Climate Change Mitigation through Modular Construction

Abstract

:1. Introduction

- What are the implications of adopting MC on CC mitigation in the CI?

- What strategies pertinent to MC could be implemented for mitigating CC?

2. Methodology

2.1. Research Strategy

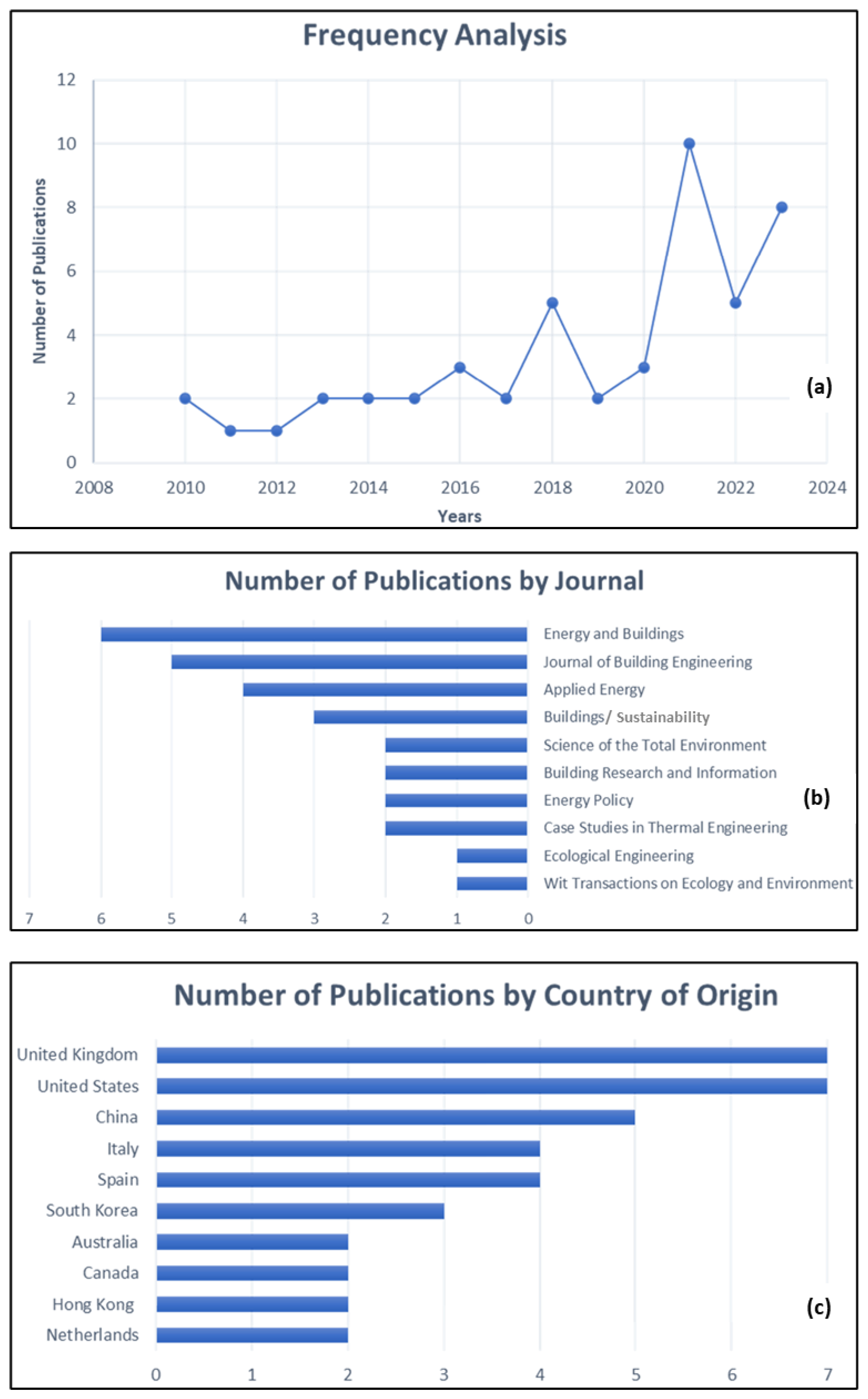

- The review process involved the assessment of articles retrieved based on keywords from the Scopus repository. These articles were published between 2010 to 2023. The specified timeframe was chosen as a massive influx of publications addressing MC was reported during this period [34].

- Articles incorporating the specified keywords in their title, abstract, introduction, or keywords sections met the eligibility criteria defined for this study.

- The information source or database used for the research is the Scopus repository, accessible at https://www.scopus.com/search/form.uri?display=basic#basic (accessed on 1 December 2023).

- The search process utilized thorough search strings, as outlined in Section 2.2 of the study.

- The article selection process involved searching and screening articles, focusing on original articles, and reviewing papers with a rigorous peer review to ensure that validated literature backed by scientific evidence was chosen for the study. Conference papers, book chapters, and data papers were excluded from consideration because of the limited peer backing attributed to them. The selection process further narrowed the study to articles published in English and excluded studies from unrelated disciplines such as business administration, gender studies, arts, etc. It also included a qualitative analysis involving the reading of titles and abstracts. Removing duplicated articles was unnecessary as the data were extracted from a single repository.

- Meta-analysis was conducted on the shortlisted articles using the Scopus “Analyze Results” tool. Metadata related to the chosen research theme, including the frequency of publications per year, country of origin, and publication sources, were extracted accordingly. Detailed discourse regarding the implications of the retrieved metadata has been documented in Section 3.1 of the study.

- A thorough screening of the extracted studies was carried out to eliminate irrelevant articles. This involved reviewing the extracted studies’ titles, abstracts, introductions, and conclusions. After this initial screening, content analysis of the eligible articles was performed by thoroughly reading the full texts of the shortlisted articles to identify the implications of MC on the environment and climate as documented in each study. Traditional construction was compared with MC, noting their effect on CC. Different strategies to address CC, which MC can facilitate, were identified in the shortlisted studies and recorded accordingly.

- To mitigate the risk of bias in the study, all retrieved articles were circulated among all authors of this study. Each author independently analyzed the contents of the eligible articles. The findings of each author were then compared and subsequently combined. Triangulating the articles among authors scrutinized the selected studies for bias before presenting the research outcomes.

- The summary measures include identifying the advantages of MC for mitigating CC and categorizing the identified benefits into relevant groups based on their intrinsic attributes.

- The results of the present study were cross-referenced with the existing literature to ensure validity and consistency in the prevailing research outcomes.

- An additional analysis was conducted to propose a conceptual framework based on the enablers of CC resistance facilitated through the utilization of MC.The relevant steps are explained in the subsequent sections of this article.

2.2. Data Collection

- Exclusively address the impact of MC on climate and its role in fostering environmentally friendly construction.

- Complete texts are accessible to readers through standard Scopus access.

- Mention MC or prefabricated or off-site construction and climate in their abstract, title, keywords, introduction, or conclusion.

