Abstract

Like most crops, sugarcane needs to be kept upright until it is harvested. The lodging of sugarcane has significant negative effects on the cane yield and sugar content of sugarcane. To keep sugarcane upright, earthing up is an essential in the cultural part of the operation. In Bangladesh, most of the sugarcane cultivation operations, including earthing-up, are generally performed in a traditional manual method which increases the production costs as well as reduces the income of sugarcane growers. Therefore, a cost-effective two-wheeled tractor (2WT)-mounted earthing-up machine was developed at the Bangladesh Sugarcrop Research Institute (BSRI), Pabna, to reduce drudgery and the cost of sugarcane production. Field tests were conducted in an experimental sugarcane field at BSRI and technical and economic performances of the developed earthing-up machine were also carried out based on the field test. The average effective field capacity and field efficiency of the earthing-up machine were found to be 0.16 ha/h and 77.41%, respectively. The 2WT-driven earthing-up machine was not found to be economically viable when it was used only for earthing-up operations. However, when the 2WT was used as the main driver for other activities, including earthing-up operation, the earthing-up machine became economically beneficial with net cash flow (NCF), net present value (NPV), internal rate of return (IRR), benefit–cost ratio (BCR), and payback period (PP) of BDT 148,497/ha, BDT 23,184, 3%, 3.81:1, and approximately 1 year, respectively. On the contrary, considering the cost of only earthing-up tool without 2WT, it was found to be economically beneficial with NCF, NPV, IRR, BCR, and PP of BDT 16,428/ha, BDT 3053, 4.7%, 2.71:1, and approximately 2 years, respectively. In Bangladesh, 2WT is commonly used for versatile farming purposes. Therefore, the versatile use of 2WT as a prime mover for other machines, including the earthing-up machine, can make earthing-up machine economically viable and beneficial for sugarcane growers in Bangladesh.

1. Introduction

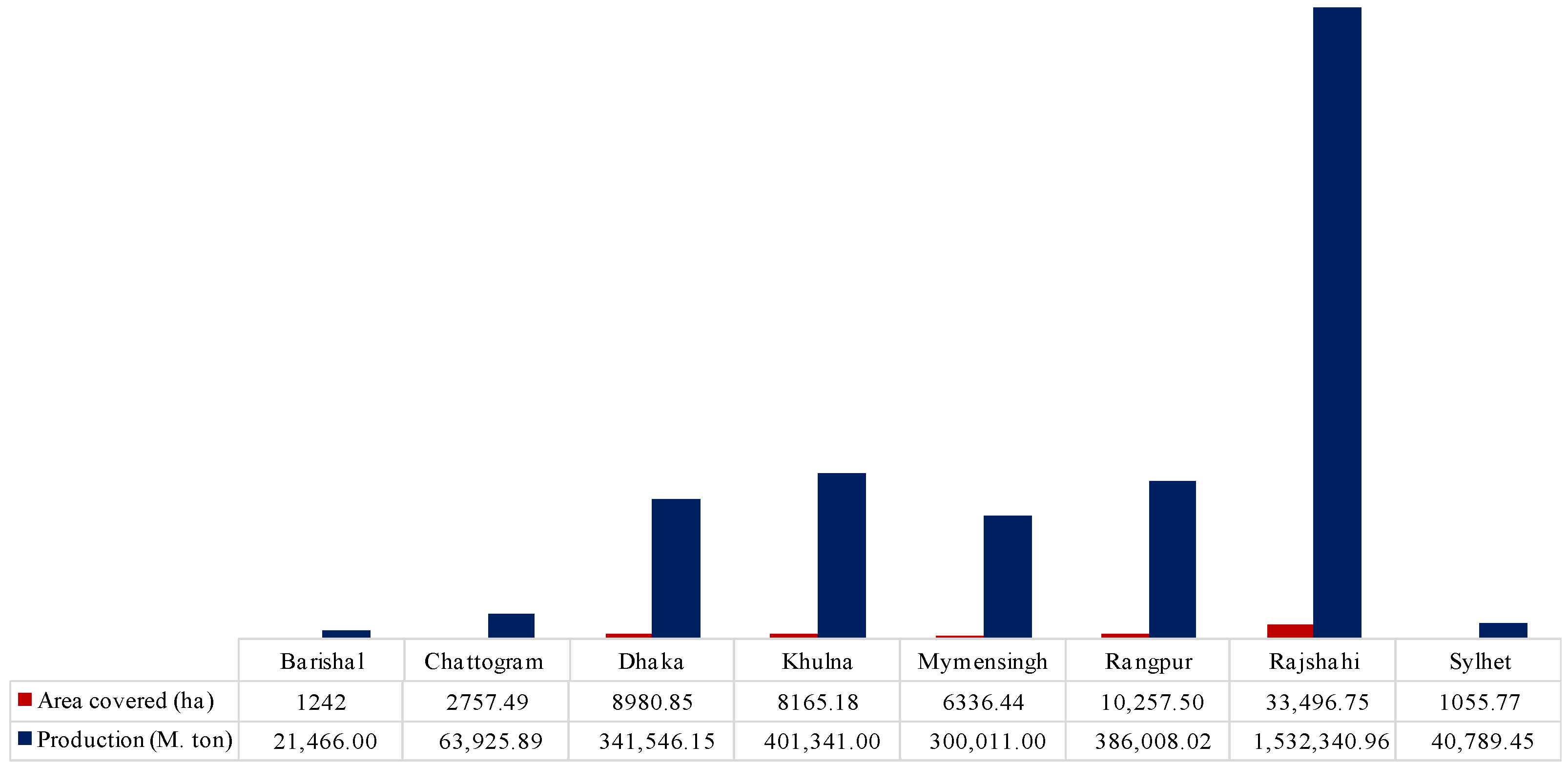

Sugarcane is an important food-cum-cash crop, which plays a vital role in augmenting the income and employment of farmers in the country, especially in the western areas of Bangladesh. Sugarcane is also an important cash crop of Bangladesh, along with jute and tea, and has an influential effect on the country’s agricultural sector GDP (10%) [1]. The main sugarcane-producing areas in Bangladesh are shown in Figure 1. Moreover, sugar and jaggery (of which the main raw material is sugarcane) are important food ingredients that have been integrated into the cultural tradition of making pithas, pies (dishes made of rice, milk, and other ingredients), and sweets in every home in Bangladesh for ages; the people of Bengal cannot do these without sugar and jaggery. However, farmers often lose their interest in sugarcane production because it is less cost-effective and has long duration features compared to other short duration cash crops. One of the major reasons for this is that it is less cost-effective because sugarcane cultivation is the human-dependent or manual farming system in Bangladesh in lieu of farm mechanization in sugarcane cultivation.

Figure 1.

Major sugarcane producing areas of Bangladesh.

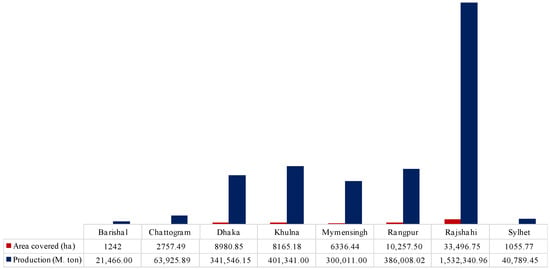

Among the SAARC countries, India is the top sugarcane (70 t ha−1) producer, followed by Pakistan (60 t ha−1), Nepal (45 t ha−1), and Bangladesh (42 t ha−1) [2]. The highest yield is led by Peru with 112 t ha−1 and the worldwide average in 2016 was 70.6 t ha−1 [3]. In 2022–23, the sugarcane production in Brazil reached 598.3 million tons, which was 3.9% higher than the previous year [4]. Brazil more than doubled its sugarcane production in recent decades to meet the demands of global bio-energy and climate change mitigation [5]. Bangladesh is a very low sugarcane-yield-producing country, according to the world’s standard, and it is necessary to apply adequate farm management strategies to increase the sugarcane yield in Bangladesh [2]. In 2021–22, the production of sugarcane in Bangladesh was 3.1 million tons with an area coverage of 72,292 ha, as shown in Figure 2 [6]. Due to the rapid urbanization and socio-economic development, farm labor is being shifted to relatively less strenuous manual labor and more prestigious work. Farm workers are becoming more scarce day by day because their daily wages are low and they are being migrated to the industrial sector. Consequently, the cost of sugarcane production in the conventional hand-operated sugarcane cultivation system is becoming very high. In such a delicate situation, for sustainable sugarcane production, mechanization is urgently necessary in all of the operations of sugarcane production systems.

Figure 2.

Area and production of sugarcane by division of Bangladesh, 2021–22.

To meet the growing demand for sugar in Bangladesh, there is a need to enhance sugarcane cultivation and sugar production per ha, while also preserving soil health and moisture. Labor force in Bangladesh is reluctant to engage in agricultural activities because of the nature of the job, low wages of labor, and lack of timeliness in the operation [7]. Therefore, the urgent adoption of modern machinery for sugarcane cultivation is necessary. Appropriate mechanization for sugarcane cultivation through suitable machinery ensures a timely operation, quality work, reduces cultivation cost, drudgery, and utilization of natural resources, and saves time and labor.

