Prediction of Residual Wear Resources of Composite Brake Pads of a Modernized Brake System of Freight Wagons

Abstract

:1. Introduction

- To carry out an inspection of composite brake pads of freight wagons with the modernized BBS in operational conditions;

- To develop a regression model for prediction of the residual lifetime of composite brake pads with the modernized BBS;

- To verify the statistical hypotheses regarding the nature of the distribution of random wear values of composite brake pads and their relationship regarding the data belonging to one general whole.

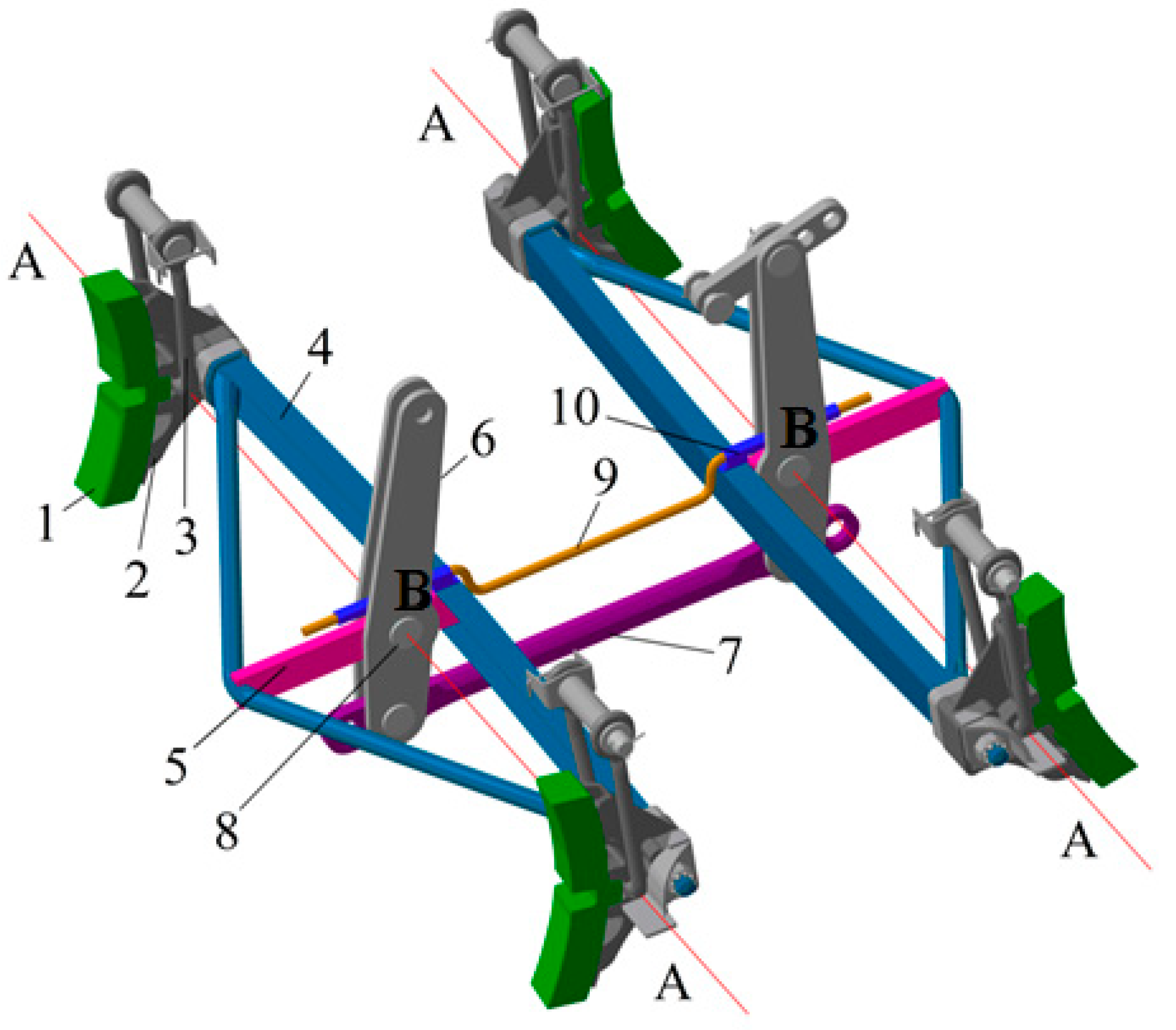

2. Research Materials and Methods

3. The Research Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kardas-Cinal, E. Statistical analysis of dynamical quantities related to running safety and ride comfort of a railway vehicle. Sci. J. Silesian Univ. Technol. Ser. Transp. 2020, 106, 63–72. [Google Scholar] [CrossRef]

- Gerlici, J.; Lovska, A.; Vatulia, G.; Pavliuchenkov, M.; Kravchenko, O.; Solcansky, S. Situational adaptation of the open wagon body to container transportation. Appl. Sci. 2023, 13, 8605. [Google Scholar] [CrossRef]

- Fischer, S.; Szürke, S.K. Detection process of energy loss in electric railway vehicles. Facta Univ. Ser. Mech. Eng. 2023, 21, 81–99. [Google Scholar] [CrossRef]

