Development and Future Scope of Renewable Energy and Energy Storage Systems

Abstract

:1. Introduction

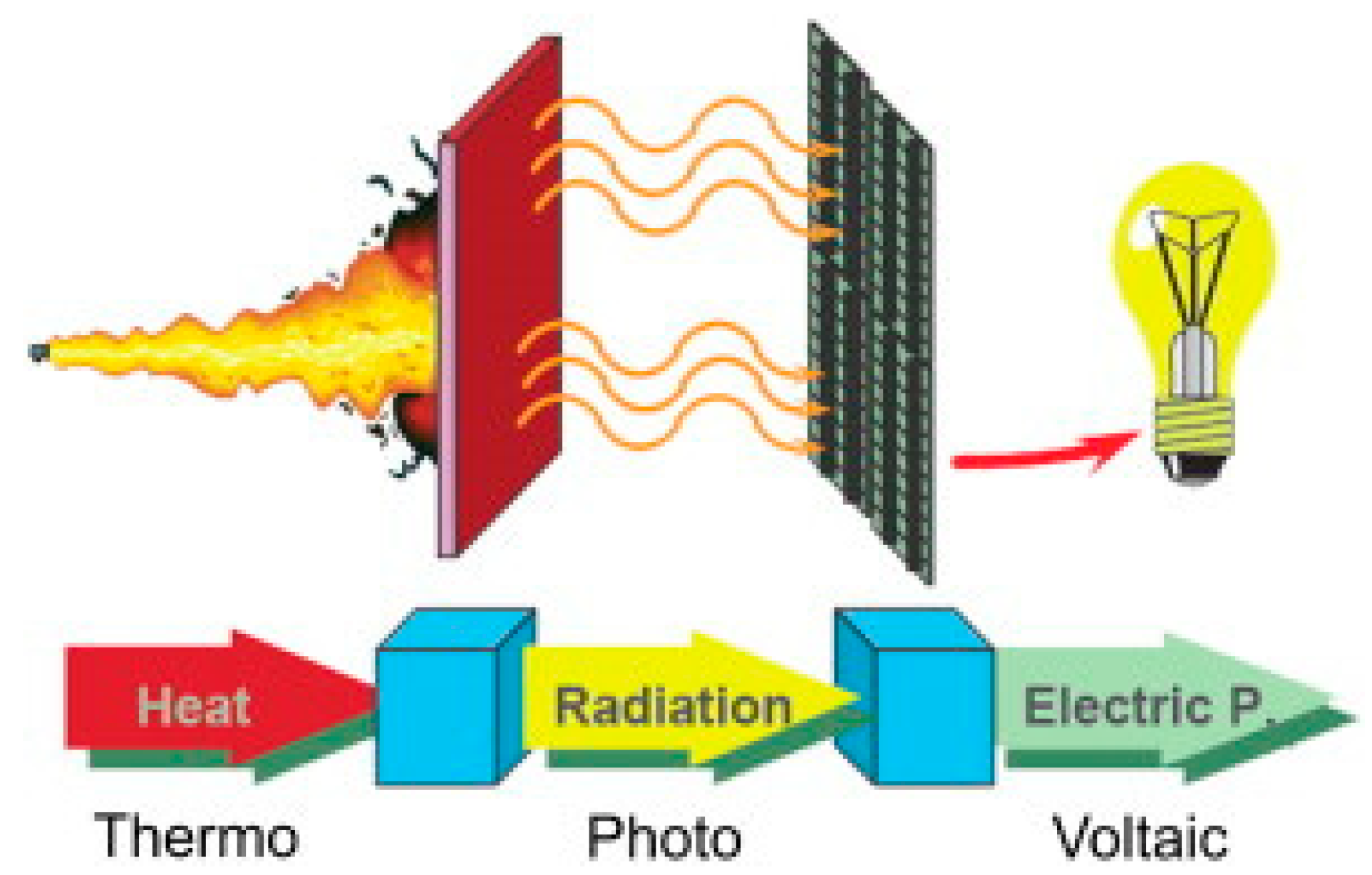

2. Renewable Energies

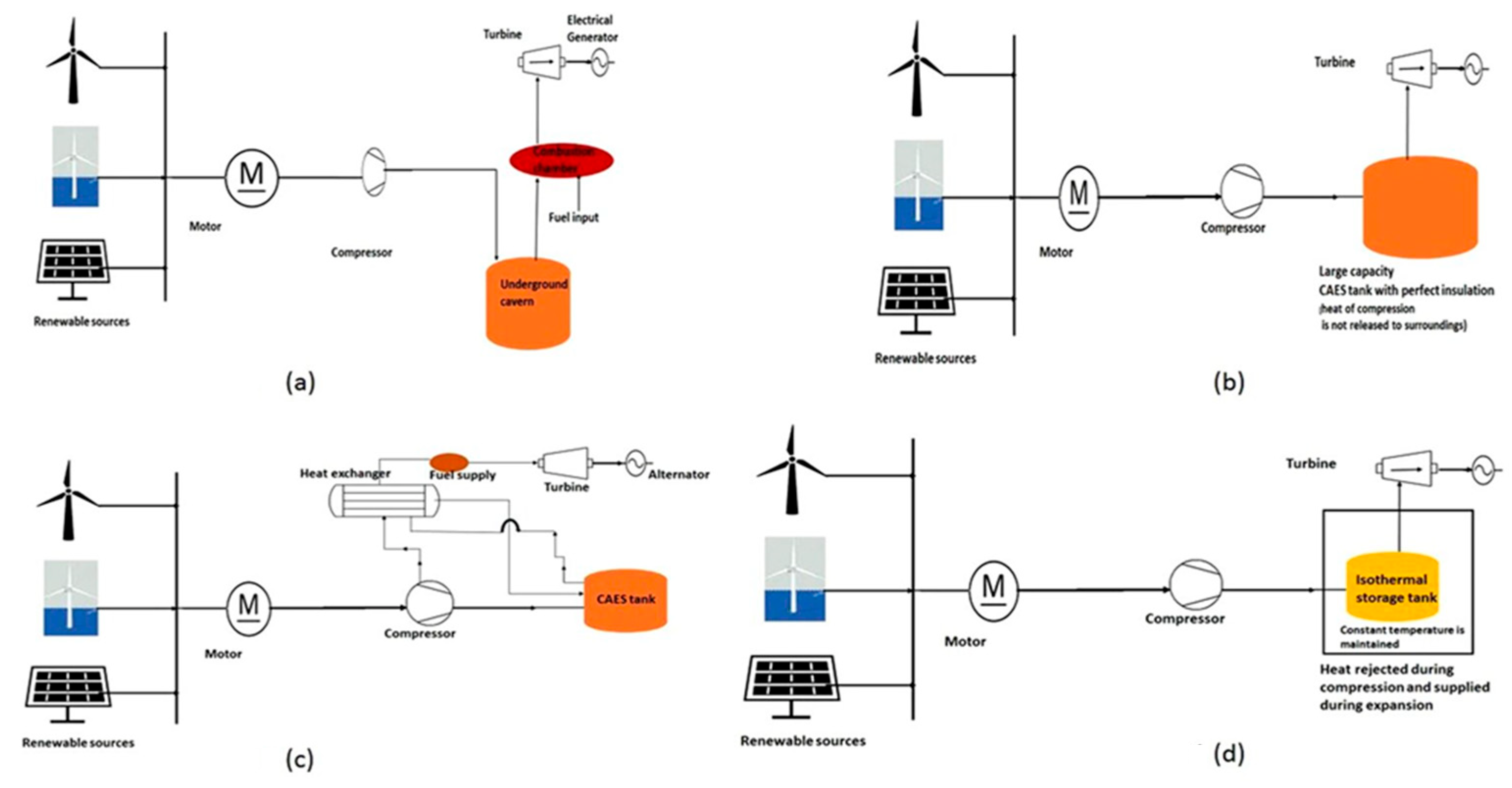

3. Compressed Air Energy Storage

4. Regenerative Fuel Cell

4.1. PEM Electrolyzer

