A Systematic Literature Review on Parameters Optimization for Smart Hydroponic Systems

Abstract

:1. Introduction

World Population and Food Insecurity

2. Sustainable and Climate-Resilient Smart Agriculture and Food Production Systems

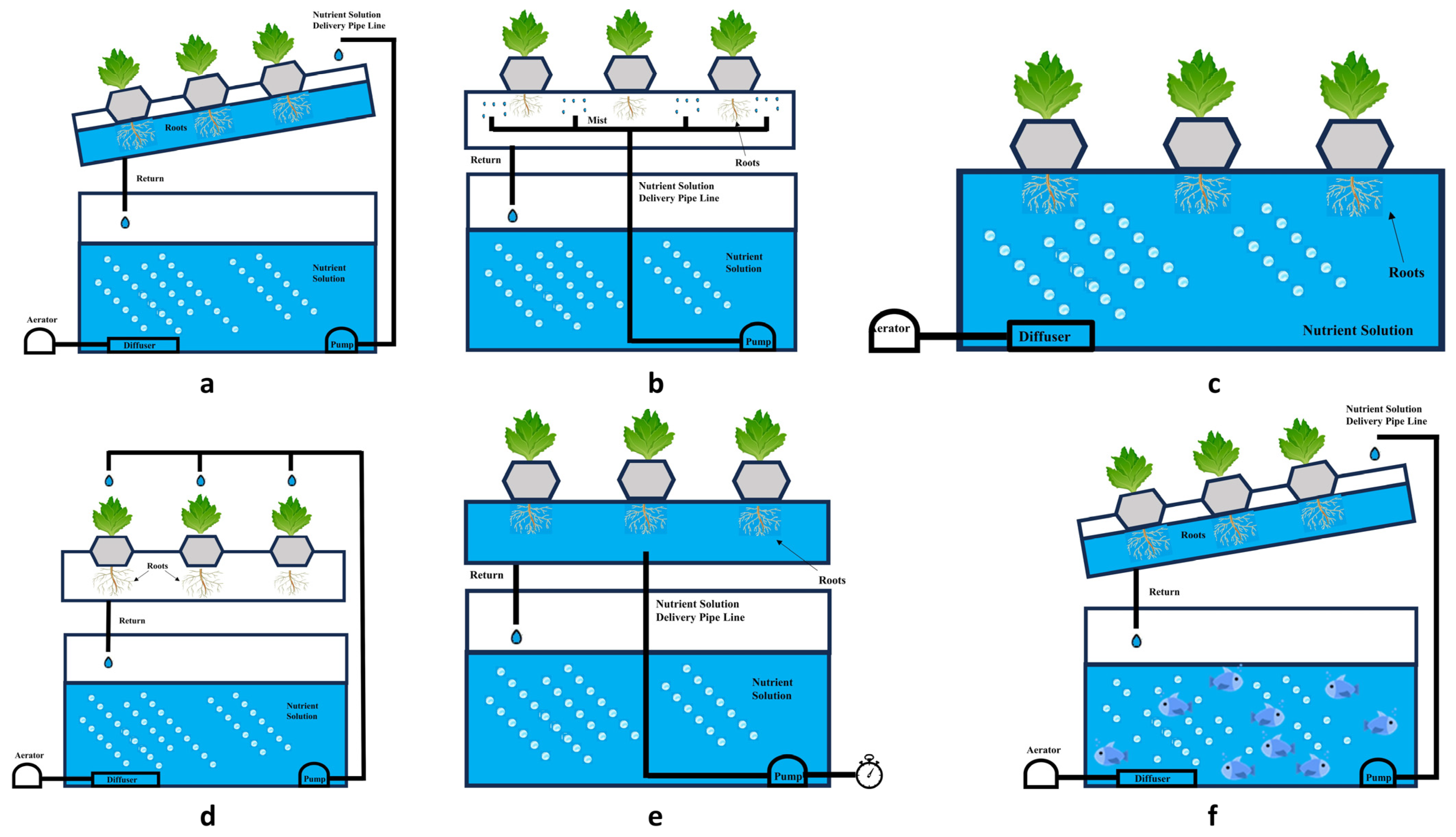

2.1. Smart Hydroponic Systems: An Efficient and Sustainable Alternative

- Ebb and flow [5]

