Leveraging 3D Printing for Resilient Disaster Management in Smart Cities

Abstract

Highlights

- 3D printing offers fast, accurate, and efficient manufacturing for smart cities.

- The process presents an opportunity to improve urban resilience, sustainability, and adaptability.

- Overcoming a high initial cost, solving regulatory problems, and training skilled operators are necessary.

- With the evolution of 3D and smart cities, resilient, efficient, and sustainable urban environments will be built.

Abstract

1. Introduction

2. Materials and Methods

3. Results

3.1. Technology Evaluation

3.1.1. Desktop 3D Printing Technologies

- Polylactic acid (PLA): A biodegradable plastic derived from renewable resources such as corn starch. PLA is easy to print with and produces minimal odor, making it ideal for home use. In disaster scenarios, PLA can be used to print a variety of items, including personal protective equipment (PPE) such as face shields and mask components, as well as educational tools and household items.

- Acrylonitrile butadiene styrene (ABS): Known for its toughness and impact resistance, ABS is often used for more demanding applications. It can produce durable parts that withstand higher temperatures and stresses. During disasters, ABS can be employed to create components for emergency shelters, temporary infrastructure repairs, and robust tools needed for various relief activities.

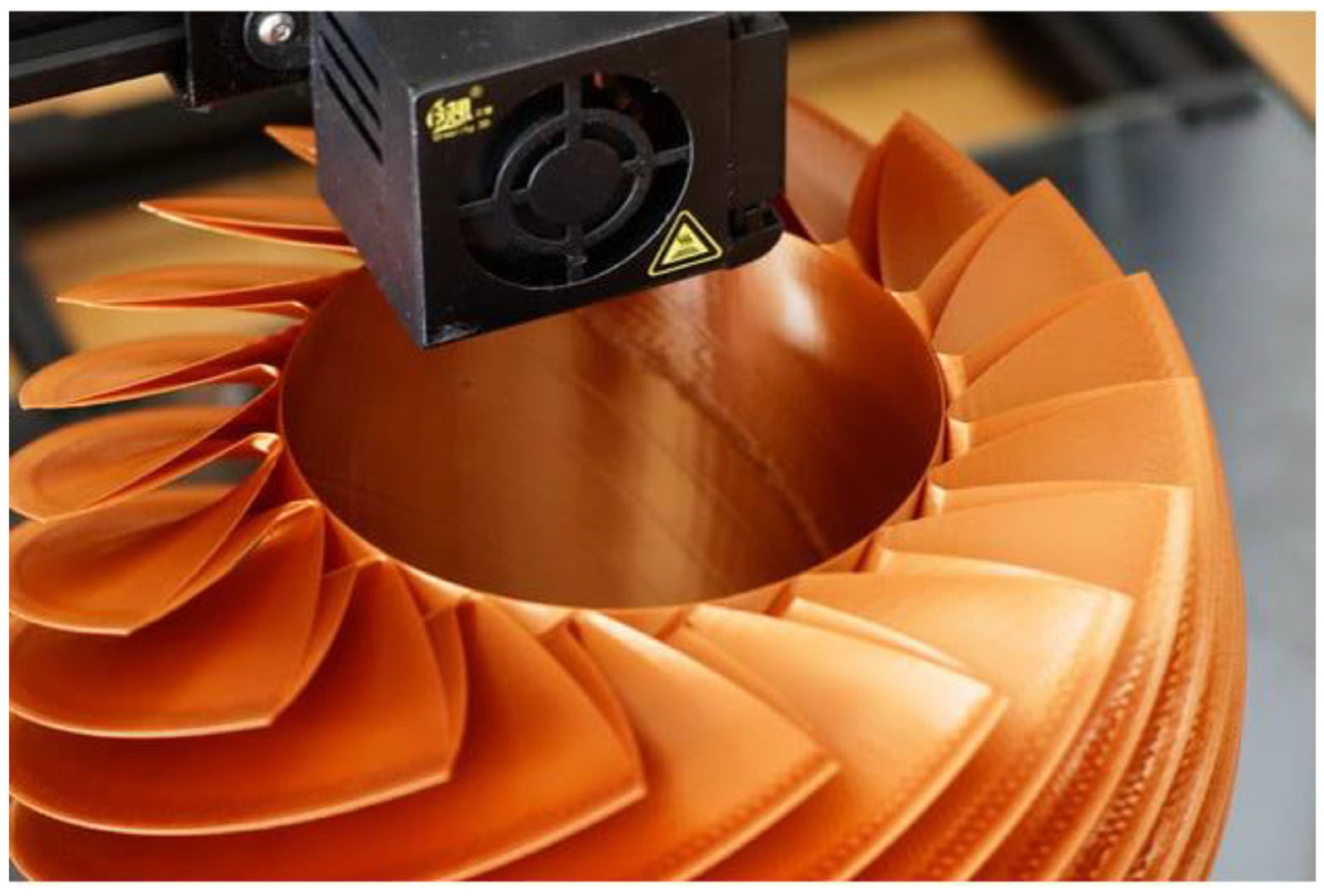

- Polyethylene terephthalate glyCol (PETG): Combining the ease of printing associated with PLA and the strength of ABS, PETG is a versatile filament suitable for creating strong, resilient parts. In emergency contexts, PETG can be used to produce medical devices, water and food containers, and other critical supplies that require durability and safety. Figure 2 depicts an FDM desktop 3D printer while fabricating a three-dimensional item [66].