- Kazemian, M.; Rad, M.M.; Shadfar, M.; Doost, A.M.; Raisi, E.H.; Fischer, S. Optimum train weighing in motion using inertial sensors. Acta Polytech. Hung. 2024, 21, 221–240. Available online: https://acta.uni-obuda.hu/Kazemian_MovahediRad_Shadfar_Doost_HadizadehRaisi_Fischer_141.pdf (accessed on 10 July 2024). [CrossRef]

- Panchenko, S.; Gerlici, J.; Vatulia, G.; Lovska, A.; Rybin, A.; Kravchenko, O. Strength assessment of an improved design of a tank container under operating conditions. Commun. Sci. Lett. Univ. Zilina 2023, 25, B.186–B.193. [Google Scholar] [CrossRef]

- Koch, S.; Köppen, E.; Gräbner, N.; von Wagner, U. On the influence of multiple equilibrium positions on brake noise. Facta Univ. Ser. Mech. Eng. 2021, 19, 613–632. [Google Scholar] [CrossRef]

- Panchenko, S.; Gerlici, J.; Vatulia, G.; Lovska, A.; Ravlyuk, V.; Harusinec, J. Studying the load of composite brake pads under high-temperature impact from the rolling surface of wheels. EUREKA Phys. Eng. 2023, 155–167. [Google Scholar] [CrossRef]

- Leitner, B. Autoregressive models in modelling and simulation of transport means working conditions. In Proceedings of the 14th International Conference Transport Means, Kaunas, Lithuania, 20–22 October 2010; pp. 21–24. [Google Scholar]

- Sventekova, E.; Leitner, B.; Dvorak, Z. Transport critical infrastructure in Slovak republic. In Proceedings of the 8th International Multi-Conference on Complexity, Informatics and Cybernetics, IMCIC 2017, Orlando, FL, USA, 21–24 March 2017; pp. 212–215. [Google Scholar]

- Adeli, H.; Mirabadi, A.; Yousefi, S.; Fazel, S. Novel Approach for Reducing Train Wheel and Brake Shoe Wear Using Speed Profile Optimization. Transp. Res. Rec. 2024, 2678, 241–250. [Google Scholar] [CrossRef]

- Casagrande, R.B.; De Souza, A.R.A.; Finimundi, A.V.; Pereira, C.H.S.; Masotti, D.; Rombaldi, R.J.; Gotardo, T. Development of Brake Shoe with Carbon Footprint Reduction; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2024. [Google Scholar] [CrossRef]

- Wang, B.; Wu, Q.; Luo, S.; Spiryagin, M.; Ma, W.; Ding, H.; Yang, Z. Wheel tread temperature assessment and its impact on rolling contact fatigue under long-term braking conditions. Tribol. Int. 2024, 200, 110162. [Google Scholar] [CrossRef]

- Vakulenko, I.; Plitchenko, S.; Bolotova, D.; Asgarov, K. Influence hot plastic deformation on the structure and properties of carbon steel of the railway wheel. Sci. J. Silesian Univ. Technol. Ser. Transp. 2023, 121, 257–266. [Google Scholar] [CrossRef]

- Kou, L.; Sysyn, M.; Liu, J. Influence of crossing wear on rolling contact fatigue damage of frog rail. Facta Univ. Ser. Mech. Eng. 2024, 22, 25–44. [Google Scholar] [CrossRef]

- Szalai, S.; Herold, B.; Kurhan, D.; Németh, A.; Sysyn, M.; Fischer, S. Optimization of 3D printed rapid prototype deep drawing tools for automotive and railway sheet material testing. Infrastructure 2023, 8, 43. [Google Scholar] [CrossRef]

- Ambikaprasad, O.C.; Abhijeet, A.R. Failure Analysis of Brake Shoe in Indian Railway Wagon. IPASJ Int. J. Mech. Eng. 2015, 3, 37–41. Available online: https://www.scribd.com/document/294429738/Failure-Analysis-of-Brake-Shoe-in-Indian-Railway-Wagon (accessed on 5 June 2024).

- Ravlyuk, V.G. Investigation of features of dual wear of pads in brake system of freight cars. Sci. Transp. Prog. 2019, 80, 111–126. (In Ukrainian) [Google Scholar] [CrossRef]

- Koropets, P.A.; Chernikov, V.D.; Kostiukevych, A.I. On uneven wear of moving friction pairs. Visn. Volodymyr Dahl East Ukr. Natl. Univ. 2010, 147, 41–45. (In Ukrainian) [Google Scholar]

- Koptovec, A.N. Identification of mine locomotive brake state in terms of structural uncertainty. Geo-Tech. Mech. 2014, 119, 241–246. (In Russian) [Google Scholar]

- Bakardzhyiev, R.O.; Komarov, A.O. Features of evaluation of results regression analysis. Collect. Work. Kirovohrad Natl. Tech. Univ. Mach. Agric. Prod. Ind. Mach. Build. Autom. 2015, 28, 255–260. Available online: https://dspace.kntu.kr.ua/server/api/core/bitstreams/e05008bf-abe4-497f-97dd-5c66717b7ee0/content (accessed on 4 June 2024). (In Ukrainian).

