1. Introduction

The automotive manufacturing sector is one of the most demanding sectors from a raw materials point of view, requiring high amounts of plastics and metals such as copper and nickel [

1,

2]. Millions of cars are sold yearly, and a growing trend is expected to reach a global fleet of almost 1.5 billion cars by 2050 [

3]. Considering not only the expected evolution of sales, but also the changes in the composition of vehicles, it can be stated that many more raw materials will be needed in the coming decades, most of them being in very short supply [

4,

5,

6].

Changes in the composition of vehicles are occurring due to the sector’s evolution towards safer and less polluting vehicles [

7,

8]. Moreover, this evolution presents no alternative since, by 2035, all vehicles sold in Europe will have to be zero-emission [

9].

The major changes in the automotive industry will also mean that a large number of vehicles will reach the end of their life proximately and should be managed and recycled. To gain an idea about the quantity of vehicles that will be managed, it is enough to bear in mind that, in a conventional year, approximately 10 million vehicles are scrapped in Europe [

10].

The arrival of this number of vehicles at the end of their life implies their management by authorized treatment centres and recycling plants to meet the recycling targets defined by the European Directive on end-of-life vehicle recycling [

11]. However, despite compliance with such legislation, between 7 and 9 million tons of waste ends in landfills annually in the treatment of end-of-life vehicles [

12].

From the point of view of the plastics situation, the European automotive sector demands 5.1 Mt per year, which accounts for 10% of the total plastic demand [

13]. From the perspective of one vehicle, plastics account for approximately 15% of the mass, but 50% of the total vehicle volume [

14,

15]. That percentage varies from 190 to 360 kg [

16,

17], encompassing the distribution of up to 40 (or more) different types of plastics and polymers [

18]. Among them, the most relevant are PP (37%), PUR (15%), polyamide—PA (12%), polyethylene—PE (8%), polyvinylchloride—PVC (7%), acrylonitrile butadiene styrene—ABS (7%), and terephthalate of polyethylene terephthalate—PET (5%) [

14].

Referring back to the end of the vehicle’s life, plastic recycling is notably less efficient compared to metals, with just 19% of a vehicle’s plastic content being recycled [

15,

19]. Moreover, plastics are one of the primary sources of pollution [

20].

While there are technologies available for treating automotive shredding residue (ASR) generated during vehicle recycling, their adoption is not widespread in Europe, and there remains substantial room for improvement in this regard. One of the main problems in recovering plastics from ASR is its heterogeneity. The concentration of plastics in ASR can vary from 14% to 43% [

21], and this fraction comprises a wide variety of polymers that are incompatible from a recycling perspective. As mentioned above, an average vehicle has approximately 40 different types of plastics and polymers, and to be reused in specific applications they must be effectively separated [

14]. Nevertheless, this separation is not easy because many car parts have surface coatings that limit the separation before shredding [

15,

22].

Another option to improve the plastic situation from a resource efficiency point of view beyond applying technologies for ASR treatment is to reduce the ASR fraction itself. However, this requires the application of disassemblability operations that separate the biggest or the most relevant plastic car parts from the rest before shredding.

The application of pretreatment operations on the most critical automotive components to improve their recyclability has been previously proposed by Ortego et al. [

5,

23]. In this sense, the disassemblability process takes center stage, although the difficulty of the process, depending on the car part, conditions its viability [

24]. In any case, Santini et al. quantified that measures such as the disassembly of bumpers, fuel tanks, and seats before shredding can reduce the mass of ASR deposited in landfills by 42% [

25]. Nevertheless, to apply these pretreatment operations, a preliminary characterization of all plastic components must be carried out to work on the most relevant ones.

This identification needs an understanding of the impact of using different types of plastics, which is a key topic due to their fossil-fuel dependency. In this sense, it is noteworthy that the main feedstock used for polymer production comes from the by-products of oil and gas refineries. Some of these by-products can be heavy hydrocarbons such as paraffin and naphtha or saturated hydrocarbons such as ethane and propane [

26].

From an energy point of view, plastics have on average 45 MJ/kg considering their lower calorific value. If the additional energy required to process and manufacture the polymers (between 36 and 54 MJ/kg) are also considered, the production of 1 kg of plastic is associated with an energy input of between 81 and 99 MJ/kg. Using European plastics production as a reference, they invest between 0.53 and 0.79 Gtoe of primary energy to manufacture polymers [

27,

28,

29,

30,

31].