- In addition to FDM, resin-based 3D printing technologies like stereolithography (SLA) and digital light processing (DLP) are also popular among desktop users. These printers use light to cure liquid resin into solid objects, resulting in high-resolution prints with fine details. SLA 3D printers use a laser to trace and solidify each layer of a liquid resin. The high precision of SLA makes it suitable for producing intricate parts and prototypes that require fine detail. In disaster management, SLA can be used to create medical models, dental devices, and other specialized components that benefit from high accuracy and smooth finishes.

- Similar to SLA, DLP uses a digital light projector to cure resin. DLP printers are generally faster than SLA, as they cure entire layers at once. This speed advantage is beneficial in disaster situations where rapid production of parts is critical. DLP can be used for similar applications to SLA, including the production of detailed medical devices and custom tools. The ability of desktop 3D printers to quickly produce customized solutions onsite is particularly valuable in disaster scenarios.

3.1.2. Large-Scale 3D Printing Technologies

3.2. Community Engagement and Educational Programs

3.3. Case Studies

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kantaros, A.; Ganetsos, T.; Piromalis, D. 3D and 4D Printing as Integrated Manufacturing Methods of Industry 4.0. Am. J. Eng. Appl. Sci. 2023, 16, 12–22. [Google Scholar] [CrossRef]

- Saripalle, S.; Maker, H.; Bush, A.; Lundman, N. 3D Printing for Disaster Preparedness: Making Life-Saving Supplies On-Site, On-Demand, On-Time. In Proceedings of the 2016 IEEE Global Humanitarian Technology Conference (GHTC), Seattle, WA, USA, 13–16 October 2016; IEEE: New York, NY, USA, 2016. [Google Scholar]

- Tönissen, D.D.; Schlicher, L. Using 3D-Printing in Disaster Response: The Two-Stage Stochastic 3D-Printing Knapsack Problem. Comput. Oper. Res. 2021, 133, 105356. [Google Scholar] [CrossRef]

- Arasteh, H.; Hosseinnezhad, V.; Loia, V.; Tommasetti, A.; Troisi, O.; Shafie-khah, M.; Siano, P. IOT-Based Smart Cities: A Survey. In Proceedings of the 2016 IEEE 16th International Conference on Environment and Electrical Engineering (EEEIC), Florence, Italy, 7–10 June 2016; IEEE: New York, NY, USA, 2016; pp. 1–6. [Google Scholar]

- Talari, S.; Shafie-khah, M.; Siano, P.; Loia, V.; Tommasetti, A.; Catalão, J. A Review of Smart Cities Based on the Internet of Things Concept. Energies 2017, 10, 421. [Google Scholar] [CrossRef]

- Gracias, J.S.; Parnell, G.S.; Specking, E.; Pohl, E.A.; Buchanan, R. Smart Cities—A Structured Literature Review. Smart Cities 2023, 6, 1719–1743. [Google Scholar] [CrossRef]

- Allam, Z.; Newman, P. Redefining the Smart City: Culture, Metabolism and Governance. Smart Cities 2018, 1, 4–25. [Google Scholar] [CrossRef]

- Radu, L.-D. Disruptive Technologies in Smart Cities: A Survey on Current Trends and Challenges. Smart Cities 2020, 3, 1022–1038. [Google Scholar] [CrossRef]

- Visvizi, A.; del Hoyo, R.P. Smart Cities and the UN SDGs; Elsevier: Amsterdam, The Netherlands, 2021; ISBN 9780323859189. [Google Scholar]

- Blasi, S.; Ganzaroli, A.; De Noni, I. Smartening Sustainable Development in Cities: Strengthening the Theoretical Linkage between Smart Cities and SDGs. Sustain. Cities Soc. 2022, 80, 103793. [Google Scholar] [CrossRef]

- Grossi, G.; Trunova, O. Are UN SDGs Useful for Capturing Multiple Values of Smart City? Cities 2021, 114, 103193. [Google Scholar] [CrossRef]

- Hadi, S. Disaster Management in the Implementation of the 2030 Sustainable Development Goals in Indonesia. JISDeP 2020, 1, 105–111. [Google Scholar] [CrossRef]

- Tandon, U.; Kumar, A. Disaster Management and Sustainable Development in the Asia and Pacific Region: Engendering the Strategies of the SDGs. In Disaster Management for 2030 Agenda of the SDG; Springer: Singapore, 2020; pp. 11–32. ISBN 9789811543234. [Google Scholar]

- Chugh, G. Land and Disaster Management for SDGs? In Disaster Management for 2030 Agenda of the SDG; Springer: Singapore, 2020; pp. 77–91. ISBN 9789811543234. [Google Scholar]

- Petrović, N.; Bošnjak, I.; Nedeljković, S. Disaster Risk Reduction for Sustainable Development Goals. Eur. Proj. Manag. J. 2017, 7, 27–35. [Google Scholar]

- Kelman, I. Linking Disaster Risk Reduction, Climate Change, and the Sustainable Development Goals. Disaster Prev. Manag. 2017, 26, 254–258. [Google Scholar] [CrossRef]

- The 17 Goals. Available online: https://sdgs.un.org/goals (accessed on 22 July 2024).