- Gorobchenko, O.; Tkachenko, V. Statistical analysis of locomotives traction motors performance. In Proceedings of the 6th International BAPT Conference “Power Transmissions 2019”, Varna, Bulgaria, 19–22 June 2019. [Google Scholar] [CrossRef]

- Leng, L.; Zhu, W. Compound Regression and Constrained Regression: Nonparametric Regression Frameworks for EIV Models. Am. Stat. 2019, 74, 226–232. [Google Scholar] [CrossRef]

- Development of Design and Technological Documentation for the Modernization of Brake Lever Gears of Freight Wagon Bogies: Report on R&D (Zvit pro NDR) (Zaklyuch.); Ukrainian State University of Railway Transport, Ukrajinskij Derzhavnij Universytet Zaliznychnoho Transportu: Kharkiv, Ukraine, 2012; 53p, No. R0111U008972.

- Zharov, A.; Makas, A. Methods of statistical processing results of brake distance measurement when evaluating efficiency of rolling stock brake systems. VNIIZHT Bull. 2009, 5, 29–33. (In Russian) [Google Scholar]

- Muradian, L.A.; Shaposhnik, V.Y.; Shikunov, O.A. Malfunctions of braking equipment and defects of wheel-sets of freight wagons. Bull. Railw. Transp. Certif. 2021, 67, 5–15. Available online: https://crust.ust.edu.ua/items/c573639c-fae1-484e-a432-763ab223c03c (accessed on 2 September 2024). (In Ukrainian).

- Muradian, L.A.; Shaposhnik, V.Y.; Vinstrot, B.U.; Mukovoz, S.P. Testing of promising brake pads on the railways of Ukraine. Locomot. Inf. 2015, 7/8, 20–22. Available online: https://crust.ust.edu.ua/items/bf014671-d296-4017-93d0-eca4560f1faf (accessed on 28 May 2024). (In Ukrainian).

- Koptovets, O.; Haddad, J.S.; Brovko, D.; Posunko, L.; Tykhonenko, V. Identification of the conditions of a mine locomotive brake system as well as its functional and morphological model with the stressed closed kinematic circuit. In Proceedings of the XIV International Research and Practice Conference “Ukrainian School of Mining Engineering”, Berdiansk, Ukraine, 7–11 September 2020; Available online: https://doi.org/10.1051/e3sconf/202020101033 (accessed on 21 November 2024). [CrossRef]

- Mazur, V.L.; Naidek, V.L.; Popov, Y.S. Comparison of cast iron and compositional with iron insert brake pad inserts for railway rolling stock. Met. Cast. Ukr. 2021, 29, 30–39. (In Ukrainian) [Google Scholar] [CrossRef]

- Instructions for Operating Rolling Stock Brakes on the Railways of Ukraine. In CT-CV-CL-0015. [Effective from 10-28-1997 No. 264-C.; Polygraph Service LLC.: Kyiv, Ukraine, 2004; 146p.

- Vakkalagadda, M.R.K.; Srivastava, D.K.; Mishra, A.; Racherla, V. Performance analyses of brake blocks used by Indian Railways. Wear 2015, 328–329, 64–76. [Google Scholar] [CrossRef]

- Vineesh, K.P.; Vakkalagadda, M.R.K.; Tripathi, A.K.; Mishra, A.; Racherla, V. Non-uniformity in braking in coaching and freight stock in Indian Railways and associated causes. Eng. Fail. Anal. 2016, 59, 493–508. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, M. The application status of unit brakes on metro vehicles in China. IOSR J. Mech. Civ. Eng. 2018, 3, 17–23. [Google Scholar] [CrossRef]

- Hodges, T. A life-cycle approach to braking costs. Int. Railw. J. 2012, 52, 47–48. Available online: https://www.railjournal.com/in_depth/a-life-cycle-approach-to-braking-costs/ (accessed on 27 August 2024).

- Cruceanu, C. Brakes for Railway Vehicles, 1st ed.; Matrix Room: Bucharest, Romania, 2007. (In Romanian) [Google Scholar]

- Cruceanu, C. Train braking. In Reliability and Safety in Railway; Perpinya, X., Ed.; IntechOpen: London, UK, 2012. [Google Scholar]

- Bucur, F.; Socalici, A.; Berghian, A.B.; Baneasa, C.B.; Pascu, L. The tribology of composite materials used for manufacturing brake shoes. Materiale Plastice 2022, 59, 13–20. [Google Scholar] [CrossRef]

- Kiss, I.; Cioata, V.; Alexa, V.; Ratiu, S. Investigations on the selection of friction materials destined to railway vehicles applications. Ann. Fac. Eng. Hunedoara-Int. J. Eng. 2016, 14, 231. [Google Scholar]

- Kiss, I. The chemical composition of phosphorous cast irons behavior in the manufacturing of brake shoes meant for the rolling stock. Acta Tech. Corviniensis-Bull. Eng. 2016, 9, 77–84. Available online: https://www.proquest.com/scholarly-journals/chemical-composition-phosphorous-cast-irons/docview/1806389126/se-2 (accessed on 30 August 2024).

