Exploring Smart Tires as a Tool to Assist Safe Driving and Monitor Tire–Road Friction

Abstract

:1. Introduction

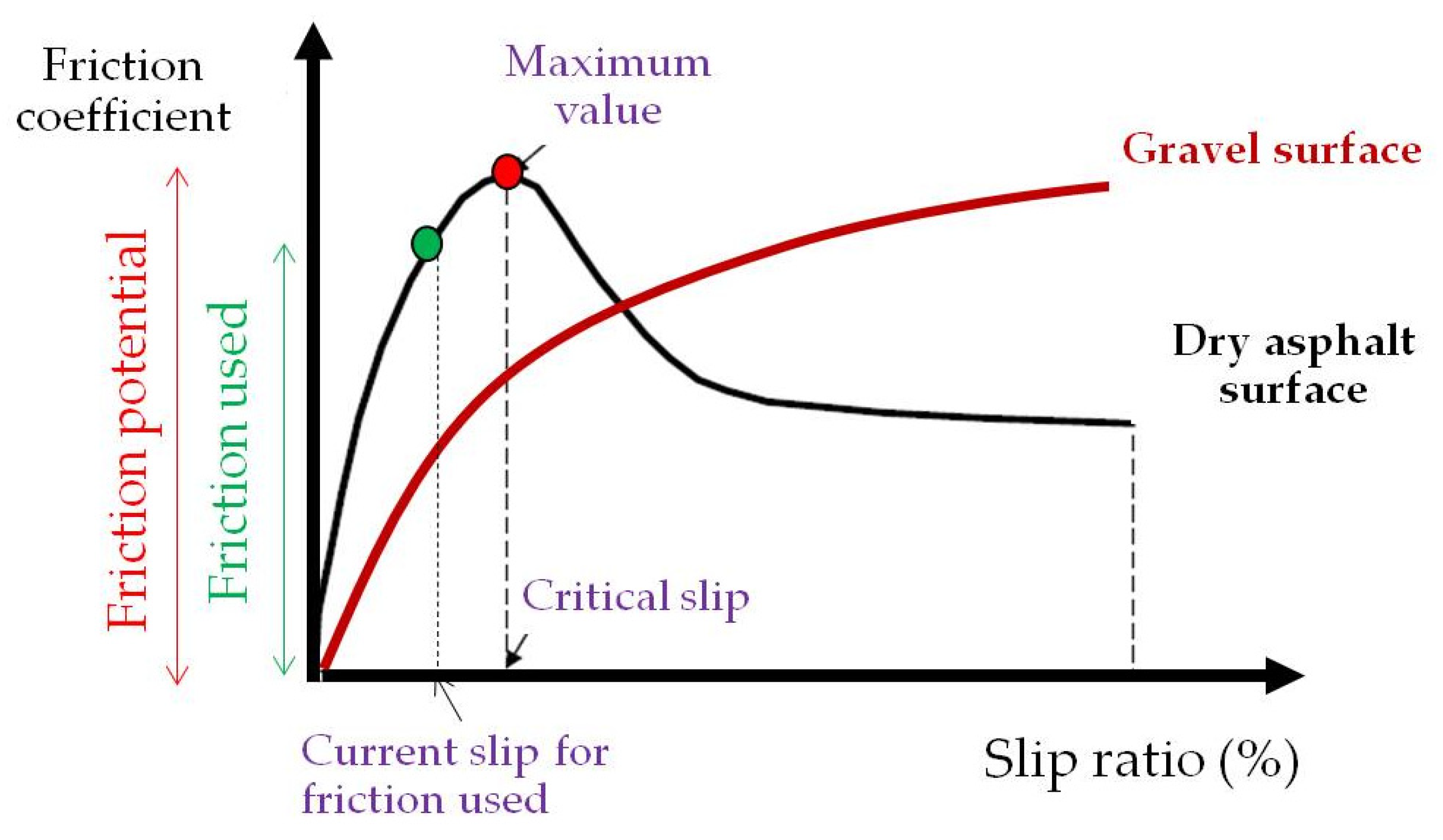

2. Tire–Road Friction

2.1. Definition

2.2. Friction and Pavement Texture Components

2.3. Weather Effects on Tire–Road Friction

2.4. Monitoring Systems and Measurement Practices

2.5. Discussion

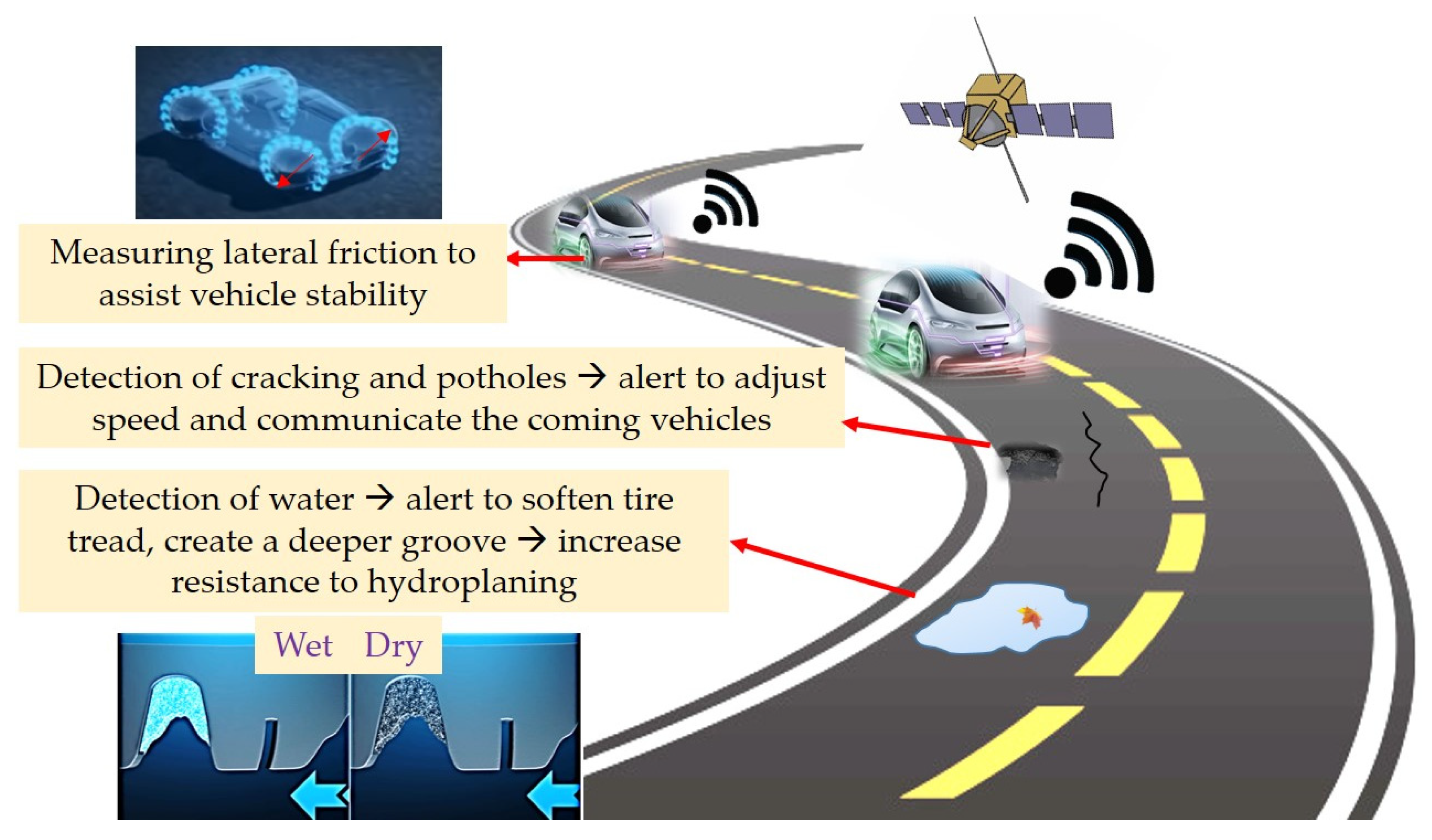

3. Smart Tire as a Tool for Sensor-Based Monitoring

- Tire radial displacement, which can be measured between the wheel and the inner liner of the tire, and displacement of the tire sidewall. Regarding the measuring devices, it has been reported that they can vary from some simple string potentiometer devices [73] to optical systems using a light source and a lens [74]. The majority of such devices are reasonably efficient, but their durability is a matter of concern [70].

- Tire acceleration can be easily measured considering the various accelerometers that are widely available, quite efficient and physically strong. However, in-tire accelerometers measure impacts, and thus, they are suitable for establishing the tire angular position, especially with respect to identification of the tire–road contact. There are also those tire sensors that directly measure the acceleration or deformation of the tire once installed inside the tire [75,76]. In general, although it may be possible to relate tire–road contact patch location and length to tire forces, it is more likely to generate information about forces when considering tire strain measurements directly [70].

- Tire strain is affected by the stiffness of the measuring sensors and their adhesive, which is normally much higher than the stiffness of tire rubber. In order to overcome this incompatibility, the utilized sensors are elastomer substrates [77,78,79]. Wheel angular velocity and position can be measured using the rotary wheel encoder, which is part of an ABS system. In addition, the angular position can be estimated using the ABS information and information on tire acceleration and critical friction.

- A convolutional layer, responsible for extracting the spatial features from the imported images inside the layer so that the CNN can identify the patterns or objects,

- A pooling layer, responsible for gathering the output data generated from the convolution layer in order to reduce the size of the output data or to highlight specific sorts of data [86], and

- A fully connected layer, which is flattened and connected to the pooling layer once all the features of the image or sequential data are sufficiently recognized, thereby leading to the final classification output.