4.2. PEM Fuel Cell

4.3. Hydrogen Storage

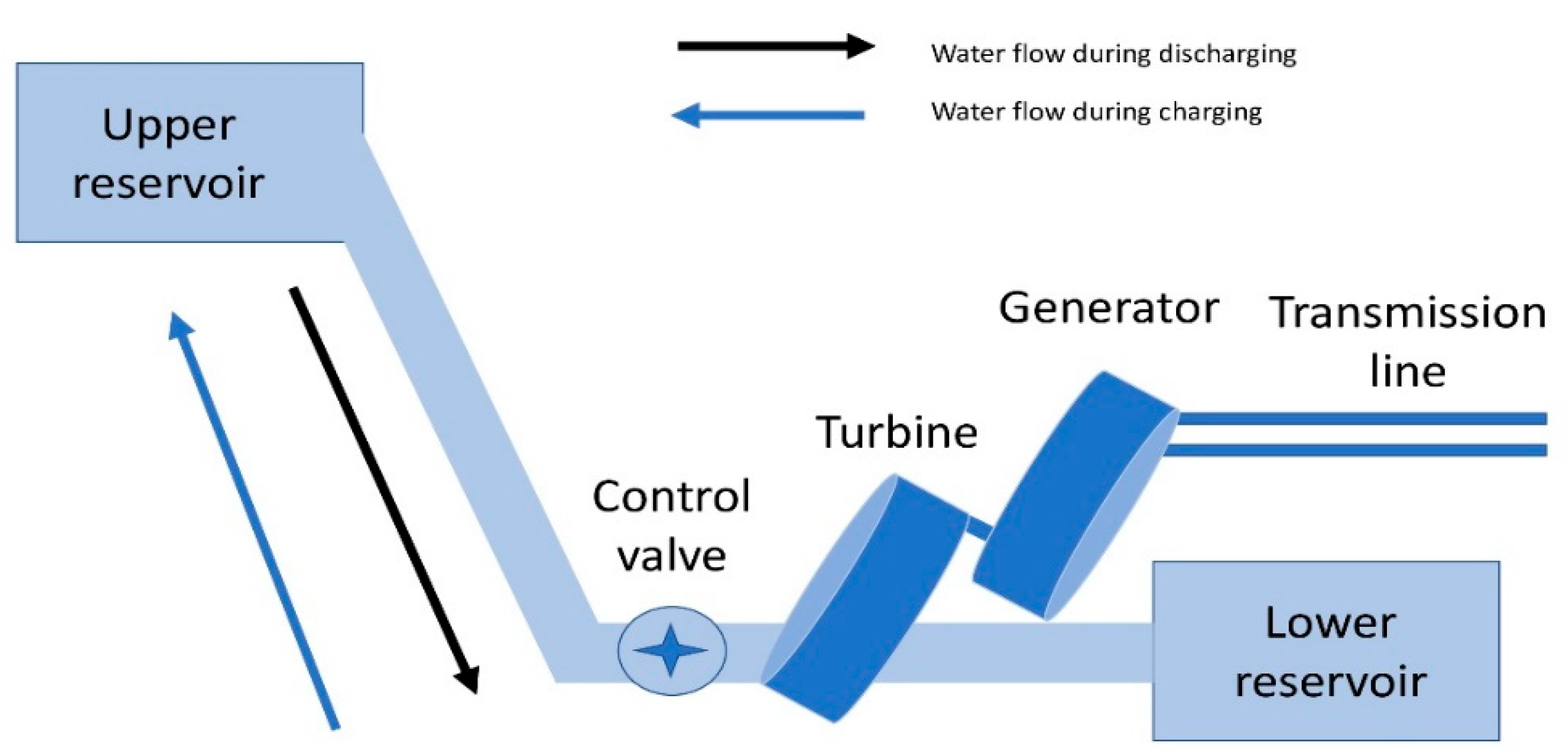

5. Pumped Hydro

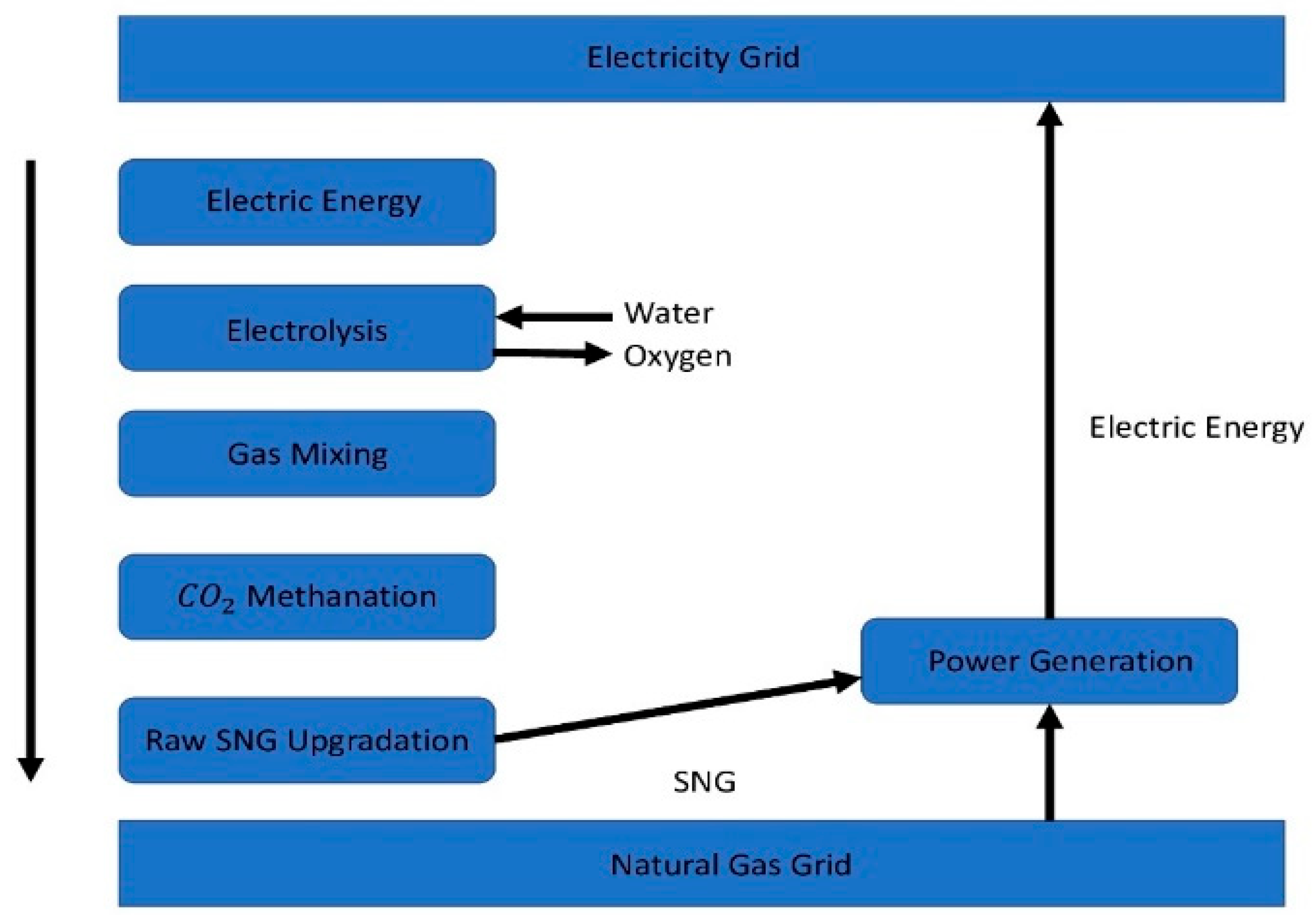

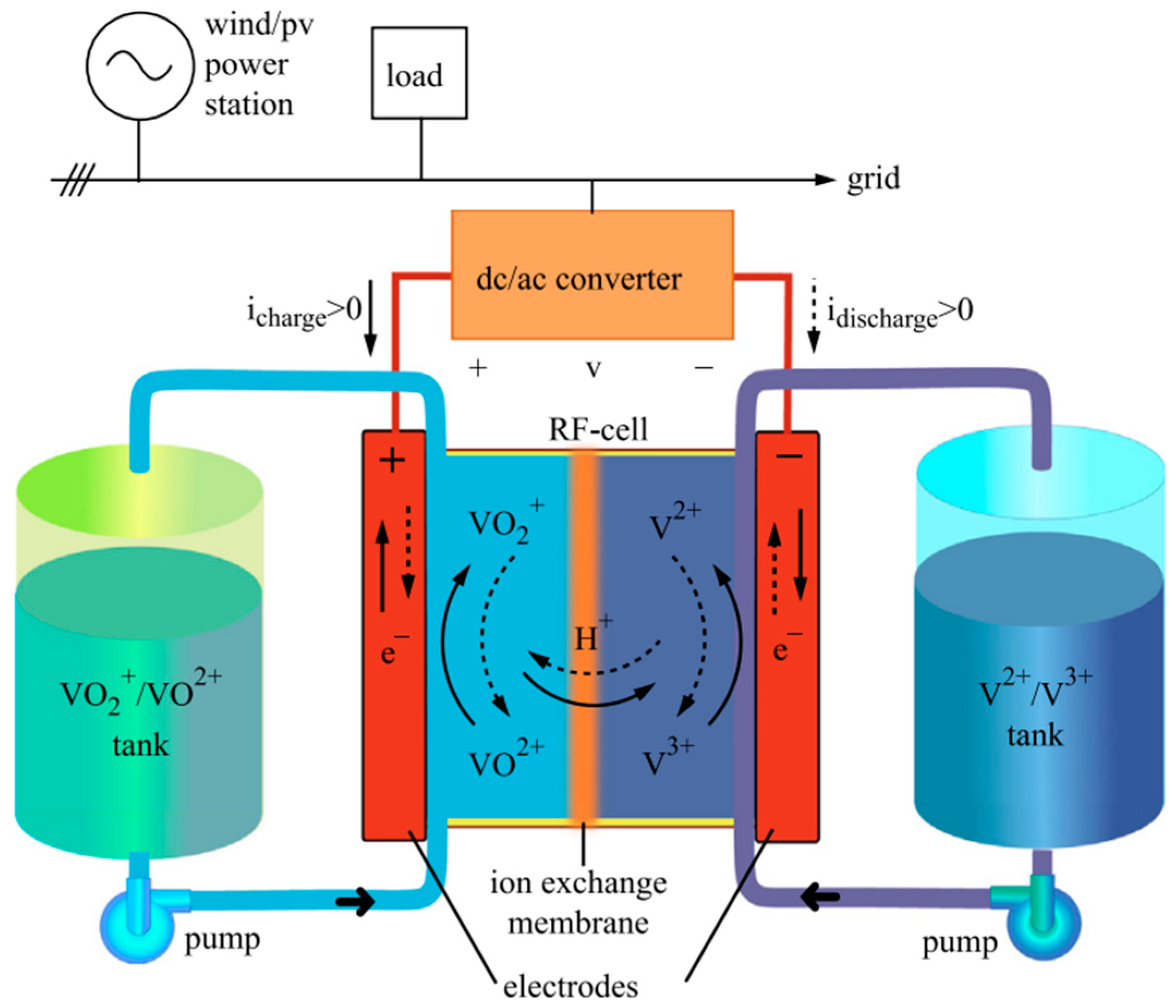

6. Power-to-Gas Technology Using Methane

- First, convert water to produce hydrogen via electrolysis.

