Distribution of Airflow and Media Moisture Content across Two Vertical Bed Biofilters

Abstract

:1. Introduction

2. Materials and Methods

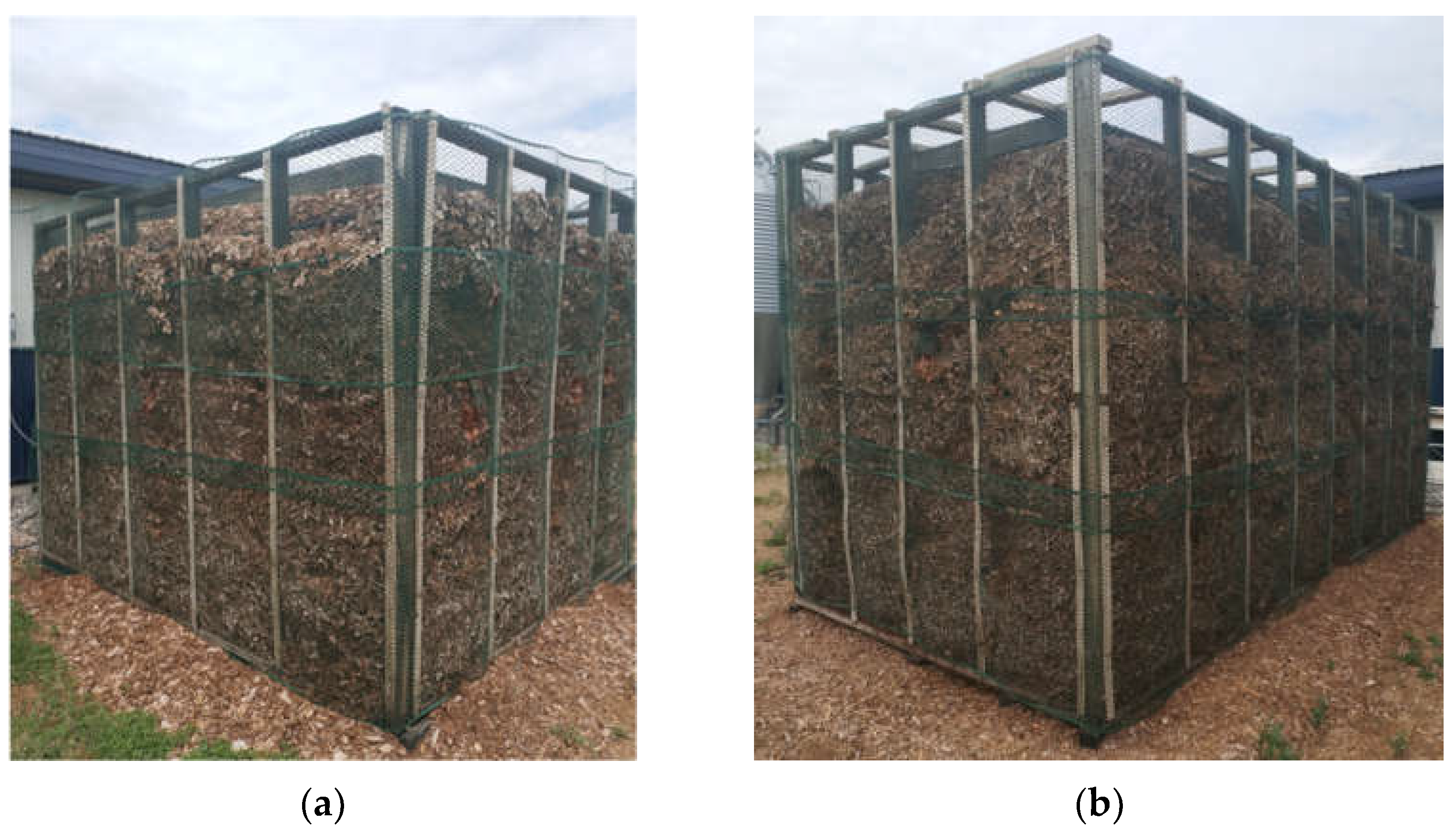

2.1. Biofilters

2.2. Air Velocity Measurement

2.3. Moisture Content Measurement

2.4. Field Monitoring and Data Analysis

3. Results and Discussion

3.1. Summary of Field Monitoring Results

3.2. Side Differences

3.3. Row Differences

3.4. Uniformity of Distribution

3.5. Others

3.6. Reasons for Non-Uniformity and Recommendations

- Solar radiation. Solar-induced water evaporation can reduce the moisture level in a biofilter. For vertical bed biofilters, the amount of solar radiation received varies with side orientation, season, and weather.