2.2. Challenges in Implementing Large-Scale Hydroponic Systems

2.3. Research Motivation and Paper Organization

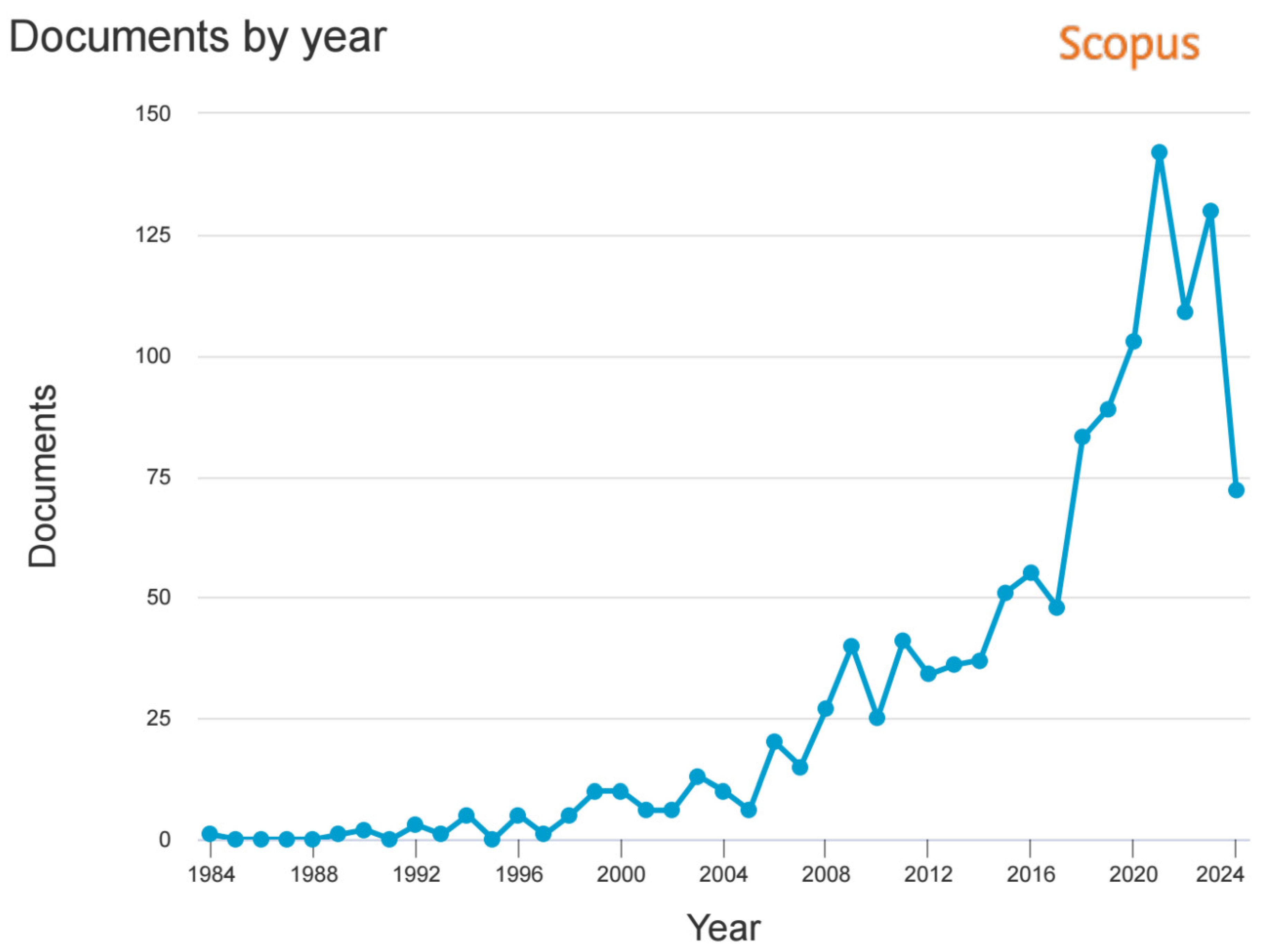

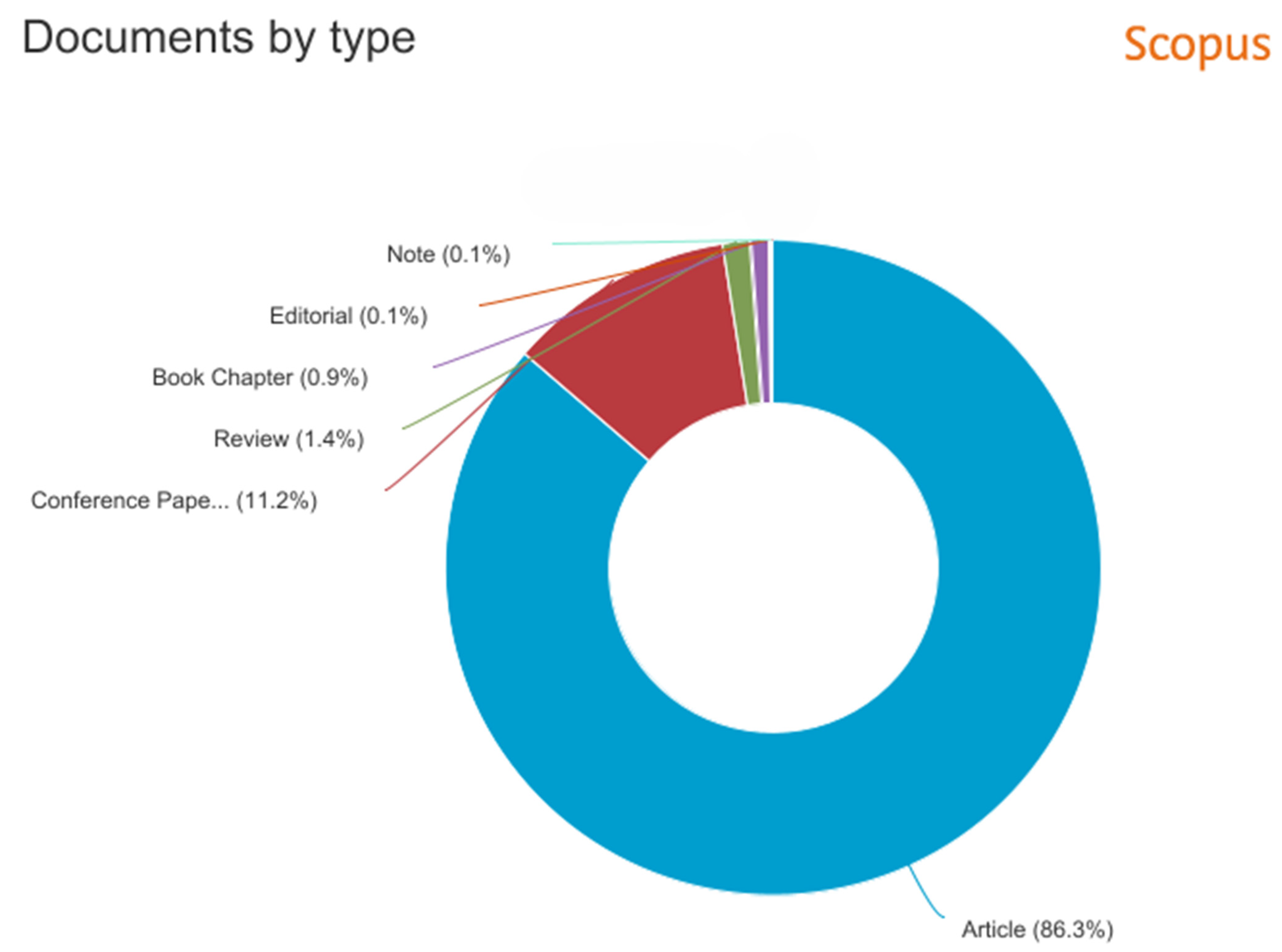

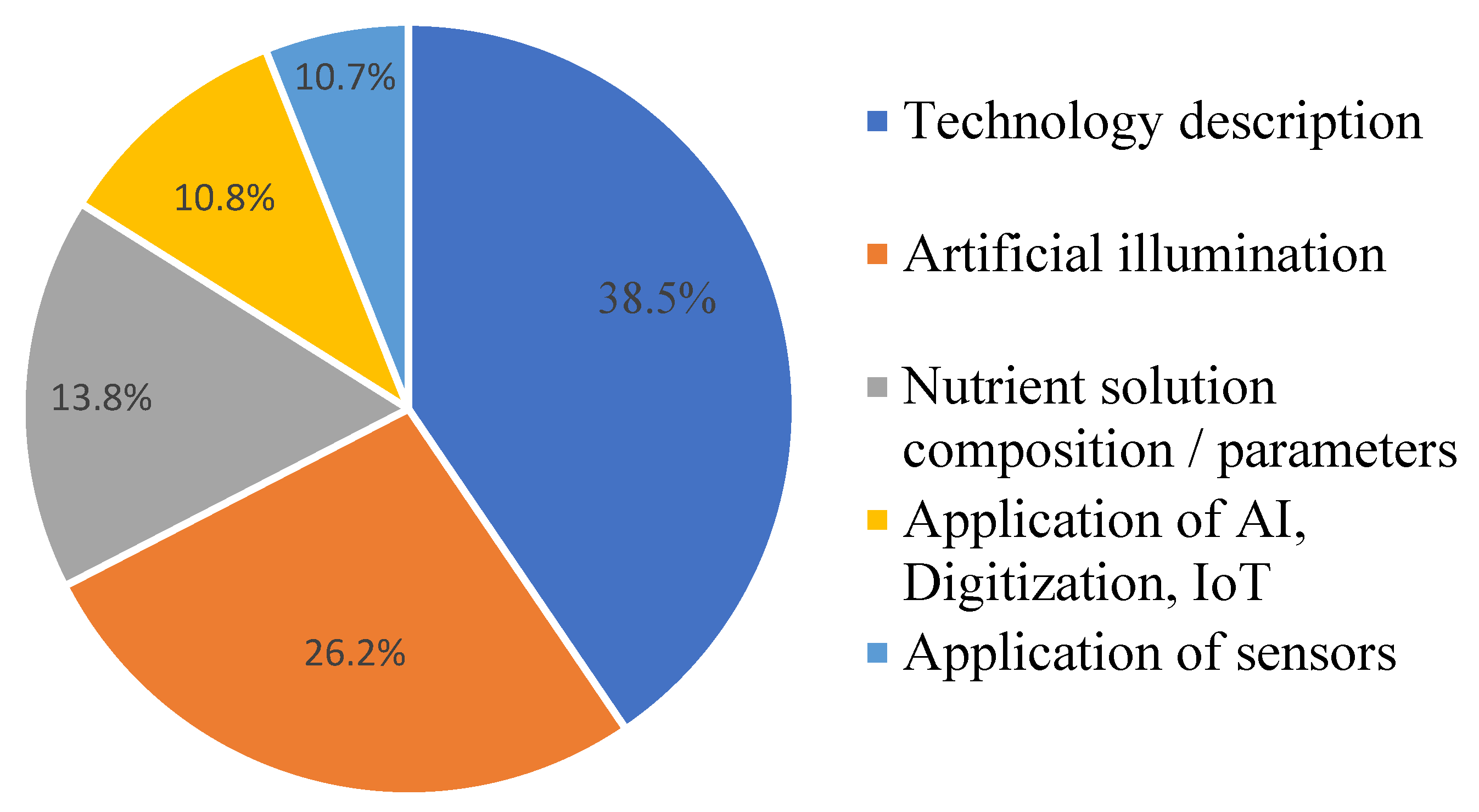

3. Research Methodology

3.1. Review Protocol

3.2. Evaluation Method: PRISMA Approach

4. Growth Parameters in Hydroponic Systems

4.1. Parameter Ranges in Hydroponic Systems

4.2. Plant Species-Based Growth Parameter Ranges for Hydroponic Systems

5. Discussion and Future Prospects

5.1. Smart Hydroponic System

5.2. IoT-Assisted Parameters Control

5.3. AI and ML for Parameters Optimization

5.4. Parameters Control in Hydroponic 4.0/5.0

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Nájera, C.; Gallegos-Cedillo, V.M.; Ros, M.; Pascual, J.A. Role of Spectrum-Light on Productivity, and Plant Quality over Vertical Farming Systems: Bibliometric Analysis. Horticulturae 2023, 9, 63. [Google Scholar] [CrossRef]

