Artificial Neural Networks for Modeling and Optimizing Egg Cost in Second-Cycle Laying Hens Based on Dietary Intakes of Essential Amino Acids

Abstract

:1. Introduction

2. Materials and Methods

2.1. Fieldwork, Experimental Design, and Diet Formulation

2.2. Zootechnical and Economic Results

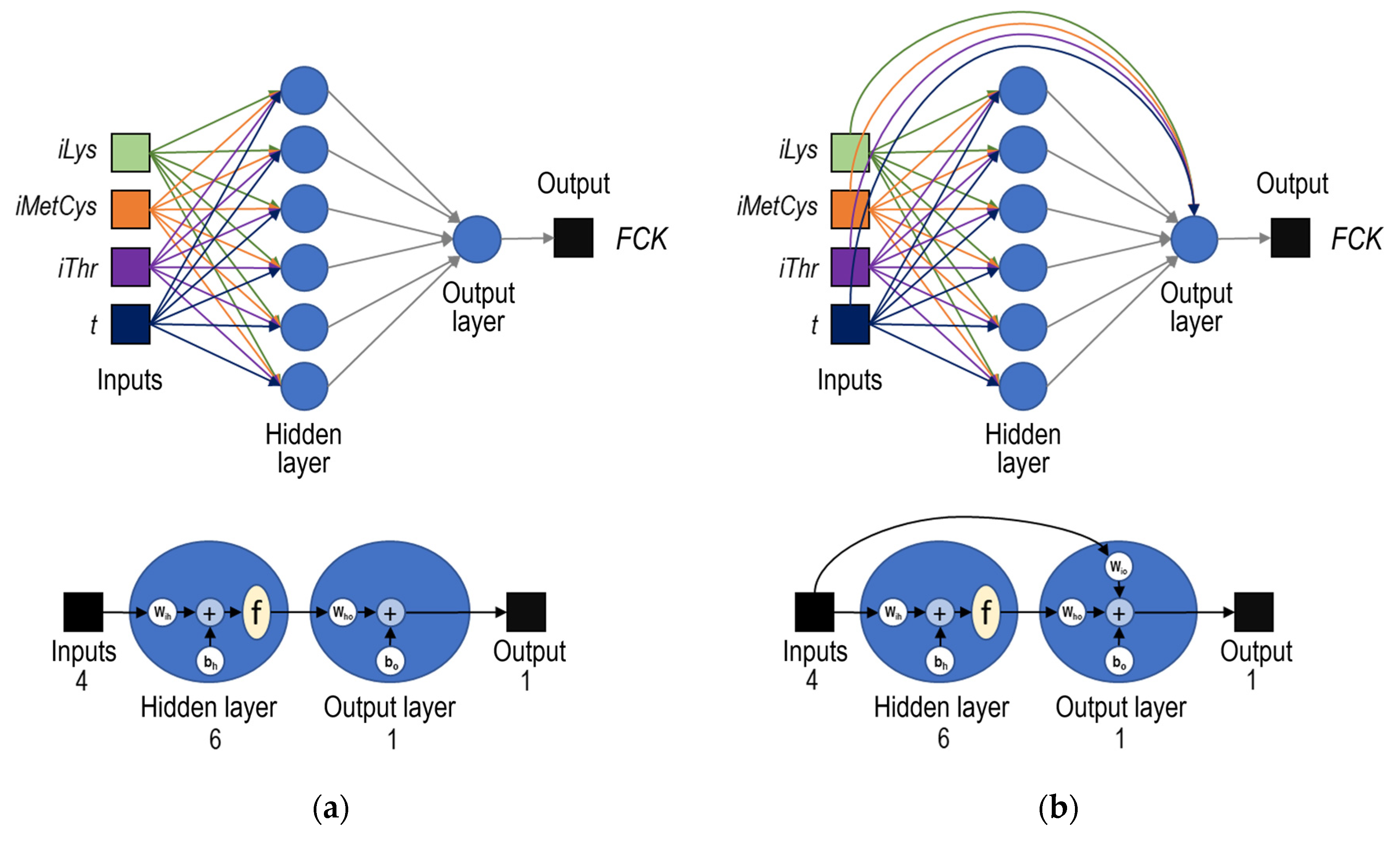

2.3. Mathematical Modeling

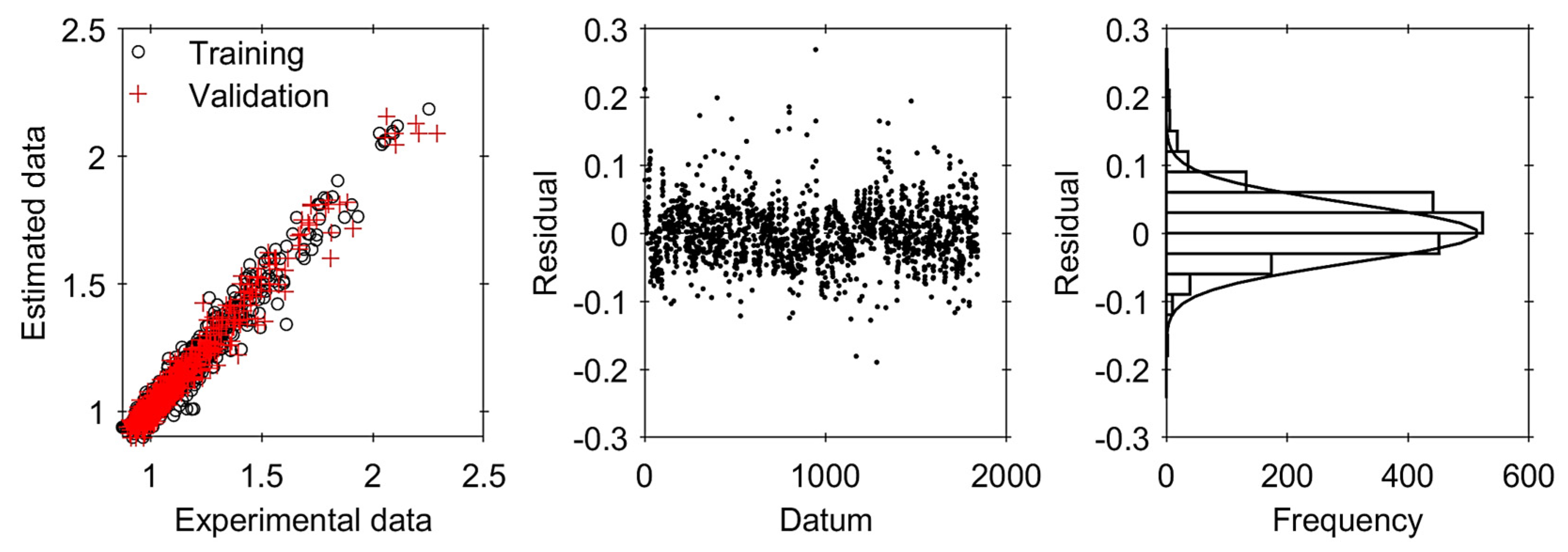

2.4. Training, Validation, and Statistical Analysis

2.5. Optimization

3. Result

3.1. Egg Cost and Zootechnical Results

3.2. Curve Fitting and Statistical Criteria

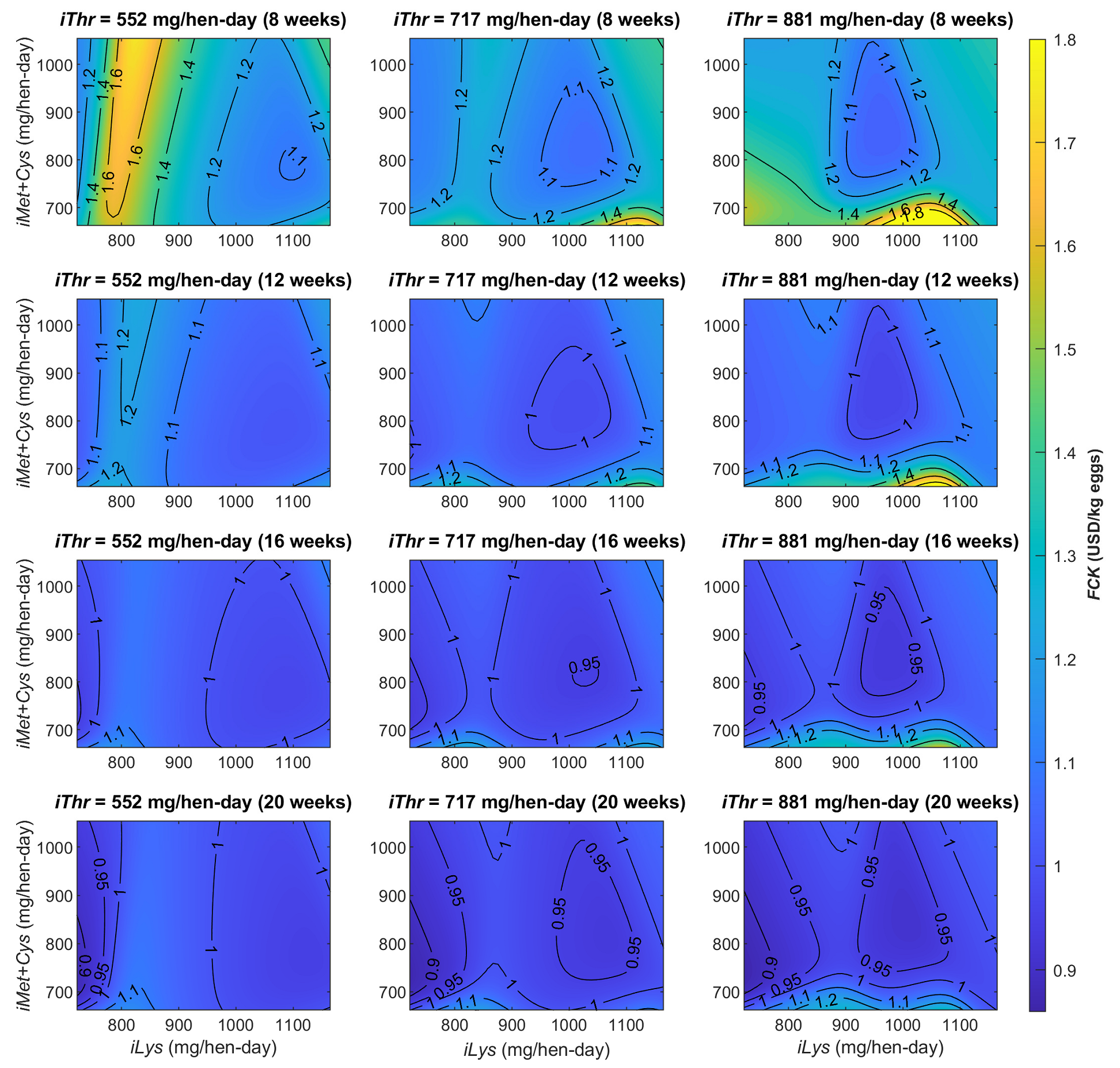

3.3. Optimization

4. Discussion

4.1. Egg Cost and Zootechnical Results

4.2. ANN Model to Analyze Egg Cost as a Function of EAAs and Time

4.3. Optimization

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- FAO. The Future of Food and Agriculture–Alternative Pathways to 2050; Food and Agriculture Organization of the United Nations: Rome, Italy, 2018. [Google Scholar]

- Morris, S.S.; Beesabathuni, K.; Headey, D. An Egg for Everyone: Pathways to Universal Access to One of Nature’s Most Nutritious Foods. Matern. Child Nutr. 2018, 14, e12679. [Google Scholar] [CrossRef] [PubMed]

