Machine Learning-Based Control of Autonomous Vehicles for Solar Panel Cleaning Systems in Agricultural Solar Farms

Abstract

1. Introduction

2. Materials and Methods

2.1. Dynamic Modeling for the Autonomous Vehicles

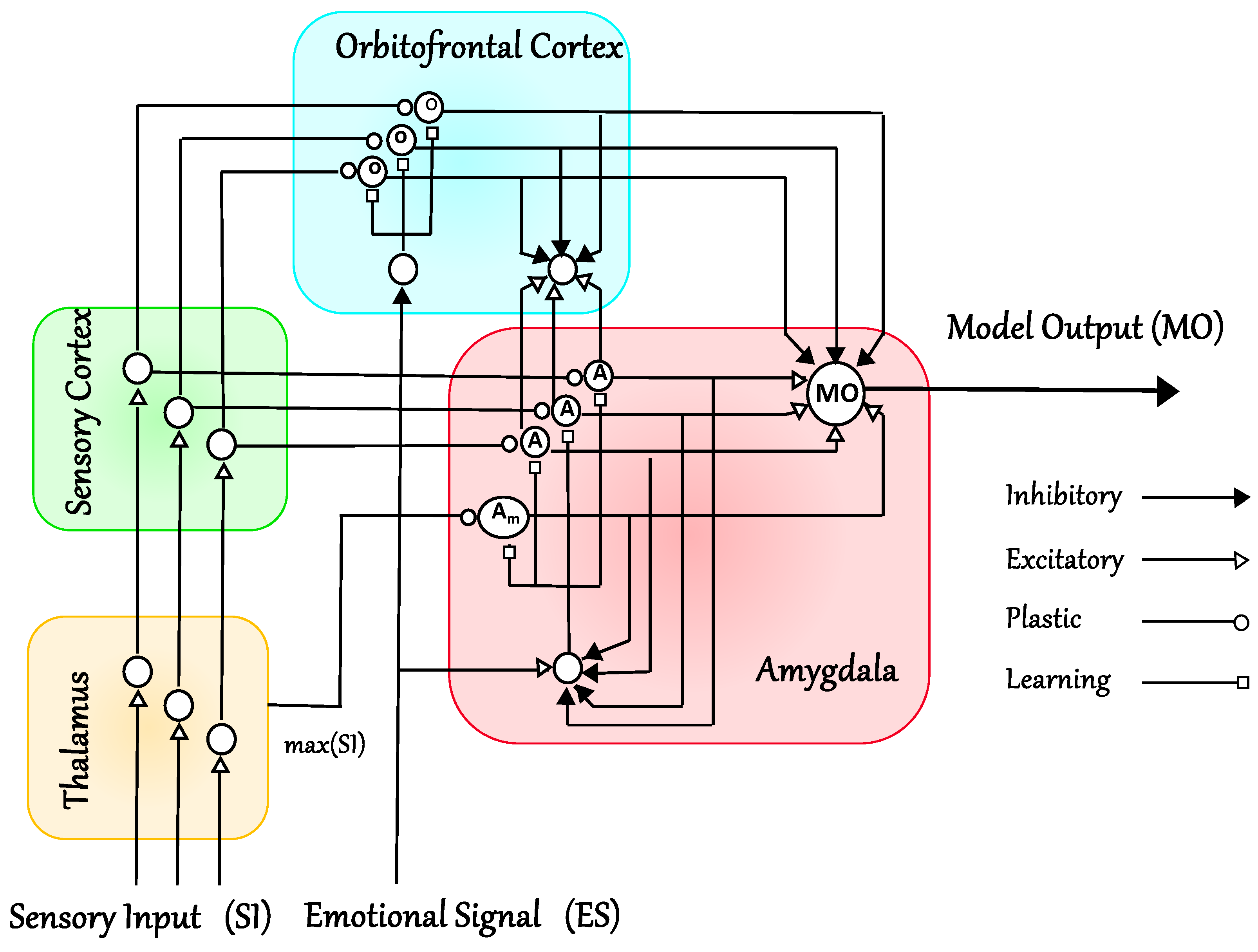

2.2. Brain Emotional Learning

2.3. Brain Emotional Learning for Closed-Loop Control of Autonomous Vehicles

- A.

- B.

3. Results

- Scenario I: Maintaining constant trajectories for AV angles and displacement.

- Scenario II: Tracking sinusoidal trajectories to maintain AV angles.

- Scenario III: Preserving AV angles and displacement in the presence of substantial external disturbances.