- Poorly controlled and adjusted watering systems. Watering timers can only control the watering duration but not flowrates. The flowrate is affected by water pressure in the pipeline. Thus, a watering system is problematic when sharing the same waterline with other farm apparatus (e.g., waterers). Watering system adjustment in this study was done based on visual inspection of biofilter conditions (e.g., woodchip wetness and ground flooding). This could cause a large uncertainty in watering rates.

- Cementing. Cementing can substantially restrict airflow. No dust concentration measurement was done in this study. Assuming an average dust concentration of 1 mg/m3 in the pit air [24], monthly dust loading would be 8.7 kg to BF#1 and 11.0 kg to BF#2 (estimated from the treated airflow rate). The inner air plenum in a vertical bed biofilter has a relatively small contact area to the exhaust air. As a result, the cementing issue could be more pronounced for vertical than horizontal biofilters (that usually have the same contact area on the inlet and outlet sides).

- Freezing. Freezing may initially develop on exceptionally cold days in winter. When it occurs, it restricts warm airflows from the barn exhaust. This in turn worsens the issue of freezing, leading to the further development of frozen spots.

- Netting attachment. The gravitational setting of woodchips is hindered by nets or meshes. It, along with the decay of woodchips, can result in void spaces and short airflows in a filtration wall after long-term operation. In this study, the issue was observed near the woodchip sampling points. After every sampling, mechanical tools were used to ensure the settling of woodchips.

- For cubic biofilters, the air plenum should be elongated along the incoming air direction to improve the airflow uniformity. Use the same filtration bed thickness. No tapered filtration wall design is necessary.

- Use a circular vertical bed biofilter design to improve the uniformity of filtration bed thickness. The thicker filtration medium at the corner of cubic biofilters is unideal from the airflow distribution standpoint.

- Use a separate waterline for biofilters if possible. Apply a higher watering rate for biofilter sides or sections that receive significant sunshine—the suggestion also applies to horizontal biofilters.

- Clean the air plenum monthly to remove dust, thereby reducing the chance of cementing. Mechanically agitate the wires or nets monthly to facilitate the medium settling.

- Use a chisel to break the freezing spot to prevent the further development of freezing if winter operation is desired.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wing, S.; Horton, R.A.; Marshall, S.W.; Thu, K.; Tajik, M.; Schinasi, L.; Schiffman, S.S. Air pollution and odor in communities near industrial swine operations. Environ. Health Perspect. 2008, 116, 1362–1368. [Google Scholar] [CrossRef] [PubMed]

- Ni, J.Q.; Robarge, W.P.; Xiao, C.; Heber, A.J. Volatile organic compounds at swine facilities: A critical review. Chemosphere 2012, 89, 769–788. [Google Scholar] [CrossRef] [PubMed]

- Mackie, R.I.; Stroot, P.G.; Varel, V.H. Biochemical identification and biological origin of key odor components in livestock waste. J. Anim. Sci. 1998, 76, 1331–1342. [Google Scholar] [CrossRef] [PubMed]

- Huang, H.; Miller, G.Y. Citizen complaints, regulatory violations, and their implications for swine operations in Illinois. Rev. Agric. Econ. 2006, 28, 89–110. [Google Scholar] [CrossRef]

- Nicolai, R.E.; Lefers, R.M. Biofilters used to reduce emissions from livestock housing: A literature review. In Workshop on Agricultural Air Quality; North Carolina State University: Raleigh, NC, USA, 2006; pp. 952–960. [Google Scholar]

- Chen, L.; Hoff, S.J. Mitigating odors from agricultural facilities: A review of literature concerning biofilters. Appl. Eng. Agric. 2009, 25, 751–766. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.C.; Han, M.F.; Jia, T.P.; Hu, X.R.; Zhu, H.Q.; Tong, Z.; Lin, Y.T.; Wang, C.; Liu, D.Z.; Peng, Y.Z.; et al. Emissions, measurement, and control of odor in livestock farms: A review. Sci. Total Environ. 2021, 776, 145735. [Google Scholar] [CrossRef] [PubMed]

- Cooper, C.D.; Alley, F.C. Air Pollution Control: A Design Approach, 4th ed.; Waveland Press: Long Grove, IL, USA, 2010; pp. 455–484. [Google Scholar]

