Justification of the Crank Tedder Parameters for Mineral Fertilizers

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussions

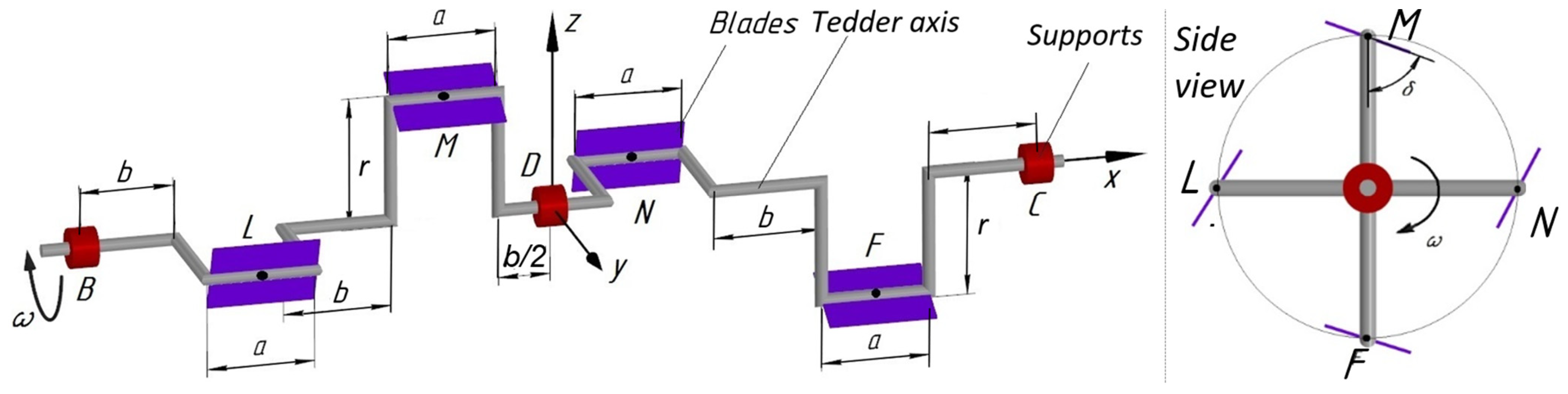

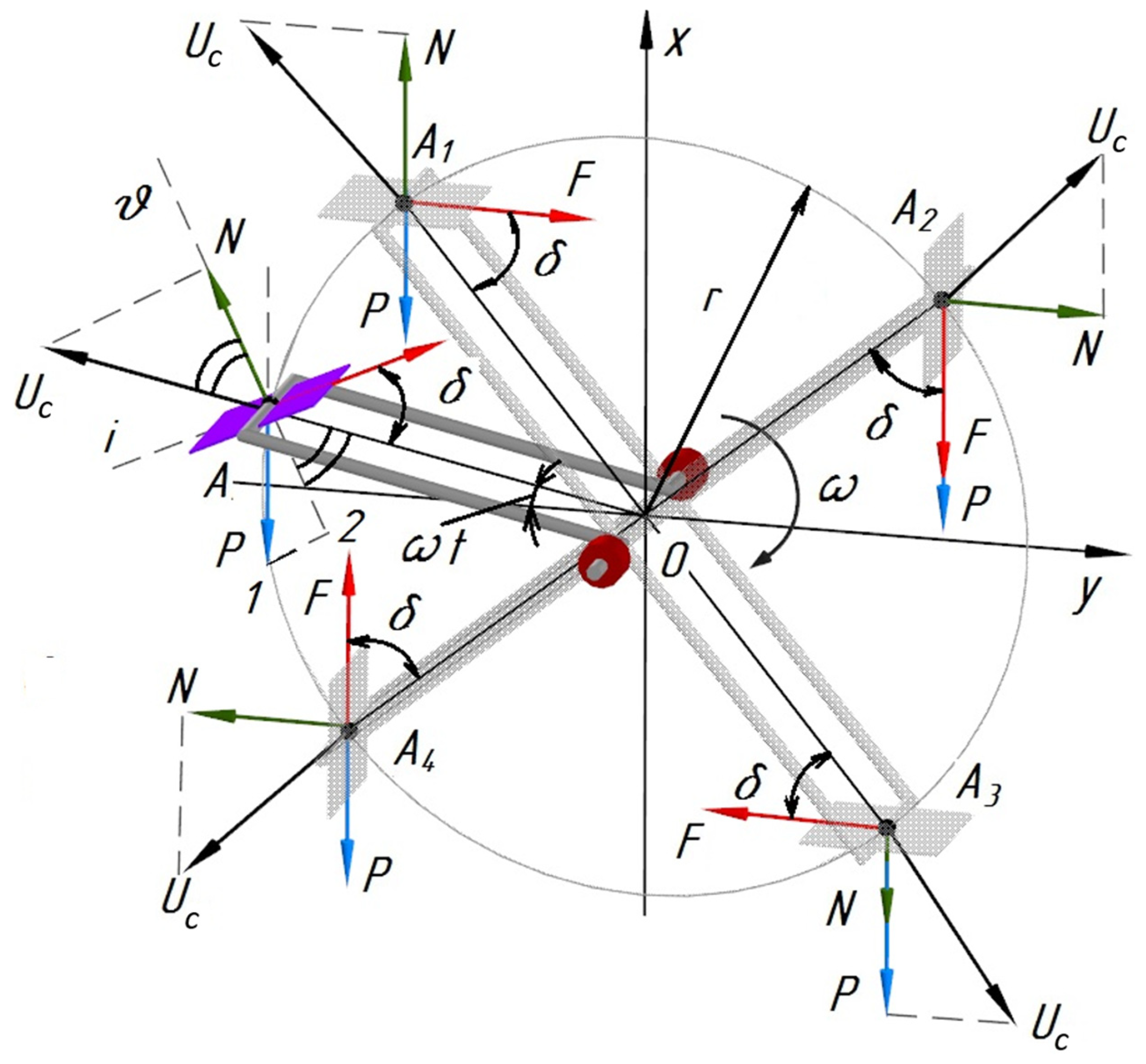

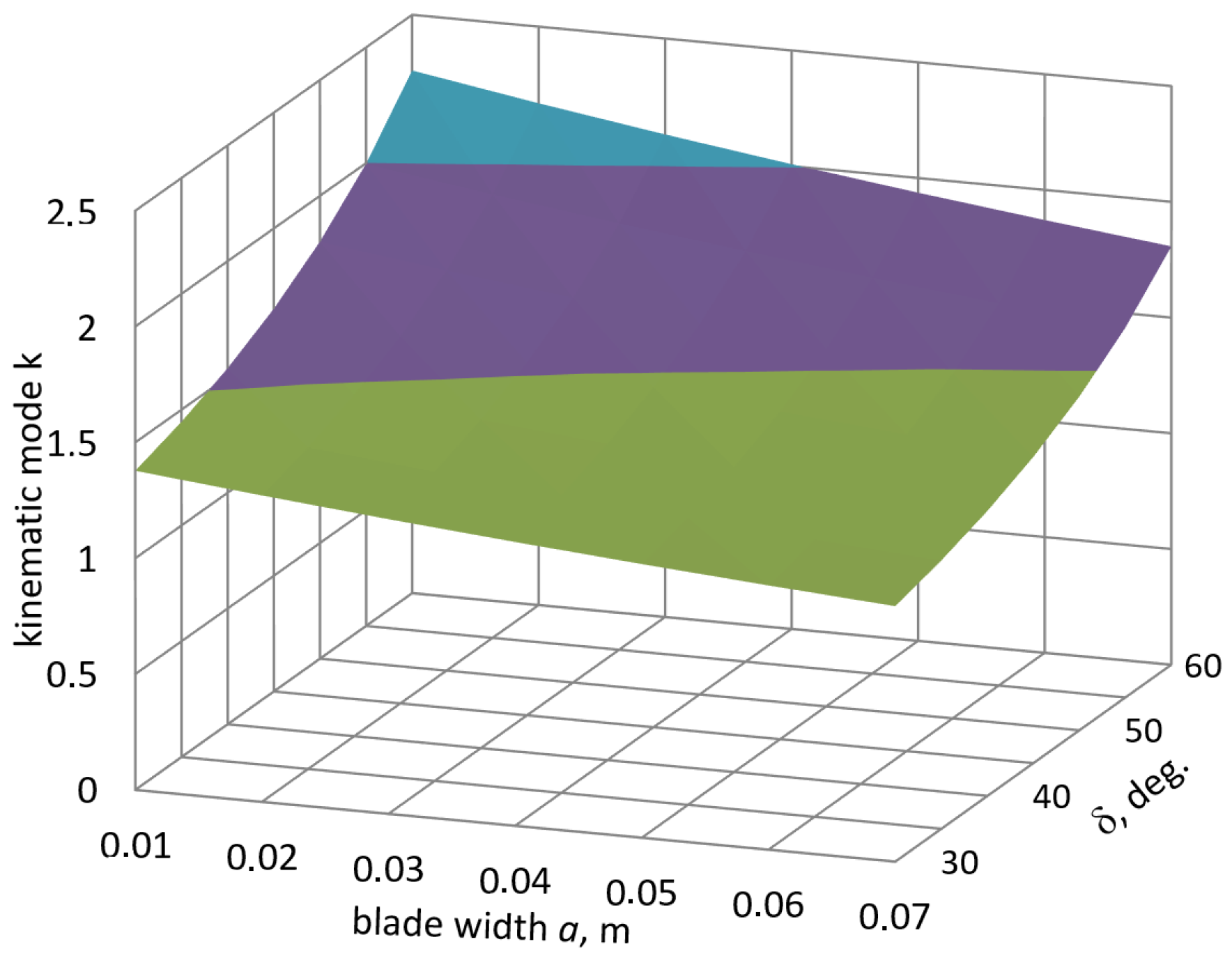

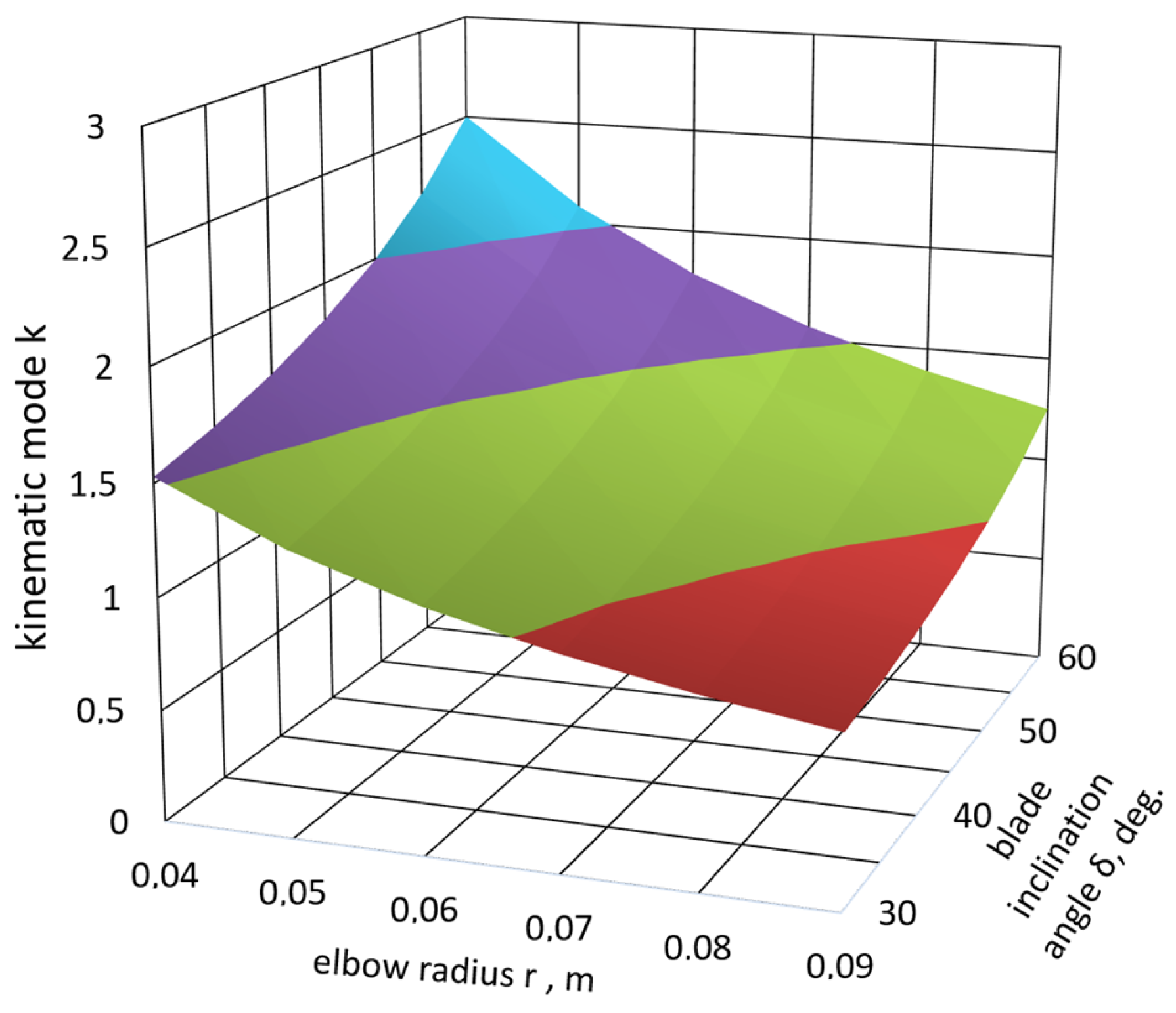

3.1. Theoretical Studies

- N—normal reaction of the surface of the blade on the fertilizer;

- P = mg—gravity of the fertilizer;

- F = fN—friction force between the blade and the fertilizer;

- Uc = mω2r—centrifugal force of the fertilizer in transport movement;

- f = tg φ—friction coefficient between fertilizer and metal;

- φ—angle of friction between fertilizer and metal;

- ω—angle of rotation of the crank tedder;

- r—radius of the blade elbow;

- t—mass of fertilizer in contact point with the blade.

y = r cos ωt.

- r = 0.06 m—radius of the elbow;

- a = 0.04 m—width of the blade;

- b = 0.23 m—distance between neighboring elbows;

- f = 0.5—coefficient of friction;

- δ = 60°—angle of location of crank blades.