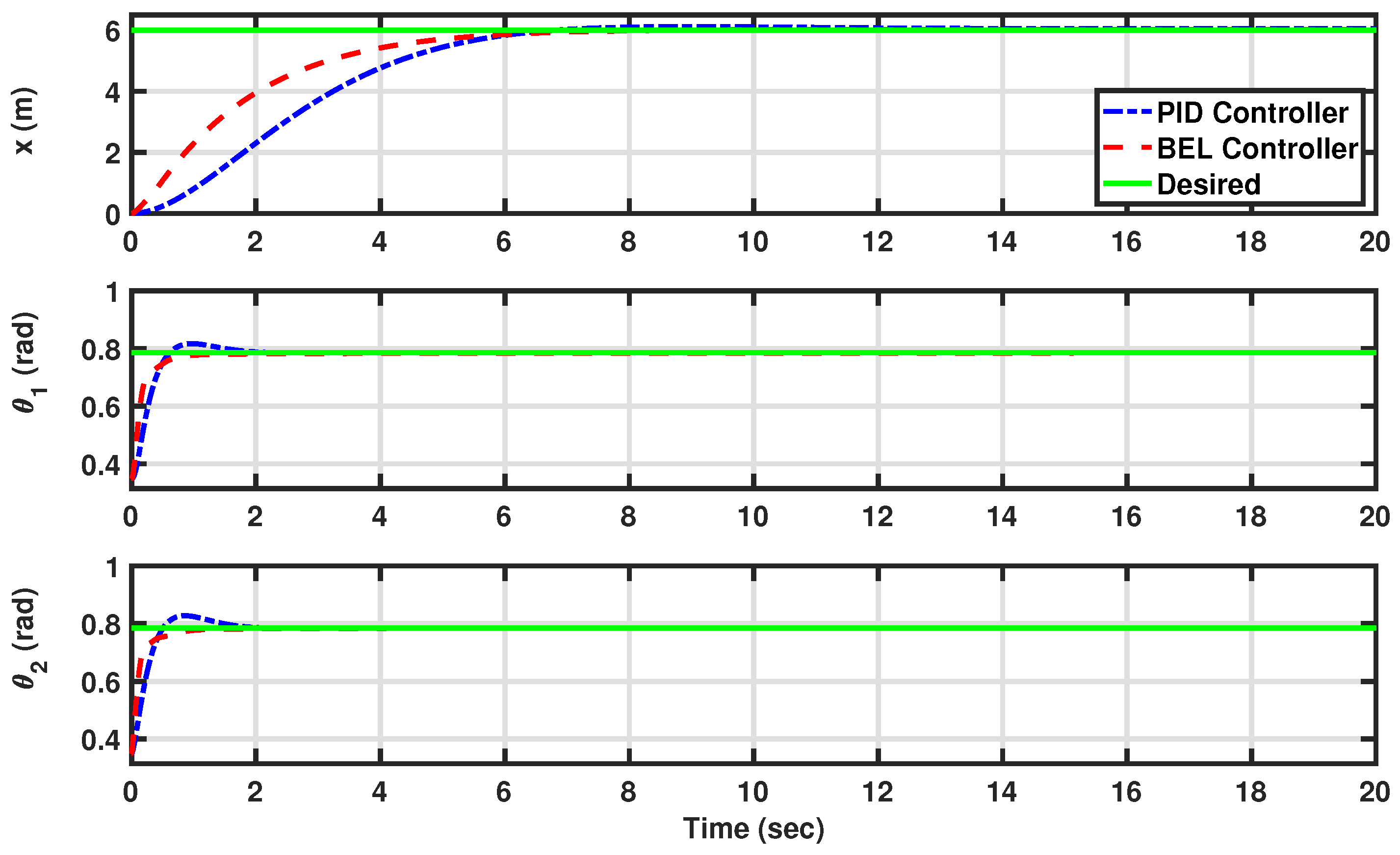

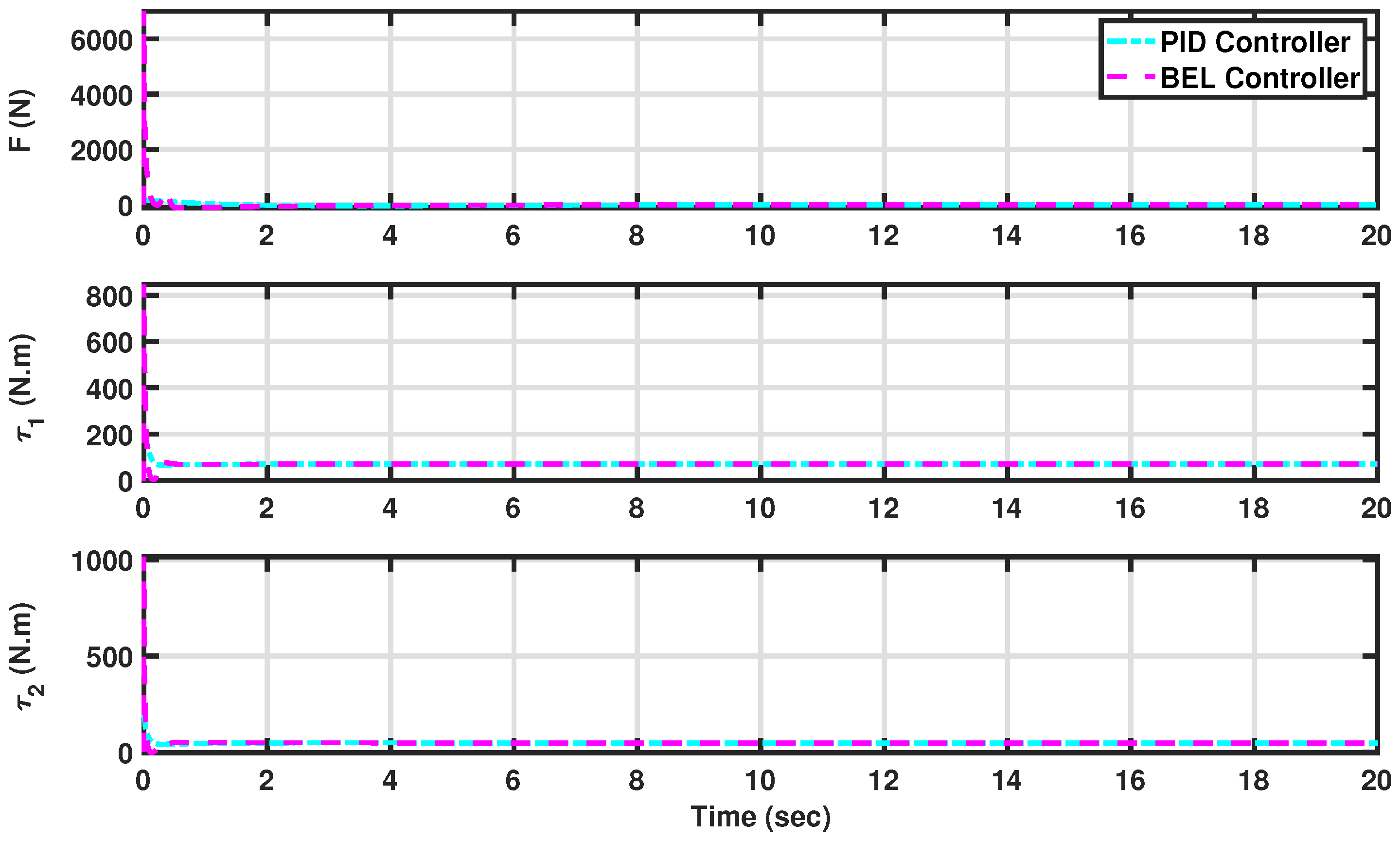

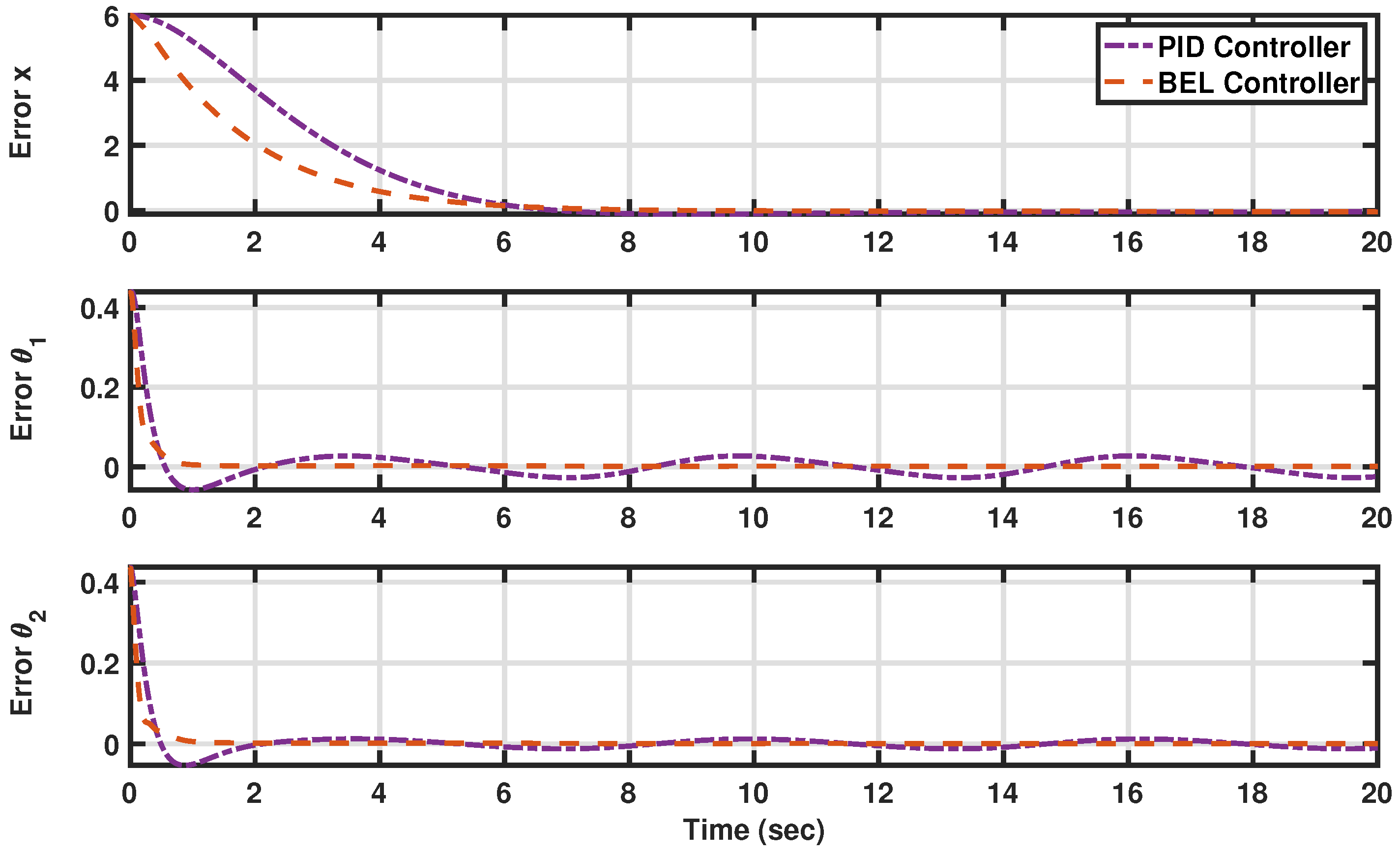

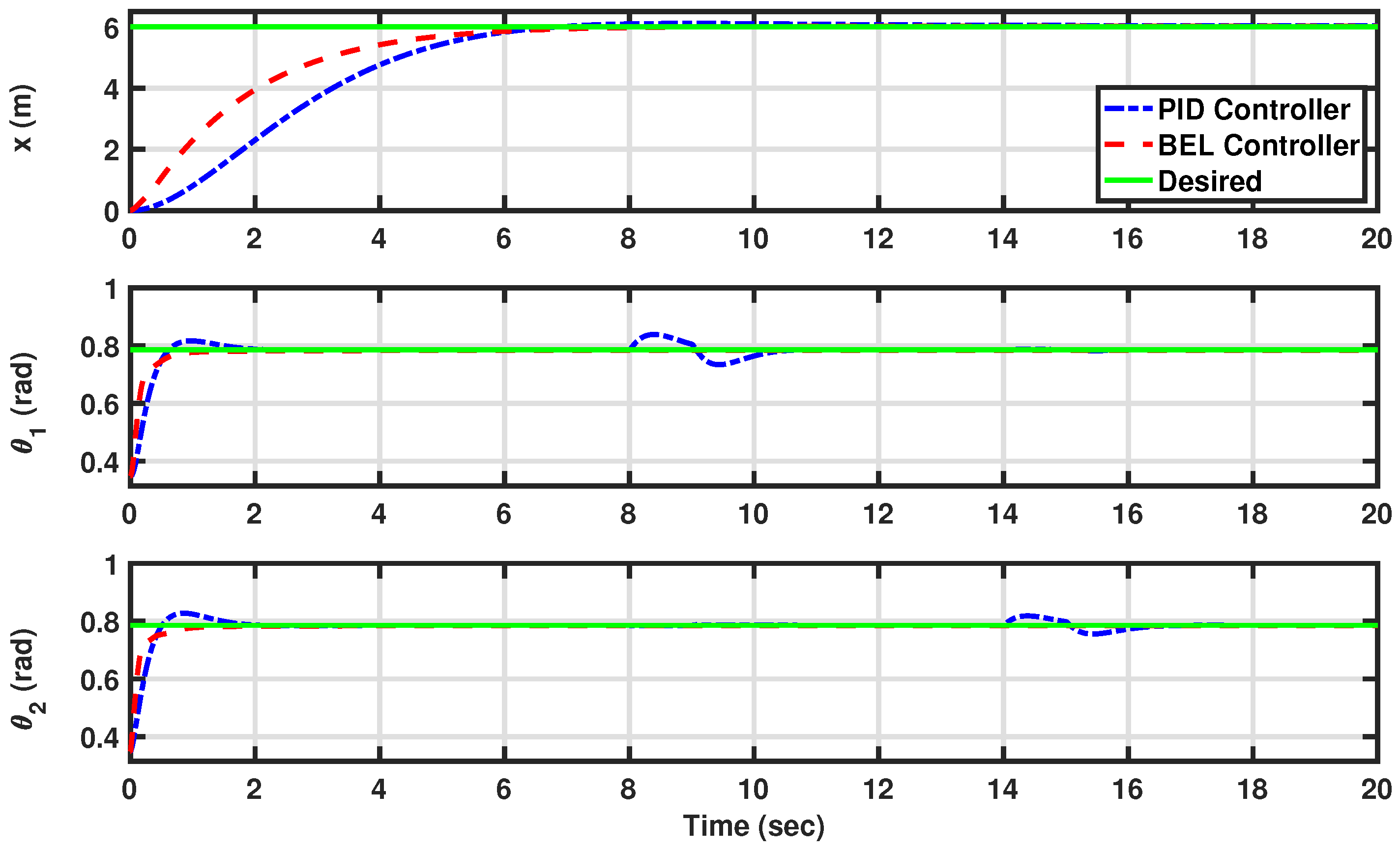

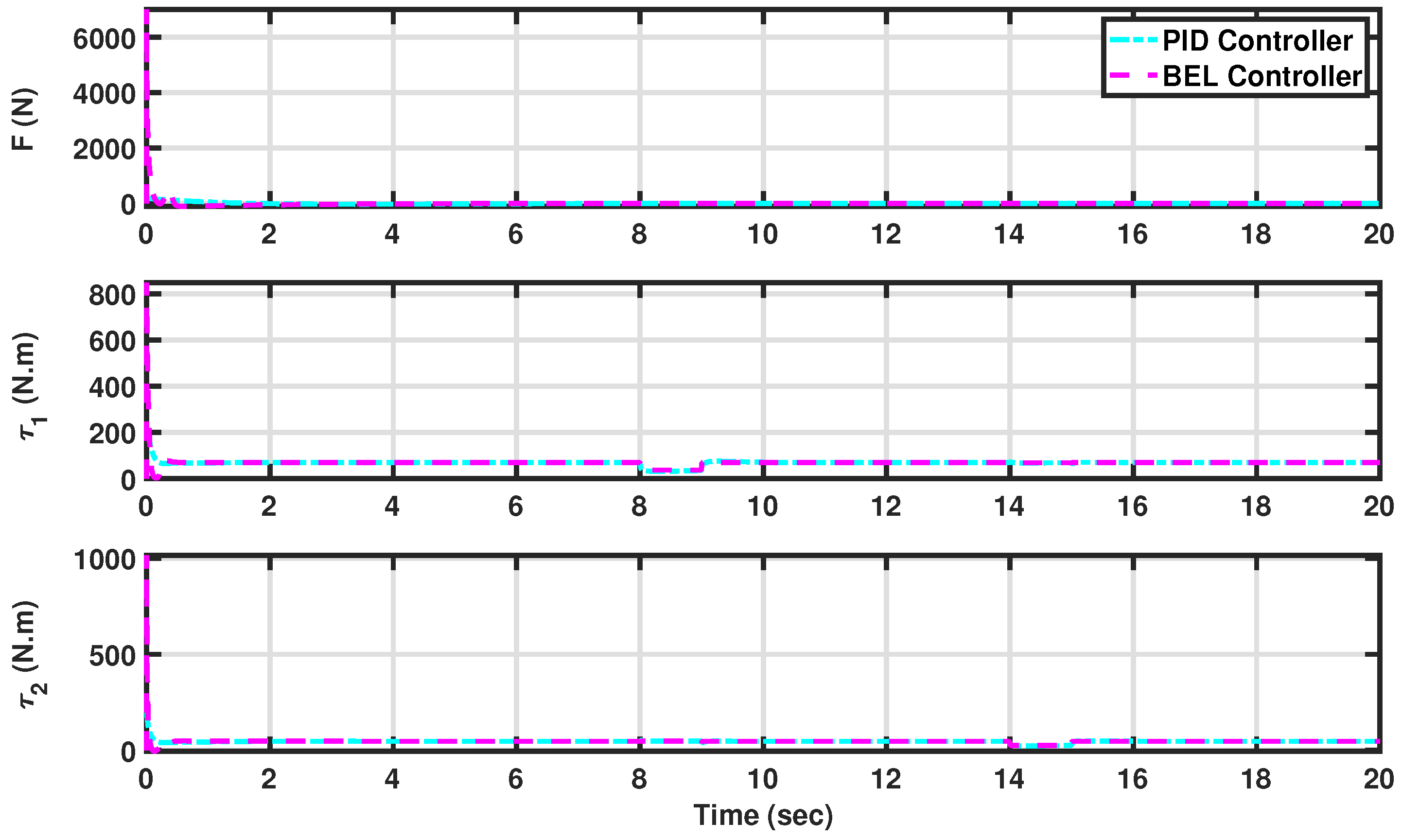

3.1. Scenario I: Maintaining Constant Trajectories for AV’s Angles and Displacement

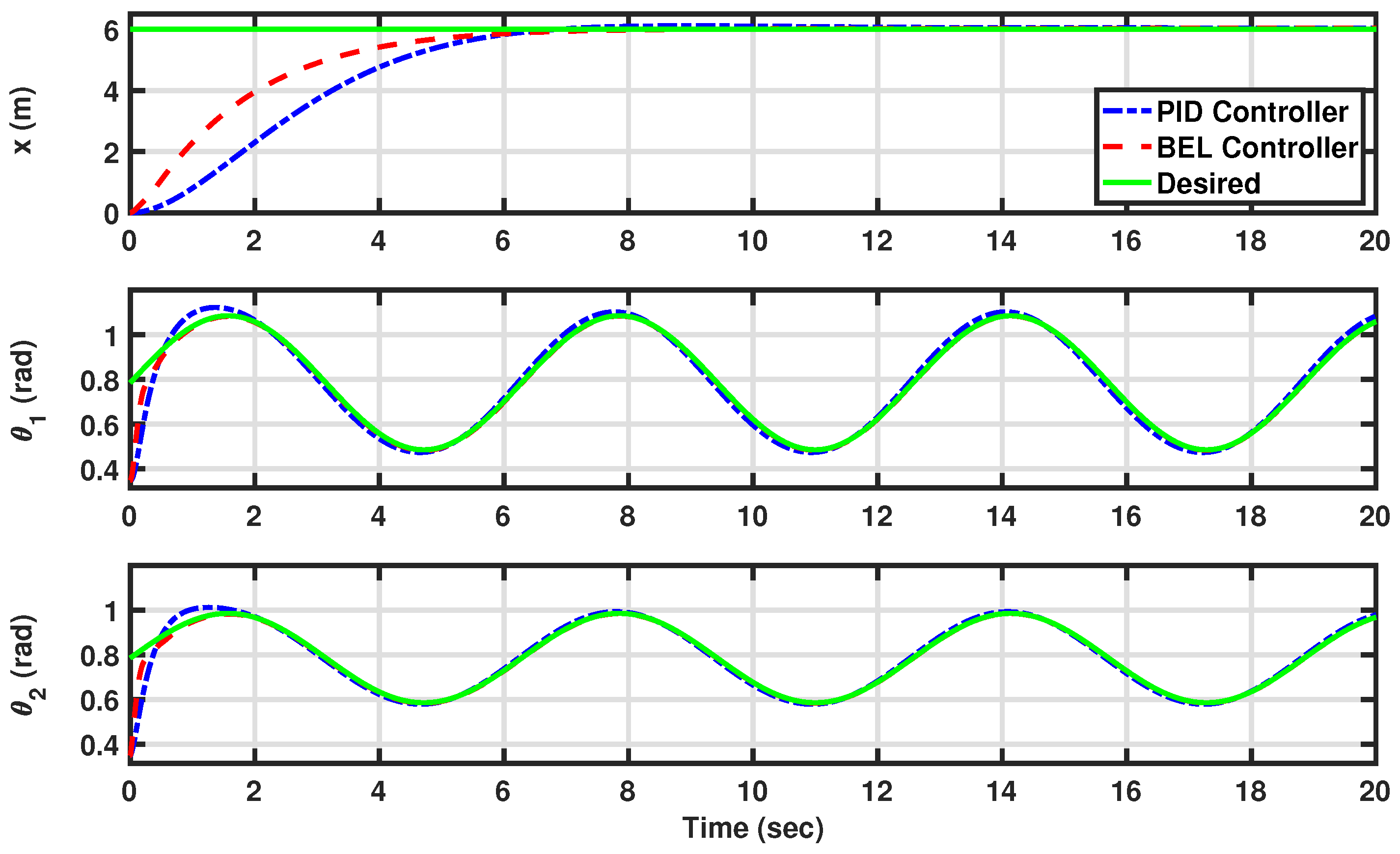

3.2. Scenario II: Tracking Sinusoidal Trajectories to Maintain AV Angles

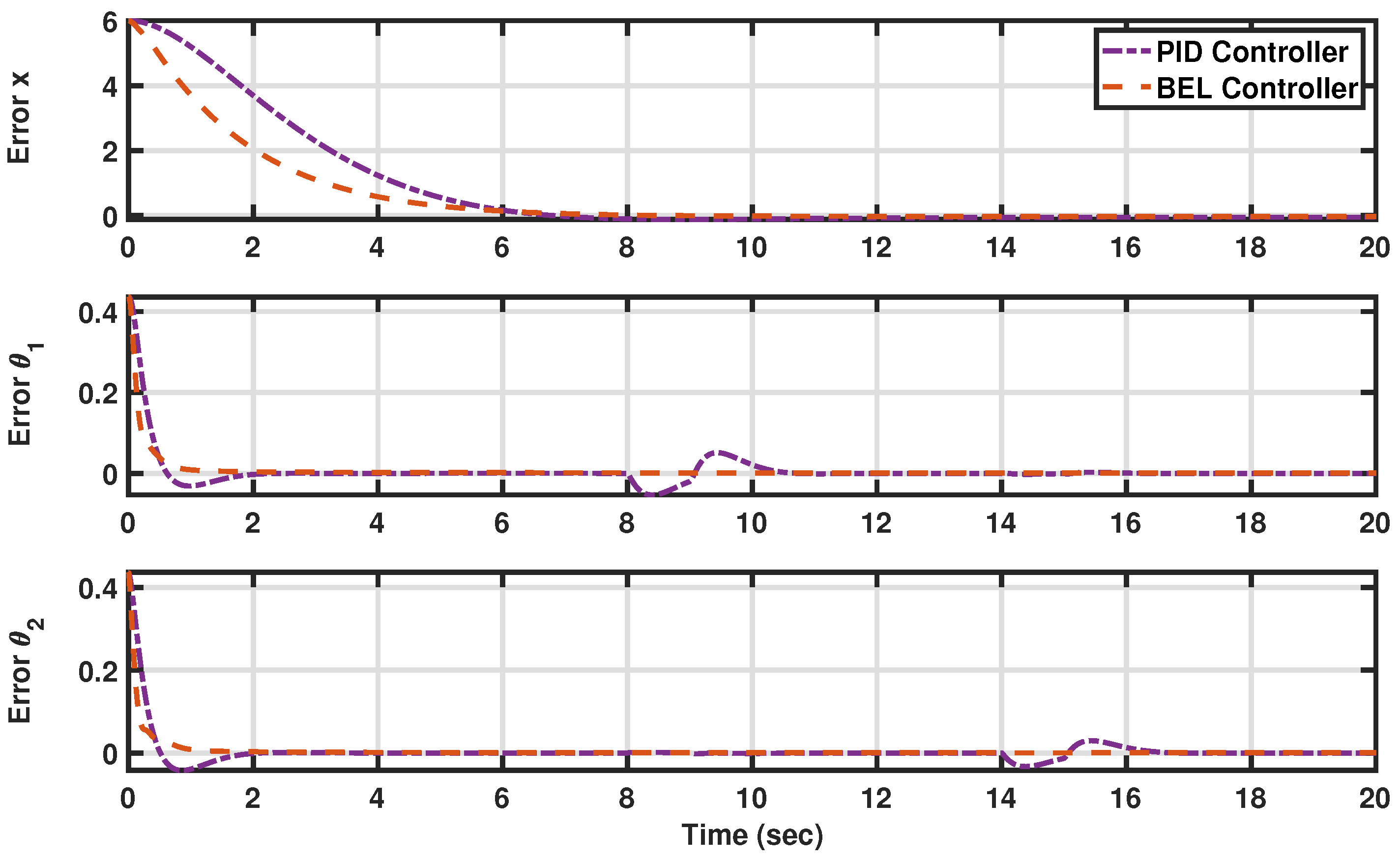

3.3. Scenario III: Preserving AV Angles and Displacement in the Presence of Substantial External Disturbances

4. Discussion and Future Work

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AV | Autonomous Vehicle |

| ML | Machine Learning |

| BEL | Brain Emotional Learning |

| PID | Proportional–Integral–Derivative |

| ES | Emotional Signal |

| SI | Sensory Input |

| MSE | Mean-Squared Error |

| RMSE | Root Mean Square Error |

| MAPE | Mean Absolute Percentage Error |

