Mortar Characterization of Historical Masonry Damaged by Riverbank Failure: The Case of Lungarno Torrigiani (Florence)

Abstract

:1. Introduction

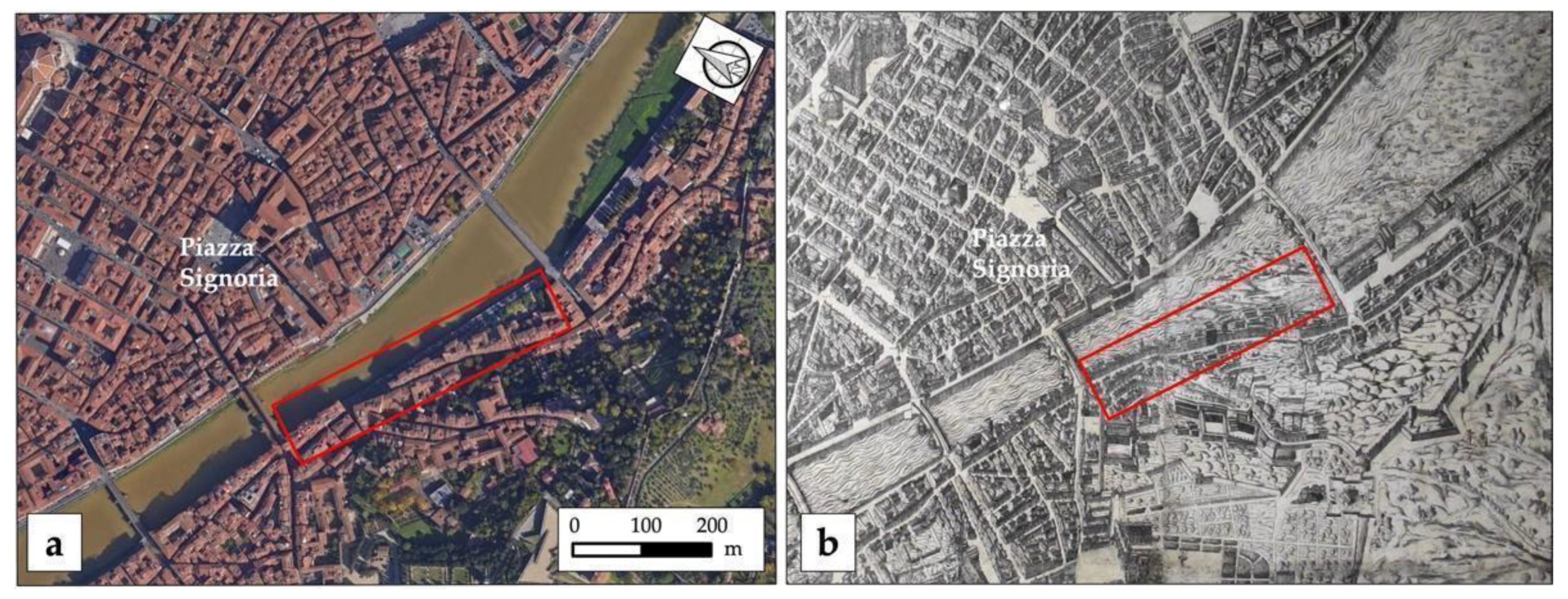

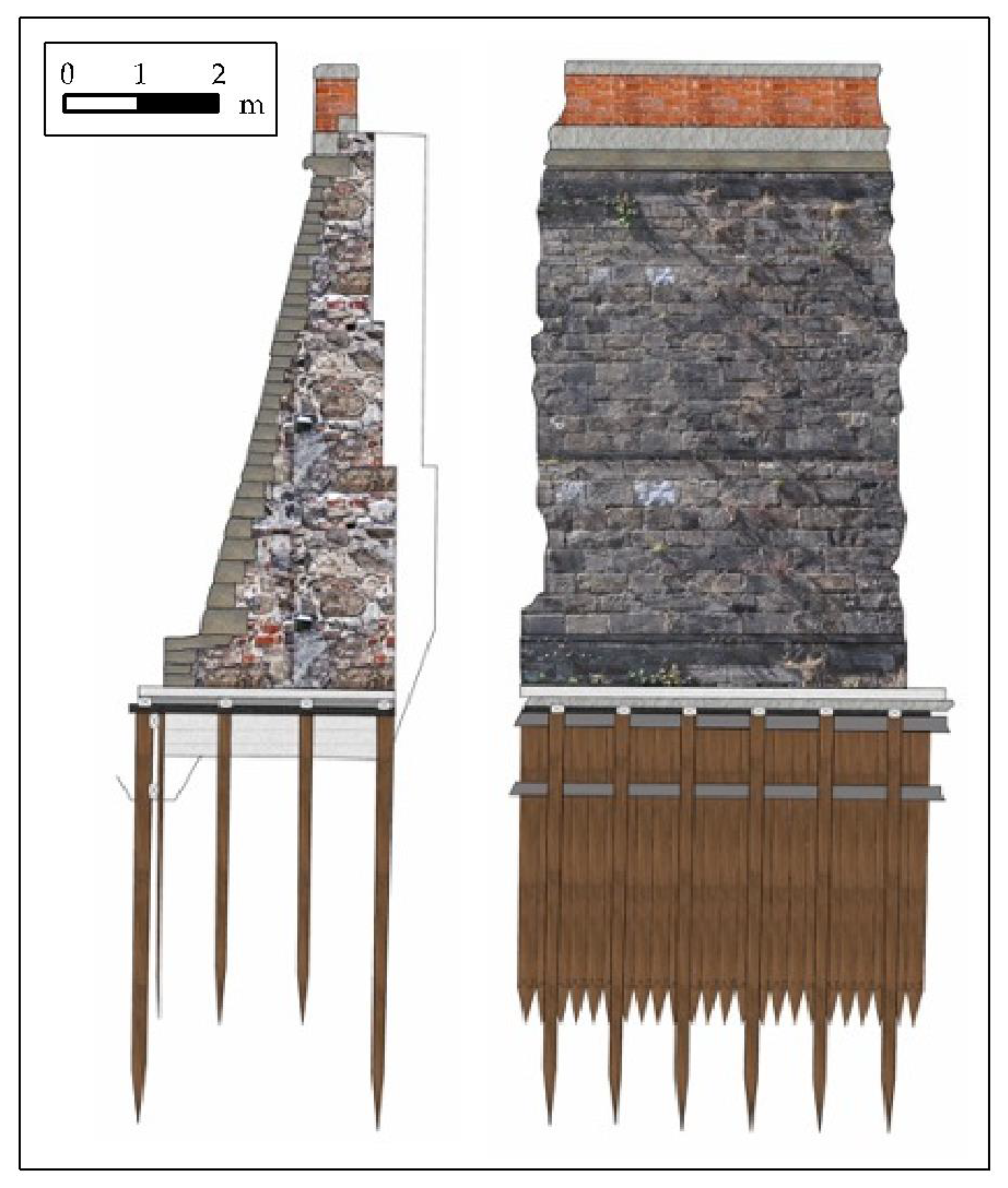

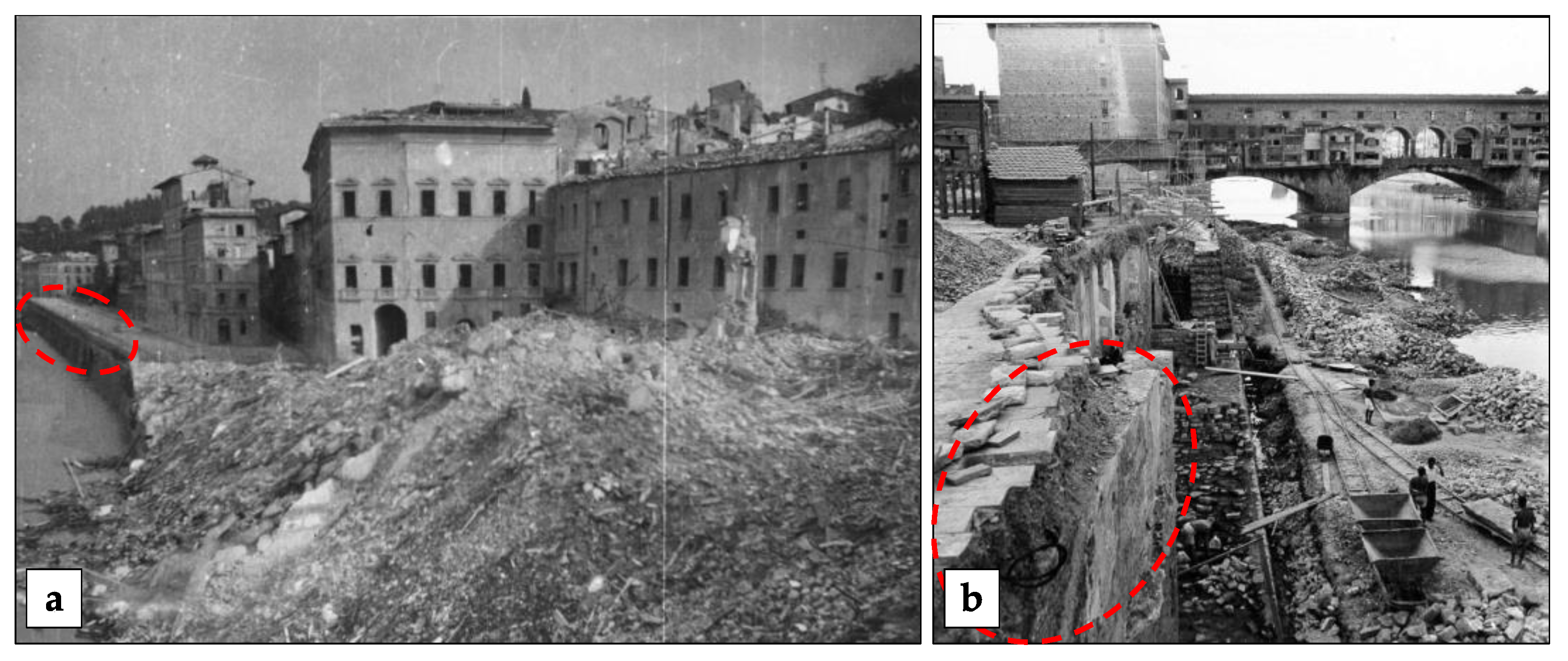

2. Historical and Area Framework

3. Materials and Methods

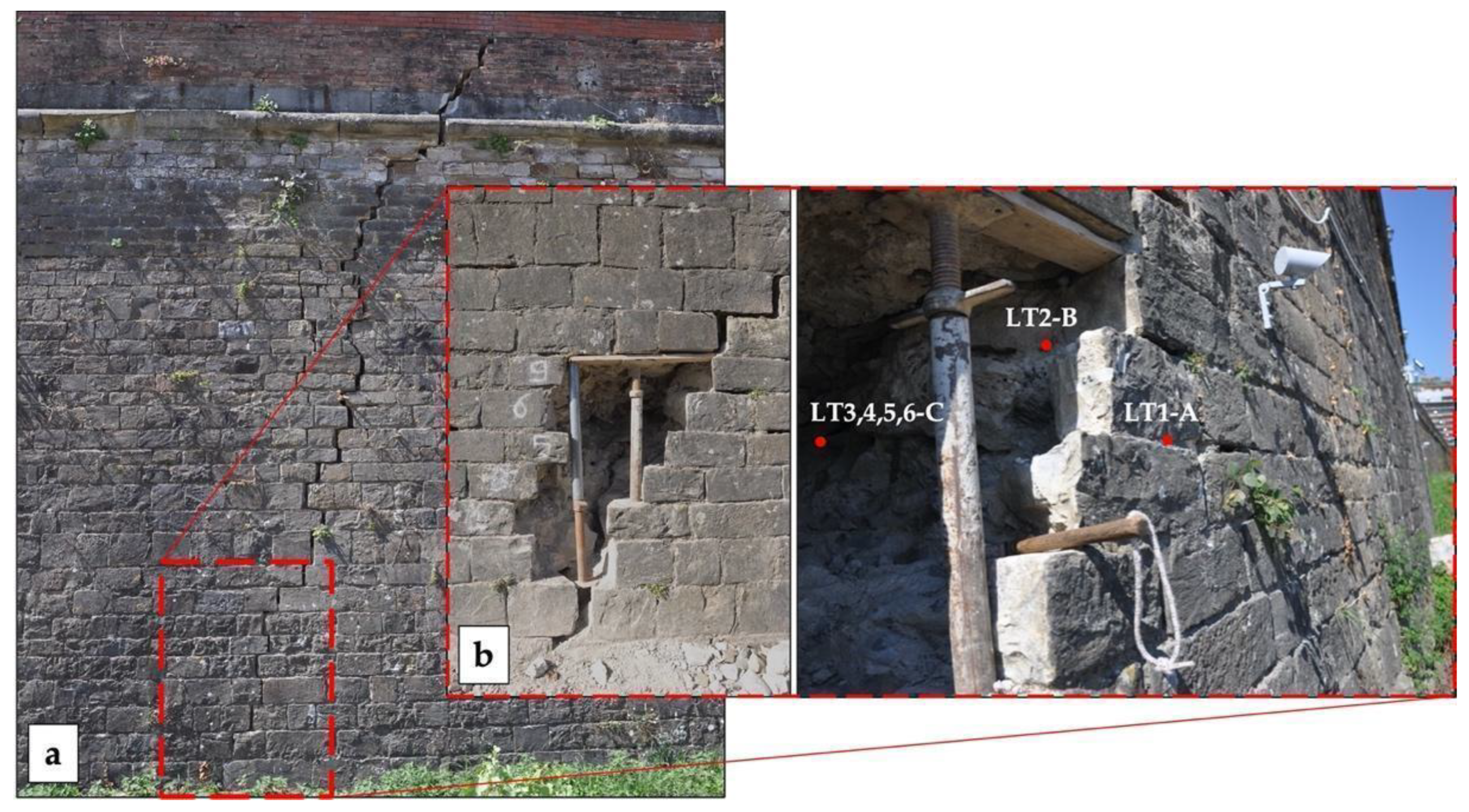

3.1. Sampling

3.2. Mineralogical–Petrographic and Microchemical Analyses

3.3. Physical and Mechanical Analysis

