral reflectance (350-2500 nm) properties of historic artists’ pigments. II. Red-orange-yellow chromates, jarosites, organics, lead(-tin) oxides, sulphides, nitrites and antimonates. J. Near Infrared Spectrosc. 2016, 24, 119–140. [Google Scholar] [CrossRef]

- Matin, M.; Tite, M.; Watson, O. On the origins of tin-opacified ceramic glazes: New evidence from early Islamic Egypt, the Levant, Mesopotamia, Iran, and Central Asia. J. Archaeol. Sci. 2018, 97, 42–66. [Google Scholar] [CrossRef]

- Tite, M.; Pradell, T.; Shortland, A. Discovery, Production and Use of Tin-Based Opacifiers in Glasses, Enamels and Glazes From the Late Iron Age Onwards: A Reassessment. Archaeometry 2008, 50, 67–84. [Google Scholar] [CrossRef]

- Schibille, N.; Degryse, P.; Corremans, M.; Specht, C. Chemical characterisation of glass mosaic tesserae from sixth-century Sagalassos (south-west Turkey): Chronology and production techniques. J. Archaeol. Sci. 2012, 39, 1480–1492. [Google Scholar] [CrossRef]

- Schibille, N.; Neri, E.; Ebanista, C.; Ammar, M.R.; Bisconti, F. Something old, something new: The late antique mosaics from the catacomb of San Gennaro (Naples). J. Archaeol. Sci. Rep. 2018, 20, 411–422. [Google Scholar] [CrossRef]

- Arletti, R.; Vezzalini, G.; Fiori, C.; Vandini, M. Mosaic glass from St Peter’s, Rome: Manufacturing techniques and raw materials employed in late 16th-century Italian opaque glass. Archaeometry 2011, 53, 364–386. [Google Scholar] [CrossRef]

- Arletti, R.; Conte, S.; Vandini, M.; Fiori, C.; Bracci, S.; Bacci, M.; Porcinai, S. Florence baptistery: Chemical and mineralogical investigation of glass mosaic tesserae. J. Archaeol. Sci. 2011, 38, 79–88. [Google Scholar] [CrossRef]

- Neri, E.; Verità, M.; Conventi, A. Glass Mosaic Tesserae from the 5th to the 6th Century Baptistery of San Giovanni alle Fonti, Milan, Italy. In New Light on Old Glass: Recent Research on Byzantine Mosaics and Glass; Faulks, S., Ed.; The British Museum: London, UK, 2013; pp. 1–10. [Google Scholar]

- James, L.; Soproni, E.; Bjørnholt, E. Mosaics by numbers. Some preliminary evidence from the Leverhulme Databse. In New Light on Old Glass: Recent Research on Byzantine Mosaics and Glass; Entwistle, C., James, L., Eds.; The British Museum: London, UK, 2013; pp. 310–328. [Google Scholar]

- James, L. Mosaics in the Medieval World; Cambridge University Press: Cambridge, UK, 2017. [Google Scholar]

- Gómez-Morón, M.A.; Palomar, T.; Alves, L.C.; Ortiz, P.; Vilarigues, M.; Schibille, N. Christian-Muslim contacts across the Mediterranean: Byzantine glass mosaics in the Great Umayyad Mosque of Córdoba (Spain). J. Archaeol. Sci. 2021, 129. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fiorentino, S. A Tale of Two Legacies: Byzantine and Egyptian Influences in the Manufacture and Supply of Glass Tesserae under the Umayyad Caliphate (661–750 AD). Heritage 2021, 4, 2810-2834. https://doi.org/10.3390/heritage4040158

Fiorentino S. A Tale of Two Legacies: Byzantine and Egyptian Influences in the Manufacture and Supply of Glass Tesserae under the Umayyad Caliphate (661–750 AD). Heritage. 2021; 4(4):2810-2834. https://doi.org/10.3390/heritage4040158

Chicago/Turabian StyleFiorentino, Sara. 2021. "A Tale of Two Legacies: Byzantine and Egyptian Influences in the Manufacture and Supply of Glass Tesserae under the Umayyad Caliphate (661–750 AD)" Heritage 4, no. 4: 2810-2834. https://doi.org/10.3390/heritage4040158

APA StyleFiorentino, S. (2021). A Tale of Two Legacies: Byzantine and Egyptian Influences in the Manufacture and Supply of Glass Tesserae under the Umayyad Caliphate (661–750 AD). Heritage, 4(4), 2810-2834. https://doi.org/10.3390/heritage4040158