- Chu, K.-D.; Lacaze, A.; Murphy, K.; Mottern, E.; Corley, K.; Frelk, J. 3D Printed Rapid Disaster Response. In Proceedings of the 2015 IEEE International Symposium on Technologies for Homeland Security (HST), Waltham, MA, USA, 14–16 April 2015; IEEE: New York, NY, USA, 2015. [Google Scholar]

- Subramanya, K.; Kermanshachi, S. Exploring Utilization of the 3D Printed Housing as Post-Disaster Temporary Shelter for Displaced People. In Construction Research Congress 2022; American Society of Civil Engineers: Reston, VA, USA, 2022. [Google Scholar]

- Dancel, R.R. 3D Printed House for Disaster- Affected Areas. In Disaster Risk Reduction and Infrastructure Development (DRRID) Forum; De La Salle University: Taft, Manila. [CrossRef]

- Kantaros, A.; Ganetsos, T. Integration of Cyber-Physical Systems, Digital Twins and 3D Printing in Advanced Manufacturing: A Synergistic Approach. Am. J. Eng. Appl. Sci. 2024, 17, 1–22. [Google Scholar] [CrossRef]

- Kantaros, A.; Soulis, E.; Petrescu, F.I.T.; Ganetsos, T. Advanced Composite Materials Utilized in FDM/FFF 3D Printing Manufacturing Processes: The Case of Filled Filaments. Materials 2023, 16, 6210. [Google Scholar] [CrossRef] [PubMed]

- Kantaros, A.; Soulis, E.; Ganetsos, T.; Petrescu, F.I.T. Applying a Combination of Cutting-Edge Industry 4.0 Processes towards Fabricating a Customized Component. Processes 2023, 11, 1385. [Google Scholar] [CrossRef]

- Kantaros, A.; Petrescu, F.; Abdoli, H.; Diegel, O.; Chan, S.; Iliescu, M.; Ganetsos, T.; Munteanu, I.; Ungureanu, L. Additive Manufacturing for Surgical Planning and Education: A Review. Appl. Sci. 2024, 14, 2550. [Google Scholar] [CrossRef]

- Loy, J.; Novak, J.; Diegel, O. 3D Printing for Product Designers: Innovative Strategies Using Additive Manufacturing; Routledge: London, UK, 2023; ISBN 9781003122203. [Google Scholar]

- Agarwal, R. The Personal Protective Equipment Fabricated via 3D Printing Technology during COVID-19. Ann. 3d Print. Med. 2022, 5, 100042. [Google Scholar] [CrossRef]

- Tarfaoui, M.; Nachtane, M.; Goda, I.; Qureshi, Y.; Benyahia, H. 3D Printing to Support the Shortage in Personal Protective Equipment Caused by COVID-19 Pandemic. Materials 2020, 13, 3339. [Google Scholar] [CrossRef]

- Wesemann, C.; Pieralli, S.; Fretwurst, T.; Nold, J.; Nelson, K.; Schmelzeisen, R.; Hellwig, E.; Spies, B.C. 3-D Printed Protective Equipment during COVID-19 Pandemic. Materials 2020, 13, 1997. [Google Scholar] [CrossRef]

- Vordos, N.; Gkika, D.A.; Maliaris, G.; Tilkeridis, K.E.; Antoniou, A.; Bandekas, D.V.; Mitropoulos, C.A. How 3D Printing and Social Media Tackles the PPE Shortage during COVID-19 Pandemic. Saf. Sci. 2020, 130, 104870. [Google Scholar] [CrossRef]

- Kantaros, A.; Laskaris, N.; Piromalis, D.; Ganetsos, T. Manufacturing Zero-Waste COVID-19 Personal Protection Equipment: A Case Study of Utilizing 3D Printing While Employing Waste Material Recycling. Circ. Econ. Sustain. 2021, 1, 851–869. [Google Scholar] [CrossRef]

- Irfan Ul Haq, M.; Khuroo, S.; Raina, A.; Khajuria, S.; Javaid, M.; Farhan Ul Haq, M.; Haleem, A. 3D Printing for Development of Medical Equipment amidst Coronavirus (COVID-19) Pandemic—Review and Advancements. Res. Biomed. Eng. 2022, 38, 305–315. [Google Scholar] [CrossRef]

- Erickson, M.M.; Richardson, E.S.; Hernandez, N.M.; Bobbert, D.W., II; Gall, K.; Fearis, P. Helmet Modification to PPE with 3D Printing during the COVID-19 Pandemic at Duke University Medical Center: A Novel Technique. J. Arthroplast. 2020, 35, S23–S27. [Google Scholar] [CrossRef] [PubMed]

