A Review of Recent Trends in High-Efficiency Induction Motor Drives

Abstract

:1. Introduction

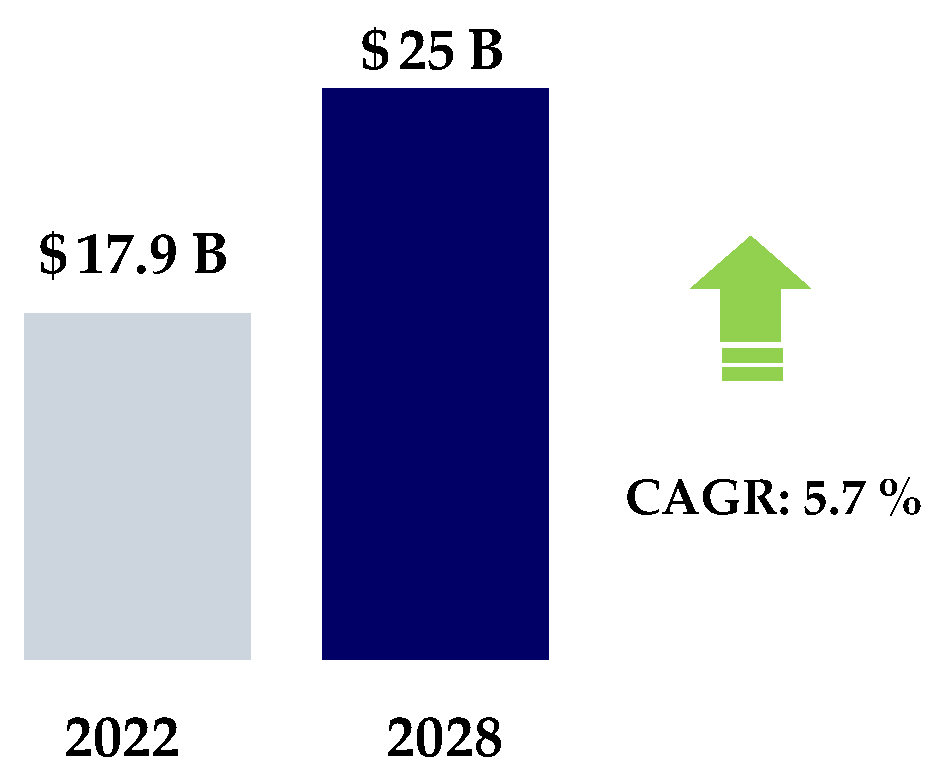

1.1. Market Size of Electrical Drives

1.2. Electric Drives and UN-SDGs

1.3. Main Contribution

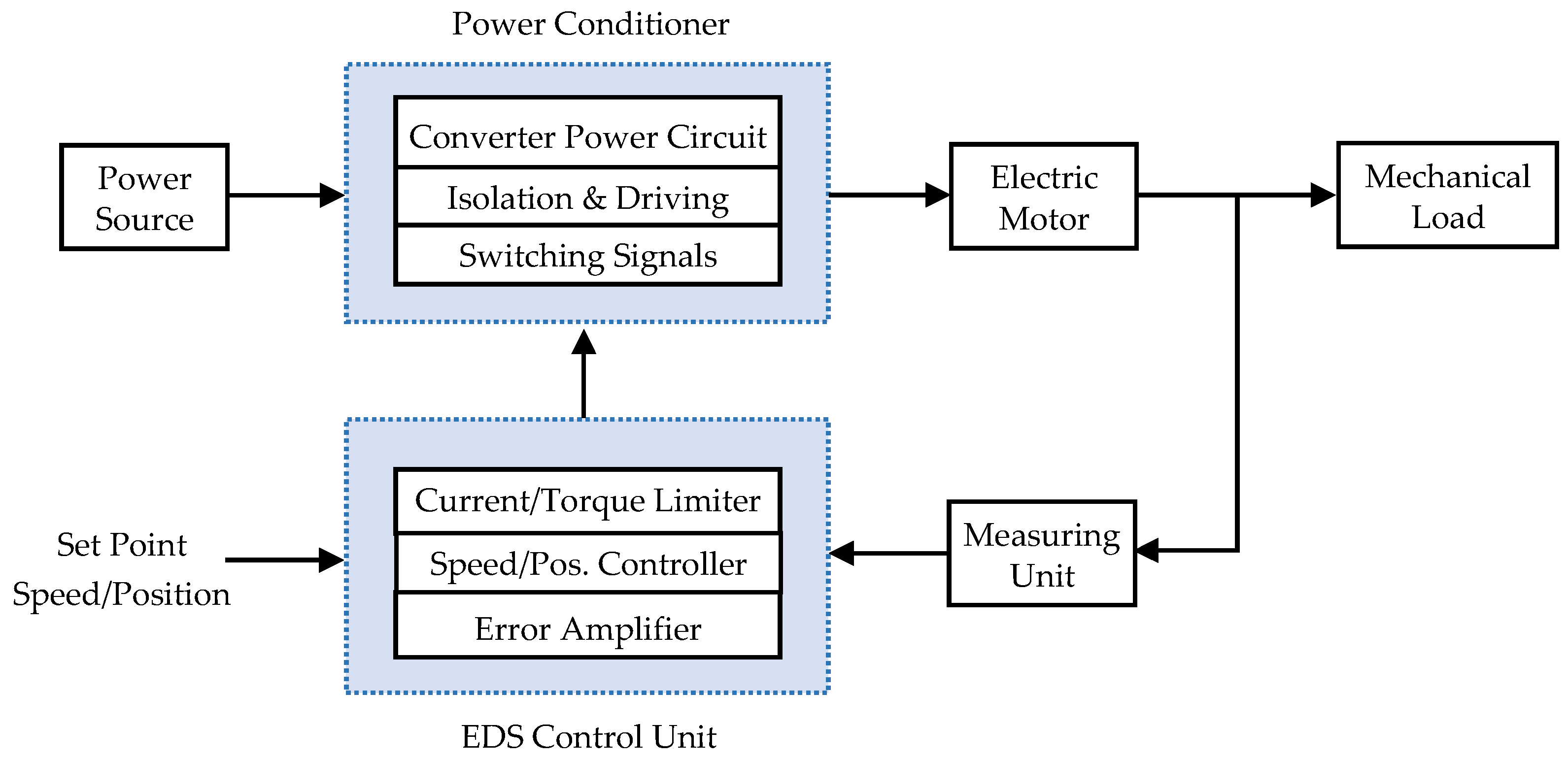

1.4. Elements of a Typical EDS

- Efficiency classes of the electric motor, where high efficiency and premium efficiency classes are employed;

- Types of the power semiconductor devices that form the power electronic converter, where a high-efficiency converter that offers minimum power losses is utilized;

- Control techniques, which can involve energy saving algorithms or guarantee operation at optimum flux level for a wide range of motor speeds.

1.5. Factors Affecting Efficiency of IM Drives

1.6. Power Losses in IM Drives

- Copper losses across the motor windings;

- Magnetic (iron) losses of the magnetic circuit;

- Losses in rotor windings (in wound rotor) or cage losses (in case of squirrel cage);

- Iron losses or core losses including hysteresis and eddy currents losses;

- Mechanical and bearing losses due to friction;

- Stray losses due to leakage flux, magnetic imperfections;

- Switching power losses of the inverter;

- Conduction power losses of the inverter;

- Cooling system losses due to fans (forced air), liquid cooling and heat sink thermal resistance;

- Inverter driving circuits power losses;

- Snubber circuits and passive filters power losses.

1.7. Advancement Directions in IM Drives

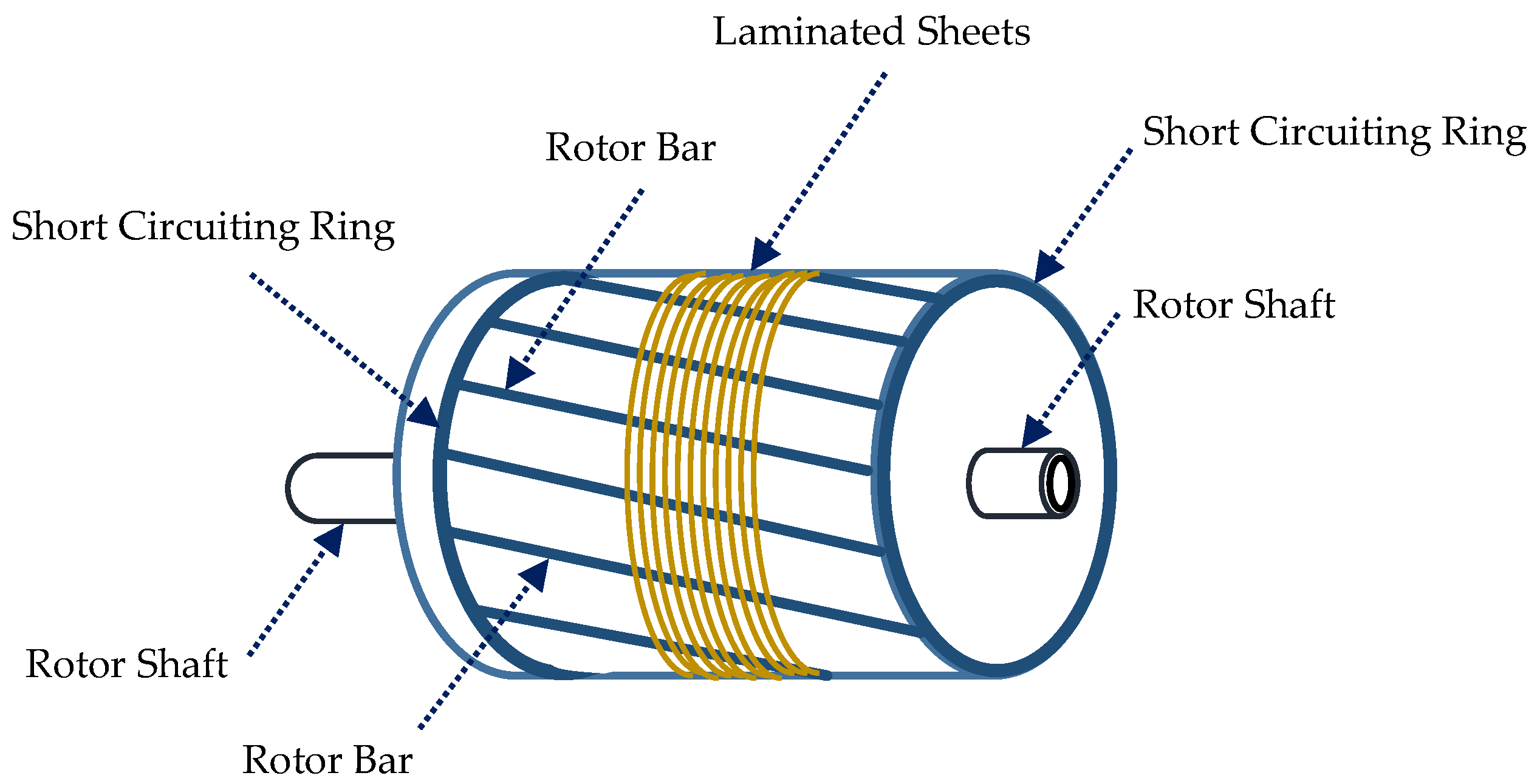

2. High-Efficiency Induction Motors

2.1. Main Features of High-Efficiency IMs

- Longer core (motor) length;

- Thinner core lamination;

- High grade core material such as grain-oriented silicon steel;

- Wider stator slots with optimized shapes (based on finite element design and analysis);

- Thicker stator windings (larger winding cross section area);

- High temperature electrical insulation class;

- Larger rotor diameter;

- Lower resistance rotor bars such as die cast copper rotor;

- Narrower air gap between the stator and rotor;

- Larger fan size with optimized aerodynamic;

- Larger cooling fins and increase cooling surface area;

- Small bearing size with lower friction losses;

- Anti-corrosion coating for the motor body.