4. Potentialities of Smart Tires: Challenges and Prospects

4.1. State of Practice

4.2. Addressing Future Needs

4.3. Integration with Current Techniques for Infrastructure Monitoring

5. Conclusions and Prospects

- A pavement’s skid resistance is directly related to tire–road friction thereby affecting vehicle maneuvering and braking under various weather conditions reflected through dry, wet, dusty and icy road surfaces or combinations of the aforementioned circumstances.

- Given its significance and its relationship to road incidents, friction is normally measured by almost every road entity at periodical time intervals with standardized equipment in the framework of a PMS.

- In parallel, the benefits of using smart sensors embedded in tires were introduced mainly as a tool to promote advanced vehicle control but also as a cost-effective yet necessary approach to evaluating in real-time the friction level of a roadway section while traveling.

- Such an approach is expected to assist drivers in adjusting their behavior (i.e., lower their speed) in case indications of reduced skid resistance are observed in favor of road safety.

- Smart tires appear as an intelligent means for enhancing road safety both for current traffic modes as well as for future mobility patterns with AVs and CAVs.

- Thanks to the connectivity aspects of smart tires, it might be feasible not only to improve driving safety but also to help to control pavement deterioration. Focusing on skid resistance, it also appears that smart tires can assist in effective roadway monitoring. Of course, the goal is not to substitute existing systems in terms of decision-making; rather, it is to complement and even ameliorate the current state of practice by identifying areas where additional monitoring effort needs to be considered for condition assessment. More relevant research is needed in these directions.

- Particular research challenges should be addressed, such as the impact of icy surfaces on the efficacy of smart tires. Icy conditions are critical for vehicle stability, and the presence of ice on a road surface induces dangerous driving conditions that require systematic investigation in conjunction with potential benefits from the use of smart tires.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Khaleghian, S.; Emami, A.; Taheri, S. A technical survey on tire-road friction estimation. Friction 2017, 5, 123–146. [Google Scholar] [CrossRef] [Green Version]

- Behroozinia, P.; Khaleghian, S.; Taheri, S.; Mirzaeifar, R. An investigation towards intelligent tyres using finite element analysis. Int. J. Pavement Eng. 2020, 21, 311–321. [Google Scholar] [CrossRef]

- Fwa, T.F. Skid resistance determination for pavement management and wet-weather road safety. Int. J. Transp. Sci. Technol. 2017, 6, 217–227. [Google Scholar] [CrossRef]

- Fwa, T.F. Determination and prediction of pavement skid resistance–connecting research and practice. J. Road Eng. 2021, 1, 43–62. [Google Scholar] [CrossRef]

- Elkhazindar, A.; Hafez, M.; Ksaibati, K. Incorporating Pavement Friction Management into Pavement Asset Management Systems: State Department of Transportation Experience. CivilEng 2022, 3, 32. [Google Scholar] [CrossRef]

- Fatality Analysis Reporting System; National Highway Traffic Safety Administration: Washington, DC, USA, 2012.

- Connelly, L.B.; Supangan, R. The economic costs of road traffic crashes: Australia, states and territories. Accid. Anal. Prev. 2006, 38, 1087–1093. [Google Scholar] [CrossRef]

- Najafi, S.; Flintsch, G.W.; Khaleghian, S. Fuzzy logic inference based Pavement Friction Management and real-time slippery warning systems: A proof of concept study. Accid. Anal. Prev. 2016, 90, 41–49. [Google Scholar] [CrossRef]

- Najafi, S.; Flintsch, G.W.; Khaleghian, S. Pavement friction management–artificial neural network approach. Int. J. Pavement Eng. 2019, 20, 125–135. [Google Scholar] [CrossRef]

- Pomoni, M.; Plati, C.; Loizos, A.; Yannis, G. Investigation of pavement skid resistance and macrotexture on a long-term basis. Int. J. Pavement Eng. 2022, 23, 1060–1069. [Google Scholar] [CrossRef]

- Ziakopoulos, A.; Yannis, G. A review of spatial approaches in road safety. Accid. Anal. Prev. 2020, 135, 105323. [Google Scholar] [CrossRef]

- Ahammed, M.A.; Tighe, S.L. Asphalt pavements surface texture and skid resistance—Exploring the reality. Can. J. Civ. Eng. 2012, 39, 1–9. [Google Scholar] [CrossRef]

- Thenuwara, H.V.; Pasindu, H. Methodology to Incorporate Frictional Performance in the Pavement Management System of Sri Lankan Expressways. In Proceedings of the 2020 Moratuwa Engineering Research Conference (MERCon), Virtual event, 28–30 July 2020; pp. 437–442. [Google Scholar] [CrossRef]

- Federal Highway Administration. Pavement Friction Management Program Utilizing Continuous Friction Measurement Equipment and State-of-the-Practice Safety Analysis Demonstration Project—Final Report; Report No. FHWA-RC-20-0009; Virginia Polytechnic Institute and State University Applied Pavement Technology, Inc.: Charlottesville, VA, USA, 2019.