- Iranpour, R.; Cox, H.H.; Deshusses, M.A.; Schroeder, E.D. Literature review of air pollution control biofilters and biotrickling filters for odor and volatile organic compound removal. Environ. Prog. 2005, 24, 254–267. [Google Scholar] [CrossRef]

- Barbusinski, K.; Kalemba, K.; Kasperczyk, D.; Urbaniec, K.; Kozik, V. Biological methods for odor treatment—A review. J. Clean. Prod. 2017, 152, 223–241. [Google Scholar] [CrossRef]

- Noren, O. Design and use of biofilters for livestock buildings. In Odour Prevention and Control of Organic Sludge and Livestock Farming; Nielsen, V.C., Voorburg, J.H., L’Hermite, P., Eds.; Taylor & Francis: Abingon, UK, 1986; pp. 234–237. [Google Scholar]

- Mann, D.D.; Garlinski, E.M. Design of a horizontal airflow biofilter. In Proceedings of the AIC 2002 Meeting, Saskatoon, SK, Canada, 14–17 July 2002; Paper No. 02-611. Canadian Society of Agricultural Engineers: Mansonville, QC, Canada, 2002. [Google Scholar]

- Nicolai, R.E.; Lefers, R.; Pohl, S.H. Configuration of a vertical biofilter. In Proceedings of the Livestock Environment 7th International Symposium, Beijing, China, 18 May 2005; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2005; pp. 358–363. [Google Scholar] [CrossRef]

- Nicolai, R.E.; Thaler, R. Vertical biofilter construction and performance. In Proceedings of the International Symposium on Air Quality and Waste Management for Agriculture, Broomfield, CO, USA, 16–19 September 2007; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2007; pp. 35–41. [Google Scholar] [CrossRef]

- Lefers, R.M. A Design of Analysis for a Vertical Bed Biofilter and Biofilter Moisture Control System. Master’s Thesis, South Dakota State University, Brookings, SD, USA, 2006. [Google Scholar]

- Devinny, J.S.; Deshusses, M.A.; Webster, T.S. Biofiltration for Air Pollution Control; CRC Press: Washington, DC, USA, 2017. [Google Scholar]

- Choi, J.H.; Kim, Y.H.; Joo, D.J.; Choi, S.J.; Ha, T.W.; Lee, D.H.; Park, I.H.; Jeong, Y.S. Removal of ammonia by biofilters: A study with flow-modified system and kinetics. J. Air Waste Manag. Assoc. 2003, 53, 92–101. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Goldstein, N. Longer life for biofilters. BioCycle 1999, 40, 62. [Google Scholar]

- Chen, L.; Hoff, S.J.; Koziel, J.A.; Cai, L.; Zelle, B.; Sun, G. Performance evaluation of a wood-chip based biofilter using solid-phase microextraction and gas chromatography–mass spectroscopy–olfactometry. Bioresour. Tech. 2008, 99, 7767–7780. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Warrick, A.W. Interrelationships of irrigation uniformity terms. J. Irrig. Drain. Eng. 1983, 109, 317–332. [Google Scholar] [CrossRef]

- Hammer, Ø.; Harper, D.A.; Ryan, P.D. PAST: Paleontological statistics software package for education and data analysis. Palaeontol. Electron. 2001, 4, 1–9. [Google Scholar]

- Garlinski, E.M.; Mann, D.D. Airflow characteristics through a horizontal-airflow biofilter. In Proceedings of the 2004 ASAE Annual Meeting, Ottawa, ON, Canada, 1–4 August 2004; Paper No. 044055. American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2004. [Google Scholar] [CrossRef]

- Ella, V.B.; Keller, J.; Reyes, M.R.; Yoder, R. A low-cost pressure regulator for improving the water distribution uniformity of a microtube-type drip irrigation system. Appl. Eng. Agric. 2013, 29, 343–349. [Google Scholar] [CrossRef]

- Yang, X.; Lee, J.; Zhang, Y.; Wang, X.; Yang, L. Concentration, size, and density of total suspended particulates at the air exhaust of concentrated animal feeding operations. J. Air Waste Manag. Assoc. 2015, 65, 903–911. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| BF#1 | ||||||||

| South Side | East Side | North Side | ||||||

| 0.16 ± 0.11 | 0.11 ± 0.02 | 0.12 ± 0.02 | 0.12 ± 0.04 | 0.18 ± 0.07 | 0.17 ± 0.06 | 0.17 ± 0.09 | 0.14 ± 0.07 | 0.13 ± 0.07 |

