Optimized Walking Route Method for Precision Coffee Farming

Abstract

:1. Introduction

2. Materials and Methods

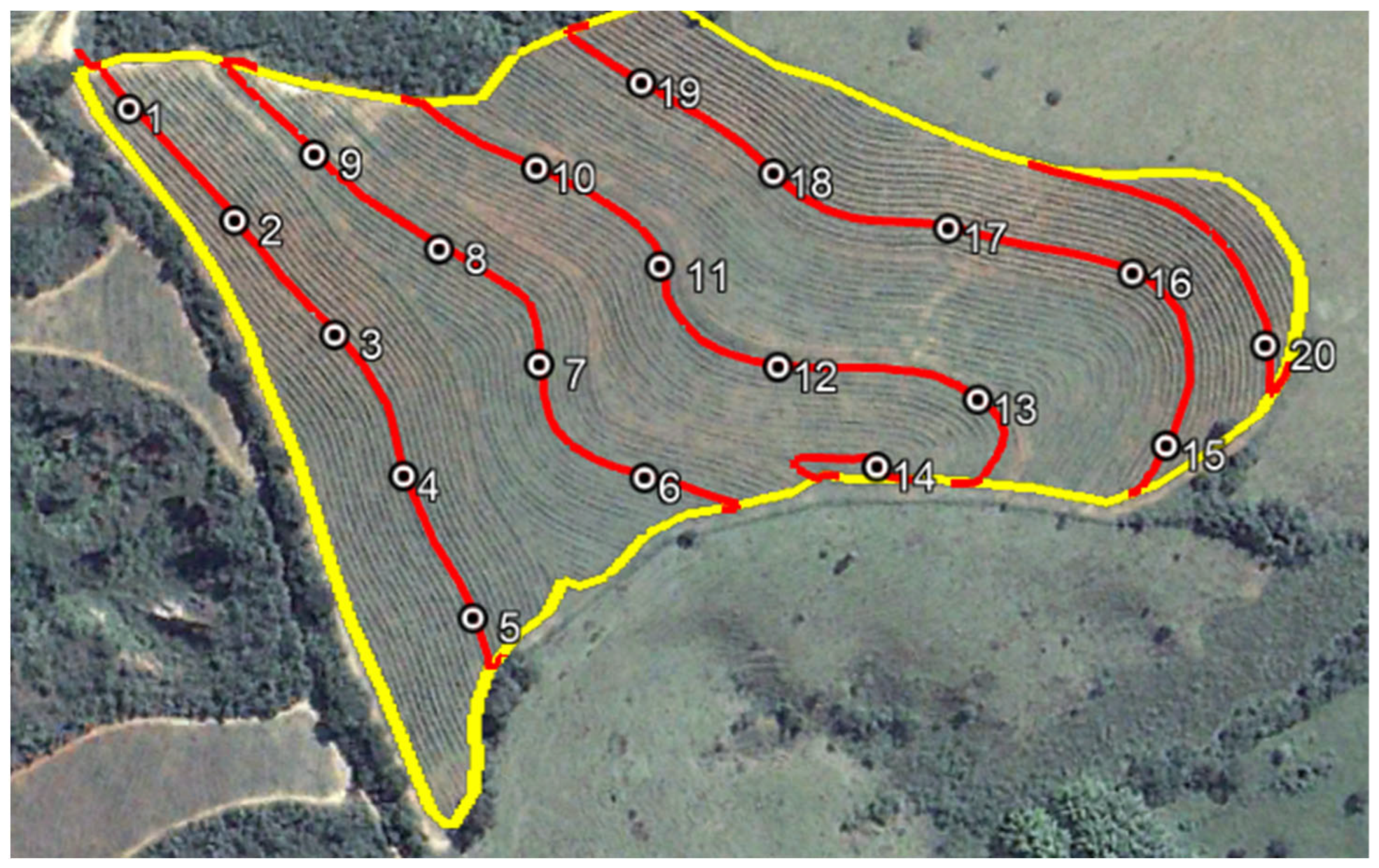

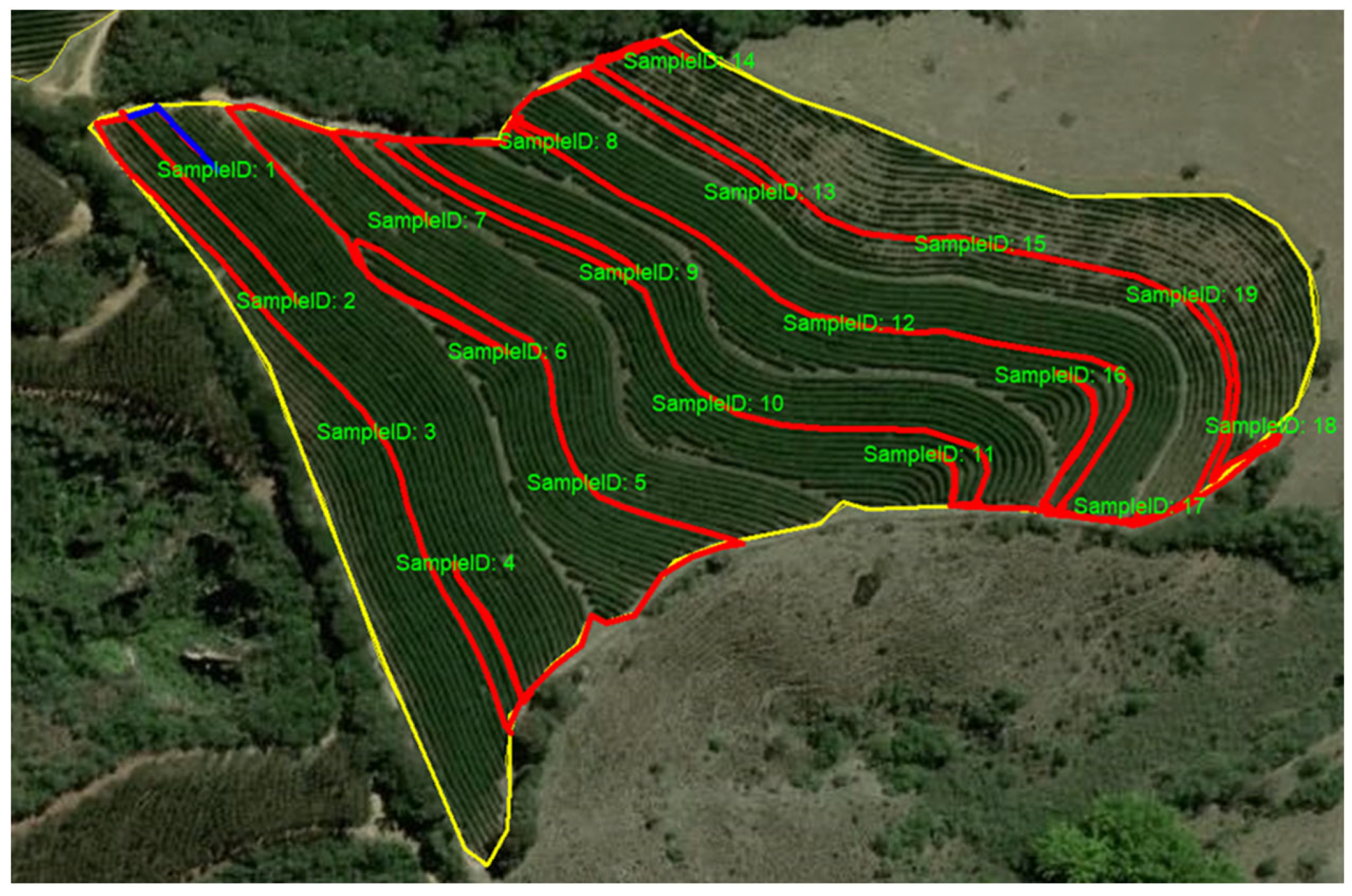

2.1. Proposed Method