Quantifying the impact derived from using polymers is not an easy task; in this sense, exergy analysis is a helpful tool for its calculation [

32,

33,

34]. Exergy analysis has previously been applied as a valuable tool when the systems have material and non-material flows of different natures [

35,

36]. The use of exergy-based indicators applied to the field of circular economy has been carried out by Stanek [

37], who applied thermo-economics to the analysis of different energy systems (for example, hard coal production).

However, exergy analysis not only serves to study energy systems, but can also assess the criticality of using non-renewable mineral resources. In this context, the application of the physical quantity Thermodynamic Rarity [

4,

38,

39] can be used to classify the criticality of components and products according to the materials used. Furthermore, it has been previously applied to assess the criticality of different types of vehicles and their components [

5,

7,

23,

40,

41].

In the case of polymers, exergy has also proved helpful in assessing their impact, considering their different production routes. In this regard, Russo et al. [

42] analyzed the production routes of the following 10 polymers used in vehicle manufacturing: PE, PP, PVC, ABS, PU, PA, PET, butadiene-styrene rubber—SBR and ethylene propylene diene monomer—EPDM.

From the state-of-the-art, the following authors have previously researched the plastic situation in vehicles. Cardamone et al. analyzed novel treatments of plastics from end of life vehicle—ELV to improve their recyclability [

43]. Miller et al. investigated the main challenges and barriers of ELV plastic recycling [

16]. Baldasarre et al. presented a material flow analysis of plastics in Europe, and from it both drivers and barriers towards a circular economy are presented [

15]. Hallack et al. proposed a method to improve the design for the recycling of exterior car parts made of plastics [

44]. In the field of composite materials, innovative manufacturing techniques such as additive manufacturing and their influence on recycling highlight the works presented by Farina et al. [

45,

46].

This literature review concludes that plastic recyclability’s improvement potential is still high. Some studies have quantified that by using available recycling technologies up to 50% of the mass of plastics in a vehicle could be recycled [

43]. Nevertheless, this improvement is not lacking in challenges to be overcome. The type of polymer influences automotive plastic recyclability, as sometimes the material cannot be recycled, or recycling causes deterioration of its properties. These technological barriers must be overcome through eco-design, adopting disassembled processes before shredding, and reverse logistics operations. By way of summary, the main technical problems of plastic recycling in cars are listed below:

Polymer compatibility: As mentioned previously, a vehicle contains almost 40 types of polymers, some incompatible from a recycling point of view. Mixing incompatible plastics results in recycled material with degraded properties, which cannot be reused for the same original application. Furthermore, this incompatibility is very sensitive, so incompatible materials have less than 2% mixing tolerances.

Use of additives and fillers: Polymers often incorporate additives and fillers to improve mechanical characteristics, fire resistance, and aesthetic properties. The use of these additives makes recycling difficult for several reasons: (1) because of the health hazard of heavy metals and halogens such as bromine, chlorine, or fluorine; (2) the incompatibility of different flame retardants added; (3) the impossibility of separating the reinforcing fibers (glass or natural) from the polymer; (4) the lack of information on the composition of the additives, which makes it impossible to classify the plastic. Generally, it can be stated that to have an output material with a loss of mechanical properties of less than 5%, the rate of impurities present in the recycling process must be less than 3%.

To overcome these barriers, it is necessary to respond to the following questions: How much and what type of plastics are used in a vehicle? What are the car parts with the highest demand for plastics? Which car parts are most sensitive to the choice of plastic in terms of impact? How is the demand for plastics in vehicles evolving?

To address these questions, this paper introduces its own methodology, which is applied to six different car models manufactured by SEAT, a part of the Volkswagen (VW) Group. Through this analysis, the paper identifies the car parts most sensitive to the choice of plastic.

It is important to note that the environmental impacts of plastics go beyond the depletion of fossil fuels. The emissions generated by their production, and the effect on health or wildlife, are areas of great importance to assess their impacts. Thus, it must be noted that the scope of this paper is to analyze the different plastics used in the manufacturing of vehicles from the perspective of fossil resources and their production processes, using thermodynamics and the concept of exergy.

