Perspectives of Building-Integrated Wind Turbines (BIWTs)

Abstract

:Highlights

- BIWTs are still a technological challenge due to their low efficiency in urban environments, their low capacity factor and their high investment and maintenance costs

- The use of new technologies such as computational fluid dynamics (CFD), 3D printing, artificial intelligence, and advanced materials is accelerating the development of more efficient BIWT.

- BIWTs will remain a niche technology in the coming years.

- Technological advances and regulatory incentives could promote their wider application, especially in coastal areas with favorable wind conditions.

Abstract

1. Introduction

2. Materials and Methods

3. Results

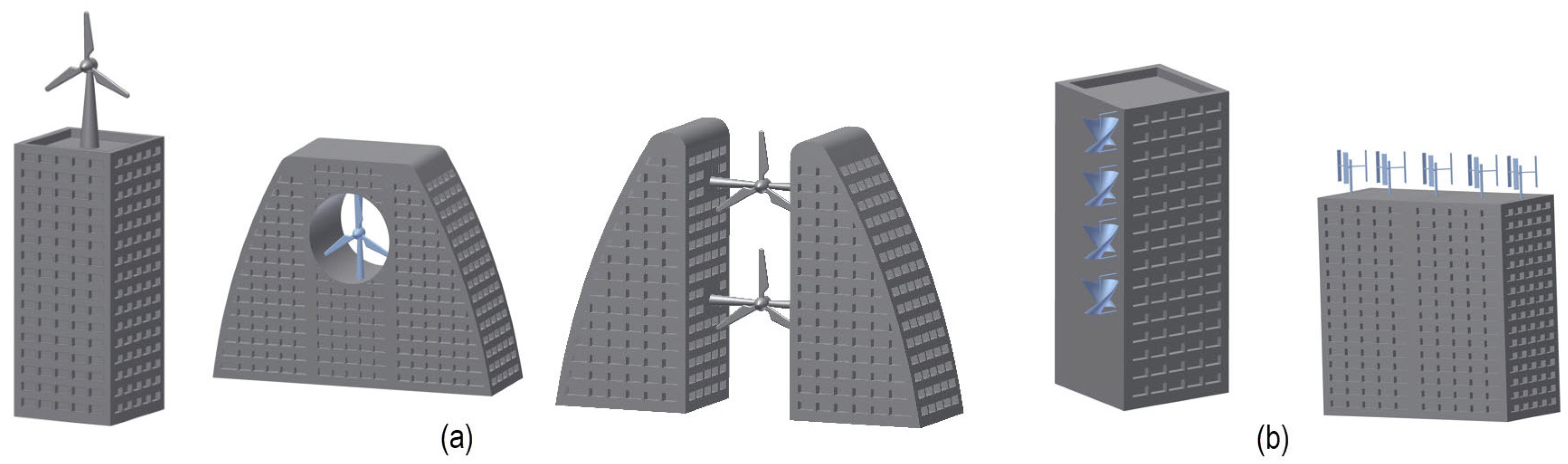

3.1. Distribution and Placement of BIWT Depending on the Installed Capacity

- (a)

- Retrofitting wind turbines on existing buildings. The term building-mounted wind turbines (BMWTs) is also used in the literature.

- (b)

- The complete integration of wind turbines into new buildings together with the architectural form.

- (c)

- The installation of free-standing wind turbines on vacant urban land.

3.2. Economic Profitability

- Feed-in tariffs (FiTs) to encourage the sale of energy to the grid;

- Production Tax Credits (PTCs) to reduce operating costs;

- Investment Tax Credits (ITCs) to support initial investment.

3.3. Security of Application

3.3.1. Structural Integrity

3.3.2. Fracture and Detachment of the Blade

3.3.3. Lightning Strikes

3.3.4. Dangers During Installation and Maintenance

3.4. Impact on People and the Environment

3.4.1. Noise

3.4.2. Flickering Shadow Effect from Turbine Blades

3.4.3. Impact on Biodiversity and Birds

3.5. Maintenance of BIWT

- Routine inspections are carried out every 6–12 months to check lubrication, tightening of screws and wear of parts;

- Predictive maintenance is based on built-in IoT devices (e.g., acoustic sensors), which enables real-time condition monitoring;

- Major overhauls are usually performed every 10–15 years to replace components for moving parts like gearboxes.