- Kuang, H.; Yang, F.; Zhang, Y.; Wang, T.; Chen, G. The Impact of Egg Nutrient Composition and Its Consumption on Cholesterol Homeostasis. Cholesterol 2018, 2018, 6303810. [Google Scholar] [CrossRef] [PubMed]

- Marventano, S.; Godos, J.; Tieri, M.; Ghelfi, F.; Titta, L.; Lafranconi, A.; Gambera, A.; Alonzo, E.; Sciacca, S.; Buscemi, S. Egg Consumption and Human Health: An Umbrella Review of Observational Studies. Int. J. Food Sci. Nutr. 2020, 71, 325–331. [Google Scholar] [CrossRef] [PubMed]

- FAO. FAOSTAT Statistical Database—Crops and Livestock Products. Available online: http://www.fao.org/faostat/en/# (accessed on 22 August 2023).

- Wongnaa, C.A.; Mbroh, J.; Mabe, F.N.; Abokyi, E.; Debrah, R.; Dzaka, E.; Cobbinah, S.; Poku, F.A. Profitability and Choice of Commercially Prepared Feed and Farmers’ Own Prepared Feed among Poultry Producers in Ghana. J. Agric. Food Res. 2023, 12, 100611. [Google Scholar] [CrossRef]

- Filho, R.L.A.; Milbradt, E.L.; Okamoto, A.S.; Silva, T.M.; Vellano, I.H.B.; Gross, L.S.; Oro, C.S.; Hataka, A. Salmonella Enteritidis Infection, Corticosterone Levels, Performance and Egg Quality in Laying Hens Submitted to Different Methods of Molting. Poult. Sci. 2019, 98, 4416–4425. [Google Scholar] [CrossRef]