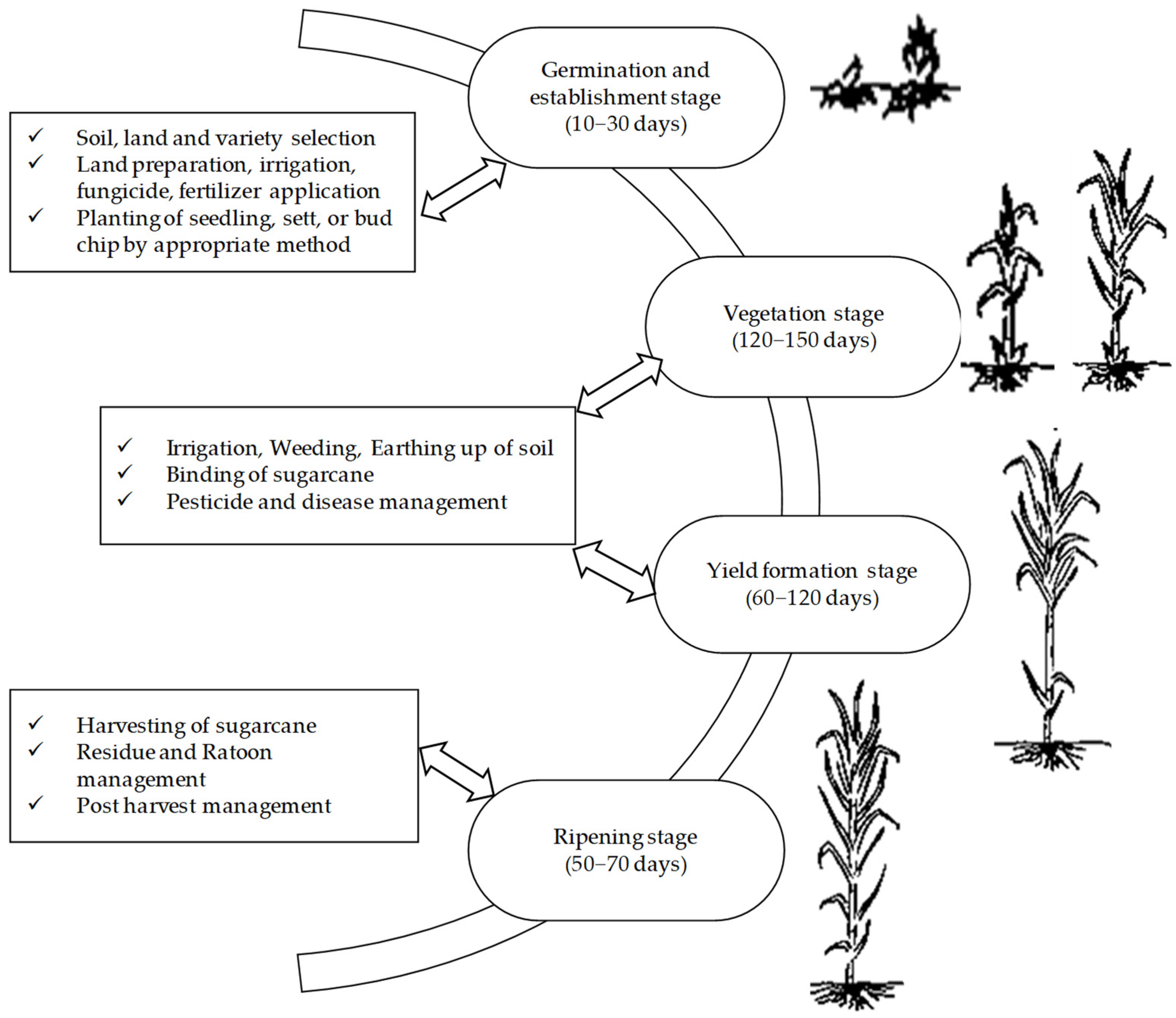

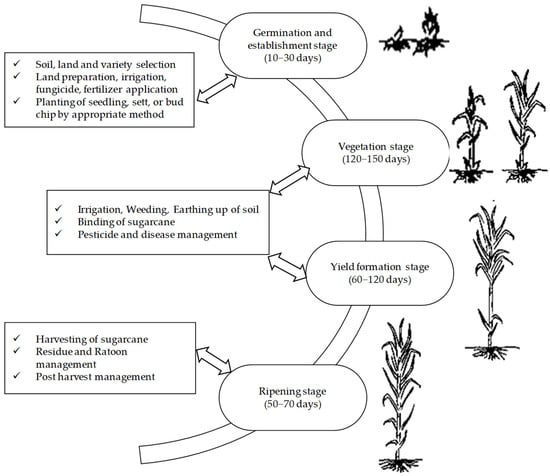

Sugarcane, an annual deep-rooted crop, undergoes various intercultural activities before harvesting. One of these activities is earthing up, which involves piling up soil near the root zone area of sugarcane tillers and is commonly referred to as ‘hilling-up’ (shown in Figure 3). Yadav and Shukla [8] described earthing-up operation as one of the most important intercultural operations for sugar crop cultivation. It maintains vegetative growth, prevents weeds, reduces lodging, and improves juice quality. In addition to these, earthing-up operation also increases plant nutrients, solar radiation, and organic matter in the soil. Sugarcane is a giant-shaped crop plant and it is important and necessary to keep it upright until harvest. Lodging, or the falling over of sugarcane, has a significant negative impact on cane yield and sugar (sucrose) content. According to the experiment conducted in Australia, the earthing-up operation can prevent lodging of canes, which increased 11–15% canes and 15–35% yields [9]. A study conducted at the Sugarcane Research Station in Punjab also found that earthing up minimizes lodging and leads to considerable cane yield [10]. This operation converts the furrows into ridges and ridges into furrows, which provide both drainages of excess water during rain, and serve as irrigation channels during the post-monsoon period. Along with that, a moderate weeding is also carried out and earthen soil helps tillers for their proper growth. In many countries with high sugar production, the earthing-up procedure is conducted in two or three phases. However, in Bangladesh, it is usually performed only once to provide soil support for sugarcane.

Figure 3.

A generalized form of conventional sugarcane cultivation in Bangladesh.

As sugarcane is cultivated in Bangladesh in a conventional method, the earthing-up operation is performed using locally manufactured hand spades. In this way, a large group of laborers (eight to ten laborers) work with hand spades from morning to afternoon (8 h/day) for about 2–3 days for a 1 ha area.

The effective field capacity of a hand spade is estimated to be 0.012–0.02 ha/h [11]. Conversely, in most leading sugarcane and sugar-producing countries, this operation is accomplished in just a few hours using machinery.

The adoption of sugarcane machinery and tools has not reached the expected level, leading to a significant mechanization gap, especially in sugarcane planting, intercultural activities, harvesting, and ratoon management. Therefore, concerted efforts are required to promote the adoption, development, and dissemination of appropriate sugarcane machinery for various operations. Singh et al. (2016) also claimed that performing earthing-up operation for sugarcane is necessary till cane formation height is not more than 0.4 m, and this can be carried outby mechanical means by a small-sized tractor or power-tiller with earthing-up equipment where row-to-row spacing is not more than 0.9 m. Above this distance, the earthen soil cannot be piled up at the sugarcane tillers stems [12].

According to the cost analysis, weeding and earthing-up operations of sugarcane fields comprise 10% of the total costs of sugar cane production [13]. Nawal et al. (2009) showed that a low hp tractor-drawn earthing-up machine had a satisfactory field efficiency above 70 percent, where the average depth of operation was 0.102 m with an average ridge height of 0.224 m along with very low average plant damage, which was only 1.11% [14]. Jadhav et al. (2013) claimed that their newly developed indigenous plough for ridging and earthing up had power requirements 0.91 hp and 1.26 hp, respectively [15]. The effective field capacity was found to be 0.18 ha/h and 0.21 ha/h for ridging and earthing-up operations, respectively, and the field efficiency of implement was found 51.55% and 56.58% for ridging and earthing-up operations, respectively.

Mechanizing the earthing-up operation can reduce the cost of sugarcane cultivation, thus increasing the income and profit for farmers. To fulfill this objective, allow hp small scale earthing-up machine (small tractor or 2WT-operated earthing-up machine) is necessary and is needed to develop suitably for sugarcane farmers of Bangladesh. Therefore, the study was carried out to develop and evaluate the performances (technical and economic) of low-cost 2WT-powered earthing-up machines for sugarcane cultivation in the context of Bangladesh to meet the above-mentioned challenges.

2. Materials and Methods

2.1. Study Location

In this study, a 2WT (power tiller)-operated earthing-up machine was designed and developed based on the concept of an anti-bed-former machine to perform the earthing-up operation of sugarcane and, finally, transformed into a rotary tiller type earthing-up machine. The fabrication, as well as the transformation of the rotary tiller type earthing-up machine, was conducted in the Workshop of Bangladesh Sugar crop Research Institute (BSRI), Ishwardi, Pabna, with the support of the Agricultural Engineering Division of the BSRI. The field performance tests were conducted at BSRI experimental sugarcane cultivation field, Pabna.

2.2. Design Considerations

To eliminate the interference of other factors, the develop dearthing-up machine was designed following variable considerations, such as line-to-line distance of sugarcane in the field, Tyne selection and adjustment for soil pulverization, depth of expected furrow after soil removal, and compaction of piled-up soil at sugarcane root.