| 0.10 ± 0.00 | 0.12 ± 0.04 | 0.18 ± 0.11 | 0.17 ± 0.14 | 0.15 ± 0.06 | 0.18 ± 0.10 | 0.14 ± 0.05 | 0.12 ± 0.04 | 0.14 ± 0.04 |

| 0.15 ± 0.07 | 0.13 ± 0.05 | 0.13 ± 0.02 | 0.14 ± 0.06 | 0.13 ± 0.05 | 0.16 ± 0.11 | 0.11 ± 0.02 | 0.15 ± 0.06 | 0.13 ± 0.05 |

| BF#2 | ||||||||

| South Side | East Side | North Side | ||||||

| 0.16 ± 0.06 | 0.15 ± 0.04 | 0.16 ± 0.08 | 0.12 ± 0.04 | 0.16 ± 0.06 | 0.19 ± 0.08 | 0.18 ± 0.12 | 0.16 ± 0.07 | 0.11 ± 0.02 |

| 0.11 ± 0.02 | 0.15 ± 0.04 | 0.14 ± 0.08 | 0.12 ± 0.04 | 0.13 ± 0.08 | 0.15 ± 0.05 | 0.11 ± 0.02 | 0.16 ± 0.06 | 0.13 ± 0.04 |

| 0.15 ± 0.05 | 0.12 ± 0.04 | 0.15 ± 0.06 | 0.13 ± 0.06 | 0.17 ± 0.05 | 0.16 ± 0.07 | 0.10 ± 0.00 | 0.13 ± 0.04 | 0.16 ± 0.06 |

| BF#1 | ||||||||

| South Side | East Side | North Side | ||||||

| 32.2 ± 12.0 | 30.2 ± 11.3 | 45.0 ± 16.8 | 43.5 ± 16.3 | 38.2 ± 14.3 | 37.5 ± 14.0 | 41.7 ± 15.6 | 49.0 ± 18.3 | 54.7 ± 20.5 |

| 44.7 ± 16.7 | 37.8 ± 14.2 | 38.0 ± 14.2 | 45.2 ± 16.9 | 36.8 ± 13.8 | 42.3 ± 15.8 | 52.2 ± 19.5 | 46.8 ± 17.5 | 52.3 ± 19.6 |

| 41.2 ± 15.4 | 41.0 ± 15.3 | 35.8 ± 13.4 | 60.5 ± 22.6 | 39.5 ± 14.8 | 49.2 ± 18.4 | 50.2 ± 18.8 | 58.5 ± 21.9 | 61.7 ± 23.1 |

| BF#2 | ||||||||

| South Side | East Side | North Side | ||||||

| 45.0 ± 12.4 | 38.4 ± 10.5 | 32.7 ± 9.0 | 47.6 ± 13.1 | 46.3 ± 12.7 | 37.3 ± 10.3 | 44.0 ± 12.1 | 62.6 ± 17.2 | 60.9 ± 16.7 |

| 34.0 ± 9.3 | 20.9 ± 5.7 | 43.8 ± 12.0 | 56.3 ± 15.4 | 21.8 ± 6.0 | 49.3 ± 13.5 | 59.8 ± 16.4 | 51.5 ± 14.1 | 60.7 ± 16.7 |

| 21.2 ± 5.8 | 10.5 ± 2.9 | 41.0 ± 11.3 | 46.4 ± 12.7 | 20.3 ± 5.6 | 30.6 ± 8.4 | 37.0 ± 10.2 | 32.0 ± 8.8 | 38.2 ± 10.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Osabutey, A.; Cromer, B.; Davids, A.; Prouty, L.; Haleem, N.; Thaler, R.; Nicolai, R.; Yang, X. Distribution of Airflow and Media Moisture Content across Two Vertical Bed Biofilters. AgriEngineering 2022, 4, 179-189. https://doi.org/10.3390/agriengineering4010013

Osabutey A, Cromer B, Davids A, Prouty L, Haleem N, Thaler R, Nicolai R, Yang X. Distribution of Airflow and Media Moisture Content across Two Vertical Bed Biofilters. AgriEngineering. 2022; 4(1):179-189. https://doi.org/10.3390/agriengineering4010013

Chicago/Turabian StyleOsabutey, Augustina, Brady Cromer, Alexander Davids, Logan Prouty, Noor Haleem, Robert Thaler, Richard Nicolai, and Xufei Yang. 2022. "Distribution of Airflow and Media Moisture Content across Two Vertical Bed Biofilters" AgriEngineering 4, no. 1: 179-189. https://doi.org/10.3390/agriengineering4010013