- Junqueira, O.M.; de Laurentiz, A.C.; da Silva Filardi, R.; Rodrigues, E.A.; Casartelli, E.M.C. Effects of Energy and Protein Levels on Egg Quality and Performance of Laying Hens at Early Second Production Cycle. J. Appl. Poult. Res. 2006, 15, 110–115. [Google Scholar] [CrossRef]

- Macelline, S.P.; Toghyani, M.; Chrystal, P.V.; Selle, P.H.; Liu, S.Y. Amino Acid Requirements for Laying Hens: A Comprehensive Review. Poult. Sci. 2021, 100, 101036. [Google Scholar] [CrossRef] [PubMed]

- Mehri, M. Optimization of Response Surface and Neural Network Models in Conjugation with Desirability Function for Estimation of Nutritional Needs of Methionine, Lysine, and Threonine in Broiler Chickens. Poult. Sci. 2014, 93, 1862–1867. [Google Scholar] [CrossRef]

- Min, Y.N.; Liu, S.G.; Qu, Z.X.; Meng, G.H.; Gao, Y.P. Effects of Dietary Threonine Levels on Growth Performance, Serum Biochemical Indexes, Antioxidant Capacities, and Gut Morphology in Broiler Chickens. Poult. Sci. 2017, 96, 1290–1297. [Google Scholar] [CrossRef]