4. Results and Discussion

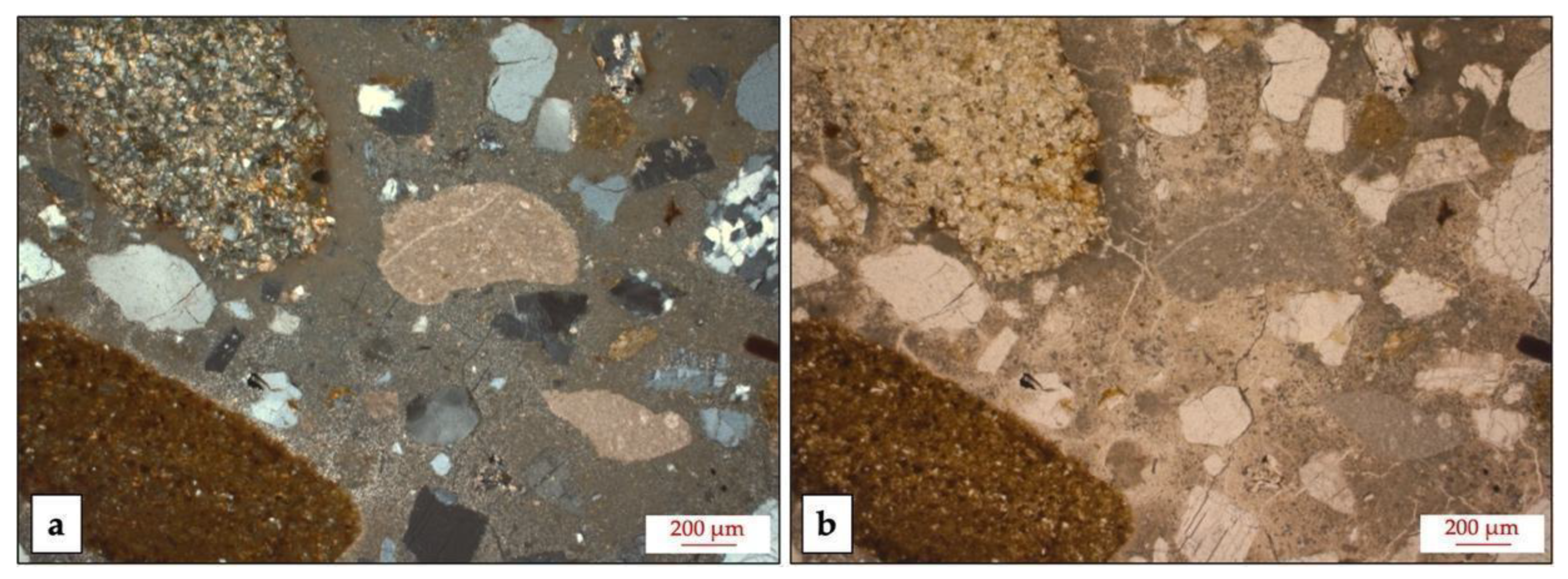

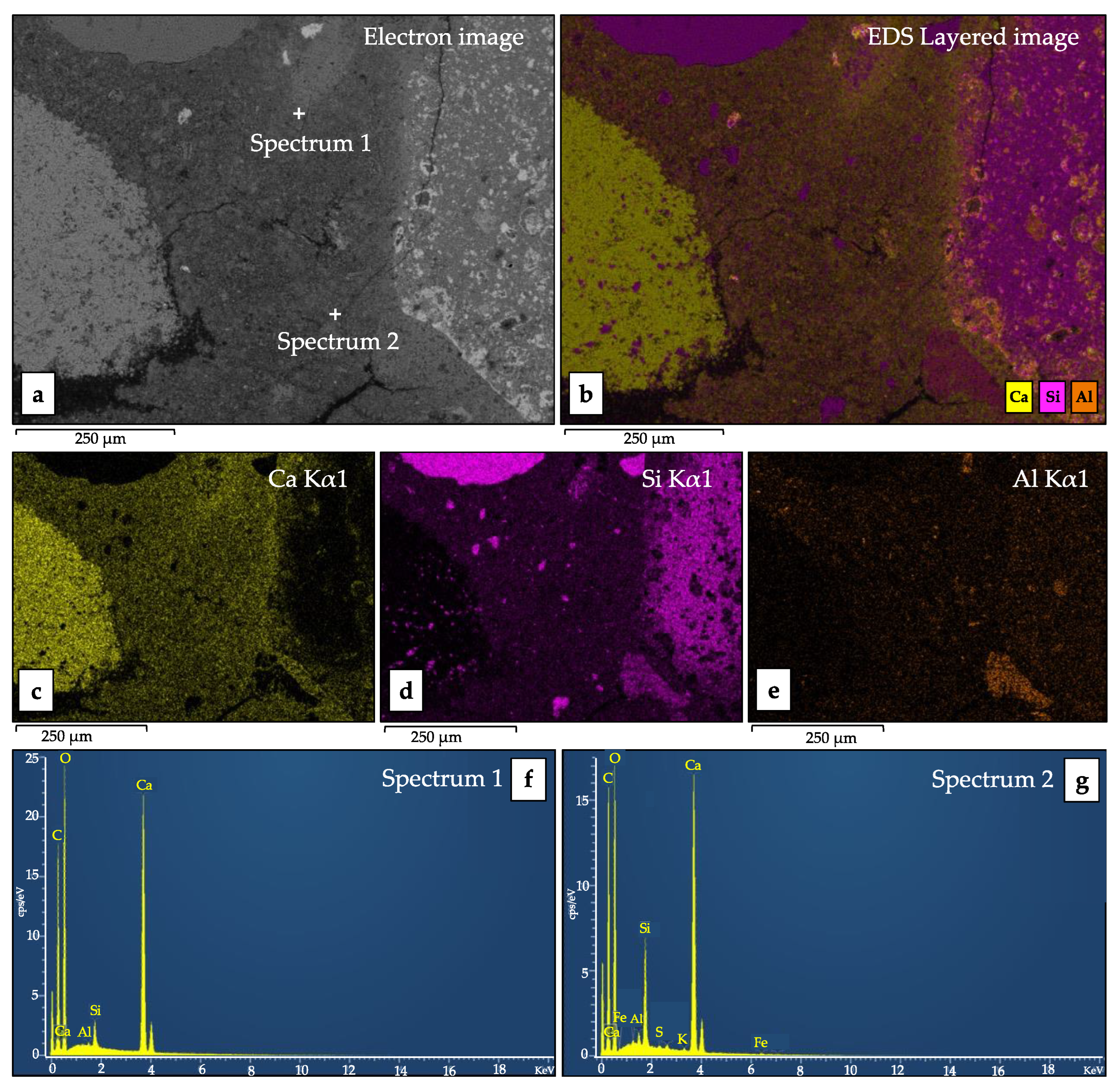

4.1. Mineralogical–Petrographic and Microchemical Data

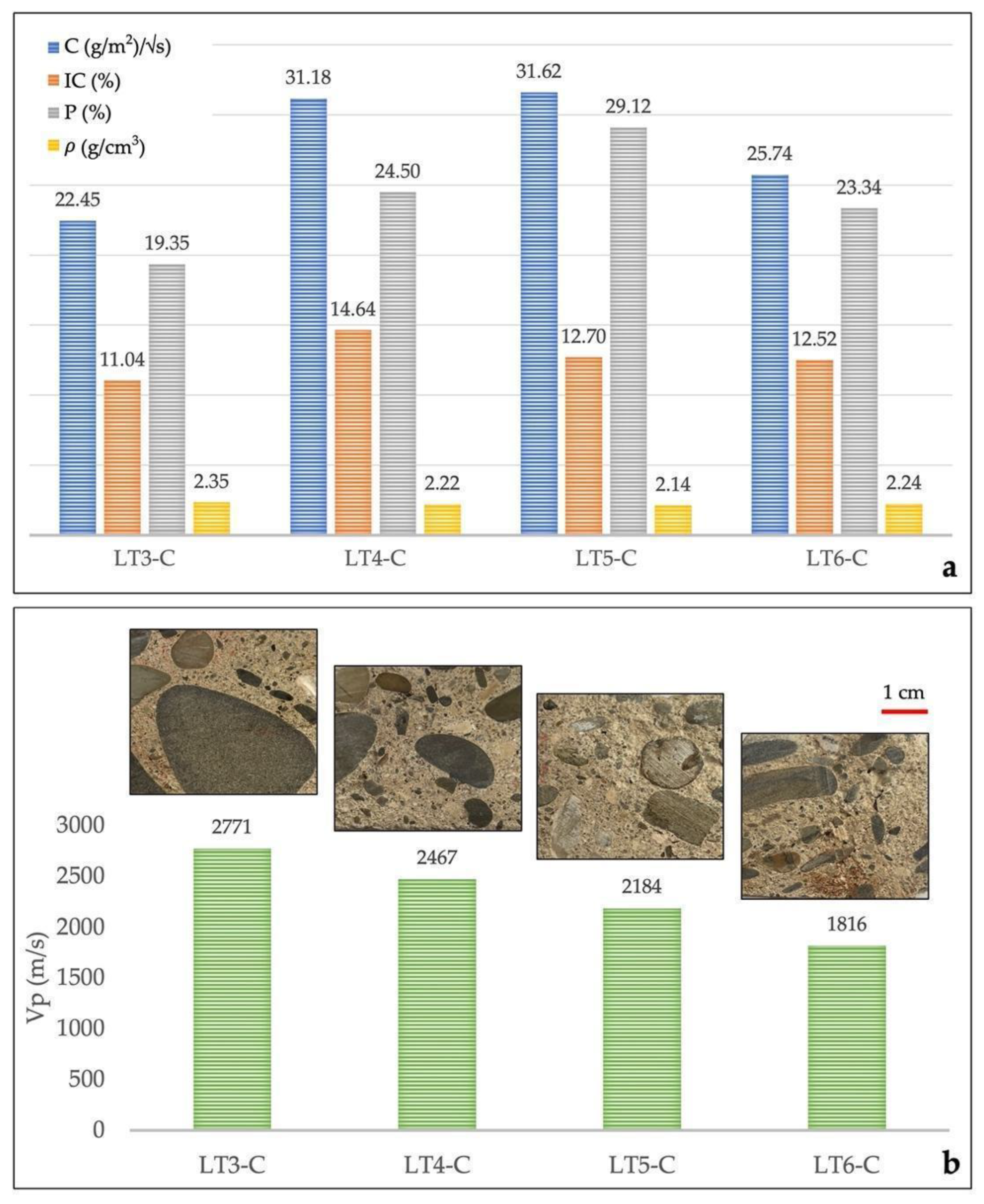

4.2. Physical and Mechanical Data

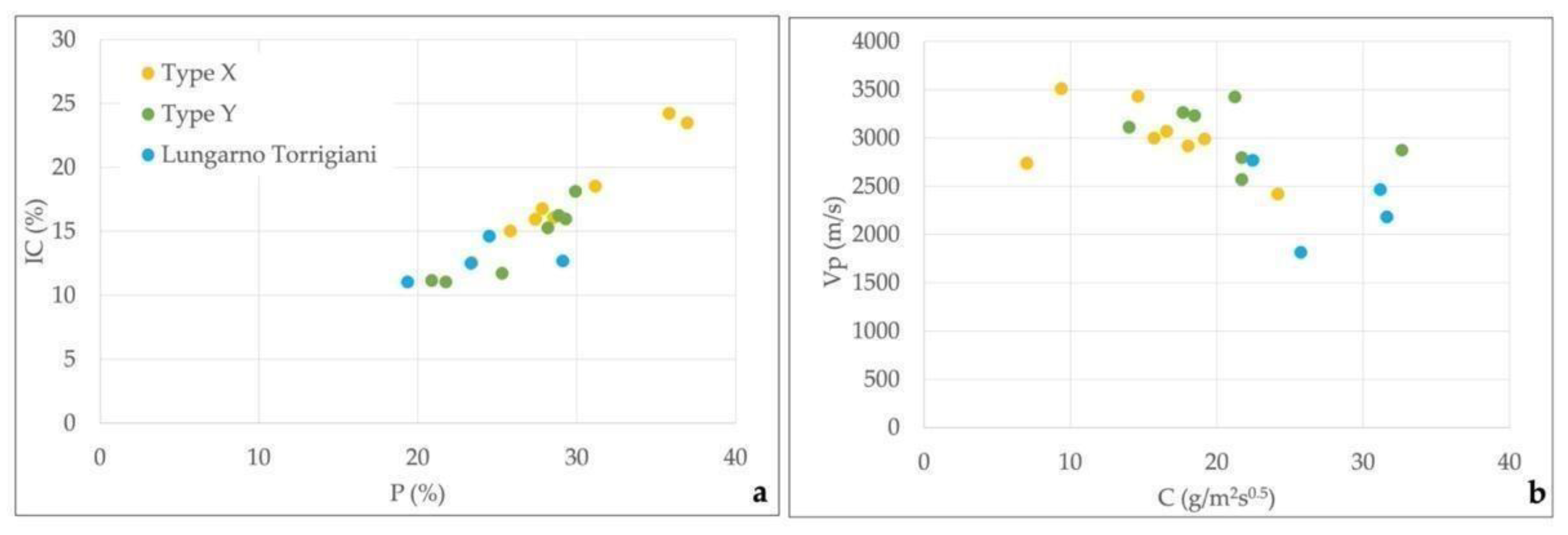

5. Discussion about the Comparison between the Lungarno Torrigiani Mortars with Lungarno degli Acciaiuoli and Lungarno delle Grazie

