Remote Monitoring of Bee Apiaries as a Tool for Crisis Management

Abstract

:1. Introduction

2. Materials and Methods

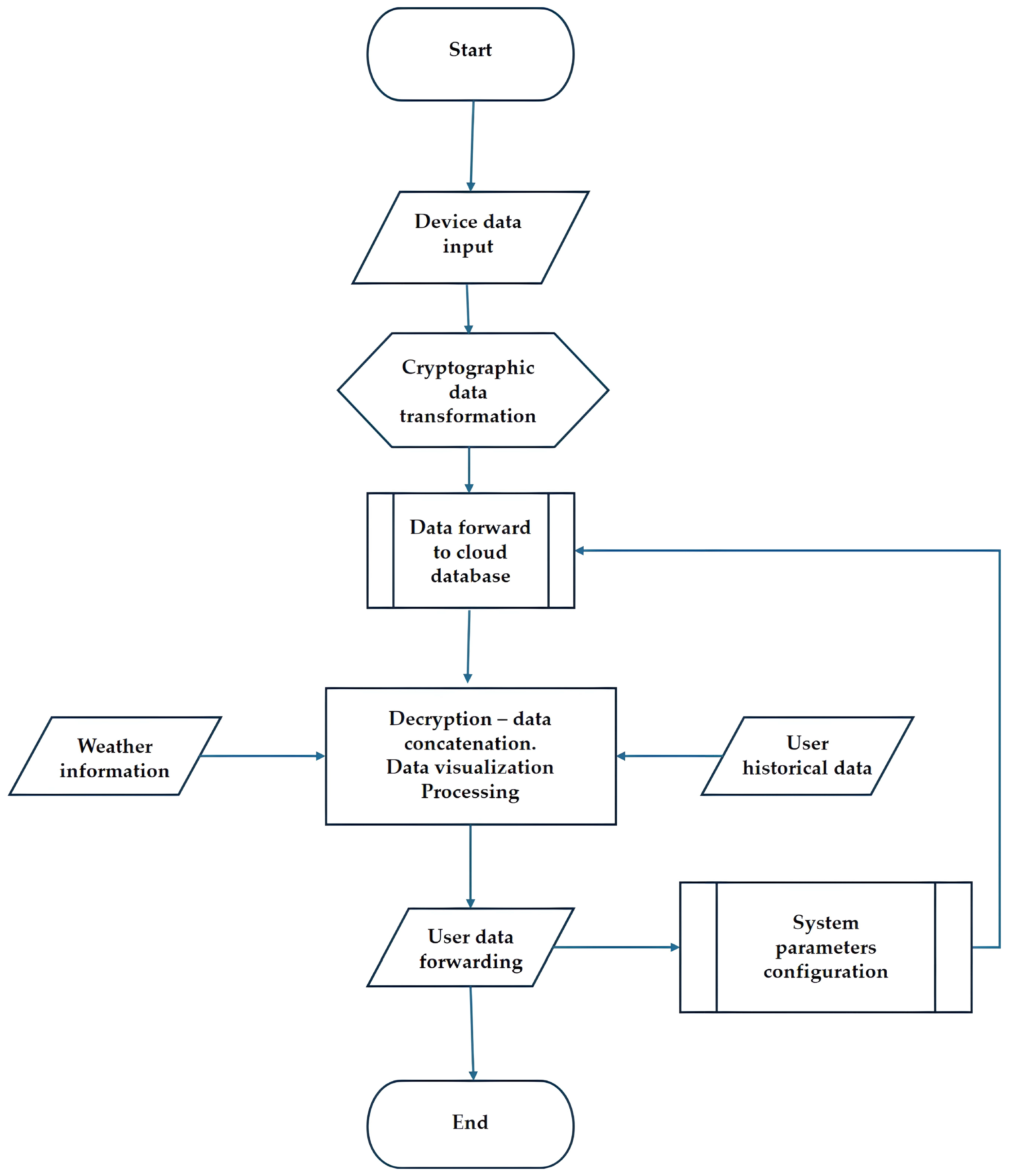

2.1. System Architecture

- Weather conditions (ambient temperature and relative humidity) of the apiary

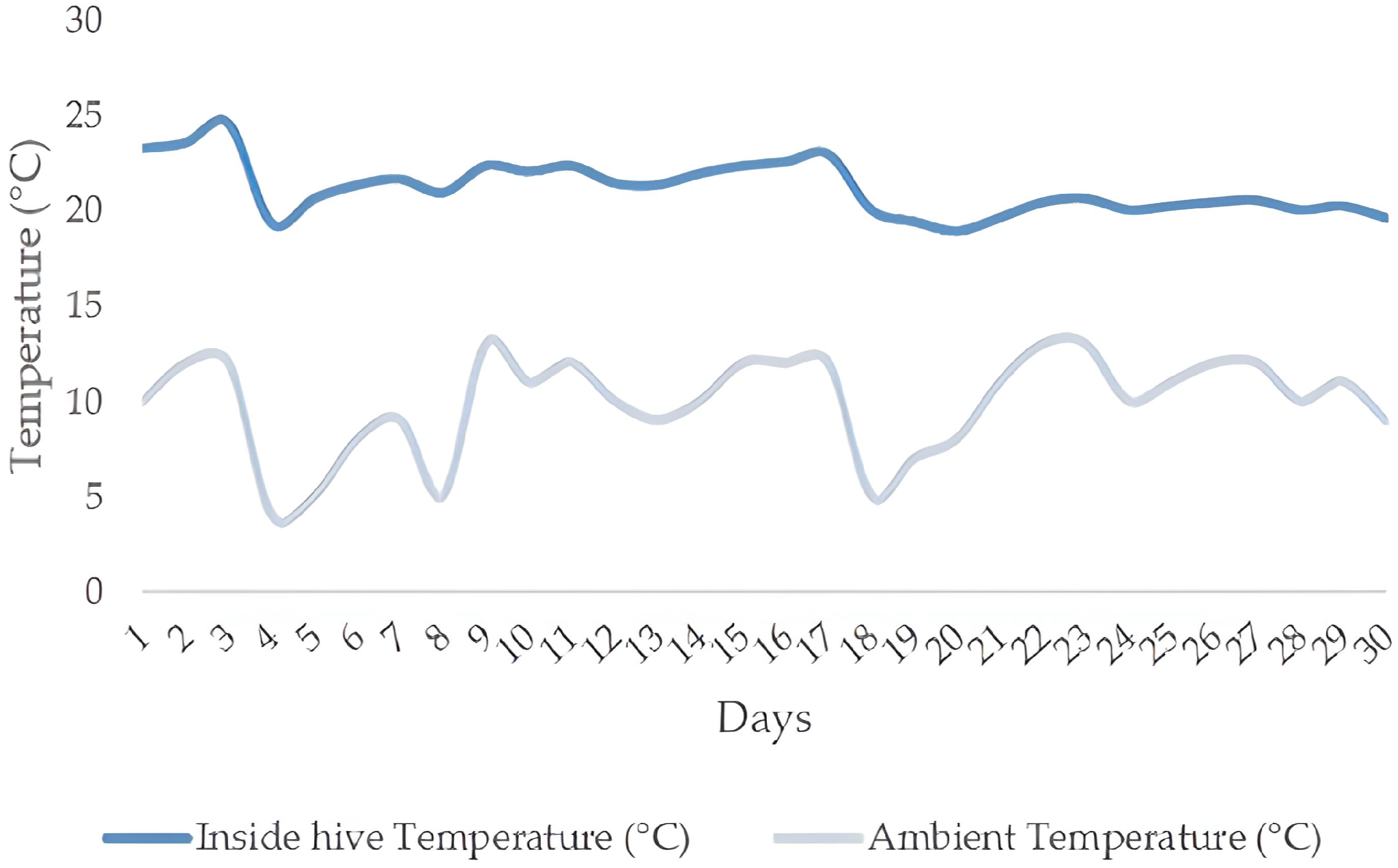

- Inside-hive temperature

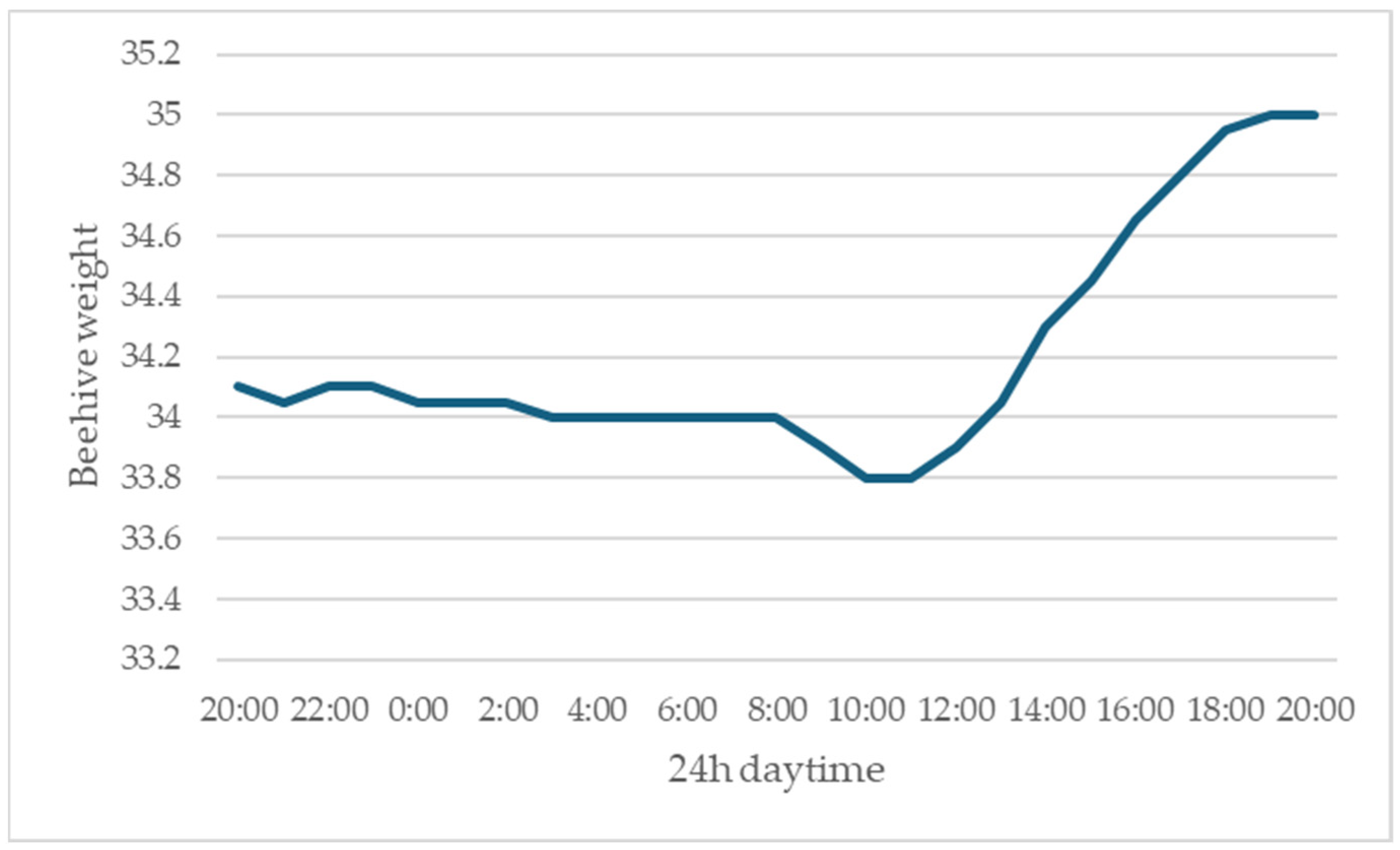

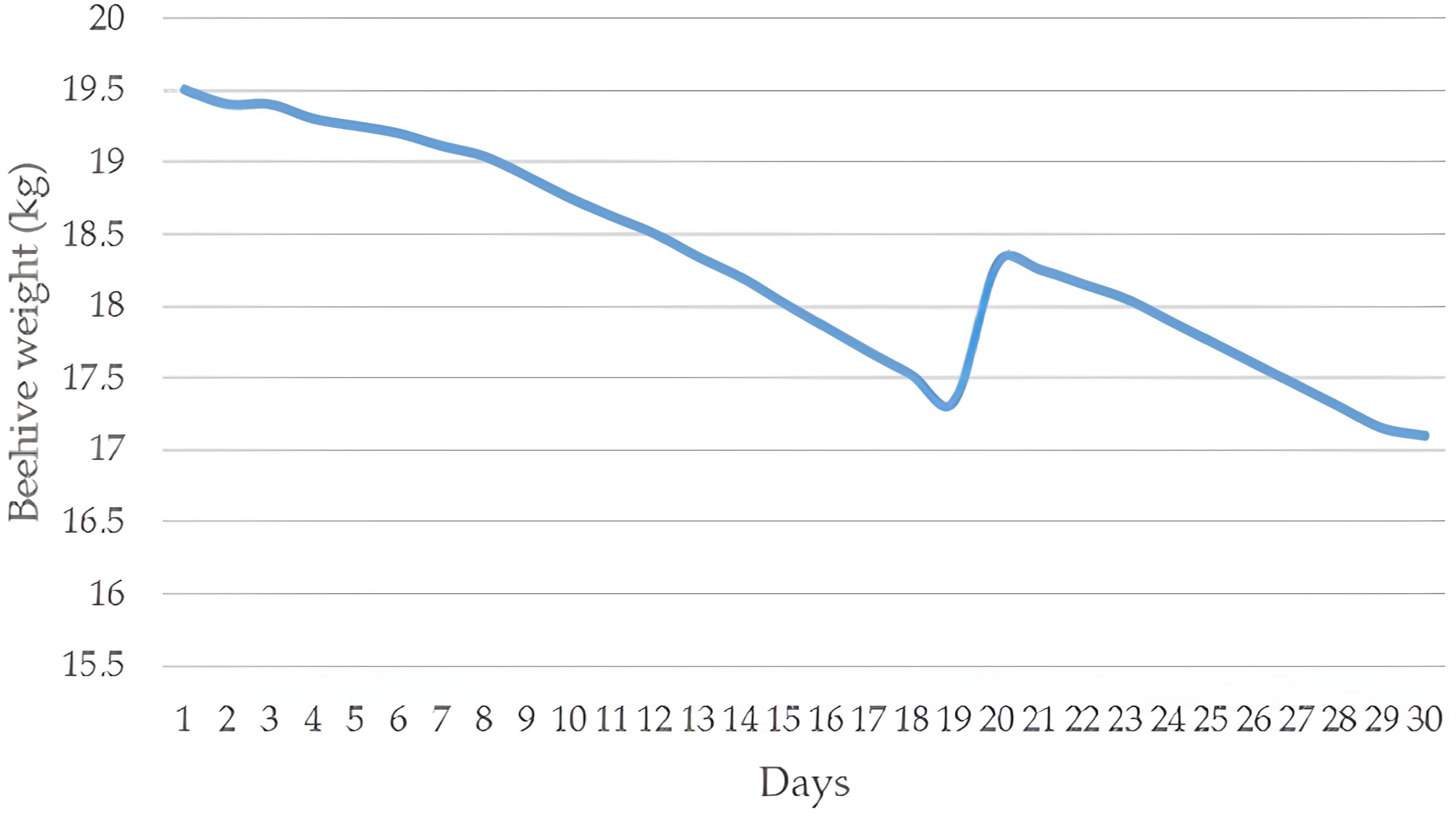

- Beehive weight