2.2. Research Contributions Related to High-Efficiency IMs

- Design and manufacturing of high- and premium-efficiency induction motors (Table 2);

- Optimization techniques and algorithms for high efficiency motor design (Table 3);

- Efforts in bearingless IMs (Table 4);

- Modeling, loss analysis, and computational tools (Table 5);

- Thermal analysis and cooling systems (Table 6).

| Main Area | Ref. | Core Contribution |

|---|---|---|

| Design and Manufacturing of High-Efficiency Motors | [9] | Design of an energy-efficient IM by combining field-circuit and analytical methods; the authors optimized the motor’s core materials and structure to minimize power losses. |

| [21,22] | Analyzing and validating different rotor slot geometries to enhance the motor efficiency and starting performance. | |

| [23] | Motor design and fabrication using amorphous alloy instead of silicon steel, reducing the core and copper losses. | |

| [24] | Design of a high-performance IM using flat wires and a copper rotor tailored for EVs, demonstrating the feasibility of a rare-earth-free solution that achieves a high-efficiency and thermally stable motor. | |

| [25] | Designing a six-pole, double-stator–double-rotor axial flux induction motor designed for electric vehicles. The innovative design reduces back iron thickness, leading to a more compact and efficient motor. | |

| [26] | Developing a low-cost IM with a totally enclosed fan-cooled aluminum cage rotor suitable for EVs. | |

| [27] | Modifying stator and rotor designs to minimize losses, using low-loss electrical steel and high-conductivity copper to comply with the premium-efficiency class. | |

| [28] | Analyzing the trade-offs between cost, thermal performance, and efficiency, recommending an optimal Al-Cu mix to achieve IE4 efficiency standards. | |

| [29] | Investigating the effects of end-ring geometric parameters (thickness, height, and extension) on the starting and rated performance characteristics of IMs. | |

| [30] | Presenting a methodology for designing energy-efficient induction motors using ANSYS software. Motor parameters are optimized with the aid of FEM. | |

| [31] | Designing of electric motors and power drive systems in compliance with contemporary efficiency standards. Addresses the importance of integrating efficiency considerations in the early design stage. | |

| [32] | Analyzing the impact of substituting aluminum with copper in squirrel cage induction motors. Evaluation of electromagnetic and thermal performance, revealing that copper cages enhance efficiency but may affect starting torque. Design guidelines to optimize motor efficiency are also presented. | |

| [33] | Presenting strategies for induction motor manufacturers to achieve higher efficiency classes in terms of material selection, manufacturing processes and design parameters. | |

| [34] | Enhancing the efficiency of three-phase squirrel cage induction motor by modifying its cooling system. Suggesting the utilization of aluminum for the stator housing, rotor bars, and end rings to raise the efficiency. | |

| [35] | Optimizing rotor and stator slot designs of induction motor that is employed for photovoltaic (PV) powered water pumping systems | |

| [36] | Presenting a design of high-efficiency IM based on modifying the rotor lamination, stack length, and winding configuration while retaining the existing stator lamination. | |

| [37] | Introducing a stator winding scheme for IMs aimed at reducing magnetomotive force (MMF) distortion. Based on a three-layer winding with varying conductor counts per slot, which has minimized harmonic components in the MMF waveform. | |

| [38] | Designing a cryogenic induction motor submerged in liquefied natural gas (LNG) for operating LNG spray pumps, operating at −163 °C; the motor’s torque characteristics differ significantly from room temperature conditions. Main design specifications for optimal performance in cryogenic environments have been addressed. | |

| [39] | Providing a comprehensive overview of the design and control methodologies for improving the energy efficiency of electric machines, including IMs, used in EVs. Also evaluates the impacts of stator and rotor designs, winding configurations, and novel materials on energy efficiency. | |

| [40] | Investigating the utilization of magnetic slot wedges in IMs with semi-closed slots to enhance efficiency. Various wedge permeabilities and geometries have been studied, demonstrating reductions in copper and core losses. | |

| [41] | Presenting a methodology to enhance the efficiency of IMs operating at low frequencies by integrating design modifications with control strategies. Motor parameters are optimized by achieving significant energy savings. |

| Main Area | Ref. | Core Contribution |

|---|---|---|

| Optimization Techniques and Algorithms for High-Efficiency Motor Design | [23] | Design optimization via evolutionary algorithms to optimize the stator and rotor slot shapes, achieving a balance between reduced losses and maintained performance |

| [25] | Employment of a Monte-Carlo random search algorithm to optimize the motor parameters. | |

| [26] | Presenting an optimal design and experimental testing of a low-cost, totally enclosed fan-cooled induction machine for city battery electric vehicles. Combines thermal calculations, and finite element analysis (FEA) to enhance the design process by minimizing prototype iterations and ensuring multi-disciplinary performance. | |

| [28] | Optimizing the motor efficiency by optimal combination of Al-Cu that can meet IE4 standards. | |

| [29] | Optimizing end-ring thickness to improve starting performance without major changes to existing designs, with a slight trade-off in efficiency, moving from IE4 to IE3 class. | |

| [42] | Optimizing the motor design via evolutionary algorithms to optimize the stator and rotor slot shapes, achieving a balance between reduced losses and maintained performance. Optimizing motor parameters to enhance efficiency for ceiling fan motors using Taguchi’s Orthogonal Arrays method. | |

| [43] | Developing a design procedure focused on field-weakening and extended-speed capabilities. The key parameters are EMF and inductance-current product. | |

| [44] | Development of a hybrid optimization algorithm, combining differential evolution with a non-dominating sorting algorithm, minimizes both the air gap MMF spatial harmonic distortion and the winding resistance, using a hybrid algorithm. The approach yields a winding configuration that reduces copper usage and enhances motor efficiency. | |

| [45] | Utilization of a machine learning-based approach for diagnosing faults and efficiency optimization in induction motors (IM) for electric vehicle EVs. This approach enables early fault detection, enhances motor reliability, and reduces maintenance costs. | |

| [46] | Utilization of genetic algorithms to optimize eight key parameters of linear induction motors (LIMs), improving efficiency at rated operating conditions. | |

| [47] | Introducing a sequential Taguchi method to optimize IM designs for electric vehicles, focusing on various stator slot and rotor bar combinations. | |

| [48] | Introducing a fractional-order finite element model to analyze the harmonic response of vehicle asynchronous motor rotors. An accelerated response surface optimization method to enhance rotor stiffness and reduce mass is proposed. | |

| [49] | Assessing various strategies to enhance induction motor efficiency. Impact of design modifications and material selection on the motor performance have been evaluated to achieve higher efficiency of IMs. | |

| [50] | Introducing a multilayer AC winding configuration for IMs to produce a high-quality magnetomotive force (MMF) with reduced space harmonics for a premium efficiency class machine. | |

| [51] | Studying the effect of stator slot geometry on the copper losses in high-speed electric machines. Identifying the optimum designs that mitigate skin and proximity effects. | |

| [52] | Presenting an optimization methodology for the stator and rotor slot design of IMs for EV applications. Utilizing FEM analysis, various slot geometries are investigated to minimize losses and enhance efficiency. | |

| [53] | Presenting a genetic algorithm-based approach to optimize the design of squirrel cage induction motors, to enhance motor efficiency and minimize costs. Material, mechanical, and performance constraints are incorporated to offer a systematic method to achieve energy-efficient motor designs. | |

| [54] | Introducing a multi-objective optimization approach for designing high-efficiency induction motors using parameter learning. The objectives terms are efficiency, torque ripple, and power factor. | |

| [55] | Presenting harmony search algorithm for optimizing the design of three-phase squirrel-cage IMs. The method explores nonlinear design items to enhance motor efficiency. | |

| [56] | Introducing a multi-objective optimization technique for IM design, utilizing Hill Climbing-based Local Search Optimization (HCLSO). The method iteratively investigates problems such as rotor current, power factor, and efficiency to enhance the motor performance. |

| Main Area | Ref. | Core Contribution |

|---|---|---|

| Bearingless IMs | [57] | Proposing a speed sensorless control strategy for bearingless induction motors (BIM) using a modified robust Kalman filter. This method enhances the accuracy of speed estimation and robustness against disturbances. |

| [58] | Introducing a direct torque control strategy for bearingless induction motors, employing super-twisting sliding mode control to enhance performance. The employed approach reduces torque and flux ripples and improves robustness against parameter variations. | |

| [59] | Introducing an enhanced repetitive control strategy to mitigate periodic synchronous rotor vibrations in bearingless induction motors, improving rotor suspension accuracy. | |

| [60] | Presenting a backstepping control strategy for bearingless induction motors, enhanced by a linear extended state observer (LESO). The utilized approach compensates for the system disturbances, enhancing rotor suspension performance and disturbance rejection. | |

| [61] | Proposing a fuzzy-enhanced linear active disturbance rejection control (Fuzzy-ELADRC) method for bearingless induction motors. The method combines dynamically adjust control parameters, balancing dynamic performance and robustness. The investigated method improves rotor suspension stability. | |

| [62] | Providing a multi-objective optimization framework based on evolutionary algorithms to optimize the design of high-speed bearingless induction motors (IMs), aiming to enhance efficiency and power density. | |

| [63] | Offering systematic design and modeling of a high-performance bearingless induction motor (IM) suitable for medium to high power applications. | |

| [64] | Developing a rotor radial position control method for bearingless IMs, aimed at enhancing machine stability, reducing mechanical vibration, and controlling rotor eccentricity. | |

| [65] | Providing a comprehensive review of bearingless motor technology. The paper reviews the motor designs, different topologies, and their performance. It discusses the major limitations in achieving the efficiency and power density for large-scale applications. | |

| [66] | Proposing a winding design for bearingless motors, enabling a single winding to generate both torque and radial suspension forces. The main feature is separating the terminals for torque and suspension, where the suspension terminals do not contribute a motional electromotive force when the rotor is centered. | |

| [67] | Investigating a pole-specific rotor design for bearingless induction machines, characterized by a common end-ring to reduce axial length, improving efficiency by preventing suspension field-induced currents. | |

| [68] | Proposing a three-speed wound bearingless induction motor with a novel winding configuration that enables operation at multiple synchronous speeds. That design enhances the efficiency and stability of the motor. | |

| [69] | Introducing a speed sensorless control strategy for bearingless induction motors based on an adaptive flux observer. This method improves the rotor suspension performance under various operating conditions. | |

| [70] | Proposing a driving scheme for three-phase bearingless induction machines with split windings, reducing the required inverter legs from six to four, which decreases the number of drivers, sensors, and current controllers, reducing the overall cost. | |

| [71] | Providing a comprehensive review of bearingless induction motors, addressing principles of operation, different schemes, and key technologies and challenges. | |

| [72] | Investigating a model predictive control strategy for direct levitation force control in bearingless induction motors. This approach enhances rotor suspension stability and dynamic response under various operating conditions. | |

| [73] | Addressing a design framework for bearingless induction motors tailored for industrial compressors. It has a pole-specific rotor winding and a combined stator winding. | |

| [74] | Suggesting a fuzzy logic controller for the radial position control of a bearingless induction motor, resulting in improved rotor stability and performance. | |

| [75] | Proposing a driving method for a two-degrees-of-freedom controlled bearingless motor, utilizing a single three-phase inverter. The staggered-tooth stator core design facilitates starting torque production. The method guarantees effective control over both rotational and radial movements. | |

| [76] | Studying a novel direct torque control method for bearingless induction motors using sliding mode control, incorporating a closed-loop radial suspension force control method based on inverse system theory. A stable suspension operation with reduced torque that enhanced both dynamic response and suspension performance was observed. |

| Main Area | Ref. | Core Contribution |

|---|---|---|

| Modeling, Loss Analysis and Computational Tools | [24] | Designing a 200 kW induction motor for electric vehicle traction systems, utilizing flat wire windings and a copper rotor. The design improves the slot fill factor. The study provides a comprehensive analysis of material selection and design considerations. |

| [25] | Development and validation of a detailed equivalent circuit model for the double-stator–double-rotor configuration using ANSYS Maxwell, providing efficient motor design. | |

| [28] | Investigating and analyzing the performance of IE4-class IMs with rotor conductors composed of varying aluminum–copper (Al-Cu) ratios. This approach aims to enhance motor efficiency while managing manufacturing costs. | |

| [44] | Developing a generalized multilayer winding model for symmetrical AC machines, incorporating integer-slot, fractional-slot, and fractional-slot concentrated windings. | |

| [45] | Development of ML models and simulation of various faults, including Short Circuit (SC), High Resistance Connection (HRC), and Open-Phase Circuit (OPC), and generation of performance data for both healthy and faulty motor conditions under variable load conditions, achieving high accuracy (up to 100%) in identifying motor conditions. | |

| [46] | Development of an integrated loss model for optimal efficiency control incorporating both motor and inverter losses for enhanced efficiency. | |

| [62] | Proposing and developing computationally efficient finite element analysis (FEA) methods that allow rapid design performance evaluations, and optimizing the bearingless IM design without excessive computation time. | |

| [63] | Introducing various finite element analysis (FEA) methods, including a modified transient FEA model, which allow for rapid and accurate performance evaluations. | |

| [64] | Finite element analysis (FEA) which validates the control approach, demonstrating reliable rotor positioning and reduced eccentricity. | |

| [77] | Presents a computationally efficient model for analyzing AC winding losses in the stator of traction motors used in high-speed railway units. The model reduces computational demands compared to conventional methods. The model is validated through experimental data and compared with other existing models, demonstrating high accuracy with significantly reduced computational cost. It can help in optimizing motor design to reduce winding losses. | |

| [78] | Carrying out harmonic and unbalance sensitivity analysis on efficiency motors. It investigates the balance between achieving higher energy efficiency motor and the potential degradation in power quality under nonideal electrical supply conditions. | |

| [79] | Providing a framework for evaluating the practical and economic impacts of upgrading to high-efficiency electric motors. The study examines the criteria used to assess the feasibility of replacing standard efficiency motors with high-efficiency motors. | |

