Comprehensive Review on Evaporative Cooling and Desiccant Dehumidification Technologies for Agricultural Greenhouses

Abstract

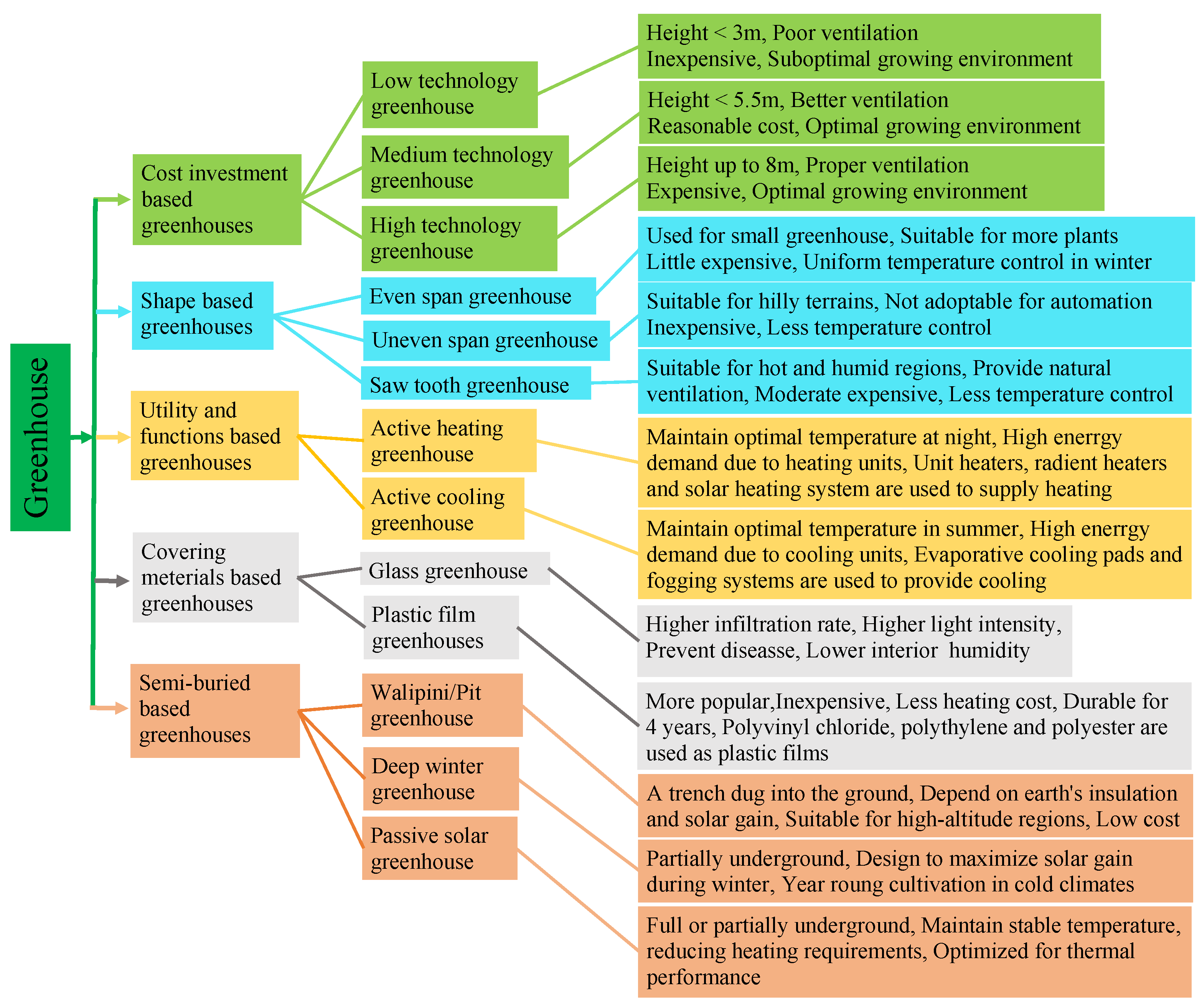

1. Introduction

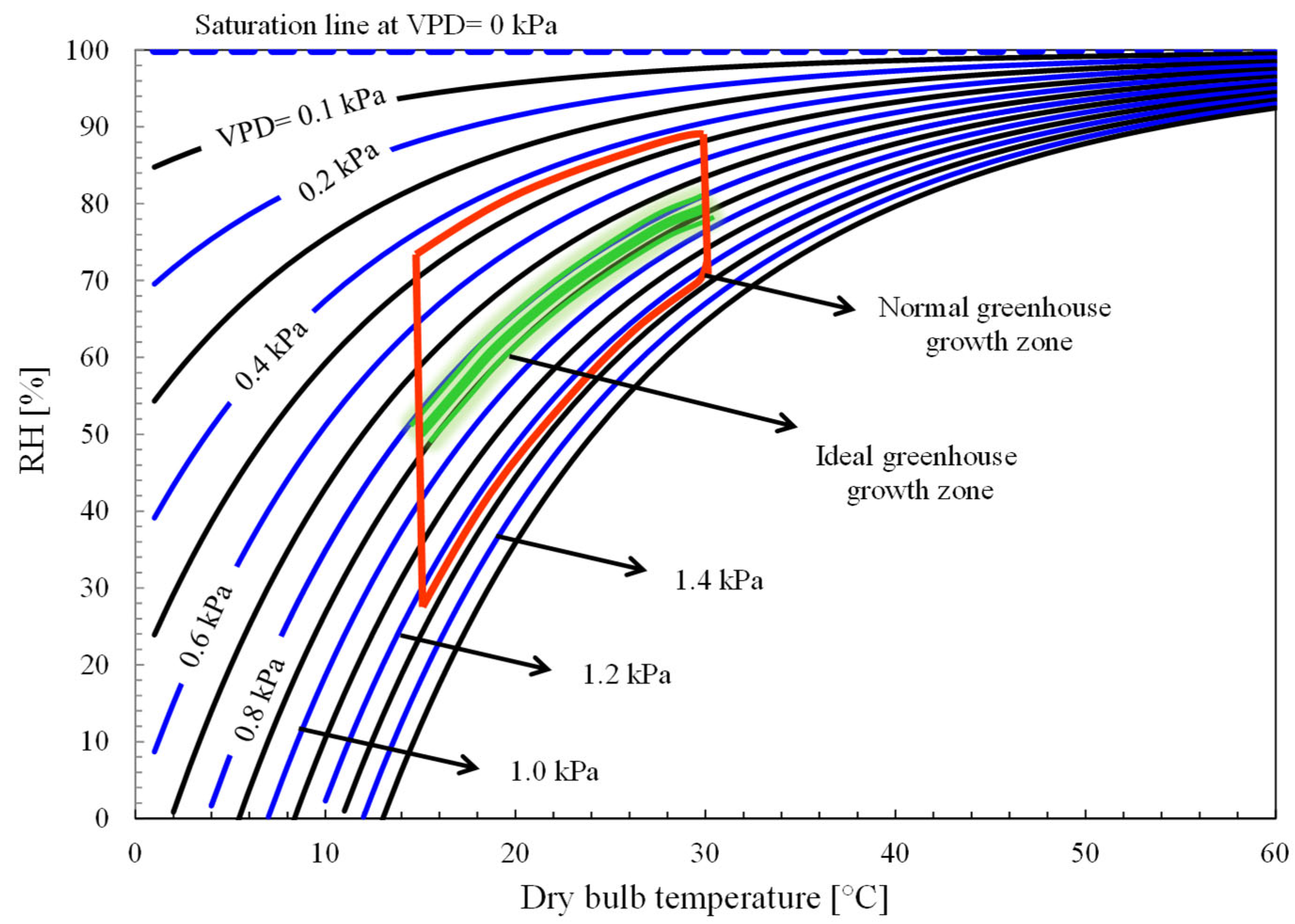

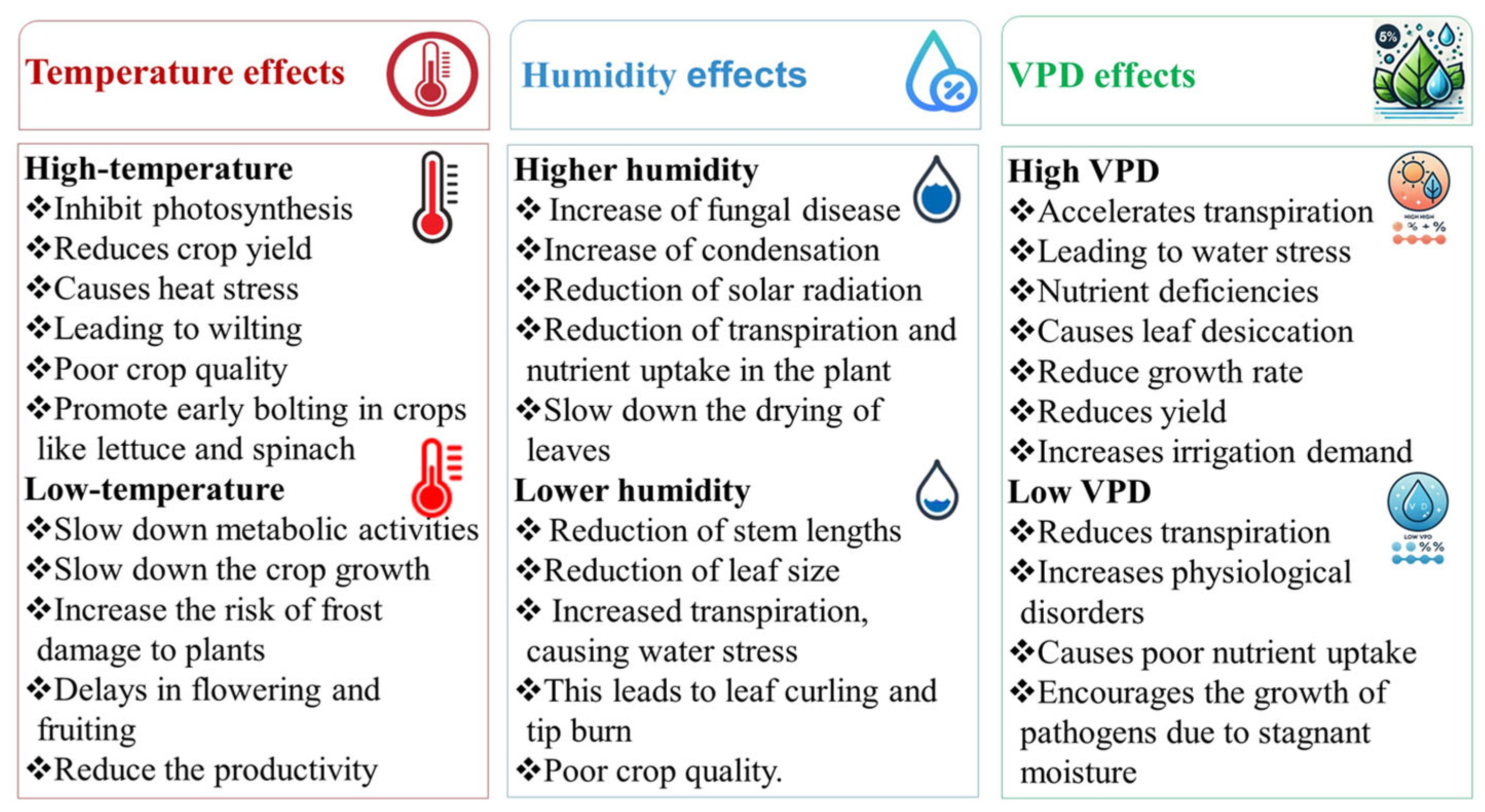

2. Significance of Greenhouse VPD and Temperature/Humidity Control

3. Traditional Temperature/Humidity Control Practices in Greenhouses

3.1. Shading Practices

3.2. Ventilation Systems

3.2.1. Natural Ventilation

3.2.2. Forced Ventilation

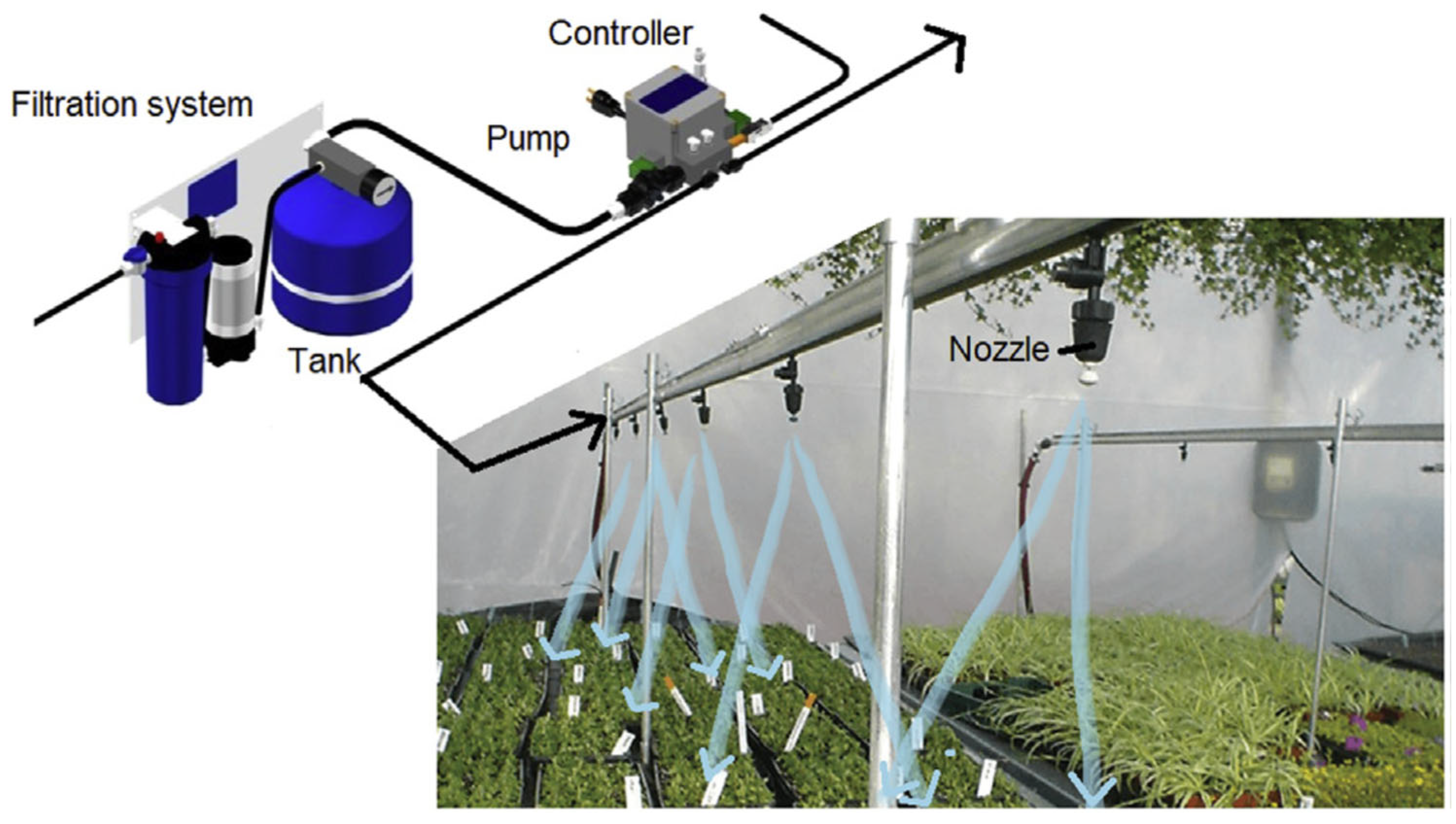

3.3. Fogging System

4. Vapor Compression Air Conditioning System

5. Evaporative Cooling Systems

5.1. Direct Evaporative Cooling System

5.2. Indirect Evaporative Cooling System

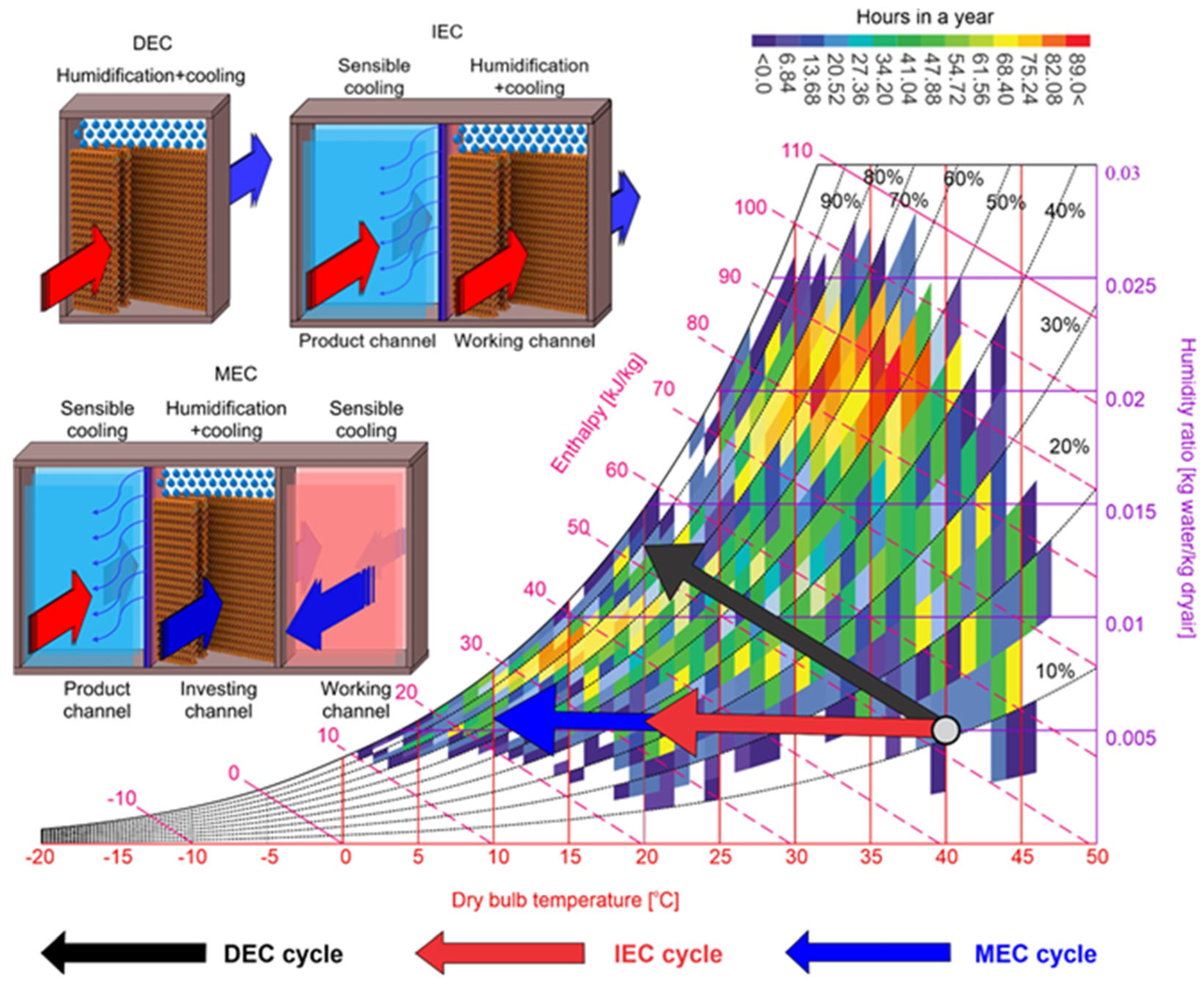

5.3. Maisotsenko-Cycle Evaporative Cooling System

| System Type | Study Type | Tamb (°C) | RHamb (%) | TGh (°C) | RHGh (%) | Greenhouse Shape | AGh (m2) | Location | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| Direct evaporative cooling | Dynamic simulation using TRNSYS 18 software | 33 37 39 40 37 34 | 37 40 45 42 40 33 | 26 27 27 27 25 25 | 78 80 89 90 90 70 | Asymmetric | - | Multan Pakistan | [79] |

| Indirect evaporative cooling | Dynamic simulation using TRNSYS 18 software | 33 37 39 40 37 34 | 37 40 45 42 40 33 | 28 30 31 31 28 29 | 62 70 79 79 75 60 | Asymmetric | - | Multan Pakistan | [79] |

| Direct evaporative cooling | CFD modeling | 40 | 23 | 21 | 67 | Canarian | 165 | Agadir | [80] |

| Ventilation with evaporative cooling | CFD modeling | 40 | 34.42 | 27 | 54 | 36 | Tunisia | [81] | |

| Maisotsenko-cycle evaporative cooling | Experiments and mathematical modeling | 40 | 32 | 29.8 32 | - | - | - | China | [82] |