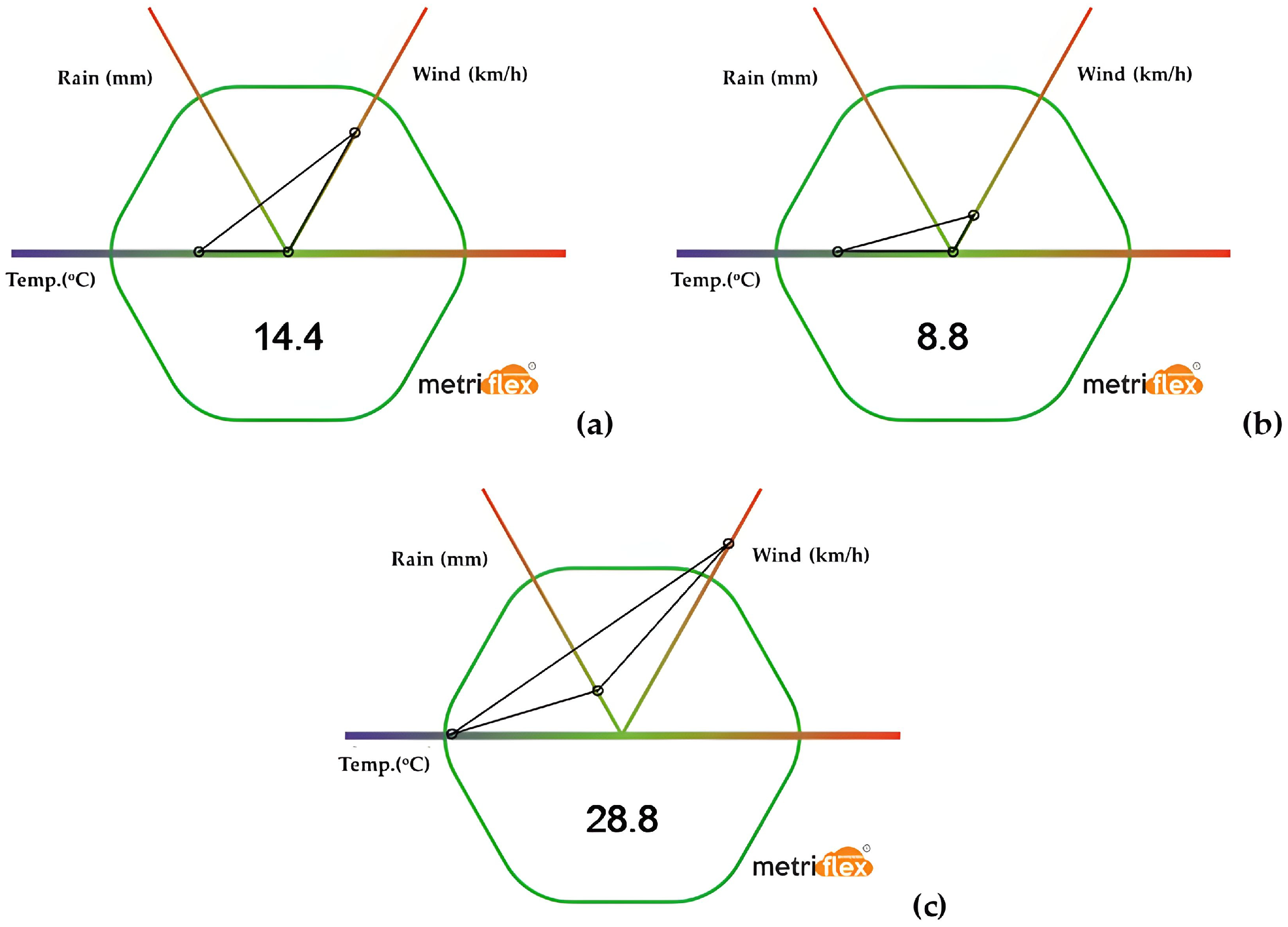

- Flight conditions assessment

- Beehive door activity

- GPS location tracking

2.2. Input/Output Data

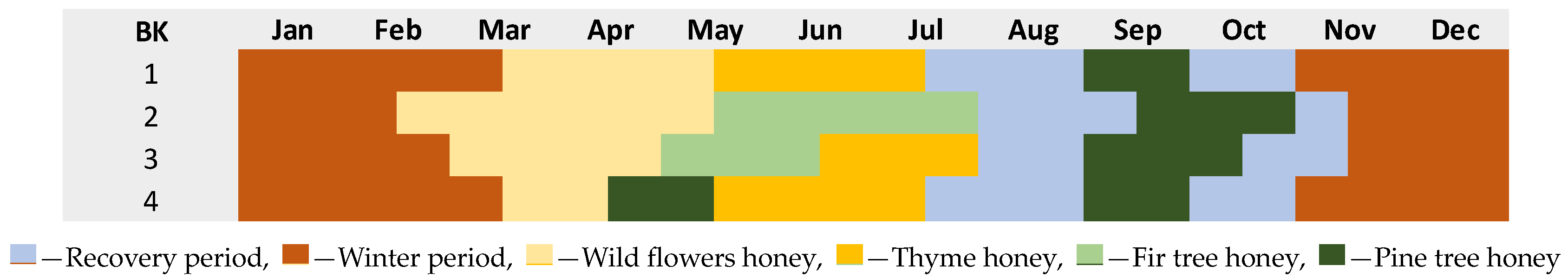

2.3. Experimental Case Studies

3. Results

3.1. Apiary Monitoring and Data

3.2. Assessed Risks and Impact

3.3. Risks Prioritization and Treatment

4. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Goap, A.; Sharma, D.; Shukla, A.K.; Krishna, C.R. An IoT