3.6. The End of Lifetime

3.6.1. Lifetime Extension

3.6.2. Repowering

3.6.3. Dismantling and Recycling

4. Discussion

4.1. Barriers to Greater Implementation of BIWT

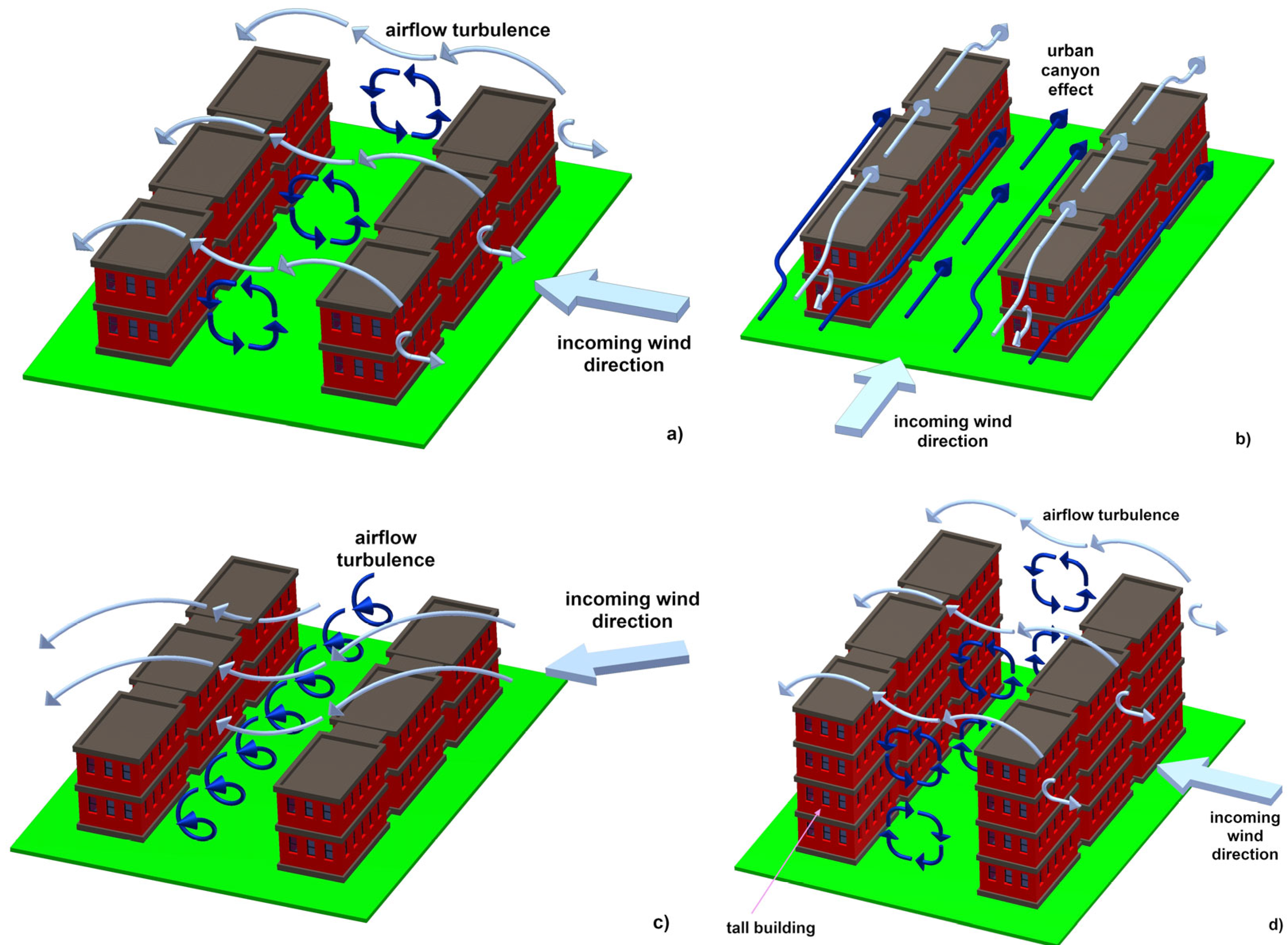

4.1.1. Unpredictable Wind Patterns and Turbulence

4.1.2. The Specific Annual Energy Yield in Urban Environments

- At locations with an average annual wind speed of around 3.7 m/s, the specific annual energy yield reaches up to 118 kWh/m2 rotor area;

- At locations with an average wind speed of around 2.4 m/s, the specific annual energy yield is significantly lower and amounts to 14 to 20 kWh/m2.

4.1.3. Structural Barriers

4.2. Opportunities for Greater Application of BIWT

4.2.1. Progress and Innovation in Technologies

4.2.2. Possibilities to Reduce Costs

4.2.3. Policy and Legal Support

4.2.4. Urbanization and Smart City Trends

4.2.5. Market Demand and Achievement of Green Transition Goals

4.2.6. Esthetic and Architectural Integration

4.2.7. Energy Independence for Rural Areas

4.3. Emerging Technologies with the Potential to Encourage Greater Use of BIWT

4.3.1. Bladeless Vibration Turbines and Vortex Turbines (Vortex Bladeless)

4.3.2. Aerodynamic Optimization Guided by Artificial Intelligence

4.3.3. Advanced Materials and Nanotechnology

4.3.4. Small and Modular Turbines

4.3.5. Magnetic Levitation Bearings

4.3.6. Hybrid Systems Consisting of Wind Farms and Building-Integrated PV Systems

4.3.7. Energy Storage in Structural Components

4.3.8. Integration of Smart Grid and Internet of Things

4.3.9. Three-Dimensional Printed and Customizable Turbines

4.4. Perspectives for BIWTs

4.4.1. Short-Term Perspectives (2025–2030)

4.4.2. Long-Term Perspectives (Beyond 2030)

- Increased demand for renewable energy sources: As part of the global transition to a low-carbon economy, BIWTs can play a role in increasing the share of RES, especially in urban areas where space is limited.

- Technological progress: Technological progress is expected to improve the efficiency and economic justification of BIWT, which would make it more competitive with other renewable energy sources.