- (i)

- Line to Line Distance of Sugarcane

In sugarcane fields, various line-to-line distances are generally practiced in Bangladesh. So, the maximum width of the earthing-up machine should be smaller than the minimum practiced distance between lines of sugarcane in the field. The most commonly practiced minimum line-to-line distance in Bangladesh is approximately 0.75 m. So, the maximum width of the earthing-up machine was kept at 0.61 m.

- (ii)

- Tyne Selection and Adjustment for Soil Pulverization

In the earthing-up operation, the soil between two adjacent lines was pulverized and then the soil was needed to move away to form a furrow and that soil was piled up at the root zone of sugarcane. Hence, R-type or J-shaped Tyne blades helped to displace the loose soil, this type of Tyne blade was selected for this machine. The blade adjustment should be in such a way that half of the shaft of the earthing-up machine was fitted with these sorts of blades facing one direction, while the other half with blades facing the opposite direction. This arrangement ensuredthat half of the pulverized soil movedtowards one side and the other half towards the other side, resulting in the formation of a furrow.

- (iii)

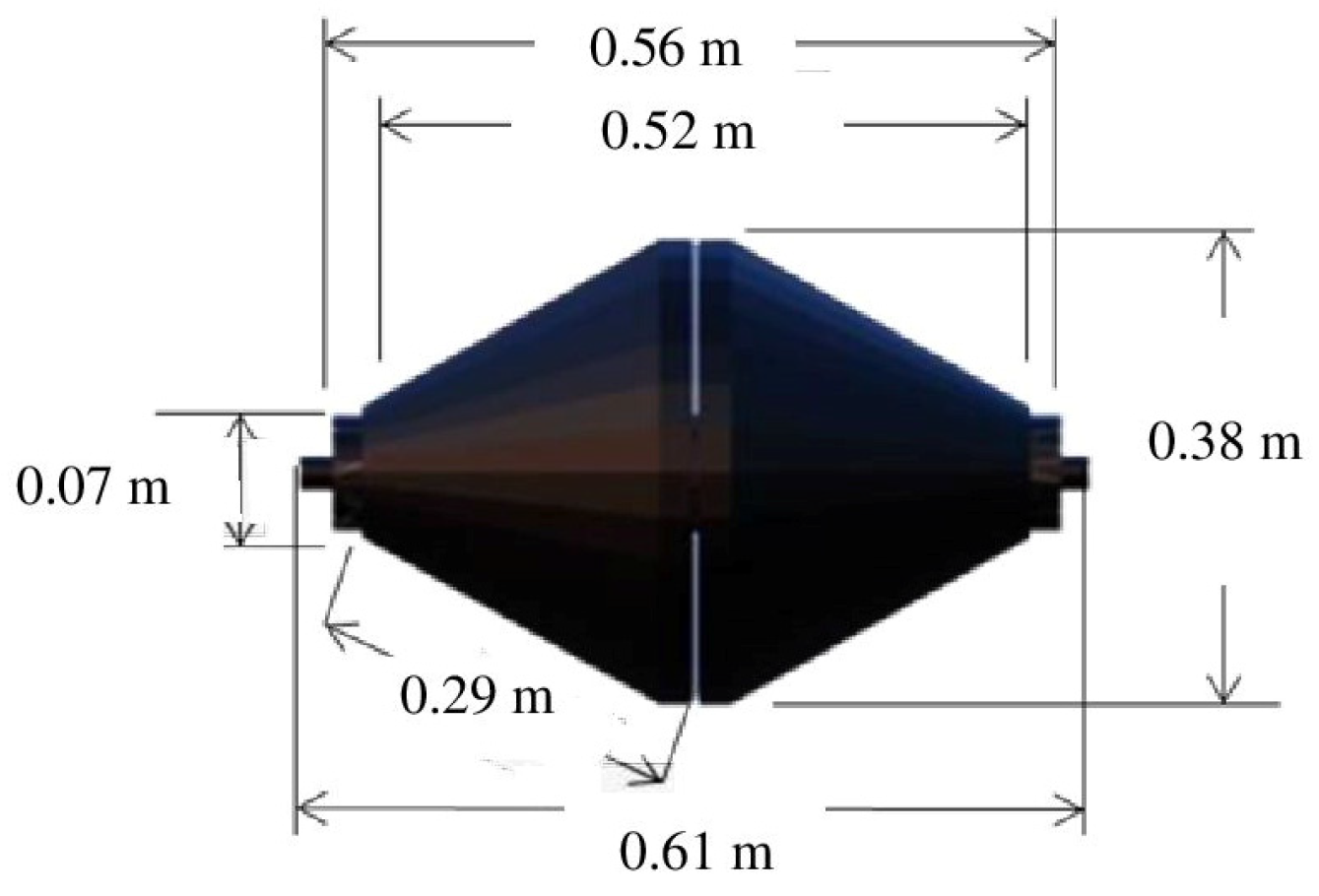

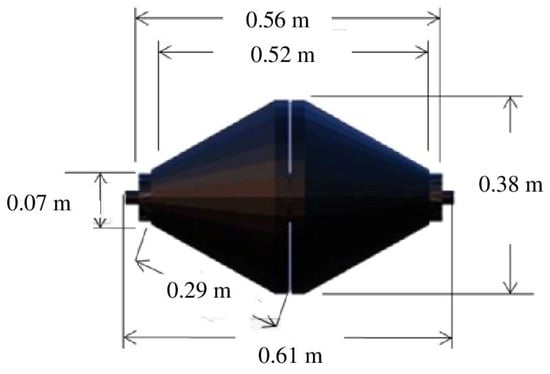

- Diameter of Soil Compactor of Earthing-up machine

The diameter of the soil compactor was kept higher than the depth of furrow created by earthing-up machine. The furrow depth was kept at 0.15 m. So, with some clearance for bearing, the diameter of the soil compactor was kept at 0.38 m. In addition, some other points were also considered before design and development such as motion of the parts, materials selection, workshop facilities, cost of construction, assembling, and safety of operation.

2.3. Raw Materials

Materials Required

Various types of materials were selected according to their strength, availability in the local market, and mechanical suitability. Types of material used for earthing-up machine and the criterion of the usage are given below and the list of materials for the earthing-up machine is shown in Table 1 as follows:

Table 1.

List of materials used for the earthing-up machine.

- (i)

- Carbon Steel Plain Sheet (ASTM 1020)

Carbon steel plain sheet (ASTM 1020) was selected for the furrower drum and covering of the tiller shaft. This material is widely used for its favorable strength-to-ductility ratio and the ability to be hardened or carburized.

- (ii)

- Mild Steel Bar and Rod (ASTM A36)

This type of material is the most-used steel due to its excellent welding properties and its suitable processing. It is a low-cost material with good ductility, weldability, and high impact strength. For these, this material was selected for structural and heavy-duty parts, like frame, shaft, etc., for the development of the earthing-up machine.