based smart irrigation management system using Machine learning and open source technologies. Comput. Electron. Agric. 2018, 155, 41–49. [Google Scholar] [CrossRef]

- Fountas, S.; Mylonas, N.; Malounas, I.; Rodias, E.; Santos, C.H.; Pekkeriet, E. Agricultural robotics for field operations. Sensors 2020, 9, 2672. [Google Scholar] [CrossRef] [PubMed]

- Bohnenkamp, D.; Behmann, J.; Mahlein, A.K. In-field detection of Yellow Rust in Wheat on the Ground Canopy and UAV Scale. Remote Sens. 2019, 21, 2495. [Google Scholar] [CrossRef]

- FAO. FAO Statistics. Available online: https://www.fao.org/faostat/en/#data/QC (accessed on 14 June 2024).

- Guruprasad, S.M.; Leiding, B. BeeOpen—An Open Data Sharing Ecosystem for Apiculture. Agriculture 2024, 14, 470. [Google Scholar] [CrossRef]

- Cota, D.; Martins, J.; Mamede, H.; Branco, F. BHiveSense: An integrated information system architecture for sustainable remote monitoring and management of apiaries based on IoT and microservices. J. Open Innov. Technol. Mark. Complex. 2023, 9, 3. [Google Scholar] [CrossRef]

- Kviesis, A.; Komasilovs, V.; Ozols, N.; Zacepins, A. Bee colony remote monitoring based on IoT using ESP-NOW protocol. PeerJ Comput. Sci. 2023, 9, e1363. [Google Scholar] [CrossRef] [PubMed]

- FAO. Good Beekeeping Practices for Sustainable Apiculture; Food and Agriculture Organization, Global: Rome, Italy, 2021. [Google Scholar]

- Pignagnoli, A.; Pignedoli, S.; Carpana, E.; Costa, C.; Prà, A.D. Carbon footprint of honey in different beekeeping systems. Sustainability 2021, 13, 11063. [Google Scholar] [CrossRef]

- Kulyukin, V.; Mukherjee, S. On video analysis of omnidirectional bee traffic: Counting bee motions with motion detection and image classification. Appl. Sci. 2019, 9, 3743. [Google Scholar] [CrossRef]