- Rasol, M.; Schmidt, F.; Ientile, S.; Adelaide, L.; Nedjar, B.; Kane, M.; Chevalier, C. Progress and Monitoring Opportunities of Skid Resistance in Road Transport: A Critical Review and Road Sensors. Remote Sens. 2021, 13, 3729. [Google Scholar] [CrossRef]

- Sattar, S.; Li, S.; Chapman, M. Road Surface Monitoring Using Smartphone Sensors: A Review. Sensors 2018, 18, 3845. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pan, Y.; Zhang, X.; Sun, M.; Zhao, Q. Object-Based and Supervised Detection of Potholes and Cracks from the Pavement Images Acquired by UAV. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2017, 42, 209–217. [Google Scholar] [CrossRef] [Green Version]

- Christodoulou, S.; Kyriakou, C.; Hadjidemetriou, G. Pavement Patch Defects Detection and Classification Using Smartphones, Vibration Signals and Video Images. In Advanced Computing Strategies for Engineering; Elsevier: Amsterdam, The Netherlands, 2019; pp. 365–380. [Google Scholar]

- Hadjidemetriou, G.M.; Christodoulou, S.E. Vision-and entropy-based detection of distressed areas for integrated pavement condition assessment. J. Comput. Civ. Eng. 2019, 33, 04019020. [Google Scholar] [CrossRef]

- Ranyal, E.; Sadhu, A.; Jain, K. Road Condition Monitoring Using Smart Sensing and Artificial Intelligence: A Review. Sensors 2022, 22, 3044. [Google Scholar] [CrossRef]

- Singh, K.B. Intelligent Tire-Based Road Friction Estimation System and Method. U.S. Patent US20160159365A1, 9 June 2016. [Google Scholar]

- Miyazaki, N. Road Surface Friction Sensor and Road Surface Friction Coefficient Detector, and Vehicle Antilock Braking Device. U.S. Patent US20020120383A1, 29 August 2002. [Google Scholar]

- Xu, N.; Huang, Y.; Askari, H.; Tang, Z. Tire Slip Angle Estimation based on the Intelligent Tire Technology. Electr. Eng. Syst. Sci. 2021, 70, 2239–2249. [Google Scholar] [CrossRef]

- Zhu, B.; Han, J.; Zhao, J. Tire-Pressure Identification Using Intelligent Tire with Three-Axis Accelerometer. Sensors 2019, 19, 2560. [Google Scholar] [CrossRef] [Green Version]

- Jalali, M.; Khosravani, S.; Khajepour, A.; Chen, S.K.; Litkouhi, B. Model predictive control of vehicle stability using coordinated active steering and differential brakes. Mechatronics 2017, 48, 30–41. [Google Scholar] [CrossRef]

- Lu, Q.; Gentile, P.; Tota, A.; Sorniotti, A.; Gruber, P.; Costamagna, F. Enhancing vehicle cornering limit through sideslip and yaw rate control. Mech. Syst. Signal Proc. 2016, 75, 455–472. [Google Scholar] [CrossRef]

- Sivaramakrishnan, S.; Siramdasu, Y.; Taheri, S. A new design tool for tire braking performance evaluations. J. Dyn. Syst. Meas. Control 2015, 137, 071013. [Google Scholar] [CrossRef]

- Guo, H.; Yin, Z.; Cao, D.; Chen, H.; Lv, C. A review of estimation for vehicle tire-road interactions toward automated driving. IEEE Trans. Syst. Man Cybern. Syst. 2019, 49, 14–30. [Google Scholar] [CrossRef]

- Askari, H.; Hashemi, E.; Khajepour, A.; Khamesee, M.B.; Wang, Z.L. Tire condition monitoring and intelligent tires using nanogenerators based on piezoelectric, electromagnetic, and triboelectric effects. Adv. Mater. Technol. 2019, 4, 1800105. [Google Scholar] [CrossRef] [Green Version]

- Continental. Available online: https://www.continental-tyres.co.uk/car/stories/technology-and-innovation/intelligent-tyres (accessed on 28 April 2022).