- Morales-Suárez, W.; Ospina-Rojas, I.C.; Méndez-Arteaga, J.J.; do Nascimento Ferreira, A.E.; Váquiro-Herrera, H.A. Multivariate Modeling Strategies to Predict Nutritional Requirements of Essential Amino Acids in Semiheavy Second-Cycle Hens. Rev. Bras. Zootec. 2021, 50, e20200262. [Google Scholar] [CrossRef]

- Soares, L.; Sakomura, N.K.; Dorigam, J.C.d.P.; Liebert, F.; Sunder, A.; do Nascimento, M.Q.; Leme, B.B. Optimal In-Feed Amino Acid Ratio for Laying Hens Based on Deletion Method. J. Anim. Physiol. Anim. Nutr. 2019, 103, 170–181. [Google Scholar] [CrossRef] [PubMed]

- Astill, J.; Dara, R.A.; Fraser, E.D.G.; Roberts, B.; Sharif, S. Smart Poultry Management: Smart Sensors, Big Data, and the Internet of Things. Comput. Electron. Agric. 2020, 170, 105291. [Google Scholar] [CrossRef]

- Faridi, A.; Gitoee, A.; Donato, D.C.Z.; France, J.; Sakomura, N.K. Broiler Responses to Digestible Threonine at Different Ages: A Neural Networks Approach. J. Anim. Physiol. Anim. Nutr. 2016, 100, 738–747. [Google Scholar] [CrossRef] [PubMed]

- Galeano-Vasco, L.; Galvan, I.M.; Aler, R.; Cerón-Muñoz, M.F. Forecasting Egg Production Curve with Neural Networks. Arch. Zootec. 2018, 67, 81–86. [Google Scholar] [CrossRef]

- Ahmad, H.A. Egg Production Forecasting: Determining Efficient Modeling Approaches. J. Appl. Poult. Res. 2011, 20, 463–473. [Google Scholar] [CrossRef] [PubMed]

- Ojo, R.O.; Ajayi, A.O.; Owolabi, H.A.; Oyedele, L.O.; Akanbi, L.A. Internet of Things and Machine Learning Techniques in Poultry Health and Welfare Management: A Systematic Literature Review. Comput. Electron. Agric. 2022, 200, 107266. [Google Scholar] [CrossRef]

- De Almeida, L.G.B.; Oliveira, E.B.; Furian, T.Q.; Borges, K.A.; da Rocha, D.T.; Salle, C.T.P.; Moraes, H.L.d.S. Artificial Neural Networks on Eggs Production Data Management. Acta Sci. Vet. 2020, 48, 1732. [Google Scholar] [CrossRef]

- Ameer, K.; Bae, S.-W.; Jo, Y.; Lee, H.-G.; Ameer, A.; Kwon, J.-H. Optimization of Microwave-Assisted Extraction of Total Extract, Stevioside and Rebaudioside-A from Stevia rebaudiana (Bertoni) Leaves, Using Response Surface Methodology (RSM) and Artificial Neural Network (ANN) Modelling. Food Chem. 2017, 229, 198–207. [Google Scholar] [CrossRef]

- Wang, S.; Chung, F.-L.; Wang, J.; Wu, J. A Fast Learning Method for Feedforward Neural Networks. Neurocomputing 2015, 149, 295–307. [Google Scholar] [CrossRef]

- Morales-Suárez, W.; Elliott, S.; Váquiro-Herrera, H.A. Multivariate Analysis of Sources of Polyunsaturated Fatty Acids, Selenium, and Chromium on the Productive Performance of Second-Cycle Laying Hens. Rev. Bras. Zootec. 2022, 51, e20210204. [Google Scholar] [CrossRef]

- Daza, L.D.; Homez-Jara, A.; Solanilla, J.F.; Váquiro, H.A. Effects of Temperature, Starch Concentration, and Plasticizer Concentration on the Physical Properties of Ulluco (Ullucus tuberosus Caldas)-Based Edible Films. Int. J. Biol. Macromol. 2018, 120, 1834–1845. [Google Scholar] [CrossRef] [PubMed]

- Mathworks. MATLAB User’s Guide; The Mathworks Inc.: Natick, MA, USA, 2019. [Google Scholar]

- Hy-Line. Management Guide for Hy-Line Brown Commercial Layers; Hy-Line International: Des Moines, IO, USA, 2014. [Google Scholar]

- Schneider, S.E. Exigência de Lisina Digestível Para Poedeiras Semipesadas. Master’s Thesis, Universidade Estadual do Oeste do Paraná, Marechal Cândido Rondon, Paraná, Argentina, 2011. [Google Scholar]

- Rostagno, H.S.; Texeira Albino, L.F.; Hannas, M.I.; Lopes Donzele, J.; Sakomura, N.; Perazzo, F.G.; de Oliveira Brito, C. Tablas Brasileñas Para Aves y Cerdos: Composición de Alimentos y Requerimientos Nutricionales, 4th ed.; Universidad Federal de Viçosa: Viçosa, MG, Brazil, 2017; ISBN 9788581791227. [Google Scholar]