- Integration with other technologies: The combination of BIWT with solar energy and energy storage can ensure a more constant flow of electricity and improve the energy security of buildings.

- Economic factors: The high initial installation costs could prevent faster growth in the use of this technology.

- Regulatory framework: The development of clear regulations that support the integration of BIWTs into existing energy systems will be crucial for their diffusion.

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| Abbreviation | Full Meaning |

| 3D | Three-Dimensional |

| AE | Acoustic emission |

| AEP | Annual Energy Production |

| AI | Artificial Intelligence |

| BAWT | Building-Augmented Wind Turbine |

| BIWT | Building-Integrated Wind Turbine |

| BMWT | Building-Mounted Wind Turbine |

| BOS | Balance of System |

| CapEx | Capital Expenditure |

| CFD | Computational Fluid Dynamics |

| CFRP | Carbon fiber reinforced polymers |

| CO2 | Carbon Dioxide |

| Cp | Coefficient of performance |

| EU | European Union |

| FBG | Blade-embedded fiber Bragg grating |

| HAWT | Horizontal-Axis Wind Turbine |

| IoT | Internet of Things |

| ITC | Investment Tax Credit |

| LCOE | Levelized Cost of Electricity |

| LEED | Leadership in Energy and Environmental Design |

| NREL | National Renewable Energy Laboratory |

| nZEB | nearly Zero Energy Building |

| PAGV | Power Augment Guiding Vanes |

| PCM | Phase change materials |

| PV | Photovoltaic |

| RES | Renewable Energy Sources |

| ROI | Return on Investment |

| VAWT | Vertical-Axis Wind Turbine |

| ZEB | Zero Emmision Building |

References

- Sim, G.Y.; Ariff, M.A.M.; Goh, H.H.; Ramli, S.N.; Sim, S.Y.; Chien, S.K. The Impact of the Guide Vane on the BIWT System for the Distributed Wind Generation in the Urban Area. Int. J. Integr. Eng. 2021, 13, 42–52. [Google Scholar] [CrossRef]

- Park, J.; Jung, H.-J.; Lee, S.-W.; Park, J. A New Building-Integrated Wind Turbine System Utilizing the Building. Energies 2015, 8, 11846–11870. [Google Scholar] [CrossRef]

- Smith, R.F.; Killa, S. Bahrain World Trade Center (BWTC): The First Large-Scale Integration of Wind Turbines in a Building. Struct. Des. Tall Spec. Build. 2007, 16, 429–439. [Google Scholar] [CrossRef]

- Li, Q.; Shu, Z.; Chen, F.B. Performance Assessment of Tall Building-Integrated Wind Turbines for Power Generation. Appl. Energy 2016, 165, 777–788. [Google Scholar] [CrossRef]

- Kim, H.-G.; Jeon, W.-H.; Kim, D.-H. Wind Resource Assessment for High-Rise BIWT Using RS-NWP-CFD. Remote Sens. 2016, 8, 1019. [Google Scholar] [CrossRef]

- Bangera, D.N.; Sudhakar, Y.N.; Nazareth, R.A. Concrete-Based Energy Storage: Exploring Electrode and Electrolyte Enhancements. RSC Adv. 2024, 14, 28854–28880. [Google Scholar] [CrossRef] [PubMed]

- Han, D.; Huang, S.; Abia Hui, P.K.; Chen, Y. Development of a New Type of Vortex Bladeless Wind Turbine for Urban Energy Systems. In Proceedings of the 2024 9th International Conference on Power and Renewable Energy, Guangzhou, China, 20–23 September 2024; pp. 973–978. [Google Scholar] [CrossRef]

- Rodriguez, C.V.; Ríos, A.; Luyo, J.E. CFD Design of Urban Wind Turbines: A Review and Critical Analysis. Int. J. Renew. Energy Res. 2021, 11, 618–638. [Google Scholar] [CrossRef]

- Mao, Z.; Yang, G.; Zhang, T.; Tian, W. Aerodynamic Performance Analysis of a Building-Integrated Savonius Turbine. Energies 2020, 13, 2636. [Google Scholar] [CrossRef]

- Calautit, K.; Johnstone, C. State-of-the-Art Review of Micro to Small-Scale Wind Energy Harvesting Technologies for Building Integration. Energy Convers. Manag. X 2023, 20, 100457. [Google Scholar] [CrossRef]

- Huang, C.; Liu, C.; Zhong, M.; Sun, H.; Gao, T.; Zhang, Y. Research on Wind Turbine Location and Wind Energy Resource Evaluation Methodology in Port Scenarios. Sustainability 2024, 16, 1074. [Google Scholar] [CrossRef]

- Alam, F.; Jin, Y. The Utilisation of Small Wind Turbines in Built-Up Areas: Prospects and Challenges. Wind 2023, 3, 418–438. [Google Scholar] [CrossRef]

- Zagubień, A.; Wolniewicz, K. Energy Efficiency of Small Wind Turbines in an Urbanized Area—Case Studies. Energies 2022, 15, 5287. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, X.; Zhao, D.; Post, S.; Chen, J. Overview of the Development and Application of Wind Energy in New Zealand. Energy Built Environ. 2023, 4, 725–742. [Google Scholar] [CrossRef]