| IoT | Internet of Things |

| STEM | Science, Technology, Engineering, and Mathematics |

References

- Amin, A.; Wang, X.; Alroichdi, A.; Ibrahim, A. Designing and Manufacturing a Robot for Dry-Cleaning PV Solar Panels. Int. J. Energy Res. 2023, 2023, 7231554. [Google Scholar] [CrossRef]

- Akyazi, Ö.; Şahin, E.; Özsoy, T.; Algül, M. A solar panel cleaning robot design and application. Avrupa Bilim Teknol. Derg. 2019, 343–348. [Google Scholar] [CrossRef]

- De Schepper, E.; Van Passel, S.; Manca, J.; Thewys, T. Combining photovoltaics and sound barriers–A feasibility study. Renew. Energy 2012, 46, 297–303. [Google Scholar] [CrossRef]

- Dupraz, C.; Marrou, H.; Talbot, G.; Dufour, L.; Nogier, A.; Ferard, Y. Combining solar photovoltaic panels and food crops for optimising land use: Towards new agrivoltaic schemes. Renew. Energy 2011, 36, 2725–2732. [Google Scholar] [CrossRef]

- Myyas, R.N.; Al-Dabbasa, M.; Tostado-Véliz, M.; Jurado, F. A novel solar panel cleaning mechanism to improve performance and harvesting rainwater. Sol. Energy 2022, 237, 19–28. [Google Scholar] [CrossRef]

- Jamil, I.; Lucheng, H.; Habib, S.; Aurangzeb, M.; Ahmed, E.M.; Jamil, R. Performance evaluation of solar power plants for excess energy based on energy production. Energy Rep. 2023, 9, 1501–1534. [Google Scholar] [CrossRef]

- Ghosh, A. Nexus between agriculture and photovoltaics (agrivoltaics, agriphotovoltaics) for sustainable development goal: A review. Sol. Energy 2023, 266, 112146. [Google Scholar] [CrossRef]

- Thomas, S.K.; Joseph, S.; Sarrop, T.; Haris, S.B.; Roopak, R. Solar panel automated cleaning (SPAC) System. In Proceedings of the 2018 International Conference on Emerging Trends and Innovations In Engineering And Technological Research (ICETIETR), Ernakulam, India, 11–13 July 2018; pp. 1–3. [Google Scholar]