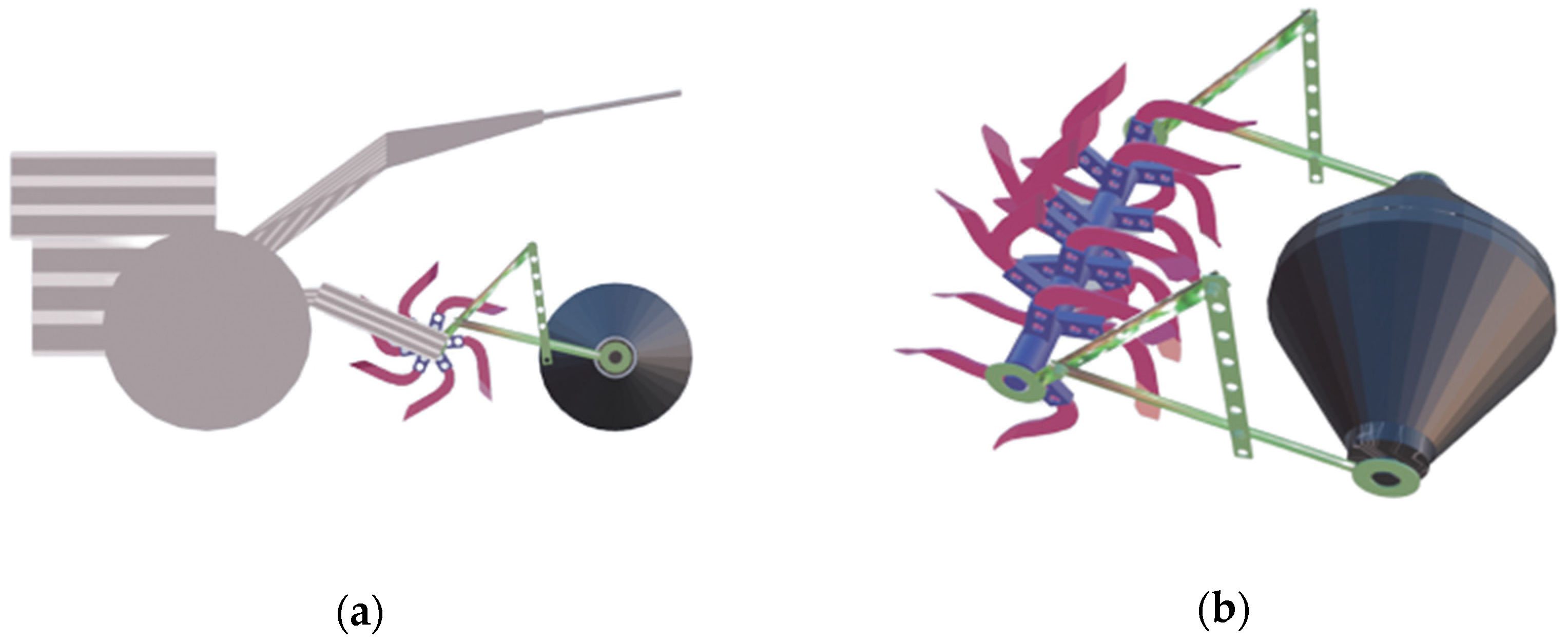

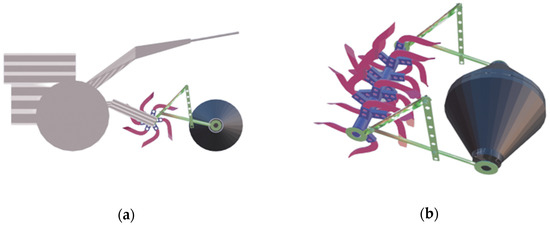

2.4. 3D Design of Earthing-Up Machine

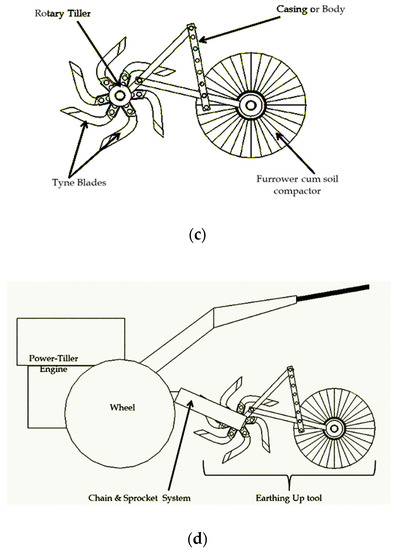

CAD software was used to create a graphical representation of an earthing-up machine that was identical to the original fabricated machine. The earthing-up machine’s 2D and 3D model designs (Figure 4a,b) were made using “Blender (version 2.8.1a)” software.

Figure 4.

Earthing-up machine: (a) 2D model with power tiller engine, (b) 3D model, (c) different parts, and (d) complete schematic view.

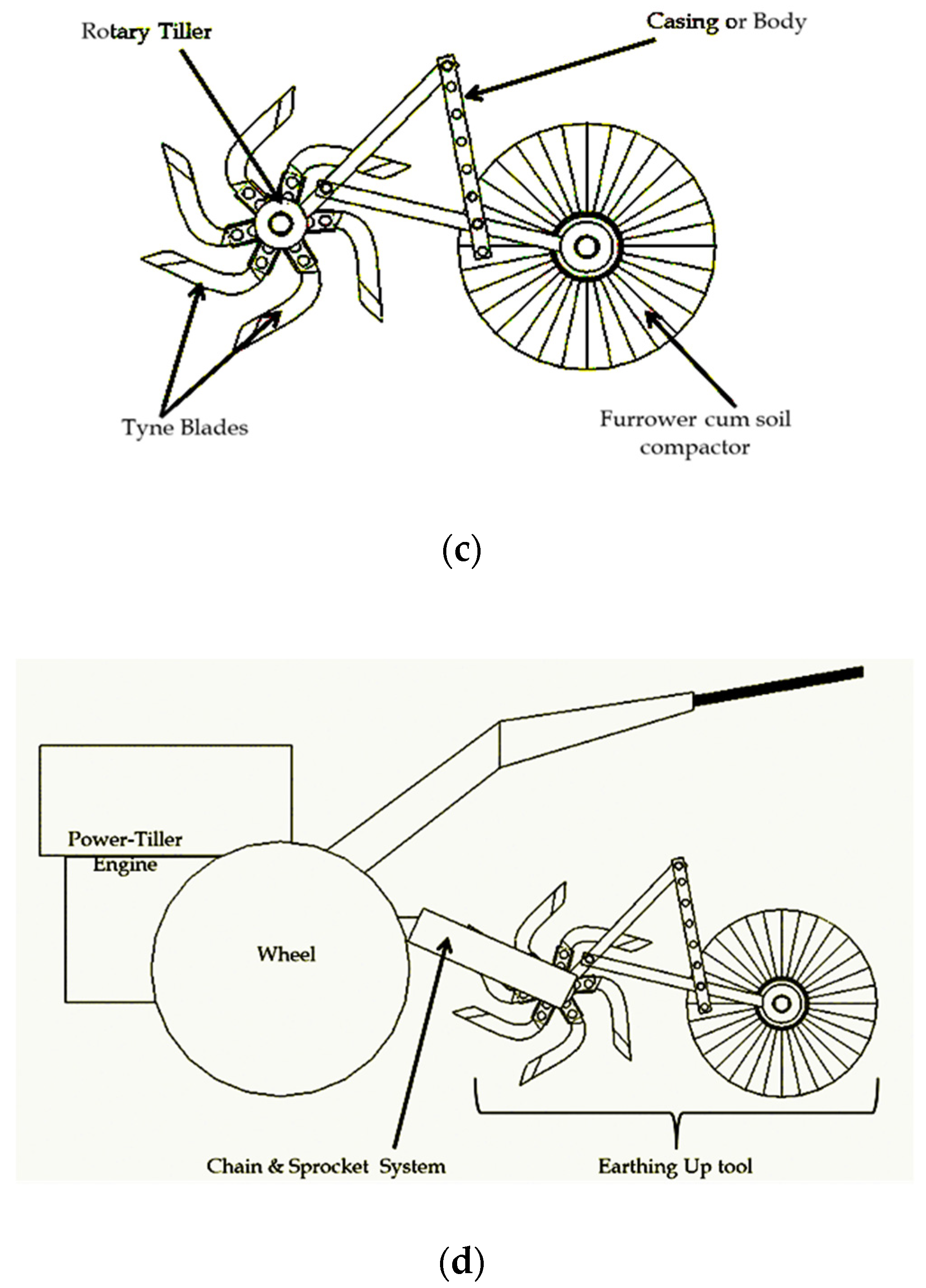

2.5. Different Parts of Earthing-Up Machine

The earthing-up tool did not have its own power supply. As a result, the earthing-up machine (Figure 4d) was powered by a small to medium-sized 2WT (two-wheeled tractor), locally named power-tiller. The earthing-up machine was mounted behind the power tiller, which wrenched it through the gap between two lines of sugarcane tillers.

The earthing-up machine consisted of some stationary and moving parts excluding the power source (power tiller engine or tractor), as shown in Figure 4c. The design and development of different parts of the earthing-up machine are shown in Figure 4.

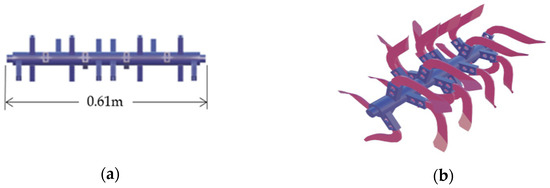

2.5.1. Rotary Tiller

The rotary tiller (Figure 5) was the nearest moving element to the power source, receiving direct power from the engine through chain and sprocket power transmission system. The rotary tiller provided power was used to rotate the tiller-shaft (rotary-shaft) in a forward direction, allowing Tyne to pulverize the soil. To wrap Tyne around the shaft, there were 22 Tyne holders (Figure 5). The main functions of a rotary tiller were to hold and rotate Tyne for breaking soil clods, pulverizing ridge soil, and sending soil backward to the ratoon root region for earthing-up.

Figure 5.

Rotary tiller (a) shaft without Tyne blades (b) shaft with Tyne blades arrangement.

2.5.2. Tyne

R-type, or J-shaped Tyne blades, were employed for earthing-up operations because of their functional benefits. This sort of Tyne blade moves the cut dirt on both sides backwards during rotational movement. To take advantage of earthing-up operations, half of the shaft of the created earthing-up machine was fitted with these sorts of blades facing one direction, while the other half blades faced the opposite direction (see Figure 5b). The soil of the ridge between two sugarcane ratoons was swept from the center to both sides of the ridge and a furrow was produced for facing the blades.

2.5.3. Furrower Cum Soil Compactor

The furrower cum soil compactor is positioned immediately after the rotary tiller and Tyne blades. It consists of a drum configuration with two cone-shaped cylinders, as illustrated in Figure 6. The drum revolved around a separate shaft. These two cone-shaped cylinders were fitted to the shaft such that the diameter in the center of the drum remains larger than the diameter on the sides. The crushed earth was rolled over this structure, which generated a V-shaped furrow. This drum structure serves to compact the soil that has been displaced around the root area of sugarcane tillers, preventing soil erosion and providing resistance against wind impacts on the ratoon soil.

Figure 6.

Furrower cum soil compactor.

2.5.4. Casing or Body

Casing (Figure 4a,b) is the frame of an earthing-up machine that holds the shaft of the furrower cum soil compactor. It kept the furrower linked to the rest of the earthing up equipment. Additionally, the casing functions as a dead weight for the soil compactor, enabling it to create a furrow. Due to its proximity to the furrower cum soil compactor, the casing also serves the purpose of cleaning mud, grass, and other debris from the furrower drum.