- Schmidt, M.; Gomes, P.C.; Teixeira, L.F.; Nunes, R.V.; Brumano, G. Níveis Nutricionais de Metionina+ Cistina Digestível Para Poedeiras Semipesadas No Segundo Ciclo de Produção. Rev. Bras. Zootec. 2009, 38, 1962–1968. [Google Scholar] [CrossRef]

- Kakhki, R.A.M.; Golian, A.; Zarghi, H. Effect of Dietary Digestible Lysine Concentration on Performance, Egg Quality, and Blood Metabolites in Laying Hens. J. Appl. Poult. Res. 2016, 25, 506–517. [Google Scholar] [CrossRef]

- Polese, C.; Nunes, R.V.; Vilela, C.G.; Murakami, A.E.; Agustini, M.A.B.; Takahashi, S.E.; Vilela, V.O.; Souza, C.; Schneider, S.E. Quantidade de Metionina+ Cistina Digestível Para Poedeiras Semipesadas de 75 a 91 Semanas de Idade. Arq. Bras. Med. Vet. Zootec. 2012, 64, 1682–1690. [Google Scholar] [CrossRef]

- Agustini, M.A.B.; Nunes, R.V.; Vilela, C.G.; Takahashi, S.E.; Vilela, V.O.; Bueno, R.S.; Polese, C. Níveis Nutricionais de Treonina Digestível Para Poedeiras Semipesadas de 75 a 90 Semanas de Idade. Semin. Cienc. Agrar. 2014, 35, 3449–3456. [Google Scholar] [CrossRef]

- Schmidt, M.; Gomes, P.C.; Rostagno, H.S.; Albino, L.F.T.; Nunes, R.V.; Cupertino, E.S.; Gomes, P.C.; Albino, L.F.T.; Cupertino, E.S.; Nunes, R.V.; et al. Exigências Nutricionais de Treonina Digestível Para Poedeiras Semipesadas No Segundo Ciclo de Produção. Rev. Bras. Zootec. 2010, 39, 1099–1104. [Google Scholar] [CrossRef]

- Sariozkan, S.; Kara, K.; Güçlü, B.K. Applicability of Non-Feed Removal Programs to Induce Molting Instead of the Conventional Feed Withdrawal Method in Brown Laying Hens. Braz. J. Poult. Sci. 2016, 18, 535–542. [Google Scholar] [CrossRef]

- Morales, W.; Rodríguez, V.; Verjan, N. Parámetros Productivos y Económicos de Gallinas Ponedoras ISA Brown En Segundo Ciclo de Producción Suplementadas Con Aminoácidos No Esenciales. Rev. Investig. Vet. Perú 2018, 29, 533–543. [Google Scholar] [CrossRef]

- Gongruttananun, N.; Guntapa, P.; Saengkudrua, K.; Boonkaewwan, C. Effects of a Short-Term Molt Using Cassava Meal, Broken Rice, or Corn Meal on Plasma Thyroxin Concentrations, Organ Weights and Intestinal Histopathology in Older (95 Wk) Laying Hens. Agric. Nat. Resour. 2017, 51, 526–531. [Google Scholar] [CrossRef]

- Domingues, C.H.d.F.; Sgavioli, S.; Praes, M.F.F.M.; Santos, E.T.; Castiblanco, D.M.C.; Petrolli, T.G.; Duarte, K.F.; Junqueira, O.M. Lisina e Metionina+ Cistina Digestíveis Sobre o Desempenho e Qualidade de Ovos de Poedeiras Comerciais: Revisão. Pubvet 2016, 10, 448–512. [Google Scholar] [CrossRef]

- Safari-Aliqiarloo, A.; Faghih-Mohammadi, F.; Zare, M.; Seidavi, A.; Laudadio, V.; Selvaggi, M.; Tufarelli, V. Artificial Neural Network and Non-Linear Logistic Regression Models to Fit the Egg Production Curve in Commercial-Type Broiler Breeders. Eur. Poult. Sci. 2017, 81. [Google Scholar] [CrossRef]

- Akilli, A.; Gorgulu, O. Comparative Assessments of Multivariate Nonlinear Fuzzy Regression Techniques for Egg Production Curve. Trop. Anim. Health Prod. 2020, 52, 2119–2127. [Google Scholar] [CrossRef]

- Carvalho, T.S.M. Metionina+ Cistina Digestível Na Dieta de Poedeiras Comerciais e Sua Influência Sobre o Desempenho, Qualidade e Perfil Aminoácidico Dos Ovos e Avaliação Econômica. Master’s Thesis, Universidade Federal de Minas Gerais, Belo Horizonte, Brazil, 2017. [Google Scholar]

- Lelis, G.; Tavernari, F.d.C.; Calderano, A.; Costa, F.A.D.; Albino, L.F.T.; Rostagno, H.; Brito, C.; de Araújo, W.A.G.; Júnior, V.R. Digestible Threonine-to-Lysine Ratio in Diets for Brown Egg-Laying Hens. J. Appl. Poult. Res. 2019, 28, 145–152. [Google Scholar] [CrossRef]