- Tino, R.; Moore, R.; Antoline, S.; Ravi, P.; Wake, N.; Ionita, C.N.; Morris, J.M.; Decker, S.J.; Sheikh, A.; Rybicki, F.J.; et al. COVID-19 and the Role of 3D Printing in Medicine. 3D Print. Med. 2020, 6, 11. [Google Scholar] [CrossRef] [PubMed]

- Oladapo, B.I.; Ismail, S.O.; Afolalu, T.D.; Olawade, D.B.; Zahedi, M. Review on 3D Printing: Fight against COVID-19. Mater. Chem. Phys. 2021, 258, 123943. [Google Scholar] [CrossRef] [PubMed]

- Rendeki, S.; Nagy, B.; Bene, M.; Pentek, A.; Toth, L.; Szanto, Z.; Told, R.; Maroti, P. An Overview on Personal Protective Equipment (PPE) Fabricated with Additive Manufacturing Technologies in the Era of COVID-19 Pandemic. Polymers 2020, 12, 2703. [Google Scholar] [CrossRef]

- Niranjan, Y.C.; Channabasavanna, S.G.; Krishnapillai, S.; Velmurugan, R.; Kannan, A.R.; Mohan, D.G.; Karganroudi, S.S. The Unprecedented Role of 3D Printing Technology in Fighting the COVID-19 Pandemic: A Comprehensive Review. Materials 2022, 15, 6827. [Google Scholar] [CrossRef]

- Salmi, M.; Akmal, J.S.; Pei, E.; Wolff, J.; Jaribion, A.; Khajavi, S.H. 3D Printing in COVID-19: Productivity Estimation of the Most Promising Open Source Solutions in Emergency Situations. Appl. Sci. 2020, 10, 4004. [Google Scholar] [CrossRef]

- Gregory, M.; Hameedaldeen, S.A.; Intumu, L.M.; Spakousky, J.J.; Toms, J.B.; Steenhuis, H.J. 3D Printing and Disaster Shelter Costs. In Proceedings of the 2016 Portland International Conference on Management of Engineering and Technology (PICMET), Honolulu, HI, USA, 4–8 September 2016; IEEE: New York, NY, USA, 2016. [Google Scholar]

- Labuda, I.; Pugliese, F.; Dzwierzynska, J. An Innovative Concept for 3D Sand-Printed Sustainable Refugee Shelters in a Sandy Desert in a Hot and Dry Climate. Sustainability 2024, 16, 2294. [Google Scholar] [CrossRef]

- Almomani, M.A.; Al-Ababneh, N.; Abdalla, K.; Shbeeb, N.I.; Pantouvakis, J.-P.; Lagaros, N.D. Selecting the Best 3D Concrete Printing Technology for Refugee Camp’s Shelter Construction Using Analytical Hierarchy Process: The Case of Syrian Refugees in Jordan. Buildings 2023, 13, 1813. [Google Scholar] [CrossRef]

- Bazli, M.; Ashrafi, H.; Rajabipour, A.; Kutay, C. 3D Printing for Remote Housing: Benefits and Challenges. Autom. Constr. 2023, 148, 104772. [Google Scholar] [CrossRef]

- Sakin, M.; Kiroglu, Y.C. 3D Printing of Buildings: Construction of the Sustainable Houses of the Future by BIM. Energy Procedia 2017, 134, 702–711. [Google Scholar] [CrossRef]

- Bibri, S.E. The Social Shaping of the Metaverse as an Alternative to the Imaginaries of Data-Driven Smart Cities: A Study in Science, Technology, and Society. Smart Cities 2022, 5, 832–874. [Google Scholar] [CrossRef]

- Vones, K.; Allan, D.; Lambert, I.; Vettese, S. 3D-Printing ‘Ocean Plastic’–Fostering Childrens’ Engagement with Sustainability. Mater. Today Commun. 2018, 16, 56–59. [Google Scholar] [CrossRef]

- Clary, K.S.; Dillian, C. Printing the Past. Public Hist. 2021, 43, 41–62. [Google Scholar] [CrossRef]

- Ratto, M.; Ree, R. Materializing Information: 3D Printing and Social Change. First Monday 2012, 17. [Google Scholar] [CrossRef]

- Novak, E.; Brannon, M.; Librea-Carden, M.R.; Haas, A.L. A Systematic Review of Empirical Research on Learning With3Dprinting Technology. J. Comput. Assist. Learn. 2021, 37, 1455–1478. [Google Scholar] [CrossRef]

- Pearson, H.A.; Dubé, A.K. 3D Printing as an Educational Technology: Theoretical Perspectives, Learning Outcomes, and Recommendations for Practice. Educ. Inf. Technol. 2022, 27, 3037–3064. [Google Scholar] [CrossRef]

- Chatzopoulos, A.; Xenakis, A.; Papoutsidakis, M.; Kalovrektis, K.; Kalogiannakis, M.; Psycharis, S. Proposing and Testing an Open-Source and Low-Cost Drone under the Engineering Design Process for Higher Education: The Mechatronics Course Use Case. In Proceedings of the 2024 IEEE Global Engineering Education Conference (EDUCON), Kos Island, Greece, 8–11 May 2024; IEEE: New York, NY, USA, 2024. [Google Scholar]