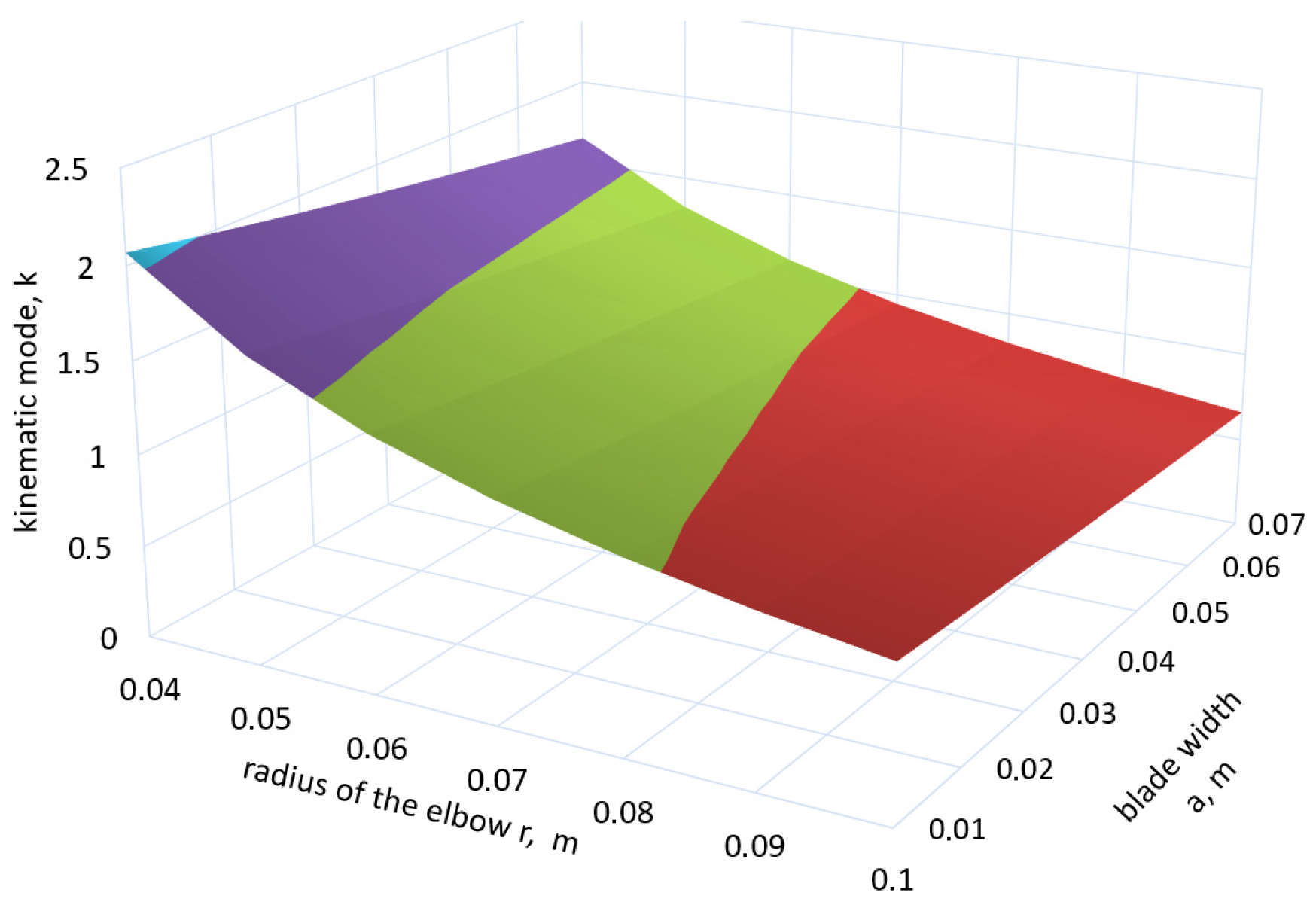

- δ = 20–65°—angle of location of crank blades;

- r = 0.01–0.1 m—radius of the elbow;

- a = 0.05–0.2 m—width of the blade.

- blade width—0.07 m;

- radius of the elbow—0.031 m;

- elbow angle—25.2°

- kinematic mode coefficient, k = 1.87.