2.6. Fabrication of Earthing-Up Machine

The selected raw materials were first cut with a cutter machine into the desired form and size. Then, the cut sheets were welded together with electric arc welding to produce two funnel-shaped drums. The shaft for the furrower was comprised of a hollow cylinder and a thick MS rod. For the simple operation of the earthing-up machine and smooth shaft rotation, two MS ball bearings were employed. R-type, or J-shaped, Tyne blades were installed in Tyne holders on the Tyne shaft. The Tyne blades were adjusted to meet the needs of the operation. Over the arrangement of tiller blades, a covering was also employed. After that, the power tiller engine was adjusted in front of the rotary tiller. The furrower cum soil compactor was positioned behind the rotary tiller once the Tyne blades were installed. The casing or body of the earthing-up machine was used to connect the furrower part. The body or casing was built of strong MS bars. A depth control bar was added to the casing, allowing the earthing up equipment to be utilized for different furrow depths.

2.7. Field Test of Developed Earthing-Up machine

The developed earthing-up machine was tested in the experimental sugarcane cultivation field in BSRI, Ishwardi, Pabna. Prior to conducting the field test, soil moisture measurements were taken using a digital soil moisture meter (Figure 7a). The data were randomly recorded from various locations within the experimental field. After soil moisture recording, the developed earthing-up machine was started and earthing-up and weeding operations were performed in that experimental sugarcane field. An experienced machine operator operated the developed machine, as shown in Figure 7b.

Figure 7.

(a) Soil moisture measurement before earthing-up operation, (b) field test of the developed earthing-up machine.

During machine operation, various measurements such as operational time and other time measurements were recorded with the help of a stopwatch. Other measurements such as furrow width, depth of furrow, running distance, and machine width were also recorded after the earthing-up operation. Using all the recorded data, the field performance of the developed machine was evaluated, and the cost was also analyzed.

2.8. Performances of Earthing-Up Machine

2.8.1. Soil Moisture Content

In this study, a digital soil moisture meter was used to measure the soil moisture content. The moisture content of the soil was promptly displayed on the digital screen after the insertion of the moisture meter. To prevent any unnecessary changes in the reading, the “Hold” button was pressed.

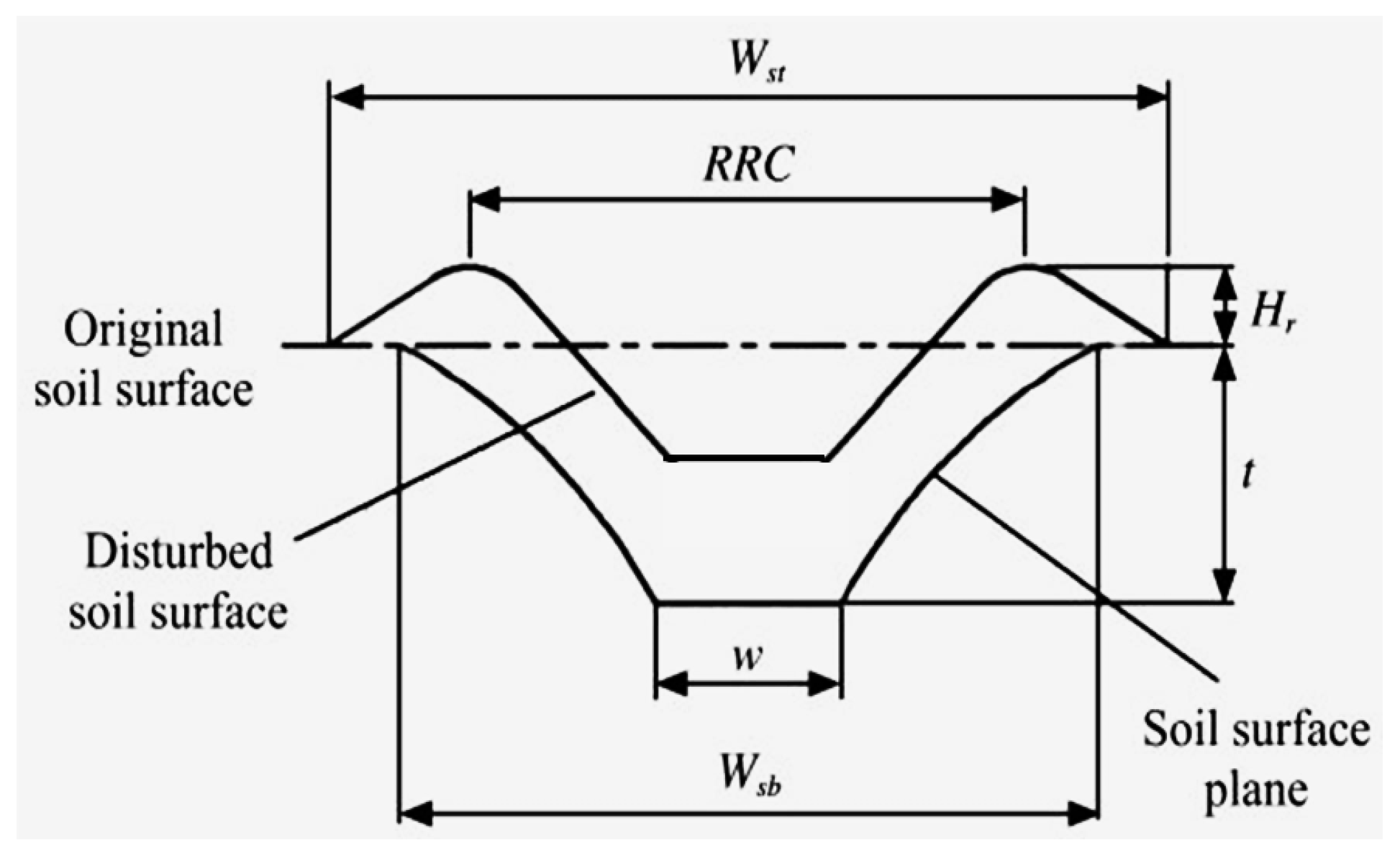

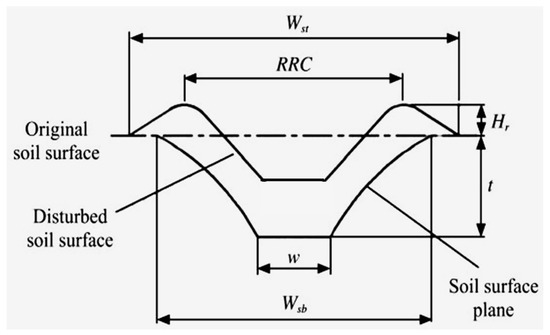

2.8.2. Soil Disturbance

While testing the earthing-up machine in the sugarcane field, the soil was inverted and the disturbed soil was earthen up, resulting in two ridges on both sides of the furrow. In Figure 8, Wst denoted the distance between the outside margins of the two ridges. The ridge-to-ridge distance is the distance between two summits of the ridges on both sides of the furrow (RRC). The rest of the disturbed soil created the furrow’s shallow groove. In Figure 8, the second line (the damaged soil surface) represents the groove’s profile. The disturbed soil was meticulously cleaned until the furrow’s contour was seen clearly. The disturbed soil surface and the furrow’s shape were meticulously measured. The top width of thefurrow (Wsb) on the original soil surface was determined by the disturbed soil cross-sectional area. The height of the ridge was measured from the top of the ridge to the original soil surface (Hr). Figure 8 depicts the aforementioned soil disturbance characteristics.

Figure 8.

Parameters used to define soil earthing up [Note: Maximum width of soil throw = Wst; Height of the ridge = Hr; Ridge to ridge distance = RRC].

Now, the area of the furrow after earthing up Af was calculated with the following equation:

where Af = Area of furrow (m2); Wsb = Top width of furrow (m); w = Bottom width of furrow (m); t = Depth of furrow (m).

Soil disturbance efficiency,

where s = Soil disturbance efficiency (%); Af = Area of furrow (m2); wc = Soil compactor middle width (m); Wc = Soil compactor edge to edge width (m); tc = Soil compactor depth (m).

2.8.3. Effective Field Capacity

The effective field capacity of the earthing-up machine was calculated using the following equation:

Effective field capacity (ha/h),

where A = Area covered at time T (m2); T = Operational time (min).

2.8.4. Theoretical Field Capacity and Field Efficiency

The theoretical field capacity of the earthing-up machine was calculated using the following equation:

Theoretical field capacity (ha/h),

where S = Speed of machine (km/h); W = Width of machine (m).

The field efficiency of the earthing-up machine was calculated using the following equation:

Field efficiency (%),

where Cth = Theoretical field capacity (ha/h); Ceff = Effective field capacity (ha/h).

2.9. Economic Analysis of the Machine

Like other farm machinery, the costs of earthing-up machineswere categorized into two: annual ownership costs, which occurred regardless of machine use, and operating costs, which varied directly with the amount of machine use [16].

- (i)

- Ownership Costs of Earthing-up machine

Ownership costs (also called fixed costs) included depreciation, interest (opportunity cost), taxes, insurance, and housing, repairandmaintenance cost.

- (a)

- Depreciation

The annual depreciation cost oftheearthing-up machine was computed in the straight-line method using thefollowing equation [16]. Depreciation (BDT/yr.),

where P = Machine price (BDT); S = Salvage value (BDT) = 5% of P; M = Economic life of earthing-up machine (yr.).

- (b)

- Annual Interest

The annual interest cost of the earthing-up machine was computed in the straight-line method using following equation [16].

Annual interest (BDT/yr.),

where P = Machine price (BDT); S = Salvage value (BDT) = 5% of P; i = Interest rate (decimal/yr.).