2. Materials and Methods

2.1. Selection of Representative Cars

Six different car models were analyzed, selected based on the following criteria: (1) representativeness of the models concerning the total sales of the brand; (2) different equipment levels; (3) different model generations considering their age.

According to the criteria, the chosen models were SEAT Leon generations II–III and SEAT Ibiza generation IV. From a representativeness point of view, both models accounted for 48%, 51%, and 39% of the total brand sales in 2019, 2020, and 2021.

In terms of equipment levels, the Reference (REF) and Formula Racing (FR) configurations have been chosen as they are the least and most equipped variants of each SEAT model.

In terms of age, the analyzed car generations cover a production period of 15 years (from 2005 to 2012 for SEAT Leon II, from 2012 to 2020 for SEAT Leon III, and from 2008 to 2017 for SEAT Ibiza IV).

2.2. Exergy Assessment

Due to the relevance of the exergy analysis in the present study, the following section provides an in-depth explanation of the process. The method is built from the previous study published by Russo et al. [

44]. In this study, the exergy of the polymers is computed as the cumulative exergy of all the stages required for their production (see

Figure 1).

The first factor, the exergy replacement cost (1), gives an insight into the value of the resource by offering a perspective on the cost of utilizing that resource in relation to its value in nature. It quantifies the cost of the formation of deposits from which oil is extracted over millions of years, originating from biomass and solar energy. Therefore, in this analysis, for the characterization of plastics used by vehicles, only the so-called embodied exergy (EE) of plastics, which encompass terms (3) and (4), is considered. The exergy of naphtha production from fossil fuels (2) and the exergy replacement cost (4) will be omitted.

There are two main reasons to make this hypothesis. Firstly, if the different production steps of a polymer are analyzed, the exergy replacement cost accounts for 94% of the total [

42]. This fact, however, diminishes the significance of the subsequent stages, yet it is these subsequent steps that can be influenced by industrial activities and technological advancements. Secondly, since all polymers originate from the same primary source (fossil fuels and then naphtha), it is not logical to utilize the exergy replacement cost of the primary source and the naphtha production process to gauge the criticality of using certain plastics in comparison to others, as this aspect of the impact remains consistent across all of them.

Therefore, and given that it is not possible to act on the ERC value of the polymers, the embodied exergy in the remaining phases (3) + (4) is used as an indicator of their criticality.

Table 1 shows the exergies incorporated by the different polymers analyzed:

As mentioned above, calculating the embodied exergy requires an in-depth analysis of the production routes of the different polymers. Given the complexity of this work and the lack of bibliographic information in some cases, in the present study the embodied exergies of those polymers whose contribution to the total plastic mass was at least higher than 1% have been used.

2.3. Methodology

Once the exergy approach has been explained, this section presents the process of identifying the most critical car parts. The methodology developed takes the material composition of the vehicles as a starting point. This information comes from an internal IT system called the Material Information System (MISS) used by SEAT. Detailed information about this system cannot be presented for confidentiality issues.

Figure 2 represents the steps developed. Based on this information, a spreadsheet was set up in which all the components of a vehicle and the material composition of each of them are available.

Once this list was compiled, the car parts were characterized based on the types of plastics they employed. Due to the diverse range of plastic types found in a vehicle, these plastics were categorized into various families, depending on whether they were thermoplastics, thermosets, elastomers, or other categories.

The harmonization process resulted in 23 different polymers, with an additional category labeled as “others”. The category “others” includes polymers with very low weight percentages, such as polymer-based resins and plastics with unidentified codes. Regarding PA (Polyamide), various types have been grouped into a general category (i.e., PA6 and PA46 are grouped into the PA category).

It must be noted that this harmonization process goes beyond the state-of-the-art applied in the automobile sector at the vehicle’s end-of-life. The most complete information about plastic characterization directed to dismantlers and recyclers comes from the International Dismantling Information System (IDIS) [

54]. The IDIS is the central repository of manufacturer-compiled treatment information about end-of-life vehicles. This system offers information to improve the safety and recyclability in end-of-life processes. However, it only considers ABS, PA, PE, PMMA, PP, PVC, PUR, and “others” from plastic characterization.

Table 2,

Table 3 and

Table 4 show the results of the harmonization process developed in this work, which goes beyond the IDIS one.