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Morelli, S.; Segoni, S.; Manzo, G.; Ermini, L.; Catani, F. Urban planning, flood risk and public policy: The case of the Arno River, Firenze, Italy. Appl. Geogr. 2012, 34, 205–218. [Google Scholar] [CrossRef]

- Morelli, S.; Pazzi, V.; Tofani, V.; Raspini, F.; Bianchini, S.; Casagli, N. Reconstruction of the slope instability conditions before the 2016 failure in an Urbanized District of Florence (Italy), a UNESCO world heritage site. In Understanding and Reducing Landslide Disaster Risk; Sendai Landslide Partnerships (Kobe-City, Japan); Kyoto Landslide Commitment 5th: Kyoto, Japan, 2021; Volume 1, pp. 449–455. [Google Scholar]

- Morelli, S.; Battistini, A.; Catani, F. Rapid assessment of flood susceptibility in urbanized rivers using digital terrain data: Application to the Arno river case study (Firenze, northern Italy). Appl. Geogr. 2014, 54, 35–53. [Google Scholar] [CrossRef]

- Morelli, S.; Pazzi, V.; Tanteri, L.; Nocentini, M.; Lombardi, L.; Gigli, G.; Casagli, N. Characterization and geotechnical investigations of a riverbank failure in Florence, Italy, UNESCO World Heritage Site. J. Geotech. Geoenviron. Eng. 2020, 146, 05020009. [Google Scholar] [CrossRef]

- Dapporto, S.; Rinaldi, M.; Casagli, N.; Vannocci, P. Mechanisms of riverbank failure along the Arno River, Central Italy. Earth Surf. Process. Landf. 2003, 28, 1303–1323. [Google Scholar] [CrossRef]

- Asioli, C.; Bertero, A.; Cribari, F.; Agostini, C.; Chiarugi, M.; Galli, O.; Tognotti, M.; Spinelli, P.; Aiello, E.; Micheloni, M. Intervento di messa in sicurezza in somma urgenza del tratto interessato da dissesto sul Lungarno Torrigiani a Firenze: Progetto ed esecuzione delle opere di consolidamento, conservazione e ripristino del muro spondale dislocate. In Proceedings of the XXVI Convegno Nazionale di Geotecnica, Rome, Italy, 20–22 June 2017; Associazione Geotecnica Italiana (AGI): Rome, Italy, 2017. [Google Scholar]