- (c)

- Total Ownership or Fixed Costs

The estimated costs of depreciation and annual interest were added together to find the total ownership cost. In the cost calculation of earthing-up machines, taxes, insurance, and housing costs were negligible. So,

where FC = Total ownership or fixed costs (BDT/yr.); D = Depreciation (BDT/yr.); I = Annual interest (BDT/yr.)

FC = D + I

- (ii)

- Operating Costs of the Machine

Operating costs or operational costs (also called variable costs) of earthing-up machines included all costs for successive machine operations. These costs encompassed expenditures on repairs, maintenance, fuel, lubrication, and operator or laborer.

- (a)

- Repairs and Maintenance Cost

Repair costs occurred because of routine maintenance, wear and tear, accidents, etc. Many experts mentioned that the total repairs and maintenance costs of most farm machines averaged about 1–2 percent of themachine price or manufacturing cost for rotary tillers. So,

where R&M = Repairs and maintenance cost (BDT/h); P = Machine price (BDT).

R&M = 0.02 × P

- (b)

- Fuel Cost

The earthing-up machine required a power tiller or small two-wheeled tractor for the power supply. As for the developed machine, the power source was the diesel engine of that power tiller. So, there was a fuel cost which was calculated using the following equation:

Fuel cost (BDT/h),

where f = Fuel consumption (liter/h); p = Price of fuel (BDT/liter).

F = f × p

- (c)

- Lubrication Oil Cost

Surveys indicated that total lubrication costs on most farms average about 15 percent of fuel costs (William et. al., 2015) [17]. The lubrication oil cost was calculated using the following equation,

Lubrication cost (BDT/h),

where F = Fuel cost (BDT/h).

O = 0.15 × F

- (d)

- Laborer (Operator) Cost

Again, at least one operator was required to operate this earthing-up machine. So, for the operation of the earthing up, the operator cost was calculated using the following equation:

Operator cost (BDT/h),

where l = wages of operator (BDT/h) =

L = l × no. of operator

- (e)

- Total Operating or Variable Costs

Repair and maintenance, fuel, lubrication, and labor costs were added to calculate thetotal operating cost of the developed machine. So,

where VC = Total operating or variable costs (BDT/h); R&M = Repairs and maintenance cost (BDT/h); F = Fuel cost (Tk./h); O = Lubrication oil cost (BDT/h); L = Labor or operator cost (BDT/h).

VC = R&M + F + O + L

- (iii)

- Total Cost of the Machine

After all costs were estimated, the total operating cost per hr was converted to cost per year, and then, this was added to the total ownership cost per year to calculate the total cost per year to own and operate the developed earthing-up machine. So, the total cost of the earthing-up machine was calculated as follows:

where TC = Total cost of earthing-up machine; FC = Total ownership or fixed costs (BDT/yr.); VC = Total operating or variable costs (BDT/h); Hye = Expected total operational time in a year (h/yr.); Ceff = Effective field capacity (ha/h).

TCyr (BDT/yr.) = FC + (VC × Hye)

Finally, total cost per year was divided by the hourly work rate in ha/h to calculate the total cost/ha as shown in Equation (16).

- (iv)

- Net Cash Flow (NCF)

Net cash flow (NCF) refers to either the gain or loss of funds over a period. As the earthing-up machine was developed to reduce the human labor for earthing-up operation, there was a difference between these two methods of earthing-up operation and the difference was the revenue of using the earthing-up machine. So,

Net cash flow (BDT/ha),

where

NCF = Cmanual − TCha

- TCha = Total cost of earthing-up machine (BDT/ha);Cmanual = Total cost by manual method (BDT/ha) = × Hym;Hym = Man-hr required (h/ha) = no. of labor (nos./ha) × no. of day × working time (h/day).

- (v)

- Net Present Value (NPV)

A technology or machine is said to be financially feasible when the net present value is positive. The bigger the net present value, the machine is more profitable. The following formula was used for calculating the net present value of the developed machine (Rahman et. al., 2018) [18].

Net present value (BDT),

where NCF = Net cash flow (BDT); i = Interest rate (decimal/yr.); P = Machine price = Initial capital investment (BDT).

- (vi)

- Internal Rate of Return (IRR)

The internal rate of return is a discount rate that makes the net present value (NPV) of all cash flows equal to zero in a discounted cash flow analysis. The net present value of the developed earthing-up machine was calculated using the following equation (Rahman et. al., 2018) [18].

Internal rate of return (decimal),

where NCF = Net cash flow (BDT/yr.); P = Machine price = Initial capital investment (BDT).

- (vii)

- Benefit–Cost Ratio of the Machine

The important tool of cost–benefit analysis is the benefit-to-cost ratio (BCR), which is the total cost of the benefits or outcomes divided by the total monetary costs of obtaining them. So, the benefit-to-cost ratio of the earthing-up machine was determined by the following equation:

Benefit–cost ratio (decimal),

where NCF = Net cash flow (BDT/ha); TCha = Total cost of earthing-up machine (BDT/ha).

- (viii)

- Pay-Back Period of the Machine

The payback period means the period that a project requires recovering the money invested in it. Therefore, the payback period of the earthing-up machine was computed using the following equation:

where NCF = Net cash flow (BDT); TChr = Total costs of theearthing-up machine (BDT/h); P = Machine price = Initial capital investment (BDT); Hye = Expected total operational time in a year (h/yr.); Ceff = Effective field capacity (ha/h).

3. Results and Discussion

All results and decisions were made after proper analyses of data obtained from field trials of the developed earthing-up machines during the earthing-up operation. Secondary data on the field and financial performances of power-tiller for tillage were also used to clarify the analysis, results, and discussion.

3.1. Specification of the Machine

The components of the developed earthing-up machine are mainly a two-wheeled tractor (power-tiller), a prime mover, and an earthing-up tool, as shown in Figure 9a,b. The specification of the developed earthing-up machine and the fabrication cost of earthing-up tool are shown in Table 2 and Table 3, respectively.

Figure 9.

Developed earthing-up machine. (a) Side view of earthing-up tool. (b) Rear view of earthing-up machine.

Table 2.

Specification of the earthing-up machine.

Table 3.

Fabrication cost of earthing-up tool.

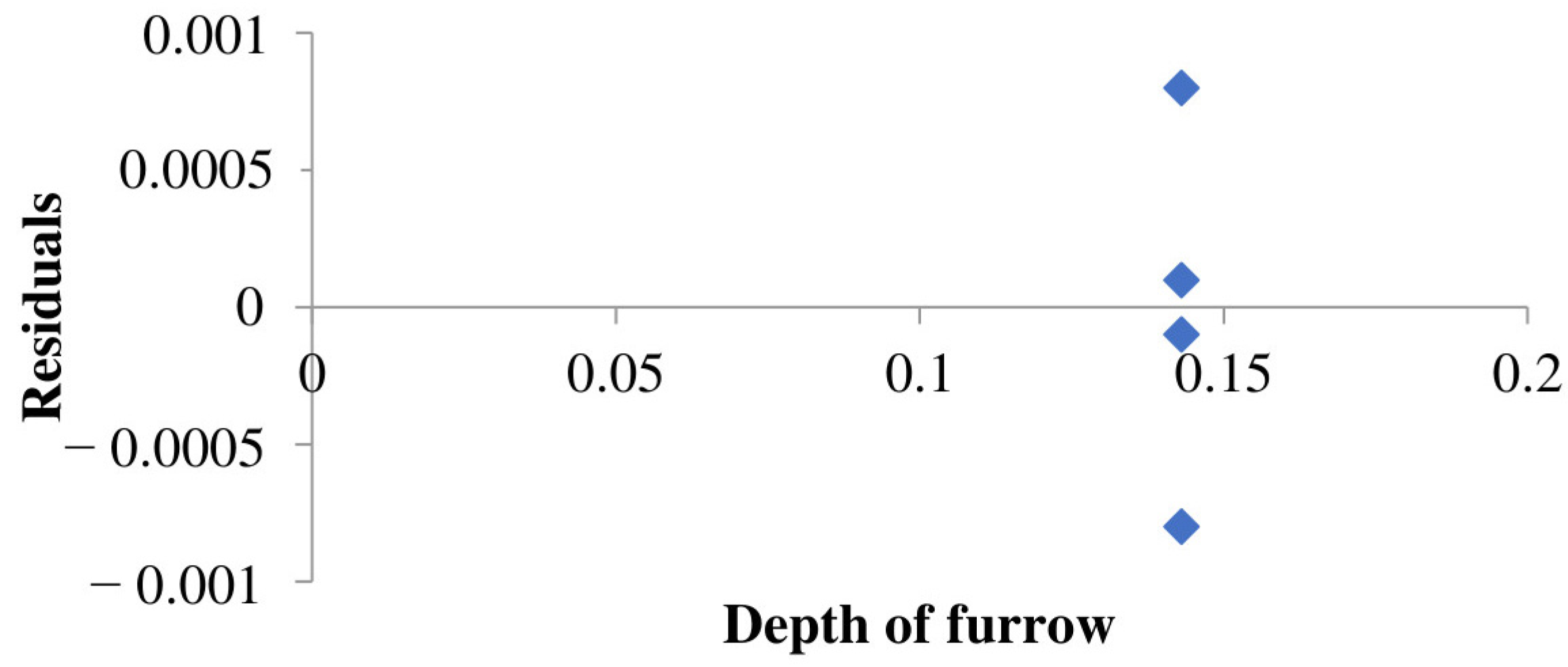

3.2. Field Performance of the Machine

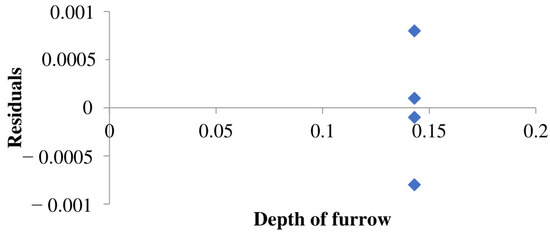

The field performance of the developed earthing-up machine depends upon its machine width, forward speed, and soil condition. The field performance test of the developed earthing-up machine was conducted at BSRI field as shown in Figure 10 and the experimental and analyzed data of field performance of the developed earthing-up machine are given in Table 4. The relationship between the residual plot and the depth of furrow is shown in Figure 11. The average effective field capacity, theoretical field capacity, and field efficiency of the developed earthing-up machine were found 0.12 ha/h, 0.16 ha/h, and 77.41%, respectively, as shown in Table 4. According to the American Society of Agricultural and Biological Engineers (ASABE) standard 2011, the developed earthing-up machine can be beneficial for the mechanization of sugarcane cultivation in Bangladesh, as its field efficiency was found to be 85.60%, and the standard range is 70–90%.