| [80] | Proposing a dynamic model for a bearingless induction motor, accounting for rotor eccentricity and load variations. It introduces a modified inductance model and a dynamic air gap function to more accurately depict system behavior, improving the system stability and accuracy of the control system. | |

| [81] | Introducing a multi-physics model to predict motor performance of axial flux induction motors for EVs. Employs a genetic algorithm-based optimization strategy to enhance efficiency, torque density, and power-to-weight ratio, resulting in better performance and reduced energy consumption in the overall EV. | |

| [82] | Proposing a machine learning-based method for diagnosing faults in IMs using stator current and vibration signals. This approach enhances diagnostic accuracy. | |

| [83] | Holding comparison between several IM models that account for iron loss in EVs. Models’ accuracies at different operating conditions have been investigated. | |

| [84] | Proposing an analytical core loss model for three-phase IMs in an arbitrary reference frame. Accurately predicts core losses under various operating conditions, including transient operation. |

| Main Area | Ref. | Core Contribution |

|---|---|---|

| Thermal Analysis and Cooling Systems | [24] | The study explores two cooling solutions: water jacket with spiral groove and oil spray methods, to manage heat dissipation at high speeds, crucial for maintaining efficiency and component longevity. |

| [85,86] | Providing a comprehensive review of thermal management techniques and cooling strategies for high-efficiency IMs. Addresses major thermal challenges, analysis techniques, and evaluate different cooling strategies. | |

| [87] | Development of a novel oil-cooling design for IMs utilized in EV applications. Addresses the thermal constraints. Demonstrates the importance of thermal management through oil cooling in enhancing motor reliability and lifespan. | |

| [88] | Addressing the various types of losses in electric machines. Explores various cooling techniques. Emphasizes the importance of temperature distribution analysis and the role of heat management in enhancing machine reliability and operational lifespan. | |

| [89] | Presenting a thermal analysis method for IMs using a Lumped Parameter Thermal Network model. Accurately predicts motor temperature distribution under varying load conditions, enhancing thermal management and preventing overheating. | |

| [90] | Providing a thermal analysis of a water-cooled, totally enclosed, non-ventilated IM. Develops a detailed thermal model to evaluate temperature distribution and cooling efficiency. The study highlights the effectiveness of water cooling of IM and enhancing its reliability. | |

| [91] | Proposing a hybrid thermal management system for IMs, combining air-cooling with an integrated water-cooling mechanism that optimizes motor cooling and improves thermal efficiency. The dual-cooling approach enhances motor reliability, and lifespan. | |

| [92] | Investigating the impact of cryogenic cooling on the performance of induction motors through experimental assessment. The study highlights cryogenic cooling as a promising approach for high-performance applications. | |

| [93] | Exploring the heat transfer performance of cooling systems using nanofluids for electric motors. Analyzes the cooling efficiency of nanofluid-based systems. The findings reveal enhanced cooling performance compared to conventional fluids, offering a novel approach to improve motor thermal management. | |

| [94] | Conducting a thermal analysis of a three-phase IM using Motor-CAD, Flux2D, and MATLAB Ver 13. Integrates electromagnetic and thermal simulations to predict temperature distribution and assess cooling performance. This multi-tool approach enhances motor design accuracy and improves thermal management. | |

| [95] | Analyzing the thermal behavior of three-phase IM under voltage unbalance and inter-turn short-circuit faults. Investigates the fault-induced heating effects and their impact on the motor performance. | |

| [96] | Providing a finite element design and thermal analysis of IMs. Develops a thermal model to predict temperature distribution, ensuring optimal motor cooling and enhanced performance. The study provides a design framework for thermally robust IM motors. | |

| [97] | Proposing a thermal management system for electric motors using L-shaped flat heat pipes. Demonstrates the heat pipes’ effectiveness in dissipating heat, reducing motor temperature and enhancing thermal stability. | |

| [98] | Providing analysis of end-winding thermal effects in an enclosed fan-cooled induction motor with a die-cast copper rotor. Models heat generation and dissipation in the end-windings, highlighting their impact on motor temperature and performance. | |

| [99] | Developing a thermal model for IMs with optimized liquid cooling tailored for different electric vehicles (EVs). Assesses cooling performance, reduces motor overheating, and enhances thermal stability under dynamic conditions. | |

| [100] | Presenting an optimal design methodology for the cooling fan of IMs using experimental validation. Enhances airflow and reduces motor temperature. Provides a systematic approach for fan design. | |

| [101] | Proposing an optimization method for the design of traction motor cooling system. The integrated thermal modeling and design algorithms enhance motor cooling efficiency. | |

| [102] | Establishing design criteria and framework for water-cooled systems in IMs. Addresses key parameters such as flow rate and cooling channel geometry. The study optimizes heat dissipation and reduces motor temperature and enhances system reliability. |

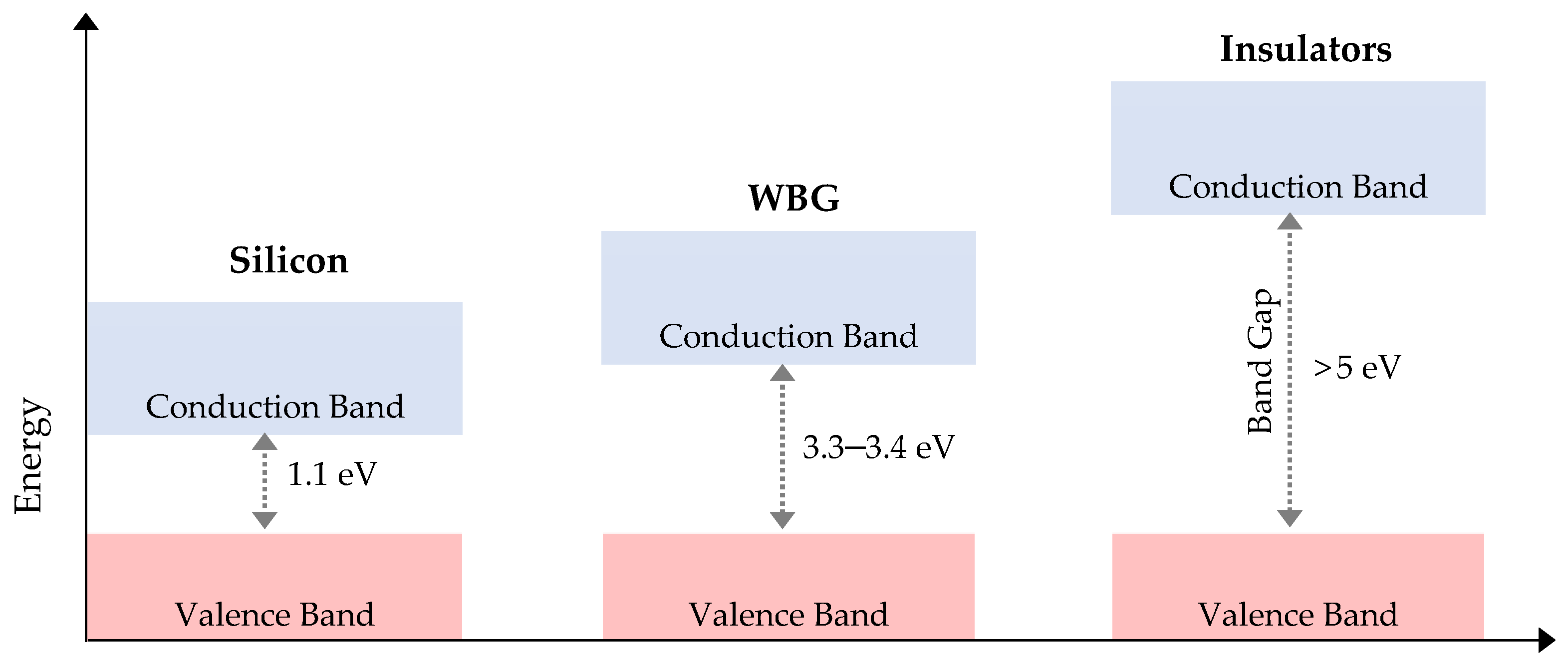

3. Wide Bandgap (WBG) Power Semiconductor Devices

3.1. Characteristics of WBG Semiconductors

3.2. Main Challenges and Design Issues

- Higher fabrication and manufacturing cost;

- Complex fabrication processes to have the final product with good quality;

- Reliability issue for GaN devices at high temperature;

- Cooling system design and analysis;

- Requirement of proper packaging to alleviate electromagnetic interference (EMI).

- Gate driving signals (voltage levels), which are different from the well-known and commonly used values of Si devices;

- The effect of parasitic inductance at operation of high switching frequencies, which requires compact and optimized PCB designs;

- EMI and electromagnetic compatibility (EMC) concerns due to high dv/dt and di/dt.

3.3. Research Contributions Related to WBG-Based Converters and AC Drives

| Main Area | Ref. | Core Contribution |

|---|---|---|

| Performance Analysis | [11] | Investigating the effects of high switching speeds and frequencies in wide bandgap (WBG) motor drives on electric machines. Identifies increased motor overvoltage at terminals and stator neutral, leading to higher insulation stress and bearing currents. |

| [109] | Proposing a hybrid DC–AC topology combining a Si-IGBT master unit with selective harmonic elimination PWM and a partial-power SiC-MOSFET slave unit. This configuration enhances efficiency, reduces switching loss, and improves power density. | |

| [110] | Providing comparative analysis of two-level and three-level SiC-based AC drive topologies for efficiency, voltage quality, and common-mode currents. Experimentally evaluates the impact of filters on mitigating high-frequency effects and meeting NEMA standards. | |

| [111] | Discussing issues such as EMI, high dv/dt, and insulation stress in case of WBG-based AC drives. Also addresses converter design trade-offs of WBG-based AC drives. | |

| [114] | Quantitative evaluation of energy savings and loss characteristics when replacing Si-IGBTs with SiC MOSFETs in railway traction inverters. | |

| [115] | Introducing a figure-of-merit (FOM) for comparing 600/650 V SiC and GaN semiconductors employed for EV drives. The paper reveals SiC’s suitability for high-temperature, low-frequency applications and GaN’s efficiency in high-frequency applications. | |

| [117] | Reviewing the state-of-the-art SiC power devices, including SiC MOSFETs and SiC SBDs, emphasizing their superior characteristics for power electronics applications. | |

| [118] | The paper introduces a novel integration of SiC devices with high-frequency transformers for high-power renewable energy applications. It designs and validates various DC–DC converter topologies with integrated SiC technology, achieving high efficiency (>98%), reduced size, and improved thermal management. | |

| [119] | Introducing a variable switching frequency PWM strategy to achieve zero-voltage switching in AC motor drives powered by two parallel SiC inverters. The scheme improves reliability and energy efficiency of AC motor drives. | |

| [122] | Analyzing the voltage distribution in stator windings of WBG-based inverter-fed motors, highlighting the anti-resonance phenomenon as a critical cause of peak voltage stress near the neutral point. | |

| [125] | Providing a comprehensive review of hybrid Si/SiC switches, highlighting their potential to combine the advantages of silicon IGBTs and silicon carbide MOSFETs for high-efficiency, high-power-density energy conversion. | |

| [126] | Addressing a historical overview of silicon carbide (SiC) power devices. Discusses the commercialization of SiC devices and their adoption across various applications, and offers insights into future developments in the field. | |

| [127] | Presenting an analytical model to predict low-frequency radiated electromagnetic interference (EMI) in three-phase motor drive systems utilizing silicon carbide (SiC) MOSFETs. Models EMI noise sources in the time domain under varying voltage and current conditions, enabling accurate EMI prediction and compliance with EMI standard. | |

| [128] | Introducing an enhanced method for analyzing parasitic elements in high-performance silicon carbide (SiC) power modules. The study accurately characterizes parasitic impedances, leading to improved design and performance of SiC power modules. | |

| [129] | Evaluating high-power silicon carbide MOSFET modules against silicon insulated-gate bipolar transistor modules. Highlights SiC MOSFETs’ superior voltage blocking and faster switching capabilities, which enhance efficiency and performance. | |

| [130] | Presenting a switching loss model for silicon carbide (SiC) power MOSFETs, incorporating parasitic components to predict losses in high-frequency applications. The model validation accounts for the discharge and charge of the output capacitance. | |

| [131] | Studying and assessing the performance of an advanced neutral-point-clamped (ANPC) converter configuration comprising two SiC MOSFETs and four Si IGBTs per phase leg, focusing on high switching frequency operations. | |

| [132] | Investigating the integration of wide bandgap (WBG) devices into the DC/DC converters of EVs. A comprehensive model is developed to compare WBG-based converters with traditional silicon counterparts, highlighting performance improvements in EV applications. | |

| [133] | Examining the efficiency gains of integrating silicon carbide (SiC) MOSFETs into traction inverters for urban e-buses. Evaluates whether these efficiency improvements can offset the higher costs of SiC devices, providing insights into the economic viability of adopting SiC technology in e-transportation. According to the study, significant energy savings can be gained when the vehicle operates mostly in the partial load area. | |