- Catania, P.; Vallone, M. Application of a precision apiculture system to monitor honey daily production. Sensors 2020, 20, 2012. [Google Scholar] [CrossRef]

- Aven, T. Risk assessment and risk management: Review of recent advances on their foundation. Eur. J. Oper. Res. 2016, 253, 1–13. [Google Scholar] [CrossRef]

- Karadas, K.; Birinci, A. Identification of risk factors affecting production of beekeeping farms and development of risk management strategies: A new approach. Rev. Bras. Zootec. 2018, 47, e20170252. [Google Scholar] [CrossRef]

- Kady, C.; Chedid, A.M.; Kortbawi, I.; Yaacoub, C.; Akl, A.; Daclin, N.; Trousset, F.; Pfister, F.; Zacharewicz, G. IoT-Driven Workflows for Risk Management and Control of Beehives. Diversity 2021, 13, 296. [Google Scholar] [CrossRef]

- Zgank, A. Bee swarm activity acoustic classification for an iot-based farm service. Sensors 2020, 20, 21. [Google Scholar] [CrossRef] [PubMed]

- Henry, E.; Adamchuk, V.; Stanhope, T.; Buddle, C.; Rindlaub, N. Precision apiculture: Development of a wireless sensor network for honeybee hives. Comput. Electron. Agric. 2019, 156, 138–144. [Google Scholar] [CrossRef]

- Bratek, P.; Dziurdzia, P. Energy-efficient wireless weight sensor for remote beehive monitoring. Sensors 2021, 21, 6032. [Google Scholar] [CrossRef] [PubMed]

- Gil-Lebrero, S.; Quiles-Latorre, F.J.; Ortiz-López, M.; Sánchez-Ruiz, V.; Gámiz-López, V.; Luna-Rodríguez, J.J. Honey bee colonies remote monitoring system. Sensors 2017, 17, 55. [Google Scholar] [CrossRef] [PubMed]

- Goulson, D.; Nicholls, E.; Botías, C.; Rotheray, E.L. Bee declines driven by combined Stress from parasites, pesticides, and lack of flowers. Science 2015, 347, 1255957. [Google Scholar] [CrossRef] [PubMed]

- Neumann, P.; Carreck, N.L. Honey bee colony losses. J. Apic. Res. 2010, 49, 1–6. [Google Scholar] [CrossRef]

- Döke, M.A.; McGrady, C.M.; Otieno, M.; Grozinger, C.M.; Frazier, M. Colony Size, Rather Than Geographic Origin of Stocks, Predicts Overwintering Success in Honey Bees (Hymenoptera: Apidae) in the Northeastern United States. J. Econ. Entomol. 2019, 112, 525–533. [Google Scholar] [CrossRef]

- Tawfik, A.I.; Ahmed, Z.H.; Abdel-Rahman, M.F.; Moustafa, A.M. Influence of winter feeding on colony development and the antioxidant system of the honey bee, Apis mellifera. J. Apic. Res. 2020, 59, 752–763. [Google Scholar] [CrossRef]

- Quinlan, G.; Döke, M.A.; Ortiz-Alvarado, Y.; Rodriguez-Gomez, N.; Koru, Y.B.; Underwood, R. Carbohydrate nutrition associated with health of overwintering honey bees. J. Insect Sci. 2023, 23, 16. [Google Scholar] [CrossRef] [PubMed]

- Rydhmer, K.; Prangsma, J.; Brydegaard, M.; Smith, H.G.; Kirkeby, C.; Kappel Schmidt, I.; Boelt, B. Scheimpflug lidar range profiling of bee activity patterns and spatial distributions. Anim. Biotelemetry 2022, 10, 14. [Google Scholar] [CrossRef]

- Jack, C.J.; Ellis, J.D. Integrated Pest Management Control of Varroa destructor (Acari: Varroidae), the Most Damaging Pest of (Apis mellifera L. (Hymenoptera: Apidae)) Colonies. J. Insect Sci. 2021, 21, 6. [Google Scholar] [CrossRef] [PubMed]