Figure 10.

Field performance test of the developed earthing-up machine. (a) Sugarcane field before earthing up. (b) Earthing up with developed machine.

Table 4.

Field performance analysis of earthing-up machine.

Figure 11.

Depth of furrow residual plot.

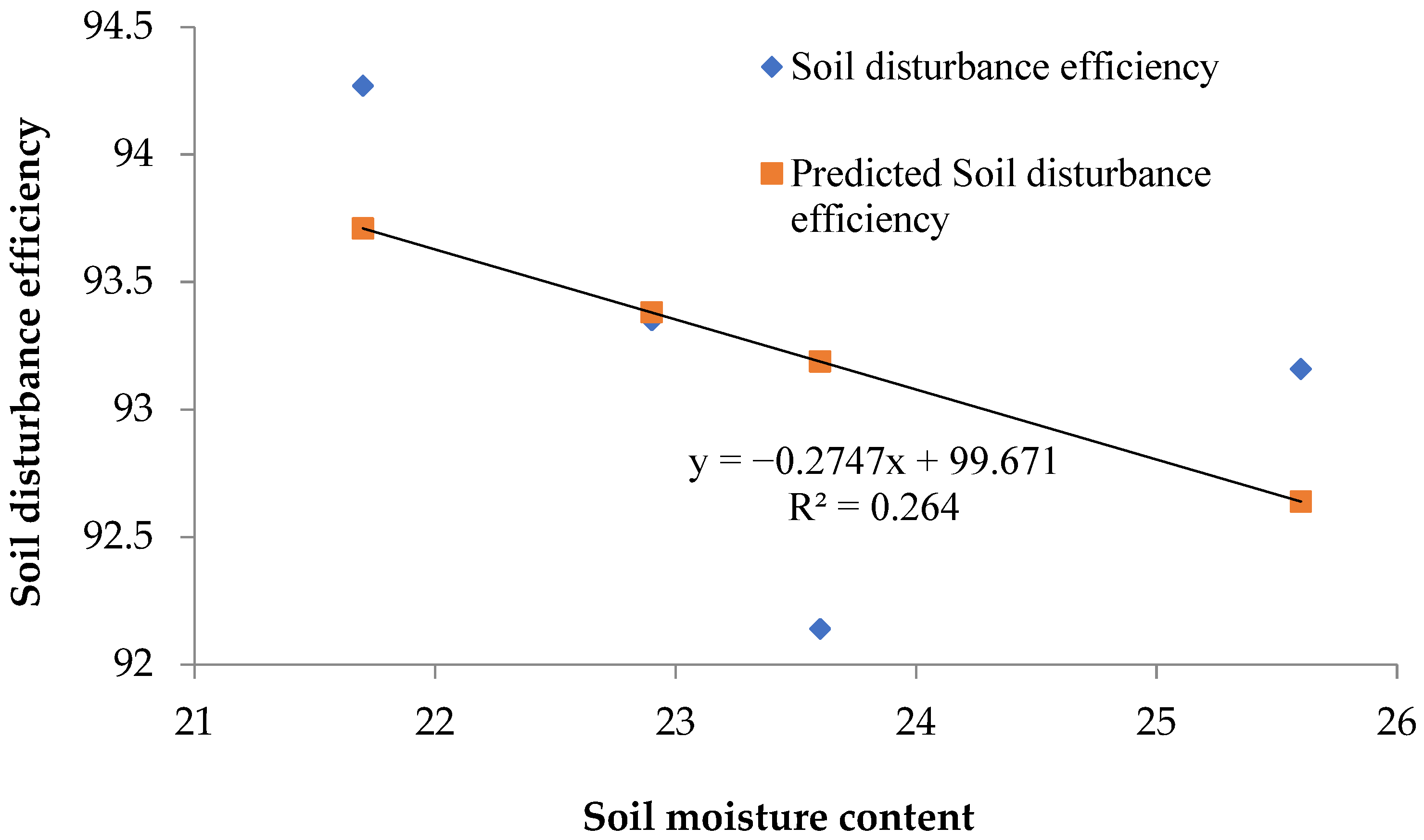

3.3. Soil Moisture and Soil Disturbance

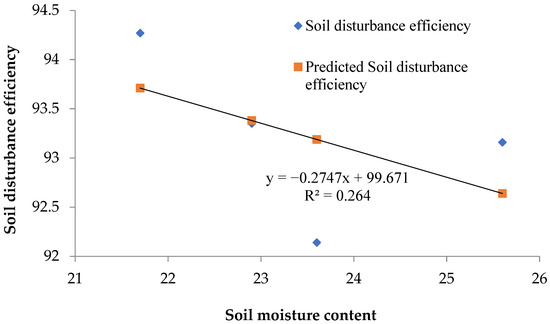

Soil moisture content affects the soil disturbance quantity of the earthing-up machine. The experimental and analyzed details data demonstrating the effect of soil moisture content on the soil disturbance during earthing-up operation by the developed machine are shown in Table 5.

Table 5.

Effect of soil moisture on soil disturbance during earthing-up machine operation.

Table 5 shows that as the soil moisture decreased, the soil disturbance efficiency rose in other words, the pulverized soil can be more displaced and piled up to the root area of the sugarcane ratoon and this is shown in Figure 12 by the regression analysis.

Figure 12.

Soil moisture content line fit plot.

From Figure 12, the Pearson correlation coefficient value was found to be 0.51378, which explains how strong the linear relationship between the soil moisture content andsoil disturbance efficiency was. Only 26.4% of the variance in soil disturbance efficiency was accounted for by the soil moisture content measures.

3.4. Financial Performance Analysis of the Machine

Financial performances of the earthing-up machine including its power source and earthing tool were analyzed from the data obtained during the earthing-up operation. The financial performance of the power-tiller-operated earthing-up machine for other field operations like tillage was also analyzed for clear comparison.

3.4.1. Earthing-Up Machine When No Other Operation by Its Power-Tiller

After financial analysis from obtained data, the ownership or fixed cost and operating or variable cost for earthing-up operation with the developed machine (when no other operation by power-tiller) were found to be BDT 14,686/yr. and BDT 3263/h, respectively, as shown in Table 6. The total cost for the earthing-up operation under these conditions amounted to BDT 2,364,550/yr., i.e., BDT 42,819/ha. On the other hand, the total cost of earthing-up operation in manual method was determined to be BDT 22,500/ha. Net cash flow for earthing-up operation of the developed machine for this condition was found negative, which was BDT 20,319/ha. The negative net cash flow indicates that relying solely on the developed earthing-up machine for the specific operation without utilizing the power-tiller for other tasks is not financially viable. This also encourages to ensure a multipurpose use of the power-tiller, such as using the power-tiller for till age operation.

Table 6.

Financial performance analysis of earthing-up machine.

3.4.2. Earthing-Up Tool without Considering Power-Tiller

The ownership or fixed cost and operating or variable cost for earthing-up tool (without investment for power-tiller) were found to be BDT 1421/yr. and BDT 463/h, respectively. The total cost for earthing operation in this case was found to be BDT 335,285/yr. which is BDT 6071/ha. On the other hand, the total cost of earthing-up operation in manual method was found to be BDT 22,500/ha. The net cash flow (NCF), net present value (NPV), and internal rate of return (IRR) were found to be BDT 16,428/ha, BDT 3053, and 4.7%, respectively, as shown in Table 6. In this case, the value of NPV and IRR both were positive. These values indicate the viability of using the developed earthing-up tool only for the use of earthing-up operation. The benefit–cost ratio and payback period for this case were found to be 2.71:1 and 1.57 years, i.e., approximately 2 years, respectively.