- Barbosa, L.M.; da Costa, P.R.d.S.; Silva, L.G.L.; de Freitas, P.V.D.X.; de Almeida Brainer, M.M.; Modesto, K.P. Digestible Threonine: Lysine Ratios for Light Laying Hens from 29 to 45 Weeks. Rev. Bras. Ciências Agrárias 2017, 12, 256–260. [Google Scholar] [CrossRef]

- Castro, M.R.; Pinheiro, S.R.F.; Oliveira, R.G.; Abreu, L.R.A.; Mota, L.F.M.; Miranda, J.A. Digestible Threonine to Lysine Ratios for Meat-Type Quails. Braz. J. Poult. Sci. 2020, 22, eRBCA-2017-0636. [Google Scholar] [CrossRef]

- Fouad, A.M.; Zhang, H.X.; Chen, W.; Xia, W.G.; Ruan, D.; Wang, S.; Zheng, C.T. Estimation of L-Threonine Requirements for Longyan Laying Ducks. Asian Australas. J. Anim. Sci. 2017, 30, 206. [Google Scholar] [CrossRef] [PubMed]

| Diet | iLys * (mg/hen-day) | iMetCys * (mg/hen-day) | iThr * (mg/hen-day) | Diet Cost (USD/kg) |

|---|---|---|---|---|

| 1 | 727.0 ± 10.0 | 661.9 ± 9.1 | 552.1 ± 7.6 | 0.3974 |

| 2 | 732.4 ± 9.6 | 666.8 ± 8.8 | 875.2 ± 11.5 | 0.4015 |

| 3 | 728.4 ± 18.0 | 852.1 ± 21.0 | 712.4 ± 17.6 | 0.4036 |

| 4 | 728.5 ± 17.2 | 1042.3 ± 24.6 | 553.2 ± 13.0 | 0.4058 |

| 5 | 736.3 ± 18.6 | 1053.5 ± 26.7 | 879.8 ± 22.3 | 0.4099 |

| 6 | 809.6 ± 11.3 | 736.6 ± 10.3 | 614.6 ± 8.6 | 0.4015 |

| 7 | 812.7 ± 18.0 | 739.5 ± 16.4 | 805.8 ± 17.9 | 0.4040 |

| 8 | 828.4 ± 22.7 | 982.6 ± 26.9 | 628.9 ± 17.2 | 0.4065 |

| 9 | 810.2 ± 11.3 | 961.9 ± 13.4 | 803.3 ± 11.2 | 0.4089 |

| 10 | 951.7 ± 17.8 | 673.7 ± 12.6 | 723.7 ± 13.6 | 0.4033 |

| 11 | 947.4 ± 19.0 | 861.7 ± 17.3 | 559.4 ± 11.2 | 0.4055 |

| 12 | 938.4 ± 13.6 | 853.6 ± 12.4 | 713.6 ± 10.3 | 0.4075 |

| 13 | 943.7 ± 12.2 | 858.3 ± 11.1 | 876.8 ± 11.3 | 0.4095 |

| 14 | 935.1 ± 12.9 | 1040.2 ± 14.3 | 711.0 ± 9.8 | 0.4117 |

| 15 | 1076.9 ± 23.4 | 751.2 ± 16.3 | 626.8 ± 13.6 | 0.4061 |

| 16 | 1066.3 ± 15.7 | 743.9 ± 10.9 | 810.7 ± 11.9 | 0.4085 |

| 17 | 1058.8 ± 14.6 | 963.9 ± 19.5 | 616.3 ± 12.5 | 0.4111 |

| 18 | 1058.5 ± 14.6 | 963.6 ± 13.3 | 804.7 ± 11.1 | 0.4135 |

| 19 | 1164.7 ± 30.3 | 674.3 ± 17.7 | 562.5 ± 14.7 | 0.4052 |

| 20 | 1143.1 ± 15.8 | 661.9 ± 9.1 | 868.8 ± 12.0 | 0.4092 |

| 21 | 1154.2 ± 18.4 | 858.7 ± 13.7 | 771.9 ± 11.4 | 0.4114 |

| 22 | 1153.3 ± 20.7 | 1049.5 ± 18.8 | 557.0 ± 10.0 | 0.4135 |

| 23 | 1159.5 ± 16.9 | 1055.1 ± 15.4 | 881.2 ± 12.3 | 0.4176 |

| Ingredient | Cost (USD/kg) |

|---|---|

| Corn | 0.29 |

| Soybean meal | 0.53 |

| Palm oil | 0.93 |

| Corn gluten | 0.92 |

| Calcium carbonate | 0.05 |

| Monocalcium phosphate | 0.62 |

| Bentonite | 0.06 |

| Choline chloride | 1.15 |

| Salt | 0.08 |

| Vitamin premix | 11.78 |

| Mineral premix | 6.42 |

| L-lysine * | 1.73 |

| DL-Methionine * | 2.56 |

| L-threonine * | 1.50 |

| Tryptophan | 9.96 |

| Arginine | 15.37 |