2.2. Methodological Flowchart for Walking Route and Sampling Point Creation

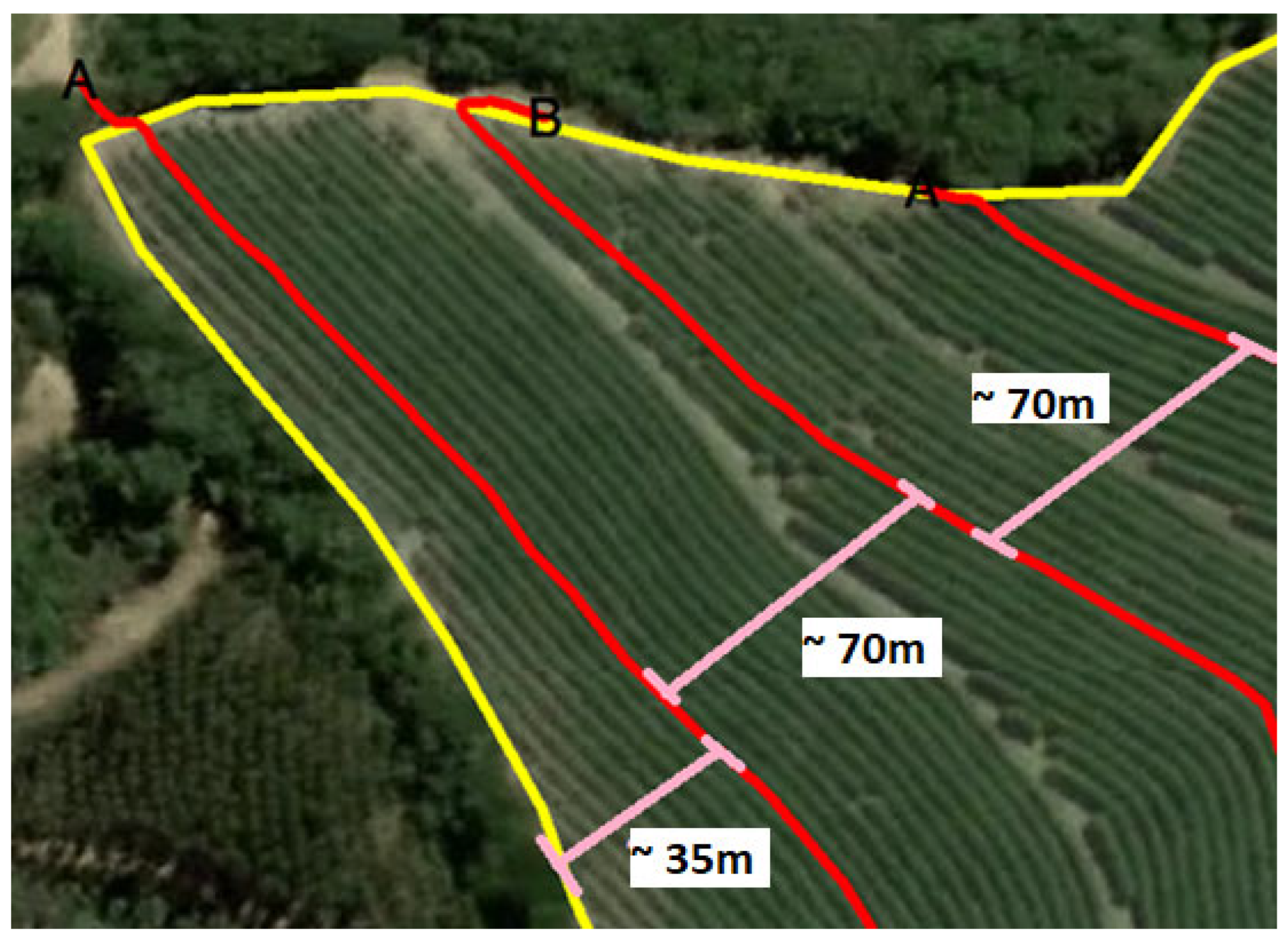

2.3. Sampling Grid Demarcation

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lanna, G.B.M.; Teixeira, E.C.; Reis, R.P. Determinantes da adoção da tecnologia de despolpamento na cafeicultura: Estudo de uma região produtora da Zona da Mata de Minas Gerais. Organ. Rurais Agroindustriais 2011, 13, 352–362. [Google Scholar]