3.4.3. Earthing-Up Machine When Its Power-Tiller Used for Other Activities

The ownership or fixed cost and operating or variable cost for earthing-up machine (when its powertillerisalso used for tillage) were found to be BDT 13,265/yr. and BDT 2963/h, respectively. The total cost for this case was found to be BDT 1,435,841/yr., which is BDT 39,002/ha. On the other hand, the total cost of the earthing-up and tillage operation using themanual method was found to be BDT 187,500/ha. Net cash flow (NCF), net present value (NPV), and internal rate of return (IRR) were found to be BDT 148,497/ha, BDT 23,184, and 3%, respectively, as shown in Table 6. In this case, the values of NPV and IRR were also positive. These values indicate the suitability of the earthing-up machine (when its power tiller was also used for other activities). The benefit–cost ratio and payback period for this case were found to be 3.81:1 and 0.58 years, i.e., approximately 1 year, respectively. Therefore, the versatile use of two-wheeled tractors (power tillers) as the main driver of other machines including earthing-up machines can make earthing-up machines financially viable for sugarcane growers.

This is the first mechanical earthing-up operation of sugarcane in Bangladesh. The major sugarcane growers of Bangladesh are landless or marginal farmers. So, for them,the low cost of the machine is an important factor. The machine was designed with readily available 2WT driving power to keep it within the farmer’s affordability and reach.

In some developed countries, tractor-operated weeder cum earthing-up machines are used for sugarcane cultivation [15,19,20]. Moreover, in many cases, 2WT-powered rotary tillers or low power (2.5–5.5 hp) self-propelled machines are being used for weeding cum earthing-up purposes [15,21,22]. Effective field capacity and efficiency of the earthing-up machines developed by Nawale et al. (2011) [21] were 0.11 ha/h and 65.57%, respectively, which was lower than that (0.16 ha/h and 77.41%) of the earthing-up machine developed by the present study. The efficiency of earthing up equipment developed by Manian et al. (2004) [20] was 60.24%. These revealed that the field performances of the present study were better and justified.

4. Conclusions

Technical and financial performances of the developed earthing-up machine were estimated based on the field data. The average effective field capacity and field efficiency were found to be satisfactory for the machine. The developed earthing-up machine alone is not financially beneficial solely for the earthing-up operations. The earthing-up machine becomes beneficial only when the two-wheeled tractor (power-tiller) was used as the main driver for other activities including earthing-up operation. Additionally, the earthing-up tool is also financially viable for sugarcane growers. Therefore, it can be concluded that the versatile and adaptive use of two-wheel tractors (power-tillers) as prime movers for earthing-up machine can bring benefits to sugarcane growers and this developed machine can be recommended to use in sugar mill zone areas throughout Bangladesh.

Author Contributions

Conceptualization, M.A.R., S.S.T. and M.S.H.; methodology, M.A.R. and M.S.H.; formal analysis, M.A.R. and M.N.F.; investigation, M.A.R.; resources, M.A.R.; data curation, M.A.R. and M.N.F.; writing—original draft preparation, M.N.F.; writing—review, editing, and revision, M.A.R. and M.R.A.; visualization, M.N.F., M.A.H., S.S.T. and M.R.; supervision, M.A.R. and M.R.A.; project administration, M.A.R.; funding acquisition, M.A.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Bangladesh Academy of Sciences (BAS) and USDA endowment program under the project “4th Phase BAS-USDA BSRI Cr-01”.

Data Availability Statement

Not applicable.

Acknowledgments

The authors are grateful to the Bangladesh Academy of Science (BAS) and USDA for the financial support to conduct the research successfully. The authors are also grateful to Md. Arabia Mostofa for his cooperation to improve the language of the manuscript.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Bangladesh Economic Review 2020—Finance Division, Ministry of Finance, Government of the People’s Republic of Bangladesh. Available online: https://mof.portal.gov.bd/site/page/28ba57f5-59ff-4426-970a-bf014242179e/Bangladesh-Economic-Review-2020 (accessed on 30 May 2022).

- Pandey, A.; Devkota, S. Prospects and challenges of sugarcane development in Nepal: Production, market and policy. Am. J. Agric. Biol. Sci. 2020, 15, 98–106. [Google Scholar] [CrossRef]

- FAO. Sugarcane Production in 2016. In Crops/Regions/World List/Production Quantity (Pick Lists); UN Food and Agriculture Organization, Corporate Statistical Database (FAOSTAT): Rome, Italy, 2016; Available online: https://www.fao.org/3/br622e/br622e.pdf (accessed on 6 June 2023).

- Vasconcelos, J.C.S.; Speranza, E.A.; Antunes, J.F.G.; Barbosa, L.A.F.; Christofoletti, D.; Severino, F.J.; De Almeida Cançado, G.M. Development and Validation of a Model Based on Vegetation Indices for the Prediction of Sugarcane Yield. Agriengineering 2023, 5, 698–719. [Google Scholar] [CrossRef]

- Bordonal, R.d.O.; Carvalho, J.L.N.; Lal, R.; Figueiredo, E.B.D.; Oliveira, B.G.D.; Scala, N.L. Sustainability of sugarcane production in Brazil. A review. Agron. Sustain. Dev. 2018, 38, 13. [Google Scholar] [CrossRef]

- BBS. 2022. Available online: http://www.bbs.gov.bd/site/page/3e838eb6-30a2-4709-be85-40484b0c16c6/Yearbook-of-Agricultural-Statistics (accessed on 25 February 2023).

- Kumar, S.; Yadav, S.P.; Singh, S.R.S.; Bharti, Y.P.; Sharma, B.L. Effect of various geometry and nutrients management methods in relation to mechanization on productivity of sugarcane (saccharum species hybrid). Plant Arch. 2018, 18, 1317–1320. [Google Scholar]

- Yadav, R.L.; Shukla, S.K. Sugarcane production technology for higher productivity. In Proceedings of the National Seminar on Varietal Planning for Improving Productivity and Sugar Recovery in Sugarcane, Pantnagar, India, 14–15 February 2008; pp. 207–209. [Google Scholar]

- Singh, G.; Chapman, S.C.; Jackson, P.A.; Lawn, R.J. Lodging reduces sucrose accumulation of sugarcane in the wet and dry tropics. Aust. J. Agric. Res. 2002, 53, 1183–1195. [Google Scholar] [CrossRef]

- Aslam, M.; Hameed, A.; Chattha, A.A. Effect of sowing depth and earthing up on lodging in presown sugarcane. Pak. Sugar J. 2008, 23, 6–8. [Google Scholar]

- Saha, K.K.; Hossain, A.; Hoque, M.A.; Jahan, M.A.H.S.; Ahmed, S.; Timsina, J. Development and Performance Evaluation of a Two-Wheeled Power-Tiller Multi-row Weeder. J. Biosyst. Eng. 2021, 46, 36–47. [Google Scholar] [CrossRef]

- Singh, S.; Singh, P.R.; Singh, A.K.; Gupta, R. Present status and future need of mechanizing sugarcane cultivation in India. Agric. Mech. Asia Afr. Lat. Am. 2016, 47, 75–81. [Google Scholar]

- Dharmawardene, M.W.N. Trends in farm mechanization by sugarcane small land holders in Sri Lanka. Sugar Tecnol. 2006, 8, 16–22. [Google Scholar] [CrossRef]

- Nawale, S.A.; Landage, R.S.; Sable, H.P.; Kadu, V.M.; Lende, A.B.; Gharte, L.V. Performance evaluation of low hp tractor drawn sugarcane earthling-up cum fertilizer applicator suitable for wide row sugarcane crop. Int. J. Agric. Environ. Biotech. 2009, 2, 471. [Google Scholar]

- Jadhav, R.T.; Rupnawar, H.D.; Suryavanshi, B.B.; Patil, A.P. Development of indigenous plough for ridging and inter cultural operations for sugarcane crop. ETI-Eng. Techol. India 2013, 4, 1–6. [Google Scholar]

- Rahman, M.A.; Zia Uddin, A.T.M.; Hossain, S.M.I. Economic evaluation of a tunnel type solar dryer. Ann. Bangladesh Agric. 2008, 12, 119–130. [Google Scholar]

- William, E. Estimating Farm Machinery Costs; Iowa State University Extension and Outreach: Ames, IA, USA, 2015. [Google Scholar]

- Rahman, M.; Møller, H.B.; Alam, M. Assessing the energy potential of agricultural residues and an approach to meet the rural energy demand: The Bangladesh perspective. Biomass Convers. Biorefinery 2018, 8, 925–934. [Google Scholar] [CrossRef]

- Gotoh, T.; Teshima, T.; Fujii, Y.; Nagasawa, N.; Ohnishi, M.; Endoh, J.; Ochi, K.; Sukigara, T. Performance and effects on soybean cultivation of disk cultivator-ridger (Part 2)—Comparison of effects on trafficability, soil pulverizing performance and earthing up performance with rotary cultivators. J. Jpn. Soc. Agric. Mach. 2012, 74, 131–139. [Google Scholar]

- Manian, R.; Kathirvel, K.; Reddy, A.; Senthilkumar, T. Development of evaluation of weeding cum earthing up equipment for cotton. Agric. Mech. Asia Afr. Lat. Am. 2004, 35, 21–25. [Google Scholar]

- Nawale, S.A.; Gharte, L.V.; Kadu, V.M.; Lende, A.B. Development and Testing of Bullock Drawn Implement for Interculturing Operations in Sugarcane Crop. Int. J. Agric. Environ. Biotech. 2011, 4, 77–81. [Google Scholar]

- Zhang, X.; Li, H.; Ma, S.; He, J.; Wang, Q.; Chen, W.; Zheng, Z. Effects of key design parameters of tine furrow opener on soil seedbed properties. Int. J. Agric. Biol. Eng. 2016, 9, 67–80. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).