- Chatzopoulos, A.; Tzerachoglou, A.; Priniotakis, G.; Papoutsidakis, M.; Drosos, C.; Symeonaki, E. Using STEM to Educate Engineers about Sustainability: A Case Study in Mechatronics Teaching and Building a Mobile Robot Using Upcycled and Recycled Materials. Sustainability 2023, 15, 15187. [Google Scholar] [CrossRef]

- Muramatsu, K.; Wangmo, S. Collaborative Design Education Using 3D Printing. In Interdisciplinary and International Perspectives on 3D Printing in Education; IGI Global: Hershey, PE, USA, 2019; pp. 286–305. ISBN 9781522570189. [Google Scholar]

- Özkil, A.G. Collective Design in 3D Printing: A Large Scale Empirical Study of Designs, Designers and Evolution. Des. Stud. 2017, 51, 66–89. [Google Scholar] [CrossRef]

- Kantaros, A.; Diegel, O.; Piromalis, D.; Tsaramirsis, G.; Khadidos, A.O.; Khadidos, A.O.; Khan, F.Q.; Jan, S. 3D Printing: Making an Innovative Technology Widely Accessible through Makerspaces and Outsourced Services. Mater. Today 2022, 49, 2712–2723. [Google Scholar] [CrossRef]

- Fidan, I.; Canfield, S.; Motevalli, V.; Chitiyo, G.; Mohammadizadeh, M. IMakerSpace Best Practices for Shaping the 21st Century Workforce. Technologies 2021, 9, 32. [Google Scholar] [CrossRef]

- Kostakis, V.; Niaros, V.; Dafermos, G.; Bauwens, M. Design Global, Manufacture Local: Exploring the Contours of an Emerging Productive Model. Futures 2015, 73, 126–135. [Google Scholar] [CrossRef]

- Beltagui, A.; Sesis, A.; Stylos, N. A Bricolage Perspective on Democratising Innovation: The Case of 3D Printing in Makerspaces. Technol. Forecast. Soc. Chang. 2021, 163, 120453. [Google Scholar] [CrossRef]

- Fordyce, R.; Heemsbergen, L.; Mignone, P.; Nansen, B. 3d Printing and University Makerspaces: Surveying Countercultural Communities in Institutional Settings. Available online: https://openurl.ebsco.com/EPDB%3Agcd%3A3%3A13947715/detailv2?sid=ebsco%3Aplink%3Ascholar&id=ebsco%3Agcd%3A111280153&crl=c (accessed on 22 July 2024).

- Manero, A.; Smith, P.; Koontz, A.; Dombrowski, M.; Sparkman, J.; Courbin, D.; Chi, A. Leveraging 3D Printing Capacity in Times of Crisis: Recommendations for COVID-19 Distributed Manufacturing for Medical Equipment Rapid Response. Int. J. Environ. Res. Public Health 2020, 17, 4634. [Google Scholar] [CrossRef] [PubMed]

- Wysoczański, A.; Kamyk, Z.; Yvinec, Y. Analysis of the Possibility of Employing 3D Printing Technology in Crisis Situations. Czas. Tech. 2021, 118, 1–11. [Google Scholar] [CrossRef]

- Eid, A.; He, X.; Bahr, R.; Lin, T.-H.; Cui, Y.; Adeyeye, A.; Tehrani, B.; Tentzeris, M.M. Inkjet-/3D-/4D-Printed Perpetual Electronics and Modules: RF and Mm-Wave Devices for 5G+, IoT, Smart Agriculture, and Smart Cities Applications. IEEE Microw. Mag. 2020, 21, 87–103. [Google Scholar] [CrossRef]

- Leelawat, N.; Suppasri, A.; Imamura, F. Disaster Recovery and Reconstruction Following the 2011 Great East Japan Earthquake and Tsunami: A Business Process Management Perspective. Int. J. Disaster Risk Sci. 2015, 6, 310–314. [Google Scholar] [CrossRef][Green Version]

- ISO/ASTM 52900:2015; Additive Manufacturing—General Principles—Terminology. International Standards Organization: Geneva, Switzerland, 2015. Available online: https://www.iso.org/standard/69669.html (accessed on 25 July 2024).

- ISO/ASTM 52910:2018; Additive Manufacturing—Design—Requirements, Guidelines and Recommendations. International Standards Organization: Geneva, Switzerland, 2018. Available online: https://www.iso.org/standard/67289.html (accessed on 25 July 2024).

- ISO 17296-2:2015; Additive Manufacturing—General Principles—Part 2: Overview of Process Categories and Feedstock. International Standards Organization: Geneva, Switzerland, 2015. Available online: https://www.iso.org/standard/61626.html (accessed on 25 July 2024).

- Standard Terminology for Additive Manufacturing—Coordinate Systems and Test Methodologies. Available online: https://www.astm.org/f2921-11.html (accessed on 25 July 2024).