| [134] | Carrying out a simulation and measurement-based analysis of efficiency improvements achieved by retrofitting a 400 V, 300 kW automotive traction inverter with SiC MOSFETs. The results refer to a considerable reduction in inverter power losses by approximately 50% compared to traditional silicon IGBT-based counterpart. | |

| [135] | Developing an analytical model to assess voltage distortions in SiC-MOSFET-based inverters for EVs, considering factors like voltage drops, dead time, and switching delays. Experimental results indicate that SiC-based systems exhibit lower voltage distortion and higher efficiency compared to traditional Si IGBT-based scheme. | |

| [136] | Performance assessment of GaN devices in an e-traction drive system for electric vehicles. The study demonstrates that GaN-based inverters enhance efficiency and dynamic response compared to traditional Si-based inverters. | |

| [137] | Holding comparison of power and energy losses in three-phase inverters using two SiC-MOSFET modules and one Si (Si-IGBT) module. It considers factors like blanking time and reverse conduction and thermal feedback drive cycles. | |

| [138] | Providing a comprehensive overview of applying finite element analysis (FEA) to the packaging of SiC power devices, addressing how (FEA) can be utilized to simulate and optimize the thermal, mechanical, and electrical performance of SiC power modules. |

| Main Area | Ref. | Core Contribution |

|---|---|---|

| System Design and Performance Improvement | [108] | Providing a comprehensive review of thermal design strategies for SiC power modules in EV motor drives. It emphasizes innovative heat sink optimization techniques and advanced simulation methods to enhance heat dissipation. |

| [112] | Developing a highly integrated dv/dt filter design for silicon carbide (SiC) inverters, combining inductors, capacitors, and damping resistors directly into the bus bars. This approach reduces filter size and weight while maintaining compliance with NEMA standards, providing efficient motor protection against high dv/dt transients and voltage overshoots. | |

| [113] | Holding comparison of 2L SiC MOSFET and 3L Si IGBT (NPC and T-NPC) inverters for high-speed drives with long cables. Evaluates efficiency, overvoltage, heat sink design, and cost under same conditions. Addresses the trade-offs between SiC’s high efficiency at low power and IGBT’s cost-effectiveness advantage. | |

| [116] | Design and implementation of a Si/SiC hybrid five-level active neutral point clamped inverter for electric aircraft propulsion. Combines low-frequency Si switches and high-frequency SiC devices. A high-performance hybrid modulation strategy is verified experimentally. | |

| [121] | Introducing a soft-switching voltage slew-rate profiling approach for SiC-based motor drives to mitigate motor overvoltage caused by the reflected wave phenomenon. By optimizing the rise/fall time of the output voltage to match the cable anti-resonance period, motor overvoltage is eliminated. | |

| [122] | Developing a multi-conductor transmission line model to identify significant stress near the neutral point. Help mitigate insulation failure by managing anti-resonance effects in motor designs. | |

| [123] | Providing design and implementation of a 500 kW air-cooled silicon carbide (SiC) three-phase inverter. Achieves a record-breaking power density of 1.246 MW/m³ and efficiency of 98.74%. | |

| [124] | Introducing a high-efficiency energy conversion system topology for 100 kW DC–DC power conversion using a 3.3 kV SiC device, achieving over 99.7% efficiency. | |

| [139] | Presenting a compact power module that combines Si IGBTs and SiC MOSFETs. The paper provides detailed gate driver designs and packaging solutions, offering guidelines for application-specific implementations. | |

| [140] | Addressing the challenge of motor overvoltage oscillations in silicon carbide (SiC)-based motor drives. A quasi-three-level PWM scheme is proposed. This technique allows voltage reflections along the cable to settle before the voltage reaches its final value, eliminating motor overvoltage oscillations in cable-fed drives. | |

| [141] | Proposing a cost-effective packaging methodology for high-power SiC intelligent power modules (IPMs) by repacking discrete SiC devices, aiming to meet the growing demand for high-current SiC power modules in EV applications. | |

| [142] | Introducing an optimized dead-time adjustment method for inverters utilizing an enhanced switching model of GaN-High Electron Mobility Transistors, reducing power losses and enhancing inverter efficiency. | |

| [143] | Presenting a SiC-based battery charger for plug-in EVs. The design attenuates the second order ripple power, enabling the use of smaller DC–link capacitors, reducing the system volume and cost. | |

| [144] | Investigating a design methodology for inverter-side resistor–inductor (RL) filters aimed at mitigating motor overvoltage in SiC-based drives. The employed approach effectively addresses issues arising from impedance mismatches between inverters and motors. | |

| [145] | Developing a 10 kV SiC-MOSFET power module. This configuration reduces parasitic inductances and capacitances, leading to a 53% increase in partial discharge inception voltage and a 90% reduction in common-mode current, enhancing high-voltage performance. | |

| [146] | Presenting a method to achieve zero switching loss in SiC MOSFETs by employing zero-voltage switching (ZVS), thereby minimizing thermal limitations, and enabling operation at higher switching frequencies. | |

| [147] | Designing a system-level tool that optimizes the power density of three-phase, two-level SiC-based inverters. The developed design tool predicts a 159% power density increase over Si-based inverters. | |

| [148] | Investigating the integration of (WBG) semiconductor devices, into renewable energy systems and smart grids. Some circuit design requirements to maximize the advantages of (WBG) have been addressed. Moreover, the merits such as efficiency and power density enhancement have been discussed as well. | |

| [149] | Addressing crosstalk and voltage oscillations in SiC MOSFET half-bridge converters by proposing a gate driver that generates a negative turn-off voltage without a negative power supply. Presents a simple snubber circuit to suppress the parasitic ringing. The findings confirm the effectiveness of the presented solutions to enhance the converter performance. | |

| [150] | Designing a high-power converter based on an SiC device, reducing conduction losses, and enhances efficiency, which is suitable for applications requiring compact and efficient power conversion solutions. | |

| [151] | Investigating a half-bridge gate driver circuit for SiC MOSFETs. The topology significantly reduces the total switching power losses by approximately 55% compared to conventional voltage source gate drivers, enhancing the converter efficiency. | |

| [152] | Introducing an inductor-less dv/dt filter for 100 kW to 1 MW voltage source converters using SiC devices. The design eliminates bulky filter inductors. | |

| [153] | Presenting a design methodology for dv/dt filters tailored to SiC-based inverters in high-frequency motor-drive systems. Thermal and electrical constraints have been addressed to mitigate insulation stress on motor stator windings caused by high slew rates in line voltages. | |

| [154] | Exploring the integration of WBG semiconductors, specifically into variable speed drive inverters. Introduces a soft-switching modulation scheme. The study also evaluates low-voltage GaN devices in multi-level inverter structures to enhance overall efficiency. | |

| [155] | Introducing a high-efficiency, high-power density On Board Chargers (OBCs) based on WBG devices. The design achieves reduced size, and lower electromagnetic interference (EMI), making it suitable for next-generation EV charging systems. | |

| [156] | Presenting high-performance GaN power transistors characterized by higher breakdown voltage and current density. The design improves the thermal performance and device scalability. Addresses the major limitations of GaN devices. | |

| [157] | Proposing a variable frequency control strategy and optimized filter design for SiC-based wind inverters. The approach maximizes energy extraction while minimizing switching losses. The method enhances the performance by dynamically adjusting the inverter’s operating frequency. | |

| [158] | Developing a reduced power losses inverter system using lower harmonic loss technology and ultra-compact inverters using SiC modules. The system reduces harmonic distortion, minimizes power losses, and permits higher power density. The weight of the developed SiC-based inverter has been reduced by 55% of a conventional IGBT inverter. | |

| [159] | Designing a current–source inverter (CSI)-integrated motor drive utilizing dual-gate four-quadrant (WBG) power switches. This design enables bidirectional power flow, reduced switching losses, and enhanced system efficiency. The approach offers a compact, high-performance solution for next-generation motor drive systems. |

| Main Area | Ref. | Core Contribution |

|---|---|---|

| Thermal Management and Cooling Systems | [160] | Developing a cost-effective, 3D-printed heatsink for rapid prototyping of WBG power converters. The design enables faster development cycles, reduces prototyping costs, and enhances thermal management in industrial and automotive applications. |

| [161] | Investigating a cooling system for automotive SiC power modules using a modular manifold with an embedded heat sink. This design improves thermal management, reduces system size, and enhances cooling efficiency. | |

| [162] | Proposing a cooling system for SiC traction inverters in EVs using heat pipes. This design enhances thermal dissipation, reduces temperature fluctuations, and improves inverter reliability and power density. | |

| [163] | Investigating cooling techniques and enclosure designs for integrated motor drives (IMDs). Evaluates various cooling methods, including liquid- and air-based systems, to optimize thermal management and enhance drive performance. | |

| [164] | Carrying out a thermal analysis of housing-cooled integrated motor drives (IMDs). The study examines the heat dissipation performance of housing-based cooling systems, highlighting design factors that improve thermal management. Their approach enables more compact, efficient, and reliable IMD designs. | |

| [165] | Developing a cooling design tool for EV SiC inverters using transient 3D-CFD simulations. The tool optimizes thermal performance by predicting heat dissipation and fluid flow dynamics. This approach enhances inverter cooling efficiency and reduces system size. | |

| [166] | Presenting a comprehensive review of cooling concepts and thermal management techniques for automotive WBG inverters. Categorizes cooling topologies, technologies, and integration strategies. | |

| [167] | Proposing a design methodology of air-cooled SiC inverters employed in EVs, optimizing thermal management, power density. The paper enables compact, efficient, and cost-effective SiC inverters. | |

| [168] | Presenting an optimal design of an integrated heat pipe air-cooled system for SiC MOSFET converters using the teaching–learning-based optimization algorithm. Their approach enhances thermal performance, minimizes cooling system size, and improves converter efficiency. | |

| [169] | Presenting an automated methodology for designing and optimizing air-cooled heatsinks for SiC power modules. Integrates genetic algorithms with finite element analysis. Complex heatsink geometries have been generated with this approach. The findings indicate that the size of the optimized heatsink is less than the conventional design approach by 27%; meanwhile, the resultant junction temperature is reduced by 6%. | |

| [170] | Introducing a thermal management design methodology for SiC power devices and systems using genetic optimization algorithms to achieve optimum geometries for liquid-cooled heat sink. This approach enables the creation of effective complex cooling structures for power electronic systems. | |

| [171] | Proposing a design optimization method for liquid-cooled heat sinks in WBG power modules, utilizing Fourier analysis and evolutionary multi-objective optimization. The developed heat sinks with this approach outperforms the conventional heat sinks shapes. | |

| [172] | Presenting a double-sided cooling method for discrete SiC MOSFETs using a press-pack package. This approach enhances thermal dissipation, enabling higher power density and reducing thermal stress. The design achieves improved heat distribution and increased device reliability. | |

| [173] | Investigating the performance of SiC and GaN devices under cryogenic cooling. The findings indicate that SiC MOSFETs have relatively greater on-state resistance and relatively slower switching speeds at low temperatures, while GaN devices demonstrate improved performance. | |

| [174] | Investigating a design of a power electronics package that integrates different materials. The design improves thermal cycling reliability of liquid-cooled aluminum SiC heat sinks. The proposed structure and layers minimize the coefficient of thermal expansion mismatch in the stack by 84%, extending the lifetime of the package and permits reduction in the volume and weight. | |

| [175] | Presenting thermal analysis and material selection methodology for SiC-based Intelligent Power Modules (IPMs). By evaluating various materials and their thermal properties, the study aims to enhance the thermal performance and reliability of SiC IPMs. | |

| [176] | Designing a thermally uniform heatsink for high-power SiC inverters employed in EVs. A novel heatsink geometry that improves cooling efficiency and thermal uniformity is presented. | |

| [177] | Investigating a thermal modeling and simulation method for optimizing power density in SiC-MOSFET inverters. The proposed approach allows for optimal placement and design of power modules, optimizing the volume and compactness of the SiC-MOSFET inverter. | |

| [178] | Proposing an optimal thermal design for SiC power modules. A double-sided cooling strategy to enhance heat dissipation and thermal uniformity is presented. Compact and reliable SiC-based power modules for high-voltage applications can be achieved. | |

| [179] | Introducing a liquid cooling method for SiC power modules. The proposed method is based on direct liquid contact with the surface of the power module, enhancing thermal dissipation and reducing thermal resistance. | |

| [180] | Presenting a passive cooling system for high-power SiC power electronic converters. The proposed heat sink enhances heat dissipation and thermal uniformity using phase-change heat transfer. The presented cooling system results in reduced thermal resistance, improving the cooling efficiency. | |

| [181] | Proposing cooling strategies and thermal management methods for WBG-based current–source inverters (CSIs) employed in motor drives. With the proposed approach, the system compactness is enhanced. | |