- Kwok, K.C.S.; Hu, G. Wind Energy System for Buildings in an Urban Environment. J. Wind Eng. Ind. Aerodyn. 2023, 234, 105349. [Google Scholar] [CrossRef]

- Ding, S.; Yang, C.; Zhang, S. Acoustic-Signal-Based Damage Detection of Wind Turbine Blades—A Review. Sensors 2023, 23, 4987. [Google Scholar] [CrossRef]

- Le, A.D.; Doan, V.H.; Thi Thu, P.N.; Tran, H.T.; Truong, V.A.; Do Van, M.; Nguyen, D.D.; Banh, M.D. Performance Assessment of Savonius Wind Turbine: Impact of the Cylindrical Deflectors with Natural Shapes. Ocean Eng. 2025, 315, 119900. [Google Scholar] [CrossRef]

- Alanis Ruiz, C.; Kalkman, I.; Blocken, B. Aerodynamic Design Optimization of Ducted Openings through High-Rise Buildings for Wind Energy Harvesting. Build. Environ. 2021, 202, 108028. [Google Scholar] [CrossRef]

- Li, D.; Li, C.; Zhang, W.; Zhu, H. Effect of Building Diffusers on Aerodynamic Performance for Building Augmented Vertical Axis Wind Turbine. J. Renew. Sustain. Energy 2021, 13, 23306. [Google Scholar] [CrossRef]

- Zhang, S.; Du, B.; Ge, M.; Zuo, Y. Study on the Operation of Small Rooftop Wind Turbines and Its Effect on the Wind Environment in Blocks. Renew. Energy 2022, 183, 708–718. [Google Scholar] [CrossRef]

- Garcia, O.; Ulazia, A.; del Rio, M.; Carreno-Madinabeitia, S.; Gonzalez-Arceo, A. An Energy Potential Estimation Methodology and Novel Prototype Design for Building-Integrated Wind Turbines. Energies 2019, 12, 2027. [Google Scholar] [CrossRef]

- Stathopoulos, T.; Alrawashdeh, H. Urban Wind Energy: A Wind Engineering and Wind Energy Cross-Roads. In Proceedings of the XV Conference of the Italian Association for Wind Engineering; Ricciardelli, F., Avossa, A.M., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 3–16. [Google Scholar]

- IEC 61400-2:2013; International Electrotechnical Commission Wind Turbines—Part 2: Small Wind Turbines 2013. International Electrotechnical Commission: Geneva, Switzerland, 2013.

- Zhou, H.; Wu, Q.; Nan, D. Analysis of Feasibility on Integration of High-Rise Building and Wind Power. In Proceedings of the 18th International Symposium on Advancement of Construction Management and Real Estate; Yang, D., Qian, Y., Eds.; Springer: Berlin/Heidelberg, Germany, 2014; pp. 91–101. [Google Scholar]

- Stehly, T.; Beiter, P.; Duffy, P. 2020 Cost of Wind Energy Review; National Renewable Energy Laboratory: Golden, CO, USA, 2022.

- Bošnjaković, M.; Martinović, M.; Đokić, K. Application of Artificial Intelligence in Wind Power Systems. Appl. Sci. 2025, 15, 2443. [Google Scholar] [CrossRef]

- The International Finance Corporation (IFC). Environmental, Health, and Safety Guidelines Wind Energy Environmental, Health, and Safety Guidelines for Wind Energy; The International Finance Corporation: Washington, DC, USA, 2015. [Google Scholar]

- Awada, A.; Younes, R.; Ilinca, A. Review of Vibration Control Methods for Wind Turbines. Energies 2021, 14, 3058. [Google Scholar] [CrossRef]

- Lecheb, S.; Chellil, A.; Mechakra, H.; Safi, B.; Beggah, Y.; Lounici, Y. Material Fracture of Dynamic VAWT Blade. In Proceedings of the Third International Symposium on Materials and Sustainable Development; Abdelbaki, B., Safi, B., Saidi, M., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 189–196. [Google Scholar]

- Wu, X.; Feng, K.; Li, Q. A Numerical Method for the Dynamics Analysis of Blade Fracture Faults in Wind Turbines Using Geometrically Exact Beam Theory and Its Validation. Energies 2024, 17, 824. [Google Scholar] [CrossRef]

- Yun, F.; Liu, J.; Liu, C.; Zhao, X. Analysis and Research on the Cause of Wind Turbine Blade Bolt Fracture. J. Phys. Conf. Ser. 2021, 2133, 012028. [Google Scholar] [CrossRef]

- Chen, X.; Eder, M.A. A Critical Review of Damage and Failure of Composite Wind Turbine Blade Structures. IOP Conf. Ser. Mater. Sci. Eng. 2020, 942, 12001. [Google Scholar] [CrossRef]

- Howard, J. Netting for Construction: Keeping Debris and Dust Contained. Available online: https://www.borisnets.co.uk/netting-for-construction-keeping-debris-and-dust-contained/ (accessed on 15 January 2025).