- Twirled Fluted Vase by Pillage_Then_Burn. Available online: https://www.thingiverse.com/thing:3018290 (accessed on 23 July 2024).

- Locally Productive, Globally Connected—Self-Sufficient Cities Fab City Whitepaper. Available online: https://fab.city/wp-content/uploads/2023/03/Fab-City_Whitepaper.pdf (accessed on 25 July 2024).

- Available online: https://amsterdamsmartcity.com/ (accessed on 25 July 2024).

- Industrial and Manufacturing. Available online: https://edc.nyc/industry/industrial-and-manufacturing (accessed on 25 July 2024).

- EEFIT Mission Report: Recovery Two Years after the 2011 Tohoku Earthquake and Tsunami. Available online: https://www.istructe.org/resources/report/eefit-mission-recovery-great-east-japan-earthquake/ (accessed on 25 July 2024).

- Snabes, S. 3D Printing Connectivity in Post-Maria Puerto Rico. Available online: https://re3d.org/3d-printing-connectivity-in-post-maria-puerto-rico/ (accessed on 25 July 2024).

- Snabes, S. 3D Printed Signs Quickly Connecting People after Hurricane Maria. Available online: https://re3d.org/3d-printed-signs-quickly-connecting-people-after-hurricane-maria/ (accessed on 25 July 2024).

- Tatis, C. 3D Printing for Disaster Relief—Loretta C. Duckworth Scholars Studio. Available online: https://sites.temple.edu/tudsc/2017/11/01/3d-printing-for-disaster-relief/ (accessed on 25 July 2024).

- Aydin, A.; Demirtas, Z.; Ok, M.; Erkus, H.; Cebi, G.; Uysal, E.; Gunduz, O.; Ustundag, C.B. 3D Printing in the Battle against COVID-19. Emergent Mater. 2021, 4, 363–386. [Google Scholar] [CrossRef]

- Armijo, P.R.; Markin, N.W.; Nguyen, S.; Ho, D.H.; Horseman, T.S.; Lisco, S.J.; Schiller, A.M. 3D Printing of Face Shields to Meet the Immediate Need for PPE in an Anesthesiology Department during the COVID-19 Pandemic. Am. J. Infect. Control 2021, 49, 302–308. [Google Scholar] [CrossRef]

- Longhitano, G.A.; Nunes, G.B.; Candido, G.; da Silva, J.V.L. The Role of 3D Printing during COVID-19 Pandemic: A Review. Prog. Addit. Manuf. 2021, 6, 19–37. [Google Scholar] [CrossRef]

- Bharti, N.; Singh, S. COVID-19: The Use of 3D Printing to Address PPE Shortage during a Pandemic—A Safety Perspective. J. Chem. Health Saf. 2020, 27, 335–340. [Google Scholar] [CrossRef] [PubMed]

- Flanagan, S.T.; Ballard, D.H. 3D Printed Face Shields: A Community Response to the COVID-19 Global Pandemic. Acad. Radiol. 2020, 27, 905–906. [Google Scholar] [CrossRef] [PubMed]

- Jafferson, J.M.; Pattanashetti, S. Use of 3D Printing in Production of Personal Protective Equipment (PPE)—A Review. Mater. Today 2021, 46, 1247–1260. [Google Scholar] [CrossRef]

- Mueller, T.; Elkaseer, A.; Charles, A.; Fauth, J.; Rabsch, D.; Scholz, A.; Marquardt, C.; Nau, K.; Scholz, S.G. Eight Weeks Later—The Unprecedented Rise of 3D Printing during the COVID-19 Pandemic—A Case Study, Lessons Learned, and Implications on the Future of Global Decentralized Manufacturing. Appl. Sci. 2020, 10, 4135. [Google Scholar] [CrossRef]

- 3D Printing Humanitarian Supplies in the Field. Available online: https://odihpn.org/publication/3d-printing-humanitarian-supplies-in-the-field/ (accessed on 25 July 2024).

- Hong, J.; Baker, M. 3D Printing, Smart Cities, Robots, and More. IEEE Pervasive Comput. 2014, 13, 6–9. [Google Scholar] [CrossRef]

- Sheresheva, M.; Skakovskaya, L.; Bryzgalova, E.; Antonov-Ovseenko, A.; Shitikova, H. The Print Media Convergence: Overall Trends and the COVID-19 Pandemic Impact. J. Risk Fin. Manag. 2021, 14, 364. [Google Scholar] [CrossRef]

- Bici, A.; Yunitsyna, A. Analysis of 3D Printing Techniques for Building Construction: A Review. Constr. Robot. 2023, 7, 107–123. [Google Scholar] [CrossRef]

- ICON Vulcan II 3D Concrete Printer. Available online: https://www.m3design.com/case-study/3d-concrete-printer-design/ (accessed on 25 July 2024).