| [182] | Investigating a thermal design methodology for WBG inverters. An optimized cooling structure is proposed. The developed design improves heat dissipation and increases the reliability of WBG inverters. |

| Main Area | Ref. | Core Contribution |

|---|---|---|

| Key Challenges and Solutions | [183] | Presenting a review including key challenges and solutions for GaN power semiconductor modules. Advancements in GaN technology has been addressed. The paper discusses the main challenges such as parasitic effects, and thermal stress. Some proposed solutions have been addressed as well. |

| [184,185] | Providing a review on the key advancements, challenges, and future trends in WBG semiconductor technologies for modern automotive and renewable energy systems. Innovations in device design and fabrication technologies have been addressed. | |

| [186] | Highlighting the superior performance of WBG devices in power electronic converters. Presents some design methodologies and addresses key challenges like parasitic effects and thermal stress. | |

| [187] | Addressing advancements in WBG devices for the automotive industry. Items such as power density, efficiency, and thermal performance, have been discussed. Moreover, main challenges, including cost, reliability, and integration, are also presented. | |

| [188] | Discussing the main challenges that affect the reliability and performance of SiC and GaN power semiconductor devices. The article suggests a roadmap for enhancing the quality and reliability of WBG devices for next generation power electronic converters. | |

| [189] | Reviewing the reliability challenges and packaging of WBG devices. The article provides information about improving the devices’ lifespan and durability for various applications. | |

| [190] | Investigating the potential of WBG in power electronics. Highlights their superior efficiency, higher switching frequencies, and elevated temperature operation compared to silicon-based devices. Main challenges have been addressed as well. | |

| [191] | Providing a review of packaging technologies and challenges of SiC power modules, like high-speed switching, thermal management, high-temperature operation, and high-voltage isolation. Discusses emerging issues in soft-switching converters and low-temperature applications of SiC devices. | |

| [192] | Addressing switching oscillations in WBG semiconductor devices. Classifies oscillation types, analyzes their causes and effects. Suppression techniques have been presented to enhance the performance and reliability of WBG-based power electronic converters. | |

| [193] | Investigating the integration of CMOS logic with WBG and ultra-WBG semiconductors. The article identifies challenges such as material defects and fabrication complexities. Also presents directions and guidelines to overcome these challenges. | |

| [194] | Discussing the potential of WBG power semiconductor devices. Presents the International Technology Roadmap for WBG devices, highlighting the challenges and strategies for accelerating adoption and commercial acceptance of WBG-based devices and converters. | |

| [195] | Addressing advancements in WBG semiconductors. The paper outlines the programs of U.S. Department of Energy that have fostered the innovations through the value chain of power electronics. | |

| [196] | Presenting the major application of SiC power devices. The article addresses the main obstacles such as the crosstalk effects, current overshoot, and electromagnetic interference. Also presents the possible solutions to alleviate the adverse effects of such obstacles. | |

| [197] | Providing a review of employment of wide bandgap (WBG) power semiconductor modules in EVs. Main design aspects such as die parallelization and Direct Bonded Copper (DBC) routing have been discussed to enhance efficiency and performance of EV drives. | |

| [198] | Designing of 30 kVA three-phase SiC-MOSFETs inverter that can operate at ambient temperatures up to 180 °C. Key challenges of operation at such high-temperature have been addressed. The findings prove that SiC-based inverters are feasible in harsh environments. | |

| [199] | Investigating the obstacles that prevent widespread and adoption of WBG semiconductors in power electronics applications. The main challenges like material defects and high manufacturing costs have been discussed. Some solutions have been addressed to overcome such challenges. | |

| [200] | Discussing the application and advantages of SiC power devices. The paper discusses challenges and suggest solutions to enhance the performance of SiC devices. | |

| [201] | Providing a comprehensive review of methods for suppressing conductive common-mode electromagnetic interference in inverter-fed motor drives. The paper also discusses the impact of emerging WBG devices on EMI. | |

| [202] | Designing an inverter for EV based on double-sided cooled SiC power modules. This method enhances thermal management and increases the power densities, thereby contributing higher reliability and compactness of the inverter. | |

| [203] | Addressing the characteristics and commercial status of GaN power devices, highlighting their potential for higher frequency and efficiency in power electronic converters compared to conventional Si devices. Also discusses some challenges such as gate driver design, unique reverse conduction behavior, and breakdown mechanisms of the device. |

4. Main Control Techniques of IM Drives

4.1. Introduction

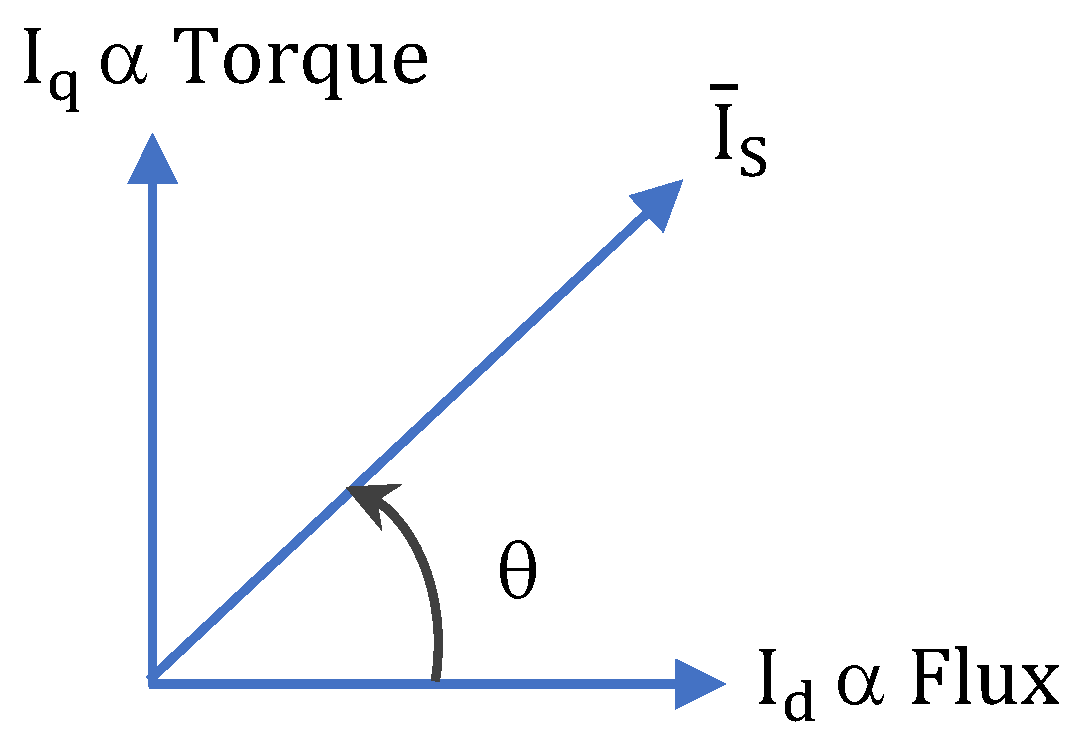

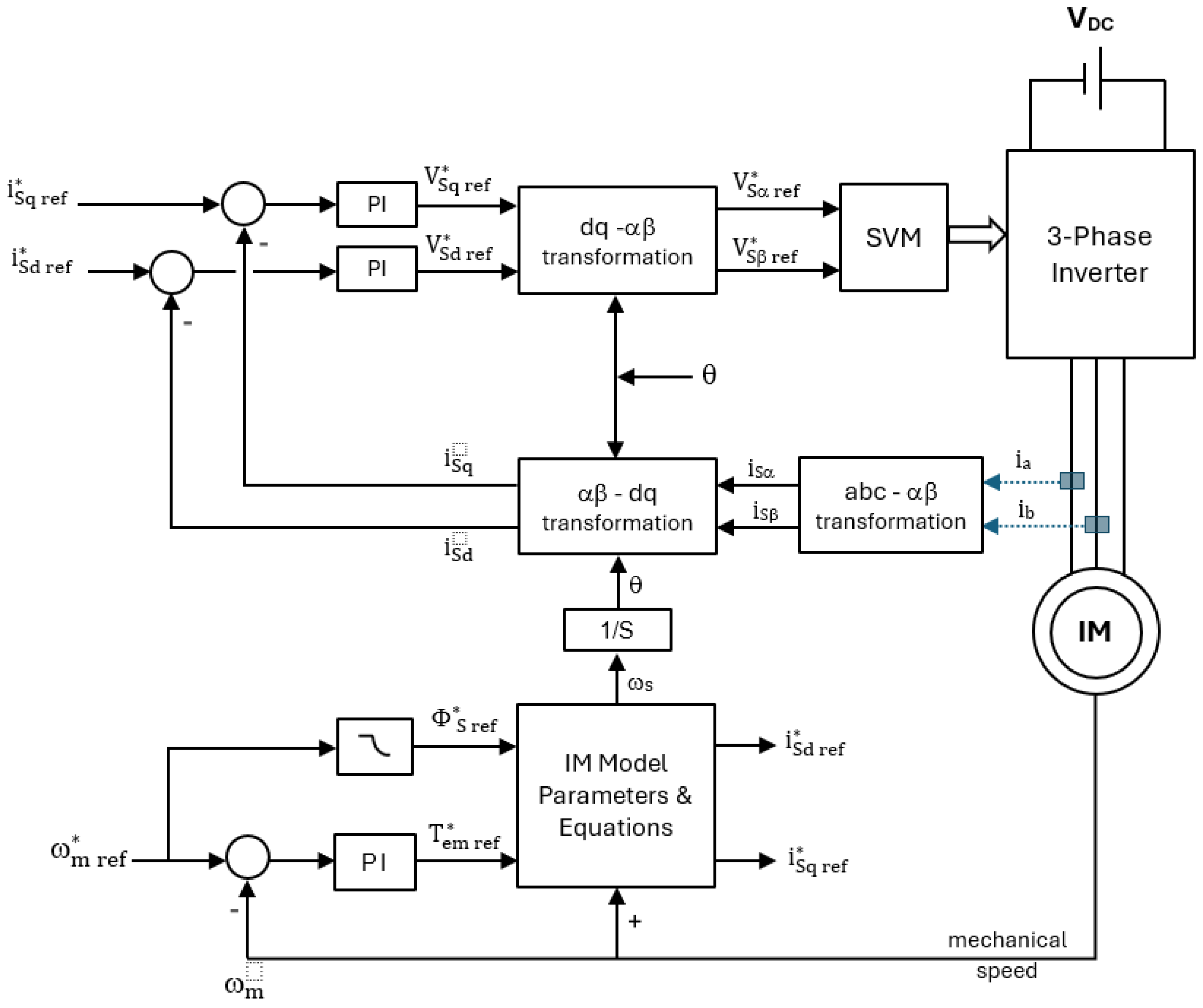

4.2. Field-Oriented Control

- 1.

- The stator flux linkage is typically aligned along the d-axis, and the q-axis flux component is zero. Accordingly: ; ;

- 2.

- The reference stator current in the d-axis is directly related to the stator flux linkage;

- 3.

- The rotor is short circuited, where: .