- Vatulia, G.; Lovska, A.; Myamlin, S.; Stanovska, I.; Holofieieva, M.; Horobets, V.; Nerubatskyi, V.; Krasnokutskyi, Y. Revealing the effect of structural components made of sandwich panels on loading the container transported by railroad. East. Eur. J. Enterp. Technol. 2023, 121, 48–56. [Google Scholar] [CrossRef]

- Fischer, S.; Liegner, N.; Bocz, P.; Vinkó, Á.; Terdik, G. Investigation of track gauge and alignment parameters of ballasted railway tracks based on real measurements using signal processing techniques. Infrastructure 2023, 8, 26. [Google Scholar] [CrossRef]

- Leitner, B.; Figuli, L. Fatigue life prediction of mechanical structures under stochastic loading. In Proceedings of the 22nd Slovak-Polish Scientific Conference on Machine Modelling and Simulations, MMS 2017, Sklene Teplice, Slovakia, 5–8 September 2017. [Google Scholar]

- Szczepański, E.; Gołȩbiowski, P.; Kondracka, B. Evaluation of the technological process of wagon processing at shunting stations using the simulation model. Sci. J. Silesian Univ. Technology. Ser. Transp. 2023, 120, 249–267. [Google Scholar] [CrossRef]

- TU U 6-05495978.017-2001; Composite Brake Pads with a Mesh-Wire Frame for Railway Freight Cars. OJSC “Tribo”: Lviv, Ukraine, 2001; 27p. (In Ukrainian)

- UIC Code 541-3; Brakes—Disc Brakes and Their Applications-General Conditions for the Certification of Brake Parts (2017). International Union of Railways: Paris, France, 2017.

- UIC 541-4; Brakes. Brakes with Composite Brake Blocks—General Conditions for the Certification of Composite Brake Blocks (2010). International Union of Railways: Paris, France, 2010.

- Pascu, L.V. Research on Improving the Quality of Brake Shoes Intended for Rolling Stock. Ph.D. Thesis, University Politehnica Timisoara, Timișoara, Romania, 2015. (In Romanian). [Google Scholar]

- Zhang, Y.; Chen, Y.; He, R.; Shen, B. Investigation of tribological properties of brake shoe materials—phosphorous cast irons with different graphite morphologies. Wear 1993, 166, 179–186. (In Ukrainian) [Google Scholar] [CrossRef]

- Jamshinsky, M.M. Analysis of brake pads and ways of evaluating their promising designs. Bull. East. Ukr. Natl. Univ. 2015, 1, 204–209. (In Ukrainian) [Google Scholar]

- STP 04-010:2018; Freight Cars. Maintenance and Repair System According to Technical Condition. Ukrzaliznytsia Stock Company: Kyiv, Ukraine, 2019; 25p. (In Ukrainian)

- Kellrich, M.B. The Basics of Wagon Reliability: A Study Guide; UkrSURT: Kharkiv, Ukraine, 2013; 106p. (In Ukrainian) [Google Scholar]

- Bidjuk, P.I.; Tkach, B.P.; Kharrinhton, T. Mathematical Statistics, 1st ed.; Personal: Kyiv, Ukraine, 2018. (In Ukrainian) [Google Scholar]

- Javala, L.L.; Slyusarchuk, Y.M.; Khromyak, Y.Y.; Tsymbal, V.M. Probability Theory, Mathematical Statistics and Probabilistic Processes: Textbook; Lviv Polytechnic: Lviv, Ukraine, 2015; 364p. (In Ukrainian) [Google Scholar]

- Kamkina, L.V.; Nadtochiy, A.A.; Grishin, A.M.; Stogniy Yu, D. Fundamentals of Scientific Research: A Textbook; NmetAU: Dnipropetrovsk, Ukraine, 2013; 89p. (In Ukrainian) [Google Scholar]

- Thrane, C. Applied Regression Analysis, 1st ed.; Taylor and Francis Group: London, UK, 2019. [Google Scholar]

- Sarip, S. Design development of lightweight disc brake for regenerative braking finite element analysis. Int. J. Appl. Phys. Math. 2013, 3, 52–58. Available online: https://www.academia.edu/26538825/Design_development_of_lightweight_disc_brake_for_regenerative_braking_finite_element_analysis (accessed on 3 September 2024). [CrossRef]

- Sarma, K.V.S.; Vishnu Vardhan, R. Multivariate Statistics Made Simple, 1st ed.; Taylor and Francis Group: New York, NY, USA, 2018. [Google Scholar]

- Donchenko, V.S.; Sidorov, M.V.-S. Probability Theory and Mathematical Statistics: A Textbook; Kyiv University: Kyiv, Ukraine, 2015; 400p. (In Ukrainian) [Google Scholar]

- Lebedev, E.O.; Livinska, G.V.; Rozora, I.V.; Sharapov, M.M. Mathematical Statistics: A Study Guide; Kyiv University: Kyiv, Ukraine, 2016; 159p. (In Ukrainian) [Google Scholar]