| Direct evaporative cooling | Experiments | 33 | 50–60 | <30 | 60–80 | Even span | 8.64 | Egypt | [83] |

| Indirect evaporative cooling | Experiments | 33 | 40–60 | - | 55–75 | Even span | 8.64 | Egypt | [83] |

| Indirect–direct evaporative cooling (IDEC) system with groundwater | Experiments | 50 | 8 | 21 | 62 | Even span | 5 | Baghdad | [84] |

| Fan and pad EC system Staw pad Celdek pad Sliced wood pad | Experiments and statistical analysis | 37.18 | 20.91 | 27.74 28.88 30.08 | 44.97 39.42 36.18 | Tunnel type | 380 | Sudan | [85] |

| Fan and pad EC system | Experiments and quantified analysis | 32.7 | 65 | 28 | 80 | Multi-span | 2304 | Shanghai | [86] |

| Evaporative cooling system Fogging system Shading screen Whitening treatment | Experiments and performance analysis | 20.9 | 59.3 | 22.4 23.2 22.6 | 74 56.3 61.9 | Parral | 882 | Almería | [87] |

| Fan-ventilated EC system | Experiments | 20.9 | 59.3 | 28 | 70 | Multi-span | 3000 | Karditsa | [88] |

| Fan-pad system supplied by photovoltaic panels | Mathematical modeling | 14–30 | 35–90 | <25 | - | Span type | 300 | Mexico | [89] |

| Fan and pad system | Experiments and performance analysis | 32 | 25 | 20–27 | 50–68 | Venlo | 64 | Turkey | [90] |

| Fan and pad system | Experiments | 35 | 30 | 25.7 | 95 | Triangular roof block | - | Turkey | [91] |

| Fan and pad system | Experiments | <35 | >10 | 27–30 | 60 | A gable roof type | 240 | Iran | [92] |

| Fan and pad system | Modeling and analysis | 36 | 50 | 30 | - | Single-span ridge | 90 | India | [93] |

| Fan and pad system | Experiments | 15–35 | - | 10–30 | 40–90 | Gable | 240 | Isparta | [94] |