| Sodium bicarbonate | 0.44 |

| Valine | 4.20 |

| Diet | Week 8 | Week 12 | Week 16 | Week 20 |

|---|---|---|---|---|

| 1 | 1.33 ± 0.04 | 1.15 ± 0.06 | 1.06 ± 0.06 | 1.02 ± 0.05 |

| 2 | 1.56 ± 0.03 | 1.21 ± 0.03 | 1.09 ± 0.03 | 1.04 ± 0.04 |

| 3 | 1.16 ± 0.02 | 1.02 ± 0.03 | 0.96 ± 0.03 | 0.94 ± 0.03 |

| 4 | 1.15 ± 0.01 | 1.03 ± 0.02 | 0.99 ± 0.02 | 0.96 ± 0.03 |

| 5 | 1.18 ± 0.02 | 1.05 ± 0.03 | 0.98 ± 0.02 | 0.95 ± 0.02 |

| 6 | 1.43 ± 0.02 | 1.16 ± 0.03 | 1.06 ± 0.03 | 1.02 ± 0.03 |

| 7 | 1.23 ± 0.04 | 1.06 ± 0.04 | 0.98 ± 0.04 | 0.94 ± 0.03 |

| 8 | 1.41 ± 0.03 | 1.15 ± 0.04 | 1.04 ± 0.04 | 0.99 ± 0.04 |

| 9 | 1.21 ± 0.01 | 1.07 ± 0.02 | 1.01 ± 0.03 | 0.98 ± 0.03 |

| 10 | 1.22 ± 0.03 | 1.08 ± 0.04 | 1.00 ± 0.03 | 1.01 ± 0.09 |

| 11 | 1.16 ± 0.02 | 1.06 ± 0.03 | 0.99 ± 0.02 | 0.97 ± 0.02 |

| 12 | 1.12 ± 0.05 | 1.01 ± 0.02 | 0.96 ± 0.02 | 0.94 ± 0.02 |

| 13 | 1.00 ± 0.04 | 0.95 ± 0.02 | 0.93 ± 0.04 | 0.92 ± 0.04 |

| 14 | 1.17 ± 0.02 | 1.05 ± 0.01 | 1.00 ± 0.02 | 0.97 ± 0.03 |

| 15 | 1.09 ± 0.03 | 1.02 ± 0.03 | 0.97 ± 0.03 | 0.95 ± 0.03 |

| 16 | 1.25 ± 0.01 | 1.11 ± 0.01 | 1.03 ± 0.02 | 1.00 ± 0.02 |

| 17 | 1.21 ± 0.02 | 1.04 ± 0.02 | 0.98 ± 0.02 | 0.95 ± 0.03 |

| 18 | 1.28 ± 0.05 | 1.09 ± 0.03 | 1.03 ± 0.03 | 1.00 ± 0.03 |

| 19 | 1.36 ± 0.04 | 1.14 ± 0.01 | 1.05 ± 0.02 | 1.01 ± 0.01 |

| 20 | 1.34 ± 0.02 | 1.16 ± 0.03 | 1.06 ± 0.04 | 1.02 ± 0.04 |

| 21 | 1.35 ± 0.03 | 1.14 ± 0.04 | 1.05 ± 0.04 | 1.02 ± 0.04 |

| 22 | 1.48 ± 0.03 | 1.20 ± 0.03 | 1.07 ± 0.03 | 1.03 ± 0.04 |

| 23 | 1.41 ± 0.04 | 1.21 ± 0.02 | 1.09 ± 0.02 | 1.04 ± 0.02 |

| Diet | Week 8 | Week 12 | Week 16 | Week 20 |

|---|---|---|---|---|

| 1 | 3.43 ± 0.23 | 2.58 ± 0.12 | 2.16 ± 0.33 | 2.22 ± 0.06 |

| 2 | 3.62 ± 0.20 | 2.62 ± 0.14 | 2.03 ± 0.15 | 2.03 ± 0.11 |

| 3 | 2.89 ± 0.11 | 2.37 ± 0.11 | 2.08 ± 0.25 | 2.25 ± 0.17 |

| 4 | 2.88 ± 0.18 | 2.20 ± 0.14 | 2.09 ± 0.26 | 2.18 ± 0.24 |

| 5 | 3.45 ± 0.44 | 1.88 ± 0.08 | 2.15 ± 0.28 | 1.95 ± 0.14 |

| 6 | 5.05 ± 0.53 | 2.17 ± 0.07 | 2.00 ± 0.23 | 2.03 ± 0.10 |

| 7 | 3.50 ± 0.36 | 2.00 ± 0.11 | 1.99 ± 0.30 | 2.09 ± 0.22 |

| 8 | 4.20 ± 0.29 | 2.16 ± 0.09 | 1.99 ± 0.18 | 2.08 ± 0.10 |

| 9 | 2.87 ± 0.26 | 2.30 ± 0.15 | 1.89 ± 0.07 | 2.17 ± 0.23 |

| 10 | 3.25 ± 0.30 | 2.34 ± 0.17 | 2.27 ± 0.23 | 2.09 ± 0.17 |

| 11 | 3.59 ± 0.26 | 2.10 ± 0.04 | 2.11 ± 0.19 | 2.23 ± 0.19 |

| 12 | 3.05 ± 0.30 | 2.01 ± 0.05 | 2.03 ± 0.18 | 2.14 ± 0.23 |

| 13 | 2.48 ± 0.20 | 2.08 ± 0.16 | 2.11 ± 0.21 | 2.18 ± 0.27 |

| 14 | 3.40 ± 0.19 | 2.12 ± 0.05 | 2.05 ± 0.14 | 2.17 ± 0.11 |

| 15 | 2.59 ± 0.30 | 2.26 ± 0.16 | 2.14 ± 0.22 | 2.59 ± 1.33 |

| 16 | 3.10 ± 0.10 | 2.43 ± 0.07 | 2.19 ± 0.21 | 2.24 ± 0.23 |

| 17 | 3.30 ± 0.22 | 2.25 ± 0.03 | 2.00 ± 0.05 | 2.18 ± 0.14 |