- Obtained hydrogen from electrolysis undergoes certain reactions to form methane.

- Methane is stored and transported as per application.

- Finally, methane may be poured into a natural gas grid if the purity requirement is reached.

6.1. Adiabatic Fixed-Bed Methanation

6.2. Cool Fixed-Beam Methanation

7. Lithium-Ion Battery

8. Flywheel Energy Storage

GT3 R Hybrid Porsche

9. Stacked Concrete Blocks Energy Storage System

10. Redox Flow Battery

Advantages of Redox Flow Batteries

11. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gross, R.; Leach, M.; Bauen, A. Progress in renewable energy. Environ. Int. 2003, 29, 105–122. [Google Scholar] [CrossRef]

- Park, S.; Salkuti, S.R. Optimal Energy Management of Railroad Electrical Systems with Renewable Energy and Energy Storage Systems. Sustainability 2019, 11, 6293. [Google Scholar] [CrossRef] [Green Version]

- Energy Storage Association. Compressed Air Energy Storage (CAES). 7 April 2021. Available online: https://energystorage.org/why-energy-storage/technologies/compressed-air-energy-storage-caes/ (accessed on 6 January 2022).

- Carvela, M.; Raschitor, A.; Rodrigo, M.; Lobato, J. Recent Progress in Catalysts for Hydrogen-Chlorine Regenerative Fuel Cells. Catalysts 2020, 10, 1263. [Google Scholar] [CrossRef]

- Tazelaar, E.; Veenhuizen, B.; Jagerman, J.; Faassen, T. Energy Management Strategies for fuel cell hybrid vehicles: An overview. In Proceedings of the 2013 World Electric Vehicle Symposium and Exhibition (EVS27), Barcelona, Spain, 17–20 November 2013. [Google Scholar] [CrossRef]

- Esteban, M.; Romeo, L.M. Techno-Economics Optimization of H2 and CO2 Compression for Renewable Energy Storage and Power-to-Gas Applications. Appl. Sci. 2021, 11, 10741. [Google Scholar] [CrossRef]

- Madondo, N.I.; Tetteh, E.K.; Rathilal, S.; Bakare, B.F. Synergistic Effect of Magnetite and Bioelectrochemical Systems on Anaerobic Digestion. Bioengineering 2021, 8, 198. [Google Scholar] [CrossRef] [PubMed]

- Khajonvittayakul, C.; Tongnan, V.; Amornraksa, S.; Laosiripojana, N.; Hartley, M.; Hartley, U.W. CO2 Hydrogenation to Synthetic Natural Gas over Ni, Fe and Co–Based CeO2–Cr2O3. Catalysts 2021, 11, 1159. [Google Scholar] [CrossRef]

- Zavarkó, M.; Imre, A.R.; Pörzse, G.; Csedő, Z. Past, Present and Near Future: An Overview of Closed, Running and Planned Biomethanation Facilities in Europe. Energies 2021, 14, 5591. [Google Scholar] [CrossRef]

- Zoungrana, L.; Sidibé, S.D.S.; Herman, B.; Coulibaly, Y.; Jeanmart, H. Design of a Gasification Reactor for Manufacturing and Operation in West Africa. Designs 2021, 5, 76. [Google Scholar] [CrossRef]

- Etacheri, V.; Marom, R.; Elazari, R.; Salitra, G.; Aurbach, D. Challenges in the development of advanced Li-ion batteries: A review. Energy Environ. Sci. 2011, 4, 3243–3262. [Google Scholar] [CrossRef]

- Harks, P.; Mulder, F.; Notten, P. In situ methods for Li-ion battery research: A review of recent developments. J. Power Sources 2015, 288, 92–105. [Google Scholar] [CrossRef] [Green Version]

- Meesala, Y.; Jena, A.; Chang, H.; Liu, R.-S. Recent Advancements in Li-Ion Conductors for All-Solid-State Li-Ion Batteries. ACS Energy Lett. 2017, 2, 2734–2751. [Google Scholar] [CrossRef]

- Liu, H.; Jiang, J. Flywheel energy storage—An upswing technology for energy sustainability. Energy Build. 2007, 39, 599–604. [Google Scholar] [CrossRef]

- Choudhury, S. Flywheel energy storage systems: A critical review on technologies, applications, and future prospects. Int. Trans. Electr. Energy Syst. 2021, 31, 9. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, S.; Tao, D.; Dai, Y.; Yu, J. Electrochemical characterization for lithium vanadium phosphate with different calcination temperatures prepared by the sol–gel method. Mater. Charact. 2015, 107, 189–196. [Google Scholar] [CrossRef]

- Vo, T.N.; Hur, J.; Kim, T., II. Enabling high performance calcium-ion batteries from Prussian blue and metalorganic compound materials. ACS Sustain. Chem. Eng. 2020, 8, 2596–2601. [Google Scholar] [CrossRef]

- Jun, L.; Bo-Xiong, C.; Guan-Jun, X.; Xiao-Xu, C.; Bo, B.; Lin-Bo, Z.; Long, C.; Dong-Dong, J.; Tao, W.; Tao, L.; et al. Self-reliance and independently developed high-finesse spherical ultrastable optical reference cavity. Acta Phys. Sin. 2017, 66, 080601. [Google Scholar] [CrossRef]

- Ostrander, J.; Younesi, R.; Mogensen, R. High Voltage Redox-Meditated Flow Batteries with Prussian Blue Solid Booster. Energies 2021, 14, 7498. [Google Scholar] [CrossRef]

- Dong, C.-Y.; Lo, W.; Sun, Y.; Teng, S.-W.; Liu, Y.; Lee, H.-S.; Chen, H.-C.; Chiou, L.-L.; Huang, G.-T.; Lin, S.-J.; et al. Multiphoton optical biopsy. Second. Asian Pac. Rim Symp. Biophotonics 2004, APBP 2004, 95–96. [Google Scholar] [CrossRef]

- Pakere, I.; Gravelsins, A.; Bohvalovs, G.; Rozentale, L.; Blumberga, D. Will Aggregator Reduce Renewable Power Surpluses? A System Dynamics Approach for the Latvia Case Study. Energies 2021, 14, 7900. [Google Scholar] [CrossRef]

- Laitsos, V.M.; Bargiotas, D.; Daskalopulu, A.; Arvanitidis, A.I.; Tsoukalas, L.H. An Incentive-Based Implementation of Demand Side Management in Power Systems. Energies 2021, 14, 7994. [Google Scholar] [CrossRef]

- Hamman, P. Citizen Energy Cooperatives in the Upper Rhine Region: Energy Transition and Social Transactions. Environ. Sci. Proc. 2021, 11, 12. [Google Scholar] [CrossRef]

- Mahto, R.; Sharma, D.; John, R.; Putcha, C. Agrivoltaics: A Climate-Smart Agriculture Approach for Indian Farmers. Land 2021, 10, 1277. [Google Scholar] [CrossRef]

- Rababah, H.E.; Ghazali, A.; Isa, M.H.M. Building Integrated Photovoltaic (BIPV) in Southeast Asian Countries: Review of Effects and Challenges. Sustainability 2021, 13, 12952. [Google Scholar] [CrossRef]

- Amaral, R.; Arranz, B.; Vega, S. Participatory Research for the Evaluation of Satisfaction with Solar Decathlon Competitions: A Survey Analysis. Sustainability 2021, 13, 12995. [Google Scholar] [CrossRef]

- Liaqait, R.A.; Warsi, S.S.; Zahid, T.; Ghafoor, U.; Ahmad, M.S.; Selvaraj, J. A Decision Framework for Solar PV Panels Supply Chain in Context of Sustainable Supplier Selection and Order Allocation. Sustainability 2021, 13, 13216. [Google Scholar] [CrossRef]

- Aleixandre-Tudo, J.L.; Castelló-Cogollos, L.; Aleixandre, J.L.; Aleixandre-Benavent, R. Renewable energies: Worldwide trends in research, funding and international collaboration. Renew. Energy 2019, 139, 268–278. [Google Scholar] [CrossRef]

- van der Heide, J.; Posthuma, N.; Flamand, G.; Geens, W.; Poortmans, J. Cost-efficient thermophotovoltaic cells based on germanium substrates. Sol. Energy Mater. Sol. Cells 2009, 93, 1810–1816. [Google Scholar] [CrossRef]

- Unishkov, V.A. Electric characteristics of germanium vertical multijunction (VMJ) photovoltaic cells under high intensity illumination. In Proceedings of the Third NREL Conference on Thermophotovoltaic Generation of Electricity, Colorado Springs, CO, USA, 20 March 1997. [Google Scholar] [CrossRef]