- Karadag, I.; Kuruçay, E. Noise Emission from Building Integrated Wind Turbines: A Case Study of a Tall Building. Sak. Univ. J. Sci. 2021, 25, 563–570. [Google Scholar] [CrossRef]

- de Santoli, L.; Albo, A.; Astiaso Garcia, D.; Bruschi, D.; Cumo, F. A Preliminary Energy and Environmental Assessment of a Micro Wind Turbine Prototype in Natural Protected Areas. Sustain. Energy Technol. Assess. 2014, 8, 42–56. [Google Scholar] [CrossRef]

- Bošnjaković, M.; Hrkać, F.; Stoić, M.; Hradovi, I. Environmental Impact of Wind Farms. Environments 2024, 11, 257. [Google Scholar] [CrossRef]

- Wei, L.; An, G. Optimization of Building Integrated Energy Scheduling Using an Improved Genetic Whale Algorithm. Sci. Rep. 2024, 14, 2386. [Google Scholar] [CrossRef]

- Schuh, P.; Schneider, D.; Funke, L.; Tracht, K. Cost-Optimal Spare Parts Inventory Planning for Wind Energy Systems. Logist. Res. 2015, 8, 4. [Google Scholar] [CrossRef]

- Katsaprakakis, D.A.; Papadakis, N.; Ntintakis, I. A Comprehensive Analysis of Wind Turbine Blade Damage. Energies 2021, 14, 5974. [Google Scholar] [CrossRef]

- Florescu, A.; Barabas, S.; Dobrescu, T. Research on Increasing the Performance of Wind Power Plants for Sustainable Development. Sustainability 2019, 11, 1266. [Google Scholar] [CrossRef]

- Stewart, S.W. The Challenges Involved in Building Integrated Wind Energy Include Wind Flow, Structure Siting, Unit Certification, and Aesthetics, Wind Systems Magazine. Available online: https://www.windsystemsmag.com/technology-21/ (accessed on 15 January 2025).

- Castellani, F.; Natili, F.; Astolfi, D.; Hirschl, A.; Peppoloni, M. Vibration Damping of a Vertical Axis Wind Turbine in Operating Conditions. J. Phys. Conf. Ser. 2022, 2265, 042081. [Google Scholar] [CrossRef]

- Fields, J.; Oteri, F.; Preus, R.; Baring-Gould, I. Deployment of Wind Turbines in the Built Environment: Risks, Lessons, and Recommended Practices. Natl. Renew. Energy Lab. 2016, 46, 1260340. [Google Scholar]

- Kumar, N.; Prakash, O. Analysis of Wind Energy Resources from High Rise Building for Micro Wind Turbine: A Review. Wind Eng. 2023, 47, 190–219. [Google Scholar] [CrossRef]

- IEA PVPS Task 15: Enabling Framework for the Acceleration of BIPV; IEA PVPS: Paris, France, 2018; ISBN 9783907281369.

- Garcia Hernandez, O.; Mario, R.; Ulazia, A.; Osa, J.; Ibarra-Berastegi, G. ROSEO: Novel Savonious-Type BIWT Design Based on the Concentration of Horizontal and Vertical Circulation of Wind on the Edge of Buildings. In Proceedings of the 8th International Conference on Smart Cities and Green ICT Systems (SMARTGREENS 2019), Dublin, Greece, 3–5 May 2019; pp. 172–178. [Google Scholar]

- Wenxin, W.; Kexin, C.; Yang, B.; Yun, X.; Jianwen, W. Influence of Wind Energy Utilization Potential in Urban Suburbs: A Case Study of Hohhot. Sci. Rep. 2021, 11, 11567. [Google Scholar] [CrossRef]

- Available online: https://www.consilium.europa.eu/en/policies/european-green-deal/ (accessed on 15 January 2025).

- Kolawole, A.; Hassan, K.; Ajewole, T. Micro-Grid Wind Energy Conversion Systems: Conventional and Modern Embedded Technologies—A Review. J. Digit. Food Energy Water Syst. 2024, 5, 1–16. [Google Scholar] [CrossRef]

- Rouhani, A.; Abasi, M.; Joorabian, M.; Davatgaran, V. Designing a Novel Optimal Energy Management to Determine the Contribution and Effect of Primary Sources on the Structure and Components Size of Smart Microgrids and Smart Buildings. In Proceedings of the 2024 9th International Conference on Technology and Energy Management, Mazandaran, Iran, 14–15 February 2024. [Google Scholar]

- Serero, D.; Couton, L.; Parisse, J.D.; Le Roy, R. Design Methodology and Evaluation of Wind Harvesting Devices Integrated to Buildings Conference on Advanced Building Skins. In Proceedings of the Advanced Building Skins International Conference, Bern, Switzerland, 10–11 October 2016. [Google Scholar]

- Bobrova, D. Building-Integrated Wind Turbines in the Aspect of Architectural Shaping. Procedia Eng. 2015, 117, 404–410. [Google Scholar] [CrossRef]

- Wood, D. Small Wind Turbines for Remote Power and Distributed Generation. Wind Eng. 2010, 34, 241–254. [Google Scholar] [CrossRef]

- Eldawy, R. A State-of-the-Art Review on Vortex Induced Vibrations Phenomenon Bladeless Wind Turbine Technology. J. Sci. Res. Rep. 2024, 30, 1045–1056. [Google Scholar] [CrossRef]

- Nord-Lock Group. Good Vibrations: Innovating Small-Scale Wind “Turbines”. Available online: https://www.nord-lock.com/learnings/knowledge/2022/bladeless-wind-turbine/ (accessed on 15 January 2025).