| 18 | 3.50 ± 0.13 | 2.15 ± 0.09 | 2.03 ± 0.14 | 2.29 ± 0.18 |

| 19 | 3.84 ± 0.30 | 2.35 ± 0.11 | 2.18 ± 0.08 | 2.05 ± 0.15 |

| 20 | 4.07 ± 0.53 | 2.36 ± 0.14 | 2.16 ± 0.10 | 2.18 ± 0.19 |

| 21 | 3.48 ± 0.21 | 2.34 ± 0.17 | 2.21 ± 0.19 | 2.08 ± 0.08 |

| 22 | 4.39 ± 0.16 | 2.35 ± 0.14 | 2.14 ± 0.26 | 2.05 ± 0.08 |

| 23 | 3.60 ± 0.18 | 2.39 ± 0.15 | 2.11 ± 0.04 | 2.02 ± 0.10 |

| Model | Specifications | Training | Validation | p-Value | bias | AIC | ||

|---|---|---|---|---|---|---|---|---|

| RMSE | R2adj | RMSE | R2adj | |||||

| Multivariate polynomial | ||||||||

| Second order | 12 parameters | 0.108 | 0.7663 | 0.111 | 0.7485 | 0.001 | 2.38 × 10−5 | 19028 |

| Third order | 28 parameters | 0.082 | 0.8642 | 0.084 | 0.8519 | 0.001 | 7.11 × 10−5 | 18621 |

| ANN | ||||||||

| Feed-forward network | Softmax transfer function Nine hidden neurons 55 parameters | 0.047 | 0.9418 | 0.045 | 0.9537 | 0.001 | 2.38 × 10−7 | 17714 |

| Cascade-forward network | Softmax transfer function Nine hidden neurons 59 parameters | 0.042 | 0.9534 | 0.043 | 0.9564 | 0.001 | 1.23 × 10−7 | 17608 |

| wih | who | wio | bh | bo |

|---|---|---|---|---|

| Week | Minimum FCK (USD/kg egg) | Optimal Intakes (mg/hen-day) | ||

|---|---|---|---|---|

| Lysine | Methionine + Cysteine | Threonine | ||

| 8 | 1.040 | 965.91 | 864.45 | 881 |

| 12 | 0.963 | 965.91 | 860.48 | 881 |

| 16 | 0.930 | 979.18 | 856.52 | 881 |

| 20 | 0.873 | 727.00 | 741.39 | 881 |

| Mean | 909.5 | 830.71 | 881 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Morales-Suárez, W.; Daza, L.D.; Váquiro, H.A. Artificial Neural Networks for Modeling and Optimizing Egg Cost in Second-Cycle Laying Hens Based on Dietary Intakes of Essential Amino Acids. AgriEngineering 2023, 5, 1832-1845. https://doi.org/10.3390/agriengineering5040112

Morales-Suárez W, Daza LD, Váquiro HA. Artificial Neural Networks for Modeling and Optimizing Egg Cost in Second-Cycle Laying Hens Based on Dietary Intakes of Essential Amino Acids. AgriEngineering. 2023; 5(4):1832-1845. https://doi.org/10.3390/agriengineering5040112

Chicago/Turabian StyleMorales-Suárez, Walter, Luis Daniel Daza, and Henry A. Váquiro. 2023. "Artificial Neural Networks for Modeling and Optimizing Egg Cost in Second-Cycle Laying Hens Based on Dietary Intakes of Essential Amino Acids" AgriEngineering 5, no. 4: 1832-1845. https://doi.org/10.3390/agriengineering5040112

APA StyleMorales-Suárez, W., Daza, L. D., & Váquiro, H. A. (2023). Artificial Neural Networks for Modeling and Optimizing Egg Cost in Second-Cycle Laying Hens Based on Dietary Intakes of Essential Amino Acids. AgriEngineering, 5(4), 1832-1845. https://doi.org/10.3390/agriengineering5040112