- Syafiq, A.; Pandey, A.; Adzman, N.; Abd Rahim, N. Advances in approaches and methods for self-cleaning of solar photovoltaic panels. Sol. Energy 2018, 162, 597–619. [Google Scholar] [CrossRef]

- Kumar, N.M.; Sudhakar, K.; Samykano, M.; Sukumaran, S. Dust cleaning robots (DCR) for BIPV and BAPV solar power plants-A conceptual framework and research challenges. Procedia Comput. Sci. 2018, 133, 746–754. [Google Scholar] [CrossRef]

- Khadka, N.; Bista, A.; Adhikari, B.; Shrestha, A.; Bista, D. Smart solar photovoltaic panel cleaning system. IOP Conf. Ser. Earth Environ. Sci. 2020, 463, 012121. [Google Scholar] [CrossRef]

- Hassan, M.U.; Nawaz, M.I.; Iqbal, J. Towards autonomous cleaning of photovoltaic modules: Design and realization of a robotic cleaner. In Proceedings of the 2017 First International Conference on Latest trends in Electrical Engineering and Computing Technologies (INTELLECT), Karachi, Pakistan, 15–16 November 2017; pp. 1–6. [Google Scholar]

- Khadka, N.; Bista, A.; Adhikari, B.; Shrestha, A.; Bista, D.; Adhikary, B. Current practices of solar photovoltaic panel cleaning system and future prospects of machine learning implementation. IEEE Access 2020, 8, 135948–135962. [Google Scholar] [CrossRef]

- Deb, D.; Brahmbhatt, N.L. Review of yield increase of solar panels through soiling prevention, and a proposed water-free automated cleaning solution. Renew. Sustain. Energy Rev. 2018, 82, 3306–3313. [Google Scholar] [CrossRef]

- Saini, A.; Nahar, A.; Yadav, A.K.; Arnim; Shekhawat, D. Solar Panel Cleaning System. Imp. J. Interdiscip. Res. 2017, 3, 26–31. [Google Scholar]

- Hajiahmadi, F.; Dehghani, M.; Zarafshan, P.; Moosavian, S.A.A.; Hassan-Beygi, S. Trajectory control of a robotic carrier for solar power plant cleaning system. In Proceedings of the 2019 7th International Conference on Robotics and Mechatronics (ICRoM), Tehran, Iran, 20–21 November 2019; pp. 463–468. [Google Scholar]