- Bianchini, A.; Heitzman, M.; Maghsoodloo, S. Evaluation of Temperature Influence on Friction Measurements. J. Transp. Eng. 2011, 137, 640–647. [Google Scholar] [CrossRef]

- Singh, K.B.; Taheri, S. Estimation of tire–road friction coefficient and its application in chassis control systems. Syst. Sci. Control. Eng. 2015, 3, 39–61. [Google Scholar] [CrossRef] [Green Version]

- Hall, J.W.; Smith, K.L.; Titus-Glover, L.; Wambold, J.C.; Yager, T.J.; Rado, Z. Guide for Pavement Friction; Contractor’s Final Report for NCHRP Project 01-43; Web-Only Document 108; NCHRP, Transportation Research Board: Washington, DC, USA, 2009. [Google Scholar]

- Rana, M.M.; Hossain, K. Impact of autonomous truck implementation: Rutting and highway safety perspectives. Mater. Pavement Des. 2021, 1–22. [Google Scholar] [CrossRef]

- Yu, M.; Wu, G.; Kong, L.; Tang, Y. Tire-Pavement Friction Characteristics with Elastic Properties of Asphalt Pavements. Appl. Sci. 2017, 7, 1123. [Google Scholar] [CrossRef] [Green Version]

- Pranjić, I.; Deluka-Tibljas, A.; Cuculic, M.; Šurdonja, S. Influence of pavement macrotexture on pavement skid resistance. Transp. Res. Procedia 2020, 45, 747–754. [Google Scholar] [CrossRef]

- Kumar, A.; Gupta, A. Review of Factors Controlling Skid Resistance at Tire-Pavement Interface. Adv. Civ. Eng. 2021, 45, 2733054. [Google Scholar] [CrossRef]

- Mataei, B.; Zakeri, H.; Zahedi, M.; Nejad, F.M. Pavement Friction and Skid Resistance Measurement Methods: A Literature Review. Open J. Civ. Eng. 2016, 6, 537–565. [Google Scholar] [CrossRef] [Green Version]

- Azzam, A.; Ali Khasawneh, M.; Al-Omari, A.A.; Masad, E.; Kassem, E. A statistical approach for predicting skid resistance of asphalt pavements. Int. J. Pavement Res. Technol. 2021, 14, 647–654. [Google Scholar] [CrossRef]

- Pomoni, M.; Plati, C.; Kane, M.; Loizos, A. Polishing behaviour of asphalt surface course containing recycled materials. Int. J. Transp. Sci. Technol. 2021; in press. [Google Scholar] [CrossRef]

- Wilson, D.J. An Analysis of the Seasonal and Short-Term Variation of Road Pavement Skid Resistance. Ph.D. Thesis, The University of Auckland, Auckland, New Zealand, 2006. [Google Scholar]

- Li, Q.J.; Zhan, Y.; Yang, G.; Pittenger, D.M.; Wang, K.C.P. 3D Characterization of Aggregates for Pavement Skid Resistance. J. Transp. Eng. Part B Pavements 2019, 145, 04019002. [Google Scholar] [CrossRef]

- White, G.; Ward, C.; Jamieson, S. Field evaluation of a handheld laser meter for pavement surface macrotexture measurement. Int. J. Pavement Eng. 2021, 22, 950–959. [Google Scholar] [CrossRef]

- Kane, M.; Do, M.T.; Cerezo, V.; Rado, Z.; Khelifi, C. Contribution to pavement friction modelling: An introduction of the wetting effect. Int. J. Pavement Eng. 2019, 20, 965–976. [Google Scholar] [CrossRef]

- Acosta, M.; Kanarachos, S.; Blundell, M. Road Friction Virtual Sensing: A Review of Estimation Techniques with Emphasis on Low Excitation Approaches. Appl. Sci. 2017, 7, 1230. [Google Scholar] [CrossRef] [Green Version]

- Moore, D.; Geyer, W. A review of adhesion theories for elastomers. Wear 1972, 22, 113–141. [Google Scholar] [CrossRef]

- Michelin. The Tyre, Grip; Société de Technologie Michelin: Clermont-Ferrand, France, 2001. [Google Scholar]

- Ottawa/Macdonald-Cartier International Airport. Transportation Safety Board of Canada; Runway Overrun (Aviation Investigation Report A10H0004); States Airlines LLC: Ottawa, ON, Canada, 2010. [Google Scholar]

- Villani, M.M.; Artamendi, I.; Kane, M.; Scarpas, A. Contribution of hysteresis component of tire rubber friction on stone surfaces. Transp. Res. Board 2011, 2227, 153–162. [Google Scholar] [CrossRef]

- Yu, M.; You, Z.; Wue, G.; Kong, L.; Liu, C.; Gao, J. Measurement and modeling of skid resistance of asphalt pavement: A review. Constr. Build. Mater. 2020, 260, 119878. [Google Scholar] [CrossRef]

- Xie, X.; Lu, G.; Liu, P.; Zhou, Y.; Wang, D.; Oeser, M. Influence of temperature on polishing behaviour of asphalt road surfaces. Wear 2018, 402–403, 49–56. [Google Scholar] [CrossRef]

- Yan, B.; Mao, H.; Zhong, S.; Zhang, P.; Zhang, X. Experimental Study on Wet Skid Resistance of Asphalt Pavements in Icy Conditions. Materials 2019, 12, 1201. [Google Scholar] [CrossRef] [Green Version]

- Dunford, A.; Roe, P.G. BOS Slag as a Surface Coarse Aggregate; Published Project Report—PPR647; Transport Research Laboratory: Berks, UK, 2010. [Google Scholar]