- United Nations Department of Economic and Social Affairs, Population Division. World Population Prospects 2022 Summary of Results; UN DESA/POP/2022/TR/NO. 3; United Nations Department of Economic and Social Affairs, Population Division: New York, NY, USA, 2022. [Google Scholar]

- World Population Clock: 8.1 Billion People (LIVE, 2024)—Worldometer. Available online: https://www.worldometers.info/world-population/ (accessed on 19 February 2024).

- Hosseini, H.; Mozafari, V.; Roosta, H.R.; Shirani, H.; van de Vlasakker, P.C.H.; Farhangi, M. Nutrient Use in Vertical Farming: Optimal Electrical Conductivity of Nutrient Solution for Growth of Lettuce and Basil in Hydroponic Cultivation. Horticulturae 2021, 7, 283. [Google Scholar] [CrossRef]

- Velazquez-Gonzalez, R.S.; Garcia-Garcia, A.L.; Ventura-Zapata, E.; Barceinas-Sanchez, J.D.O.; Sosa-Savedra, J.C. A Review on Hydroponics and the Technologies Associated for Medium- and Small-Scale Operations. Agriculture 2022, 12, 646. [Google Scholar] [CrossRef]

- The Sustainable Development Agenda—United Nations Sustainable Development. Available online: https://www.un.org/sustainabledevelopment/development-agenda/ (accessed on 19 February 2024).

- Gillani, S.A.; Abbasi, R.; Martinez, P.; Ahmad, R. Review on Energy Efficient Artificial Illumination in Aquaponics. Clean. Circ. Bioeconomy 2022, 2, 100015. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations. Sustainable Food Systems Concept and Framework: What Is a Sustainable Food System? Why Take a Food Systems Approach? Changing Food Systems; FAO: Rome, Italy, 2018. [Google Scholar]

- St. Clair, S.B.; Lynch, J.P. The Opening of Pandora’s Box: Climate Change Impacts on Soil Fertility and Crop Nutrition in Developing Countries. Plant Soil 2010, 335, 101–115. [Google Scholar] [CrossRef]

- Trivellini, A.; Toscano, S.; Romano, D.; Ferrante, A. The Role of Blue and Red Light in the Orchestration of Secondary Metabolites, Nutrient Transport and Plant Quality. Plants 2023, 12, 2026. [Google Scholar] [CrossRef] [PubMed]

- World Bank Publications. World Development Report 2016: Digital Dividends; World Bank Publications: Chicago, IL, USA, 2016. [Google Scholar]

- Buehler, D.; Junge, R. Global Trends and Current Status of Commercial Urban Rooftop Farming. Sustainability 2016, 8, 1108. [Google Scholar] [CrossRef]

- Ward, R.; Jans-Singh, M.; Choudhary, R. Quantifying the Environmental and Energy Benefits of Food Growth in the Urban Environment. In Smart Plant Factory: The Next Generation Indoor Vertical Farms; Springer: Singapore, 2018; pp. 245–287. ISBN 9789811310652. [Google Scholar]

- Togawa, T.; Fujita, T.; Dong, L.; Fujii, M.; Ooba, M. Feasibility Assessment of the Use of Power Plant-Sourced Waste Heat for Plant Factory Heating Considering Spatial Configuration. J. Clean. Prod. 2014, 81, 60–69. [Google Scholar] [CrossRef]

- Electrical Conductivity and PH Guide for Hydroponics. Available online: https://www.researchgate.net/publication/309293679_Electrical_Conductivity_and_pH_Guide_for_Hydroponics?channel=doi&linkId=5808bddc08ae5ed04c012573&showFulltext=true (accessed on 21 August 2024). [CrossRef]

- Torabi, M.; Mokhtarzadeh, A.; Mahlooji, M. The Role of Hydroponics Technique as a Standard Methodology in Various Aspects of Plant Biology Researches. In Hydroponics—A Standard Methodology for Plant Biological Researches; Asao, T., Ed.; InTech: Rijeka, Croatia, 2012. [Google Scholar]

- Hydroponics|Oklahoma State University. Available online: https://extension.okstate.edu/fact-sheets/hydroponics.html (accessed on 21 August 2024).