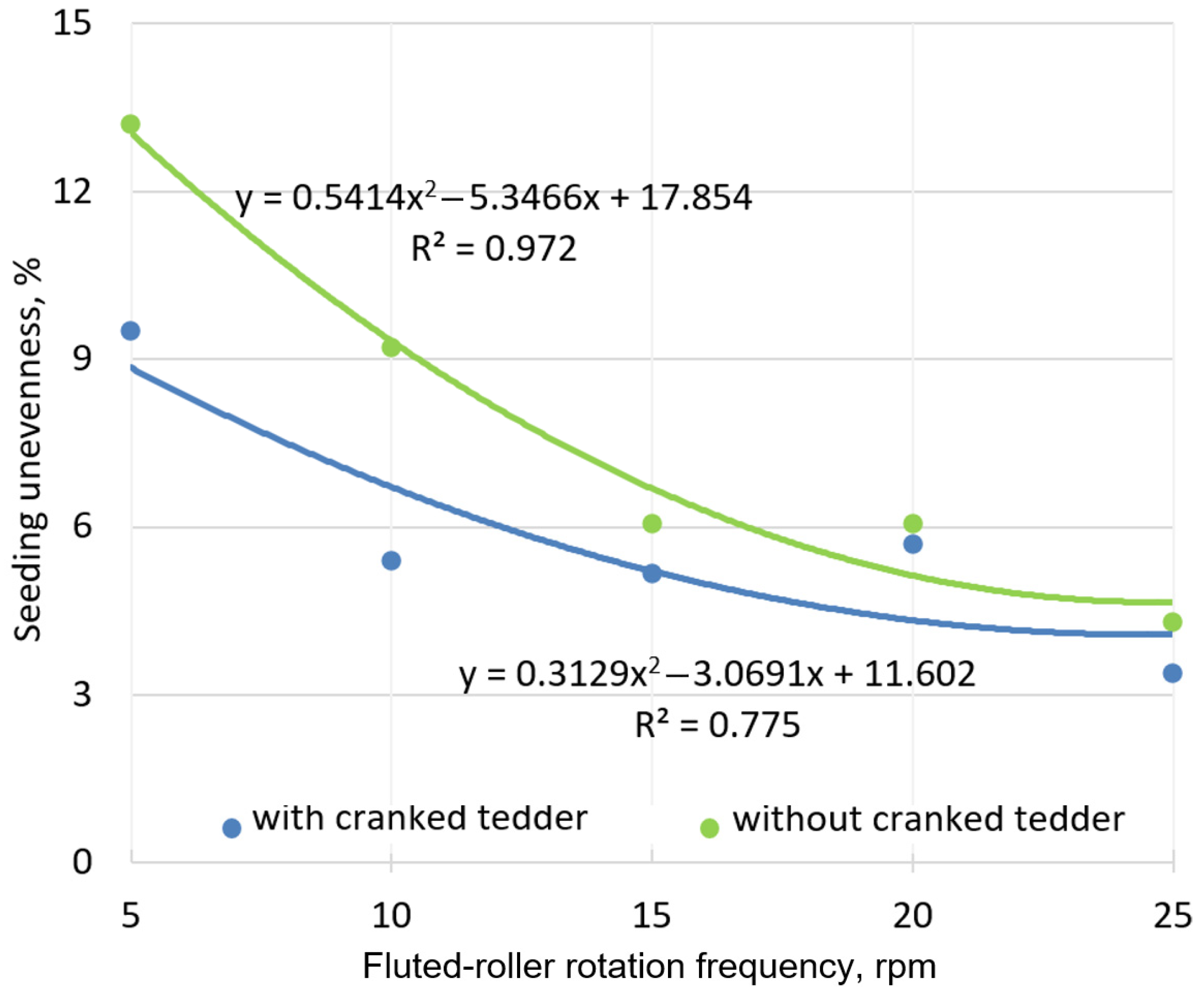

3.2. Results of Experiments

3.2.1. Determination of Sowing Quality

3.2.2. Degree of Granule Damage in Fertilizer

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lu, Y.; Liu, M.; Li, C.; Liu, X.; Cao, C.; Li, X.; Kan, Z. Precision Fertilization and Irrigation: Progress and Applications. Agric. Eng. 2022, 4, 626–655. [Google Scholar] [CrossRef]

- Gavrilović, M.; Dimitrijević, A.; Radojičin, M.; Mileusnić, Z.; Miodragović, R. Effects of the application system on the physical and mechanical properties of mineral fertilizers. J. Process. Energy Agric. 2018, 22, 180–183. [Google Scholar] [CrossRef]

- Tanbayev, K.; Nukeshev, S.; Engin, T.; Saktaganov, B. Flat Spray Nozzle for Intra-Soil Application of Liquid Mineral Fertilizers. Acta Technol. Agric. 2023, 26, 65–71. [Google Scholar] [CrossRef]

- Wang, S.; Yan, Y.; Ji, S. Transition of granular flow patterns in a conical hopper based on superquadric DEM simulations. Granul. Matter 2020, 22, 79. [Google Scholar] [CrossRef]

- Magalhães, F.G.R.; Atman, A.P.; Moreira, J.G.; Herrmann, H.J. Analysis of the velocity field of granular hopper flow. Granul. Matter 2016, 18, 33. [Google Scholar] [CrossRef]