Due to the extensive number of car parts containing plastic materials, a decision was made to focus on the most significant ones. To achieve this, the selection process involved identifying car parts with a plastic mass exceeding 1 kg and where at least 80% of the car part’s mass consisted of plastics. Once the list of the most relevant parts, in terms of their contribution to plastics, was established, exergy characterization was performed. It is important to note that exergy calculations were carried out for those polymers whose contribution to the total plastic mass exceeded 1%.

Understanding this, the embodied exergy of each part is calculated using the following equation:

where m

pol_i is the mass of each polymer in a car part and EE

pol_i is the embodied exergy for each polymer.

Finally, after performing the exergy characterization, the most critical car parts are selected, specifically, the top ten parts with the highest embodied exergy for each vehicle.

3. Results

3.1. Plastic Characterization

Table 5 illustrates the plastic content of each studied vehicle. It is evident that the REF and FR versions of the Leon Gen II model have the highest total weight, although the contribution of plastics in both cases is quite similar to the Gen III versions. Notably, in the SEAT Leon Gen II and Gen III models, the FR versions require more plastic than the REF (11.1 kg and 7.8 kg, respectively). On average, the FR version requires 9.5 kg more plastic than the REF version.

It is also noteworthy that there are no significant differences in the plastic proportion between the Leon II and Leon III models, with their values ranging between 18.2% and 18.4%. In the Ibiza Gen IV model, the contribution of plastic to the total weight is relatively lower than in the previous cases, standing at 16.4% and 16.7% for the REF and FR trims, respectively.

In conclusion, considering the six studied vehicles, the average model contains 222 kg of plastics, accounting for 17.7% of its total weight.

Table 6 displays the filtered car parts primarily manufactured from plastic and of substantial size (with a weight exceeding 1 kg and comprising at least 80% of plastic material). These car parts contribute to the total plastic mass in the range of 44.7% (Leon Gen III FR) to 50.8% (Leon Gen II FR). These findings indicate that 47.5% of the plastic mass is concentrated in parts weighing more than 1 kg and primarily composed of plastics (comprising over 80% of their composition).

Figure 3 illustrates the contribution of harmonized categories of plastics based on car parts weighing more than 1 kg and having a plastic composition exceeding 80% of their weight.

PP is the polymer with the highest contribution, accounting for 24.31% of the total, followed by E/P, which contributes 22.42%. The contribution of PU is also noteworthy, accounting for 14.23%. On the other hand, a large atomization of plastics contributes less than 1% of the mass, including POM, SBR, PMMA, FKM, EVOH, PS, PPS, PES, total PVC, and PES.