6. Desiccant Dehumidification System

6.1. Solid Desiccant Dehumidification System

6.2. Liquid Desiccant Dehumidification System

7. Integration of Technologies for Energy Efficiency Enhancement

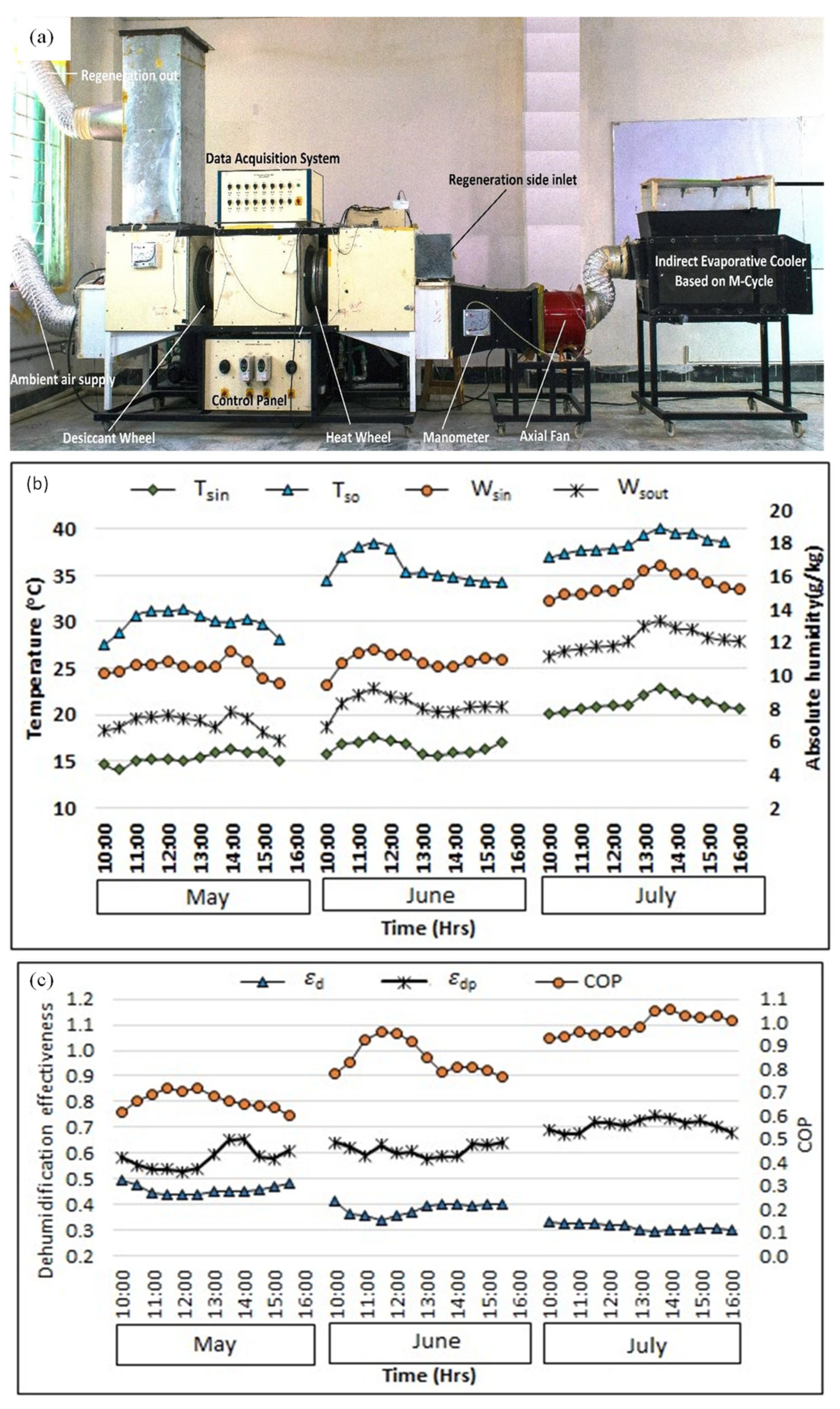

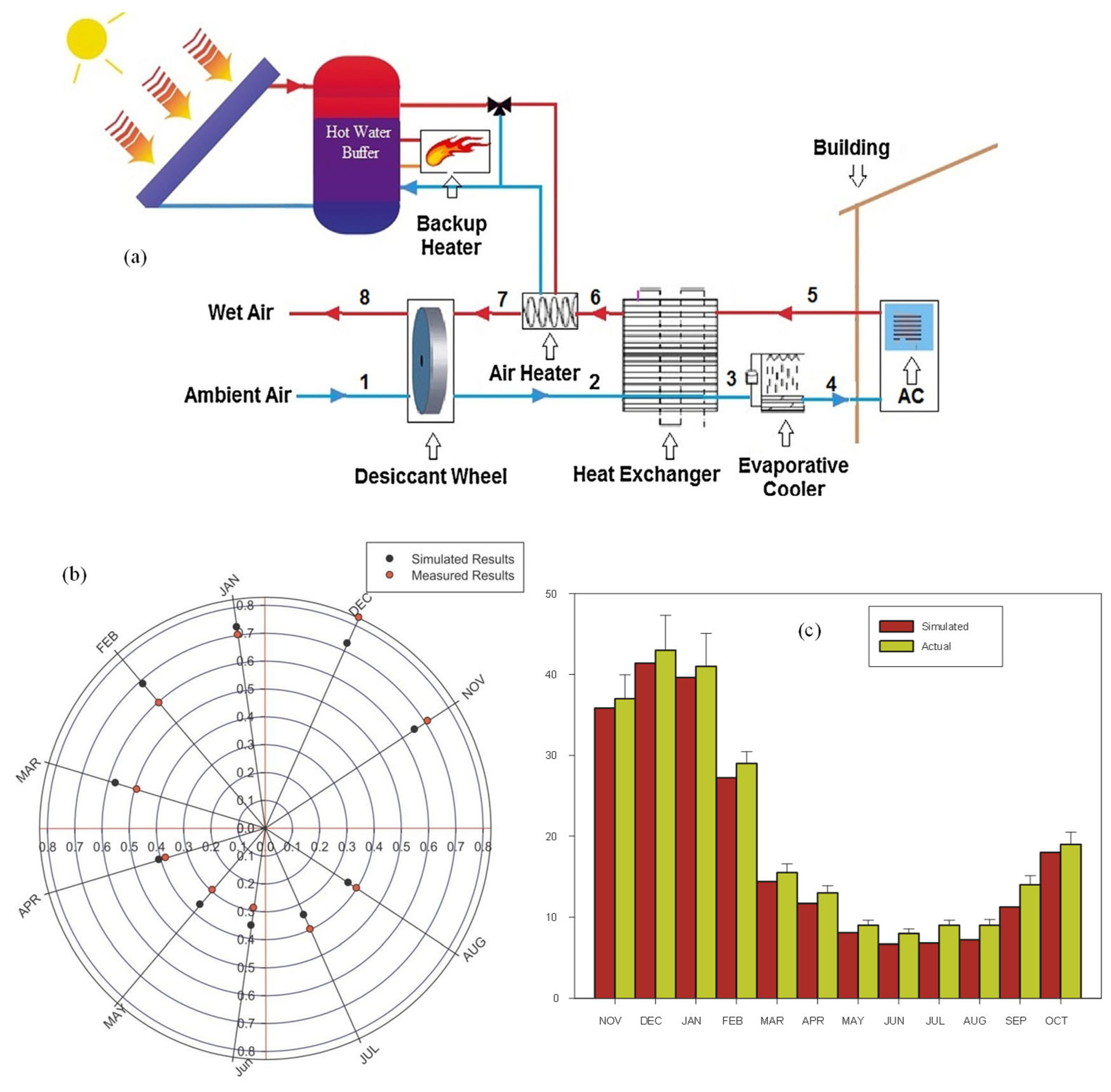

7.1. Integrated Desiccant and Evaporative Cooling System

| System Type | Study Type | Treg (°C) | Tout (°C) | RHout (%) | Tin (°C) | RHin (%) | COP | CC (kW) | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| Desiccant-assisted indirect evaporative system | Analysis through heat and mass transfer equations | 70 | 35 | 40.46 | 21 | 64.45 | COPe = >22 COPt = 0.4 | 2 | [121] |

| Integrated liquid desiccant-assisted indirect evaporative cooling system | Thermodynamic modeling in MATLAB 2021b | - | 35 | 80 | 26 | 50 | 0.93 | 1.14 | [122] |

| Integrated air conditioning system combining desiccant dehumidification, indirect evaporative cooling | Parametric analysis | 70 | 35 | 80 | 16.5 | 50 | 0.93 | - | [100] |

| Solar-assisted regenerative desiccant air conditioning with an IEC system | Theoretical and experimental analysis | 80 | 26–34.7 | 77.8–92.5 | 23.2–26.1 | 51.4–59.7 | 1.81–2.97 | 1.78–2.90 | [123] |

| Desiccant with a two-stage evaporative cooling system | Simulation-based numerical analysis | 73.12 for two-stage 74.81 for single-stage | 19.60 for two-stage 17.71 for single-stage | - | 26.05 for two-stage 24.79 for single-stage | 55.48 for two-stage 59.69 for single-stage | - | - | [124] |

| Desiccant air conditioning system with IEC | Numerical analysis | 45–60 | 25–40 | 28.09–50.59 | 17–21 | 59.37–68.85 | 0.7–1.9 | - | [125] |

| Solid desiccant evaporative cooling system configurations Ventilation cycle Recirculation cycle Dunkle cycle Ventilated-recirculated cycle | Performance analysis | 70 | 15–37 | 26–85 | 24 | 60 | 1.418 0.846 1.144 0.786–0.842 | 49.48 59.32 56.92 53.4–58.5 | [126] |

| A desiccant evaporative cooling system using a DIEC Configuration-I Configuration-II Configuration-III | Energetic and exergetic analysis | 78.8 | 30–40 | 37.76–42.75 | 26 | 47.67 | 0.34–0.32 0.56–0.5 0.59–0.58 | 19.2–19 15.1–15 17.9–17.8 | [127] |

| Solar desiccant-integrated M-cycle evaporative system | Experimental analysis | 70 | 30–40 | 40.68–45.17 | 18–22 | 54.63–78.43 | 0.91 | 3.78 | [120] |

| Solar-assisted desiccant-integrated M-cycle evaporative system | Transient seasonal analysis/seasonal basis analysis | 58–78 | 28 | 58.97 | 16–18 | 85.29–88.17 | 0.78–1.13 | 8–24 | [128] |

| Standalone M-cycle evaporative system | Experimental and computational analysis | 50–60 | 33.1–36.5 | 30.29–33.51 | 21.1–22.3 | 77.87–80.89 | - | 1.23 | [129] |

| Desiccant with a dew-point evaporative cooling system | Experimental assessments | 50–90 | 27–35 | 58.80–71.23 | 22 | - | 15.9 | - | [130] |

| Two-stage desiccant air conditioning incorporating M-cycle cooling system | Full transient analysis | 41–60 41–80 | 41 | 32.24 | 24 | 50 | 1.77 | 46.2 | [131] |

| Cross-flow dew point evaporative cooler with and without dehumidification | Experimental and mathematical modeling analysis | 60–90 | 30 | 67.12 | 25.5 | 86.34 | 4.6 | 2.2 | [132] |

| Desiccant-assisted Maisotsenko-cycle evaporative cooling system | Modeling | 39.2 | 43.75 | 21.9 | 100 | [133] | |||

| MOF-based desiccant with IEC system | Experiments | 45–75 | 27 | 62 | 23 | 90 | 2.7–6 times > than silica gel | [134] |