- Sharma, A.; Manpoong, C.; Devadas, V.S.; Kartha, B.D.; Pandey, H.; Wangsu, M. Crop Hydroponics, Phyto-Hydroponics, Crop Production, and Factors Affecting Soilless Culture. ACS Agric. Sci. Technol. 2022, 2, 1134–1150. [Google Scholar] [CrossRef]

- Niu, G.; Masabni, J. Hydroponics. In Plant Factory Basics, Applications and Advances; Academic Press: Cambridge, MA, USA, 2022; pp. 153–166. [Google Scholar] [CrossRef]

- Spehia, R.S.; Devi, M.; Singh, J.; Sharma, S.; Negi, A.; Singh, S.; Chauhan, N.; Sharma, D.; Sharma, J.C. Lettuce Growth and Yield in Hoagland Solution with an Organic Concoction. Int. J. Veg. Sci. 2018, 24, 557–566. [Google Scholar] [CrossRef]

- Lakhiar, I.A.; Gao, J.; Syed, T.N.; Chandio, F.A.; Buttar, N.A. Modern Plant Cultivation Technologies in Agriculture under Controlled Environment: A Review on Aeroponics. J. Plant Interact. 2018, 13, 338–352. [Google Scholar] [CrossRef]

- Ragaveena, S.; Shirly Edward, A.; Surendran, U. Smart Controlled Environment Agriculture Methods: A Holistic Review. Rev. Environ. Sci. Biotechnol. 2021, 20, 887–913. [Google Scholar] [CrossRef]

- Reyes Yanes, A.; Abbasi, R.; Martinez, P.; Ahmad, R. Digital Twinning of Hydroponic Grow Beds in Intelligent Aquaponic Systems. Sensors 2022, 22, 7393. [Google Scholar] [CrossRef]

- Abbasi, R.; Martinez, P.; Ahmad, R. The Digitization of Agricultural Industry—A Systematic Literature Review on Agriculture 4.0. Smart Agric. Technol. 2022, 2, 100042. [Google Scholar] [CrossRef]

- Ahmed, N.; Turchini, G.M. Recirculating Aquaculture Systems (RAS): Environmental Solution and Climate Change Adaptation. J. Clean. Prod. 2021, 297, 126604. [Google Scholar] [CrossRef]

- Reyes-Yanes, A.; Gelio, S.; Martinez, P.; Ahmad, R. Wireless Sensing Module for IoT Aquaponics Database Construction. Int. J. Electron. Electr. Eng. 2021, 9, 43–47. [Google Scholar] [CrossRef]

- Oliver, L.P.; Coyle, S.D.; Bright, L.A.; Shultz, R.C.; Hager, J.V.; Tidwell, J.H. Comparison of Four Artificial Light Technologies for Indoor Aquaponic Production of Swiss Chard, Beta Vulgaris, and Kale, Brassica Oleracea. J. World Aquac. Soc. 2018, 49, 837–844. [Google Scholar] [CrossRef]

- Abbasi, R.; Yanes, A.R.; Martinez Villanuera, E.; Ahmad, R. Real-Time Implementation of Digital Twin for Robot Based Production Line. In Proceedings of the Conference on Learning Factories (CLF) 2021, Edmonton, AB, Canada, 4 June 2021. [Google Scholar] [CrossRef]

- Yang, T.; Kim, H.J. Comparisons of Nitrogen and Phosphorus Mass Balance for Tomato-, Basil-, and Lettuce-Based Aquaponic and Hydroponic Systems. J. Clean. Prod. 2020, 274, 122619. [Google Scholar] [CrossRef]

- Pringle, A.M.; Handler, R.M.; Pearce, J.M. Aquavoltaics: Synergies for Dual Use of Water Area for Solar Photovoltaic Electricity Generation and Aquaculture. Renew. Sustain. Energy Rev. 2017, 80, 572–584. [Google Scholar] [CrossRef]

- Ghamkhar, R.; Hartleb, C.; Wu, F.; Hicks, A. Life Cycle Assessment of a Cold Weather Aquaponic Food Production System. J. Clean. Prod. 2020, 244, 118767. [Google Scholar] [CrossRef]

- Saiz-Rubio, V.; Rovira-Más, F. From Smart Farming towards Agriculture 5.0: A Review on Crop Data Management. Agronomy 2020, 10, 207. [Google Scholar] [CrossRef]

- Yanes, A.R.; Martinez, P.; Ahmad, R. Towards Automated Aquaponics: A Review on Monitoring, IoT, and Smart Systems. J. Clean. Prod. 2020, 263, 121571. [Google Scholar] [CrossRef]

- Maucieri, C.; Nicoletto, C.; Junge, R.; Schmautz, Z.; Sambo, P.; Borin, M. Hydroponic Systems and Water Management in Aquaponics: A Review. Ital. J. Agron. 2018, 13, 1–11. [Google Scholar] [CrossRef]

- Silva, L.; Valdés-Lozano, D.; Escalante, E.; Gasca-Leyva, E. Dynamic Root Floating Technique: An Option to Reduce Electric Power Consumption in Aquaponic Systems. J. Clean. Prod. 2018, 183, 132–142. [Google Scholar] [CrossRef]

- Kikuchi, Y.; Kanematsu, Y.; Yoshikawa, N.; Okubo, T.; Takagaki, M. Environmental and Resource Use Analysis of Plant Factories with Energy Technology Options: A Case Study in Japan. J. Clean. Prod. 2018, 186, 703–717. [Google Scholar] [CrossRef]

- Arakkal Thaiparambil, N.; Radhakrishnan, V. Challenges in Achieving an Economically Sustainable Aquaponic System: A Review. Aquac. Int. 2022, 30, 3035–3066. [Google Scholar] [CrossRef]

- Kelly, N.; Choe, D.; Meng, Q.; Runkle, E.S. Promotion of Lettuce Growth under an Increasing Daily Light Integral Depends on the Combination of the Photosynthetic Photon Flux Density and Photoperiod. Sci. Hortic. 2020, 272, 109565. [Google Scholar] [CrossRef]

