A Comprehensive Review of Life Cycle Assessment (LCA) Studies in Roofing Industry: Current Trends and Future Directions

Abstract

:Highlights

- There is significant variability in LCA methods and impact categories in roofing studies.

- Only a few studies have examined roofing components at the urban scale.

- Standardized LCA methods are needed for consistent assessments in the roofing industry.

- More urban-scale LCA studies are needed to better understand the environmental impact of roofing materials.

Abstract

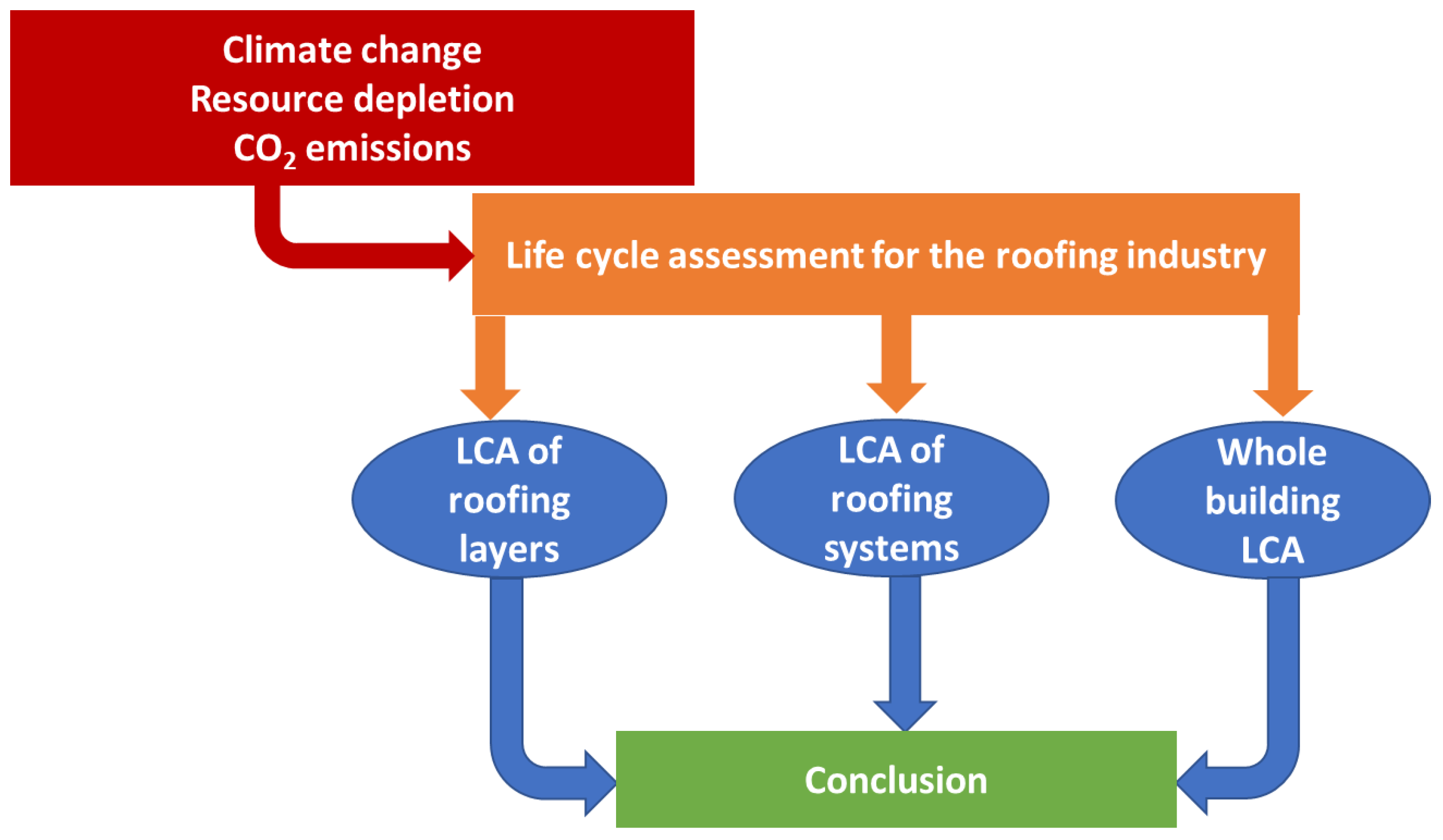

1. Introduction

2. Materials and Methods

3. Results

3.1. LCA Studies Examining Individual Roofing Materials

3.2. LCA of Roofing Systems

3.3. Whole-Building LCA

4. Conclusions and Future Work

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Aggarwal, C.; Ge, H.; Defo, M. Assessing mould growth risk of wood-frame walls using partial least squares (PLS) regression considering climate model uncertainties. Build. Environ. 2023, 238, 110374. [Google Scholar] [CrossRef]