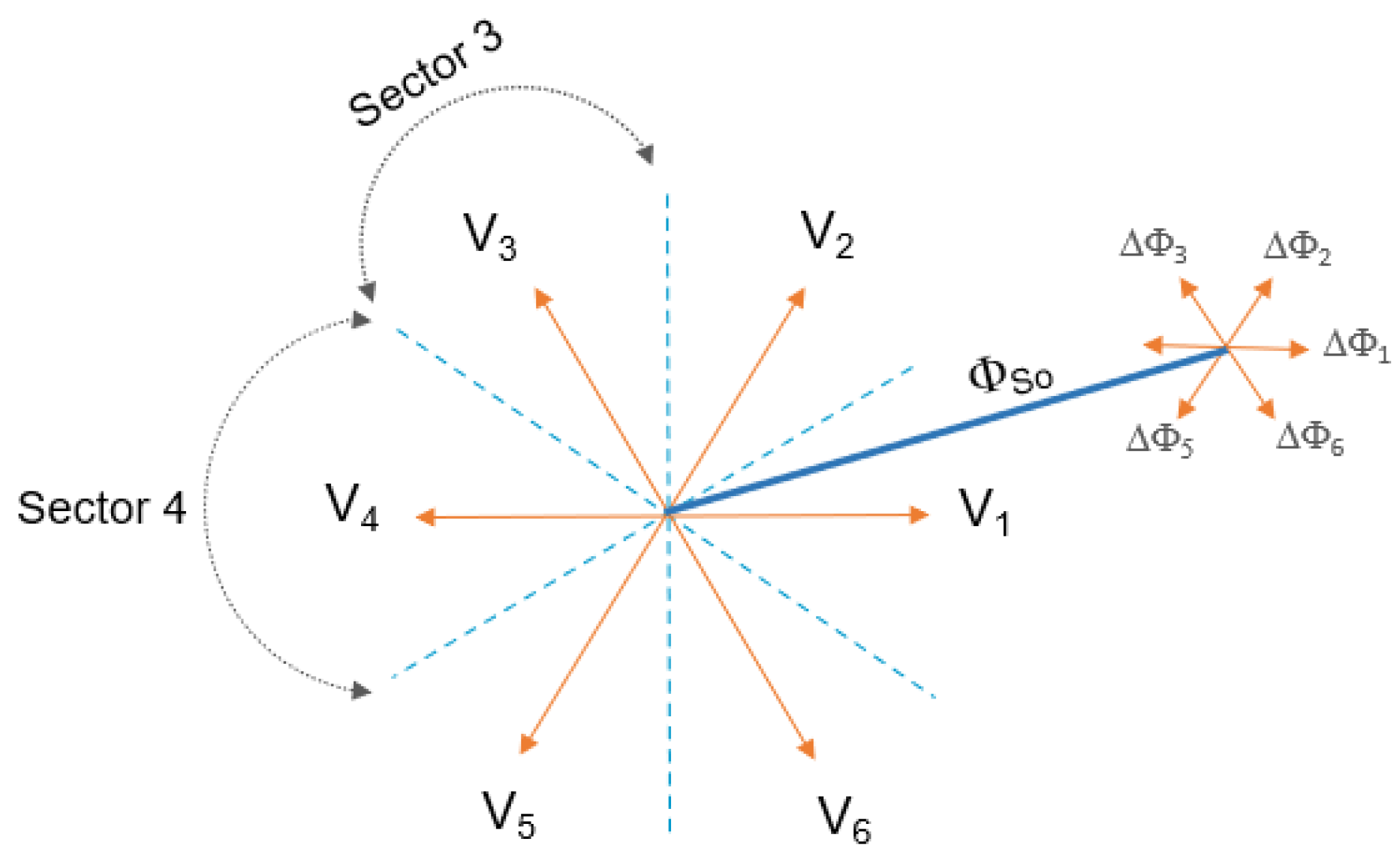

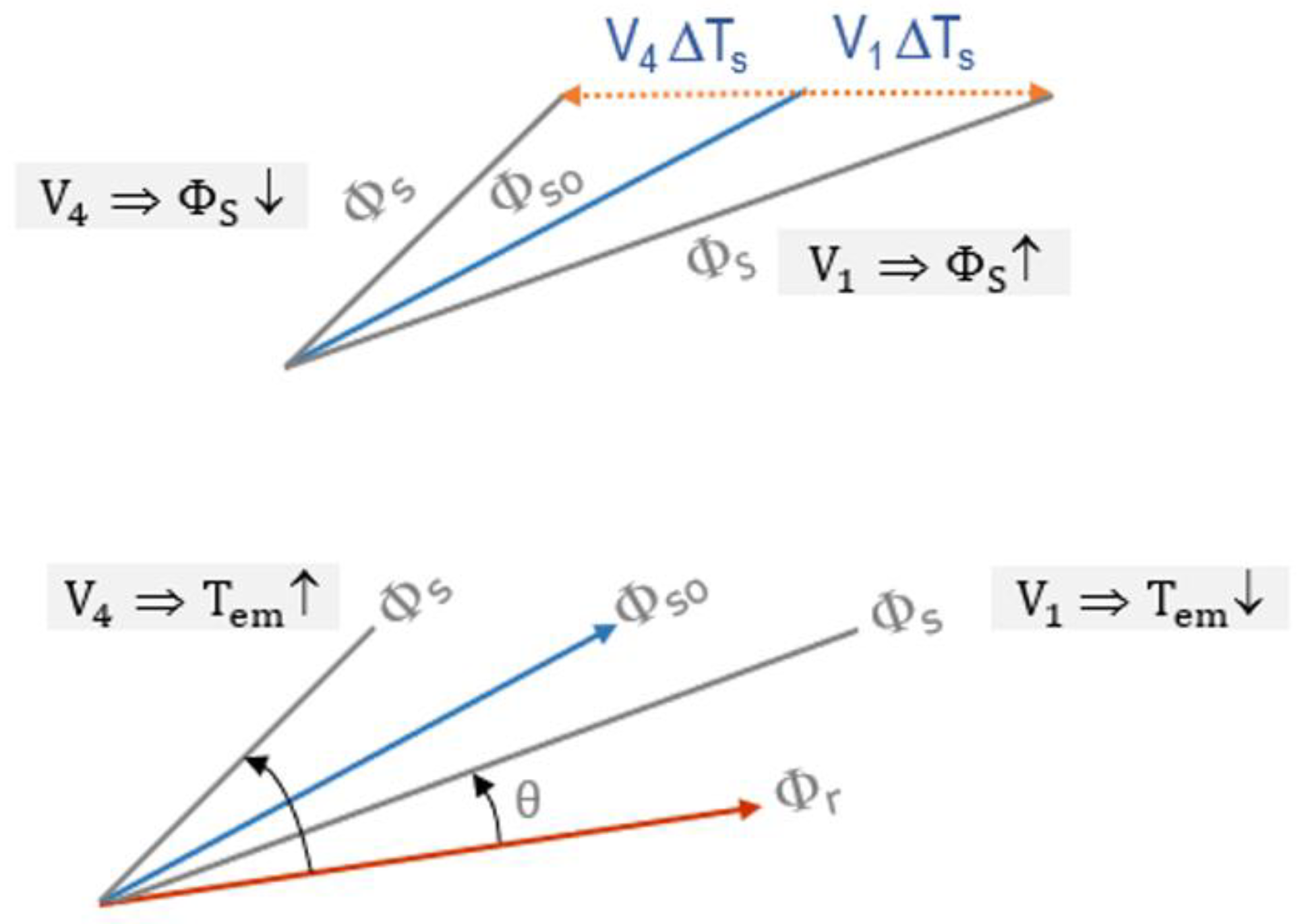

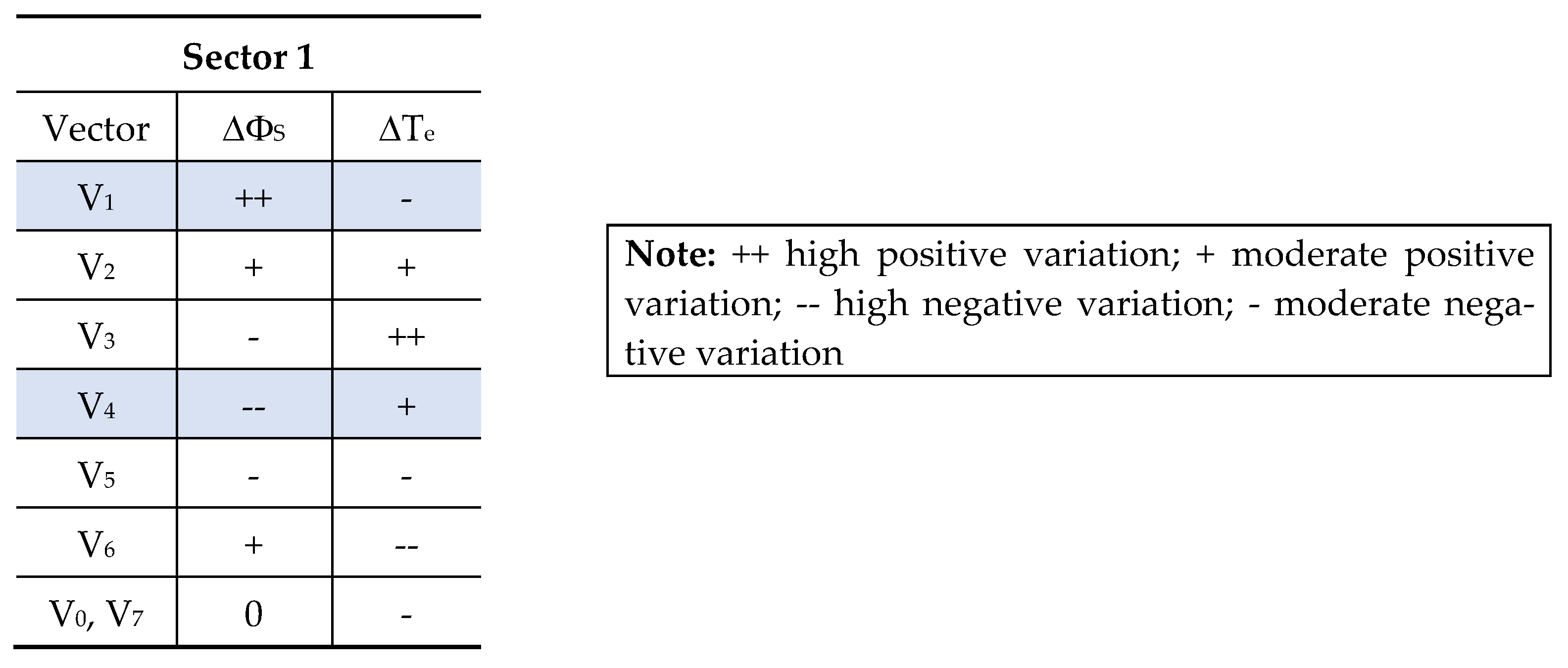

4.3. Direct Torque Control

- Motor transient model to calculate the instantaneous value of the stator flux vector and electromagnetic torque.

- Two hysteresis ON/OFF controllers: one for the stator flux and the other for the torque.

- Optimum switching table whose output is the instantaneous values of the inverter switching state, such that the flux and torque track the set points (reference values).

4.4. Model Predictive Control

- Speed control loop and reference signals generation of torque and flux. The output of the PI speed controller represents the desired electromagnetic torque, while the reference stator flux is kept constant at the rated value for the entire range of speed from zero to the rated value. Above the rated value, the flux is reduced inversely to verify field weakening mode.

- Computation of stator currents and stator voltages components in the (α–β) stationary reference frame.

- FCS-MPC algorithm, which is composed of several blocks and functions, such as prediction of stator currents and stator flux components in the stationary reference frame (α–β) one sample ahead, and prediction of electromagnetic torque one sample ahead as well. Finally, in FCS-MPC, the customized cost function is calculated and checked for all inverter switching states. Then, the optimum inverter switching state that instantaneously provide minimum cost function is chosen and applied to the IM.

4.5. Regenerative Braking and Energy Saving

5. Manufacturers of Industrial IM Drives

6. Modern Applications of IM Drives

- Industrial automation and robotics arms;

- Electric vehicles, trucks, and buses;

- High-speed electric trains;

- Energy saving HVAC systems and inverter-based home air conditions;

- Drilling rigs in oil and gas industry;

- Flywheel energy storage systems;

- Electric propulsion systems in marine applications;

- Multi-motor conveyor systems;

- Hoist and crane control to achieve a safe and high-performance operation in terms of anti-sway, including the possibility of regenerative braking to provide quick stopping.

7. Conclusions

- Development and adoption of high-efficiency AC drives, especially IM drives, is an important opportunity in the modern industry to reduce energy consumption in different sectors, in accordance with energy efficiency standards and restrictions.

- Design and implementation of high-efficiency and premium-efficiency IMs have commercial acceptance, as many manufacturers fabricate considerable products covering a wide power range serving multiple applications.

- Design of high-efficiency IMs using evolutionary optimization techniques and modern analysis tools such as finite element design has received great interest from academia and industry.

- Many recent research papers are interested in studying and investigating thermal equivalent circuits of IMs to optimize and enhance motor cooling system and increase their efficiency.

- WBG power semiconductor devices are gradually being incorporated into the development of commercial IM drives due to salient advantages; e.g., SiC devices are suitable for high power applications, while GaN is convenient for low voltage/low power application/very high frequency applications.

- Some fabrication challenges of WBG power devices still exist; however, considerable research efforts are tackling these obstacles and finding solutions to most of them. Thus, the prices of WBG devices are decreasing with the time to get commercial acceptance.

- The industrial IM drives still depend on scalar control techniques for general purpose application. Meanwhile, vector control IM drives are used when high-performance drives are required.

- Until now, few industrial drive manufacturers have adopted or fabricated DTC-based drives since the development of the first drive by ABB in 1996.

- MPC have not received commercial or industrial acceptance until recently. However, considerable research papers have adopted and recommended the utilization of FCS-MPC in high-performance IM drives.

- Modern IM drives have the option of regenerative braking to provide quick stopping and motor braking. Moreover, regenerative braking participates in a reduction in the overall energy consumption of AC drives. In EVs and electric transportation systems, regenerative braking extends the distance range of the vehicle battery by trickle charging during EV speed reductions and stopping.