- Consultants, U. Bladeless Turbines: What Are They and How Do They Work? Available online: https://www.utmconsultants.com/news/bladeless-turbines-what-are-they-and-how-do-they-work/42157/ (accessed on 27 February 2025).

- Graciano, D.M.; Sierra-espinosa, F.Z.; García, J.C. Numerical Simulation of Vortex-Induced Vibration in a Bladeless Turbine: Effects of Separation Distance between Tandem Harvesters. Metascience Aerosp. 2024, 1, 309–328. [Google Scholar] [CrossRef]

- University of Birmingham. The Birmingham Blade: The World’s First Geographically Tailored Urban Wind Turbine Designed by AI. Available online: https://www.birmingham.ac.uk/news/2024/the-birmingham-blade-the-worlds-first-geographically-tailored-urban-wind-turbine-designed-by-ai (accessed on 27 February 2025).

- Juan, Y.-H.; Rezaeiha, A.; Montazeri, H.; Blocken, B.; Yang, A.-S. Improvement of Wind Energy Potential through Building Corner Modifications in Compact Urban Areas. J. Wind Eng. Ind. Aerodyn. 2024, 248, 105710. [Google Scholar] [CrossRef]

- Teng, H.; Li, S.; Cao, Z.; Li, S.; Li, C.; Ko, T.J. Carbon Fiber Composites for Large-Scale Wind Turbine Blades: Applicability Study and Comprehensive Evaluation in China. J. Mar. Sci. Eng. 2023, 11, 624. [Google Scholar] [CrossRef]

- Mishnaevsky, L.; Branner, K.; Petersen, H.N.; Beauson, J.; McGugan, M.; Sørensen, B.F. Materials for Wind Turbine Blades: An Overview. Materials 2017, 10, 1285. [Google Scholar] [CrossRef] [PubMed]

- Kapil, A.; Raju, N.S.; Dharmaraju, D.; Sateesh, D.N. Design and Specific Strength Analysis of Carbon Fiber-Reinforced Thermoplastic Wind Turbine Blade Using Fem Method. Int. J. Creat. Res. Thoughts 2024, 12, 794–801. [Google Scholar]

- Wind Power: What Are the Challenges and How Can Graphene Meet Them? Available online: https://www.carbon-waters.com/en/wind-power-what-are-the-challenges-and-how-can-graphene-meet-them/ (accessed on 17 February 2025).

- Maity, S.K.; Tyagi, U.; Kumar, R.; Kumar, K.; Sheoran, N.; Singh, S.; Kumar, G. Graphene-Enhanced Polymer Composites: A State-of-the-Art Perspective on Applications. FlatChem 2025, 49, 100797. [Google Scholar] [CrossRef]

- Gesellschaft, F.; Der, Z.U.R.F.; Forschung, A. Wind Blade Using Cost-Effective Advanced Composite Lightweight Design Final Report Summary—WALID (Wind Blade Using Cost-Effective Advanced Composite Lightweight Design). 2024, pp. 1–16. Available online: https://cordis.europa.eu/project/id/309985/reporting (accessed on 15 January 2025).

- The Climate Technology Centre and Network (CTCN). Building-Integrated Wind Turbines. Available online: https://www.ctc-n.org/technologies/building-integrated-wind-turbines (accessed on 17 February 2025).

- Yavuz, H. Hybrid Composites for Very Large Lightweight Wind Turbine Blades: Structural and Materials Aspects. In Advanced Composites in Aerospace Engineering Applications; Mazlan, N., Sapuan, S.M., Ilyas, R.A., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 421–433. ISBN 978-3-030-88192-4. [Google Scholar]

- Halli, S.K.; Meti, N.G.; Hittalamani, S.J.; Dandinavar, M.M.; Reddy, A.S. International Journal of Current Engineering and Technology Design and Development of Low Friction More Efficient Magnetically Levitated Wind Turbines. Int. J. Curr. Eng. Technol. 2017, 7, 907–914. [Google Scholar]

- Lalit Uttamrao, N.; Ajinkya Uttamrao, C.; Kiran Bhausaheb, D.; Jitendra Shravan, D. Review Paper on Maglev Vertical Axis Wind Turbine. Int. J. Creat. Res. Thoughts 2018, 6, 442. [Google Scholar]

- Azad, D.D.; Sai, D.S.; Ramakrishna, K.; Raviteja, P.; Gowtham, K.; Kumar, R.K. Performance of Wind Turbine with Magnetic Levitation. Int. J. Res. Appl. Sci. Eng. Technol. 2023, 11, 2627–2632. [Google Scholar] [CrossRef]

- Navaneethakrishnan, P.L.; Ramesh Kumar, K.V.; Karthikeyan, V.; Deepakkumar, C.; Nandhakumar, T. An Experimental Investigation on Magnetically Levitated Vertical Axis Wind Mill: A Review. J. Res. 2019, 4, 1–4. [Google Scholar]

- Muhammad, N.; Hosnan, A.M.; Anuar, K.; Nor, M.; Ahmad, N.I.; Mokhtaruddin, H.; Hidayah, D.; Rahman, A.; Saad, S.S.; Zakariya, M.Z.; et al. Development of Vertical Axis Wind Turbine (VAWT) Using Magnetic Levitation (MAGLEV). J. Adv. Res. Eng. Knowl. J. Homepage 2020, 10, 23–35. [Google Scholar]

- Manoj, L.; Nithesh, J.; Manjunath, T.; Gowreesh, S.S. Power Generation Using Magnetic Levitation Vertical Axis Wind Turbine. Int. J. Eng. Adv. Technol. 2019, 9, 365–369. [Google Scholar] [CrossRef]

- Liu, S.; Bian, Z.; Cheng, Z. The Application of the Permanent Magnet Bearings in the Vertical Axis Wind Turbine 2 The Structure Design of the Permanent Magnetic Axial Bearing in the Wind Turbine. pp. 1–6. Available online: https://www.magneticbearings.org/app/uploads/publications/ismb13/ismb13_submission_48.pdf (accessed on 15 January 2025).