- Aggarwal, C.; Ge, H.; Defo, M.; Lacasse, M.A. Hygrothermal performance assessment of wood frame walls under historical and future climates using partial least squares regression. Build. Environ. 2022, 223, 109501. [Google Scholar] [CrossRef]

- Aggarwal, C.; Molleti, S. State-of-the-Art Review: Effects of Using Cool Building Cladding Materials on Roofs. Buildings 2024, 14, 2257. [Google Scholar] [CrossRef]

- Bhyan, P.; Tyagi, P.; Doddamani, S.; Kumar, N.; Shrivastava, B. Life cycle assessment of lightweight and sustainable materials. In Lightweight and Sustainable Composite Materials: Preparation, Properties and Applications; Elsevier: Amsterdam, The Netherlands, 2023; pp. 117–142. [Google Scholar] [CrossRef]

- Bribián, I.Z.; Capilla, A.V.; Usón, A.A. Life cycle assessment of building materials: Comparative analysis of energy and environmental impacts and evaluation of the eco-efficiency improvement potential. Build. Environ. 2011, 46, 1133–1140. [Google Scholar] [CrossRef]

- Vaz, W.; Sheffield, J. Preliminary assessment of greenhouse gas emissions for atactic polypropylene (APP) modified asphalt membrane roofs. Build. Environ. 2014, 78, 95–102. [Google Scholar] [CrossRef]

- Sravani, T.; Venkatesan, R.P.; Madhumathi, A. A comparative LCA study of passive cooling roof materials for a residential building: An Indian Case study. Mater. Today Proc. 2022, 64, 1014–1022. [Google Scholar] [CrossRef]

- Kulatunga, A.K.; Peiris, R.L.; Kamalakkannan, S. Evaluation of Environment Sustainability of Clay Roof Tiles Manufacturing Practices in Sri Lanka using LCA Technique. Eng. J. Inst. Eng. Sri Lanka 2020, 53, 21. [Google Scholar] [CrossRef]

- Binh, A.; Lea, D.; Whyte, A.; Biswas, W.K. Carbon footprint and embodied energy assessment of roof covering materials 2. Clean Technol. Environ. Policy 2019, 21, 1913–1923. [Google Scholar]

- Kayan, B.A.; Ashraf, N.N. Evaluating the environmental maintenance impact (EMI): A carbon life cycle assessment (LCA) of the Singgora roof tiles repair in heritage buildings. Int. J. Build. Pathol. Adapt. 2023, 41, 905–925. [Google Scholar] [CrossRef]

- Hafner, A.; Schäfer, S. Comparative LCA study of different timber and mineral buildings and calculation method for substitution factors on building level. J. Clean. Prod. 2017, 167, 630–642. [Google Scholar] [CrossRef]

- de Souza, D.M.; Lafontaine, M.; Charron-Doucet, F.; Bengoa, X.; Chappert, B.; Duarte, F.; Lima, L. Comparative Life Cycle Assessment of ceramic versus concrete roof tiles in the Brazilian context. J. Clean. Prod. 2015, 89, 165–173. [Google Scholar] [CrossRef]

- Maiolo, M.; Carini, M.; Capano, G.; Nigro, G.; Piro, P. Life Cycle Assessment of a Bitumen Anti-root Barrier on a Green Roof in the Mediterranean Area. Int. J. Petrochem. Res. 2018, 1, 92–95. [Google Scholar] [CrossRef]

- Ma, L.; Azari, R.; Elnimeiri, M. A Building Information Modeling-Based Life Cycle Assessment of the Embodied Carbon and Environmental Impacts of High-Rise Building Structures: A Case Study. Sustainability 2024, 16, 569. [Google Scholar] [CrossRef]

- Lei, B.; Yu, L.; Chen, Z.; Yang, W.; Deng, C.; Tang, Z. Carbon Emission Evaluation of Recycled Fine Aggregate Concrete Based on Life Cycle Assessment. Sustainability 2022, 14, 14448. [Google Scholar] [CrossRef]

- Bianchini, F.; Hewage, K. How “green” are the green roofs? Lifecycle analysis of green roof materials. Build. Environ. 2012, 48, 57–65. [Google Scholar] [CrossRef]

- Rincón, L.; Coma, J.; Pérez, G.; Castell, A.; Boer, D.; Cabeza, L.F. Environmental performance of recycled rubber as drainage layer in extensive green roofs. A comparative Life Cycle Assessment. Build. Environ. 2014, 74, 22–30. [Google Scholar] [CrossRef]