- Lan, Q.; Dhanasekar, M.; Handoko, Y.A. Wear damage of out-of-round wheels in rail wagons under braking. Eng. Fail. Anal. 2019, 102, 170–186. [Google Scholar] [CrossRef]

- Jóvér, V.; Gáspár, L.; Fischer, S. Investigation of tramway line No. 1, in Budapest, based on dynamic measurements. Acta Polytech. Hung. 2022, 19, 65–76. Available online: https://acta.uni-obuda.hu/Jover_Gaspar_Fischer_121.pdf (accessed on 24 June 2024). [CrossRef]

- Lu, B.; Chen, X.; Qu, B.; Zhang, H. Research on wheel-shoe wear for high friction composite brake shoes based foundation brake rigging in railway wagon. Key Eng. Mater. 2016, 667, 530–535. [Google Scholar] [CrossRef]

- Jover, V.; Fischer, S. Statistical Analysis of Track Geometry Parameters on Tramway Line No. 1 in Budapest. Balt. J. Road Bridge Eng. 2022, 17, 76–106. [Google Scholar] [CrossRef]

- Presciani, P.; Rinchi, M.; Pugi, L. Banchi per la certificazione del componenti frenanti. Ing. Ferrov. 2003, 58, 285–294. [Google Scholar]

- Panchenko, S.; Gerlici, H.; Lovska, A.; Ravlyuk, V. Substantiation of the environmental efficiency of the device for parallel retraction of brake shoes for freight wagons. In Proceedings of the Current problems in rail vehicles—PRORAIL 2023, Žilina, Slovakia, 20–23 September 2023; pp. 109–118. [Google Scholar] [CrossRef]

| Inventory Number of an Examined Wagon | The Sequence of Thickness Reduction of the Upper Part of the Brake Pads yi [mm] with Increasing Mileage S [Thousand km] | ||||||

|---|---|---|---|---|---|---|---|

| 4.60 | 16.20 | 24.10 | 74.10 | 121.30 | 164.60 | 197.80 | |

| 61138707 | 0.75 | 3.63 | 5.75 | 17.38 | 25.50 | 33.25 | 40.63 |

| 61139481 | 0.50 | 3.13 | 5.88 | 16.00 | 23.63 | 32.75 | 40.63 |

| 61138970 | 0.50 | 4.13 | 6.75 | 13.63 | 22.00 | 29.75 | 37.13 |

| 61139168 | 0.13 | 2.88 | 6.25 | 16.00 | 24.25 | 33.13 | 39.50 |

| 61139317 | 0.88 | 3.25 | 6.13 | 16.13 | 23.88 | 31.63 | 38.25 |

| 61139176 | 1.13 | 3.63 | 6.88 | 16.00 | 24.88 | 32.38 | 38.38 |

| 61139556 | 0.25 | 3.25 | 5.38 | 15.13 | 22.75 | 30.63 | 37.25 |

| 61139531 | 0.25 | 3.00 | 6.25 | 16.00 | 22.75 | 31.25 | 39.25 |

| 61140083 | 1.13 | 3.88 | 6.25 | 17.50 | 25.00 | 33.25 | 39.63 |

| 61140307 | 0.38 | 3.00 | 5.63 | 16.00 | 23.38 | 30.63 | 37.38 |

| Average value for all wagons | 0.59 | 3.38 | 6.12 | 15.98 | 23.80 | 31.87 | 38.80 |

| Inventory Number of an Experimental Wagon | The Sequence of Thickness Reduction of the Bottom Part of the Brake Pads yi [mm] with Increasing Mileage S [Thousand km] | ||||||

|---|---|---|---|---|---|---|---|

| 4.60 | 16.20 | 24.10 | 74.10 | 121.30 | 164.60 | 197.80 | |

| 61138707 | 0.50 | 3.25 | 5.25 | 13.25 | 20.63 | 29.50 | 36.50 |

| 61139481 | 0.63 | 3.25 | 6.25 | 15.88 | 23.38 | 31.75 | 39.38 |

| 61138970 | 0.63 | 4.00 | 7.00 | 14.00 | 22.38 | 30.25 | 37.00 |

| 61139168 | 0.38 | 3.38 | 6.13 | 15.38 | 23.63 | 31.38 | 38.25 |

| 61139317 | 0.63 | 3.25 | 5.88 | 14.5 | 22.25 | 29.75 | 36.38 |

| 61139176 | 0.38 | 2.63 | 6.00 | 14.75 | 22.25 | 29.75 | 36.50 |

| 61139556 | 0.63 | 3.13 | 5.88 | 15.38 | 23.13 | 30.88 | 38.00 |

| 61139531 | 0.63 | 2.88 | 5.50 | 18.00 | 25.88 | 33.25 | 40.50 |

| 61140083 | 0.38 | 2.50 | 5.13 | 14.88 | 22.75 | 30.63 | 37.50 |

| 61140307 | 0.88 | 3.13 | 5.88 | 16.13 | 24.13 | 30.75 | 37.25 |

| Average value for all wagons | 0.57 | 3.14 | 5.89 | 15.22 | 23.04 | 30.79 | 37.73 |