- Sapkota, S.; Sapkota, S.; Liu, Z. Effects of Nutrient Composition and Lettuce Cultivar on Crop Production in Hydroponic Culture. Horticulturae 2019, 5, 72. [Google Scholar] [CrossRef]

- Johkan, M.; Shoji, K.; Goto, F.; Hahida, S.; Yoshihara, T. Effect of Green Light Wavelength and Intensity on Photomorphogenesis and Photosynthesis in Lactuca Sativa. Environ. Exp. Bot. 2012, 75, 128–133. [Google Scholar] [CrossRef]

- Thakulla, D.; Dunn, B.; Hu, B.; Goad, C.; Maness, N. Nutrient Solution Temperature Affects Growth And◦ Brix Parameters of Seventeen Lettuce Cultivars Grown in an NFT Hydroponic System. Horticulturae 2021, 7, 321. [Google Scholar] [CrossRef]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G. Guidelines and Guidance Preferred Reporting Items for Systematic Reviews and Meta-Analyses: The PRISMA Statement. Ann. Intern. Med. 2009, 151, 264–269. [Google Scholar] [CrossRef] [PubMed]

- Sarkar, A.; Majumder, M. Fuzzy Logic Approach in Prioritization of Crop Growing Parameters in Protected Farms: A Case in North East India. CIGR J. 2017, 19, 211–217. [Google Scholar]

- Abbasi, R.; Martinez, P.; Ahmad, R. Data Acquisition and Monitoring Dashboard for IoT Enabled Aquaponics Facility. In Proceedings of the 2022 10th International Conference on Control, Mechatronics and Automation (ICCMA), Belval, Luxembourg, 9–12 November 2022; pp. 168–172. [Google Scholar] [CrossRef]

- Sambo, P.; Nicoletto, C.; Giro, A.; Pii, Y.; Valentinuzzi, F.; Mimmo, T.; Lugli, P.; Orzes, G.; Mazzetto, F.; Astolfi, S.; et al. Hydroponic Solutions for Soilless Production Systems: Issues and Opportunities in a Smart Agriculture Perspective. Front. Plant Sci. 2019, 10, 923. [Google Scholar] [CrossRef] [PubMed]

- Trejo-Téllez, L.I.; Gómez-Merino, F.C. Nutrient Solutions for Hydroponic Systems. In Hydroponics—A Standard Methodology for Plant Biological Researches; Asao, T., Ed.; InTech: Rijeka, Croatia, 2012. [Google Scholar]

- Nguyen, T.P.D.; Jang, D.C.; Tran, T.T.H.; Nguyen, Q.T.; Kim, I.S.; Hoang, T.L.H.; Vu, N.T. Influence of Green Light Added with Red and Blue Leds on the Growth, Leaf Microstructure and Quality of Spinach (Spinacia oleracea L.). Agronomy 2021, 11, 1724. [Google Scholar] [CrossRef]

- Baiyin, B.; Tagawa, K.; Yamada, M.; Wang, X.; Yamada, S.; Yamamoto, S.; Ibaraki, Y. Study on Plant Growth and Nutrient Uptake under Different Aeration Intensity in Hydroponics with the Application of Particle Image Velocimetry. Agriculture 2021, 11, 1140. [Google Scholar] [CrossRef]

- Chowdhury, M.E.H.; Khandakar, A.; Ahmed, S.; Al-Khuzaei, F.; Hamdalla, J.; Haque, F.; Reaz, M.B.I.; Al Shafei, A.; Al-Emadi, N. Design, Construction and Testing of Iot Based Automated Indoor Vertical Hydroponics Farming Test-Bed in Qatar. Sensors 2020, 20, 5637. [Google Scholar] [CrossRef]

- Yegül, U. Development of an Embedded Software and Control Kit to Be Used in Soilless Agriculture Production Systems. Sensors 2023, 23, 3706. [Google Scholar] [CrossRef]

- Chuah, Y.D.; Lee, J.V.; Tan, S.S.; Ng, C.K. Implementation of Smart Monitoring System in Vertical Farming. IOP Conf. Ser. Earth Environ. Sci. 2019, 268, 012083. [Google Scholar] [CrossRef]

- Mamatha, V.; Kavitha, J.C. Machine Learning Based Crop Growth Management in Greenhouse Environment Using Hydroponics Farming Techniques. Meas. Sens. 2023, 25, 100665. [Google Scholar] [CrossRef]

- Fimbres-Acedo, Y.E.; Servín-Villegas, R.; Garza-Torres, R.; Endo, M.; Fitzsimmons, K.M.; Emerenciano, M.G.C.; Magallón-Servín, P.; López-Vela, M.; Magallón-Barajas, F.J. Hydroponic Horticulture Using Residual Waters from Oreochromis Niloticus Aquaculture with Biofloc Technology in Photoautotrophic Conditions with Chlorella Microalgae. Aquac. Res. 2020, 51, 4340–4360. [Google Scholar] [CrossRef]

- Ibrahim, L.A.; Shaghaleh, H.; El-Kassar, G.M.; Abu-Hashim, M.; Elsadek, E.A.; Alhaj Hamoud, Y. Aquaponics: A Sustainable Path to Food Sovereignty and Enhanced Water Use Efficiency. Water 2023, 15, 4310. [Google Scholar] [CrossRef]