- Chenani, S.B.; Lehvävirta, S.; Häkkinen, T. Life cycle assessment of layers of green roofs. J. Clean. Prod. 2015, 90, 153–162. [Google Scholar] [CrossRef]

- Takano, A.; Winter, S.; Hughes, M.; Linkosalmi, L. Comparison of life cycle assessment databases: A case study on building assessment. Build. Environ. 2014, 79, 20–30. [Google Scholar] [CrossRef]

- Scolaro, T.P.; Ghisi, E. Life cycle assessment of green roofs: A literature review of layers materials and purposes. Sci. Total Environ. 2022, 829, 154650. [Google Scholar] [CrossRef]

- Peri, G.; Traverso, M.; Finkbeiner, M.; Rizzo, G. Embedding “substrate” in environmental assessment of green roofs life cycle: Evidences from an application to the whole chain in a Mediterranean site. J. Clean. Prod. 2012, 35, 274–287. [Google Scholar] [CrossRef]

- Brachet, A.; Schiopu, N.; Clergeau, P. Biodiversity impact assessment of building’s roofs based on Life Cycle Assessment methods. Build. Environ. 2019, 158, 133–144. [Google Scholar] [CrossRef]

- Berardi, U.; GhaffarianHoseini, A.H.; GhaffarianHoseini, A. State-of-the-art analysis of the environmental benefits of green roofs. Appl. Energy 2014, 115, 411–428. [Google Scholar] [CrossRef]

- Kosareo, L.; Ries, R. Comparative environmental life cycle assessment of green roofs. Build. Environ. 2007, 42, 2606–2613. [Google Scholar] [CrossRef]

- Vacek, P.; Struhala, K.; Matějka, L. Life-cycle study on semi intensive green roofs. J. Clean. Prod. 2017, 154, 203–213. [Google Scholar] [CrossRef]

- Alshamrani, O.S. Life Cycle Assessment for Modular Roof Systems of Large-Span Building. In Lecture Notes in Civil Engineering; Springer: Berlin/Heidelberg, Germany, 2021; Volume 98, pp. 1288–1303. [Google Scholar] [CrossRef]

- Shafique, M.; Azam, A.; Rafiq, M.; Ateeq, M.; Luo, X. An overview of life cycle assessment of green roofs. J. Clean. Prod. 2020, 250, 119471. [Google Scholar] [CrossRef]

- Roy, K.; Dani, A.A.; Ichhpuni, H.; Fang, Z.; Lim, J.B.P. Improving Sustainability of Steel Roofs: Life Cycle Assessment of a Case Study Roof. Appl. Sci. 2022, 12, 5943. [Google Scholar] [CrossRef]

- Balasbaneh, A.T.; Bin Marsono, A.K.; Kermanshahi, E.K. Balancing of life cycle carbon and cost appraisal on alternative wall and roof design verification for residential building. Constr. Innov. 2018, 18, 274–300. [Google Scholar] [CrossRef]

- Vijayaraghavan, K. Green roofs: A critical review on the role of components, benefits, limitations and trends. Renew. Sustain. Energy Rev. 2016, 57, 740–752. [Google Scholar] [CrossRef]

- Carretero-Ayuso, M.J.; García-Sanz-Calcedo, J. Comparison between building roof construction systems based on the LCA. Rev. Constr. 2018, 17, 123–136. [Google Scholar] [CrossRef]

- El Bachawati, M.; Manneh, R.; Belarbi, R.; Dandres, T.; Nassab, C.; El Zakhem, H. Cradle-to-gate Life Cycle Assessment of traditional gravel ballasted, white reflective, and vegetative roofs: A Lebanese case study. J. Clean. Prod. 2016, 137, 833–842. [Google Scholar] [CrossRef]

- Pakdel, A.; Ayatollahi, H.; Sattary, S. Embodied energy and CO2 emissions of life cycle assessment (LCA) in the traditional and contemporary Iranian construction systems. J. Build. Eng. 2021, 39, 102310. [Google Scholar] [CrossRef]

- Susca, T. Enhancement of life cycle assessment (LCA) methodology to include the effect of surface albedo on climate change: Comparing black and white roofs. Environ. Pollut. 2012, 163, 48–54. [Google Scholar] [CrossRef] [PubMed]

- Carvalho, M.; Menezes, V.L.; Gomes, K.C.; Pinheiro, R. Carbon footprint associated with a mono-Si cell photovoltaic ceramic roof tile system. Environ. Prog. Sustain. Energy 2019, 38, 13120. [Google Scholar] [CrossRef]