- Hagen, A.; Chisling, M.; House, K.; Katz, T.; Abelseth, L.; Fraser, I.; Bradley, S.; Kirsch, R.; Morris, J.; Giles, J.W.; et al. 3D Printing for Medical Applications: Current State of the Art and Perspectives during the COVID-19 Crisis. Surgeries 2021, 2, 244–259. [Google Scholar] [CrossRef]

- Pletcher, K.; Rafferty, J.P. Japan Earthquake and Tsunami of 2011. In Encyclopedia Britannica; Encyclopædia Britannica, Inc.: Chicago, IL, USA, 2024. [Google Scholar]

- Kamin, D. Maybe in Your Lifetime, People Will Live on the Moon and Then Mars. NY Times. 2023. Available online: https://www.nytimes.com/2023/10/01/realestate/nasa-homes-moon-3-d-printing.html (accessed on 25 July 2024).

- Palmer, C. 3D Printing Advances on Multiple Fronts. Engineering 2020, 6, 590–592. [Google Scholar] [CrossRef]

- Thajeel, M.M.; Balázs, G.L. 3D Printing for Earth Construction—Review. Concr. Struct. 2022, 23, 64–67. [Google Scholar] [CrossRef]

- Arif Kamal, M. Analyzing the Competency of 3D Printing Technology in Architectural, Interior and Product Design. E3S Web Conf. 2023, 410, 04014. [Google Scholar] [CrossRef]

- Youssef, M.; Abbas, L. Applying 3d Printing Technology in Constructing Sustainable Houses. Archit. Plan. J. (APJ) 2023, 29, 4. [Google Scholar] [CrossRef]

- Moretti, M. WASP in the Edge of 3D Printing. In 3D Printing for Construction with Alternative Materials; Springer International Publishing: Cham, Switzerland, 2023; pp. 57–65. ISBN 9783031093180. [Google Scholar]

- Wilson, T.T.; Mativenga, P.T.; Marnewick, A.L. Sustainability of 3D Printing in Infrastructure Development. Procedia CIRP 2023, 120, 195–200. [Google Scholar] [CrossRef]

- Voorend, C.J.G. 3D Printed Façade Panel. Available online: https://research.tue.nl/en/studentTheses/3d-printed-fa%C3%A7ade-panel (accessed on 25 July 2024).

- Jung, C.; Al Qassimi, N.; Sherzad, M. The Comparative Analysis of 3D Printing Technology Development for Building Construction. Int. J. Adv. Res. Technol. Innov. 2022, 4, 56–67. [Google Scholar]

- Guamán-Rivera, R.; Martínez-Rocamora, A.; García-Alvarado, R.; Muñoz-Sanguinetti, C.; González-Böhme, L.F.; Auat-Cheein, F. Recent Developments and Challenges of 3D-Printed Construction: A Review of Research Fronts. Buildings 2022, 12, 229. [Google Scholar] [CrossRef]

- Ali, M.H.; Issayev, G.; Shehab, E.; Sarfraz, S. A Critical Review of 3D Printing and Digital Manufacturing in Construction Engineering. Rapid Prototyp. J. 2022, 28, 1312–1324. [Google Scholar] [CrossRef]

- Rael, R.; Fratello, V.S. Printing Architecture: Innovative Recipes for 3D Printing; Chronicle Books: San Francisco, CA, USA, 2018; ISBN 9781616897475. [Google Scholar]

- Teixeira, J.; Schaefer, C.O.; Rangel, B.; Maia, L.; Alves, J.L. A Road Map to Find in 3D Printing a New Design Plasticity for Construction—The State of Art. Front. Arch. Res. 2023, 12, 337–360. [Google Scholar] [CrossRef]

- Puppos, A. Printing Clay: Design Optimization for 3d Printing Sustainable and High-Performance Housing. Master’s Thesis, The University of Arizona, Tucson, AZ, USA, 2021. [Google Scholar]

- Lu, Y.W. Evaluation of 3D Printed Construction; University of Wisconsin—Stout: Menomonie, WI, USA, 2023. [Google Scholar]

- Bello, N.D.; Memari, A.M. Comparative Review of the Technology and Case Studies of 3D Concrete Printing of Buildings by Several Companies. Buildings 2022, 13, 106. [Google Scholar] [CrossRef]

- Agnihotri, A.; Bhattacharya, S. 3D-Printed Houses: Is Icon Disrupting the Housing Construction Market? SAGE Publications: London, UK, 2023; ISBN 9781529611540. [Google Scholar]

- Residit s.r.o Mexico Builds the World’s First 3D Printed Community Houses. Available online: http://www.odbornecasopisy.cz/en/post/mexico-builds-the-world-s-first-3d-printed-community-houses--4171 (accessed on 25 July 2024).

- Griffin, M. World’s First 3D Printed Community Unveiled in Mexico. Available online: https://www.311institute.com/worlds-first-3d-printed-community-unveiled-in-mexico/ (accessed on 25 July 2024).