- Hajiahmadi, F.; Dehghani, M.; Zarafshan, P.; Moosavian, S.A.A.; Hassan-Beygi, S.R. Initial analysis and development of an automated maintenance system for Agrivoltaics plants. Agric. Eng. Int. CIGR J. 2023, 25, 130–145. [Google Scholar]

- Jafari, M.; Reyhanoglu, M.; Kozhabek, Z. Simple Learning-Based Robust Nonlinear Control of an Electric Pump for Liquid-Propellant Rocket Engines. Electronics 2023, 12, 3527. [Google Scholar] [CrossRef]

- LeDoux, J.E. Brain mechanisms of emotion and emotional learning. Curr. Opin. Neurobiol. 1992, 2, 191–197. [Google Scholar] [CrossRef] [PubMed]

- Morén, J.; Balkenius, C. A computational model of emotional learning in the amygdala. Anim. Animat. 2000, 6, 115–124. [Google Scholar]

- Lucas, C.; Shahmirzadi, D.; Sheikholeslami, N. Introducing BELBIC: Brain emotional learning based intelligent controller. Intell. Autom. Soft Comput. 2004, 10, 11–21. [Google Scholar] [CrossRef]

- Johnson, M.A.; Moradi, M.H. PID Control; Springer: Berlin/Heidelberg, Germany, 2005. [Google Scholar]

- Wang, L. PID Control System Design and Automatic Tuning Using MATLAB/Simulink; John Wiley & Sons: Hoboken, NJ, USA, 2020. [Google Scholar]

- Hajiahmadi, F.; Zarafshan, P.; Dehghani, M.; Moosavian, S.A.A.; Hassan-Beygi, S. Dynamics modeling and position control of a robotic carrier for solar panel cleaning system. In Proceedings of the 2019 7th International Conference on Robotics and Mechatronics (ICRoM), Tehran, Iran, 20–21 November 2019; pp. 613–618. [Google Scholar]

- Spong, M.W.; Hutchinson, S.; Vidyasagar, M. Robot Modeling and Control; John Wiley & Sons: Hoboken, NJ, USA, 2020. [Google Scholar]

- Craig, J.J. Introduction to Robotics; Pearson Educacion: London, UK, 2006. [Google Scholar]

- Hajiahmadi, F.; Zarafshan, P.; Dehghani, M.; Moosavian, S.A.A.; Hassanbeigi, R. Dynamic modeling and control of cleaning robot for agro-photovoltaic. Amirkabir J. Mech. Eng. 2021, 53, 3465–3478. [Google Scholar]

- Jafari, M.; Xu, H.; Carrillo, L.R.G. Brain emotional learning-based path planning and intelligent control co-design for unmanned aerial vehicle in presence of system uncertainties and dynamic environment. In Proceedings of the 2018 IEEE Symposium Series on Computational Intelligence (SSCI), Bangalore, India, 18–21 November 2018; pp. 1435–1440. [Google Scholar]

- Jafari, M.; Xu, H. Biologically-inspired intelligent flocking control for networked multi-UAS with uncertain network imperfections. Drones 2018, 2, 33. [Google Scholar] [CrossRef]

- Jafari, M.; Shahri, A.M.; Elyas, S.H. Optimal tuning of brain emotional learning based intelligent controller using clonal selection algorithm. In Proceedings of the ICCKE 2013, Mashhad, Iran, 31 October–1 November 2013; pp. 30–34. [Google Scholar]

- Ghobadpour, A.; Monsalve, G.; Cardenas, A.; Mousazadeh, H. Off-road electric vehicles and autonomous robots in agricultural sector: Trends, challenges, and opportunities. Vehicles 2022, 4, 843–864. [Google Scholar] [CrossRef]

- Karunathilake, E.; Le, A.T.; Heo, S.; Chung, Y.S.; Mansoor, S. The path to smart farming: Innovations and opportunities in precision agriculture. Agriculture 2023, 13, 1593. [Google Scholar] [CrossRef]

- Dobrilovic, D.; Pekez, J.; Ognjenovic, V.; Desnica, E. Analysis of Using Machine Learning Techniques for Estimating Solar Panel Performance in Edge Sensor Devices. Appl. Sci. 2024, 14, 1296. [Google Scholar] [CrossRef]

- Tilahun, F.B. Machine learning interfaces for modular modelling and operation-based design optimization of solar thermal systems in process industry. Eng. Appl. Artif. Intell. 2024, 127, 107285. [Google Scholar] [CrossRef]

- Rodriguez-Vazquez, J.; Prieto-Centeno, I.; Fernandez-Cortizas, M.; Perez-Saura, D.; Molina, M.; Campoy, P. Real-Time Object Detection for Autonomous Solar Farm Inspection via UAVs. Sensors 2024, 24, 777. [Google Scholar] [CrossRef] [PubMed]

- Xu, S.; Rai, R. Vision-based autonomous navigation stack for tractors operating in peach orchards. Comput. Electron. Agric. 2024, 217, 108558. [Google Scholar] [CrossRef]

- Loukatos, D.; Kondoyanni, M.; Kyrtopoulos, I.V.; Arvanitis, K.G. Enhanced robots as tools for assisting agricultural engineering students’ development. Electronics 2022, 11, 755. [Google Scholar] [CrossRef]

- Yazdinejad, A.; Zolfaghari, B.; Azmoodeh, A.; Dehghantanha, A.; Karimipour, H.; Fraser, E.; Green, A.G.; Russell, C.; Duncan, E. A review on security of smart farming and precision agriculture: Security aspects, attacks, threats and countermeasures. Appl. Sci. 2021, 11, 7518. [Google Scholar] [CrossRef]

- Bui, H.T.; Aboutorab, H.; Mahboubi, A.; Gao, Y.; Sultan, N.H.; Chauhan, A.; Parvez, M.Z.; Bewong, M.; Islam, R.; Islam, Z.; et al. Agriculture 4.0 and Beyond: Evaluating Cyber Threat Intelligence Sources and Techniques in Smart Farming Ecosystems. Comput. Secur. 2024, 140, 103754. [Google Scholar] [CrossRef]

- Yazdinejad, A.; Dehghantanha, A.; Karimipour, H.; Srivastava, G.; Parizi, R.M. An efficient packet parser architecture for software-defined 5g networks. Phys. Commun. 2022, 53, 101677. [Google Scholar] [CrossRef]

- Rudrakar, S.; Rughani, P. IoT based agriculture (Ag-IoT): A detailed study on architecture, security and forensics. Inf. Process. Agric. 2023. Available online: https://www.sciencedirect.com/science/article/pii/S2214317323000665?via%3Dihub (accessed on 16 April 2024).