- Eastwood, C.; Klerkx, L.; Nettle, R. Dynamics and distribution of public and private research and extension roles for technological innovation and diffusion: Case studies of the implementation and adaptation of precision farming technologies. J. Rural Stud. 2017, 49, 1–12. [Google Scholar] [CrossRef]

- Schmidhalter, U.; Maidl, F.X.; Heuwinkel, H.; Demmel, M.; Auernhammer, H.; Noack, P.O.; Rothmund, M. Precision Farming—Adaptation of Land Use Small Scale Heterogeneity. In Perspectives for Agroecosystem Management: Environmental and Socio-Economic Demands; Elsevier: Amsterdam, The Netherlands, 2008; pp. 121–199. [Google Scholar]

- Molin, J.; Junior, P.V.; Neto, D.D.; Faulin, G.; Mascarin, L. Variação Espacial na Produtividade de Milho Safrinha Devido aos Macronutrientes e à População de Plantas. Rev. Bras. Milho Sorgo 2007, 6, 309–324. [Google Scholar] [CrossRef]

- Silva, F.M.D.; Alves, M.D.C. Cafeicultura de Precisão; Editora UFLA: Lavras, Brazil, 2013. [Google Scholar]

- Araújo, G.; Ferraz, S.; da Silva, F.M.; da Costa, P.A.N.; Silva, A.C.; de Melo Carvalho, F. Agricultura de precisão no estudo de atributos químicos do solo e da produtividade de lavoura cafeeira. Coffee Sci. 2012, 7, 59–67. [Google Scholar]

- Ferreira, G.F.P. Espacialização de Atributos do Solo e do Cafeeiro Arábica em Densidades Amostrais no Planalto de Vitória da Conquista-BA. Ph.D. Thesis, UESB, Vitória da Conquista, Brazil, 2020; 110p. [Google Scholar]

- Faulin, G.D.C.; Molin, J.P. Utilização dos conceitos da agricultura de precisão na cultura do café (Coffea arabica L.). In 5° Simposio de Pesquisas dos Cafes do Brasil; Consórcio Pesquisa Café: Águas de Lindóia, Brazil, 2007; pp. 70–75. [Google Scholar]

- Ferraz, G.A.e.S.; De Oliviera, M.S.; Da Silva, F.M.; Avelar, R.C.; Da Silva, F.C.; Ferraz, P.F.P. Methodology to determine the soil sampling grid for precision agriculture in a coffee field. Dyna 2017, 84, 316–325. [Google Scholar] [CrossRef]

- Figueiredo, V.C.; Mantovani, J.R.; Leal, R.M.; Miranda, J.M. Levantamento da fertilidade do solo de lavouras cafeeiras em produção, no sul de minas gerais. Coffee Sci. 2013, 8, 306–313. [Google Scholar]

- Molin, J.P.; Motomiya, A.V.d.A.; Frasson, F.R.; Faulin, G.D.C.; Tosta, W. Test procedure for variable rate fertilizer on coffee. Acta Sci. Agron. 2010, 32, 569–575. [Google Scholar] [CrossRef]

- Molin, J.; Faulin, G.; Stanislavski, W. Yield mapping and variable rate of fertilizers for coffee in brazil. Acta Hortic. 2009, 261–266. [Google Scholar] [CrossRef]

- Carvalho, L.C.C.; Silva, F.M.D.; Ferraz, G.A.; Figueiredo, V.C.; Cunha, J.P.B. Comparação entre amostragem foliar convencional e de precisão para analise de micronutrientes na cafeicultura. Coffee Sci. 2017, 12, 272–281. [Google Scholar] [CrossRef]