7.2. Hybrid Systems

7.3. EU Subsidies and Life Cycle Assessment of Advanced Climate Control Technologies

8. Challenges and Future Perspectives

9. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| T | temperature (°C) |

| ω | humidity ratio (kg/kgDA) |

| RH | relative humidity (%) |

| h | enthalpy (kJ/kg) |

| ε | effectiveness |

| A | area (m2) |

| ∆T | temperature difference (K) |

| CFD | computational fluid dynamics |

| VAC | vapor compression air conditioning |

| DEC | direct evaporative cooling |

| IEC | indirect evaporative cooling |

| MEC | Maisotsenko cycle evaporative cooling system |

| CC | cooling capacity (kW) |

| COP | coefficient of performance (-) |

| Subscript | |

| in | inlet |

| out | outlet |

| wb | wet-bulb |

| db | dry-bulb |

| dp | dew-point |

| amb | Ambient |

| Gh | greenhouse |

| reg | regeneration |

| po | process outlet air |

| pi | process inlet air |

| ri | Regenerated inlet air |

References

- Badji, A.; Benseddik, A.; Bensaha, H.; Boukhelifa, A.; Hasrane, I. Design, technology, and management of greenhouse: A review. J. Clean. Prod. 2022, 373, 133753. [Google Scholar] [CrossRef]

- Soussi, M.; Chaibi, M.T.; Buchholz, M.; Saghrouni, Z. Comprehensive Review on Climate Control and Cooling Systems in Greenhouses under Hot and Arid Conditions. Agronomy 2022, 12, 626. [Google Scholar] [CrossRef]

- Akpenpuun, T.D.; Ogunlowo, Q.O.; Na, W.H.; Rabiu, A.; Adesanya, M.A.; Dutta, P.; Zakir, E.; Ogundele, O.M.; Kim, H.-T.; Lee, H.W. Review of Temperature Management Strategies and Techniques in the Greenhouse Microenvironment. Adeleke Univ. J. Eng. Technol. 2023, 6, 126–147. [Google Scholar]

- Sultan, M.; Miyazaki, T.; Koyama, S.; Saha, B.B. Utilization of Desiccant Air-Conditioning System for Improvement in Greenhouse Productivity: A Neglected Area of Research in Pakistan. Int. J. Environ. 2014, 4, 1–10. [Google Scholar]

- Hatfield, J.L.; Prueger, J.H. Temperature extremes: Effect on plant growth and development. Weather Clim. Extrem. 2015, 10, 4–10. [Google Scholar] [CrossRef]

- Dalai, S. Green-houses: Types and Structural Components. In Protected Cultivation and Smart Agriculture; New Delhi Publishers: New Delhi, India, 2020. [Google Scholar] [CrossRef]

- Mohammadi, S.; Khalife, E.; Kaveh, M.; Sayyah, A.H.A.; Nikbakht, A.M.; Szymanek, M.; Dziwulski, J. Comparison of Optimized and Conventional Models of Passive Solar Greenhouse—Case Study: The Indoor Air Temperature, Irradiation, and Energy Demand. Energies 2021, 14, 5369. [Google Scholar] [CrossRef]

- Masterpole, Z. Nonprofit Use of Deep Winter Greenhouses: Minnesota Case Studies; Center for Urban and Regional Affairs: Minneapolis, MN, USA, 2020. [Google Scholar]

- Sultan, M.; El-Sharkawy, I.I.; Miyazaki, T.; Saha, B.B.; Koyama, S. An overview of solid desiccant dehumidification and air conditioning systems. Renew. Sustain. Energy Rev. 2015, 46, 16–29. [Google Scholar] [CrossRef]

- Lai, L.; Wang, X.; Kefayati, G.; Hu, E. Evaporative cooling integrated with solid desiccant systems: A review. Energies 2021, 14, 5982. [Google Scholar] [CrossRef]

- Maraveas, C. Incorporating Artificial Intelligence Technology in Smart Greenhouses: Current State of the Art. Appl. Sci. 2023, 13, 14. [Google Scholar]

- Hoseinzadeh, S.; Garcia, D.A. Ai-driven innovations in greenhouse agriculture: Reanalysis of sustainability and energy efficiency impacts. Energy Convers. Manag. X 2024, 24, 100701. [Google Scholar] [CrossRef]

- Sultan, M.; Miyazaki, T. Energy-Efficient Air-Conditioning Systems for Nonhuman Applications. In Refrigeration; Ekren, O., Ed.; InTech Open: London, UK, 2017; Volume 9, pp. 97–117. [Google Scholar] [CrossRef]

- Sultan, M.; Miyazaki, T.; Saha, B.B.; Koyama, S. Steady-state investigation of water vapor adsorption for thermally driven adsorption based greenhouse air-conditioning system. Renew. Energy 2016, 86, 785–795. [Google Scholar] [CrossRef]

- Pawlowski, A.; Guzman, J.L.; Rodríguez, F.; Berenguel, M.; Sánchez, J.; Dormido, S. Simulation of greenhouse climate monitoring and control with wireless sensor network and event-based control. Sensors 2009, 9, 232–252. [Google Scholar] [CrossRef]

- Prasad, R.P.; Gill, R.; Gupta, V.; Bordoloi, P.; Ahmed, M.; Rao, R.K. Recent Advances in Agricultural Science and Technology for Sustainable India; Mahima Research Foundation and Social Welfare: Varanasi, India, 2022. [Google Scholar]

- Sultan, M.; Ashraf, H.; Miyazaki, T.; Shamshiri, R.R.; Hameed, I.A. Temperature and Humidity Control for the Next Generation Greenhouses: Overview of Desiccant and Evaporative Cooling Systems. In Next-Generation Greenhouses for Food Security; IntechOpen Ltd.: London, UK, 2021. [Google Scholar]

- Ghoulem, M.; El Moueddeb, K.; Nehdi, E.; Boukhanouf, R.; Kaiser Calautit, J. Greenhouse design and cooling technologies for sustainable food cultivation in hot climates: Review of current practice and future status. Biosyst. Eng. 2019, 183, 121–150. [Google Scholar] [CrossRef]

- Ahemd, H.A.; Al-Faraj, A.A.; Abdel-Ghany, A.M. Shading greenhouses to improve the microclimate, energy and water saving in hot regions: A review. Sci. Hortic. 2016, 201, 36–45. [Google Scholar] [CrossRef]

- Hahn, F. Automatic handling of shade net and irrigation in greenhouse with tomatoes. Sci. Agropecu. 2011, 2, 31–37. [Google Scholar]

- Chand Singh, M.; Singh, J.P.; Kumar Pandey, S.; Gladwin Cutting, N.; Sharma, P.; Shrivastav, V.; Sharma, P. A Review of Three Commonly Used Techniques of Controlling Greenhouse Microclimate. Int. J. Curr. Microbiol. Appl. Sci. 2018, 7, 3491–3505. [Google Scholar] [CrossRef]

- López-Díaz, G.; Carreño-Ortega, A.; Fatnassi, H.; Poncet, C.; Díaz-Pérez, M. The Effect of Different Levels of Shading in a Photovoltaic Greenhouse with a North–South Orientation. Appl. Sci. 2020, 10, 882. [Google Scholar] [CrossRef]

- Kacira, M.; Sase, S.; Okushima, L. Effects of side vents and span numbers on wind-induced natural ventilation of a gothic multi-span greenhouse. Japan Agric. Res. Q. 2004, 38, 227–233. [Google Scholar] [CrossRef]

- Amani, M.; Foroushani, S.; Sultan, M.; Bahrami, M. Comprehensive review on dehumidification strategies for agricultural greenhouse applications. Appl. Therm. Eng. 2020, 181, 115979. [Google Scholar] [CrossRef]

- Cengel, Y.A.; Boles, M.A. Solutions Manual for Thermodynamics: An Engineering Approach 8th Edition Chapter 1 Introduction and Basic Concepts. In Thermodynamics; McGraw-Hill: New York, NY, USA, 2015. [Google Scholar]

- Baptista, F.J.; Bailey, B.J.; Randall, J.M.; Meneses, J.F. Greenhouse ventilation rate: Theory and measurement with tracer gas techniques. J. Agric. Eng. Res. 1999, 72, 363–374. [Google Scholar] [CrossRef]

- Benni, S.; Tassinari, P.; Bonora, F.; Barbaresi, A.; Torreggiani, D. Efficacy of greenhouse natural ventilation: Environmental monitoring and CFD simulations of a study case. Energy Build. 2016, 125, 276–286. [Google Scholar] [CrossRef]

- Boulard, T.; Draoui, B. Natural Ventilation of a Greenhouse with Continuous Roof Vents: Measurements and Data Analysis. J. Agric. Eng. Res. 1995, 61, 27–35. [Google Scholar] [CrossRef]

- Papadakis, G.; Mermier, M.; Meneses, J.F.; Boulard, T. Measurement and Analysis of Air Exchange Rates in a Greenhouse with Continuous Roof and Side Openings. J. Agric. Eng. Res. 1996, 63, 219–227. [Google Scholar] [CrossRef]

- Boulard, T.; Baille, A. Modelling of Air Exchange Rate in a Greenhouse Equipped with Continuous Roof Vents. J. Agric. Eng. Res. 1995, 61, 37–47. [Google Scholar] [CrossRef]

- Bartzanas, T.; Boulard, T.; Kittas, C. Effect of Vent Arrangement on Windward Ventilation of a Tunnel Greenhouse. Biosyst. Eng. 2004, 88, 479–490. [Google Scholar] [CrossRef]

- Rico-Garci, E.; Lopez-Cruz, I.L.; Herrera-Ru, G.; Soto-Zaraz, G.M.; Castaneda-, R. Effect of Temperature on Greenhouse Natural Ventilation under Hot Conditions: Computational Fluid Dynamics Simulations. J. Appl. Sci. 2008, 8, 4543–4551. [Google Scholar] [CrossRef]

- Boulard, T.; Feuilloley, P.; Kittas, C. Natural Ventilation Performance of Six Greenhouse and Tunnel Types. J. Agric. Eng. Res. 1997, 67, 249–266. [Google Scholar] [CrossRef]

- Boulard, T.; Fatnassi, H.; Roy, J.C.; Lagier, J.; Fargues, J.; Smits, N.; Rougier, M.; Jeannequin, B. Effect of greenhouse ventilation on humidity of inside air and in leaf boundary-layer. Agric. For. Meteorol. 2004, 125, 225–239. [Google Scholar] [CrossRef]

- Bournet, P.E.; Khaoua, S.A.O.; Boulard, T.; Migeon, C.; Chasseriaux, G. Effect of Roof and Side Opening Combinations on the Ventilation of a Greenhouse Using Computer Simulation. Trans. ASABE 2007, 50, 201–212. [Google Scholar] [CrossRef]

- Campen, J.; Bot, G.P. Determination of Greenhouse-specific Aspects of Ventilation using Three-dimensional Computational Fluid Dynamics. Biosyst. Eng. 2003, 84, 69–77. [Google Scholar] [CrossRef]

- Fernández, J.E.; Bailey, B.J. Measurement and prediction of greenhouse ventilation rates. Agric. For. Meteorol. 1992, 58, 229–245. [Google Scholar] [CrossRef]

- Boulard, T.; Haxaire, R.; Lamrani, M.A.; Roy, J.C.; Jaffrin, A. Characterization and Modelling of the Air Fluxes induced by Natural Ventilation in a Greenhouse. J. Agric. Eng. Res. 1999, 74, 135–144. [Google Scholar] [CrossRef]

- Ganguly, A.; Ghosh, S. Model development and experimental validation of a floriculture greenhouse under natural ventilation. Energy Build. 2009, 41, 521–527. [Google Scholar] [CrossRef]