- Mabindisa, R.; Tambwe, K.; Mciteka, L.; Ross, N. Organic Nanostructured Materials for Sustainable Application in Next Generation Solar Cells. Appl. Sci. 2021, 11, 11324. [Google Scholar] [CrossRef]

- Parmeshwarappa, P.; Gundlapalli, R.; Jayanti, S. Power and Energy Rating Considerations in Integration of Flow Battery with Solar PV and Residential Load. Batteries 2021, 7, 62. [Google Scholar] [CrossRef]

- Lew, G.; Sadowska, B.; Chudy-Laskowska, K.; Zimon, G.; Wójcik-Jurkiewicz, M. Influence of Photovoltaic Development on Decarbonization of Power Generation—Example of Poland. Energies 2021, 14, 7819. [Google Scholar] [CrossRef]

- Hassan, Q.; Jaszczur, M. Self-Consumption and Self-Sufficiency Improvement for Photovoltaic System Integrated with Ultra-Supercapacitor. Energies 2021, 14, 7888. [Google Scholar] [CrossRef]

- Hedar, A.-R.; Almaraashi, M.; Abdel-Hakim, A.E.; Abdulrahim, M. Hybrid Machine Learning for Solar Radiation Prediction in Reduced Feature Spaces. Energies 2021, 14, 7970. [Google Scholar] [CrossRef]

- Chen, S.; Dewancker, B.J.; Yang, S.; Mao, J.; Chen, J. Study on the Roof Solar Heating Storage System of Traditional Residences in Southern Shaanxi, China. Int. J. Environ. Res. Public Health 2021, 18, 12600. [Google Scholar] [CrossRef]

- Ou, Y.-T.; Kabtamu, D.M.; Bayeh, A.W.; Ku, H.-H.; Kuo, Y.-L.; Wang, Y.-M.; Hsu, N.-Y.; Chiang, T.-C.; Huang, H.-C.; Wang, C.-H. Metal-Organic Frameworks Derived Catalyst for High-Performance Vanadium Redox Flow Batteries. Catalysts 2021, 11, 1188. [Google Scholar] [CrossRef]

- Chebotareva, G.; Tvaronavičienė, M.; Gorina, L.; Strielkowski, W.; Shiryaeva, J.; Petrenko, Y. Revealing Renewable Energy Perspectives via the Analysis of the Wholesale Electricity Market. Energies 2022, 15, 838. [Google Scholar] [CrossRef]

- Mostafa, S.; Zekry, A.; Youssef, A.; Anis, W.R. Raspberry Pi Design and Hardware Implementation of Fuzzy-PI Controller for Three-Phase Grid-Connected Inverter. Energies 2022, 15, 843. [Google Scholar] [CrossRef]

- Maślak, G.; Orłowski, P. Microgrid Operation Optimization Using Hybrid System Modeling and Switched Model Predictive Control. Energies 2022, 15, 833. [Google Scholar] [CrossRef]

- Ge, L.; Li, Y.; Li, Y.; Yan, J.; Sun, Y. Smart Distribution Network Situation Awareness for High-Quality Operation and Maintenance: A Brief Review. Energies 2022, 15, 828. [Google Scholar] [CrossRef]

- Gribkova, D.; Milshina, Y. Energy Transition as a Response to Energy Challenges in Post-Pandemic Reality. Energies 2022, 15, 812. [Google Scholar] [CrossRef]

- Wlas, M.; Galla, S.; Kouzou, A.; Kolodziejek, P. Analysis of an Energy Management System of a Small Plant Connected to the Rural Power System. Energies 2022, 15, 719. [Google Scholar] [CrossRef]

- Karystinos, C.; Vasilakis, A.; Kotsampopoulos, P.; Hatziargyriou, N. Local Energy Exchange Market for Community Off-Grid Microgrids: Case Study Los Molinos del Rio Aguas. Energies 2022, 15, 703. [Google Scholar] [CrossRef]

- Şahin, M.E.; Blaabjerg, F.; Sangwongwanich, A. A Comprehensive Review on Supercapacitor Applications and Developments. Energies 2022, 15, 674. [Google Scholar] [CrossRef]

- Pietrzak, M.B.; Olczyk, M.; Kuc-Czarnecka, M.E. Assessment of the Feasibility of Energy Transformation Processes in European Union Member States. Energies 2022, 15, 661. [Google Scholar] [CrossRef]

- Correa-Quezada, R.; Tituaña-Castillo, M.D.C.; Río-Rama, M.D.L.C.D.; Álvarez-García, J. Effects of Increased Renewable Energy Consumption on Electricity Prices: Evidence for Six South American Countries. Energies 2022, 15, 620. [Google Scholar] [CrossRef]

- Margeta, K.; Glasnovic, Z.; Zabukovec Logar, N.; Tišma, S.; Farkaš, A. A Concept for Solving the Sustainability of Cities Worldwide. Energies 2022, 15, 616. [Google Scholar] [CrossRef]

- Ramanathan, G.G.; Urasaki, N. Non-Isolated Interleaved Hybrid Boost Converter for Renewable Energy Applications. Energies 2022, 15, 610. [Google Scholar] [CrossRef]

- Abualigah, L.; Abu Zitar, R.; Almotairi, K.H.; Hussein, A.M.; Elaziz, M.A.; Nikoo, M.R.; Gandomi, A.H. Wind, Solar, and Photovoltaic Renewable Energy Systems with and without Energy Storage Optimization: A Survey of Advanced Machine Learning and Deep Learning Techniques. Energies 2022, 15, 578. [Google Scholar] [CrossRef]

- Mokhtar, M.; Marei, M.I.; Sameh, M.A.; Attia, M.A. An Adaptive Load Frequency Control for Power Systems with Renewable Energy Sources. Energies 2022, 15, 573. [Google Scholar] [CrossRef]

- Juszczyk, O.; Juszczyk, J.; Juszczyk, S.; Takala, J. Barriers for Renewable Energy Technologies Diffusion: Empirical Evidence from Finland and Poland. Energies 2022, 15, 527. [Google Scholar] [CrossRef]

- Farooq, Z.; Rahman, A.; Hussain, S.M.S.; Ustun, T.S. Power Generation Control of Renewable Energy Based Hybrid Deregulated Power System. Energies 2022, 15, 517. [Google Scholar] [CrossRef]

- Kaushik, E.; Prakash, V.; Mahela, O.P.; Khan, B.; El-Shahat, A.; Abdelaziz, A.Y. Comprehensive Overview of Power System Flexibility during the Scenario of High Penetration of Renewable Energy in Utility Grid. Energies 2022, 15, 516. [Google Scholar] [CrossRef]

- Yang, Y.; Javanroodi, K.; Nik, V.M. Climate Change and Renewable Energy Generation in Europe—Long-Term Impact Assessment on Solar and Wind Energy Using High-Resolution Future Climate Data and Considering Climate Uncertainties. Energies 2022, 15, 302. [Google Scholar] [CrossRef]

- Sobocińska, M. Processes of Modernization of Consumption in Poland in the Context of the Sustainable Consumption and the Functioning of the Renewable Energy Market. Energies 2022, 15, 289. [Google Scholar] [CrossRef]

- Grigorescu, A.; Ion, A.-E.; Lincaru, C.; Pirciog, S. Synergy Analysis of Knowledge Transfer for the Energy Sector within the Framework of Sustainable Development of the European Countries. Energies 2021, 15, 276. [Google Scholar] [CrossRef]

- Rubio, A.; Schuldt, F.; Klement, P.; von Maydell, K. Optimal Power Dispatch in Energy Systems Considering Grid Constraints. Energies 2021, 15, 192. [Google Scholar] [CrossRef]

- Robba, M.; Rossi, M. Optimal Control of Hybrid Systems and Renewable Energies. Energies 2021, 15, 78. [Google Scholar] [CrossRef]

- Sun, L.; Lin, J.; Kong, D.; Luo, K.; Fan, J. Three-Dimensional Computation Fluid Dynamics Simulation of CO Methanation Reactor with Immersed Tubes. Energies 2022, 15, 321. [Google Scholar] [CrossRef]

- Morady, E.; Soltani, M.; Kashkooli, F.M.; Ziabasharhagh, M.; Al-Haq, A.; Nathwani, J. Improving Energy Efficiency by Utilizing Wetted Cellulose Pads in Passive Cooling Systems. Energies 2022, 15, 369. [Google Scholar] [CrossRef]

- Eikeland, O.F.; Bianchi, F.M.; Holmstrand, I.S.; Bakkejord, S.; Santos, S.; Chiesa, M. Uncovering Contributing Factors to Interruptions in the Power Grid: An Arctic Case. Energies 2022, 15, 305. [Google Scholar] [CrossRef]

- Gui, X.; Xue, H.; Gao, R.; Zhan, X.; Zhao, F. Study on Structural Performance of Horizontal Axis Wind Turbine with Air Duct for Coal Mine. Energies 2021, 15, 225. [Google Scholar] [CrossRef]

- Pothireddy, K.M.R.; Vuddanti, S.; Salkuti, S.R. Impact of Demand Response on Optimal Sizing of Distributed Generation and Customer Tariff. Energies 2021, 15, 190. [Google Scholar] [CrossRef]

- Sharma, H.; Mishra, S.; Dhillon, J.; Sharma, N.K.; Bajaj, M.; Tariq, R.; Rehman, A.U.; Shafiq, M.; Hamam, H. Feasibility of Solar Grid-Based Industrial Virtual Power Plant for Optimal Energy Scheduling: A Case of Indian Power Sector. Energies 2022, 15, 752. [Google Scholar] [CrossRef]