- Noh, K.; Jeong, B.R. Increased Carbon Dioxide by Occupants Promotes Growth of Leafy Vegetables Grown in Indoor Cultivation System. Sustainability 2021, 13, 13288. [Google Scholar] [CrossRef]

- Yessenamanova, M.; Yessenamanova, Z.; Tlepbergenova, A.; Moldir, M.; Nurgul, B. Optimization of Acidity and Electrical Conductivity in Hydroponic Vegetable Production: A STEM Educational Perspective. Int. J. Des. Nat. Ecodynamics 2023, 18, 1517–1524. [Google Scholar] [CrossRef]

- Wang, L.; Ning, S.; Zheng, W.; Guo, J.; Li, Y.; Li, Y.; Chen, X.; Ben-Gal, A.; Wei, X. Performance Analysis of Two Typical Greenhouse Lettuce Production Systems: Commercial Hydroponic Production and Traditional Soil Cultivation. Front. Plant Sci. 2023, 14. [Google Scholar] [CrossRef]

- Priya, G.L.; Baskar, C.; Deshmane, S.S.; Adithya, C.; Das, S. Revolutionizing Holy-Basil Cultivation with AI-Enabled Hydroponics System. IEEE Access 2023, 11, 82624–82639. [Google Scholar] [CrossRef]

- Atmaja, P.; Surantha, N. Smart Hydroponic Based on Nutrient Film Technique and Multistep Fuzzy Logic. Int. J. Electr. Comput. Eng. 2022, 12, 3146–3157. [Google Scholar] [CrossRef]

- Custódio, M.; Villasante, S.; Calado, R.; Lillebø, A.I. Testing the Hydroponic Performance of the Edible Halophyte Halimione Portulacoides, a Potential Extractive Species for Coastal Integrated Multi-Trophic Aquaculture. Sci. Total Environ. 2021, 766, 144378. [Google Scholar] [CrossRef] [PubMed]

- Sutulienė, R.; Laužikė, K.; Pukas, T.; Samuolienė, G. Effect of Light Intensity on the Growth and Antioxidant Activity of Sweet Basil and Lettuce. Plants 2022, 11, 1709. [Google Scholar] [CrossRef]

- Boros, I.F.; Székely, G.; Balázs, L.; Csambalik, L.; Sipos, L. Effects of LED Lighting Environments on Lettuce (Lactuca sativa L.) in PFAL Systems—A Review. Sci. Hortic. 2023, 321, 112351. [Google Scholar] [CrossRef]

- Carotti, L.; Pistillo, A.; Zauli, I.; Meneghello, D.; Martin, M.; Pennisi, G.; Gianquinto, G.; Orsini, F. Improving Water Use Efficiency in Vertical Farming: Effects of Growing Systems, Far-Red Radiation and Planting Density on Lettuce Cultivation. Agric. Water Manag. 2023, 285, 108365. [Google Scholar] [CrossRef]

- Piovene, C.; Orsini, F.; Bosi, S.; Sanoubar, R.; Bregola, V.; Dinelli, G.; Gianquinto, G. Optimal Red:Blue Ratio in Led Lighting for Nutraceutical Indoor Horticulture. Sci. Hortic. 2015, 193, 202–208. [Google Scholar] [CrossRef]

- Naznin, M.T.; Lefsrud, M.; Gravel, V.; Azad, M.O.K. Blue Light Added with Red LEDs Enhance Growth Characteristics, Pigments Content, and Antioxidant Capacity in Lettuce, Spinach, Kale, Basil, and Sweet Pepper in a Controlled Environment. Plants 2019, 8, 93. [Google Scholar] [CrossRef] [PubMed]

- Custódio, M.; Cartaxana, P.; Villasante, S.; Calado, R.; Lillebø, A.I. Led Lighting and High-Density Planting Enhance the Cost-Efficiency of Halimione Portulacoides Extraction Units for Integrated Aquaculture. Appl. Sci. 2021, 11, 4995. [Google Scholar] [CrossRef]

- Yang, T.; Samarakoon, U.; Altland, J.; Ling, P. Photosynthesis, Biomass Production, Nutritional Quality, and Flavor-Related Phytochemical Properties of Hydroponic-Grown Arugula (Eruca sativa Mill.) ‘Standard’ under Different Electrical Conductivities of Nutrient Solution. Agronomy 2021, 11, 1340. [Google Scholar] [CrossRef]

- Carotti, L.; Potente, G.; Pennisi, G.; Ruiz, K.B.; Biondi, S.; Crepaldi, A.; Orsini, F.; Gianquinto, G.; Antognoni, F. Pulsed Led Light: Exploring the Balance between Energy Use and Nutraceutical Properties in Indoor-Grown Lettuce. Agronomy 2021, 11, 1106. [Google Scholar] [CrossRef]

- Dou, H.; Niu, G.; Gu, M.; Masabni, J.G. Responses of Sweet Basil to Different Daily Light Integrals in Photosynthesis, Morphology, Yield, and Nutritional Quality. HortScience 2018, 53, 496–503. [Google Scholar] [CrossRef]

- Kong, Y.; Nemali, A.; Mitchell, C.; Nemali, K. Spectral Quality of Light Can Affect Energy Consumption and Energy-Use Efficiency of Electrical Lighting in Indoor Lettuce Farming. HortScience 2019, 54, 865–872. [Google Scholar] [CrossRef]