- Pazzi, V.; Lotti, A.; Chiara, P.; Lombardi, L.; Nocentini, M.; Casagli, N. Monitoring of the vibration induced on the Arno masonry embankment wall by the conservation works after the May 25, 2016 riverbank landslide. Geoenviron. Disasters 2017, 4, 6. [Google Scholar] [CrossRef]

- Ponce-Antón, G.; Arizzi, A.; Cultrone, G.; Zuluaga, M.C.; Ortega, L.A.; Agirre Mauleon, J. Investigating the manufacturing technology and durability of lime mortars from Amaiur Castle (Navarre, Spain): A chemical–mineralogical and physical study. Constr. Build. Mater. 2021, 299, 123975. [Google Scholar] [CrossRef]

- Sardella, A.; Canevarolo, S.; Marrocchino, E.; Tittarelli, F.; Bonazza, A. Investigation of Building Materials Belonging to the Ruins of the Tsogt Palace in Mongolia. Heritage 2021, 4, 2494–2514. [Google Scholar] [CrossRef]

- Columbu, S.; Lisci, C.; Sitzia, F.; Lorenzetti, G.; Lezzerini, M.; Pagnotta, S.; Raneri, S.; Legnaioli, S.; Palleschi, V.; Gallello, G.; et al. Mineralogical, petrographic and physical-mechanical study of Roman construction materials from the Maritime Theatre of Hadrian’s Villa (Rome, Italy). Measurement 2018, 127, 264–276. [Google Scholar] [CrossRef]

- Franzoni, E.; Santandrea, M.; Gentilini, C.; Fregni, A.; Carloni, C. The role of mortar matrix in the bond behavior and salt crystallization resistance of FRCM applied to masonry. Constr. Build. Mater. 2019, 209, 592–605. [Google Scholar] [CrossRef]

- Haneefa, K.M.; Rani, S.D.; Ramasamy, R.; Santhanam, M. Microstructure and geochemistry of lime plaster mortar from a heritage structure. Constr. Build. Mater. 2019, 225, 538–554. [Google Scholar] [CrossRef]

- Calandra, S.; Salvatici, T.; Centauro, I.; Cantisani, E.; Garzonio, C.A. The Mortars of Florence Riverbanks: Raw Materials and Technologies of Lungarni Historical Masonry. Appl. Sci. 2022, 12, 5200. [Google Scholar] [CrossRef]

- Cresti, C.; Zangheri, L. Architetti e Ingegneri nella Toscana dell’800; UNEDIT: Florence, Italy, 1978. [Google Scholar]

- Poggi, G. Sui Lavori per L’ingrandimento di Firenze. Relazione di G.P. (1864–1877); Barbera, G., Ed.; Fiorentinagas—Giunti: Florence, Italy, 1882. [Google Scholar]

- Del Badia, I. Pianta topografica della città di Firenze di don Stefano Bonsignori dell’anno 1584. In Proceedings of the Atti del III Congresso Geografico Italiano, Florence, Italy, 12–17 April 1898; pp. 570–577. [Google Scholar]

- Fei, S.; Spini, G. Nascita e Sviluppo di Firenze Città Borghese; Editrice: Alberobello, Italy, 1971. [Google Scholar]

- Fantozzi Micali, O. Piani di Ricostruzione e Città Storiche 1945–1955; Alinea: Florence, Italy, 1998. [Google Scholar]

- Gabellini, P.; Ragghianti, R. Edoardo Detti 1913–1984. In Le Sculture di Paolo Borghi Omaggio agli Urbanisti del Novecento; Ministero dei Lavori Pubblici: Rome, Italy, 2001. [Google Scholar]

- UNI EN 12407; Natural Stone Test Methods—Petrographic Examination. Ente Nazionale Italiano di Normazione: Milan, Italy, 2007.

- UNI EN 13925-1; Non-Destructive Testing—X-Ray Diffraction from Polycrystalline and Amorphous Material—Part 1: General Principles. Ente Nazionale Italiano di Normazione: Milan, Italy, 2006.

- UNI EN 13925-2; Non-Destructive Testing—X-Ray Diffraction from Polycrystalline and Amorphous Materials—Part 2: Procedures. Ente Nazionale Italiano di Normazione: Milan, Italy, 2006.

- UNI-EN 13925-3; Non-Destructive Testing—X-Ray Diffraction from Polycrystalline and Amorphous Materials—Part 3: Instruments. Ente Nazionale Italiano di Normazione: Milan, Italy, 2006.

- Pouchou, J.L.; Pichoir, F. Quantitative Analysis of Homogeneous or Stratified Microvolumes Applying the Model “PAP”. In Electron Probe Quantitation; Springer: Boston, MA, USA, 1991; pp. 31–75. [Google Scholar] [CrossRef]

- UNI EN 1015-18:2002; Methods of Test for Mortar for Masonry—Part 18: Determination of Water Absorption Coefficient due to Capillary Action of Hardened Mortar. Ente Nazionale Italiano di Normazione: Milan, Italy, 2002.