- Do, M.-T.; Tang, Z.; Kane, M.; de Larrard, F. Pavement polishing—Development of a dedicated laboratory test and its correlation with road results. Wear 2007, 263, 36–42. [Google Scholar] [CrossRef]

- Pomoni, M. Investigation of Asphalt Pavements Surface Friction in the Framework of Sustainable Road Infrastructures. Ph.D. Thesis, National Technical University of Athens, Athens, Greece, 2021. [Google Scholar]

- Anupam, K.; Srirangam, S.K.; Scarpas, A.; Kasbergen, C. Influence of temperature on tire-pavement friction: Analyses. Transp. Res. Board 2013, 2369, 114–124. [Google Scholar] [CrossRef]

- Kouchaki, S.; Roshani, H.; Prozzi, J.A.; Garcia, N.Z.; Hernandez, J.B. Field Investigation of Relationship between Pavement Surface Texture and Friction. Transp. Res. Board 2018, 2672, 395–407. [Google Scholar] [CrossRef]

- ASTM E303-93; Standard Test Method for Measuring Surface Frictional Properties Using the British Pendulum Tester. ASTM International: West Conshohocken, PA, USA, 2018.

- Sanders, P.D.; McRobbie, S.; Gopaldas, J.; Viner, H.E. Development of a Reference Surface for the Assessment of Pavement Skid Resistance Measurement Devices; Published Project Report Ppr771; Transport Research Laboratory: Berks, UK, 2015. [Google Scholar]

- EU Project TYROSAFE. Deliverable D05: Report on Analysis and Findings of Previous Skid Resistance Harmonization Research Projects; FEHRL: Brussels, Belgium, 2009. [Google Scholar]

- Choi, Y. Austroads Technical Report: Review of Skid Resistance and Measurement Methods; Austroads Ltd.: Sydney, Australia, 2011. [Google Scholar]

- Neaylon, K. Austroads Research Report: Guidance for the Development of Policy to Manage Skid Resistance; Austroads Ltd.: Sydney, Australia, 2011. [Google Scholar]

- Choi, Y. Austroads Research Report: Review of Variability in Skid Resistance Measurement and Data Management; Austroads Ltd.: Sydney, Australia, 2013. [Google Scholar]

- Ueckermann, A.; Wang, D.; Oeser, M.; Steinauer, B. Calculation of skid resistance from texture measurements. J. Traffic Transp. Eng. 2015, 2, 3–16. [Google Scholar] [CrossRef] [Green Version]

- Afonso, M.L.; Dinis-Almeida, M.; Sena Fael, C. Characterization of the Skid Resistance and Mean Texture Depth in a Permeable Asphalt Pavement. IOP Conf. Ser. Mater. Sci. Eng. 2019, 471, 022029. [Google Scholar] [CrossRef]

- Hofko, B.; Kugler, H.; Chankov, G.; Spielhofer, R. A laboratory procedure for predicting skid and polishing resistance of road surfaces. Int. J. Pavement Eng. 2019, 20, 439–447. [Google Scholar] [CrossRef] [Green Version]

- Wang, D.; Zhang, Z.; Kollmann, J.; Oeser, M. Development of aggregate micro-texture during polishing and correlation with skid resistance. Int. J. Pavement Eng. 2020, 21, 629–641. [Google Scholar] [CrossRef]

- Jin, X.; Yin, G.; Chen, N. Advanced Estimation Techniques for Vehicle System Dynamic State: A Survey. Sensors 2019, 19, 4289. [Google Scholar] [CrossRef] [Green Version]

- Mazzilli, V.; Ivone, D.; De Pinto, S.; Pascali, L.; Contrino, M.; Tarquinio, G.; Gruber, P.; Sorniotti, A. On the benefit of smart tyre technology on vehicle state estimation. Veh. Syst. Dyn. 2021; in press. [Google Scholar] [CrossRef]

- Bastiaan, J.M. Design of a Smart Tire Sensor System; University of Waterloo: Waterloo, ON, Canada, 2015. [Google Scholar]

- Guo, M.; Zhou, X. Tire-Pavement Contact Stress Characteristics and Critical Slip Ratio at Multiple Working Conditions. Adv. Mater. Sci. Eng. 2019, 2019, 5178516. [Google Scholar] [CrossRef] [Green Version]

- Douglas, R.A.; Woodward, W.D.H.; Woodside, A.R. Road contact stresses and forces under tires with low inflation pressure. Can. J. Civ. Eng. 2000, 27, 1248–1258. [Google Scholar] [CrossRef]

- National Highway Traffic Safety Administration. Mechanics of Pneumatic Tires; United States Department of Transportation: Washington, DC, USA, 1981; Chapter 9.