2.3. Data Analysis

3. Results

3.1. Meta-Analysis

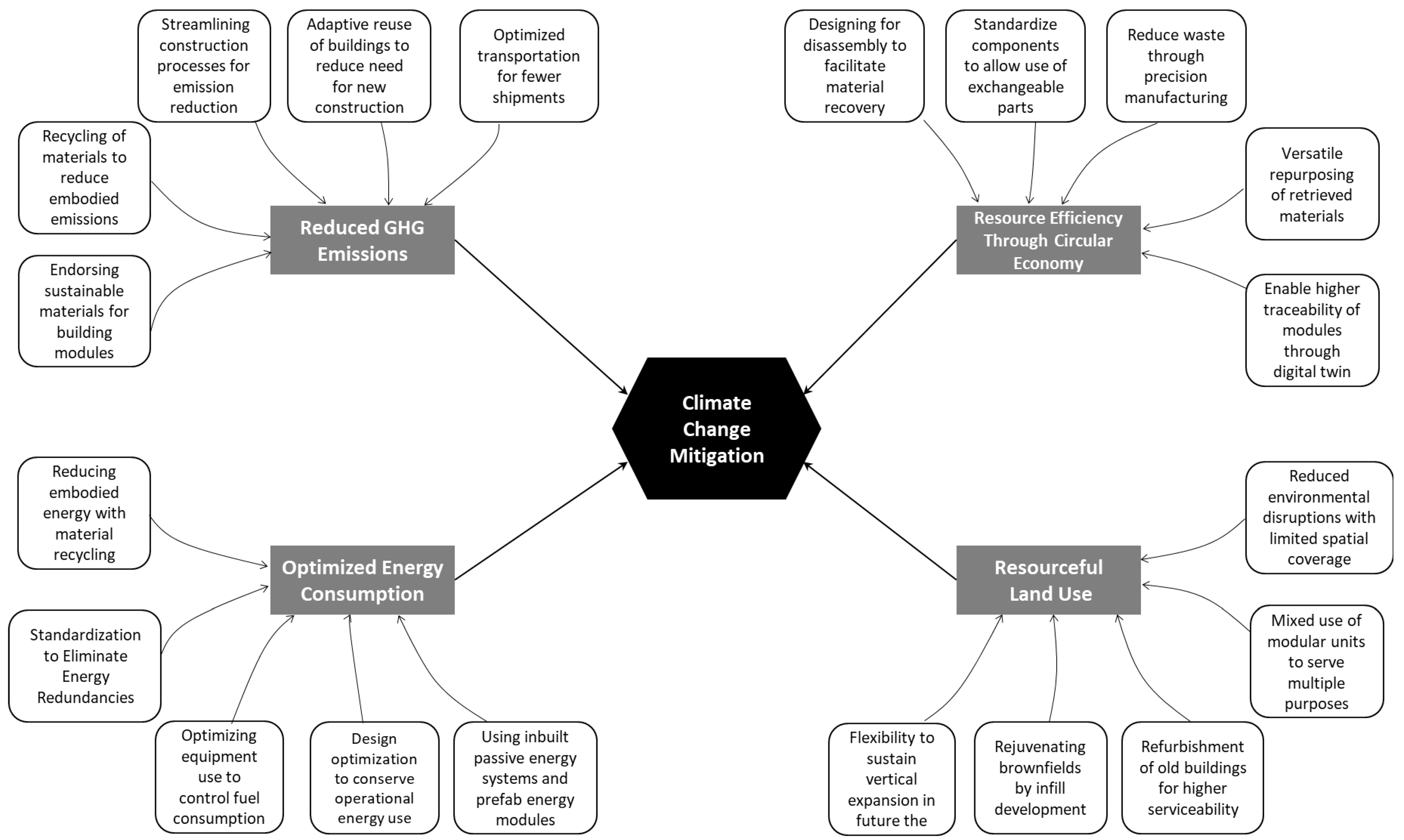

3.2. Content Analysis

- (1)

- Reducing GHG emissions;

- (2)

- Curtailing resource intensiveness by enabling a CE;

- (3)

- Enhancing energy efficiency;

- (4)

- Fostering resourceful land use and management.