- Al-Talib, A.A.M.; Md Redzuan, M.R.; Hamid, A.R.A. A Levitating Frictionless_Vertical Windmill. In Proceedings of the 2022 International Conference on Artificial Life and Robotics, Oita, Japan, 20–23 January 2022; pp. 892–899. [Google Scholar] [CrossRef]

- Lee, J.; Park, J.; Jung, H.-J.; Park, J. Renewable Energy Potential by the Application of a Building Integrated Photovoltaic and Wind Turbine System in Global Urban Areas. Energies 2017, 10, 2158. [Google Scholar] [CrossRef]

- WindStream Technologies: Tehnical Manual. Available online: https://d1io3yog0oux5.cloudfront.net/windstreaminc/files/pages/resources/technical-support/SolarMill+Tech+Manual+(Updated).pdf (accessed on 15 January 2025).

- Odukomaiya, A.; Woods, J.; James, N.; Kaur, S.; Gluesenkamp, K.R.; Kumar, N.; Mumme, S.; Jackson, R.; Prasher, R. Addressing Energy Storage Needs at Lower Cost via On-Site Thermal Energy Storage in Buildings. Energy Environ. Sci. 2021, 14, 5315–5329. [Google Scholar] [CrossRef]

- Choorikat, A.; Pazhamannil, R.; Alkhedher, M.; Kumar, P. Experimental and CFD Performance Analysis of 3D Printed Seashell Type Wind Turbine. Prog. Addit. Manuf. 2025, 10, 1–12. [Google Scholar] [CrossRef]

- Zarzoor, A.; Jaber, A.; Shandookh, A. 3D Printing for Wind Turbine Blade Manufacturing: A Review of Materials, Design Optimization, and Challenges. Eng. Technol. J. 2024, 42, 895–911. [Google Scholar] [CrossRef]

| Building Type | Description |

|---|---|

| Tall Skyscrapers | BIWTs are often integrated into tall buildings, e.g., skyscrapers several hundred meters high, in order to make efficient use of wind energy, which increases with height. |

| Commercial Complexes | Large commercial buildings use BIWT to reduce energy costs and increase sustainability. The turbines can be placed on the roof or integrated into the building envelope. |

| Educational Institutions | Universities and other schools are increasingly using BIWT for educational purposes and to demonstrate their commitment to renewable energy. The Viikki Environment House in Finland is one such example. |

| Mixed-Use buildings | BIWTs can be integrated into mixed-use complexes that combine residential, commercial and public spaces. This approach not only increases energy efficiency but also promotes the use of renewable energy. |

| Rooftop Installations | BIWTs of smaller capacity and size can be installed on the roofs of various buildings, including warehouses and factories, to generate electricity on site without the need to acquire and occupy additional land. |

| Local government buildings | Local government buildings can incorporate BIWT as part of their sustainability initiatives to provide renewable energy for local needs and activities while exploring “green energy”. |

| Author(s) | Aim | Main Results | Ref. |

|---|---|---|---|

| Christian V. Rodriguez Alberto Ríos, Jaime E. Luyo (2020) | This article critically examines and analyzes recent advances in the field of CFD design of BIWTs. | In terms of CFD modeling, the standard k–ε turbulence model has been most commonly used. Simulation of BIWT has evolved from 2D to 3D analyzes that include more details on modeling BIWT and urban environments. | [8] |

| Mao et al. (2021) | The aim of the research is to estimate the efficiency of a Savonius wind turbine installed on the edges of a tall building using transient 2D CFD methods. | The wind angle has a considerable influence on the power output of a Savonious turbine. The average Cp value of the turbine at a wind angle of 360° is 0.4256, which is 92.5% higher than that of a turbine with a steady flow. | [9] |

| Calautit, K (2023) | The research objective is to assess the status, challenges and limitations of BIWT and micro or small wind vibration technologies in order to improve their performance, efficiency, reliability and cost-effectiveness. | The authors emphasize how important it is to take advantage of the acceleration of wind speed caused by the shape of the building roof when using wind energy technologies. | [10] |

| Huang, C.; et al. (2024) | The aim is to evaluate methods for determining the location of wind turbines and assessing resources. | Development of methods to optimize the placement of turbines in port and city scenarios. | [11] |

| Alam, F. et al. (2023) | The main objective of this study is to analyze the limitations of using wind energy through small wind turbines to generate electricity in built-up areas for residential and commercial purposes. | The design of current small wind turbines needs to be modified to take advantage of the aerodynamic benefits of the local wind profile in built-up areas. | [12] |