- Nukeshev, S.; Slavov, V.; Karaivanov, D.; Balabekova, A.; Zhaksylykova, Z. Forced vibrations of the hopper of fertilizer applying machine. Mechanika 2019, 24, 798–804. [Google Scholar] [CrossRef]

- Mundhe, R.; Thakkar, M.; Suwase, A.; Sharma, J.; Bhosale, V. Design and manufacturing of fertilizer spreader machine. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Nukeshev, S.; Kossatbekova, D.; Ramaniuk, M.; Sagitov, A.; Akhmetov, Y.; Mamyrbayeva, I.; Tanbayev, K.; Tleumbetov, K. Traction Force, Sowing Quality, and Deformation Characteristics of the Coulter of a Grain–Fertilizer–Grass Seeder. Agric. Eng. 2024, 6, 2326–2351. [Google Scholar] [CrossRef]

- Méndez, D.; Hidalgo, R.C.; Maza, D. The role of the hopper angle in silos: Experimental and CFD analysis. Granul. Matter 2021, 23, 34. [Google Scholar] [CrossRef]

- Pobedinsky, P.N. Methodology for assessing the quality of mineral fertilizer application. Tech. Agric. 1988, 4, 48. (In Russian) [Google Scholar]

- Lozano, C.; Lumay, G.; Zuriguel, I.; Hidalgo, R.C.; Garcimartín, A. Breaking arches with vibrations: The role of defects. Phys. Rev. Lett. 2012, 109, 068001. [Google Scholar] [CrossRef] [PubMed]

