1. Introduction

A recent report by the international panel on climate change (IPCC) highlighted anthropogenic climate change as a major threat to humanity and life on earth [

1]. The IPCC determined that climate change, if not addressed, would cause an increase in mean temperature in many regions. Some regions would also see an increase in the frequency and intensity of droughts, while some would be affected by a rise in sea levels. The main cause of anthropogenic climate change is the ever-increasing amount of greenhouse gas (GHG) emissions. Therefore, GHG emissions must be drastically reduced in order to prevent the negative consequences of climate change [

2]. Currently, the transportation sector accounts for a large portion of GHG (mainly CO

2) emissions. In Canada, Clean Energy Canada found that the transportation sector was responsible for 23% of Canada’s GHG emissions as of 2016 [

3]. The Canadian transportation sector is dominated by internal combustion engine vehicles (ICEVs). Aside from CO

2, ICEVs also emit other hazardous gases including carbon monoxide (CO), sulfur dioxide (SO

2), nitrous oxides (NO

x) and volatile organic compounds (VOCs). These air pollutants were found to increase one’s risk of dementia, diabetes, asthma and premature death.

A viable alternative to ICEVs is electric vehicles (EVs). EVs use a motor, often powered by a lithium-ion (Li-ion) battery pack, to propel the vehicle [

4]. EVs have lower environmental and health impacts compared to ICEVs because they do not emit exhaust, thus, they do not directly release any emissions or pollutants [

5]. EVs can help prevent climate change, thus protecting the environment and public health [

6]. Although electricity production is usually much cleaner than oil and gas consumption, the degree of which depends on the method that the electricity was produced. Hence, EVs are more favorable in regions that use nuclear and renewable sources to generate electricity [

7]. For example, a study done in Texas showed that EVs powered by coal increased air pollution by 350%, while EVs powered by renewable energy or natural gas decreased air pollution by 50% and 70%, respectively [

8]. In Ontario, Canada, there is a surplus of electricity produced from different energy sources, and therefore, the market penetration of EVs would be beneficial [

9].

However, there are several issues that prevent the widespread adoption of EVs, including the high cost of the vehicles, the lack of charging infrastructure, and the limited range associated with EVs [

10,

11]. A solution to the limited range and high cost of EVs is to utilize a range extender, which is an auxiliary energy storage system (ESS) that provides the vehicle with additional energy to complement the primary battery in propelling the vehicle [

12]. There are several different types of range extenders, including ICE, fuel cell, free-piston linear generator (FPLG) and micro gas turbine (MGT) [

13]. An ICE range extender converts gasoline into electricity using a fuel converter. The ICE unit is comprised of an electronically controlled combustion engine connected to a generator, which supplies the required electricity to the motor [

14]. A fuel cell extended-range EV has a tank of hydrogen fuel, which gets converted into usable electricity by the fuel cell to support the battery in powering the vehicle [

15]. The fuel cell range extender can increase the range and performance of the vehicle while still drastically reducing emissions. An FPLG range extender uses a combustion and linear generator to convert chemical energy into electrical energy [

16]. An MGT range extender draws in clean air, compresses it, and passes it through a turbine at extremely high revolutions to generate energy [

17]. Despite their advantages, all of the aforementioned range-extending solutions have some drawbacks. ICE is not environmentally friendly, fuel cell and FPLG are not cost-effective, and MGT is not efficient. In recent years, the concept of using a zinc–air (Zn–air) battery pack as a range extender for EVs has been investigated [

18].

Metal–air batteries have gained some attention for their potential use in EVs because of their high energy density and low cost [

19]. The feasible cell chemistries include lithium–air (Li–air), aluminum–air (Al–air) and Zn–air. Li–air batteries have the highest energy density, but there are many potential deficiencies and safety concerns hindering their commercialization [

20]. Al–air batteries have an aqueous electrolyte, making them safer than Li–air batteries. The drawback of Al–air batteries is that they are not easily recharged and need to be replaced once they are drained [

19]. Zn–air batteries have a lower energy density than Li–air and Al–air batteries. However, Zn–air batteries have attracted significant commercial and research interest for several reasons. The raw materials required to manufacture Zn–air batteries are abundant, which lowers the cost of the pack significantly [

21]. Zn–air batteries also have a greater energy density and specific energy than Li-ion batteries. They have good resistance to aging degradation but are susceptible to cycling degradation [

19]. This means that they can last a long time if left unused but cannot be cycled as many times as Li-ion batteries.