3.2. Exergy Assessment—10 Most Critical Car Parts

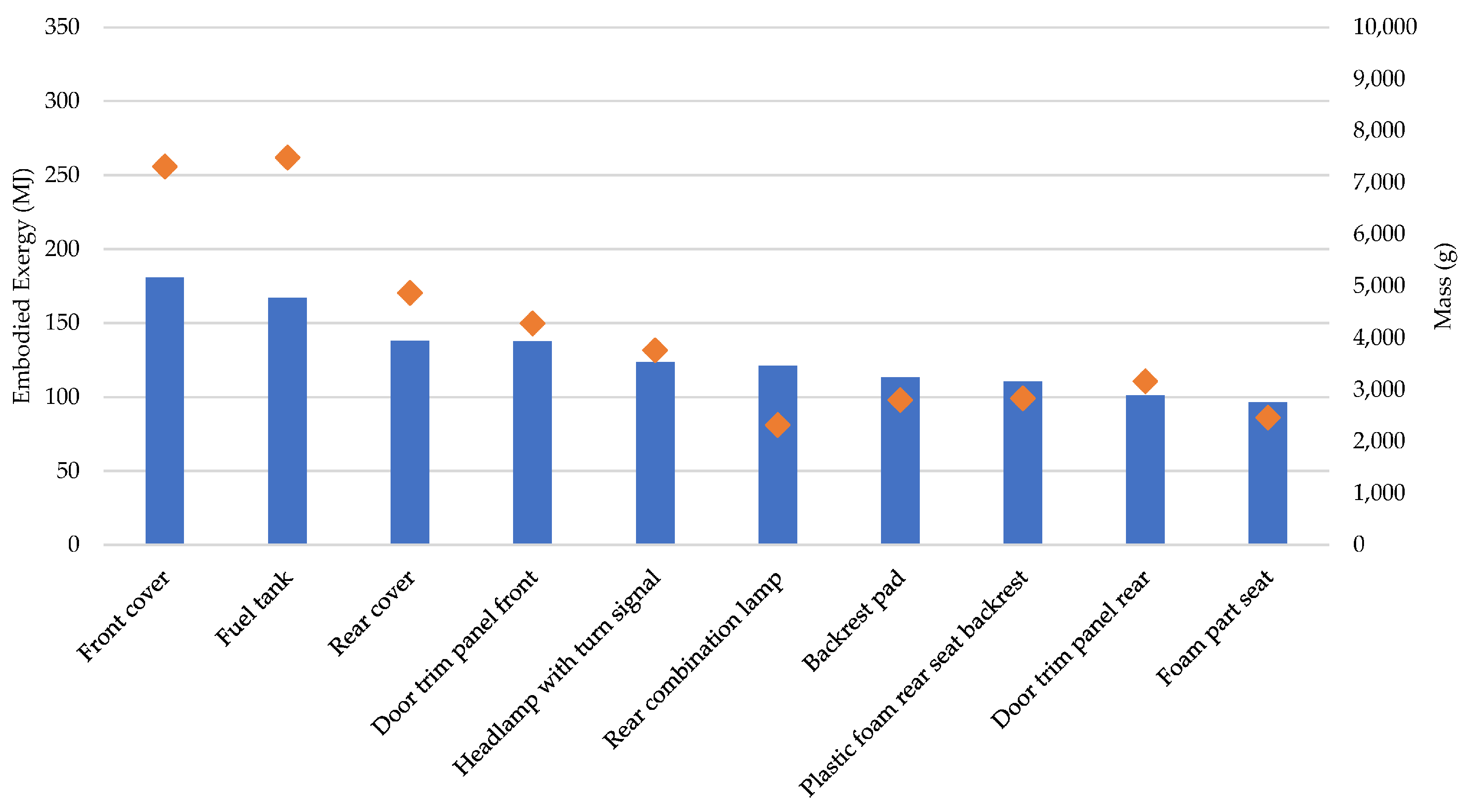

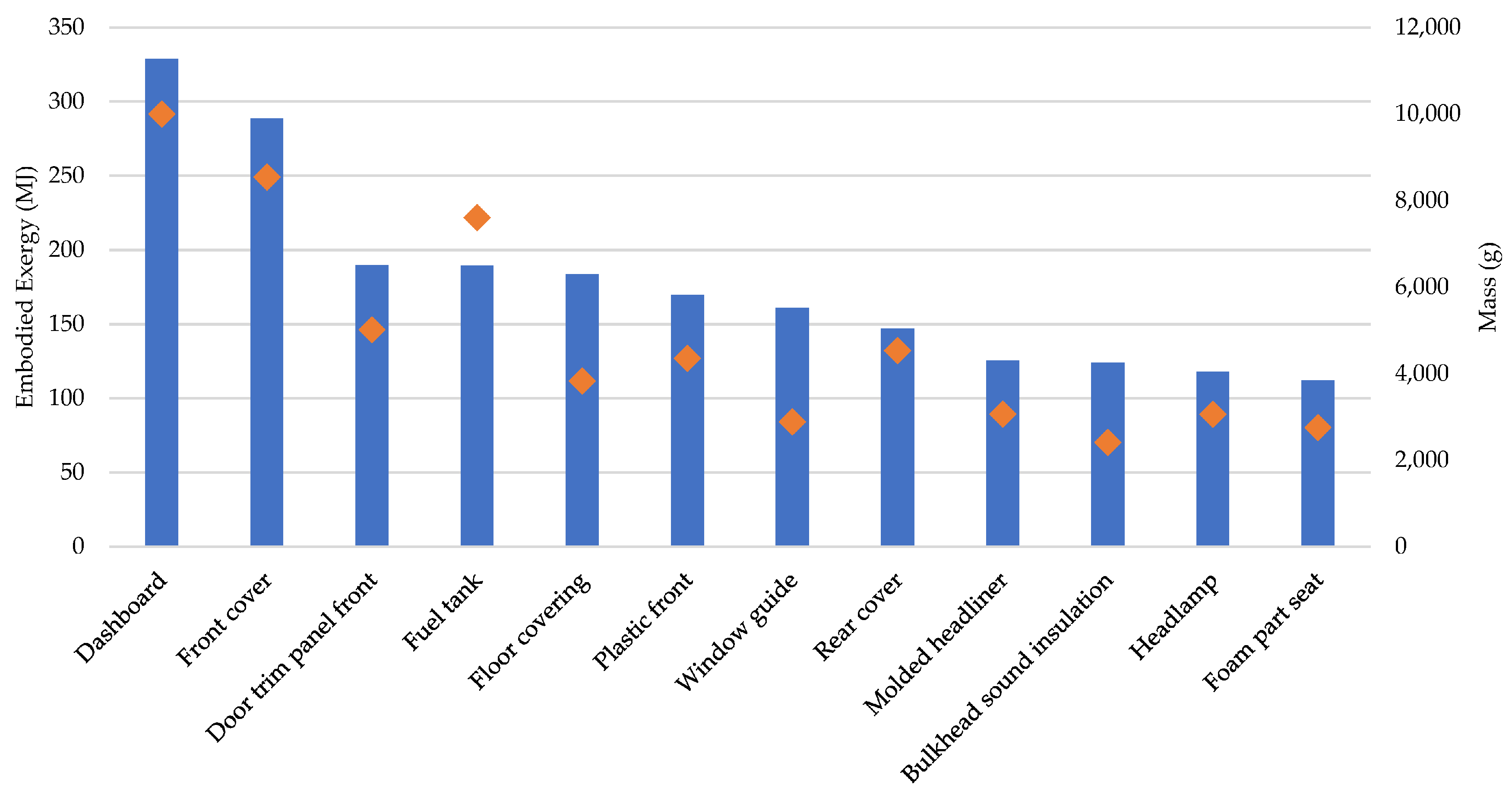

The 10 most critical parts for each model are presented below (ordered from highest to lowest embodied exergy in each case) from

Figure 4,

Figure 5,

Figure 6,

Figure 7,

Figure 8 and

Figure 9. Moreover, the mass for each car part is also represented—orange marker—to compare the ranking between exergy and mass in each case. As

supplementary material, plastic composition and embodied exergy of all critical car parts are included in

Tables S1–S6.

In the case of the SEAT Ibiza IV (

Figure 4 and

Figure 5), it is worth noting that the front cover is the most critical car part in both cases. However, due to the higher specification of the FR version, the embodied exergy for the FR is 345 MJ, while for the REF, it is 187 MJ. A similar situation occurs with the rear bumpers. Regarding the fuel tank, despite its substantial weight, it is not as significant in terms of embodied exergy. This is due to its composition, primarily made of PE, which has the lowest exergy among the analyzed polymers.

In the case of the SEAT Leon II (

Figure 6 and

Figure 7), the most critical car part is the dashboard, with an embodied exergy of 365 MJ for the FR version and 329 MJ for the REF version. It is also noteworthy that, in this model, one of the most critical car parts is the front section. Typically, this car part is made of steel, but for the purpose of reducing weight, this model is manufactured using PP.

In the case of the SEAT Leon III (as shown in

Figure 8 and

Figure 9), the most critical car part remains the dashboard, which aligns with the findings from previous cases. Similarly, the covers and fuel tank are also identified as critical car parts. These critical car parts are shared among the models, with the exception of the wheel trim, which is not considered critical in the FR version due to the presence of aluminum wheels. Instead, the plastic front takes its place in the ranking of critical car parts for the FR version.

Table 7 provides a summary of critical car parts, including their mass and embodied exergy. Among all the studied vehicles, a total of 18 different car parts have been identified as critical.

Table 8 presents the 18 critical car parts grouped by the number of matches among the studied models. Additionally, it provides information on the three most important polymers in terms of embodied exergy and their contribution to the total. These polymers and their respective shares are calculated as the average across the car parts identified as critical in the models.

The following car parts can be considered critical in all models: front door trim panels, front and rear covers, and fuel tanks. Floor coverings are critical in all models except the Ibiza IV REF. Front lightings, dashboards, and rear door trim panels are critical in four models. The following parts are critical in two models: plastic front ends, backrest pads, door trim panel pockets, plastic foam rear seats, rear lightings, window guides, molded headliners, and bulkhead sound insulation. Lastly, foam seat parts and wheel trims are critical in only one model.