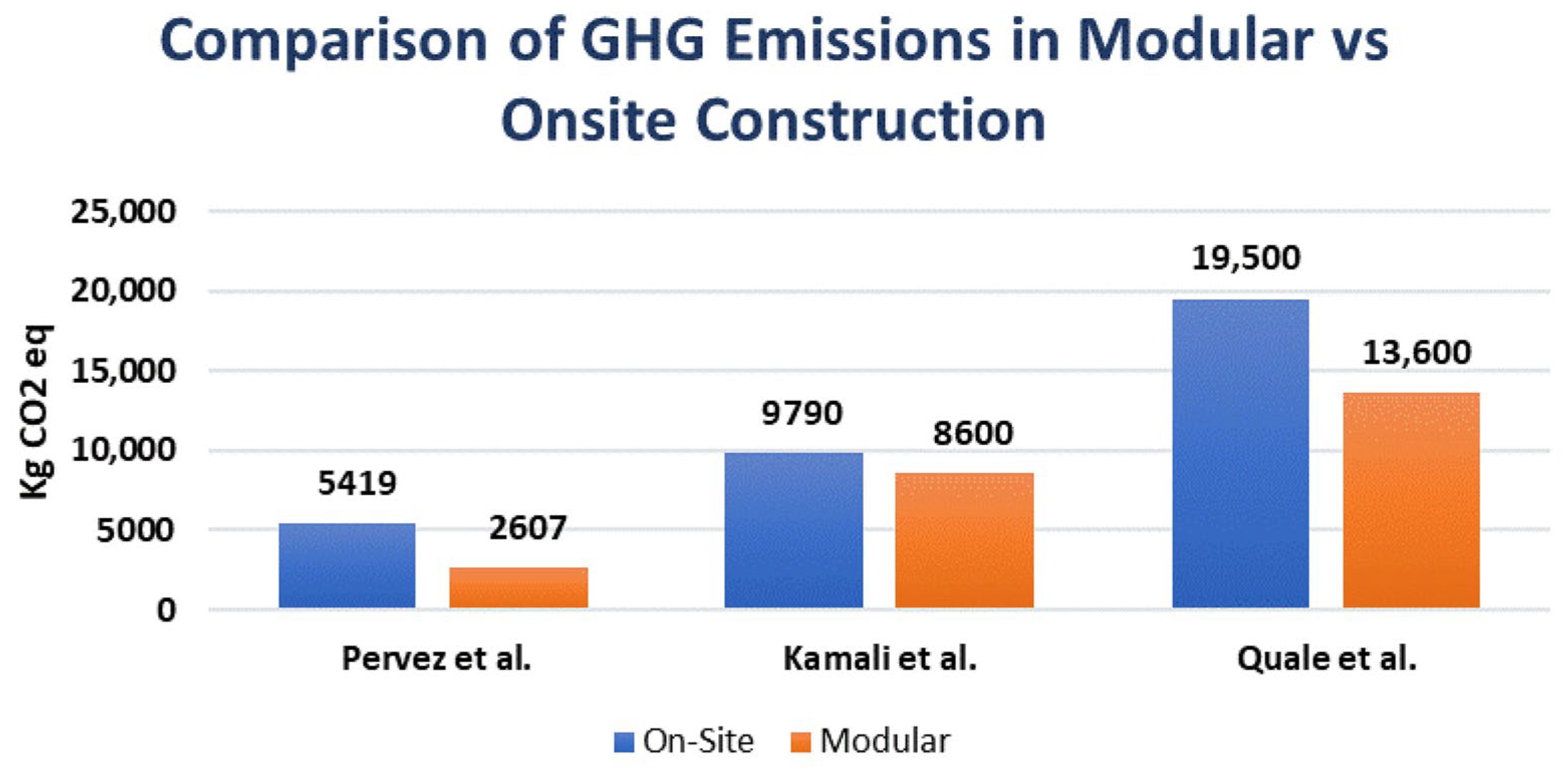

3.2.1. Reducing GHG Emissions

| Author | Unit | On-Site Construction | Modular Construction | References | |

|---|---|---|---|---|---|

| Concrete | Steel | Timber | |||

| De Wolf et al. | kg CO2e/m2 | 380 | 350 | 200 | [54] |

| Hart et al. | kg CO2e/m2 | 228 | 185 | 119 | [53] |

| Tavares et al. | kg CO2e | 29,000 | 21,000 | 15,000 | [46] |

| Roni et al. | kg CO2e | 409,932 | - | 292,901 | [56] |

| Alireza et al. | kg CO2e/m3 | 602 | 209 | 96 | [57] |

3.2.2. Curtailing Resource Intensiveness by Enabling a Circular Economy

3.2.3. Fomenting Energy Efficiency in Construction

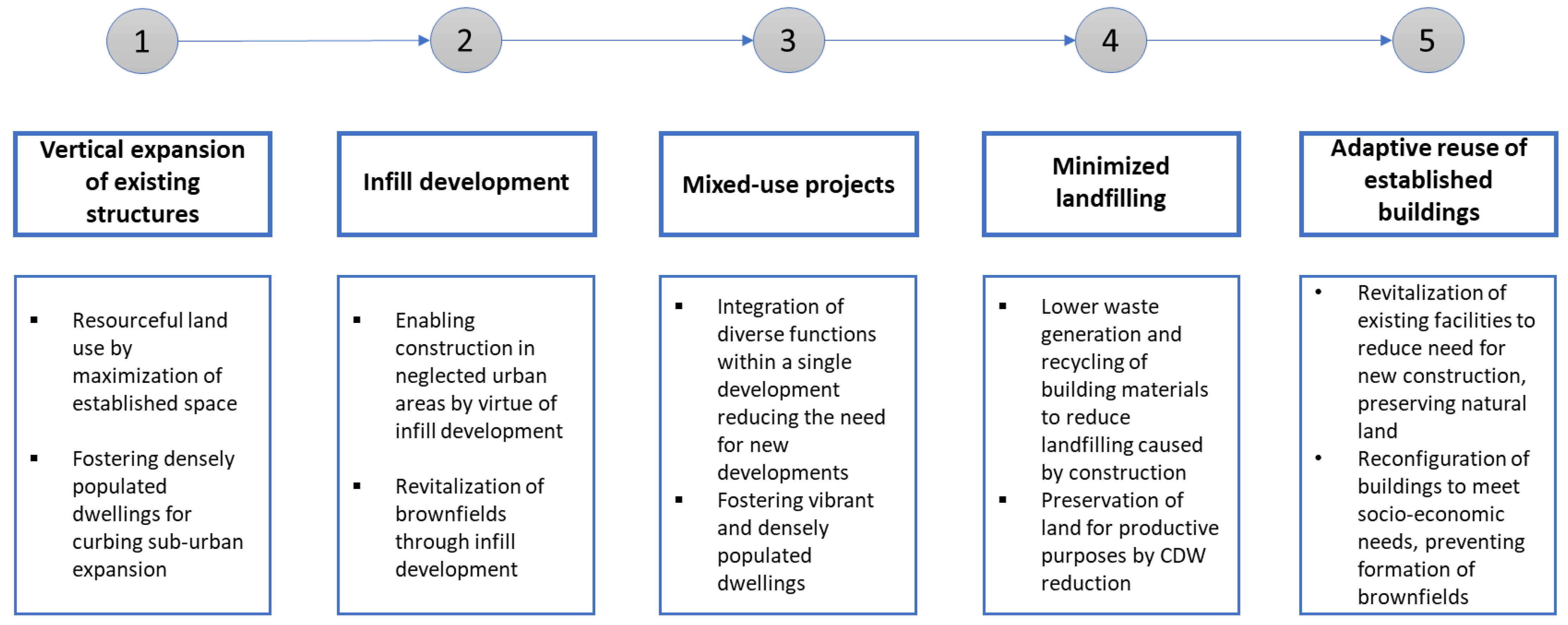

3.2.4. Fostering Resourceful Land Use and Management

3.2.5. Conceptual Framework for Mitigating Climate Change through Modular Construction

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| ID | Title | Author | Year | Journal |

|---|---|---|---|---|

| 1 | Conventional versus modular construction methods: a comparative cradle-to-gate LCA for residential buildings | M. Kamali, K. Hewage, R. Sadiq [24] | 2019 | Energy and Buildings |

| 2 | A quantitative assessment of greenhouse gas (GHG) emissions from conventional and modular construction: a case of developing country | H. Pervez, Y. Ali, A. Pertillo [43] | 2021 | Journal of Cleaner Production |

| 3 | Innovative, modular building facades—as a tool to counteract the effects of and to prevent climate change | P. Kaminska, H. Michalak [119] | 2023 | Civil and Environmental Engineering Reports |

| 4 | Assessment of modular construction system made with low environmental impact construction materials for achieving sustainable housing projects | G. Romero, M. Javier, C. Rojas, K. Rodriguez [35] | 2023 | Sustainability |

| 5 | Embodied energy and greenhouse gas emissions analysis of a prefabricated modular house: the “moby” case study | V. Tavares, N. Lacerda, F. Freire [46] | 2019 | Journal of Cleaner Production |

| 6 | Climate change and the energy performance of buildings in the future—a case study for prefabricated buildings in the UK | F. Ismail, F. Haji, S. Donyavi, P. Boyd, D. Sohrab [120] | 2021 | Journal of Building Engineering |

| 7 | Circular economy strategies in modern timber construction as a potential response to climate change | M. Ghobadi, S. Sepasgozar [121] | 2023 | Journal of Building Engineering |

| 8 | Is it a possibility to achieve energy plus prefabricated building worldwide? | A. Alkhalidi, A. Abuothman, A. Aldweik, A. Al-Baaz [122] | 2021 | International Journal of Low-Carbon Technologies |

| 9 | Sustainability in modular design and construction: a case study of ‘the stack’ | Y. Ahn, K. Kim [123] | 2014 | International Journal of Sustainable Building Technology and Urban Development |

| 10 | Timber-based façades with different connections and claddings: assessing materials’ reusability, water use and global warming potential | M. Juaristi, I. Sebastiani, S. Avesani [124] | 2022 | Journal of Facade Design and Engineering |

| 11 | New residential construction building and composite post and beam structure toward global warming mitigation | A. Balasbaneh, A. Marsono [125] | 2018 | Environmental Progress and Sustainable Energy |

| 12 | Carbon emission reduction in prefabrication construction during materialization stage: a BIM-based life-cycle assessment approach | J. Hao, B. Cheng, W. Lu, J. Xu, J. Wang, W. Bu, Z. Guo [126] | 2020 | Science of the Total Environment |

| 13 | Thirty years of climate mitigation: lessons from the 1989 options appraisal for the UK | E. Lees, N. Eyre [127] | 2021 | Energy Efficiency |

| 14 | Comparative analysis of off-site precast concrete and cast-in-place concrete in low-carbon built environment | C. Liu, F. Zhang, H. Zhang [128] | 2020 | Fresenius Environmental Bulletin |

| 15 | Numerical study on the thermal performance of lightweight temporary building integrated with phase change materials | L. Zhu, Y. Yang, S. Chen, Y. Sun [129] | 2018 | Applied Thermal Engineering |

| 16 | Minimizing upfront carbon emissions of steel-framed modular housing: a case study | S. Kechidi, N. Banks [130] | 2023 | Journal of Building Engineering |

| 17 | Design and prototyping of a FRCC modular and climate responsive affordable housing system for underserved people in the pacific island nations | D. Rockwood, J. Silva, S. Olsen, I. Robertson, T. Tran [131] | 2015 | Journal of Building Engineering |

| 18 | Systematic review on the integration of building information modelling and prefabrication construction for low-carbon building delivery | S. Yevu, E. Owusu, A. Chan, K. Sarpong [132] | 2023 | Building Research and Information |

| 19 | Air temperature cooling by extensive green roofs in Toronto Canada | J. MacIvor, L. Margolis, M. Perotto, J. Drake [133] | 2016 | Ecological Engineering |

| 20 | The mediterranean smart adaptive wall. An experimental design of a smart and adaptive facade module for the mediterranean climate | M. Iommi [134] | 2018 | Energy and Buildings |

| 21 | Finite element study of hyperstructure systems with modular light-frame construction in high-rise buildings | N. Labrecque, S. Ménard M. Oudjene, P. Blanchet [135] | 2022 | Buildings |

| 22 | Analytical solutions for the dynamic analysis of a modular floating structure for urban expansion | S. Wang [136] | 2022 | Ocean Engineering |

| 23 | The carbon emission assessment of a building with different prefabrication rates in the construction stage | Q. Han, J. Chang, G. Liu, H. Zhang [137] | 2022 | International Journal of Environmental Research and Public Health |