- de Halleux, D.; Gauthier, L. Energy Consumption Due to Dehumidification of Greenhouses under Northern Latitudes. J. Agric. Eng. Res. 1998, 69, 35–42. [Google Scholar] [CrossRef]

- Harmanto; Tantau, H.J.; Salokhe, V.M. Optimization of ventilation opening area of a naturally ventilated net greenhouse in a humid tropical environment. Acta Hortic. 2006, 719, 165–172. [Google Scholar] [CrossRef]

- He, K.; Chen, D.; Sun, L.; Liu, Z.; Huang, Z. The effect of vent openings on the microclimate inside multi-span greenhouses during summer and winter seasons. Eng. Appl. Comput. Fluid Mech. 2015, 9, 399–410. [Google Scholar] [CrossRef]

- Kolokotsa, D.; Saridakis, G.; Dalamagkidis, K.; Dolianitis, S.; Kaliakatsos, I. Development of an intelligent indoor environment and energy management system for greenhouses. Energy Convers. Manag. 2010, 51, 155–168. [Google Scholar] [CrossRef]

- Wang, H.; Mao, H. Experimental research on regulating and controlling of the temperature and humidity in a TAZ4. 9 PC board multi-span greenhouse. Agric. Equip. Technol. 2005, 31, 1–19. [Google Scholar]

- Abdel-Ghany, A.M.; Kozai, T. Cooling Efficiency of Fogging Systems for Greenhouses. Biosyst. Eng. 2006, 94, 97–109. [Google Scholar] [CrossRef]

- Eduard, R.; Ruslan, W.; Iskandar, I.; Setyanto, D. Setting Temperature and Humidity with a Misting System in a Pilot Greenhouse at Cisauk-Tangerang, Indonesia. Appl. Sci. 2022, 12, 9192. [Google Scholar] [CrossRef]

- Handarto; Hayashi, M.; Kozai, T. Air and Leaf Temperatures and Relative Humidity in a Naturally Ventilated Single-Span Greenhouse with a Fogging System for Cooling and Its Evaporative Cooling Efficiency. Environ. Control Biol. 2005, 43, 3–11. [Google Scholar] [CrossRef]

- Ozturk, H.H. Evaporative cooling efficiency of a fogging system in a rose greenhouse. Aust. J. Exp. Agric. 2006, 46, 1231. [Google Scholar] [CrossRef]

- Yasutake, D.; Yu, X.; Asano, T.; Ishikawa, M.; Mori, M.; Kitano, M.; Ishikawa, K. Control of Greenhouse Humidity and Airflow with Fogging and Circulation Systems and Its Effect on Leaf Conductance in Cucumber Plants. Environ. Control Biol. 2014, 52, 101–105. [Google Scholar] [CrossRef]

- Arbel, A.; Barak, M.; Shklyar, A. Combination of Forced Ventilation and Fogging Systems for Cooling Greenhouses. Biosyst. Eng. 2003, 84, 45–55. [Google Scholar] [CrossRef]

- Arbel, A.; Yekutieli, O.; Barak, M. Performance of a Fog System for Cooling Greenhouses. J. Agric. Eng. Res. 1999, 72, 129–136. [Google Scholar] [CrossRef]

- Linker, R.; Kacira, M.; Arbel, A. Robust climate control of a greenhouse equipped with variable-speed fans and a variable-pressure fogging system. Biosyst. Eng. 2011, 110, 153–167. [Google Scholar] [CrossRef]

- Tamimi, E.; Kacira, M.; Choi, C.Y.; An, L. Analysis of Microclimate Uniformity in a Naturally Vented Greenhouse with a High-Pressure Fogging System. Trans. ASABE 2013, 56, 1241–1254. [Google Scholar] [CrossRef]

- Öztürk, H.H. Evaporative cooling efficiency of a fogging system for greenhouses. Turkish J. Agric. For. 2003, 27, 49–57. [Google Scholar]

- Park, S.H.; Moon, J.P.; Kim, J.K.; Kim, S.H. Development of Fog Cooling Control System and Cooling Effect in Greenhouse. Prot. Hortic. Plant Fact. 2020, 29, 265–276. [Google Scholar] [CrossRef]

- Ishii, M.; Okushima, L.; Moriyama, H.; Sase, S.; Takakura, T.; Kacira, M. Effects of natural ventilation rate on temperature and relative humidity in a naturally ventilated greenhouse with high pressure fogging system. Acta Hortic. 2014, 1037, 1127–1132. [Google Scholar] [CrossRef]

- Katsoulas, N.; Kitta, E.; Kittas, C.; Tsirogiannis, I.L.; Stamati, E.; Sayvas, D. Greenhouse cooling by a fog system: Effects on microclimate and on production and quality of a soilless pepper crop. Acta Hortic. 2006, 719, 455–462. [Google Scholar] [CrossRef]

- Alsouda, F.; Bennett, N.S.; Saha, S.C.; Salehi, F.; Islam, M.S. Vapor Compression Cycle: A State-of-the-Art Review on Cycle Improvements, Water and Other Natural Refrigerants. Clean Technol. 2023, 5, 584–608. [Google Scholar] [CrossRef]

- Choudhury, M.; Karim, S. Experimental Setup and Study of A Vapor Compression Refrigeration Unit. Bachelor’s Thesis, Ahsanullah University of Science & Technology, Dhaka, Bangladesh, 2015. [Google Scholar]

- Benson, O. Design, Fabrication, and Performance Evaluation of a Petrol-Driven Refrigerating System for Effective Vaccine Storage in Remote Areas. World Acad. J. Eng. Sci. 2023, 10, 53–63. [Google Scholar]

- Woods, J.; James, N.; Kozubal, E.; Bonnema, E.; Brief, K.; Voeller, L.; Rivest, J. Humidity’s impact on greenhouse gas emissions from air conditioning. Joule 2022, 6, 726–741. [Google Scholar] [CrossRef]

- Rafique, M.M.; Gandhidasan, P.; Rehman, S.; Al-hadhrami, L.M. A review on desiccant based evaporative cooling systems. Renew. Sustain. Energy Rev. 2015, 45, 145–159. [Google Scholar] [CrossRef]

- Sultan, M.; Miyazaki, T.; Koyama, S.; Khan, Z.M. Performance evaluation of hydrophilic organic polymer sorbents for desiccant air-conditioning applications. Adsorpt. Sci. Technol. 2018, 36, 311–326. [Google Scholar] [CrossRef]

- Hasan, A. Going below the wet-bulb temperature by indirect evaporative cooling: Analysis using a modified ε-NTU method. Appl. Energy 2012, 89, 237–245. [Google Scholar] [CrossRef]

- Glanville, P.; Kozlov, A.; Maisotsenko, V. Dew point evaporative cooling: Technology review and fundamentals. ASHRAE Trans. 2011, 117, 111–118. [Google Scholar]

- Mahmood, M.H.; Sultan, M.; Miyazaki, T.; Koyama, S.; Maisotsenko, V.S. Overview of the Maisotsenko cycle—A way towards dew point evaporative cooling. Renew. Sustain. Energy Rev. 2016, 66, 537–555. [Google Scholar] [CrossRef]

- Lertsatitthanakorn, C.; Rerngwongwitaya, S.; Soponronnarit, S. Field Experiments and Economic Evaluation of an Evaporative Cooling System in a Silkworm Rearing House. Biosyst. Eng. 2006, 93, 213–219. [Google Scholar] [CrossRef]

- Raza, H.M.U.; Ashraf, H.; Shahzad, K.; Sultan, M.; Miyazaki, T.; Usman, M.; Shamshiri, R.R.; Zhou, Y.; Ahmad, R. Investigating Applicability of Evaporative Cooling Systems for Thermal Comfort of Poultry Birds in Pakistan. Appl. Sci. 2020, 10, 4445. [Google Scholar] [CrossRef]

- American Society of Heating Refrigerating; Air-Conditioning Engineers. ASHRAE Handbook of Fundamentals; Amer Society of Heating: Atlanta, GA, USA, 2009; Volume 30329, ISBN 9781933742540. [Google Scholar]

- Asfahan, H.M.; Sajjad, U.; Sultan, M.; Hussain, I.; Hamid, K.; Ali, M.; Wang, C.-C.; Shamshiri, R.R.; Khan, M.U. Artificial Intelligence for the Prediction of the Thermal Performance of Evaporative Cooling Systems. Energies 2021, 14, 3946. [Google Scholar] [CrossRef]

- Dai, Y.J.; Sumathy, K. Theoretical study on a cross-flow direct evaporative cooler using honeycomb paper as packing material. Appl. Therm. Eng. 2002, 22, 1417–1430. [Google Scholar] [CrossRef]

- Gupta, S.K.; Arora, B.B.; Arora, A. Thermo-economic assessment of air conditioner utilizing direct evaporative cooling: A comprehensive analysis. Int. J. Refrig. 2024, 158, 68–88. [Google Scholar] [CrossRef]

- Duan, Z.; Zhan, C.; Zhang, X.; Mustafa, M.; Zhao, X.; Alimohammadisagvand, B.; Hasan, A. Indirect evaporative cooling: Past, present and future potentials. Renew. Sustain. Energy Rev. 2012, 16, 6823–6850. [Google Scholar] [CrossRef]

- Porumb, B.; Ungure, P.; Fechete, L.; Alexandru, Ş.; Mugur, B. A review of indirect evaporative cooling technology. Energy Procedia 2016, 85, 461–471. [Google Scholar] [CrossRef]

- Anisimov, S.; Pandelidis, D. International Journal of Heat and Mass Transfer Numerical study of the Maisotsenko cycle heat and mass exchanger. Int. J. Heat Mass Transf. 2014, 75, 75–96. [Google Scholar] [CrossRef]

- Buyadgie, D.; Buyadgie, O.; Drakhnia, O.; Brodetsky, P.; Maisotsenko, V. Solar low-pressure turbo-ejector Maisotsenko cycle-based power system for electricity, heating, cooling and distillation. Int. J. Low-Carbon Technol. 2015, 10, 157–164. [Google Scholar] [CrossRef]

- Anisimov, S.; Pandelidis, D.; Danielewicz, J. Numerical study and optimization of the combined indirect evaporative air cooler for air-conditioning systems. Energy 2015, 80, 452–464. [Google Scholar] [CrossRef]

- Tertipis, D.; Rogdakis, E. Maisotsenko cycle: Technology overview and energy-saving potential in cooling systems. Energy Emiss. Control Technol. 2015, 2015, 15–22. [Google Scholar] [CrossRef]

- Riaz, N.; Sultan, M.; Ashraf, H.; Mahmood, M.H.; Ahmad, F.; Khan, M.U.; Farooq, M.; Sajjad, U. Study on Evaporative Cooling Assisted Temperature and Humidity Control Systems for Greenhouse Farming in Pakistan. In Air Conditioning Technologies and Applications; Intechopen: London, UK, 2024. [Google Scholar]

- Allali, F.E.; Fatnassi, H.; Demrati, H.; Aiz, F.D.M.; Gourdo, L.; Errami, Y.; Wifaya, A.; Aharoune, A. Cfd-based optimization of Direct evaporative cooling systems for canarian greenhouses in Semi-Arid regions. Energy Build. 2024, 323, 114767. [Google Scholar]

- Ghoulem, M.; El, K.; Nehdi, E.; Zhong, F.; Calautit, J. Analysis of passive downdraught evaporative cooling windcatcher for greenhouses in hot climatic conditions: Parametric study and impact of neighbouring structures. Biosyst. Eng. 2020, 197, 105–121. [Google Scholar] [CrossRef]