- Pierobon, F.; Huang, M.; Simonen, K.; Ganguly, I. Environmental benefits of using hybrid CLT structure in midrise non-residential construction: An LCA based comparative case study in the U.S. Pacific Northwest. J. Build. Eng. 2019, 26, 100862. [Google Scholar] [CrossRef]

- Islam, H.; Jollands, M.; Setunge, S.; Haque, N.; Bhuiyan, M.A. Life cycle assessment and life cycle cost implications for roofing and floor designs in residential buildings. Energy Build. 2015, 104, 250–263. [Google Scholar] [CrossRef]

- Fiorentin, D.P.; Martín-Gamboa, M.; Rafael, S.; Quinteiro, P. Life Cycle Assessment of green roofs: A comprehensive review of methodological approaches and climate change impacts. Sustain. Prod. Consum. 2024, 45, 598–611. [Google Scholar] [CrossRef]

- Costa, D.; Serra, J.; Quinteiro, P.; Dias, A.C. Life cycle assessment of wood-based panels: A review. J. Clean. Prod. 2024, 444, 140955. [Google Scholar] [CrossRef]

- Gargari, C.; Bibbiani, C.; Fantozzi, F.; Campiotti, C.A. Environmental Impact of Green Roofing: The Contribute of a Green Roof to the Sustainable use of Natural Resources in a Life Cycle Approach. Agric. Agric. Sci. Procedia 2016, 8, 646–656. [Google Scholar] [CrossRef]

- Wu, H.; Zhou, W.; Chen, K.; Zhang, L.; Zhang, Z.; Li, Y.; Hu, Z. Carbon Emissions Assessment for Building Decoration Based on Life Cycle Assessment: A Case Study of Office Buildings. Sustainability 2023, 15, 14055. [Google Scholar] [CrossRef]

- Ji, S.; Kyung, D.; Lee, W. Life cycle assessment (LCA) of roof-waterproofing systems for reinforced concrete building. Adv. Environ. Res. 2014, 3, 367–377. [Google Scholar] [CrossRef]

- Chen, C.X.; Pierobon, F.; Jones, S.; Maples, I.; Gong, Y.; Ganguly, I. Comparative life cycle assessment of mass timber and concrete residential buildings: A case study in China. Sustainability 2021, 14, 144. [Google Scholar] [CrossRef]

- Morau, D.; Tsiorimalala, N.R.; Rakotondramiarana, H.T. Rakotondramiarana. Life Cycle Analysis of Green Roof Implemented in a Global South Low-Income Country. Br. J. Environ. Clim. Chang. 2017, 7, 43–55. [Google Scholar] [CrossRef]

- Napolano, L.; Menna, C.; Asprone, D.; Prota, A.; Manfredi, G. Life cycle environmental impact of different replacement options for a typical old flat roof. Int. J. Life Cycle Assess. 2015, 20, 694–708. [Google Scholar] [CrossRef]

- Katebi, A.; Tushmanlo, H.S.; Asadollahfardi, G. Environmental life cycle assessment and economic comparison of different roof systems. J. Build. Eng. 2023, 76, 107316. [Google Scholar] [CrossRef]

- Chippagiri, R.; Biswal, D.; Mandavgane, S.; Bras, A.; Ralegaonkar, R. Life Cycle Assessment of a Sustainable Prefabricated Housing System: A Cradle-to-Site Approach Based on a Small-Scale Experimental Model. Buildings 2023, 13, 964. [Google Scholar] [CrossRef]

- Vilches, A.; Garcia-Martinez, A.; Sanchez-Montañes, B. Life cycle assessment (LCA) of building refurbishment: A literature review. Energy Build. 2017, 135, 286–301. [Google Scholar] [CrossRef]

- Alotaibi, B.S.; Khan, S.A.; Abuhussain, M.A.; Al-Tamimi, N.; Elnaklah, R.; Kamal, M.A. Life Cycle Assessment of Embodied Carbon and Strategies for Decarbonization of a High-Rise Residential Building. Buildings 2022, 12, 1203. [Google Scholar] [CrossRef]

- Di Santo, N.; Henriquez, L.G.; Dotelli, G.; Imperadori, M. Holistic Approach for Assessing Buildings’ Environmental Impact and User Comfort from Early Design: A Method Combining Life Cycle Assessment, BIM, and Active House Protocol. Buildings 2023, 13, 1315. [Google Scholar] [CrossRef]

- Kamali, M.; Hewage, K.; Sadiq, R. Conventional versus modular construction methods: A comparative cradle-to-gate LCA for residential buildings. Energy Build. 2019, 204, 109479. [Google Scholar] [CrossRef]

- Evangelista, P.P.; Kiperstok, A.; Torres, E.A.; Gonçalves, J.P. Environmental performance analysis of residential buildings in Brazil using life cycle assessment (LCA). Constr. Build. Mater. 2018, 169, 748–761. [Google Scholar] [CrossRef]