| 24 | Rapid deployment modular building solutions and climatic adaptability: case based study of a novel approach to “thermal capacity on demand” | B. Ceranic, J. Beardmore, A. Cox [138] | 2018 | Energy and Buildings |

| 25 | Carbon emission energy management analysis of LCA-based fabricated building construction | L. Luo, Y. Chen [139] | 2020 | Sustainable Computing: Informatics and Systems |

| 26 | City regeneration through modular phase change materials (PCM) envelopes for climate neutral buildings | J. Messana, V. Lopez, T. Pellicer [140] | 2022 | Sustainability (Switzerland) |

| 27 | A research methodology for mitigating climate change in the restoration of buildings: rehabilitation strategies and low-impact prefabrication in the “El Rodezno” water mill | A. Carranza, R. Anon-Abajas, G. Lamela [141] | 2021 | Sustainability (Switzerland) |

| 28 | Design and climate-responsiveness performance evaluation of an integrated envelope for modular prefabricated buildings | W. Wang., J. Huang, S. Lu, J. Li [66] | 2018 | Advances in Materials Science and Engineering |

| 29 | Exploring the potential of climate-adaptive container building design under future climates scenarios in three different climate zones | J. Shen., B. Copertaro, X. Zhang, J. Koke [142] | 2020 | Sustainability (Switzerland) |

| 30 | BIM-based building geometric modeling and automatic generative design for sustainable off-site construction | V. Gan [143] | 2022 | Journal of Construction Engineering and Management |

| 31 | Life cycle and energy performance assessment of three wall types in south-eastern Europe region | N. Maodus, B. Agarski, I. Budak, M. Radeka [144] | 2016 | Energy and Buildings |

References

- Akter, S. Australia’s Black Summer wildfires recovery: A difference-in-differences analysis using nightlights. Glob. Environ. Change 2023, 83, 102743. [Google Scholar] [CrossRef]

- Waseem, H.B. Floods in Pakistan: A state-of-the-art review. Nat. Hazards Res. 2023, 3, 359–373. [Google Scholar] [CrossRef]

- Wake, B. Buildings at risk. Nat. Clim. Chang. 2021, 11, 642. [Google Scholar] [CrossRef]

- Lenzen, M.; Malik, A.; Kenway, S.; Daniels, P.; Lam, K.L.; Geschke, A.J.N.H.; Sciences, E.S. Economic damage and spillovers from a tropical cyclone. Nat. Hazards Earth Syst. Sci. 2019, 19, 137–151. [Google Scholar] [CrossRef]

- Fawzy, S.; Osman, A.I.; Doran, J.; Rooney, D.W. Strategies for mitigation of climate change: A review. Environ. Chem. Lett. 2020, 18, 2069–2094. [Google Scholar] [CrossRef]

- Fernandez, G.; Ahmed, I. “Build back better” approach to disaster recovery: Research trends since 2006. Prog. Disaster Sci. 2019, 1, 100003. [Google Scholar] [CrossRef]

- Gallego-Schmid, A.; Chen, H.M.; Sharmina, M.; Mendoza, J.M.F. Links between circular economy and climate change mitigation in the built environment. J. Clean. Prod. 2020, 260, 121115. [Google Scholar] [CrossRef]

- Oyedele, L.O.; Ajayi, S.O.; Kadiri, K.O. Use of recycled products in UK construction industry: An empirical investigation into critical impediments and strategies for improvement. Resour. Conserv. Recycl. 2014, 93, 23–31. [Google Scholar] [CrossRef]

- Dimoudi, A.; Tompa, C. Energy and environmental indicators related to construction of office buildings. Resour. Conserv. Recycl. 2008, 53, 86–95. [Google Scholar] [CrossRef]

- Assaad, R.H.; El-adaway, I.H.; Hastak, M.; LaScola Needy, K. The COVID-19 pandemic: A catalyst and accelerator for offsite construction technologies. J. Manag. Eng. 2022, 38, 04022062. [Google Scholar] [CrossRef]

- Tunji-Olayeni, P.F.; Omuh, I.O.; Afolabi, A.O.; Ojelabi, R.A.; Eshofonie, E.E. Climate change mitigation and adaptation strategies for construction activities within planetary boundaries: Limitations of developing countries. J. Phys. Conf. Ser. 2019, 1299, 012006. [Google Scholar] [CrossRef]

- Zhou, J.; Ren, D. A hybrid model of external environmental benefits compensation to practitioners for the application of prefabricated con-struction. Environ. Impact Assess. Rev. 2020, 81, 106358. [Google Scholar] [CrossRef]

- Roy, K. ‘Build back Better’ Requires a Framework That Focuses on the Full Life of a House—From Materials to its End of Life. Available online: https://theconversation.com/build-back-better-requires-a-framework-that-focuses-on-the-full-life-of-a-house-from-materials-to-its-end-of-life-203325 (accessed on 7 January 2024).

- Masood, R.; Lim, J.B.; González, V.A.; Roy, K.; Khan, K.I.A. A systematic review on supply chain management in prefabricated house-building research. Buildings 2022, 12, 40. [Google Scholar] [CrossRef]

- Lu, N. The Current Use of Offsite Construction Techniques in the United States Construction Industry. In Building a Sustainable Future, Proceedings of the 2009 Construction Research Congress, Construction Institute of American Society of Civil Engineers, Seattle, WA, USA, 5–7 April 2009; American Society of Civil Engineers: Reston, VA, USA, 2009; pp. 946–955. [Google Scholar] [CrossRef]

- Jaillon, L.; Poon, C.S. Sustainable construction aspects of using prefabrication in dense urban environment: A Hong Kong case study. Constr. Manag. Econ. 2008, 26, 953–966. [Google Scholar] [CrossRef]

- Thurairajah, N.; Rathnasinghe, A.; Ali, M.; Shashwat, S. Unexpected Challenges in the Modular Construction Implementation: Are UK Contractors Ready? Sustainability 2023, 15, 8105. [Google Scholar] [CrossRef]

- O’Connor, J.T.; O’Brien, W.J.; Choi, J.O. Critical Success Factors and Enablers for Optimum and Maximum Industrial Modularization. J. Constr. Eng. Manag. 2014, 140, 04014012. [Google Scholar] [CrossRef]

- Pan, W.; Gibb, A.F.; Dainty, A.R.J. Perspectives of UK housebuilders on the use of offsite modern methods of construction. Constr. Manag. Econ. 2007, 25, 183–194. [Google Scholar] [CrossRef]

- Sandamini, K.Y.; Waidyasekara, K.G.A.S.; Weerapperuma, U.S. Cost-benefits of relocatable modular buildings (RMB) for construction site offices: The case of Sri Lanka. FARU J. 2023, 10, 29–38. [Google Scholar] [CrossRef]

- Karthik, S.; Sharareh, K.; Behzad, R. Modular Construction vs. Traditional Construction: Advantages and Limitations: A Comparative Study. Creat. Constr. Conf. 2020, 12, 11–19. [Google Scholar] [CrossRef]

- Ferdous, W.; Bai, Y.; Ngo, T.D.; Manalo, A.; Mendis, P. New advancements, challenges and opportunities of multi-storey modular buildings—A state-of-the-art review. Eng. Struct. 2019, 183, 883–893. [Google Scholar] [CrossRef]

- Lacey, A.W.; Chen, W.; Hao, H.; Bi, K. Structural response of modular buildings—An overview. J. Build. Eng. 2018, 16, 45–56. [Google Scholar] [CrossRef]

- Kamali, M.; Hewage, K.; Sadiq, R. Conventional versus modular construction methods: A comparative cradle-to-gate LCA for residential buildings. Energy Build. 2019, 204, 109479. [Google Scholar] [CrossRef]

- Hořínková, D. Advantages and disadvantages of modular construction, including environmental impacts. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1203, 32002. [Google Scholar] [CrossRef]