- Liu, X.; Jing, C.; Li, Y.; Lu, S. Study on performance of perforated dew point indirect evaporative coolers. Sci. Rep. 2025, 15, 939. [Google Scholar]

- Newir, A.E.; Ibrahim, M.A.; Halawa, M.A.; Abdellatif, O.E. Direct and Indirect Evaporative Cooling for Closed Greenhouse during the Summer Peak Hours. Benha J. Appl. Sci. 2017, 2, 105–111. [Google Scholar] [CrossRef]

- Aljubury, I.M.A.; Ridha, H.D. Enhancement of evaporative cooling system in a greenhouse using geothermal energy. Renew. Energy 2017, 111, 321–331. [Google Scholar] [CrossRef]

- Ahmed, E.M.; Abaas, O.; Ahmed, M.; Ismail, M.R. Performance evaluation of three different types of local evaporative cooling pads in greenhouses in Sudan. Saudi J. Biol. Sci. 2011, 18, 45–51. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Li, Y.; Wang, R.Z.; Liu, W.; Zhou, P. Experimental performance of evaporative cooling pad systems in greenhouses in humid subtropical climates. Appl. Energy 2015, 138, 291–301. [Google Scholar] [CrossRef]

- Meca, D.; López, J.C.; Gázquez, J.C.; Baeza, E.; Parra, J.P.; Zaragoza, G. A comparison of three different cooling systems in parral type greenhouses in Almería. Span. J. Agric. Res. 2007, 5, 285–292. [Google Scholar]

- Kittas, C.; Karamanis, M.; Katsoulas, N. Air temperature regime in a forced ventilated greenhouse with rose crop. Energy Build. 2005, 37, 807–812. [Google Scholar] [CrossRef]

- Romantchik, E.; Ríos, E.; Sánchez, E.; López, I.; Sánchez, J.R. Determination of energy to be supplied by photovoltaic systems for fan-pad systems in cooling process of greenhouses. Appl. Therm. Eng. 2017, 114, 1161–1168. [Google Scholar] [CrossRef]

- Dayioğlu, M.A. Performance Analysis of a Greenhouse Fan-Pad Cooling System: Gradients of Horizontal Temperature and Relative Humidity. Tarım Bilim. Derg. 2014, 21, 132. [Google Scholar] [CrossRef]

- Oz, H.; Atilgan, A.; Buyuktas, K.; Alagoz, T. The efficiency of fan-pad cooling system in greenhouse and building up of internal greenhouse temperature map. Afri. J. Biotechnol. 2009, 8, 5436–5444. [Google Scholar]

- Saberian, A.; Sajadiye, S.M. Assessing the variable performance of fan-and-pad cooling in a subtropical desert greenhouse. Appl. Therm. Eng. 2020, 179, 115672. [Google Scholar] [CrossRef]

- Ganguly, A.; Ghosh, S. Modeling and analysis of a fan–pad ventilated floricultural greenhouse. Energy Build. 2007, 39, 1092–1097. [Google Scholar] [CrossRef]

- Öz, H.; Atılgan, A. Determination of effects of outdoor relative humidity on fan pad cooling effects. Infrastruct. Ecol. Rural. Areas 2015, 3, 759–767. [Google Scholar] [CrossRef]

- Frein, A.; Muscherà, M.; Scoccia, R.; Aprile, M.; Motta, M. Field testing of a novel hybrid solar assisted desiccant evaporative cooling system coupled with a vapour compression heat pump. Appl. Therm. Eng. 2018, 130, 830–846. [Google Scholar] [CrossRef]

- Misha, S.; Mat, S.; Ruslan, M.H.; Sopian, K. Review of solid/liquid desiccant in the drying applications and its regeneration methods. Renew. Sustain. Energy Rev. 2012, 16, 4686–4707. [Google Scholar] [CrossRef]

- Hua, Z.; Cai, S.; Xu, H.; Yuan, W.; Li, S.; Tu, Z. Investigations of Silica/MOF composite coating and its dehumidification performance on a desiccant-coated heat exchanger. Energy 2024, 307, 132576. [Google Scholar] [CrossRef]

- Aziz, A.N.; Mahmoud, S.; Al-Dadah, R.; Ismail, M.A.; Al Mesfer, M.K. Numerical and experimental investigation of desiccant cooling system using metal organic framework materials. Appl. Therm. Eng. 2022, 215, 118940. [Google Scholar] [CrossRef]

- La, D.; Dai, Y.J.; Li, Y.; Wang, R.Z.; Ge, T.S. Technical development of rotary desiccant dehumidification and air conditioning: A review. Renew. Sustain. Energy Rev. 2010, 14, 130–147. [Google Scholar] [CrossRef]

- Yang, B.; Wang, C.; Ji, X.; Nie, J.; Zhang, R.; Li, Y.; Chen, Q. A solar-assisted regenerative desiccant air conditioning with indirect evaporative cooling for humid climate region. Appl. Therm. Eng. 2024, 243, 122598. [Google Scholar] [CrossRef]

- Kousar, R.; Ali, M.; Sheikh, N.A.; Ihtsham, S.; Khushnood, S. Energy for Sustainable Development Holistic integration of multi-stage dew point counter fl ow indirect evaporative cooler with the solar-assisted desiccant cooling system: A techno-economic evaluation. Energy Sustain. Dev. 2021, 62, 163–174. [Google Scholar] [CrossRef]

- Ali Mandegari, M.; Pahlavanzadeh, H. Introduction of a new definition for effectiveness of desiccant wheels. Energy 2009, 34, 797–803. [Google Scholar] [CrossRef]

- Vivekh, P.; Kumja, M.; Bui, D.T.; Chua, K.J. Recent developments in solid desiccant coated heat exchangers—A review. Appl. Energy 2018, 229, 778–803. [Google Scholar] [CrossRef]

- Hilal, M.A.; Abbas, S.J. Numerical Analysis of Optimising Liquid Desiccant Dehumidification for Sustainable Building Cooling: A Data-Driven Method Using Response Surface Methodology. Processes 2024, 12, 2322. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, H.; Yang, H.; Chen, Y.; Leung, C.W. Optimization of the Liquid Desiccant Cooling Systems in Hot and Humid Areas. Sustainability 2023, 15, 13511. [Google Scholar] [CrossRef]

- Chimankare, R.V.; Das, S.; Kaur, K.; Magare, D. A review study on the design and control of optimised greenhouse environments. J. Trop. Ecol. 2023, 39, e26. [Google Scholar] [CrossRef]

- Bhowmik, M.; Giampieri, A.; Bean, J.; Paul Roskilly, A.; Ma, Z. Feasibility of a heat pump-assisted liquid desiccant system for continuous dehumidification and regeneration in temperate oceanic climatic greenhouses. Energy Convers. Manag. 2025, 323, 119256. [Google Scholar] [CrossRef]

- Davies, P.A. A solar cooling system for greenhouse food production in hot climates. Sol. Energy 2005, 79, 661–668. [Google Scholar] [CrossRef]

- Ghosh, A.; Ganguly, A. Performance analysis of a partially closed solar regenerated desiccant assisted cooling system for greenhouse lettuce cultivation. Sol. Energy 2017, 158, 644–653. [Google Scholar] [CrossRef]

- Abu-Hamdeh, N.H.; Almitani, K.H. Solar liquid desiccant regeneration and nanofluids in evaporative cooling for greenhouse food production in Saudi Arabia. Sol. Energy 2016, 134, 202–210. [Google Scholar] [CrossRef]

- Lychnos, G.; Davies, P.A. Modelling and experimental verification of a solar-powered liquid desiccant cooling system for greenhouse food production in hot climates. Energy 2012, 40, 116–130. [Google Scholar] [CrossRef]

- Ali, A.; Ishaque, K.; Lashin, A.; Al Arifi, N. Modeling of a liquid desiccant dehumidification system for close type greenhouse cultivation. Energy 2017, 118, 578–589. [Google Scholar] [CrossRef]

- Pasqualin, P.; Davies, P.A. Dynamic simulation of a novel liquid desiccant air-conditioning system for greenhouse cooling and water recovery. Appl. Therm. Eng. 2024, 242, 122495. [Google Scholar] [CrossRef]

- Rahman, M.S.; Han, J.; Ge, G.; Ahamed, M.S.; Guo, H. Experimental evaluation of three different dehumidifiers for greenhouses in cold regions. Appl. Therm. Eng. 2023, 234, 121324. [Google Scholar] [CrossRef]

- Liu, X.H.; Yi, X.Q.; Jiang, Y. Mass transfer performance comparison of two commonly used liquid desiccants: LiBr and LiCl aqueous solutions. Energy Convers. Manag. 2011, 52, 180–190. [Google Scholar] [CrossRef]

- Koronaki, I.P.; Christodoulaki, R.I.; Papaefthimiou, V.D.; Rogdakis, E.D. Thermodynamic analysis of a counter flow adiabatic dehumidifier with different liquid desiccant materials. Appl. Therm. Eng. 2013, 50, 361–373. [Google Scholar] [CrossRef]

- Elmer, T.; Worall, M.; Wu, S.; Riffat, S. An experimental study of a novel integrated desiccant air conditioning system for building applications. Energy Build. 2016, 111, 434–445. [Google Scholar] [CrossRef]

- Chua, K.J. Heat and mass transfer of composite desiccants for energy efficient air dehumidification: Modelling and experiment. Appl. Therm. Eng. 2015, 89, 703–716. [Google Scholar] [CrossRef]

- Alghamdi, F.; Krarti, M. Review Analysis for the Energy Performance of Integrated Air-Conditioning Systems. Energies 2025, 18, 1611. [Google Scholar] [CrossRef]

- Chaudhary, G.Q.; Ali, M.; Sheikh, N.A.; Ihtsham, S.; Khushnood, S. Integration of solar assisted solid desiccant cooling system with efficient evaporative cooling technique for separate load handling. Appl. Therm. Eng. 2018, 140, 696–706. [Google Scholar] [CrossRef]

- Goldsworthy, M.; White, S. Optimisation of a desiccant cooling system design with indirect evaporative cooler. Int. J. Refrig. 2011, 34, 148–158. [Google Scholar] [CrossRef]

- Luo, J.; Shen, Y.; Yang, H. Investigations on an integrated air-conditioning system using technologies of desiccant dehumidification, indirect evaporative cooling and CO2 capture. Appl. Energy 2024, 369, 123601. [Google Scholar] [CrossRef]

- Comino, F.; Castillo González, J.; Navas-Martos, F.J.; Ruiz de Adana, M. Experimental energy performance assessment of a solar desiccant cooling system in Southern Europe climates. Appl. Therm. Eng. 2020, 165, 114579. [Google Scholar] [CrossRef]

- El Hourani, M.; Ghali, K.; Ghaddar, N. Effective desiccant dehumidification system with two-stage evaporative cooling for hot and humid climates. Energy Build. 2014, 68, 329–338. [Google Scholar] [CrossRef]

- Kamrani, F.; Montazeri, M.; Banakar, A.; Ghobadian, B. Energy Conversion and Management: X Experimental performance and evaluation of direct evaporative cooling system coupled with a desiccant wheel in a closed greenhouse. Energy Convers. Manag. X 2023, 20, 100497. [Google Scholar] [CrossRef]

- Ali, M.; Vukovic, V.; Ahmed, N.; Ali, H.M. Performance investigation of solid desiccant evaporative cooling system configurations in different climatic zones. Energy Convers. Manag. 2015, 97, 323–339. [Google Scholar] [CrossRef]