- Zdonek, I.; Tokarski, S.; Mularczyk, A.; Turek, M. Evaluation of the Program Subsidizing Prosumer Photovoltaic Sources in Poland. Energies 2022, 15, 846. [Google Scholar] [CrossRef]

- Chomać-Pierzecka, E.; Kokiel, A.; Rogozińska-Mitrut, J.; Sobczak, A.; Soboń, D.; Stasiak, J. Analysis and Evaluation of the Photovoltaic Market in Poland and the Baltic States. Energies 2022, 15, 669. [Google Scholar] [CrossRef]

- Wolniak, R.; Skotnicka-Zasadzień, B. Development of Photovoltaic Energy in EU Countries as an Alternative to Fossil Fuels. Energies 2022, 15, 662. [Google Scholar] [CrossRef]

- Le, H.T.-T.; Sanseverino, E.R.; Nguyen, D.-Q.; Di Silvestre, M.L.; Favuzza, S.; Pham, M.-H. Critical Assessment of Feed-In Tariffs and Solar Photovoltaic Development in Vietnam. Energies 2022, 15, 556. [Google Scholar] [CrossRef]

- Moraga-Contreras, C.; Cornejo-Ponce, L.; Vilca-Salinas, P.; Estupiñan, E.; Zuñiga, A.; Palma-Behnke, R.; Tapia-Caroca, H. Evolution of Solar Energy in Chile: Residential Opportunities in Arica and Parinacota. Energies 2022, 15, 551. [Google Scholar] [CrossRef]

- Pandey, A.; Pandey, P.; Tumuluru, J.S. Solar Energy Production in India and Commonly Used Technologies—An Overview. Energies 2022, 15, 500. [Google Scholar] [CrossRef]

- Reddy, S.S.; Jung, C.M. Overview of Energy Storage Technologies: A Techno-Economic Comparison. Int. J. Appl. Eng. Res. 2017, 12, 12872–12879. [Google Scholar]

- Duda, J.; Kusa, R.; Pietruszko, S.; Smol, M.; Suder, M.; Teneta, J.; Wójtowicz, T.; Żdanowicz, T. Development of Roadmap for Photovoltaic Solar Technologies and Market in Poland. Energies 2021, 15, 174. [Google Scholar] [CrossRef]

- Zheng, J.; Xiao, L.; Wu, M.; Lang, S.; Zhang, Z.; Chen, M.; Yuan, J. Numerical Analysis of Thermal Stress for a Stack of Planar Solid Oxide Fuel Cells. Energies 2022, 15, 343. [Google Scholar] [CrossRef]

- Chung, J.; Jeon, N.J.; Noh, J.H. Solar-Driven Simultaneous Electrochemical CO2 Reduction and Water Oxidation Using Perovskite Solar Cells. Energies 2021, 15, 270. [Google Scholar] [CrossRef]

- Alhammad, A.; Sun, Q.; Tao, Y. Optimal Solar Plant Site Identification Using GIS and Remote Sensing: Framework and Case Study. Energies 2022, 15, 312. [Google Scholar] [CrossRef]

- Lund, H.; Salgi, G. The role of compressed air energy storage (CAES) in future sustainable energy systems. Energy Convers. Manag. 2009, 50, 1172–1179. [Google Scholar] [CrossRef]

- Venkataramani, G.; Ramalingam, V.; Viswanathan, K. Harnessing Free Energy From Nature For Efficient Operation of Compressed Air Energy Storage System and Unlocking the Potential of Renewable Power Generation. Sci. Rep. 2018, 8, 9981. [Google Scholar] [CrossRef] [PubMed]

- Mbungu, N.T.; Naidoo, R.M.; Bansal, R.C.; Siti, M.W.; Tungadio, D.H. An overview of renewable energy resources and grid integration for commercial building applications. J. Energy Storage 2020, 29, 101385. [Google Scholar] [CrossRef]

- Luo, X.; Wang, J.; Dooner, M.; Clarke, J.; Krupke, C. Overview of Current Development in Compressed Air Energy Storage Technology. Energy Procedia 2014, 62, 603–611. [Google Scholar] [CrossRef] [Green Version]

- Dinker, A.; Agarwal, M.; Agarwal, G. Heat storage materials, geometry and applications: A review. J. Energy Inst. 2017, 90, 1–11. [Google Scholar] [CrossRef]

- Nease, J.; Adams, T.A. Systems for peaking power with 100% CO2 capture by integration of solid oxide fuel cells with compressed air energy storage. J. Power Sources 2013, 228, 281–293. [Google Scholar] [CrossRef]

- Nease, J.; Adams, T.A. Coal-fuelled systems for peaking power with 100% CO2 capture through integration of solid oxide fuel cells with compressed air energy storage. J. Power Sources 2014, 251, 92–107. [Google Scholar] [CrossRef]

- Budt, M.; Wolf, D.; Span, R.; Yan, J. A review on compressed air energy storage: Basic principles, past milestones and recent developments. Appl. Energy 2016, 170, 250–268. [Google Scholar] [CrossRef]

- Hino, T.; Lejeune, A. Pumped Storage Hydropower Developments. Compr. Renew. Energy 2012, 6, 405–434. [Google Scholar] [CrossRef]

- Keeney, J.W. Investigation of Compressed Air Energy Storage Efficiency. Master’s Thesis, California Polytechnic State University, San Luis Obispo, CA, USA, 2013. [Google Scholar] [CrossRef] [Green Version]

- Breeze, P. Chapter 3—Compressed Air Energy Storage. In Power System Energy Storage Technologies; Breeze, P., Ed.; Academic Press: Cambridge, MA, USA, 2018; pp. 23–31. ISBN 9780128129029. [Google Scholar] [CrossRef]

- Khaitan, S.K.; Raju, M. Detailed system-level simulation of compressed air energy storage. In Computational Models for CO2 Geo-Sequestration & Compressed Air Energy Storage; CRC Press: Boca Raton, FL, USA, 2014; pp. 539–565. [Google Scholar] [CrossRef]

- Smith, W. The role of fuel cells in energy storage. J. Power Sources 2000, 86, 74–83. [Google Scholar] [CrossRef]

- Chadly, A.; Azar, E.; Maalouf, M.; Mayyas, A. Techno-economic analysis of energy storage systems using reversible fuel cells and rechargeable batteries in green buildings. Energy 2022, 247, 123466. [Google Scholar] [CrossRef]

- Spiegel, D.C. The Use of Hydrogen as an Energy Storage System. Fuel Cell Store. Available online: https://www.fuelcellstore.com/blog-section/use-of-hydrogen-as-an-energy-storage-system (accessed on 7 December 2021).

- Mohammadi, A.; Mehrpooya, M. A comprehensive review on coupling different types of electrolyzer to renewable energy sources. Energy 2018, 158, 632–655. [Google Scholar] [CrossRef]

- Smolinka, T.; Ojong, E.T.; Garche, J. Chapter 8—Hydrogen Production from Renewable Energies—Electrolyzer Technologies. In Electrochemical Energy Storage for Renewable Sources and Grid Balancing; Moseley, P.T., Garche, J., Eds.; Elsevier: Amsterdam, The Netherlands, 2015; pp. 103–128. ISBN 9780444626165. [Google Scholar] [CrossRef]

- Ni, M.; Leung, M.; Leung, D.Y. Technological development of hydrogen production by solid oxide electrolyzer cell (SOEC). Int. J. Hydrogen Energy 2008, 33, 2337–2354. [Google Scholar] [CrossRef]

- Kumar, S.S.; Himabindu, V. Hydrogen production by PEM water electrolysis—A review. Mater. Sci. Energy Technol. 2019, 2, 442–454. [Google Scholar] [CrossRef]

- Millet, P. PEM water electrolysis. Hydrog. Prod. 2015, 63–116. [Google Scholar] [CrossRef]

- Barthelemy, H.; Weber, M.; Barbier, F. Hydrogen storage: Recent improvements and industrial perspectives. Int. J. Hydrogen Energy 2017, 42, 7254–7262. [Google Scholar] [CrossRef]

- Aceves, S. Analytical and experimental evaluation of insulated pressure vessels for cryogenic hydrogen storage. Int. J. Hydrogen Energy 2000, 25, 1075–1085. [Google Scholar] [CrossRef]

- Borodina, T.; Grigoriev, D.; Möhwald, H.; Shchukin, D. Hydrogenstorage materials protected by a polymer shell. J. Mater. Chem. 2009, 20, 1452–1456. [Google Scholar] [CrossRef]

- Fuel Cells. Energy.gov. (n.d.). Available online: https://www.energy.gov/eere/fuelcells/fuel-cells (accessed on 7 December 2021).