- Yazdinejad, A.; Dehghantanha, A.; Srivastava, G.; Karimipour, H.; Parizi, R.M. Hybrid privacy preserving federated learning against irregular users in Next-generation Internet of Things. J. Syst. Archit. 2024, 148, 103088. [Google Scholar] [CrossRef]

- Fathy, C.; Ali, H.M. A secure IoT-based irrigation system for precision agriculture using the expeditious cipher. Sensors 2023, 23, 2091. [Google Scholar] [CrossRef] [PubMed]

| Symbol | Parameter | Value | Unit |

|---|---|---|---|

| Length of link1 | 0.3535533906 | m | |

| Length of link2 | 0.3535533906 | m | |

| Length of the end effector | 1.65 | m | |

| Mass of body | 50 | kg | |

| Mass of link1 | 1.5 | kg | |

| Mass of link2 | 3 | kg | |

| Mass of link3 | 0.2 | kg | |

| Mass of link4 | 0.2 | kg | |

| Mass of link5 | 0.2 | kg | |

| Mass of link6 | 3 | kg | |

| Mass of link7 | 1.5 | kg | |

| Mass of the end effector | 20 | kg | |

| g | Acceleration due to gravity | 9.81 | m/s2 |

| a | Length of body | 1.35 | m |

| b | Distance between motor 3’s center and the ground | 0.5 | m |

| Moment of inertia of body | kg·m2 | ||

| Moment of inertia of link1 | kg·m2 | ||

| Moment of inertia of link2 | kg·m2 | ||

| Moment of inertia of link3 | kg·m2 | ||

| Moment of inertia of link4 | kg·m2 | ||

| Moment of inertia of link5 | kg·m2 | ||

| Moment of inertia of link6 | kg·m2 | ||

| Moment of inertia of link7 | kg·m2 | ||

| Moment of inertia of the end effector | 1.6 | kg·m2 |

| Controller | Rise Time (s) | Settling Time (s) | Overshoot (%) |

|---|---|---|---|

| 4.1538 | 6.3904 | 1.1553 | |

| 3.6840 | 6.4638 | 0 | |

| 0.4067 | 1.4694 | 3.9919 | |

| 0.2840 | 0.7265 | 0 | |

| 0.3426 | 1.4541 | 5.3550 | |

| 0.1824 | 0.7780 | 0 |

| Improve (%) Rise Time | Improve (%) Settling Time | Improve (%) Overshoot | |

|---|---|---|---|

| x | 11.31 | 100 | |

| 30.16 | 50.56 | 100 | |

| 46.76 | 46.50 | 100 |

| Scenario I | Scenario II | Scenario III | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Controller | MSE | RMSE | MAPE | MSE | RMSE | MAPE | MSE | RMSE | MAPE |

| 3.2878 | 1.8132 | 14.1795 | 3.2879 | 1.8133 | 14.1788 | 3.2878 | 1.8132 | 14.1789 | |

| 1.8015 | 1.3422 | 9.2147 | 1.8009 | 1.3419 | 9.2663 | 1.8015 | 1.3422 | 9.2147 | |

| 0.0017 | 0.0411 | 0.8769 | 0.0022 | 0.0463 | 2.9569 | 0.0018 | 0.0429 | 1.4051 | |

| 0.0009 | 0.0304 | 0.7150 | 0.0009 | 0.0305 | 0.6834 | 0.0009 | 0.0304 | 0.7101 | |

| 0.0013 | 0.0366 | 0.7964 | 0.0015 | 0.0385 | 1.7258 | 0.0014 | 0.0374 | 1.1238 | |

| 0.0007 | 0.0257 | 0.5639 | 0.0007 | 0.0258 | 0.5362 | 0.0007 | 0.0257 | 0.5623 |

| Scenario I Improve (%) | Scenario II Improve (%) | Scenario III Improve (%) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| MSE | RMSE | MAPE | MSE | RMSE | MAPE | MSE | RMSE | MAPE | |

| x | 45.21 | 25.98 | 35.01 | 45.23 | 25.99 | 34.65 | 45.21 | 25.98 | 35.01 |

| 45.16 | 25.95 | 18.46 | 56.64 | 34.15 | 76.89 | 49.83 | 29.17 | 49.46 | |

| 50.67 | 29.77 | 29.19 | 54.94 | 32.87 | 68.93 | 52.71 | 31.23 | 49.97 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hajiahmadi, F.; Jafari, M.; Reyhanoglu, M. Machine Learning-Based Control of Autonomous Vehicles for Solar Panel Cleaning Systems in Agricultural Solar Farms. AgriEngineering 2024, 6, 1417-1435. https://doi.org/10.3390/agriengineering6020081

Hajiahmadi F, Jafari M, Reyhanoglu M. Machine Learning-Based Control of Autonomous Vehicles for Solar Panel Cleaning Systems in Agricultural Solar Farms. AgriEngineering. 2024; 6(2):1417-1435. https://doi.org/10.3390/agriengineering6020081

Chicago/Turabian StyleHajiahmadi, Farima, Mohammad Jafari, and Mahmut Reyhanoglu. 2024. "Machine Learning-Based Control of Autonomous Vehicles for Solar Panel Cleaning Systems in Agricultural Solar Farms" AgriEngineering 6, no. 2: 1417-1435. https://doi.org/10.3390/agriengineering6020081

APA StyleHajiahmadi, F., Jafari, M., & Reyhanoglu, M. (2024). Machine Learning-Based Control of Autonomous Vehicles for Solar Panel Cleaning Systems in Agricultural Solar Farms. AgriEngineering, 6(2), 1417-1435. https://doi.org/10.3390/agriengineering6020081