- Asadi, A.; Roshanzadeh, B. Improving performance of two-stage desiccant cooling system by analyzing different regeneration configurations. J. Build. Eng. 2019, 25, 100807. [Google Scholar] [CrossRef]

- Waheed, M.; Qadar, G.; Sajjad, U.; Abbas, N.; Yan, W. Case Studies in Thermal Engineering Performance investigation of solar assisted desiccant integrated Maisotsenko cycle cooler in subtropical climate conditions. Case Stud. Therm. Eng. 2023, 44, 102864. [Google Scholar] [CrossRef]

- Rogdakis, E.D.; Koronaki, I.P.; Tertipis, D.N. Experimental and computational evaluation of a Maisotsenko evaporative cooler at Greek climate. Energy Build. 2014, 70, 497–506. [Google Scholar] [CrossRef]

- Chen, W.; Cui, X.; Huang, Z.F.; Shao, Y.L.; Chua, K.J. Developing an integrated solid desiccant dehumidifier and dew-point evaporative cooler for green air conditioning. J. Build. Eng. 2024, 96, 110404. [Google Scholar] [CrossRef]

- Gadalla, M.; Saghafifar, M. Performance assessment and transient optimization of air precooling in multi-stage solid desiccant air conditioning systems. Energy Convers. Manag. 2016, 119, 187–202. [Google Scholar] [CrossRef]

- Lin, J.; Wang, R.Z.; Kumja, M.; Bui, T.D.; Chua, K.J. Modelling and experimental investigation of the cross-flow dew point evaporative cooler with and without dehumidification. Appl. Therm. Eng. 2017, 121, 1–13. [Google Scholar] [CrossRef]

- Ashraf, H.; Sultan, M.; Shamshiri, R.R.; Abbas, F.; Farooq, M.; Sajjad, U.; Md-Tahir, H.; Mahmood, M.H.; Ahmad, F.; Taseer, Y.R.; et al. Dynamic evaluation of desiccant dehumidification evaporative cooling options for greenhouse air-conditioning application in multan (Pakistan). Energies 2021, 14, 1097. [Google Scholar] [CrossRef]

- Shahvari, S.Z.; Kalkhorani, V.A.; Clark, J.D. Performance evaluation of a metal organic frameworks based combined dehumidification and indirect evaporative cooling system in different climates. Int. J. Refrig. 2022, 140, 186–197. [Google Scholar] [CrossRef]

- Jani, D.B.; Mishra, M.; Sahoo, P.K. Performance prediction of solid desiccant—Vapor compression hybrid air-conditioning system using artificial neural network. Energy 2016, 103, 618–629. [Google Scholar] [CrossRef]

- Fahad, F.G.; Al-Humairi, S.T.; Al-Ezzi, A.T.; Majdi, H.S.; Sultan, A.J.; Alhuzaymi, T.M.; Aljuwaya, T.M. Advancements in Liquid Desiccant Technologies: A Comprehensive Review of Materials, Systems, and Applications. Sustainability 2023, 15, 14021. [Google Scholar] [CrossRef]

- Jacob, T.A.; Shah, N.; Park, W.Y. Evaluation of hybrid evaporative-vapor compression air conditioners for different global climates. Energy Convers. Manag. 2021, 249, 114841. [Google Scholar] [CrossRef]

- Baniyounes, A.M.; Rasul, M.G.; Khan, M.M.K. Experimental assessment of a solar desiccant cooling system for an institutional building in subtropical Queensland, Australia. Energy Build. 2013, 62, 78–86. [Google Scholar] [CrossRef]

- Al Horr, Y.; Tashtoush, B.; Chilengwe, N.; Musthafa, M. Performance Assessment of a Hybrid Vapor Compression and Evaporative Cooling Fresh-Air-Handling Unit Operating in Hot Climates. Processes 2019, 7, 872. [Google Scholar] [CrossRef]

- Jani, D.B.; Mishra, M.; Sahoo, P.K. Performance studies of hybrid solid desiccant-vapor compression air-conditioning system for hot and humid climates. Energy Build. 2015, 102, 284–292. [Google Scholar] [CrossRef]

- Pan, A.; Chen, Y.; Lin, K.; Bai, S.; Chung, T.; Yan, C. Numerical investigations of novel hybrid solid desiccant cooling systems combined with passive radiative cooling panels. Renew. Energy 2024, 226, 120400. [Google Scholar] [CrossRef]

- Venkatesh, R. Performance study on a hybrid solid desiccant—Vapor compression air—Conditioning system for hot—Humid ambient conditions. Heat Transf. 2025, 54, 507–529. [Google Scholar] [CrossRef]

- Coca-Ortegón, A.; Prieto, J.; Coronas, A. Modelling and dynamic simulation of a hybrid liquid desiccant system regenerated with solar energy. Appl. Therm. Eng. 2016, 97, 109–117. [Google Scholar] [CrossRef]

- Dai, Y.; Wang, R.; Zhang, H.; Yu, J. Use of liquid desiccant cooling to improve the performance of vapor compression air conditioning. Appl. Therm. Eng. 2001, 21, 1185–1202. [Google Scholar] [CrossRef]

- Bhowmik, M.; Rath, S.; Jayson Varela, R.; Muthukumar, P.; Anandalakshmi, R.; Saito, K. Performance assessment of integrated liquid desiccant dehumidification with vapor-compression system for energy-efficient air conditioning applications. Appl. Therm. Eng. 2022, 216, 119118. [Google Scholar] [CrossRef]

- Patel, P.; Patel, V.K.; Patel, R. A Liquid Desiccant-Assisted Dehumidification and VCR-Based Air Conditioning (LDVC) System Using Calcium Chloride Solution: An Experimental Investigation, Exergy Analysis, and Economic Assessment. Heat Transf. 2025, 54, 2967–2989. [Google Scholar] [CrossRef]

- Jia, C.X.; Dai, Y.J.; Wu, J.Y.; Wang, R.Z. Analysis on a hybrid desiccant air-conditioning system. Appl. Therm. Eng. 2006, 26, 2393–2400. [Google Scholar] [CrossRef]

- Dhar, P.L.; Singh, S.K. Studies on solid desiccant based hybrid air-conditioning systems. Appl. Therm. Eng. 2001, 21, 119–134. [Google Scholar] [CrossRef]

- Chen, Q.; Kum Ja, M.; Burhan, M.; Akhtar, F.H.; Shahzad, M.W.; Ybyraiymkul, D.; Ng, K.C. A hybrid indirect evaporative cooling-mechanical vapor compression process for energy-efficient air conditioning. Energy Convers. Manag. 2021, 248, 114798. [Google Scholar] [CrossRef]

- Paris, B.; Vandorou, F.; Balafoutis, A.T.; Vaiopoulos, K.; Kyriakarakos, G.; Manolakos, D.; Papadakis, G. Energy Use in Greenhouses in the EU: A Review Recommending Energy Efficiency Measures and Renewable Energy Sources Adoption. Appl. Sci. 2022, 12, 5150. [Google Scholar] [CrossRef]

- Chevillard, N.; Dubina, L.; Fox, A.; Maltese, L.; Aronson, J. Agrisolar Handbook; SolarPower Europe: Brussels, Belgium, 2024; ISBN 9789464669213. [Google Scholar]

- Available online: https://clean-energy-islands.ec.europa.eu/countries/italy/legal/res-heating-and-cooling/subsidy-conto-termico (accessed on 16 February 2025).

- Marletta, L.; Evola, G.; Arena, R.; Gagliano, A. Are subsidies for thermally-driven solar-assisted cooling systems consistent? A critical investigation for Southern Italy. Energy Rep. 2022, 8, 7751–7763. [Google Scholar] [CrossRef]

- Smart and local Renewable Energy District Heating and Cooling Solutions for Sustainable Living. Available online: https://cordis.europa.eu/project/id/857801/results (accessed on 15 March 2025).

- Heuvelmans, R.; Johra, H.; Hoxha, E. Life Cycle Assessment of an Evaporative Cooling System in Denmark-Supplementary Material; Department of the Built Environment, Aalborg University: Aalborg, Denmark, 2024. [Google Scholar]

- Harrouz, J.P.; Katramiz, E.; Ghali, K.; Ouahrani, D.; Ghaddar, N. Life cycle assessment of desiccant—Dew point evaporative cooling systems with water reclamation for poultry houses in hot and humid climate. Appl. Therm. Eng. 2022, 210, 118419. [Google Scholar] [CrossRef]

- Beccali, M.; Cellura, M.; Longo, S. LCA and Techno-Eco Comparison Between Reference and New Systems. Department of Energy, Information Engineering and Mathematical Models—University of Palermo. 2018. Available online: https://www.iea-shc.org/Data/Sites/1/publications/IEA-SHC-Task53-A5-Final-Report.pdf (accessed on 15 March 2025).

- ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- Misra, D.; Ghosh, S. Evaporative cooling technologies for greenhouses: A comprehensive review. Agric. Eng. Int. CIGR J. 2018, 20, 1–15. [Google Scholar]

- Hussain, G.; Aleem, M.; Sultan, M.; Sajjad, U.; Ibrahim, S.M.; Shamshiri, R.R.; Farooq, M.; Khan, M.U.; Bilal, M. Evaluating Evaporative Cooling Assisted Solid Desiccant Dehumidification System for Agricultural Storage Application. Sustainability 2022, 14, 1479. [Google Scholar] [CrossRef]

| Plant Type | Tday (°C) | Tnight (°C) | RH (%) |

|---|---|---|---|

| Tomato | 23–27 | 13–16 | 50–80 |

| Cucumber | 25–30 | 16–18 | 70–90 |

| Cabbage | 15–16 | 2 | 70–80 |

| Peas | 25–30 | 16–18 | 70–80 |

| Pepper | 22–30 | 14–16 | 50–70 |

| Beans | 22–26 | 16–18 | 70–80 |

| Aubergine | 25–28 | 14–16 | 50–60 |

| Lettuce | 24–28 | 13–16 | 60–80 |

| Courgettes | 20–22 | 17–18 | 65–80 |

| Strawberry | 20–26 | 13–16 | 50–65 |

| Ventilation Driving Force | Study Type | Location | AGh (m2) | Greenhouse Type | Plant Type | Wind Speed (m/s) | Wind Direction | ∆T (K) | Ratio of the Ventilator Opening Area (%) | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|

| Wind-driven | Experimental and theoretical | UK | 204.8 | Four span types | Tomato | <1 | Northeast Southeast | 281.15–287.15 | 10 20 | [26] |

| Wind-driven | Numerical modeling through CFD software | Italy | 307 | Italian type | Ornamental plants | 0.67 0.89 0.11 | Southeast | 275.55–275.95 | 47 | [27] |

| Wind-driven | Experiments and modeling | France | 416 | Polyethylene two-span | Tomato | 0–8.2 | Parallel to the vents | 271.15–285.15 | 7.69 | [28] |

| Wind-driven | Experiments and dynamic tracer gas method analysis | Greece | 384 | Plastic type | - | 0.1–7.6 | North South | 273.95–287.85 | 1.2–23.8 | [29] |

| Buoyancy-driven | Simulation by using CFD | France | 225 | Single-span type | - | 0.3 | - | 275.15 | 65 | [30] |

| Wind-driven | Numerical investigation using the CFD code | Greece | 160 | Tunnel type | Tomato | 0.2–0.7 | Perpendicular to the opening of the tunnel | 279.15 | 22.5 | [31] |

| Buoyancy-driven | CFD simulation/analysis | Israel | 960 | Multi-span type | Pepper | 0.5–3 | North to south | 279.15–280.15 | - | [32] |