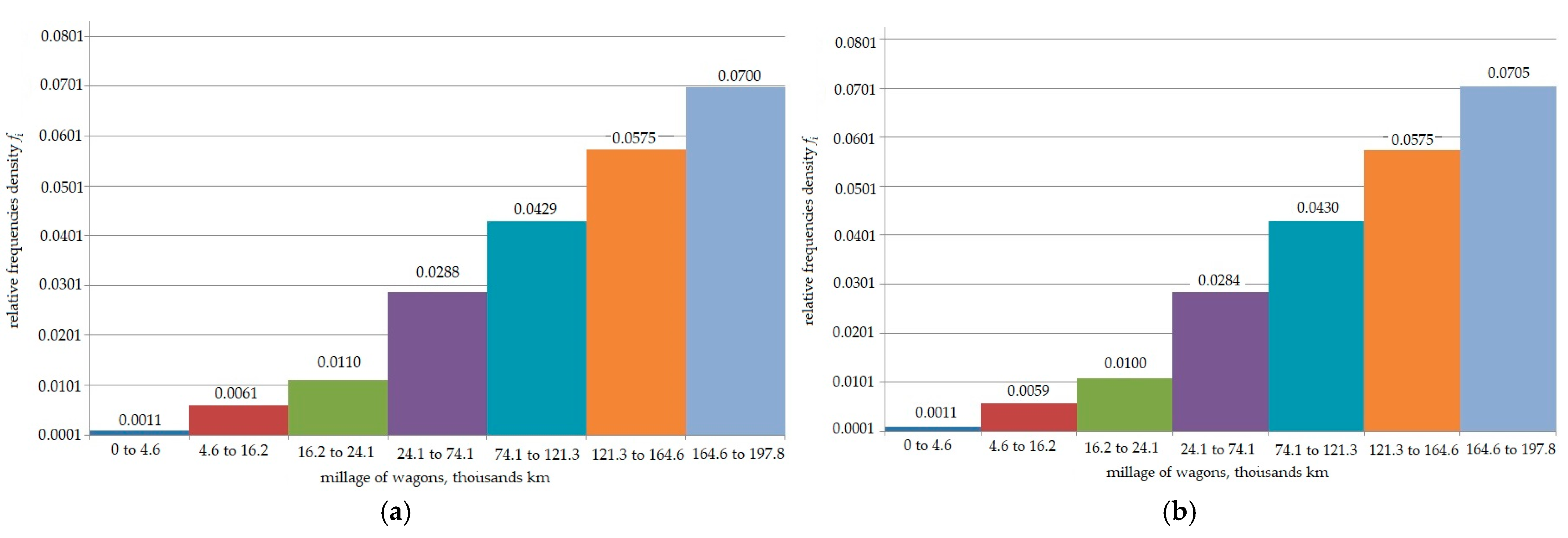

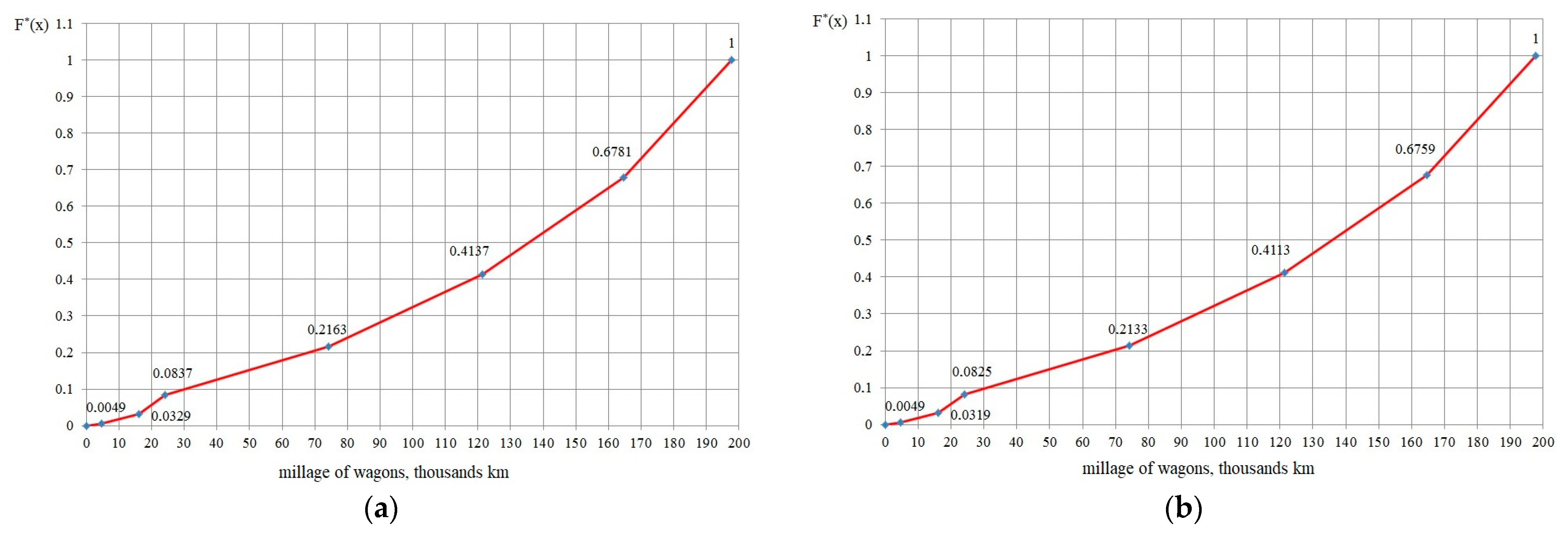

| Mileage Interval (Thousand km) | ai−1 | ai | xi | ni | xini | xi2ni | ωi | fi | sni | sωi |