Funding

Conflicts of Interest

Abbreviations

| ASIC | Application specific integrated circuit |

| BLDC | Brushless DC motor |

| CAGR | Compound annual growth rate |

| CCW | Counterclockwise |

| CW | Clockwise |

| DAQ | Data acquisition system |

| DSP | Digital signal processor |

| DTC | Direct torque control |

| ED | Electric drives |

| EDS | Electric drive system |

| EMC | Electromagnetic compatibility |

| EMI | Electromagnetic interference |

| EV | Electric vehicle |

| FCS-MPC | Finite control set model predictive control |

| FO | Field orientation |

| FOC | Field-oriented control |

| FPGA | Field programmable gate array |

| GaN | Gallium nitride |

| HIL | Hardware in the loop |

| IM | Induction motor |

| MPC | Model predictive control |

| PM | Permanent magnet |

| PWM | Pulse width modulation |

| PE | Power electronics |

| RISC | Reduced instruction set computer |

| SC | Scalar control |

| SDGs | Sustainable development goals |

| SRM | Switched reluctance motor |

| SVM | Space vector modulation |

| SiC | Silicon carbide |

| SRM | Switched reluctance motor |

| THD | Total harmonic distortion |

| WBG | Wide bandgap |

| UN | United nations |

| VC | Vector control |

| VSI | Voltage source inverter |

Appendix A

Appendix A.1. Sustainable Development Goals of the United Nations

Appendix A.2. Summary of Sustainable Development Goals of the United Nations

- No Poverty.

- Zero Hunger.

- Good Health and Well-Being.

- Quality Education.

- Gender Equality.

- Clean Water and Sanitation.

- Affordable and Clean Energy.

- Decent Work and Economic Growth.

- Industry, Innovation and Infrastructure.

- Reduce Inequality.

- Sustainable Cities and Communities.

- Responsible Consumption and Production.

- Climate Action.

- Life Below Water.

- Life on Land.

- Peace, Justice and Strong Institutions.

- Partnerships for the Goals

References

- Electric Drives Market Analysis Report. Available online: https://www.mordorintelligence.com/industry-reports/electric-drives-market (accessed on 15 December 2024).

- Global AC Drives Industry Research Report. Growth Trends and Competitive Analysis 2022–2028. Available online: https://www.360researchreports.com/global-ac-drives-industry-21727719 (accessed on 15 December 2024).

- UN-SDGs. Report 2024. Available online: https://unstats.un.org/sdgs/files/report/2024/SG-SDG-Progress-Report-2024-advanced-unedited-version.pdf (accessed on 15 December 2024).

- UN-SDGs. Report 2023. Available online: https://unstats.un.org/sdgs/report/2023/The-Sustainable-Development-Goals-Report-2023.pdf (accessed on 15 December 2024).

- Zhao, J.; Xi, X.; Na, Q.; Wang, S.; Kadry, S.N.; Kumar, P.M. The technological innovation of hybrid and plug-in electric vehicles for environment carbon pollution control. Environ. Impact Assess. Rev. 2021, 86, 106506. [Google Scholar] [CrossRef]

- Fuinhas, J.A.; Koengkan, M.; Leitão, N.C.; Nwani, C.; Uzuner, G.; Dehdar, F.; Relva, S.; Peyerl, D. Effect of Battery Electric Vehicles on Greenhouse Gas Emissions in 29 European Union Countries. Sustainability 2021, 13, 13611. [Google Scholar] [CrossRef]

- Azab, M. Low-Cost DTC Drive Using Four-Switch Inverter for Low Power Ranges. Vehicles 2024, 6, 895–919. [Google Scholar] [CrossRef]

- Parv, A.L.; Daicu, R.; Dragoi, M.V.; Rusu, M.; Oancea, G. A Method to Design Assembling Lines for Super Premium Efficiency Motors. Processes 2023, 11, 215. [Google Scholar] [CrossRef]

- Dems, M.; Komeza, K. Designing an Energy-Saving Induction Motor Operating in a Wide Frequency Range. IEEE Trans. Ind. Electron. 2022, 69, 4387–4397. [Google Scholar] [CrossRef]

- Chen, Z.; Huang, A.Q. Extreme high efficiency enabled by silicon carbide (SiC) power devices. Mater. Sci. Semicond. Process. 2024, 172, 108052. [Google Scholar] [CrossRef]

- Xu, Y.; Yuan, X.; Ye, F.; Wang, Z.; Zhang, Y.; Diab, M.; Zhou, W. Impact of High Switching Speed and High Switching Frequency of Wide-Bandgap Motor Drives on Electric Machines. IEEE Access 2021, 9, 82866–82880. [Google Scholar] [CrossRef]

- Takahashi, I.; Noguchi, T. A new quick-response and high-efficiency control strategy of an induction motor. IEEE Trans. Indus. App. 1986, 22, 820–827. [Google Scholar] [CrossRef]

- Mirzaeva, G.; Mo, Y. Model Predictive Control for Industrial Drive Applications. IEEE Trans. Ind. Appl. 2023, 59, 7897–7907. [Google Scholar] [CrossRef]

- Karatzaferis, I.; Tatakis, E.C.; Papanikolaou, N. Investigation of Energy Savings on Industrial Motor Drives Using Bidirectional Converters. IEEE Access 2017, 5, 17952–17961. [Google Scholar] [CrossRef]

- Farhani, F.; Zaafouri, A.; Chaari, A. Real time induction motor efficiency optimization. J. Frankl. Inst. 2017, 354, 3289–3304. [Google Scholar] [CrossRef]

- Available online: https://www.ti.com/lit/pdf/sprabq0 (accessed on 15 December 2024).

- Available online: https://www.typhoon-hil.com/solutions/power-electronics/electric-motor-drives/ (accessed on 15 December 2024).

- Wu, Z.; Xie, B.; Li, Z.; Mitsuoka, M.; Inoue, E.; Okayasu, T.; Hirai, Y. DSPACE based Hardware in the loop Testing Platform for Powertrain Management Unit of Electric Tractor. J. Fac. Agric. Kyushu Univ. 2019, 64, 309–317. [Google Scholar] [CrossRef]

- Kim, H.-J.; Lee, C.-S. Shape Parameters Design for Improving Energy Efficiency of IPM Traction Motor for EV. IEEE Trans. Veh. Technol. 2021, 70, 6662–6673. [Google Scholar] [CrossRef]

- Lu, S.-M. A review of high-efficiency motors: Specification, policy, and technology. Renew. Sustain. Energy Rev. 2016, 59, 1–12. [Google Scholar] [CrossRef]

- Nardo, M.D.; Marfoli, A.; Degano, M.; Gerada, C. Rotor Slot Design of Squirrel Cage Induction Motors with Improved Rated Efficiency and Starting Capability. IEEE Trans. Ind. Appl. 2022, 58, 3383–3393. [Google Scholar] [CrossRef]

- Marfoli, A.; Nardo, M.D.; Degano, M.; Gerada, C.; Chen, W. Rotor Design Optimization of Squirrel Cage Induction Motor-Part I: Problem Statement. IEEE Trans. Energy Convers. 2021, 36, 1271–1279. [Google Scholar] [CrossRef]

- Zhang, J.; Cui, R.; Wei, Y.; Yu, D.; Xie, S.; Fang, S.; Shen, J. Optimization and Experimental Validation of Amorphous Alloy High-Speed Asynchronous Motor for Simultaneous Reduction on Core and Copper Losses. IEEE Access 2023, 11, 101112–101122. [Google Scholar] [CrossRef]

- Popescu, M.; Di Leonardo, L.; Fabri, G.; Volpe, G.; Riviere, N.; Villani, M. Design of Induction Motors with Flat Wires and Copper Rotor for E-Vehicles Traction System. IEEE Trans. Ind. Appl. 2023, 59, 3889–3900. [Google Scholar] [CrossRef]

- Mei, J.; Lee, C.H.T.; Kirtley, J.L. Design of Axial Flux Induction Motor with Reduced Back Iron for Electric Vehicles. IEEE Trans. Veh. Technol. 2020, 69, 293–301. [Google Scholar] [CrossRef]

- Tran, T.-V.; Nègre, E.; Mikati, K.; Pellerey, P.; Assaad, B. Optimal Design of TEFC Induction Machine and Experimental Prototype Testing for City Battery Electric Vehicle. IEEE Trans. Ind. Appl. 2020, 56, 635–643. [Google Scholar] [CrossRef]

- Ion, C.P.; Peter, I. Manufacturing of induction motors with Super Premium Efficiency. In Proceedings of the 2022 International Conference and Exposition on Electrical and Power Engineering (EPE), Iasi, Romania, 20–22 October 2022; pp. 47–50. [Google Scholar] [CrossRef]

- Kim, M.-S.; Park, J.-H.; Lee, K.-S.; Lee, S.-H.; Choi, J.-Y. Performance Characteristics of the Rotor Conductor of an IE4 Class Induction Motor with Varying Al-Cu Ratio. IEEE Trans. Magn. 2022, 58, 1–6. [Google Scholar] [CrossRef]

- Gundogdu, T.; Suli, S. Role of End-Ring Configuration in Shaping IE4 Induction Motor Performance. CES Trans. Electr. Mach. Syst. 2024, 8, 245–254. [Google Scholar] [CrossRef]

- Aishwarya, M.; Brisilla, R.M. Design of Energy-Efficient Induction motor using ANSYS software. Results Eng. 2022, 16, 100616. [Google Scholar] [CrossRef]

- Alberti, L.; Troncon, D. Design of Electric Motors and Power Drive Systems According to Efficiency Standards. IEEE Trans. Ind. Electron. 2021, 68, 9287–9296. [Google Scholar] [CrossRef]

- Marfoli, A.; DiNardo, M.; Degano, M.; Gerada, C.; Jara, W. Squirrel Cage Induction Motor: A Design-Based Comparison between Aluminium and Copper Cages. IEEE Open J. Ind. Appl. 2021, 2, 110–120. [Google Scholar] [CrossRef]

- Cavagnino, A.; Vaschetto, S.; Ferraris, L.; Gmyrek, Z.; Agamloh, E.B.; Bramerdorfer, G. Striving for the Highest Efficiency Class with Minimal Impact for Induction Motor Manufacturers. IEEE Trans. Ind. Appl. 2020, 56, 194–204. [Google Scholar] [CrossRef]

- Usha, S.; Subramani, C.; Raman, A.; Bhaduri, M.; Doss, M.A.N.; Puri, R. Efficiency Improvement of Induction Motor Through Altered Design. Int. J. Recent Technol. Eng. 2019, 8, 3429–3435. [Google Scholar]

- Khan, K.; Shukla, S.; Sing, B. Design and Development of High Efficiency Induction Motor for PV Array Fed Water Pumping. In Proceedings of the 2018 IEEE International Conference on Power Electronics, Drives and Energy Systems (PEDES), Chennai, India, 18–21 December 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Tig, I.; Imeryuz, M.; Akcomak, M.; Polat, A. Design of High Efficient 1.1 kW 8 Pole Induction Motor for Industrial Application. In Proceedings of the 2023 14th International Conference on Electrical and Electronics Engineering (ELECO), Bursa, Türkiye, 30 November–2 December 2023; pp. 1–5. [Google Scholar] [CrossRef]

- Asgharpour-Alamdari, H.; Alinejad-Beromi, Y.; Yaghobi, H. Improvement of induction motor operation using a new winding scheme for reduction of the magnetomotive force distortion. IET Electr. Power Appl. 2018, 12, 323–331. [Google Scholar] [CrossRef]

- Kim, H.M.; Lee, K.W.; Kim, D.G.; Park, J.H.; Park, G.S. Design of Cryogenic Induction Motor Submerged in Liquefied Natural Gas. IEEE Trans. Magn. 2018, 54, 1–4. [Google Scholar] [CrossRef]

- Verucchi, C.; Ruschetti, C.; Giraldo, E.; Bossio, G.; Bossio, J. Efficiency optimization in small induction motors using magnetic slot wedges. Electr. Power Syst. Res. 2017, 152, 1–8. [Google Scholar] [CrossRef]

- Shao, L.; Karci, A.E.H.; Tavernini, D.; Sorniotti, A.; Cheng, M. Design Approaches and Control Strategies for Energy-Efficient Electric Machines for Electric Vehicles—A Review. IEEE Access 2020, 8, 116900–116913. [Google Scholar] [CrossRef]

- Dems, M.; Komeza, K.; Szulakowski, J.; Kubiak, W. Increase the Efficiency of an Induction Motor Feed from Inverter for Low Frequencies by Combining Design and Control Improvements. Energies 2022, 15, 530. [Google Scholar] [CrossRef]

- Sharma, U.; Singh, B. Design and Development of Energy Efficient Single Phase Induction Motor for Ceiling Fan Using Taguchi’s Orthogonal Arrays. IEEE Trans. Ind. Appl. 2021, 57, 3562–3572. [Google Scholar] [CrossRef]

- Zhao, N.; Schofield, N. An Induction Machine Design with Parameter Optimization for a 120-kW Electric Vehicle. IEEE Trans. Transp. Electrif. 2020, 6, 592–601. [Google Scholar] [CrossRef]

- Silva, A.M.; Ferreira, F.J.T.E.; Cistelecan, M.V.; Antunes, C.H. Multiobjective Design Optimization of Generalized Multilayer Multiphase AC Winding. IEEE Trans. Energy Convers. 2019, 34, 2158–2167. [Google Scholar] [CrossRef]