- Martys, N.S.; Ferraris, C.F. Capillarity transport in mortars and concrete. Cem. Concr. Res. 1997, 27, 747–760. [Google Scholar] [CrossRef]

- Lanzón, M.; García-Ruiz, P.A. Evaluation of capillary water absorption in rendering mortars made with powdered waterproofing additives. Constr. Build. Mater. 2009, 23, 3287–3291. [Google Scholar] [CrossRef]

- Cunha, S.; Aguiar, J.; Ferreira, V.; Tadeu, A. Mortars based in different binders with incorporation of phase-change materials: Physical and mechanical properties. Eur. J. Environ. Civ. Eng. 2015, 19, 1216–1233. [Google Scholar] [CrossRef]

- UNI-EN 1097-6; Tests for Mechanical and Physical Properties of Aggregates—Part 6: Determination of Particle Density and Water Absorption. Ente Nazionale Italiano di Normazione: Milan, Italy, 2013.

- UNI EN 1936; Natural Stones Test Methods: Determination of Real Density and Apparent Density and of Total and Open Porosity. Ente Nazionale Italiano di Normazione: Milan, Italy, 2007.

- Fratini, F.; Cantisani, E.; Pecchioni, E.; Pandeli, E.; Vettori, S. Pietra Alberese: Building Material and Stone for Lime in the Florentine Territory (Tuscany, Italy). Heritage 2020, 3, 1520–1538. [Google Scholar] [CrossRef]

- Pecchioni, E.; Fratini, F.; Cantisani, E. Atlas of the Ancient Mortars in Thin Section under Optical Microscope, 2nd ed.; Nardini: Florence, Italy, 2020; p. 78. [Google Scholar]

- Cantisani, E.; Fratini, F.; Pecchioni, E. Optical and electronic microscope for minero-petrographic and microchemical studies of lime binders of ancient mortars. Minerals 2022, 12, 41. [Google Scholar] [CrossRef]

- Veiga, R.; Velosa, A.; Magalhaes, A. Experimental applications of mortars with pozzolanic additions: Characterization and performance evaluation. Constr. Build. Mater. 2009, 23, 318–327. [Google Scholar] [CrossRef]

- Aragon, G.; Aragon, A.; Santamaria, A.; Esteban, A.; Fiol, F. Physical and mechanical characterization of a commercial rendering mortar using destructive and non-destructive techniques. Constr. Build. Mater. 2019, 224, 835–849. [Google Scholar] [CrossRef]

- Cantisani, E.; Calandra, S.; Barone, S.; Caciagli, S.; Fedi, M.; Garzonio, C.A.; Vettori, S. The mortars of Giotto’s Bell Tower (Florence, Italy): Raw materials and technologies. Constr. Build. Mater. 2021, 267, 120801. [Google Scholar] [CrossRef]

- Moropoulou, A.; Bakolas, A.; Anagnostopoulou, S. Composite materials in ancient structures. Cem. Concr. Compos. 2005, 27, 295–300. [Google Scholar] [CrossRef]

- Arizzi, A.; Cultrone, G. The influence of aggregate texture, morphology and grading on the carbonation of non-hydraulic (aerial) lime-based mortars. Q. J. Eng. Geol. Hydrogeol. 2013, 46, 507–520. [Google Scholar] [CrossRef]

| Sample | Quartz | Calcite | Feldspars | Micas | Clay Minerals |

|---|---|---|---|---|---|

| LT1-A | xxx | xx | x | tr | tr |

| LT2-B | xxx | xx | x | tr | tr |

| LT3-C | xxx | x | x | tr | tr |

| LT4-C | xxx | xx | x | tr | tr |

| LT5-C | xxx | xx | x | tr | tr |

| LT6-C | xxx | xx | tr | tr | tr |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Calandra, S.; Salvatici, T.; Pecchioni, E.; Centauro, I.; Garzonio, C.A. Mortar Characterization of Historical Masonry Damaged by Riverbank Failure: The Case of Lungarno Torrigiani (Florence). Heritage 2023, 6, 3820-3834. https://doi.org/10.3390/heritage6050203

Calandra S, Salvatici T, Pecchioni E, Centauro I, Garzonio CA. Mortar Characterization of Historical Masonry Damaged by Riverbank Failure: The Case of Lungarno Torrigiani (Florence). Heritage. 2023; 6(5):3820-3834. https://doi.org/10.3390/heritage6050203

Chicago/Turabian StyleCalandra, Sara, Teresa Salvatici, Elena Pecchioni, Irene Centauro, and Carlo Alberto Garzonio. 2023. "Mortar Characterization of Historical Masonry Damaged by Riverbank Failure: The Case of Lungarno Torrigiani (Florence)" Heritage 6, no. 5: 3820-3834. https://doi.org/10.3390/heritage6050203

APA StyleCalandra, S., Salvatici, T., Pecchioni, E., Centauro, I., & Garzonio, C. A. (2023). Mortar Characterization of Historical Masonry Damaged by Riverbank Failure: The Case of Lungarno Torrigiani (Florence). Heritage, 6(5), 3820-3834. https://doi.org/10.3390/heritage6050203