- Lozano, C.; Zuriguel, I.; Garcimartín, A. Stability of clogging arches in a silo submitted to vertical vibrations. Phys. Rev. E Stat. Nonlin. Soft Matter Phys. 2015, 91, 062203. [Google Scholar] [CrossRef] [PubMed]

- Nukeshev, S.; Mamyrbayeva, I.; Eskhozhin, K.; Balabekova, A.; Zhaksylykova, Z. The results of theoretical studies of the vibrator compensating chamber of the dispenser of mineral fertilizers. J. Eng. Appl. Sci. 2018, 13, 130–136. [Google Scholar]

- Nukeshev, S.; Tanbayev, K.; Ramaniuk, M.; Kakabayev, N.; Sugirbay, A.; Moldazhanov, A. Spray Angle and Uniformity of the Flat Fan Nozzle of Deep Loosener Fertilizer for Intra-Soil Application of Fertilizers. Agric. Eng. 2024, 6, 1365–1394. [Google Scholar] [CrossRef]

- Carlevaro, C.M.; Kuperman, M.N.; Bouzat, S.; Pugnaloni, L.A.; Madrid, M.A. On the use of magnetic particles to enhance the flow of vibrated grains through narrow apertures. Granul. Matter 2022, 24, 51. [Google Scholar] [CrossRef]

- Ebrahim, I.Z.; Ibrahima, M.M.; El-Saadanya, M.A.; Foudab, O.A. Agitator Unit in Auger Metering Device for Fertilizer Applicator. AMA Agric. Mech. Asia Afr. Lat. Am. 2011, 42, 36–41. [Google Scholar]

- Andreev, K.P.; Kostenko, M.Y.; Shemyakin, A.V. Force interaction of the tedder blade with the fertiliser layer. In Bulletin of Ulyanovsk State Agricultural Academy; Russian, 2017; Volume 2. Available online: https://cyberleninka.ru/article/n/silovoe-vzaimodeystvie-lopasti-voroshitelya-so-sloem-udobreniy (accessed on 15 November 2024). (In Russian).

- Rogachev, S.Y.; Vasilenko, E.V.; Radchenko, A.I.; Sobchak, P.A.; Zelensky, N. Z Rotary Vault Breaker of Bulk. Materials. Patent RU1800934C, 7 March 1993. Bulletin No. 9. [Google Scholar]

- Klenin, N.I.; Kiselev, S.N.; Levshin, A.G. Agricultural Machines: Textbook and Manual; Kolos: Moscow, Russia, 2008; p. 816. (In Russian) [Google Scholar]

- Collection of agrotechnical requirements for agricultural machinery and tractors. In T.XI.—M.: CNTIITEN of Agricultural Machinery; 1990; p. 342. (In Russian)

- Adamchuk, V.V. Justification of the Process of Work and Parameters of Auger Distributive-Sowing Systems of Machines for Application of Solid Mineral Fertilisers: Dissertation Cand. of Technical Sciences; Ukrainian Institute of Mechanization and Electrification of Rural Industries: Glevakha, Ukraine, 1985; p. 284. (In Russian)

- McCartney, D.; Hultgreen, G.; Boyden, A.; Stevenson, C. Development of agitators for seeding forages using air delivery systems. Rangel. Ecol. Manag. 2005, 58, 199–203. [Google Scholar] [CrossRef]

- Beshnikhin, A.Y. Efficiency of tedder application in pneumatic seeders. In Achievements of Science and Technology of Agroindustrial Complex; 2007. Available online: https://elibrary.ru/item.asp?id=10429086 (accessed on 15 November 2024). (In Russian).

- Ryabov, N.V. Mechanism of vaulting of loose bodies at their flow from hoppers. In Izvestiya Vuzov. North-Caucasian Region. Series: Technical Sciences; 2012. Available online: https://cyberleninka.ru/article/n/mehanizm-svodoobrazovaniya-sypuchih-tel-pri-ih-istechenii-iz-bunkerov (accessed on 15 November 2024). (In Russian).