- Robayo-Salazar, R.; Mejía de Gutiérrez, R.; Villaquirán-Caicedo, M.A.; Delvasto Arjona, S. 3D Printing with Cementitious Materials: Challenges and Opportunities for the Construction Sector. Autom. Constr. 2023, 146, 104693. [Google Scholar] [CrossRef]

- Arcos-Novillo, D.A.; Güemes-Castorena, D. Development of an Additive Manufacturing Technology Scenario for Opportunity Identification—The Case of Mexico. Futures 2017, 90, 1–15. [Google Scholar] [CrossRef]

| Applications | Description |

|---|---|

| Medical supplies | During health crises or disasters, there is often an urgent need for medical supplies. Desktop 3D printers can produce items such as face shields, mask components, and even parts for ventilators. The rapid prototyping capabilities of these printers ensure that designs can be greatly improved and tailored to specific needs. |

| Emergency tools and components | Natural disasters frequently damage infrastructure, necessitating quick repairs. Desktop 3D printers can create tools and replacement parts for equipment, helping restore functionality quickly. Items such as wrenches, connectors, and brackets can be printed on demand, reducing downtime and dependency on external supplies. |

| Customization and adaptability | One of the major strengths of desktop 3D printing is its ability to produce customized solutions tailored to specific needs. Whether it is a custom-fit orthopedic brace or a uniquely designed component for a water filtration system, the adaptability of 3D printing ensures that solutions are precisely suited to the requirements of the situation. |

| Feature | Description |

|---|---|

| Speed of construction | In disaster-stricken areas, providing immediate shelter is paramount. Contour crafting can significantly reduce construction time compared to traditional methods. A typical house can be constructed in a matter of days rather than weeks or months. This rapid construction capability is crucial in providing quick relief to displaced populations. |

| Cost-efficiency | Traditional construction methods often involve high labor costs and significant material waste. Contour crafting minimizes these issues by using precise amounts of material and reducing the need for skilled labor. The automation of the building process also ensures consistent quality and reduces the likelihood of human error. |

| Structural integrity and design flexibility | The layers of material extruded by the robotic arm create strong, stable structures that can withstand harsh environmental conditions. Additionally, the flexibility of the technology allows for the construction of complex designs that can be tailored to specific needs, such as integrating disaster-resistant features or optimizing space for community use. |

| Feature | Description |

|---|---|

| Durability and strength | SLS-produced items are renowned for their robustness and durability. This makes them ideal for constructing parts of emergency shelters, temporary infrastructure, and other critical components that need to withstand severe environmental stressors. |

| Material versatility | SLS can utilize a wide range of materials, including pol ymers, metals, and composites. This versatility allows for the production of various essential items, from structural components to complex machinery parts, ensuring that the specific needs of disaster management can be met effectively. |

| Onsite production and flexibility | One of the significant advantages of SLS technology is the ability to produce items onsite, reducing the need for transportation and logistical delays. This is particularly beneficial in remote or inaccessible areas where delivering supplies can be challenging. Onsite production also allows for real-time customization and adjustments based on the evolving needs of the disaster situation. |

| Smart Cities | Description |

|---|---|

| Barcelona, Spain | Barcelona’s Fab City initiative includes a network of makerspaces that are integral to the city’s disaster preparedness strategy. These spaces are equipped with 3D printers and other digital fabrication tools, enabling the local production of emergency supplies and infrastructure components. During the COVID-19 pandemic, these makerspaces played a crucial role in producing PPE and medical equipment, demonstrating their capacity to respond to urgent needs [67]. |

| Amsterdam, Netherlands | Amsterdam has integrated 3D printing into its educational programs and community projects. The city’s makerspaces host regular workshops and training sessions, teaching residents how to use 3D printing technology for various applications. In disaster scenarios, these skills have proven invaluable, with community members able to produce critical items such as water filtration components and temporary housing structures [68]. |

| New York City, USA | New York City has developed a comprehensive approach to integrating 3D printing into its disaster management plans. Through partnerships with local schools, libraries, and community centers, the city offers extensive training programs and access to 3D printing facilities. This widespread availability and knowledge of 3D printing technology have empowered residents to contribute actively to disaster response efforts, from creating customized medical supplies to repairing damaged infrastructure [69]. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kantaros, A.; Petrescu, F.I.T.; Brachos, K.; Ganetsos, T.; Petrescu, N. Leveraging 3D Printing for Resilient Disaster Management in Smart Cities. Smart Cities 2024, 7, 3705-3726. https://doi.org/10.3390/smartcities7060143

Kantaros A, Petrescu FIT, Brachos K, Ganetsos T, Petrescu N. Leveraging 3D Printing for Resilient Disaster Management in Smart Cities. Smart Cities. 2024; 7(6):3705-3726. https://doi.org/10.3390/smartcities7060143

Chicago/Turabian StyleKantaros, Antreas, Florian Ion Tiberiu Petrescu, Konstantinos Brachos, Theodore Ganetsos, and Nicolae Petrescu. 2024. "Leveraging 3D Printing for Resilient Disaster Management in Smart Cities" Smart Cities 7, no. 6: 3705-3726. https://doi.org/10.3390/smartcities7060143

APA StyleKantaros, A., Petrescu, F. I. T., Brachos, K., Ganetsos, T., & Petrescu, N. (2024). Leveraging 3D Printing for Resilient Disaster Management in Smart Cities. Smart Cities, 7(6), 3705-3726. https://doi.org/10.3390/smartcities7060143