- Rinne, R.; Ilgın, H.E.; Karjalainen, M. Comparative Study on Life-Cycle Assessment and Carbon Footprint of Hybrid, Concrete and Timber Apartment Buildings in Finland. Int. J. Environ. Res. Public Health 2022, 19, 774. [Google Scholar] [CrossRef] [PubMed]

- Rabani, M.; Madessa, H.B.; Ljungström, M.; Aamodt, L.; Løvvold, S.; Nord, N. Life cycle analysis of GHG emissions from the building retrofitting: The case of a Norwegian office building. Build. Environ. 2021, 204, 108159. [Google Scholar] [CrossRef]

- Asif, M.; Muneer, T.; Kelley, R. Life cycle assessment: A case study of a dwelling home in Scotland. Build. Environ. 2007, 42, 1391–1394. [Google Scholar] [CrossRef]

- Li, K.; Teng, Y.; Pan, W. Briefing: Life-cycle carbon assessment of prefabricated buildings: Challenges and solutions. Proc. Inst. Civ. Eng. Eng. Sustain. 2018, 172, 3–8. [Google Scholar] [CrossRef]

- Wu, T.; Gong, M.; Xiao, J. Preliminary sensitivity study on an life cycle assessment (LCA) tool via assessing a hybrid timber building. J. Bioresour. Bioprod. 2020, 5, 108–113. [Google Scholar] [CrossRef]

- Al-Nassar, F.; Ruparathna, R.; Chhipi-Shrestha, G.; Haider, H.; Hewage, K.; Sadiq, R. Sustainability assessment framework for low rise commercial buildings: Life cycle impact index-based approach. Clean Technol. Environ. Policy 2016, 18, 2579–2590. [Google Scholar] [CrossRef]

- Akyüz, M.K.; Altuntaş, Ö.; Söğüt, M.Z. Economic and environmental optimization of an airport terminal building’s wall and roof insulation. Sustainability 2017, 9, 1849. [Google Scholar] [CrossRef]

- Trovato, M.R.; Nocera, F.; Giuffrida, S. Life-cycle assessment and monetary measurements for the carbon footprint reduction of public buildings. Sustainability 2020, 12, 3460. [Google Scholar] [CrossRef]

- Chen, Z.; Gu, H.; Bergman, R.D.; Liang, S. Comparative life-cycle assessment of a high-rise mass timber building with an equivalent reinforced concrete alternative using the athena impact estimator for buildings. Sustainability 2020, 12, 4708. [Google Scholar] [CrossRef]

- Mohebbi, G.; Bahadori-Jahromi, A.; Ferri, M.; Mylona, A. The role of embodied carbon databases in the accuracy of life cycle assessment (LCA) calculations for the embodied carbon of buildings. Sustainability 2021, 13, 7988. [Google Scholar] [CrossRef]

| Year | Location | Focus | Key Findings | Ref. |

|---|---|---|---|---|

| 2023 | India | Lightweight Construction Materials | The study compared traditional stone, burnt clay bricks, and precast concrete, with bricks having the lowest emissions. | [4] |

| 2011 | Spain | Different Bricks and Tiles | The study highlighted the high environmental impacts of ceramic tiles, fiber cement roofs, and insulation materials. | [5] |

| 2014 | United States | Atactic Polypropylene (APP)-Modified Asphalt Membrane Roofs | The manufacturing stage contributed most to GHG emissions, and APP-modified asphalt had lower emissions. | [6] |

| 2022 | India | Passive Cooling Roof Materials | Insulation reduces CO2 emissions, and different roofing materials have varying impacts. | [7] |

| 2020 | Sri Lanka | Clay Roofing Tiles | The study highlighted the environmental sustainability of clay roofing tiles compared to other practices. | [8] |

| 2019 | Western Australia | Roofing Materials | Concrete tiles had the highest carbon footprint, while clay tiles had the lowest footprint. | [9] |

| 2023 | Malaysia | Singgora Roof Tiles | Embodied carbon emissions for repairing Singgora tiles on heritage buildings were quantified. | [10] |

| 2017 | Germany, Austria | Timber and Mineral Building Designs | Timber buildings have lower GWP than mineral counterparts, especially in single/two-family houses. | [11] |

| 2015 | Brazil | Roof Tiles | Ceramic tiles have lower impacts on climate change, resource depletion, and water withdrawal compared to concrete tiles. | [12] |

| 2018 | Southern Italy | Bitumen Anti-Root Barriers | Bitumen membranes have high environmental costs, mainly due to CO2 emissions, contrasting with green roof benefits. | [13] |