- Wang, Y.; Diaz, D.F.R.; Chen, K.S.; Wang, Z.; Adroher, X.C. Materials, technological status, and fundamentals of PEM fuel cells—A review. Mater. Today 2020, 32, 178–203. [Google Scholar] [CrossRef]

- Hwang, H.T.; Varma, A. Hydrogen Storage Methods for Fuel Cell Vehicles: Current Status. In Reference Module in Chemistry, Molecular Sciences and Chemical Engineering; Elsevier: Amsterdam, The Netherlands, 2015; ISBN 9780124095472. [Google Scholar] [CrossRef]

- Zhao, L.; Dai, H.; Pei, F.; Ming, P.; Wei, X.; Zhou, J. A Comparative Study of Equivalent Circuit Models for Electro-Chemical Impedance Spectroscopy Analysis of Proton Exchange Membrane Fuel Cells. Energies 2022, 15, 386. [Google Scholar] [CrossRef]

- Liu, Y.; Lei, D.; Guo, X.; Ma, T.; Wang, F.; Chen, Y. Scale Effect on Producing Gaseous and Liquid Chemical Fuels via CO2 Reduction. Energies 2022, 15, 335. [Google Scholar] [CrossRef]

- Stangarone, T. South Korean efforts to transition to a hydrogen economy. Clean Technol. Environ. Policy 2020, 23, 509–516. [Google Scholar] [CrossRef]

- Xu, B.; Zhang, J.; Egusquiza, M.; Zhang, J.; Chen, D.; Egusquiza, E. Exploring the Regulation Reliability of a Pumped Storage Power Plant in a Wind–Solar Hybrid Power Generation System. Water 2021, 13, 2548. [Google Scholar] [CrossRef]

- Connolly, D.; MacLaughlin, S.; Leahy, M. Development of a computer program to locate potential sites for pumped hydroelectric energy storage. Energy 2010, 35, 375–381. [Google Scholar] [CrossRef]

- Rehman, S.; Al-Hadhrami, L.M.; Alam, M.M. Pumped hydro energy storage system: A technological review. Renew. Sustain. Energy Rev. 2015, 44, 586–598. [Google Scholar] [CrossRef]

- Liu, J.; Li, J.; Xiang, Y.; Hu, S. Optimal Sizing of Hydro-PV-Pumped Storage Integrated Generation System Considering Uncertainty of PV, Load and Price. Energies 2019, 12, 3001. [Google Scholar] [CrossRef] [Green Version]

- Potashnikov, V.; Golub, A.; Brody, M.; Lugovoy, O. Decarbonizing Russia: Leapfrogging from Fossil Fuel to Hydrogen. Energies 2022, 15, 683. [Google Scholar] [CrossRef]

- Srinath, A.N.; López, P.; Fashandi, S.A.M.; Lechat, S.; di Legge, G.; Nabavi, S.A.; Nikolaidis, T.; Jafari, S. Thermal Management System Architecture for Hydrogen-Powered Propulsion Technologies: Practices, Thematic Clusters, System Architectures, Future Challenges, and Opportunities. Energies 2022, 15, 304. [Google Scholar] [CrossRef]

- Youngok, K.; Eunkyung, Y.; Hyunik, S. Russia’s Policy Transition to a Hydrogen Economy and the Implications of South Korea–Russia Cooperation. Energies 2021, 15, 127. [Google Scholar] [CrossRef]

- Farias, C.B.B.; Barreiros, R.C.S.; da Silva, M.F.; Casazza, A.A.; Converti, A.; Sarubbo, L.A. Use of Hydrogen as Fuel: A Trend of the 21st Century. Energies 2022, 15, 311. [Google Scholar] [CrossRef]

- Wessel, M.; Madlener, R.; Hilgers, C. Economic Feasibility of Semi-Underground Pumped Storage Hydropower Plants in Open-Pit Mines. Energies 2020, 13, 4178. [Google Scholar] [CrossRef]

- Rönsch, S.; Schneider, J.; Matthischke, S.; Schlüter, M.; Götz, M.; Lefebvre, J.; Prabhakaran, P.; Bajohr, S. Review on methanation—From fundamentals to current projects. Fuel 2016, 166, 276–296. [Google Scholar] [CrossRef]

- Collet, P.; Flottes, E.; Favre, A.; Raynal, L.; Pierre, H.; Capela, S.; Peregrina, C. Techno-economic and Life Cycle Assessment of methane production via biogas upgrading and power to gas technology. Appl. Energy 2017, 192, 282–295. [Google Scholar] [CrossRef] [Green Version]

- Gorre, J.; Ortloff, F.; van Leeuwen, C. Production costs for synthetic methane in 2030 and 2050 of an optimized Power-to-Gas plant with intermediate hydrogen storage. Appl. Energy 2019, 253, 113594. [Google Scholar] [CrossRef]

- Götz, M.; Lefebvre, J.; Mörs, F.; McDaniel Koch, A.; Graf, F.; Bajohr, S.; Reimert, R.; Kolb, T. Renewable Power-to-Gas: A technological and economic review. Renew. Energy 2016, 85, 1371–1390. [Google Scholar] [CrossRef] [Green Version]

- Wang, D.; Li, S.; He, S.; Gao, L. Coal to substitute natural gas based on combined coal-steam gasification and one-step methanation. Appl. Energy 2019, 240, 851–859. [Google Scholar] [CrossRef]

- Moioli, E.; Mutschler, R.; Züttel, A. Renewable energy storage via CO2 and H2 conversion to methane and methanol: Assessment for small scale applications. Renew. Sustain. Energy Rev. 2019, 107, 497–506. [Google Scholar] [CrossRef]

- Thema, M.; Weidlich, T.; Hörl, M.; Bellack, A.; Mörs, F.; Hackl, F.; Kohlmayer, M.; Gleich, J.; Stabenau, C.; Trabold, T.; et al. Biological CO2-Methanation: An Approach to Standardization. Energies 2019, 12, 1670. [Google Scholar] [CrossRef] [Green Version]

- Mohaideen, K.K.; Kim, W.; Yoon, W.L. Highly efficient non-noble metal based nanostructured catalysts for selective CO methanation. Catal. Commun. 2015, 71, 7–12. [Google Scholar] [CrossRef]

- Ngo, S.I.; Lim, Y.-I. Solution and Parameter Identification of a Fixed-Bed Reactor Model for Catalytic CO2 Methanation Using Physics-Informed Neural Networks. Catalysts 2021, 11, 1304. [Google Scholar] [CrossRef]

- Candelaresi, D.; Moretti, L.; Perna, A.; Spazzafumo, G. Heat Recovery from a PtSNG Plant Coupled with Wind Energy. Energies 2021, 14, 7660. [Google Scholar] [CrossRef]

- Novichkov, S. Efficiency of waste heat recovery from exhaust recovery boiler gas at a binary cycle & cogeneration plant. Energy Saf. Energy Econ. 2020, 1, 29–35. [Google Scholar] [CrossRef]

- Hashemi, S.E.; Lien, K.M.; Hillestad, M.; Schnell, S.K.; Austbø, B. Thermodynamic Insight in Design of Methanation Reactor with Water Removal Considering Nexus between CO2 Conversion and Irreversibilities. Energies 2021, 14, 7861. [Google Scholar] [CrossRef]

- Netskina, O.; Mucha, S.; Veselovskaya, J.; Bolotov, V.; Komova, O.; Ishchenko, A.; Bulavchenko, O.; Prosvirin, I.; Pochtar, A.; Rogov, V. CO2 Methanation: Nickel–Alumina Catalyst Prepared by Solid-State Combustion. Materials 2021, 14, 6789. [Google Scholar] [CrossRef]

- Janusz-Cygan, A.; Jaschik, J.; Tańczyk, M. Upgrading Biogas from Small Agricultural Sources into Biomethane by Membrane Separation. Membranes 2021, 11, 938. [Google Scholar] [CrossRef]

- Paredes-Sánchez, B.M.; Paredes-Sánchez, J.P.; García-Nieto, P.J. Evaluation of Implementation of Biomass and Solar Resources by Energy Systems in the Coal-Mining Areas of Spain. Energies 2021, 15, 232. [Google Scholar] [CrossRef]

- Jurczyk, M.; Węcel, D.; Uchman, W.; Skorek-Osikowska, A. Assessment of Operational Performance for an Integrated ‘Power to Synthetic Natural Gas’ System. Energies 2021, 15, 74. [Google Scholar] [CrossRef]

- Hestenes, J.C.; May, R.; Sadowski, J.T.; Munich, N.; Marbella, L.E. Resolving Chemical and Spatial Heterogeneities at Complex Electrochemical Interfaces in Li-Ion Batteries. Chem. Mater. 2021, 34, 232–243. [Google Scholar] [CrossRef]

- Li, Q.; Chen, J.; Fan, L.; Kong, X.; Lu, Y. Progress in electrolytes for rechargeable Li-based batteries and beyond. Green Energy Environ. 2016, 1, 18–42. [Google Scholar] [CrossRef] [Green Version]

- Croy, J.R.; Abouimrane, A.; Zhang, Z. Next-generation lithium-ion batteries: The promise of near-term advancements. MRS Bull. 2014, 39, 407–415. [Google Scholar] [CrossRef]

- Wang, Y.; Yi, J.; Xia, Y. Recent Progress in Aqueous Lithium-Ion Batteries. Adv. Energy Mater. 2012, 2, 830–840. [Google Scholar] [CrossRef]

- Xu, K. Nonaqueous Liquid Electrolytes for Lithium-Based Rechargeable Batteries. ChemInform 2004, 35. [Google Scholar] [CrossRef]

- Tron, A.; Jo, Y.N.; Oh, S.H.; Park, Y.D.; Mun, J. Surface modification of the LiFePO4 cathode for the aqueous rechargeable lithium ion battery. ACS Appl. Mater. Interfaces 2017, 9, 14. [Google Scholar] [CrossRef]