| Zagubień, A. et al. (2022) | The aim of this study was to determine whether the wind zone that characterizes a particular area in open space is reflected in the built-up area that lies within the zone | It has been shown that the planning of small wind turbines in urban areas requires data on the annual measurement of wind characteristics at the location and height of each planned turbine. | [13] |

| Zhang et al. (2023) | This article analyzes the feasibility of using small wind turbines for private households in New Zealand cities with regard to their construction and operation. | It has been shown that small wind turbines for households have considerable potential for generating electricity and bring economic benefits in the long term. | [14] |

| Kwok, KCS (2023) | This article analyzes a perspective for wind energy research based on the aerodynamics of buildings and cities. | An overview of current developments in wind energy systems in the built environment is given. | [15] |

| Ding, TJ (2022) | This overview aims to capture the fact that recent advances in wind energy systems can bring tangible benefits to the entire renewable energy industry. | This study provides readers with a knowledge platform to explore possible methods of utilizing urban wind profiles with minimal vibration, noise and space requirements. | [16] |

| Anh Dinh Lee et al. (2025) | In this study, the effects of novel cylindrical deflector systems on the aerodynamic performance of the Savonius turbine are investigated numerically. | The analysis has shown that the existing natural obstacle shapes can be effectively used as deflectors to improve the aerodynamic performance of the Savonius wind turbine. | [17] |

| Ruiz, Claudio Alanis et al. (2021) | The aim of the work is to investigate the aerodynamic advantages of ventilation openings in buildings and the possibilities of their use for wind energy utilization. | A CFD analysis of the dimensions of the openings in the building was carried out in order to make the best possible use of wind energy. | [18] |

| Dongxu Li et al. (2021) | The aim of the work is to investigate the aerodynamic performance of the BA-VAWT with different diffuser parameters by numerical simulation. | The results show that diffusers have a major influence on the aerodynamic performance of the BA-VAWT. The trapezoidal diffuser is the most efficient with a power coefficient of 1.56 and an optimum tip speed ratio of 4.62. | [19] |

| Shuaibin Zhang (2022) | The aim of the study is to understand the wind resources of a neighborhood, the operation of small rooftop turbines and their impact on wind conditions in the neighborhood. | We note that the flow over the urban area shows a clear acceleration due to the displacement effect of the urban area and the turbulence intensity increases drastically. | [20] |

| Garcia, O et al. (2019) | The study examines ROSEO-BIWT, a new building-integrated wind turbine (BIWT) intended for installation on the edge of buildings. | According to the results, an increase in wind speed by a factor of three would lead to an increase in working hours at rated power due to the edge effect and concentration plumes, which means more than 2000 h per year. | [21] |

| Class | Subclass | Rotor Diameter (m) | Swept Area (m2) | Power Rating (kW) | |||

|---|---|---|---|---|---|---|---|

| From | To | From | To | From | To | ||

| Small-scale | Micro | 0.50 | 1.25 | 0.2 | 1.2 | 0.01 | 0.40 |

| Mini | 1.25 | 3 | 1.2 | 7.1 | 0.40 | 2.5 | |

| Medium | 3 | 16 | 7 | 200 | 2.5 | 50 | |

| Commercial | Small | 16 | 25 | 200 | 490 | 50 | 100 |

| Medium | 25 | 50 | 490 | 1962 | 100 | 1000 | |

| Large | 50 | 310 | 1962 | 75,400 | 1000 | 20,000 | |

| Land-Based | Offshore | Distributed (Single Turbine) | |||||

|---|---|---|---|---|---|---|---|

| Parameter | Units | Utility Scale | Fixed Bottom | Floating | Residential | Commercial | Large |

| Wind turbine rating | MW | 3.3 | 12 | 12 | 0.020 | 0.10 | 1.5 |

| Capital expenditures (CapEx) | $/kW | 1968 | 5411 | 7349 | 8665 | 6800 | 3362 |

| Operational expenditures (OpEx) | $/kW/yг | 43 | 135 | 108 | 41 | 41 | 41 |

| Net annual energy production | MWh/MW/yг | 4104 | 4295 | 3346 | 2580 | 2846 | 3326 |

| Levelized cost of energy (LCOE) | $/MWh | 42 | 117 | 181 | 240 | 174 | 80 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bošnjaković, M.; Veljić, N.; Hradovi, I. Perspectives of Building-Integrated Wind Turbines (BIWTs). Smart Cities 2025, 8, 55. https://doi.org/10.3390/smartcities8020055

Bošnjaković M, Veljić N, Hradovi I. Perspectives of Building-Integrated Wind Turbines (BIWTs). Smart Cities. 2025; 8(2):55. https://doi.org/10.3390/smartcities8020055

Chicago/Turabian StyleBošnjaković, Mladen, Nataša Veljić, and Ivan Hradovi. 2025. "Perspectives of Building-Integrated Wind Turbines (BIWTs)" Smart Cities 8, no. 2: 55. https://doi.org/10.3390/smartcities8020055

APA StyleBošnjaković, M., Veljić, N., & Hradovi, I. (2025). Perspectives of Building-Integrated Wind Turbines (BIWTs). Smart Cities, 8(2), 55. https://doi.org/10.3390/smartcities8020055