- Carvalho, L.C.C.; Da Silva, F.M.; Ferraz, G.A.E.S.; Stracieri, J.; Ferraz, P.F.P.; Ambrosano, L. Geostatistical analysis of Arabic coffee yield in two crop seasons. Rev. Bras. Eng. Agric. E Ambient. 2017, 21, 410–414. [Google Scholar] [CrossRef]

- Ferraz, G.A.E.S.; Da Silva, F.M.; De Oliveira, M.S.; Da Silva, F.C.; Carvalho, L.C.C. Comparativo entre os atributos químicos do solo amostrados de forma convencional e em malha. Coffee Sci. 2017, 12, 17–29. [Google Scholar] [CrossRef]

- Figueiredo, V.C.; Da Silva, F.M.; Ferraz, G.A.E.S.; De Oliveira, M.S.; Dos Santos, S.A. Development of a methodology to determine the best grid sampling in precision coffee growing. Coffee Sci. 2018, 13, 312–323. [Google Scholar] [CrossRef]

- Oliveira, R.B.; Silva, A.F.D.; Quartezani, W.Z.; Lima, J.S.S.; Zimback, C.R. Levantamento do tipo de malha amostral, tamanho de área e número de pontos utilizados em análise geoestatística. In Proceedings of the II Simpósio de Geoestatística Aplicada em Ciências Agrárias, Botucatu, Brazil, 19–20 May 2011; UNESP: Botucatu, Brazil, 2011. [Google Scholar]

- Colaço, A.F.; Molin, J.P. Agricultura de Precisão. In Boletim Técnico 02; Laboratório de Agricultura de Precisão-LAP: Piracicaba, Brazil, 2015. [Google Scholar]

- Inamasu, R.Y.; Molin, J.P. Agricultura de Precisão. In Boletin Técnico; MAPA: Brasilia, Brazil, 2013. [Google Scholar]

- Mesquita, C.M.D.; Resende, J.E.; Carvalho, J.S.; Fabri Junior, M.A.; Moraes, N.C.; Dias, P.T.; Carvalho, R.M.; Araújo, W.G. Manual do Café: Implantação de Cafezais; EMATER: Belo Horizonte, Brazil, 2016; p. 50. [Google Scholar]

- Nogueira, F.A.A. A Cultura do Café no Sul de Minas Gerais; Universidade Federal de Santa Catarina: Florianópolis, Brazil, 1998. [Google Scholar]

- Carvalho, L.C.C. Determinação da densidade amostral ótima para a geração de mapas temáticos na cafeicultura de precisão. Ph.D. Thesis, UFLA, Lavras, Brazil, 2016; 195p. [Google Scholar]

- Figueiredo, V.C. Estudo de Malhas Amostrais em Cafeicultura de Precisão; Universidade Federal de Lavras: Lavras, Brazil, 2016. [Google Scholar]

- Figueiredo, V.C.; Ferraz, G.A.S.; Silva, F.D.; Conceição, F.D.; Carvalho, L.C.C. Analysis of spatial variability of force detachment of coffee fruits in central pivot. Coffee Sci. 2017, 12, 84–92. [Google Scholar]

- Morgan, M.; Ess, D. The Precision Farming Guide for Agriculturists; Deere: Moline, IL, USA, 1997; p. 117. [Google Scholar]

- Silva, A.P. Variabilidade Espacial de Atributos Físicos do Solo. Ph.D. Thesis, Escola Superior de Agricultura “Luiz Queiroz”, Piracicaba, Brazil, 1988. [Google Scholar]

- Lucas, E.; Junior, E.; Appel, E. Aspectos Práticos Sobre a Variabilidade Espacial em Atributos do Solo. In Proceedings of the 23º Simpósio Nacional de Probabilidade e Estatística, Aguas de São Pedro, Brazil, 23–28 September 2018. [Google Scholar]