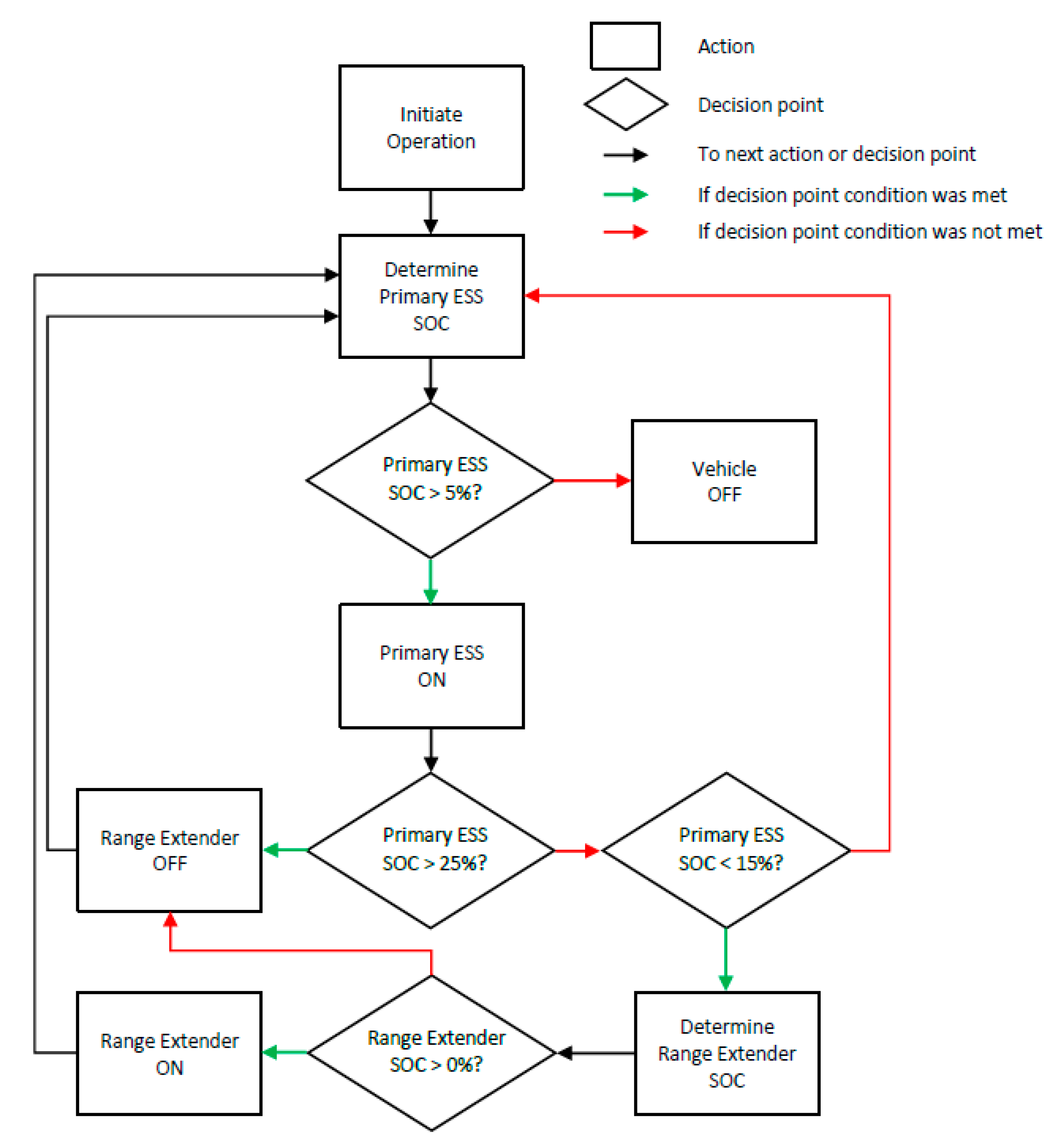

Recent breakthroughs in Li-ion battery research have allowed for increased range of EVs. However, the current solution to the range problem involves a larger Li-ion battery pack, which is expensive and redundant for daily use of EVs, as most people only use their vehicles to commute short distances between work and home. In our previous work, we proposed a novel powertrain design, incorporating a Li-ion battery pack as the primary ESS and a Zn–air battery pack as the range extender, with the necessary electronic controls to facilitate their coordination and optimization [

18]. The Li-ion battery pack would be used for daily commutes while the Zn–air battery pack would serve as a range extender for longer trips. By utilizing these two ESS units in one powertrain, a smaller Li-ion pack can be used, which would lower the cost of the vehicle. In addition, the Zn–air pack is only used on longer trips, which reduces the cycling of the pack and eliminates its exposure to cycling degradation. Therefore, this design allows each battery to contribute its strengths while minimizing its weaknesses.

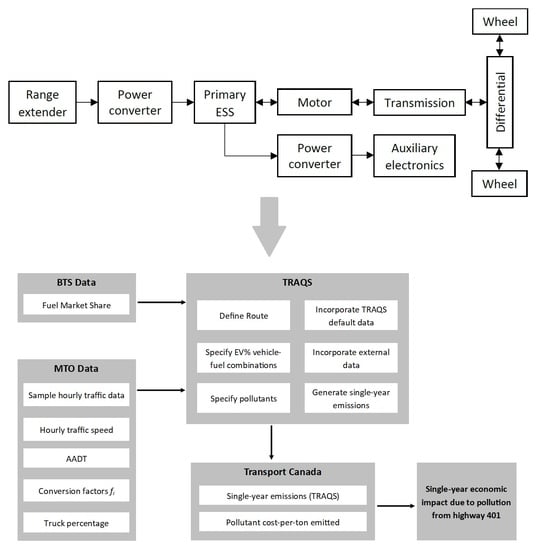

In this study, the environmental and economic implications of the proposed novel dual-battery-pack powertrain are examined, since only the design and performance aspects of the powertrain were investigated in our previous study. The analysis should provide a more complete picture of the feasibility and benefits of the proposed powertrain design. The results from the dual-pack powertrain are compared with values from a standard single-pack Li-ion battery EV and a conventional ICEV. In addition, an air pollution model is used to determine the amount of certain pollutants released annually by the transportation sector on Highway 401 in Ontario, Canada. The benefits of the pollution reduction from mass EV rollout are then analyzed for this case study. The rest of this study is organized as follows.

Section 2 provides the analysis of the environmental and economic benefits of the proposed powertrain design, while

Section 3 presents the benefit analysis of pollution reduction from the potential market penetration of EVs. Finally,

Section 4 outlines some concluding remarks.