- Jokisalo, J.; Kurnitski, J.; Korpi, M.; Kalamees, T.; Vinha, J. Building leakage, infiltration, and energy performance analyses for Finnish detached houses. Build. Environ. 2009, 44, 377–387. [Google Scholar] [CrossRef]

- Gunawarden, T.; Mendis, P. Prefabricated Building Systems—Design and Construction. Encyclopedia 2022, 2, 70–95. [Google Scholar] [CrossRef]

- Innella, F.; Arashpour, M.; Bai, Y. Lean Methodologies and Techniques for Modular Construction: Chronological and Critical Review. J. Constr. Eng. Manag. 2019, 145, 04019076. [Google Scholar] [CrossRef]

- Lim, Y.W.; Ling, P.C.H.; Tan, C.S.; Chong, H.Y.; Thurairajah, A. Planning and coordination of modular construction. Autom. Constr. 2022, 141, 104455. [Google Scholar] [CrossRef]

- Olawumi, T.O.; Chan, D.W.M.; Ojo, S.; Yam, M.C.H. Automating the modular construction process: A review of digital technologies and future directions with blockchain technology. J. Build. Eng. 2022, 46, 103720. [Google Scholar] [CrossRef]

- Iqbal, F.; Ahmed, S.; Amin, F.; Qayyum, S.; Ullah, F. Integrating BIM–IoT and Autonomous Mobile Robots for Construction Site Layout Printing. Buildings 2023, 13, 2212. [Google Scholar] [CrossRef]

- Wuni, I.Y.; Shen, G.Q. Barriers to the adoption of modular integrated construction: Systematic review and meta-analysis, integrated conceptual framework, and strategies. J. Clean. Prod. 2020, 249, 119347. [Google Scholar] [CrossRef]

- Masood, R.; Lim, J.B.; González, V.A. Society. Performance of the supply chains for New Zealand prefabricated house-building. Sustain. Cities Soc. 2021, 64, 102537. [Google Scholar] [CrossRef]

- Quale, J.; Eckelman, M.J.; Williams, K.W.; Sloditskie, G.; Zimmerman, J.B. Construction Matters: Comparing Environmental Impacts of Building Modular and Conventional Homes in the United States. J. Ind. Ecol. 2012, 16, 243–253. [Google Scholar] [CrossRef]

- Romero Quidel, R.G.; Soto Acuña, M.J.; Rojas Herrera, C.J.; Rodríguez Neira, K.; Cárdenas-Ramírez, J.P. Assessment of Modular Construction System Made with Low Environmental Impact Construction Materials for Achieving Sustainable Housing Projects. Sustainability 2023, 15, 8386. [Google Scholar] [CrossRef]

- Greer, F.; Horvath, A. Modular construction’s capacity to reduce embodied carbon emissions in California’s housing sector. Build. Environ. 2023, 240, 110432. [Google Scholar] [CrossRef]

- Akadiri, P.O.; Chinyio, E.A.; Olomolaiye, P.O. Design of A Sustainable Building: A Conceptual Framework for Implementing Sustainability in the Building Sector. Buildings 2012, 2, 126–152. [Google Scholar] [CrossRef]

- Wrigley, P.A.; Wood, P.; O’Neill, S.; Hall, R.; Robertson, D. Off-site modular construction and design in nuclear power: A systematic literature review. Prog. Nucl. Energy 2021, 134, 103664. [Google Scholar] [CrossRef]

- Ullah, F.; Qayyum, S.; Thaheem, M.J.; Al-Turjman, F.; Sepasgozar, S.M.E. Risk management in sustainable smart cities governance: A TOE framework. Technol. Forecast. Soc. Chang. 2021, 167, 120743. [Google Scholar] [CrossRef]

- Akhimien, N.G.; Latif, E.; Hou, S.S. Application of circular economy principles in buildings: A systematic review. J. Build. Eng. 2021, 38, 102041. [Google Scholar] [CrossRef]

- Yang, M. Circular economy strategies for combating climate change and other environmental issues. Environ. Chem. Lett. 2022, 21, 55–80. [Google Scholar] [CrossRef]

- Luo, H.; Liu, J.; Li, C.; Chen, K.; Zhang, M. Ultra-rapid delivery of specialty field hospitals to combat COVID-19: Lessons learned from the Leishenshan Hospital project in Wuhan. Autom. Constr. 2020, 119, 103345. [Google Scholar] [CrossRef]

- Pervez, H.; Ali, Y.; Petrillo, A. A quantitative assessment of greenhouse gas (GHG) emissions from conventional and modular construction: A case of developing country. J. Clean. Prod. 2021, 294, 126210. [Google Scholar] [CrossRef]

- Kamali, M.; Hewage, K. Development of performance criteria for sustainability evaluation of modular versus conventional construction methods. J. Clean. Prod. 2017, 142, 3592–3606. [Google Scholar] [CrossRef]

- Vijayavenkataraman, S.; Iniyan, S.; Goic, R. A review of climate change, mitigation and adaptation. Renew. Sustain. Energy Rev. 2012, 16, 878–897. [Google Scholar] [CrossRef]

- Tavares, V.; Soares, N.; Raposo, N.; Marques, P.; Freire, F. Prefabricated versus conventional construction: Comparing life-cycle impacts of alternative structural materials. J. Build. Eng. 2021, 41, 102705. [Google Scholar] [CrossRef]

- Attia, P.M. Reducing embodied carbon emissions of concrete modules in high-rise buildings through structural design optimisation. IOP Conf. Ser. Earth Environ. Sci. 2022, 1101, 22023. [Google Scholar] [CrossRef]

- Biricik, Ö.; Aytekin, B.; Mardani, A. Effect of waste binder material usage rate on thixotropic behaviour of cementitious systems. Constr. Build. Mater. 2023, 403, 133197. [Google Scholar] [CrossRef]

- Denman, M.; Ullah, F.; Qayyum, S.; Olatunji, O. Post-Construction Defects in Multi-Unit Australian Dwellings: An Analysis of the Defect Type, Causes, Risks, and Impacts. Buildings 2024, 14, 231. [Google Scholar] [CrossRef]

- Belaïd, F. How does concrete and cement industry transformation contribute to mitigating climate change challenges? Resour. Conserv. Recycl. Adv. 2022, 15, 200084. [Google Scholar] [CrossRef]

- Iuorio, O.; Napolano, L.; Fiorino, L.; Landolfo, R. The environmental impacts of an innovative modular lightweight steel system: The Elissa case. J. Clean. Prod. 2019, 238, 117905. [Google Scholar] [CrossRef]

- Dong, Y.H.; Jaillon, L.; Chu, P.; Poon, C.S. Comparing carbon emissions of precast and cast-in-situ construction methods—A case study of high-rise private building. Constr. Build. Mater. 2015, 99, 39–53. [Google Scholar] [CrossRef]

- Hart, J.; D’Amico, B.; Pomponi, F. Whole-life embodied carbon in multistory buildings: Steel, concrete and timber structures. J. Ind. Ecol. 2021, 25, 403–418. [Google Scholar] [CrossRef]

- Wolf, C.D.; Hoxha, E.; Hollberg, A.; Fivet, C.; Ochsendorf, J. Database of Embodied Quantity Outputs: Lowering Material Impacts through Engineering. J. Archit. Eng. 2020, 26, 4020016. [Google Scholar] [CrossRef]

- Bhaliya, P.; Rajgor, M.; Shah, D.A. Evaluation of Feasibility for Novel Modular Block Construction. ECS Trans. 2022, 107, 4011–4020. [Google Scholar] [CrossRef]

- Rinne, R.; Ilgın, H.E.; Karjalainen, M. Comparative Study on Life-Cycle Assessment and Carbon Footprint of Hybrid, Concrete and Timber Apartment Buildings in Finland. Int. J. Environ. Res. Public Health 2022, 19, 774. [Google Scholar] [CrossRef] [PubMed]