- Shegaw, T.; Arke, A.; Belay, N.; Giorgis, D.H. Diagnostic survey on varroa mite (Varroa distractor) prevalence in South-Western Ethiopia. Cogent Food Agric. 2022, 8, 2143610. [Google Scholar] [CrossRef]

| Type of Data | BK1 Example | |

|---|---|---|

| Input | Beehive weight (kg) | 44.70 |

| Ambient temperature (°C) | 26.0 | |

| Ambient relative humidity (%) | 83 | |

| Inside hive temperature (°C) | 33 | |

| Wind speed (km/h) | 25.4 | |

| Wind direction | NW | |

| Daily beehive weight change (kg) | +0.40 | |

| Direct beehive weight change 1 (kg) | +0.25 | |

| Battery (%) | 83 | |

| GSM Signal | 17/31 | |

| Weather | Mostly sunny | |

| Location (incl. Google Maps link) | Lat.: 38.270550 N | Lon.: 22.938683 E | |

| Output | Status 2 | Periodical 2 |

| 24 h beehive variance | See Figure 5 | |

| Polygon BFCI chart | 9 | |

| Cumulative beehive weight change (kg) 3 | 5.25 | |

| Door activity monitoring | N/A | |

| Flight Conditions Class | Range |

|---|---|

| Excellent | 0–10 |

| Good | 11–15 |

| Moderate | 16–20 |

| Bad | 21–25 |

| Very bad | >26 |

| Risk Categories | Risks | Risk Impact Rating |

|---|---|---|

| Security | Thieves | 3 |

| Wild animals | 5 | |

| Bee-eater | 4 | |

| Weather | Unstable/bad weather conditions | 8 |

| Bad flight conditions | 6 | |

| Production | Door activity | 4 |

| Colony health | 7 | |

| Varroa mite | 8 | |

| Viruses | 7 | |

| Overwintering | Bad feeding | 6 |

| Low inside temperatures | 6 |

| Risks | Risk Impact Rating | Smart Solutions |

|---|---|---|

| Thieves | 3 | Surveillance cameras Alarm system GPS trackers Beehive scale |

| Bee-eater | 4 | Alarm system Intimidating sounds |

| Door activity | 4 | Door activity detector Surveillance cameras Beehive scale |

| Wild animals | 5 | Surveillance cameras Alarm system Intimidating sounds Electric fence |

| Bad flight conditions | 6 | Smart weather forecast and meteorological sensors Beehive scale |

| Low inside temperatures | 6 | Modern hives Insulation solutions Inside temperature monitoring |

| Bad feeding | 6 | Beehive scale |

| Colony health | 7 | Beehive scale Inside hive temperature Door activity detector |

| Viruses | 7 | Beehive scale |

| Varroa mite | 8 | Beehive portable varroa tester Beehive scale |

| Unstable/bad weather | 8 | Weather forecasting Beehive scale |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodias, E.; Kilimpas, V. Remote Monitoring of Bee Apiaries as a Tool for Crisis Management. AgriEngineering 2024, 6, 2269-2282. https://doi.org/10.3390/agriengineering6030133

Rodias E, Kilimpas V. Remote Monitoring of Bee Apiaries as a Tool for Crisis Management. AgriEngineering. 2024; 6(3):2269-2282. https://doi.org/10.3390/agriengineering6030133

Chicago/Turabian StyleRodias, Efthymios, and Vasileios Kilimpas. 2024. "Remote Monitoring of Bee Apiaries as a Tool for Crisis Management" AgriEngineering 6, no. 3: 2269-2282. https://doi.org/10.3390/agriengineering6030133

APA StyleRodias, E., & Kilimpas, V. (2024). Remote Monitoring of Bee Apiaries as a Tool for Crisis Management. AgriEngineering, 6(3), 2269-2282. https://doi.org/10.3390/agriengineering6030133