| Wind and stack driven | Ventilation performance analysis by using a neural network | France | 30–416 230 210 | Tunnel type Richel tunnel type Roof type | Tomato | 1.3 1.2 10.6 | - | 8.1 7.4 9.4 | 0.8 3 7.5 | [33] |

| Wind-driven | Experiments | France | 368 | Classically ventilated tunnel Largely open tunnel | Tomato | 2.7 in the daytime 2.1 at nighttime | West–northwest East–southeast | 273.65 in the daytime 271.35 at nighttime | 7 in the daytime, 1 and 3 at nighttime 18 for daytime and nighttime | [34] |

| Wind-driven | Simulation using CFD software | France | 2600 | Four-span | Ornamental kalanchoe plants | 1.26 for configuration-I 1.40 for configuration-II | West to east West to east East to west | 9.1 0.03 2.2 | - | [35] |

| Wind-driven | Experiments and analysis with a three-dimensional CFD model | Spain | 882 | Parral | - | 6 | East side West side | - | 3.45 10.46 | [36] |

| Wind-driven | Experimental | UK | 422.4 | Multi-span | Tomato | 1–8 | - | 7 | 2.704 | [37] |

| Buoyancy driven | Analysis with CFD Model | - | 3.3 | Mono-span | - | 0.3 | Perpendicular to the opening area | 275.15 | 25.61 | [38] |

| Wind-driven | Parametric analysis | India | 90 | Single-span ridge type | Flowers | 1–3 | - | 273.85 | 15 | [39] |

| Wind-driven | Simulation using GX software | Canada | 10,000 | Venlo type | Tomato | 2.69–4.42 | - | - | - | [40] |

| Wind-driven | Experiment and analysis using ANOVA general linear model | Thailand | 200 | Net type | Tomato | 2.1 | - | 276.85 | 1.05 | [41] |

| Wind-driven | Experiments and CFD Analysis | Shanghai | 1980 | Multi-span plastic | Lettuce | 1.3 during summer 2 during winter | Perpendicular to the greenhouse orientation | 274.15 during summer 282.05 during winter | - | [42] |

| System Type | Study Type | AGh (m2) | Tamb (°C) | RHamb (%) | TGh (°C) | RHGh (%) | Plant Type | Greenhouse Type | Location | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|

| Fogging system | Design and experiments | 200 | 32 | 86 | 27.6–35.1 29.8–36.9 | 65.57–91.29 65–87 | Mustard green Watercress | Piolet type | Indonesia | [46] |

| Fogging system | Experiments | - | 25–25.9 | 47–52 | 20.6–21.9 | 79–84 | Tomato | Single span | Japan | [47] |

| Fogging system | Experiments | 21,730 | 35.4 | 30–58 | 30.5 | 60–80 | Rose | Multi-span plastic | Turkey | [48] |

| Fogging system | Experiments | 26 | 36–42 | - | 33–38 | - | Tomato | Single span | Japan | [45] |

| Fogging and circulation system | Experiments | 84 | 28–45 | 30–80 | 25–40 | 30–80 | Cucumber | - | Japan | [49] |

| Combined force ventilation and fogging system | Experiments | 868 | 28–40 | - | 28 | 80 | Pepper | Even Span- | Israel | [50] |

| Fogging system | Experiments and mathematical modeling | 32 | 35–38.5 | 22–30 | 24.5–28.5 27 | 60–90 70 | - | Two-span | Israel | [51] |

| Fogging system | Experiments | 108 | - | - | 20–35 | 80 | - | Single-span | Israel | [52] |

| Naturally vented greenhouse with a pressure fogging system | Experiment simulation | 270 | 35 | 35 | 28.1 28.2 | 73 82 | Tomato | Single-span | Arizona | [53] |

| Fogging system | Experiments | 21,648 | 35.4 | 25–50 | 31.6 | 60–80 | - | Multi-span plastic | Turkey | [54] |

| Fogging system | Experiments | 504 | - | 32 | - | 40–80 | Cucumber | Multi-span | - | [55] |

| The fogging system with natural ventilation | Experiments | 417.6 | 30.9 | 60 | 28 | 88.2 | Tomato | Twin-span | Japan | [56] |

| Fogging system | Experiments | 600 | 34 | >80 | <26 | <80 | - | Aluminized thermal screen type | Arta Western Greece | [57] |

| Properties | Fixed Bed Desiccant Systems | Rotary Wheel Desiccant System | Desiccant-Coated Heat Exchanger System |

|---|---|---|---|

| Adsorption capacity | Minimum | Minimum | Maximum |

| Pressure drops | Maximum | Minimum | Minimum |

| Desiccant material utilization | Minimum | Maximum | Maximum |

| Cooling load | Remain constant | Remain constant | Reduce cooling load |

| Heat transfer efficiency | Minimum | Minimum | Maximum |

| Continuous dehumidification | More than one bed is required | One single rotary wheel is required | Two desiccant-coated heat exchangers are required |

| System Type | Desiccant Material | Treg (°C) | Tamb (°C) | RHamb (%) | TGh (°C) | RHGh (%) | COP | AGh (m2) | Plant Type | Location | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Solar-regenerated desiccant evaporative cooling system | CaCl2 LiCl | 60 | 37.5 | 35 | 30 | 55 | 0.5 | 250 | Lettuce Tomato Cucumber | Gulf | [108] |

| Solar-regenerated desiccant evaporative cooling system | LiCl MgCl2 | 35–50 | 34.2 | - | 24–28 | 50–80 | 0.64–0.74 | 224 | Lettuce | Kolkata Bangladesh Italy India Oman | [109] |

| Solar-assisted desiccant and nanofluid evaporative cooling system | Al2O3 Fe3O4 ZnO | 85 | 38.6 | - | 6 °C > Conventional system | - | - | 300 | Cucumber | Saudi Arabia | [110] |

| Solar-powered desiccant cooling system | MgCl2 | - | 34–36 | 65–71 | 22.5–24.5 | - | 0.41 | 1000 | Lettuce Soya Bean Tomato Cucumber | Mumbai Chittagong Messina Muscat Havana | [111] |

| Desiccant dehumidification system | CaCl2 | 80 | 20 | 60 | 25 | 65 | 0.75 | 40 | Cucumber | Netherland | [112] |

| Nanofiltration-regenerated assisted liquid desiccant air conditioning. | MgCl2 | 60–80 | - | - | 25–33 | 70–90 | 5.3 7.6 | 512 | Tomato | Mecca Colombo Bangkok Lahore Cairo | [113] |

| State point liquid desiccant dehumidifier | Br | 50 | 10–20 | 40–90 | 18–26 | 85 | - | 5900 4200 | Tomato Roses | Ontario Kingsville | [114] |

| Performance comparison of the mass transfer of two desiccants | LiBr LiCl | 55 | 25.4–35.4 26.9–35.1 | 46.97–50.60 44.32–56.86 | 19.7–27.2 21.8–29 | - | 0.45 0.47 | - | - | China | [115] |

| Counter-flow adiabatic dehumidifier | LiCl CaCl2 LiBr | 55 | 30–42 | 28.88–48.48 | 14–30 | - | 0.13–0.20 0.10–0.15 0.12–0.18 | - | - | Greece | [116] |

| Integrated desiccant air conditioning system | CHKO2 | 60 | 30.1–34.7 | 51.4–70.6 | 25.1–25.8 | - | 0.72 | - | - | UK | [117] |

| Desiccant dehumidification system | Silica gel LiCl | 80 100 120 | 26–34 | 50–80 | 23–27 | 65 | 1–2.6 0.4–2.2 | - | - | Singapore | [118] |

| System Type | Study Type | Treg (°C) | Tout (°C) | RHout (%) | Tin (°C) | RHin (%) | COP | CC (kW) | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| Hybrid solid desiccant with VAC system | Simulation analysis by using TRNSYS | 94 | 26 | 50.02 | 16 | 50.43 | 4.5 | 1.8 | [140] |

| Hybrid solid desiccant with VAC system | Experiments and modeling by using an artificial neural network | 98.6–141 | 26.1–33.2 | 59.1–86.3 | 7.5–11.2 | 76.2–94.6 | 1.27 for experiments 1.265 for ANN | 3.567 for experiments 3.617 for ANN | [135] |

| Hybrid evaporative VAC system | Feasibility analysis | 30–55 | 40–80 | 26.7 | - | - | 3.5 | [137] | |

| Hybrid solid desiccant cooling system with passive radiative cooling panels | Numerical analysis | 110 | 31 | 50 | 26 | 50 | 0.99 | 3.714 | [141] |

| Hybrid solid desiccant with VAC system | Experimental and simulation | 120 | 33 | 67 | 27 | 65 | - | 22 | [142] |

| Desiccant evaporative cooling system with VAC system | Experimental analysis | 60 | 32 | 46.87 | 22 | 54.64 | 4.06 | - | [95] |

| Liquid desiccant with VAC system | Modeling and dynamic simulation | 70 | 33.9 | 62.4 | 25 | 60 | 0.55 | - | [143] |

| Liquid desiccant with VAC system | Experimental analysis | 51 | 14.6 | 58 | 24.5 | 50.17 | 0.638 | 1.758 | [144] |

| Liquid desiccant with vapor compression air conditioning system | Numerical analysis | 33–60 | 33 | 66.94 | 22 | 55 | 3.32 | - | [145] |

| Liquid desiccant-assisted dehumidification and vapor compression refrigeration air conditioning system | Experimental analysis | - | 36.63 | 77.81 | 26.07 | 84.42 | 2.23 | - | [146] |

| Solid desiccant-assisted VAC | Experimental Simulation | 100 | 30.05 30 | 54.1 55 | 19.8 18.9 | 59.6 64 | 4.82 5.05 | - | [147] |

| Solid desiccant-assisted VAC system | Mathematical modeling | 80 60 | 43.2 38.6 | 13.38 37.41 | 25 | 50 | - | - | [148] |

| Hybrid indirect evaporative cooling system with mechanical VAC system | Experimentally | - | 30–42 | 38.46–48.85 | 24–27 | 62.52–63.35 | 4.96–6.05 | - | [149] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abbas, F.; Sultan, M.; Shahzad, M.W.; Farooq, M.; Raza, H.M.U.; Mahmood, M.H.; Sajjad, U.; Zhang, Z. Comprehensive Review on Evaporative Cooling and Desiccant Dehumidification Technologies for Agricultural Greenhouses. AgriEngineering 2025, 7, 222. https://doi.org/10.3390/agriengineering7070222

Abbas F, Sultan M, Shahzad MW, Farooq M, Raza HMU, Mahmood MH, Sajjad U, Zhang Z. Comprehensive Review on Evaporative Cooling and Desiccant Dehumidification Technologies for Agricultural Greenhouses. AgriEngineering. 2025; 7(7):222. https://doi.org/10.3390/agriengineering7070222

Chicago/Turabian StyleAbbas, Fakhar, Muhammad Sultan, Muhammad Wakil Shahzad, Muhammad Farooq, Hafiz M. U. Raza, Muhammad Hamid Mahmood, Uzair Sajjad, and Zhaoli Zhang. 2025. "Comprehensive Review on Evaporative Cooling and Desiccant Dehumidification Technologies for Agricultural Greenhouses" AgriEngineering 7, no. 7: 222. https://doi.org/10.3390/agriengineering7070222

APA StyleAbbas, F., Sultan, M., Shahzad, M. W., Farooq, M., Raza, H. M. U., Mahmood, M. H., Sajjad, U., & Zhang, Z. (2025). Comprehensive Review on Evaporative Cooling and Desiccant Dehumidification Technologies for Agricultural Greenhouses. AgriEngineering, 7(7), 222. https://doi.org/10.3390/agriengineering7070222