- Bahrami, A.; Olsson, M.; Svensson, K. Carbon Dioxide Emissions from Various Structural Frame Materials of Single-Family Houses in Nordic Countries. Int. J. Innov. Res. Sci. Stud. 2022, 5, 112–120. [Google Scholar] [CrossRef]

- Boafo, F.E.; Kim, J.H.; Kim, J.T. Performance of Modular Prefabricated Architecture: Case Study-Based Review and Future Pathways. Sustainability 2016, 8, 558. [Google Scholar] [CrossRef]

- Cao, X.; Li, X.; Zhu, Y.; Zhang, Z. A comparative study of environmental performance between prefabricated and traditional residential buildings in China. J. Clean. Prod. 2015, 109, 131–143. [Google Scholar] [CrossRef]

- Labaran, Y.H.; Mathur, V.S.; Muhammad, S.U.; Musa, A.A. Carbon footprint management: A review of construction industry. Clean. Eng. Technol. 2022, 9, 100531. [Google Scholar] [CrossRef]

- Biswas, W.K. Carbon footprint and embodied energy consumption assessment of building construction works in Western Australia. Int. J. Sustain. Built Environ. 2014, 3, 179–186. [Google Scholar] [CrossRef]

- Du, Q.; Bao, T.; Li, Y.; Huang, Y.; Shao, L. Impact of prefabrication technology on the cradle-to-site CO2 emissions of residential buildings. Clean Technol. Environ. Policy 2019, 21, 1499–1514. [Google Scholar] [CrossRef]

- Aghasizadeh, S.; Tabadkani, A.; Hajirasouli, A.; Banihashemi, S. Environmental and economic performance of prefabricated construction: A review. Environ. Impact Assess. Rev. 2022, 97, 106897. [Google Scholar] [CrossRef]

- Roberts, M.; Allen, S.; Clarke, J.; Searle, J.; Coley, D. Understanding the global warming potential of circular design strategies: Life cycle assessment of a design-for-disassembly building. Sustain. Prod. Consum. 2023, 37, 331–343. [Google Scholar] [CrossRef]

- Paudel, P.; Dulal, S.; Bhandari, M.; Tomar, A.K. Study on Pre-fabricated Modular and Steel Structures. Int. J. Civ. Eng. 2019, 3, 8–15. [Google Scholar] [CrossRef]

- Li, J.; Lu, S.; Wang, W.; Huang, J.; Chen, X.; Wang, J. Design and climate-responsiveness performance evaluation of an integrated envelope for modular prefabricated buildings. Adv. Mater. Sci. Eng. 2018, 2018, 8082368. [Google Scholar] [CrossRef]

- Park, B.; Cho, J.; Jeong, Y. Thermal performance assessment of flexible modular housing units for energy independence following disasters. Sustainability 2019, 11, 5561. [Google Scholar] [CrossRef]

- Yu, S.; Liu, Y.; Wang, D.; Bahaj, A.S.; Wu, Y.; Liu, J. Review of thermal and environmental performance of prefabricated buildings: Implications to emission reductions in China. Renew. Sustain. Energy Rev. 2021, 137, 110472. [Google Scholar] [CrossRef]

- Lin, Z.; Hong, T.; Xu, X.; Chen, J.; Wang, W. Evaluating energy retrofits of historic buildings in a university campus using an urban building energy model that considers uncertainties. Sustain. Cities Soc. 2023, 95, 104602. [Google Scholar] [CrossRef]

- Liu, S.; Wang, Y.; Liu, X.; Yang, L.; Zhang, Y.; He, J. How does future climatic uncertainty affect multi-objective building energy retrofit decisions? Evidence from residential buildings in subtropical Hong Kong. Sustain. Cities Soc. 2023, 92, 104482. [Google Scholar] [CrossRef]

- Aye, L.; Ngo, T.; Crawford, R.H.; Gammampila, R.; Mendis, P. Life cycle greenhouse gas emissions and energy analysis of prefabricated reusable building modules. Energy Build. 2012, 47, 159–168. [Google Scholar] [CrossRef]

- Loizou, L.; Barati, K.; Shen, X.; Li, B. Quantifying Advantages of Modular Construction: Waste Generation. Buildings 2021, 11, 622. [Google Scholar] [CrossRef]

- Zhang, Y.; Pan, W. Reducing Construction Waste through Modular Construction. In Proceedings of the 26th International Symposium on Advancement of Construction Management and Real Estate, CRIOCM 2021, Beijing, China, 20–22 November 2021; Guo, H., Fang, D., Lu, W., Peng, Y., Eds.; Springer: Singapore, 2022; pp. 339–347. [Google Scholar]

- Zhang, Y.; Pan, W. Quality Control in Modular Construction Manufacturing During COVID-19: Process and Management Standardization. In Proceedings of the 27th International Symposium on Advancement of Construction Management and Real Estate, CRIOCM 2022, Hong Kong, China, 5–6 December 2022; Li., J., Lu, W., Peng, Y., Yuan, H., Wang, D., Eds.; Springer: Singapore, 2023; pp. 1437–1447. [Google Scholar]

- Martínez-Muñoz, D.; Martí, J.V.; Yepes, V. Comparative Life Cycle Analysis of Concrete and Composite Bridges Varying Steel Recycling Ratio. Materials 2021, 14, 4218. [Google Scholar] [CrossRef] [PubMed]

- Kirchherr, J.; Yang, N.H.N.; Schulze-Spüntrup, F.; Heerink, M.J.; Hartley, K. Conceptualizing the Circular Economy (Revisited): An Analysis of 221 Definitions. Resour. Conserv. Recycl. 2023, 194, 107001. [Google Scholar] [CrossRef]

- Torres, J. Plug and Play Modular Façade Construction System for Renovation for Residential Buildings. Buildings 2021, 11, 419. [Google Scholar] [CrossRef]

- MacKenbach, S.; Zeller, J.C.; Osebold, R. A Roadmap towards Circularity—Modular Construction as a Tool for Circular Economy in the Built Environment. IOP Conf. Ser. Earth Environ. Sci. 2020, 558, 052027. [Google Scholar] [CrossRef]

- Garusinghe, G.D.A.U.; Perera, B.A.K.S.; Weerapperuma, U.S. Integrating Circular Economy Principles in Modular Construction to Enhance Sustainability. Sustainability 2023, 15, 11730. [Google Scholar] [CrossRef]

- Kirchherr, J. Barriers to the Circular Economy: Evidence From the European Union (EU). Ecol. Econ. 2018, 150, 246–272. [Google Scholar] [CrossRef]

- Rios, F.C.; Chong, W.K.; Grau, D. Design for Disassembly and Deconstruction—Challenges and Opportunities. Procedia Eng. 2015, 118, 1296–1304. [Google Scholar] [CrossRef]

- Minunno, R.; O’Grady, T.; Morrison, G.M.; Gruner, R.L. Exploring environmental benefits of reuse and recycle practices: A circular economy case study of a modular building. Resour. Conserv. Recycl. 2020, 160, 104855. [Google Scholar] [CrossRef]

- Schraven, D.; Bukvić, U.; Maio, F.D.; Hertogh, M. Circular transition: Changes and responsibilities in the Dutch stony material supply chain. Resour. Conserv. Recycl. 2019, 150, 104359. [Google Scholar] [CrossRef]

- Dixit, M.K. Embodied energy analysis of building materials: An improved IO-based hybrid method using sectoral disaggregation. Energy 2017, 124, 46–58. [Google Scholar] [CrossRef]

- Yuefei, L.; Jing, L. Research on Regional Difference of Energy Consumption in Production Stage of Civil Building Materials based on Theil Index. IOP Conf. Ser. Earth Environ. Sci. 2021, 647, 012032. [Google Scholar] [CrossRef]

- Hong, B. General Optimization Model of Modular Equipment Selection and Serialization for Shale Gas Field. Front. Energy Res. 2021, 9, 711974. [Google Scholar] [CrossRef]