|---|---|---|---|---|---|---|---|---|---|---|

| 0 to 4.6 | 0 | 4.6 | 2.3 | 0.59 | 1.36 | 3.12 | 0.0049 | 0.0011 | 0.59 | 0.0049 |

| 4.6 to 16.2 | 4.6 | 16.2 | 10.4 | 3.38 | 35.15 | 365.58 | 0.028 | 0.0061 | 3.97 | 0.0329 |

| 16.2 to 24.1 | 16.2 | 24.1 | 20.2 | 6.12 | 123.62 | 2497.2 | 0.0508 | 0.011 | 10.09 | 0.0837 |

| 24.1 to 74.1 | 24.1 | 74.1 | 49.1 | 15.98 | 784.62 | 38,524.74 | 0.1326 | 0.0288 | 26.07 | 0.2163 |

| 74.1 to 121.3 | 74.1 | 121.3 | 97.7 | 23.8 | 2325.3 | 227,177.9 | 0.1974 | 0.0429 | 49.87 | 0.4137 |

| 121.3 to 164.6 | 121.3 | 164.6 | 143 | 31.87 | 4557.4 | 651,709.6 | 0.2644 | 0.0575 | 81.74 | 0.6781 |

| 164.6 to 197.8 | 164.6 | 197.8 | 181.2 | 38.8 | 7030.6 | 1,273,937 | 0.3219 | 0.07 | 120.54 | 1 |

| Total | 120.54 | 14,858 | 2,194,216 | 1 | ||||||

| Mileage Interval (Thousand km) | ai−1 | ai | xi | ni | xini | xi2ni | ωi | fi | sni | sωi |

|---|---|---|---|---|---|---|---|---|---|---|

| 0 to 4.6 | 0 | 4.6 | 2.3 | 0.57 | 1.31 | 3.02 | 0.0049 | 0.0011 | 0.57 | 0.0049 |

| 4.6 to 16.2 | 4.6 | 16.2 | 10.4 | 3.14 | 32.66 | 339.62 | 0.027 | 0.0059 | 3.71 | 0.0319 |

| 16.2 to 24.1 | 16.2 | 24.1 | 20.2 | 5.89 | 118.98 | 2403.36 | 0.0506 | 0.011 | 9.6 | 0.0825 |

| 24.1 to 74.1 | 24.1 | 74.1 | 49.1 | 15.22 | 747.3 | 36,692.53 | 0.1308 | 0.0284 | 24.82 | 0.2133 |

| 74.1 to 121.3 | 74.1 | 121.3 | 97.7 | 23.04 | 2251 | 219,923.5 | 0.198 | 0.043 | 47.86 | 0.4113 |

| 121.3 to 164.6 | 121.3 | 164.6 | 143 | 30.79 | 4403 | 629,624.7 | 0.2646 | 0.0575 | 78.65 | 0.6759 |

| 164.6 to 197.8 | 164.6 | 197.8 | 181.2 | 37.73 | 6836.7 | 1,238,806 | 0.3242 | 0.0705 | 116.38 | 1.0 |