- Montanino, M.; Passerini, S.; Appetecchi, G. Electrolytes for rechargeable lithium batteries. In Rechargeable Lithium Batteries; Woodhead Publishing: Shaston, UK, 2015; pp. 73–116. [Google Scholar] [CrossRef]

- Li, W.; Dahn, J.R.; Root, J.H. Lithium Intercalation from Aqueous Solutions. MRS Proc. 1994, 369. [Google Scholar] [CrossRef]

- Armand, M.; Endres, F.; MacFarlane, D.; Ohno, H.; Scrosati, B. Ionic-liquid materials for the electrochemical challenges of the future. Nat. Mater. 2009, 8, 621–629. [Google Scholar] [CrossRef]

- Fergus, J.W. Ceramic and polymeric solid electrolytes for lithium-ion batteries. J. Power Sources 2010, 195, 4554–4569. [Google Scholar] [CrossRef]

- Gong, Z.; Yang, Y. Recent advances in the research of polyanion-type cathode materials for Li-ion batteries. Energy Environ. Sci. 2011, 4, 3223–3242. [Google Scholar] [CrossRef] [Green Version]

- Yi, T.-F.; Zhu, Y.-R.; Tao, W.; Luo, S.; Xie, Y.; Li, X.-F. Recent advances in the research of MLi2Ti6O14 (M = 2Na, Sr, Ba, Pb) anode materials for Li-ion batteries. J. Power Sources 2018, 399, 26–41. [Google Scholar] [CrossRef]

- Zhao, G.; Wang, X.; Negnevitsky, M. A Study of Variable Cell Spacings to the Heat Transfer Efficiency of Air-Cooling Battery Thermal Management System. Appl. Sci. 2021, 11, 11155. [Google Scholar] [CrossRef]

- Sources: “How Does a Lithium-Ion Battery Work?”. Available online: https://www.energy.gov/eere/articles/how-does-lithium-ion-battery-work (accessed on 17 May 2022).

- Liu, Y.; Li, Y.; Liao, Y.G.; Lai, M.-C. Effects of State-of-Charge and Penetration Location on Variations in Temperature and Terminal Voltage of a Lithium-Ion Battery Cell during Penetration Tests. Batteries 2021, 7, 81. [Google Scholar] [CrossRef]

- Lionetto, F.; Bagheri, S.; Mele, C. Sustainable Materials from Fish Industry Waste for Electrochemical Energy Systems. Energies 2021, 14, 7928. [Google Scholar] [CrossRef]

- Widyantara, R.D.; Naufal, M.A.; Sambegoro, P.L.; Nurprasetio, I.P.; Triawan, F.; Djamari, D.W.; Nandiyanto, A.B.D.; Budiman, B.A.; Aziz, M. Low-Cost Air-Cooling System Optimization on Battery Pack of Electric Vehicle. Energies 2021, 14, 7954. [Google Scholar] [CrossRef]

- Khalid, A.; Stevenson, A.; Sarwat, A.I. Performance Analysis of Commercial Passive Balancing Battery Management System Operation Using a Hardware-in-the-Loop Testbed. Energies 2021, 14, 8037. [Google Scholar] [CrossRef]

- Ibarra-Gutiérrez, S.; Bouchard, J.; Laflamme, M.; Fytas, K. Perspectives of Lithium Mining in Quebec, Potential and Advantages of Integration into a Local Battery Production Chain for Electric Vehicles. Mater. Proc. 2021, 5, 33. [Google Scholar] [CrossRef]

- Li, C.; Zhao, B.; Yang, J.; Zhang, L.; Fang, Q.; Wang, X. Li2ZrO3-Coated Monocrystalline LiAl0.06Mn1.94O4 Particles as Cathode Materials for Lithium-Ion Batteries. Nanomaterials 2021, 11, 3223. [Google Scholar] [CrossRef]

- Choi, M.; Shim, S.-J.; Jung, Y.-I.; Kim, H.-S.; Seo, B.-K. The Effect of Annealing Temperature on the Synthesis of Nickel Ferrite Films as High-Capacity Anode Materials for Lithium Ion Batteries. Nanomaterials 2021, 11, 3238. [Google Scholar] [CrossRef]

- Kim, J.; Kwon, J.; Kim, M.J.; O, M.J.; Jung, D.S.; Roh, K.C.; Jang, J.; Kim, P.J.; Choi, J. A Strategic Approach to Use Upcycled Si Nanomaterials for Stable Operation of Lithium-Ion Batteries. Nanomaterials 2021, 11, 3248. [Google Scholar] [CrossRef]

- Rollo-Walker, G.; Malic, N.; Wang, X.; Chiefari, J.; Forsyth, M. Development and Progression of Polymer Electrolytes for Batteries: Influence of Structure and Chemistry. Polymers 2021, 13, 4127. [Google Scholar] [CrossRef]

- Ansari, S.; Ayob, A.; Lipu, M.S.H.; Hussain, A.; Saad, M.H.M. Data-Driven Remaining Useful Life Prediction for Lithium-Ion Batteries Using Multi-Charging Profile Framework: A Recurrent Neural Network Approach. Sustainability 2021, 13, 13333. [Google Scholar] [CrossRef]

- Schougaard, S.B.; Bélanger, D. 8. Electrochemical energy storage systems. In Functional Materials: For Energy, Sustainable Development and Biomedical Sciences; Leclerc, M., Gauvin, R., Eds.; De Gruyter: Berlin/München, Germany; Boston, MA, USA, 2014; pp. 171–188. [Google Scholar] [CrossRef]

- Chen, K.; Song, M.; Wei, W.; Wang, S. Design of the structure of battery pack in parallel air-cooled battery thermal management system for cooling efficiency improvement. Int. J. Heat Mass Transf. 2019, 132, 309–321. [Google Scholar] [CrossRef]

- Integration of Electric Vehicles and Battery Storage Systems; MDPI: Basel, Switzerland, 2021. [CrossRef]

- Naidu, K.C.B.; Kumar, N.S.; Boddula, R.; Ramesh, S.; Pothu, R.; Banerjee, P.; Sarma, M.; Manjunatha, H.; Kishore, B. Recent Advances in Nanomaterials for Li-ion Batteries. Lithium-Ion Batter. 2020, 80, 148–160. [Google Scholar] [CrossRef]

- Briongos, F.; Platero, C.A.; Sánchez-Fernández, J.A.; Nicolet, C. Evaluation of the Operating Efficiency of a Hybrid Wind–Hydro Powerplant. Sustainability 2020, 12, 668. [Google Scholar] [CrossRef] [Green Version]

- Kumar, V.; Pandey, A.S.; Sinha, S.K. Grid integration and power quality issues of wind and Solar Energy System: A Review. In Proceedings of the 2016 International Conference on Emerging Trends in Electrical Electronics & Sustainable Energy Systems (ICETEESES), Sultanpur, India, 11–12 March 2016. [Google Scholar] [CrossRef]

- Lv, S.; Wang, X.; Lu, W.; Zhang, J.; Ni, H. The Influence of Temperature on the Capacity of Lithium Ion Batteries with Different Anodes. Energies 2021, 15, 60. [Google Scholar] [CrossRef]

- Szczepaniak, M.; Otręba, P.; Otręba, P.; Sikora, T. Use of the Maximum Power Point Tracking Method in a Portable Lithium-Ion Solar Battery Charger. Energies 2021, 15, 26. [Google Scholar] [CrossRef]

- Simão, M.; Ramos, H.M. Hybrid Pumped Hydro Storage Energy Solutions towards Wind and PV Integration: Improvement on Flexibility, Reliability and Energy Costs. Water 2020, 12, 2457. [Google Scholar] [CrossRef]

- Salkuti, S.R. Modeling of Various Renewable Energy Resources for Smart Electrical Power Systems. In Next Generation Smart Grids: Modeling, Control and Optimization; Lecture Notes in Electrical Engineering; Salkuti, S.R., Ray, P., Eds.; Springer: Singapore, 2022; Volume 824. [Google Scholar] [CrossRef]

- Bolund, B.; Bernhoff, H.; Leijon, M. Flywheel energy and power storage systems. Renew. Sustain. Energy Rev. 2007, 11, 235–258. [Google Scholar] [CrossRef]

- onteh, M.A.; Nsofor, E.C. Composite flywheel material design for high-speed energy storage. J. Appl. Res. Technol. 2016, 14, 184–190. [Google Scholar] [CrossRef]

- Akshay, A.; Kiran, D.; Chandramohan, P.; Duraiswamy, P. Design and analysis of phase-locked loop for low power wireless applications. In Proceedings of the 2016 Conference on Emerging Devices and Smart Systems (ICEDSS), Namakkal, India, 4–5 March 2016. [Google Scholar] [CrossRef]

- Fehrmann, E.; Kenny, B. Automating the transition between sensorless motor control methods for the NASA Glenn research centre flywheel energy storage system. In Proceedings of the 2nd International Energy Conversion Engineering Conference, Manipal, India, 23–25 January 2014. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Momoh, J.A.; Reddy, S.S. Prony analysis of damping characteristic for micro-grid with energy storage system. In Proceedings of the 2014 North American Power Symposium (NAPS), Pullman, WA, USA, 7–9 September 2014; pp. 1–4. [Google Scholar] [CrossRef]

- Hedlund, M.; Lundin, J.; De Santiago, J.; Abrahamsson, J.; Bernhoff, H. Flywheel Energy Storage for Automotive Applications. Energies 2015, 8, 10636–10663. [Google Scholar] [CrossRef] [Green Version]

- Tegler, E. Why Did the Flywheel Hybrid System Never Catch on for Road Cars? Ars Technica. 2021. Available online: https://arstechnica.com/cars/2021/02/whatever-happened-to-williams-f1s-flywheel-hybrid-idea/ (accessed on 9 November 2021).