| 2024 | United States | High-rise Building Structures | Concrete contributes significantly to embodied carbon in high-rise buildings, especially during the product stage. | [14] |

| 2022 | China | Recycled Fine Aggregate Concrete | Increasing the recycled fine aggregate ratio reduces emissions, but it affects compressive strength. | [15] |

| 2012 | Canada | Green Roof Layers | The production of polymers for green roof layers has significant CO2 emissions. | [16] |

| 2014 | Spain | Recycled Rubber Crumbs | Recycled rubber as a drainage layer reduces the operational phase’s environmental impact compared to conventional materials. | [17] |

| 2015 | Finland | Extensive Green Roof Systems | The selection of substrate components is crucial for minimizing environmental impacts in extensive green roof systems. | [18] |

| 2014 | Finland | Different Roofing Materials | Significant differences exist in GHG emissions across databases, highlighting the importance of data transparency. | [19] |

| Year | Location | Focus | Key Findings | Ref. |

|---|---|---|---|---|

| 2022 | - | Green Roof Layers and Materials | Polyethylene root barrier had lower impacts than PVC; light non-woven polypropylene protection layer had lower impacts than heavy version; recycled high-impact polystyrene drainage layer had lower impacts than virgin material; recycled textile fibers for water retention layer had lower impacts than rock wool; zeolite among lightweight soil components had highest impact; recommendation for using recycled materials and simple green roof design to reduce environmental impacts | [20] |

| 2012 | Italy | Extensive Green Roof System | Growing medium composition significantly influenced environmental impacts, with fertilizers used for maintenance contributing most to eutrophication and terrestrial ecotoxicity; disposal of growing medium and bitumen in landfills during end-of-life had the highest impacts on human toxicity and marine aquatic ecotoxicity | [21] |

| 2019 | France | Different Roof Systems | Consideration of “ex situ” biodiversity impacts, particularly for conventional roofs; intensive green roofs demonstrated 37% lower impact than conventional roofs per ReCiPe; the importance of considering biodiversity impacts to preserve biodiversity during the building’s life cycle | [22] |

| 2014 | - | Environmental Benefits of Green Roofs | Green roofs reduce roof surface and ambient air temperature compared to conventional roofs; increasing vegetation density improves energy performance benefits across different cities; complex heat and mass transfer processes influence the thermal performance of green roofs | [23] |

| 2007 | United States | Life Cycle Assessment of Green Roofs | Extensive green roofs have lower environmental impacts across categories like acidification, eutrophication, and global warming potential compared to conventional roofs when accounting for reduced operational energy use; operational benefits offset higher upfront material and installation impacts over the full life cycle | [24] |

| 2017 | Czech Republic | Semi-Intensive Green Roof Assembly Configurations | Assembly with XPS insulation had the highest impacts in categories like global warming potential due to energy-intensive XPS production; mineral wool panels as near-total substrate replacement had the highest impacts on acidification and eutrophication potentials; the importance of selecting substrate components and insulation materials to minimize the environmental effects over green roof life cycle | [25] |

| 2021 | Canada | Modular Roof Systems | Wood and steel roof systems demonstrated substantially lower energy consumption, greenhouse gas emissions, and environmental impacts compared to precast and composite roofs across all life cycle stages | [26] |

| 2020 | - | Overview of LCA Studies on Green Roofs | An increasing trend in LCA studies on green roofs over the past decade; the importance of using safer, more sustainable materials and optimizing design for reduced lifecycle impacts | [27] |

| 2022 | New Zealand | LCA Analysis of Steel Roofing Systems | Steel roofing systems contribute significantly to acidification, eutrophication, and abiotic resource depletion impacts over their life cycle; recommendations provided to improve the accuracy and completeness of environmental assessments for steel roofing systems in New Zealand | [28] |

| 2018 | Malaysia | LCA and LCC Analysis for Residential Buildings | Timber-based wall and roof design (W5R1) was identified as the optimal sustainable choice for residential construction in Malaysia to minimize carbon footprint and life cycle costs | [29] |

| 2016 | - | Review of Green Roofs | Importance of selecting appropriate vegetation and substrates for stormwater management, energy savings, and mitigation of urban heat island effects; the potential of green roofs to improve air and water quality in urban areas | [30] |

| 2018 | Spain | Comparison of Roof Construction Systems | Trade-offs between different roof systems in terms of environmental impacts, economic factors, and practical considerations; consideration of embodied energy use, CO2 emissions, waste generation, cost, labor time, maintenance requirements, and execution risk | [31] |

| 2016 | Lebanon | LCA Analysis of Roof Types | Green roofs are preferable over conventional roofs due to reduced energy demand and extended roof membrane life; growing medium composition significantly influences environmental impacts | [32] |