- Thirunavukkarasu, K. Sustainable performance of a modular building system made of built-up cold-formed steel beams. Buildings 2021, 11, 460. [Google Scholar] [CrossRef]

- Sfakianaki, A.; Pagalou, E.; Pavou, K.; Santamouris, M.; Assimakopoulos, M.N. Theoretical and experimental analysis of the thermal behaviour of a green roof system installed in two residential buildings in Athens, Greece. Int. J. Energy Res. 2009, 33, 1059–1069. [Google Scholar] [CrossRef]

- Ju, X. Application of Building Integrated Active and Passive Solar Technology in Harsher Climate Area--Design of the Central Control Building of PV Demonstration Area in Turpan Area, Xinjiang Uygur Autonomous Region, China. Energy Procedia 2014, 57, 1659–1668. [Google Scholar] [CrossRef]

- Abbasi, A.; Saberi, V.; Eghbali, H.; Saberi, H. Views from construction professionals on hospital project construction management using modular prefabricated materials and building information modeling support. Archit. Struct. Constr. 2023, 1–15. [Google Scholar] [CrossRef]

- Li, J.; Andersen, L.V.; Hudert, M.M. The Potential Contribution of Modular Volumetric Timber Buildings to Circular Construction: A State-of-the-Art Review Based on Literature and 60 Case Studies. Sustainability 2023, 15, 16203. [Google Scholar] [CrossRef]

- Nabi, M.A.; El-adaway, I.H. Modular Construction: Determining Decision-Making Factors and Future Research Needs. J. Manag. Eng. 2020, 36, 04020085. [Google Scholar] [CrossRef]

- Rahman, G.; Chandio, N.H.; Moazzam, M.F.U.; Ansari, N.A. Urban expansion impacts on agricultural land and thermal environment in Larkana, Pakistan. Front. Environ. Sci. 2023, 11, 1115553. [Google Scholar] [CrossRef]

- Mandeli, K. Public space and the challenge of urban transformation in cities of emerging economies: Jeddah case study. Cities 2019, 95, 102409. [Google Scholar] [CrossRef]

- Thai, H.T.; Ngo, T.; Uy, B. A review on modular construction for high-rise buildings. Structures 2020, 28, 1265–1290. [Google Scholar] [CrossRef]

- Aly, S.S.; Attwa, Y.A. Infill Development As An Approach For Promoting Compactness Of Urban Form. WIT Trans. Ecol. Environ. 2013, 173, 455–466. [Google Scholar] [CrossRef]

- Na, S.; Kim, S.; Moon, S. Additive manufacturing (3D Printing)-applied construction: Smart node system for an irregular building façade. J. Build. Eng. 2022, 56, 104743. [Google Scholar] [CrossRef]

- Shahi, S.; Esfahani, M.E.; Bachmann, C.; Haas, C. A definition framework for building adaptation projects. Sustain. Cities Soc. 2020, 63, 102345. [Google Scholar] [CrossRef] [PubMed]

- Farjam, R.; Motlaq, S.M.H. Does urban mixed use development approach explain spatial analysis of inner city decay? J. Urban Manag. 2019, 8, 245–260. [Google Scholar] [CrossRef]

- Wu, G. Factors influencing the application of prefabricated construction in China: From perspectives of technology promotion and cleaner production. J. Clean. Prod. 2019, 219, 753–762. [Google Scholar] [CrossRef]

- Ghannad, P.; Lee, Y.-C.; Choi, J.O. Investigating Stakeholders’ Perceptions of Feasibility and Implications of Modular Construction-Based Post-Disaster Reconstruction. In Proceedings of the Modular and Offsite Construction (MOC) Summit Proceedings, Edmonton, AB, Canada, 21–24 May 2019; pp. 504–513. [Google Scholar]

- Wang, X.; Zhou, Z.; Lv, X.; Yang, L.; Yuan, P.F.; Chen, L. Intelligent renovation of existing Olympic venues: Digital design and construction strategy of a DfD-based prefabricated structure system. Archit. Intell. 2023, 2, 4. [Google Scholar] [CrossRef]

- Fernandes, J.; Ferrão, P. A New Framework for Circular Refurbishment of Buildings to Operationalize Circular Economy Policies. Environments 2023, 10, 51. [Google Scholar] [CrossRef]

- Lawson, R.M.; Ogden, R.G.; Bergin, R. Application of modular construction in high-rise buildings. J. Archit. Eng. 2012, 18, 148–154. [Google Scholar] [CrossRef]

- Ding, L.; Wang, T.; Chan, P.W. Forward and reverse logistics for circular economy in construction: A systematic literature review. J. Clean. Prod. 2023, 388, 135981. [Google Scholar] [CrossRef]

- Aslam, B.; Maqsoom, A.; Inam, H.; Basharat, M.u.; Ullah, F. Forecasting Construction Cost Index through Artificial Intelligence. Societies 2023, 13, 219. [Google Scholar] [CrossRef]

- Ullah, F. Towards Smart Tech 4.0 in the Built Environment: Applications of Disruptive Digital Technologies in Smart Cities, Construction, and Real Estate; Multidisciplinary Digital Publishing Institute (MDPI): Basel, Switzerland, 2023. [Google Scholar]

- Sharma, P.; Tyagi, S.S. C4 Model to manage pandemic using machine learning Curate| Compare| Calculate| Curb. Int. J. Grid Distrib. Comput. 2020, 13, 1882–1898. [Google Scholar]

- Ullah, F.; Al-Turjman, F. Applications. A conceptual framework for blockchain smart contract adoption to manage real estate deals in smart cities. Neural Comput. Appl. 2023, 35, 5033–5054. [Google Scholar] [CrossRef]

- Hossain, M.U.; Sohail, A.; Ng, S.T. Developing a GHG-based methodological approach to support the sourcing of sustainable construction materials and products. Resour. Conserv. Recycl. 2019, 145, 160–169. [Google Scholar] [CrossRef]

- Jang, H.; Ahn, Y.; Roh, S. Comparison of the Embodied Carbon Emissions and Direct Construction Costs for Modular and Conventional Residential Buildings in South Korea. Buildings 2022, 12, 51. [Google Scholar] [CrossRef]

- Turner, C.; Oyekan, J.; Stergioulas, L.K. Distributed Manufacturing: A New Digital Framework for Sustainable Modular Construction. Sustainability 2021, 13, 1515. [Google Scholar] [CrossRef]

- Chang, Y.; Wilkinson, S.; Potangaroa, R.; Seville, E. Economics. Identifying factors affecting resource availability for post-disaster reconstruction: A case study in China. Constr. Manag. Econ. 2011, 29, 37–48. [Google Scholar] [CrossRef]

- Rosni, N.A.; Noor, N.M. A Review of Literature on Urban Sprawl: Assessment of Factors and Causes. J. Archit. Plan. Constr. Manag. 2016, 6, 12–35. [Google Scholar]

- Ankrah, N.A. Implementation of Cradle to Cradle diversity principles in business site development scheme. Int. J. Urban Sustain. Dev. 2018, 10, 92–108. [Google Scholar] [CrossRef]

- Kucukvar, M. How Can Collaborative Circular Economy Practices in Modular Construction Help Fédération Internationale de Football Association World Cup Qatar 2022 to Achieve Its Quest for Sustainable Development and Ecological Systems? Front. Sustain. 2021, 2, 758174. [Google Scholar] [CrossRef]

- Hamza, M. Exploring Perceptions of the Adoption of Prefabricated Construction Technology in Pakistan Using the Technology Ac-ceptance Model. Sustainability 2023, 15, 8281. [Google Scholar] [CrossRef]

- Oorschot, J.A.; Halman, J.I.; Hofman, E. The adoption of green modular innovations in the Dutch housebuilding sector. J. Clean. Prod. 2021, 319, 128524. [Google Scholar] [CrossRef]

- Kaminska, P.; Michalak, H. Innovative, modular building facades—As a tool to counteract the effects of and to prevent climate change. Civ. Environ. Eng. Rep. 2023, 32, 184–209. [Google Scholar] [CrossRef]