| Total | 116.38 | 14,,391 | 2,127,792 | 1 | ||||||

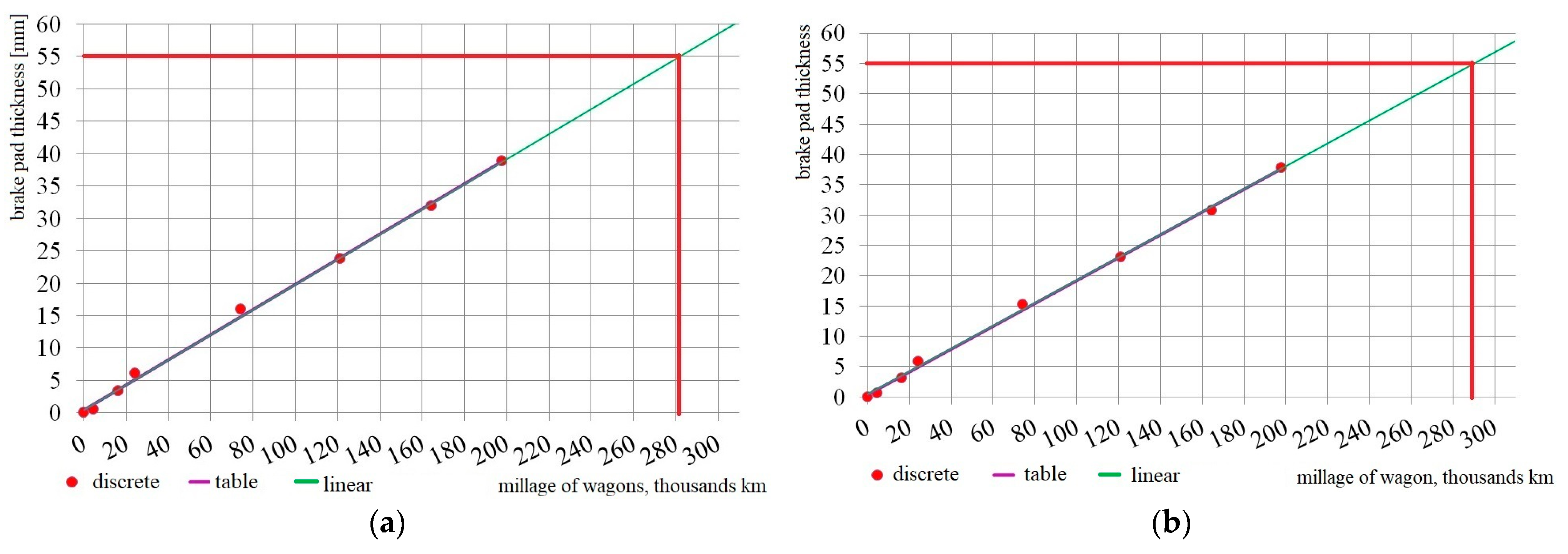

| x | x2 | ylin | dbid | d2 | ||

|---|---|---|---|---|---|---|

| 0 | 0 | 0 | 0 | 0.46936 | −0.4694 | 0.22029 |

| 4.6 | 0.59 | 21.16 | 2.714 | 1.3607 | −0.7707 | 0.59397 |

| 16.2 | 3.38 | 262.44 | 54.756 | 3.60843 | −0.2284 | 0.05218 |

| 24.1 | 6.12 | 580.81 | 147.492 | 5.13921 | 0.98079 | 0.96195 |

| 74.1 | 15.98 | 5490.81 | 1184.12 | 14.8277 | 1.15229 | 1.32777 |

| 121.3 | 23.8 | 14,713.7 | 2886.94 | 23.9737 | −0.1737 | 0.03016 |

| 164.6 | 31.87 | 27,093.2 | 5245.8 | 32.3639 | −0.4939 | 0.24393 |

| 197.8 | 38.8 | 39,124.8 | 7674.64 | 38.7971 | 0.00295 | 8.7 × 10−6 |

| 602.7 | 120.54 | 87,287 | 17,196 | - | - | 3.4303 |

| x | x2 | ylin | dbid | d2 | ||

|---|---|---|---|---|---|---|

| 0 | 0 | 0 | 0 | 0.37035 | −0.3704 | 0.13716 |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| 4.6 | 0.57 | 21.16 | 2.622 | 1.23599 | −0.666 | 0.44354 |

| 16.2 | 3.14 | 262.44 | 50.868 | 3.4189 | −0.2789 | 0.07778 |

| 24.1 | 5.89 | 580.81 | 141.949 | 4.90553 | 0.98447 | 0.96917 |

| 74.1 | 15.22 | 5490.81 | 1127.8 | 14.3146 | 0.90538 | 0.8197 |

| 121.3 | 23.04 | 14,713.7 | 2794.75 | 23.1968 | −0.1568 | 0.02459 |

| 164.6 | 30.79 | 27,093.2 | 5068.03 | 31.3451 | −0.5551 | 0.30811 |

| 197.8 | 37.73 | 39,124.8 | 7462.99 | 37.5927 | 0.13728 | 0.01885 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Panchenko, S.; Gerlici, J.; Lovska, A.; Ravlyuk, V.; Dižo, J. Prediction of Residual Wear Resources of Composite Brake Pads of a Modernized Brake System of Freight Wagons. Vehicles 2024, 6, 1975-1994. https://doi.org/10.3390/vehicles6040097

Panchenko S, Gerlici J, Lovska A, Ravlyuk V, Dižo J. Prediction of Residual Wear Resources of Composite Brake Pads of a Modernized Brake System of Freight Wagons. Vehicles. 2024; 6(4):1975-1994. https://doi.org/10.3390/vehicles6040097

Chicago/Turabian StylePanchenko, Sergii, Juraj Gerlici, Alyona Lovska, Vasyl Ravlyuk, and Ján Dižo. 2024. "Prediction of Residual Wear Resources of Composite Brake Pads of a Modernized Brake System of Freight Wagons" Vehicles 6, no. 4: 1975-1994. https://doi.org/10.3390/vehicles6040097

APA StylePanchenko, S., Gerlici, J., Lovska, A., Ravlyuk, V., & Dižo, J. (2024). Prediction of Residual Wear Resources of Composite Brake Pads of a Modernized Brake System of Freight Wagons. Vehicles, 6(4), 1975-1994. https://doi.org/10.3390/vehicles6040097