- Cleary, P.W.; Mark, L.S. DEM Modelling of Industrial Granular Flows: 3D Case Studies and the Effect of Particle Shape on Hopper Discharge. Appl. Math. Model. 2002, 26, 89–111. [Google Scholar] [CrossRef]

- Bansal, R.; Gharras, O.E.; Hamilton, J. A roller-type positive-feed mechanism for seed metering. J. Agric. Eng. Res. 1989, 43, 23–31. [Google Scholar] [CrossRef]

- Preobrazhenskiy, P.A.; Lange, B.Y.; Alexandrovskiy, A.A. Calculation of a double-spiral mixer with coupled spirals. In Spiral-screw Conveyors (Flexible Screws) and Mixers; Kazan, Russian, 1970; pp. 138–152. (In Russian) [Google Scholar]

- GOST 28714-2007; Interstate Standard. Machines for Application of Solid Mineral Fertilizers. Moscow, Russia, 2008. Available online: https://agronomy.emu.ee/wp-content/uploads/2021/06/AR2021_Raamat_3_Tehnika_S1_V_trukk.pdf (accessed on 15 November 2024).

- ISO 5690-1:1985; Equipment for Distributing Fertilizers—Test Methods—Part 1: Full Width Fertilizer Distributors. International Organization for Standardization: Geneva, Switzerland, 1985.

- Drong, V.I.; Dubinin, V.V.; Ilyin, M.M.; Kolesnikov, K.S.; Kosmodemyansky, V.A.; Nazarenko, B.P.; Pankratov, A.A.; Rusanov, P.G.; Saratov, Y.S.; Stepanchuk, Y.M. Course of Theoretical Mechanics; Under Edition of Kolesnikov, K.S. M.; Bauman MSTU Publishing House: Moscow, Russia, 2005; p. 736. (In Russian) [Google Scholar]

- Markeev, A.P. Theoretical Mechanics. In Textbook for Universities; 1999; p. 572.

- Klenin, N.I.; Sakun, V.A. Agricultural and Meliorative Machines; Izd. 2; Kolos: Moscow, Russia, 1980; p. 671. (In Russian) [Google Scholar]

- Listopad, G.E.; Demidov, G.K.; Zonov, B.D. Agricultural and Meliorative Machines; Agropromizdat: Moscow, Russia, 1986; p. 688. (In Russian) [Google Scholar]

- Alferov, K.V.; Zenkov, R.L. Bunker Installations. Design, Calculation and Operation; Mashgiz: Moscow, Russia, 1955; p. 308. (In Russian) [Google Scholar]

- Salman, A.; Fu, J.; Gorham, D.; Hounslow, M. Impact breakage of fertiliser granules. Powder Technol. 2003, 130, 359–366. [Google Scholar] [CrossRef]

| Granule Size, mm | Granule Damage,% |

|---|---|

| >5 | 14.64 |

| 3–5 | 3.38 |

| 2–3 | 2.95 |

| 1–2 | 2.84 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nukeshev, S.; Yeskhozhin, K.; Akhmetov, Y.; Gorbunov, B.; Kossatbekova, D.; Tanbayev, K.; Sugirbay, A.; Tleumbetov, K. Justification of the Crank Tedder Parameters for Mineral Fertilizers. AgriEngineering 2025, 7, 239. https://doi.org/10.3390/agriengineering7070239

Nukeshev S, Yeskhozhin K, Akhmetov Y, Gorbunov B, Kossatbekova D, Tanbayev K, Sugirbay A, Tleumbetov K. Justification of the Crank Tedder Parameters for Mineral Fertilizers. AgriEngineering. 2025; 7(7):239. https://doi.org/10.3390/agriengineering7070239

Chicago/Turabian StyleNukeshev, Sayakhat, Kairat Yeskhozhin, Yerzhan Akhmetov, Boris Gorbunov, Dinara Kossatbekova, Khozhakeldi Tanbayev, Adilet Sugirbay, and Kaldybek Tleumbetov. 2025. "Justification of the Crank Tedder Parameters for Mineral Fertilizers" AgriEngineering 7, no. 7: 239. https://doi.org/10.3390/agriengineering7070239

APA StyleNukeshev, S., Yeskhozhin, K., Akhmetov, Y., Gorbunov, B., Kossatbekova, D., Tanbayev, K., Sugirbay, A., & Tleumbetov, K. (2025). Justification of the Crank Tedder Parameters for Mineral Fertilizers. AgriEngineering, 7(7), 239. https://doi.org/10.3390/agriengineering7070239