- Aishwarya, M.; Brisilla, R.M. Design and Fault Diagnosis of Induction Motor Using ML-Based Algorithms for EV Application. IEEE Access 2023, 11, 34186–34197. [Google Scholar] [CrossRef]

- Xu, W.; Xiao, X.; Du, G.; Hu, D.; Zou, J. Comprehensive Efficiency Optimization of Linear Induction Motors for Urban Transit. IEEE Trans. Veh. Technol. 2020, 69, 131–139. [Google Scholar] [CrossRef]

- Mahmouditabar, F.; Baker, N.J. Design Optimization of Induction Motors with Different Stator Slot Rotor Bar Combinations Considering Drive Cycle. Energies 2023, 17, 154. [Google Scholar] [CrossRef]

- Lei, A.; Song, C.-X.; Lei, Y.-L.; Fu, Y. Design optimization of vehicle asynchronous motors based on fractional harmonic response analysis. Mech. Sci. 2021, 12, 689–700. [Google Scholar] [CrossRef]

- Bortoni, E.C.; Bernardes, J.V.; da Silva, P.V.; Faria, V.A.; Vieira, P.A. Evaluation of manufacturers strategies to obtain high-efficient induction motors. Sustain. Energy Technol. Assess. 2019, 31, 221–227. [Google Scholar] [CrossRef]

- Kabir, M.A.; Jaffar, M.Z.M.; Wan, Z.; Husain, I. Design, Optimization, and Experimental Evaluation of Multilayer AC Winding for Induction Machine. IEEE Trans. Ind. Appl. 2019, 55, 3630–3639. [Google Scholar] [CrossRef]

- Bianchini, C.; Vogni, M.; Torreggiani, A.; Nuzzo, S.; Barater, D.; Franceschini, G. Slot Design Optimization for Copper Losses Reduction in Electric Machines for High Speed Applications. Appl. Sci. 2020, 10, 7425. [Google Scholar] [CrossRef]

- Akhtar, M.J.; Behera, R.K. Optimal design of stator and rotor slot of induction motor for electric vehicle applications. IET Electr. Syst. Transp. 2019, 9, 35–43. [Google Scholar] [CrossRef]

- Mallik, S.; Mallik, K.; Barman, A.; Maiti, D.; Biswas, S.K.; Deb, N.K.; Basu, S. Efficiency and Cost Optimized Design of an Induction Motor Using Genetic Algorithm. IEEE Trans. Ind. Electron. 2017, 64, 9854–9863. [Google Scholar] [CrossRef]

- Kim, M.-S.; Kim, C.-E. Multi-Objective Optimum Design of Premium High Efficiency Induction Motor Using Parameter Learning. Trans. Korean Inst. Electr. Eng. KIEE 2021, 70, 991–998. [Google Scholar] [CrossRef]

- Laouar, I.; Boukadoum, A. Design Optimization of a Three-Phase Squirrel-Cage Induction Motor by Algorithm Harmony Search. In Proceedings of the 2022 IEEE International Conference on Electrical Sciences and Technologies in Maghreb (CISTEM), Tunis, Tunisia, 26–28 October 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Srimathi, R.; Ponmurugan, P.; Iqbal, A.; Kamatchi, K.V.; Lakshmanan, M.; Nadin, E.S. A More Efficient Induction Machine based on Hill Climbing Local Search Optimization. In Proceedings of the 2022 International Virtual Conference on Power Engineering Computing and Control: Developments in Electric Vehicles and Energy Sector for Sustainable Future (PECCON), Chennai, India, 5–6 May 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Bian, Y.; Yang, Z.; Sun, X.; Wang, X. Speed Sensorless Control of a Bearingless Induction Motor Based on Modified Robust Kalman Filter. J. Electr. Eng. Technol. 2024, 19, 1179–1190. [Google Scholar] [CrossRef]

- Su, Y.; Yang, Z.; Sun, X.; Shen, Z. Direct torque control of bearingless induction motor based on super-twisting sliding mode control. J. Control. Decis. 2024, 1–11. [Google Scholar] [CrossRef]

- Ye, X.; Tang, X.; Xing, K.; Wang, H.; Yao, J.; Zhang, T. Repetitive Control for Vibration Suppression of Bearingless Induction Motor. IEEE Access 2024, 12, 60532–60540. [Google Scholar] [CrossRef]

- Su, Y.; Yang, Z.; Sun, X.; Ding, Q. Backstepping control of a bearingless induction motor based on a linear extended state observer. Electr Eng 2023, 105, 4569–4579. [Google Scholar] [CrossRef]

- Yang, Z.; Jia, J.; Sun, X.; Xu, T. A Fuzzy-ELADRC Method for a Bearingless Induction Motor. IEEE Trans. Power Electron. 2022, 37, 11803–11813. [Google Scholar] [CrossRef]

- Chen, J.; Fujii, Y.; Johnson, M.W.; Farhan, A.; Severson, E.L. Optimal Design of the Bearingless Induction Motor. IEEE Trans. Ind. Appl. 2021, 57, 1375–1388. [Google Scholar] [CrossRef]

- Chen, J.; Severson, E.L. Design and Modeling of the Bearingless Induction Motor. In Proceedings of the 2019 IEEE International Electric Machines & Drives Conference (IEMDC), San Diego, CA, USA, 12–15 May 2019; pp. 343–350. [Google Scholar] [CrossRef]

- Sinervo, A.; Arkkio, A. Rotor Radial Position Control and its Effect on the Total Efficiency of a Bearingless Induction Motor with a Cage Rotor. IEEE Trans. Magn. 2014, 50, 1–9. [Google Scholar] [CrossRef]

- Chen, J.; Zhu, J.; Severson, E.L. Review of Bearingless Motor Technology for Significant Power Applications. IEEE Trans. Ind. Appl. 2020, 56, 1377–1388. [Google Scholar] [CrossRef]

- Severson, E.L.; Nilssen, R.; Undeland, T.; Mohan, N. Design of Dual Purpose No-Voltage Combined Windings for Bearingless Motors. IEEE Trans. Ind. Appl. 2017, 53, 4368–4379. [Google Scholar] [CrossRef]

- Chen, J.; Johnson, M.W.; Farhan, A.; Wang, Z.; Fujii, Y.; Severson, E.L. Reduced Axial Length Pole-Specific Rotor for Bearingless Induction Machines. IEEE Trans. Energy Convers. 2022, 37, 2285–2297. [Google Scholar] [CrossRef]

- Yang, Z.; Ding, Q.; Sun, X.; Lu, C. Design and Analysis of a Three-Speed Wound Bearingless Induction Motor. IEEE Trans. Ind. Electron. 2022, 69, 12529–12539. [Google Scholar] [CrossRef]

- Fang, W.; Yang, Z.; Sun, X.; Wang, G.; Xu, T. Speed Sensorless Control of Bearingless Induction Motors Based on Adaptive Flux Observer. J. Electr. Eng. Technol. 2022, 17, 1803–1813. [Google Scholar] [CrossRef]

- Carvalho Souza, F.E.; Silva, W.; Ortiz Salazar, A.; Paiva, J.; Moura, D.; Villarreal, E.R.L. A Novel Driving Scheme for Three-Phase Bearingless Induction Machine with Split Winding. Energies 2021, 14, 4930. [Google Scholar] [CrossRef]

- Ye, X.; Yang, Z. Development of bearingless induction motors and key technologies. IEEE Access 2019, 7, 121055–121066. [Google Scholar] [CrossRef]

- Lu, J.; Yang, Z.; Sun, X.; Bao, C.; Chen, X. Direct Levitation Force Control for a Bearingless Induction Motor Based on Model Prediction. IEEE Access 2019, 7, 65368–65378. [Google Scholar] [CrossRef]

- Chen, J.; Severson, E.L. Optimal Design of the Bearingless Induction Motor for Industrial Applications. In Proceedings of the 2019 IEEE Energy Conversion Congress and Exposition (ECCE), Baltimore, MD, USA, 29 September–3 October 2019; pp. 5265–5272. [Google Scholar] [CrossRef]

- Nunes, E.A.D.F.; Salazar, A.O.; Villarreal, E.R.L.; Souza, F.E.C.; Dos Santos Júnior, L.P.; Lopes, J.S.B.; Luque, J.C.C. Proposal of a fuzzy controller for radial position in a bearingless induction motor. IEEE Access 2019, 7, 114808–114816. [Google Scholar] [CrossRef]

- Asama, J.; Oi, T.; Oiwa, T.; Chiba, A. Simple Driving Method for a 2-DOF Controlled Bearingless Motor Using One Three-Phase Inverter. IEEE Trans. Ind. Appl. 2018, 54, 4365–4376. [Google Scholar] [CrossRef]

- Yang, Z.; Chen, L.; Sun, X.; Sun, W.; Zhang, D. A Bearingless Induction Motor Direct Torque Control and Suspension Force Control Based on Sliding Mode Variable Structure. Math. Probl. Eng. 2017, 2409179, 11. [Google Scholar] [CrossRef]

- Han, P.-W.; Seo, U.-J.; Paul, S.; Chang, J. Computationally Efficient Stator AC Winding Loss Analysis Model for Traction Motors Used in High-Speed Railway Electric Multiple Unit. IEEE Access 2022, 10, 28725–28738. [Google Scholar] [CrossRef]

- Tabora, J.M.; Tostes, M.E.D.L.; Bezerra, U.H.; De Matos, E.O.; Filho, C.L.P.; Soares, T.M.; Rodrigues, C.E.M. Assessing Energy Efficiency and Power Quality Impacts Due to High-Efficiency Motors Operating Under Nonideal Energy Supply. IEEE Access 2021, 9, 121871–121882. [Google Scholar] [CrossRef]

- Gómez, J.R.; Sousa, V.; Eras, J.J.C.; Gutiérrez, A.S.; Viego, P.R.; Quispe, E.C.; de León, G. Assessment criteria of the feasibility of replacement standard efficiency electric motors with high-efficiency motors. Energy 2022, 239, 121877. [Google Scholar] [CrossRef]

- Yang, Z.; Sun, C.; Sun, X.; Sun, Y. An improved dynamic model for bearingless induction motor considering rotor eccentricity and load change. IEEE Trans. Ind. Electron. 2021, 69, 3439–3448. [Google Scholar] [CrossRef]

- Mei, J.; Zuo, Y.; Lee, C.H.T.; Kirtley, J.L. Modeling and Optimizing Method for Axial Flux Induction Motor of Electric Vehicles. IEEE Trans. Veh. Technol. 2020, 69, 12822–12831. [Google Scholar] [CrossRef]

- Ali, M.Z.; Shabbir, M.N.S.K.; Liang, X.; Zhang, Y.; Hu, T. Machine learning-based fault diagnosis for single- and multi-faults in induction motors using measured stator currents and vibration signals. IEEE Trans. Ind. Appl. 2019, 55, 2378–2391. [Google Scholar] [CrossRef]

- Wang, K.; Huai, R.; Yu, Z.; Zhang, X.; Li, F.; Zhang, L. Comparison Study of Induction Motor Models Considering Iron Loss for Electric Drives. Energies 2019, 12, 503. [Google Scholar] [CrossRef]

- Liu, Y.; Bazzi, A.M. A General Analytical Three-Phase Induction Machine Core Loss Model in the Arbitrary Reference Frame. IEEE Trans. Ind. Appl. 2017, 53, 4210–4220. [Google Scholar] [CrossRef]

- Konda, Y.R.; Ponnaganti, V.K.; Reddy, P.V.S.; Singh, R.R.; Mercorelli, P.; Gundabattini, E.; Solomon, D.G. Thermal Analysis and Cooling Strategies of High-Efficiency Three-Phase Squirrel-Cage Induction Motors—A Review. Computation 2024, 12, 6. [Google Scholar] [CrossRef]

- Madhavan, S.; P B, R.D.; Gundabattini, E.; Mystkowski, A. Thermal Analysis and Heat Management Strategies for an Induction Motor, a Review. Energies 2022, 15, 8127. [Google Scholar] [CrossRef]

- Assaad, B.; Mikati, K.; Tran, T.V.; Negre, E. Experimental Study of Oil Cooled Induction Motor for Hybrid and Electric Vehicles. In Proceedings of the 2018 XIII International Conference on Electrical Machines (ICEM), Alexandroupoli, Greece, 3–6 September 2018; pp. 1195–1200. [Google Scholar] [CrossRef]

- Gundabattini, E.; Kuppan, R.; Solomon, D.G.; Kalam, A.; Kothari, D.; Abu Bakar, R. A review on methods of finding losses and cooling methods to increase the efficiency of electric machines. Ain Shams Eng. J. 2021, 12, 497–505. [Google Scholar] [CrossRef]

- Cabral, P.; Adouni, A. Induction Motor Thermal Analysis Based on Lumped Parameter Thermal Network. KnE Eng. 2020, 5, 451–464. [Google Scholar] [CrossRef]