| 2021 | Iran | Comparison of Traditional and Contemporary Construction Systems | Traditional Iranian construction methods like TTM demonstrated significant environmental benefits compared to contemporary energy-intensive construction due to the use of low-impact natural materials and passive design strategies | [33] |

| 2012 | United States | Impact of Surface Albedo on Climate Change | Incorporating surface albedo effects enhances LCA methodology by accounting for key properties influencing climate change impacts; demonstrated the potential of high-albedo surfaces like white roofs to offset CO2 equivalents | [34] |

| 2019 | Brazil | Carbon Footprint of Photovoltaic Roof Systems | Building-integrated photovoltaic roof tiles offer architectural benefits despite a slightly higher carbon footprint compared to traditional photovoltaic panel systems; potential reduction in carbon footprint by using poly-crystalline silicon cells in roof tiles | [35] |

| 2019 | U.S. Pacific Northwest | LCA Comparison of Hybrid CLT and Concrete Buildings | Hybrid cross-laminated timber (CLT) construction achieved a significant reduction in global warming potential compared to reinforced concrete buildings, primarily due to lower embodied emissions and carbon storage in wood | [36] |

| 2015 | Australia | LCA and LCC Analysis of Roofing and Flooring Designs | Higher star-rated designs like gable tile roofs and skillion flat roofs perform better when considering greenhouse gas emissions, cumulative energy demand, and life cycle costs together | [37] |

| 2024 | - | Review of LCA Studies on Green Roofs | Variability in LCA methods applied to green roofs; need for standardization and primary data to improve reliability of results on environmental performance | [38] |

| 2024 | - | Systematic Review of LCA Studies of Wood-Based Panels | Wide range of climate change impacts per m2 of wood-based panel area across studies; key contributors identified as materials and life cycle stages like construction | [39] |

| 2016 | Italy | Environmental Impacts of Green Roof Solutions | Green roofs generally have lower impacts compared to conventional roofs; the importance of growing medium composition, particularly using recycled materials, in reducing impacts | [40] |

| 2023 | China | Life Cycle Carbon Emissions Assessment for Building Decoration | Total carbon emissions during the building decoration life cycle, mainly from materials’ embodied impact stage; the importance of reducing emissions from materials production and operation stages for sustainable building decoration | [41] |

| 2014 | South Korea | LCA of Roof-Waterproofing Systems | Importance of considering the full life cycle, including maintenance requirements, when selecting roof waterproofing systems to minimize environmental impacts like greenhouse gas emissions | [42] |

| 2022 | China | Comparison of LCA of Mass Timber with Concrete Residential Buildings | The potential environmental benefits of using CLT as an alternative showed that timber buildings achieved a 25% reduction in global warming potential compared to concrete buildings, primarily due to lower impacts from material production. | [43] |

| 2017 | Global south | LCA of Extensive and Intensive Green Roof Systems | Non-treated and imported materials like cement, virgin plastics, and soil have higher environmental impacts compared to recycled or locally sourced materials. The substrate layer significantly contributes to impacts, especially for intensive green roofs, due to the larger quantities required | [44] |

| 2015 | Italy | LCA of Three Flat-Roof Systems | The polystyrene option had the lowest environmental impact across most categories due to polystyrene recycling benefits. Reductions in concrete consumption are effective for lowering eutrophication impacts, and reductions in rebar consumption can lower acidification impacts for most roof types. | [45] |

| 2023 | Iran | Environmental Impacts of Various Roof Types | Uboot concrete slab roofs had the highest environmental impact across global warming, eutrophication, and acidification potentials. Concrete and chromite beam roofs with polystyrene blocks generated the least environmental impact. | [46] |

| 2023 | India | LCA of a Sustainable Prefabricated Housing System Using Agro-industrial Waste | The successful construction of a small-scale prefabricated model house using optimized mix designs for CFA-based concrete and LW mix, achieving satisfactory strength and thermal properties. | [47] |

| Year | Location | Focus | Key Findings | Ref. |

|---|---|---|---|---|

| 2017 | - | Building refurbishment | Refurbishment reduced operational energy by 30–82%; improving building envelope insulation yielded significant energy benefits; embodied energy payback times ranged from 0.01–4.8 years, emphasizing the need for standardized LCA practices tailored to building refurbishment. | [48] |

| 2022 | India | Decarbonization of high-rise residential building | Adopted BIM-based LCA approach, reducing embodied carbon to 135 kg CO2-eq./m2/year with decarbonization strategies; integration of BIM and LCA enables systematic assessment of decarbonization strategies for high-rise residential buildings. | [49] |