From a compositional standpoint, it is noteworthy that, in all cases, the two main polymers account for more than 80% of the embodied exergy (EE) of the entire car part. Backrest pads, seats, and molded headliners primarily use PU as the most relevant polymer, accounting for 80%, 94%, and 100% of the EE, respectively. In the case of lightings, PC is also significant, comprising 64% and 96% of the EE in the front and rear lightings, respectively. EPDM is crucial for insulations and window guides, contributing 76% and 99% of the EE, respectively. PE is the most important polymer for the fuel tank, representing 95% of the EE. E/P and PP are extensively used in various critical car parts, with different proportions. While E/P is prominent in door trims, rear covers, and dashboards, PP is utilized in rear covers and plastic fronts.

4. Discussion

When examining the results, it becomes apparent that a classification based on exergy yields a different ranking compared to a classification based on mass. A noteworthy example is the fuel tank, which is highly representative. Despite being the heaviest part in most models, it is primarily composed of PE, which has the lowest exergy among the analyzed polymers and, therefore, it is not the most critical part in any model.

Based on the analysis, the following parts have been identified as critical: backrest pad, floor covering, fuel tank, front cover, rear cover, door panels (front and rear), plastic front-end carrier, dashboard, glove compartment, plastic foam rear, bulkhead sound insulation, and front window guides.

These parts can be grouped into two main categories. On one hand, there are foams and fillers primarily made of PU or EPDM. On the other hand, there are housings and structural elements made primarily of PP, E/P, and PA. These parts not only have different compositions but also vary in terms of accessibility. For instance, bumpers and door panels are easily removable, while upholstery and insulation require more effort.

It is important to note that, in addition to the aforementioned critical parts, the following components should also be considered due to their ease of accessibility: engine cover (made of PA), wheel housing liner, air filter box, windshield washer reservoir, and trunk lid (mainly made of PP).

Considering the aforementioned differences in critical parts (foams and fillers versus casings and structural elements), it is also important to evaluate other parameters that influence the circular economy, such as recyclability. Due to the wide variety of plastics used in cars, recycling them poses a significant challenge. It is not surprising that the amount of plastic recycled at the end of a vehicle’s life is still very small, indicating that the automotive sector is far from achieving a closed polymer cycle. Currently, the primary approach to increasing circularity in cars is by incorporating recycled materials from other sectors to manufacture new components.

It should be noted that this work was carried out on a selection of vehicles that covers an important part of SEAT production. SEAT belongs to the VW group and shares a large number of components and platforms with other brands of the group, such as VW, Audi, and Skoda, so its results could also be extrapolated to similar models of these brands. However, to establish further conclusions it would be necessary to extend the study to more brands, sizes, or types, such as SUVs or electrics.

5. Conclusions

After conducting the exergy analysis on the six models studied, it can be concluded that utilizing the embodied exergy of plastics is a valuable tool for identifying the most critical plastic components in cars.

From the circular economy point of view, the concentration of a significant amount of plastics in a few car parts is advantageous when disassembling these parts before the fragmentation and dispersion processes. It should be noted that the identified critical car parts in the studied vehicles accounted for only 18% on average. Considering these parts and the studied vehicle, they represent 61% of the embodied exergy in car parts weighing over 1 kg and where the plastic content is at least 80% of the weight.

Reducing the number of different polymers would facilitate higher recycling rates as there would be fewer compatibility issues during the recovery processes. Similar to metallurgical challenges, certain plastic mixtures create low-quality plastics, limiting their market acceptance for the same or other applications. Ideally, the trend should move towards a mono-polymer vehicle, focusing on those with well-established recycling chains and processes. Based on the results, the main candidate for plastic parts would be polypropylene (PP). PP offers excellent versatility for various shapes and applications, good resistance to environmental stress cracking, a low coefficient of linear thermal expansion, and a very low specific weight (0.095 g/cm2) compared to other plastics. PP is currently used for manufacturing bumpers, chemical tanks, cable insulation, carpet fibers, dashboards, and door trim.

For future works, the differences in the accessibility and disassemblability of the critical car parts identified must be researched. Efforts aimed at improving their disassemblability at the end of their useful life will also prevent these plastics from being fragmented and ending up in landfills.