- Read, M.; Smith, R.; Pullen, K. Optimisation of flywheel energy storage systems with geared transmission for hybrid vehicles. Mech. Mach. Theory 2015, 87, 191–209. [Google Scholar] [CrossRef]

- Sebastián, R.; Penaalzola, R.; Quesada, J.; Colmenar-Santos, A. Sizing and simulation of a low-cost flywheel based energy storage system for wind-diesel hybrid systems. In Proceedings of the 2012 IEEE International Energy Conference and Exhibition (ENERGYCON), Florence, Italy, 9–12 September 2012. [Google Scholar] [CrossRef]

- Dhand, A.; Pullen, K. Characterization of Flywheel Energy Storage System for Hybrid Vehicles; SAE Technical Paper 2014-01-1796; SAE International: Warrendale, PA, USA, 2014. [Google Scholar] [CrossRef]

- Rufer, A. Design and Control of a KE (Kinetic Energy)—Compensated Gravitational Energy Storage System. In Proceedings of the 2020 22nd European Conference on Power Electronics and Applications (EPE’20 ECCE Europe), Lyon, France, 7–11 September 2020; pp. 1–11. [Google Scholar] [CrossRef]

- Rathi, A. Stacking Concrete Blocks Is a Surprisingly Efficient Way to Store Energy. Quartz. Available online: https://qz.com/1355672/stacking-concrete-blocks-is-a-surprisingly-efficient-way-to-store-energy/ (accessed on 12 December 2021).

- Lüthy, M. A New Type of Battery, Made of Concrete. Medium. 29 October 2021. Available online: https://onezero.medium.com/the-new-super-battery-made-of-concrete-aeee436ecc67 (accessed on 12 December 2021).

- Spector, J. Can Newcomer Energy Vault Break the Curse of Mechanical Grid Storage? Greentech Media. 14 November 2018. Available online: https://www.greentechmedia.com/articles/read/energy-vault-stacks-concrete-blocks-to-store-energy (accessed on 12 December 2021).

- Energy Vault—Energy Storage Made of Concrete Blocks and Cranes. Balkan Green Energy News. Available online: https://balkangreenenergynews.com/energy-vault-energy-storage-made-of-concrete-blocks-and-cranes/ (accessed on 30 October 2020).

- Grossman, D. Are concrete blocks the next batteries? Popular Mechanics. 2 November 2021. Available online: https://www.popularmechanics.com/technology/infrastructure/a29463165/concrete-block-energy-storage/ (accessed on 12 December 2021).

- Lang, F. Concrete Blocks Serving as the Future of Renewable Energy Storage. Interesting Engineering. 17 October 2019. Available online: https://interestingengineering.com/concrete-blocks-serving-as-the-future-of-renewable-energy-storage (accessed on 12 December 2021).

- Mombelli, A. Revolutionary Idea to Store Green Power for the Grid. SWI swissinfo.ch. 1 January 2020. Available online: https://www.swissinfo.ch/eng/energy-vault_revolutionary-idea-to-store-green-power-for-the-grid/45467684 (accessed on 12 December 2021).

- Jayanti, S. Regenerative Fuel Cells. In Encyclopedia of Energy Storage; Cabeza, L.F., Ed.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 329–337. ISBN 9780128197301. [Google Scholar] [CrossRef]

- Skyllaskazacos, M.; Chakrabarti, M.H.; Hajimolana, S.A.; Mjalli, F.S.; Saleem, M. Progress in Flow Battery Research and Development. J. Electrochem. Soc. 2011, 158, R55–R79. [Google Scholar] [CrossRef]

- Wang, W.; Luo, Q.; Li, B.; Wei, X.; Li, L.; Yang, Z. Recent Progress in Redox Flow Battery Research and Development. Adv. Funct. Mater. 2012, 23, 970–986. [Google Scholar] [CrossRef]

- Rychcik, M.; Skyllas-Kazacos, M. Characteristics of a new all-vanadium redox flow battery. J. Power Sources 1988, 22, 59–67. [Google Scholar] [CrossRef]

- Sun, C.-Y.; Zhang, H.; Luo, X.-D.; Chen, N. A comparative study of Nafion and sulfonated poly(ether ether ketone) membrane performance for iron-chromium redox flow battery. Ionics 2019, 25, 4219–4229. [Google Scholar] [CrossRef]

- Son, T.Y.; Im, K.S.; Jung, H.N.; Nam, S.Y. Blended Anion Exchange Membranes for Vanadium Redox Flow Batteries. Polymers 2021, 13, 2827. [Google Scholar] [CrossRef]

- Parasuraman, A.; Lim, T.M.; Menictas, C.; Skyllas-Kazacos, M. Review of material research and development for vanadium redox flow battery applications. Electrochim. Acta 2013, 101, 27–40. [Google Scholar] [CrossRef]

- Alotto, P.; Guarnieri, M.; Moro, F. Redox flow batteries for the storage of renewable energy: A review. Renew. Sustain. Energy Rev. 2014, 29, 325–335. [Google Scholar] [CrossRef]

- Lin, K.; Chen, Q.; Gerhardt, M.R.; Tong, L.; Kim, S.B.; Eisenach, L.; Valle, A.W.; Hardee, D.; Gordon, R.G.; Aziz, M.J.; et al. Alkaline quinone flow battery. Science 2015, 349, 1529–1532. [Google Scholar] [CrossRef] [Green Version]

- Fischer, P.; Mazúr, P.; Krakowiak, J. Family Tree for Aqueous Organic Redox Couples for Redox Flow Battery Electrolytes: A Conceptual Review. Molecules 2022, 27, 560. [Google Scholar] [CrossRef] [PubMed]

- Narasimha, S.; Salkuti, S.R. Design and implementation of smart uninterruptable power supply using battery storage and photovoltaic arrays. Int. J. Eng. Technol. 2018, 7, 960–965. [Google Scholar] [CrossRef]

- Sánchez-Díez, E.; Ventosa, E.; Guarnieri, M.; Trovò, A.; Flox, C.; Marcilla, R.; Soavi, F.; Mazur, P.; Aranzabe, E.; Ferret, R. Redox flow batteries: Status and perspective towards sustainable stationary energy storage. J. Power Sources 2021, 481, 228804. [Google Scholar] [CrossRef]

- Barelli, L.; Cardelli, E.; Pelosi, D.; Ciupageanu, D.A.; Ottaviano, P.A.; Longo, M.; Zaninelli, D. Energy from the Waves: Integration of a HESS to a Wave Energy Converter in a DC Bus Electrical Architecture to Enhance Grid Power Quality. Energies 2021, 15, 10. [Google Scholar] [CrossRef]

| Source of Energy | Global Energy Potential (in Trillion Watts) |

|---|---|

| Wind | 1700 |

| Wave | 2700 |

| Geothermal | 45 |

| Hydroelectric | 1900 |

| Tidal | 3700 |

| Solar (photovoltaic) | 6500 |

| Direct sunshine | 4600 |

| Country | Capacity |

|---|---|

| China | 30,320 MW |

| Japan | 21,894 MW |

| United States | 19,140 MW |

| Germany | 5355 MW |

| India | 4786 MW |

| South Korea | 4700 MW |

| Italy | 3940 MW |

| Supplier | Technology Employed |

|---|---|

| Air Liquide | Lurgi methanation |

| Haldor Topsoe | TREMP |

| Clariant and Foster Wheeler | Vesta |

| Johnson Matthey | HICOM |

| Linde | Linde isothermal reactor |

| Plant Name | Location (Country) |

|---|---|

| GAYA | France |

| GOBIOGAS | Sweden |

| BioSNG | Austria |

| Great Syn Fuels Plant | USA |

| DemoSNG | Sweden |

| CPIProject | China |

| Keqi Project | China |

| POSCO Project | South Korea |

| Project | Capacity | Location |

|---|---|---|

| Hornsdale Power | 150 MW | Australia |

| Stocking Pelham | 50 MW | Germany |

| Jardelund | 48 MW | United Kingdom |

| Minamisoma Substation | 40 MW | Japan |

| Nishi-Sendai Substation | 40 MW | Japan |

| Laurel AES | 32 MW | United States |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sridhar, S.; Salkuti, S.R. Development and Future Scope of Renewable Energy and Energy Storage Systems. Smart Cities 2022, 5, 668-699. https://doi.org/10.3390/smartcities5020035

Sridhar S, Salkuti SR. Development and Future Scope of Renewable Energy and Energy Storage Systems. Smart Cities. 2022; 5(2):668-699. https://doi.org/10.3390/smartcities5020035

Chicago/Turabian StyleSridhar, Sushyanth, and Surender Reddy Salkuti. 2022. "Development and Future Scope of Renewable Energy and Energy Storage Systems" Smart Cities 5, no. 2: 668-699. https://doi.org/10.3390/smartcities5020035

APA StyleSridhar, S., & Salkuti, S. R. (2022). Development and Future Scope of Renewable Energy and Energy Storage Systems. Smart Cities, 5(2), 668-699. https://doi.org/10.3390/smartcities5020035