| 2023 | Italy | Environmental impact assessment of early-stage building design | Integrated BIM, LCA, and Active House protocol for early-stage building design assessment, achieving reductions in global warming potential through envelope and material refinements, highlighting the effectiveness of the proposed method for informed decision-making. | [50] |

| 2019 | Canada | Comparative LCA of conventional vs. modular construction | Modular construction outperformed conventional in the construction phase but had varied impacts in material production; modular construction’s overall cradle-to-gate life cycle impacts depend on materials, energy use, and transportation. | [51] |

| 2018 | Brazil | LCA of typical Brazilian residential buildings | The operational phase had the greatest environmental impacts; foundation, structure, masonry, and coating subsystems were key contributors during construction; concrete, ceramic tiles, and steel made the largest material contributions; low-standard dwellings had the highest impacts per unit area; operational phase dominates the impact across different Brazilian residential typologies. | [52] |

| 2022 | Finland | Comparative LCA of hybrid vs. timber vs. concrete apartment building | Timber buildings had the lowest overall life cycle emissions, demonstrating environmental advantages; the hybrid building had potential benefits beyond the life cycle, highlighting the role of hybrid solutions in reducing emissions compared to traditional concrete buildings. | [53] |

| 2021 | Norway | GHG emissions from retrofitting a Norwegian office building | Embodied emissions are mainly from concrete, steel, and insulation; retrofitting to all-air constant air volume resulted in the lowest total emissions, showcasing the importance of material selection and system efficiency in retrofit strategies. | [54] |

| 2007 | Scotland | LCA primary energy analysis of wood-framed vs. concrete/steel buildings | Wood-frame buildings had significantly lower embodied primary energy over the life cycle, with operational energy dominating; wood cladding further reduced embodied energy; highlighted the environmental benefits of wood-based construction systems. | [55] |

| 2018 | - | Challenges and solutions for reliable LCCA of prefabricated buildings | Proposed regression model and five-level framework to enhance reliability and validity of LCCA research on prefabricated buildings, addressing implicit system boundary inconsistencies and offering a systematic approach for reducing life cycle carbon emissions of prefabricated buildings. | [56] |

| 2020 | United States | Sensitivity study of LCA tool on hybrid timber building | A preliminary study using Athena IE4B software showcased the sensitivity of environmental indicators to material choices, indicating the feasibility of software for initial LCA analysis to understand the impact of material choices. | [57] |

| 2016 | Canada | Sustainability assessment of wall–roof material combinations | The steel–wood system was identified as the most sustainable environmentally; the concrete–steel system was most economical; emphasized the importance of organizational priorities in weighing triple bottom-line dimensions when evaluating building material choices. | [58] |

| 2017 | Turkey | Economic and environmental optimization of wall and roof insulation | Insulating terminal building envelope was found to be environmentally favorable, with energy and emissions savings outweighing production impacts within a few years; emphasized the role of insulation in reducing energy consumption and emissions in buildings. | [59] |

| 2020 | Italy | Economic–environmental valuation of energy retrofit project | Retrofit strategies reduced energy needs and carbon footprint; sustainable materials increased socio-environmental–economic–financial results; tax benefits are crucial for cost savings and environmental benefits, highlighting the importance of policy support. | [60] |

| 2020 | United States | Comparative LCA of mass timber vs. reinforced concrete building | Mass timber buildings had lower embodied carbon emissions, stored more CO2, and displaced fossil-fuel-intensive materials, indicating a lower embodied carbon footprint of timber building design. | [61] |

| 2021 | United Kingdom | Impact of ECF databases on LCA accuracy for building embodied carbon | The choice of the ECF database significantly impacts embodied carbon calculations, emphasizing the need for standardized, comprehensive databases to improve the reliability and comparability of embodied carbon assessments. | [62] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aggarwal, C.; Molleti, S.; Ghobadi, M. A Comprehensive Review of Life Cycle Assessment (LCA) Studies in Roofing Industry: Current Trends and Future Directions. Smart Cities 2024, 7, 2781-2801. https://doi.org/10.3390/smartcities7050108

Aggarwal C, Molleti S, Ghobadi M. A Comprehensive Review of Life Cycle Assessment (LCA) Studies in Roofing Industry: Current Trends and Future Directions. Smart Cities. 2024; 7(5):2781-2801. https://doi.org/10.3390/smartcities7050108

Chicago/Turabian StyleAggarwal, Chetan, Sudhakar Molleti, and Mehdi Ghobadi. 2024. "A Comprehensive Review of Life Cycle Assessment (LCA) Studies in Roofing Industry: Current Trends and Future Directions" Smart Cities 7, no. 5: 2781-2801. https://doi.org/10.3390/smartcities7050108