- Koskinen, S.; Peussa, P. FRICTION Final Report; Technical Report No. FP6-IST-2004-4-027006; Information Society Technologies (IST) Programme, European Union: Tampere, Finland, 2009. [Google Scholar]

- Baffet, G.; Charara, A.; Lechner, D. Estimation of vehicle sideslip, tire force and wheel cornering stiffness. Control. Eng. Pract. 2009, 17, 1255–1264. [Google Scholar] [CrossRef] [Green Version]

- Savaresi, S.M.; Tanelli, M. Active Braking Control Systems Design for Vehicles; Springer: London, UK, 2010. [Google Scholar]

- Matsuzaki, R.; Keating, T.; Todoroki, A.; Hiraoka, N. Rubber-Based Strain Sensor Fabricated Using Photolithography for Intelligent Tires. Sens. Actuators A Phys. 2008, 148, 1–9. [Google Scholar] [CrossRef]

- Miyoshi, A. Method for Estimating Tire Force Acting on Rolling Tire. U.S. Patent US20080245459A1, 9 October 2008. [Google Scholar]

- Mendoza-Petit, M.F.; García-Pozuelo, D.; Díaz, V.; Olatunbosun, O. A Strain-Based Intelligent Tire to Detect Contact Patch Features for Complex Maneuvers. Sensors 2020, 20, 1750. [Google Scholar] [CrossRef] [PubMed]

- Klein, S.D. Friction Estimation and Detection for an Electric Power Steering System. U.S. Patent US9150244B2, 6 October 2015. [Google Scholar]

- Hattori, Y. Method for Detecting Strain State of Tire, Device for Detecting the Strain State, Sensor Unit for the Method and Device, and Tire Provided with the Sensor Unit. U.S. Patent US20050146423A1, 7 July 2005. [Google Scholar]

- Singh, K.B.; Parsons, A.W.; Engel, M.; Suh, P.J.M. Tire Load Estimation System Using Road Profile Adaptive Filtering. U.S. Patent US8844346B1, 30 September 2014. [Google Scholar]

- Balkwill, K.J.; Hopkins, R.F. Surface friction measuring device. U.S. Patent US20070283744A1, 13 December 2007. [Google Scholar]

- Abe, Y.; Sawa, T. Dynamic Friction Coefficient Measuring Apparatus. U.S. Patent US4594878A, 17 June 1986. [Google Scholar]

- Miyoshi, A.; Tsurita, T.; Kunii, M. System and Method for Determining Tire Force. U.S. Patent US7249498B2, 31 July 2007. [Google Scholar]

- Lee, D.; Kim, J.-C.; Kim, M.; Lee, H. Intelligent Tire Sensor-Based Real-Time Road Surface Classification Using an Artificial Neural Network. Sensors 2021, 21, 3233. [Google Scholar] [CrossRef]

- Singh, K.B.; Ali Arat, M.; Taheri, S. An Intelligent Tire Based Tire-Road Friction Estimation Technique and Adaptive Wheel Slip Controller for Antilock Brake System. J. Dyn. Systems. Meas. Control. 2013, 135, 031002. [Google Scholar] [CrossRef]

- Umeno, T.; Ono, E.; Asano, K.; Ito, S.; Tanaka, A.; Yasui, Y.; Sawada, M. Estimation of Tire-Road Friction Using Tire Vibration Model. J. Passeng. Car Mech Syst. J. 2002, 111, 1553–1558. [Google Scholar] [CrossRef]

- Sainath, T.; Kingbury, B.; Saon, G.; Soltau, H.; Mohamed, A.-R.; Dahl, G.; Ramabhadran, B. Deep convolutional neural networks for large-scale speech tasks. Neural Netw. 2015, 64, 39–48. [Google Scholar] [CrossRef]

- Fontaine, M.; Coiret, A.; Cesbron, J.; Baltazart, V.; Bétaille, D. In-Tire Distributed Optical Fiber (DOF) Sensor for the Load Assessment of Light Vehicles in Static Conditions. Sensors 2021, 21, 6874. [Google Scholar] [CrossRef]

- Pais, J.C.; Amorim, S.I.R.; Minhoto, M.J.C. Impact of Traffic Overload on Road Pavement Performance. J. Transp. Eng. 2013, 139, 873–879. [Google Scholar] [CrossRef]

- Lee, H.; Taheri, S. Intelligent Tires—A Review of Tire Characterization Literature. IEEE Intell. Transp. Syst. Mag. 2017, 9, 114–135. [Google Scholar] [CrossRef]

- Matsuzaki, R.; Todoroki, A. Wireless Monitoring of Automobile Tires for Intelligent Tires. Sensors 2008, 8, 8123–8138. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nokian. Available online: https://www.nokiantyres.com/company/news-article/smart-tires-are-coming-how-consumers-will-benefit-from-sensor-technology/ (accessed on 28 April 2022).

- Pirelli. Available online: https://www.pirelli.com/global/en-ww/road/from-the-tarmac-to-5g-pirelli-s-smart-tyres-describe-the-road-surface (accessed on 28 April 2022).