- Andriotti, J.L.S. Fundamentos de Estatística e Geoestatística, 1st ed.; Editora UNISINOS: Porto Alegre, Brazil, 2003. [Google Scholar]

- Trangmar, B.B.; Yost, R.S.; Uehara, G. Application of Geostatistics to Spatial Studies of Soil Properties. Adv. Agron. 1985, 38, 45–94. [Google Scholar]

- Rocha, H.G.; Silva, A.D.; Nogueira, D.A.; Miranda, J.M.; Mantovani, J.R. Coffee productivity mapping from mathematical models for prediction of harvest. Coffee Sci. 2016, 11, 108–116. [Google Scholar]

- Lima, J.S.D.S.; Silva, S.D.A.; Oliveira, R.B.D.; Fonseca, A.S.D. Estimativa da produtividade de café conilon utilizando técnicas de cokrigagem. Rev. Ceres 2016, 63, 54–61. [Google Scholar] [CrossRef]

- Balastreire, L.A.; Amaral, J.R.; Leal, J.C.G.; Baio, F.H.R. Agricultura de precisão: Mapeamento da produtividade de uma cultura de café. In Congresso Brasileiro De Engenharia Agrícola; SBEA: Jaboticabal, Brazil, 2001. [Google Scholar]

- Silva, C.; Moretto, A.; Rodrigues, R. Viabilidade Econômica Da Agricultura De Precisão: O Caso Do Paraná; UFV: Viçosa, Brazil, 2000; pp. 1–10. [Google Scholar]

| Plot | Conventional Method * (m) | Proposed Method * (m) |

|---|---|---|

| ZE06 | 191.7 | 136.1 |

| ZE08 | 215.0 | 117.5 |

| ZE03 | 199.3 | 103.9 |

| ZE02 | 448.3 | 170.8 |

| Mean | 263.2 ** | 132.8 ** |

| Plot | Year | C0 | a |

|---|---|---|---|

| ZE02 | 2017 | 1.44 | 155.87 |

| ZE02 | 2018 | 44.58 | 224.85 |

| ZE03 | 2017 | 8.08 | 209.30 |

| ZE03 | 2018 | 0 | 112.47 |

| ZE06 | 2017 | 0.28 | 118.52 |

| ZE06 | 2018 | 0.22 | 125.79 |

| ZE08 | 2017 | 0 | 167.68 |

| ZE08 | 2018 | 36.86 | 78.95 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Faria, R.d.O.; Silva, F.M.d.; Ferraz, G.A.e.S.; Oliveira e Silva, M.d.L.; Herrera, M.A.D.; Soares, D.V.; Marques Filho, A.C. Optimized Walking Route Method for Precision Coffee Farming. AgriEngineering 2024, 6, 2130-2143. https://doi.org/10.3390/agriengineering6030125

Faria RdO, Silva FMd, Ferraz GAeS, Oliveira e Silva MdL, Herrera MAD, Soares DV, Marques Filho AC. Optimized Walking Route Method for Precision Coffee Farming. AgriEngineering. 2024; 6(3):2130-2143. https://doi.org/10.3390/agriengineering6030125

Chicago/Turabian StyleFaria, Rafael de Oliveira, Fábio Moreira da Silva, Gabriel Araújo e Silva Ferraz, Mirian de Lourdes Oliveira e Silva, Miguel Angel Diaz Herrera, Daniel Veiga Soares, and Aldir Carpes Marques Filho. 2024. "Optimized Walking Route Method for Precision Coffee Farming" AgriEngineering 6, no. 3: 2130-2143. https://doi.org/10.3390/agriengineering6030125

APA StyleFaria, R. d. O., Silva, F. M. d., Ferraz, G. A. e. S., Oliveira e Silva, M. d. L., Herrera, M. A. D., Soares, D. V., & Marques Filho, A. C. (2024). Optimized Walking Route Method for Precision Coffee Farming. AgriEngineering, 6(3), 2130-2143. https://doi.org/10.3390/agriengineering6030125