- Ismail, F.; Haji, F.; Donyavi, S.; Boyd, P.; Sohrab, D. Climate change and the energy performance of buildings in the future—A case study for prefabricated buildings in the UK. J. Build. Eng. 2021, 39, 102285. [Google Scholar] [CrossRef]

- Ghobadi, M.; Sepasgozar, S. Circular economy strategies in modern timber construction as a potential response to climate change. J. Build. Eng. 2023, 77, 107229. [Google Scholar] [CrossRef]

- Alkhalidi, A.; Abuothman, A.; Aldweik, A.; Al-Baaz, A. Is it a possibility to achieve energy plus prefabricated building worldwide? Int. J. Low-Carbon Technol. 2021, 16, 220–228. [Google Scholar] [CrossRef]

- Ahn, Y.; Kim, K. Sustainability in modular design and construction: A case study of ‘the stack’. Int. J. Sustain. Build. Technol. Urban Dev. 2014, 5, 250–259. [Google Scholar] [CrossRef]

- Juaristi, M.; Sebastiani, I.; Avesani, S. Timber-based façades with different connections and claddings: Assessing materials’ reusability, water use and global warming potential. J. Facade Des. Eng. 2022, 10, 71–86. [Google Scholar] [CrossRef]

- Balasbaneh, A.; Marsono, A. New residential construction building and composite post and beam structure toward global warming mitigation. Environ. Prog. Sustain. Energy 2018, 37, 1394–1402. [Google Scholar] [CrossRef]

- Hao, J.; Cheng, B.; Lu, W.; Xu, J.; Wang, J.; Bu, W.; Guo, Z. Carbon emission reduction in prefabrication construction during materialization stage: A BIM-based life-cycle assessment approach. Sci. Total Environ. 2020, 723, 137870. [Google Scholar] [CrossRef]

- Lees, E.; Eyre, N. Thirty years of climate mitigation: Lessons from the 1989 options appraisal for the UK. Energy Effic. 2021, 14, 37. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Zhang, F.; Zhang, H. Comparative analysis of off-site precast concrete and cast-in-place concrete in low-carbon built environment. Fresenius Environ. Bull. 2020, 29, 1804–1812. [Google Scholar]

- Zhu, L.; Yang, Y.; Chen, S.; Sun, Y. Numerical study on the thermal performance of lightweight temporary building integrated with phase change materials. Appl. Therm. Eng. 2018, 138, 35–47. [Google Scholar] [CrossRef]

- Kechidi, S.; Banks, N. Minimizing upfront carbon emissions of steel-framed modular housing: A case study. J. Build. Eng. 2023, 72, 106707. [Google Scholar] [CrossRef]

- Rockwood, D.; Silva, J.; Olsen, S.; Robertson, I.; Tran, T. Design and prototyping of a FRCC modular and climate responsive affordable housing system for underserved people in the pacific island nations. J. Build. Eng. 2015, 4, 268–282. [Google Scholar] [CrossRef]

- Yevu, S.; Owusu, E.; Chan, A.; Sarpong, K. Systematic review on the integration of building information modelling and prefabrication construction for low-carbon building delivery. Build. Res. Inf. 2023, 51, 279–300. [Google Scholar] [CrossRef]

- MacIvor, J.; Margolis, L.; Perotto, M.; Drake, J. Air temperature cooling by extensive green roofs in Toronto Canada. Ecol. Eng. 2016, 95, 36–42. [Google Scholar] [CrossRef]

- Iommi, M. The mediterranean smart adaptive wall. An experimental design of a smart and adaptive facade module for the mediterranean climate. Energy Build. 2018, 158, 1450–1460. [Google Scholar] [CrossRef]

- Labrecque, N.; Oudjene, S.M.M.; Blanchet, P. Finite element study of hyperstructure systems with modular light-frame construction in high-rise buildings. Buildings 2022, 12, 330. [Google Scholar] [CrossRef]

- Wang, S. Analytical solutions for the dynamic analysis of a modular floating structure for urban expansion. Ocean. Eng. 2022, 266, 112878. [Google Scholar] [CrossRef]

- Han, Q.; Chang, J.; Liu, G.; Zhang, H. The carbon emission assessment of a building with different prefabrication rates in the construction stage. Int. J. Environ. Res. Public Health 2022, 19, 2366. [Google Scholar] [CrossRef] [PubMed]

- Ceranic, B.; Beardmore, J.; Cox, A. Rapid deployment modular building solutions and climatic adaptability: Case based study of a novel approach to “thermal capacity on demand”. Energy Build. 2018, 167, 124–135. [Google Scholar] [CrossRef]

- Luo, L.; Chen, Y. Carbon emission energy management analysis of LCA-based fabricated building construction. Sustain. Comput. Inform. Syst. 2020, 27, 100405. [Google Scholar] [CrossRef]

- Messana, J.; Lopez, V.; Pellicer, T. City regeneration through modular phase change materials (PCM) envelopes for climate neutral buildings. Sustainability 2022, 14, 8902. [Google Scholar] [CrossRef]

- Carranza, A.; Anon-Abajas, R.; Lamela, G. A research methodology for mitigating climate change in the restoration of buildings: Rehabilitation strategies and low-impact prefabrication in the “El Rodezno” water mill. Sustainability 2021, 13, 8869. [Google Scholar] [CrossRef]

- Shen, J.; Copertaro, B.; Zhang, X.; Koke, J. Exploring the potential of climate-adaptive container building design under future climates scenarios in three different climate zones. Sustainability 2020, 12, 108. [Google Scholar] [CrossRef]

- Gan, V. BIM-based building geometric modeling and automatic generative design for sustainable off-site construction. J. Constr. Eng. Manag. 2022, 148, 04022111. [Google Scholar] [CrossRef]

- Maodus, N.; Agarski, B.; Budak, I.; Radeka, M. Life cycle and energy performance assessment of three wall types in south-eastern Europe region. Energy Build. 2016, 133, 605–614. [Google Scholar] [CrossRef]

| Construction Method | Cost Saving | Fast- Tracking | Engaging Local Workforce | Quality Control | Fewer Size Limitations | Reusability | Design Flexibility | Higher Salvage Value | Energy Conservation | Resource Optimization | References |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Modular | ✓ | ✓ | x | ✓ | x | ✓ | ✓ | ✓ | ✓ | ✓ | [17,18,19,20,21,22] |

| Traditional | x | x | ✓ | x | ✓ | x | x | x | x | x |

| Sr No. | Type of Analysis | Output | Tools | |

|---|---|---|---|---|

| 1 | Frequency analysis | Number of papers published per year addressing MC and CC mitigation | Scopus Analyze | MS Excel |

| 2 | Journal source | Number of articles published by various journals pertaining to MC and its impact on CC | Scopus Analyze | MS Excel |

| 3 | Number of publications by country or region | Number of articles regarding MC and CC originating from different nations | Scopus Analyze | MS Excel |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sajid, Z.W.; Ullah, F.; Qayyum, S.; Masood, R. Climate Change Mitigation through Modular Construction. Smart Cities 2024, 7, 566-596. https://doi.org/10.3390/smartcities7010023

Sajid ZW, Ullah F, Qayyum S, Masood R. Climate Change Mitigation through Modular Construction. Smart Cities. 2024; 7(1):566-596. https://doi.org/10.3390/smartcities7010023

Chicago/Turabian StyleSajid, Zeerak Waryam, Fahim Ullah, Siddra Qayyum, and Rehan Masood. 2024. "Climate Change Mitigation through Modular Construction" Smart Cities 7, no. 1: 566-596. https://doi.org/10.3390/smartcities7010023

APA StyleSajid, Z. W., Ullah, F., Qayyum, S., & Masood, R. (2024). Climate Change Mitigation through Modular Construction. Smart Cities, 7(1), 566-596. https://doi.org/10.3390/smartcities7010023