- Goodyear. Available online: https://www.washingtonpost.com/technology/2021/06/16/goodyear-smart-car-tires/ (accessed on 28 April 2022).

- Lee, D.-H.; Yoon, D.-S.; Kim, G.-W. New Indirect Tire Pressure Monitoring System Enabled by Adaptive Extended Kalman Filtering of Vehicle Suspension Systems. Electronics 2021, 10, 1359. [Google Scholar] [CrossRef]

- Goodyear. Available online: https://supplychainbeyond.com/future-of-transportation-smart-tire/ (accessed on 28 April 2022).

- Szczucka-Lasota, B.; Węgrzyn, T.; Łazarz, B.; Kaminska, J.A. Tire pressure remote monitoring system reducing the rubber waste. Transp. Res. Part D 2021, 98, 102987. [Google Scholar] [CrossRef]

- Continental. Available online: https://www.tiretechnologyinternational.com/news/research-development/continental-reveals-tire-braking-test-vehicle.html (accessed on 12 July 2022).

- Andersson, P.; Ivehammar, P. Benefits and costs of autonomous trucks and cars. J. Transp. Technol. 2019, 9, 121–145. [Google Scholar] [CrossRef] [Green Version]

- Machiani, S.G.; Ahmadi, A.; Musial, W.; Katthe, A.; Melendez, B.; Jahangiri, A. Implications of a Narrow Automated Vehicle-Exclusive Lane on Interstate 15 Express Lanes. J. Adv. Transp. 2021, 6617205. [Google Scholar]

- Litman, T. Autonomous Vehicle Implementation Predictions: Implications for Transport Planning; Victoria Transport Policy Institute: Victoria, BC, Canada, 2020. [Google Scholar]

- Okte, E.; Al-Qadi, I.L. Impact of Autonomous and Human-Driven Trucks on Flexible Pavement Design. Transp. Res. Record, 2022; in press. [Google Scholar] [CrossRef]

- Zhou, F.; Hu, S.; Chrysler, S.T.; Kim, Y.; Damnjanovic, I.; Talebpour, A.; Espejo, A. Optimization of lateral wandering of automated vehicles to reduce hydroplaning potential and to improve pavement life. Transp. Res. Rec. 2019, 2673, 81–89. [Google Scholar] [CrossRef]

| Study | Estimated Parameters | Summary of Invention |

|---|---|---|

| Klein [80] | Friction coefficient | Use of a steering system controlled by a control module to estimate steering gain and steering load hysteresis. |

| Miyazaki [22] | Tire forces, friction coefficient | Several strain sensors attached to the vicinity of the wheel on the axle generate strain signals that are used to estimate the tire forces and tire–road friction coefficient. |

| Hattori [81] | Tire strain state | A series of conductors composed of many conductor pieces (embedded in lines at specific intervals in the circumferential direction of the tire) is used to provide the strain states of the tire and a monitoring device releases strain signals and also receives the reflected one to assess the stress–strain state of the tire. |

| Singh et al. [82] | Tire sidewall force | A piezo sensor is used to generate a signal within the contact patch area indicating the sidewall deformation. The power-to-load map for different tire pressure is used to estimate the force. |

| Balkwill and Hopkins [83] | Surface friction | A method of measuring surface friction in which drag due to contaminant lying on a said surface is isolated, and a continuous friction measuring device for effecting the measurement. |

| Abe and Sawa [84] | Dynamic friction coefficient | A new device was developed, including a disk with a measuring rubber member, a driving disk adapted to rotate co-axially with the disk and a dynamometer that interconnects the disk and the driving disk. Using the output signal records from friction measurements leads to the estimation of the dynamic friction coefficient. |

| Miyoshi et al. [85] | Tire longitudinal force | Two magnetic sensors were used to measure the rotation angle of the wheel and wheel axle. A computing device was used to calculate the tire warp angle, which is derived from the difference between tire rotational angle during load and no-load conditions. Tire longitudinal force is estimated as a function of tire warp angle. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pomoni, M. Exploring Smart Tires as a Tool to Assist Safe Driving and Monitor Tire–Road Friction. Vehicles 2022, 4, 744-765. https://doi.org/10.3390/vehicles4030042

Pomoni M. Exploring Smart Tires as a Tool to Assist Safe Driving and Monitor Tire–Road Friction. Vehicles. 2022; 4(3):744-765. https://doi.org/10.3390/vehicles4030042

Chicago/Turabian StylePomoni, Maria. 2022. "Exploring Smart Tires as a Tool to Assist Safe Driving and Monitor Tire–Road Friction" Vehicles 4, no. 3: 744-765. https://doi.org/10.3390/vehicles4030042

APA StylePomoni, M. (2022). Exploring Smart Tires as a Tool to Assist Safe Driving and Monitor Tire–Road Friction. Vehicles, 4(3), 744-765. https://doi.org/10.3390/vehicles4030042