- Ercan Karaayak, P.; Inanoglu, S.; Karwe, M.V. Impact of Cold Plasma Treatment of Sweet Basil Seeds on the Growth and Quality of Basil Plants in a Lab-Scale Hydroponic System. ACS Agric. Sci. Technol. 2023, 3, 675–682. [Google Scholar] [CrossRef]

- Farooq, A.; Verma, A.K.; Hittinahalli, C.M.; Varghese, T.; Pathak, M.S. Iron Supplementation in Aquaculture Wastewater and Its Impact on Osmoregulatory, Haematological, Blood Biochemical, and Stress Responses of Pangasius with Spinach in Nutrient Film Technique Based Aquaponics. Aquaculture 2023, 567, 739250. [Google Scholar] [CrossRef]

- Nursyahid, A.; Agung Setyawan, T.; Sriyanto Nugroho, A.; Novitasari, M.; Pramono, S.; Dwi Wardihani, E. Performance of Acidity Nutrient Automation Using MQTT Protocol in Dutch Bucket System Hydroponic. J. Eng. Sci. Technol. 2023, 18, 214–228. [Google Scholar]

- Langenfeld, N.J.; Pinto, D.F.; Faust, J.E.; Heins, R.; Bugbee, B. Principles of Nutrient and Water Management for Indoor Agriculture. Sustainability 2022, 14, 10204. [Google Scholar] [CrossRef]

- Abd Ghani, R.; Omar, S.; Jolánkai, M.; Tarnawa, Á.; Khalid, N.; Kassai, M.K.; Kende, Z. Response of Shoot and Root Growth, Yield, and Chemical Composition to Nutrient Concentrations in Soybean Varieties Grown under Soilless and Controlled Environment Conditions. Agriculture 2023, 13, 1925. [Google Scholar] [CrossRef]

- Stathopoulou, P.; Tsoumalakou, E.; Levizou, E.; Vanikiotis, T.; Zaoutsos, S.; Berillis, P. Iron and Potassium Fertilization Improve Rocket Growth without Affecting Tilapia Growth and Histomorphology Characteristics in Aquaponics. Appl. Sci. 2021, 11, 5681. [Google Scholar] [CrossRef]

- Wei, Y.; Li, W.; An, D.; Li, D.; Jiao, Y.; Wei, Q. Equipment and Intelligent Control System in Aquaponics: A Review. IEEE Access 2019, 7, 169306–169326. [Google Scholar] [CrossRef]

- Kim, H.; Oh, D.; Jang, H.; Koo, C.; Hong, T.; Kim, J. Development of a Multi-Node Monitoring System for Analyzing Plant Growth and Indoor Environment Interactions: An Empirical Study on a Plant Factory. Comput. Electron. Agric. 2023, 214, 108311. [Google Scholar] [CrossRef]

- Lam, V.P.; Kim, S.J.; Park, J.S. Optimizing the Electrical Conductivity of a Nutrient Solution for Plant Growth and Bioactive Compounds of Agastache Rugosa in a Plant Factory. Agronomy 2020, 10, 76. [Google Scholar] [CrossRef]

- Kudirka, G.; Viršilė, A.; Sutulienė, R.; Laužikė, K.; Samuolienė, G. Precise Management of Hydroponic Nutrient Solution PH: The Effects of Minor PH Changes and MES Buffer Molarity on Lettuce Physiological Properties. Horticulturae 2023, 9, 837. [Google Scholar] [CrossRef]

- Fussy, A.; Papenbrock, J. An Overview of Soil and Soilless Cultivation Techniques—Chances, Challenges and the Neglected Question of Sustainability. Plants 2022, 11, 1153. [Google Scholar] [CrossRef]

- Vatistas, C.; Avgoustaki, D.D.; Bartzanas, T. A Systematic Literature Review on Controlled-Environment Agriculture: How Vertical Farms and Greenhouses Can Influence the Sustainability and Footprint of Urban Microclimate with Local Food Production. Atmosphere 2022, 13, 1258. [Google Scholar] [CrossRef]

- Sipos, L.; Balázs, L.; Székely, G.; Jung, A.; Sárosi, S.; Radácsi, P.; Csambalik, L. Optimization of Basil (Ocimum basilicum L.) Production in LED Light Environments—A Review. Sci. Hortic. 2021, 289, 110486. [Google Scholar] [CrossRef]

- Warner, R.; Wu, B.S.; MacPherson, S.; Lefsrud, M. How the Distribution of Photon Delivery Impacts Crops in Indoor Plant Environments: A Review. Sustainability 2023, 15, 4645. [Google Scholar] [CrossRef]

- Hendrickson, T.; Dunn, B.L.; Goad, C.; Hu, B.; Singh, H. Effects of Elevated Water Temperature on Growth of Basil Using Nutrient Film Technique. HortScience 2022, 57, 925–932. [Google Scholar] [CrossRef]

- Naim Khalid, S.M. FAO Crop Production Manual a Guide to Fruit and Vegetable Production in the Federated States of Micronesia; FAO: Rome, Italy, 2020. [Google Scholar]

- Lefsrud, M.G.; Kopsell, D.A.; Sams, C.E. Irradiance from Distinct Wavelength Light-Emitting Diodes Affect Secondary Metabolites in Kale. HortScience 2008, 43, 2243–2244. [Google Scholar] [CrossRef]

- How to Grow Hydroponic Asparagus—Hydrobuilder Learning Center. Available online: https://hydrobuilder.com/learn/hydroponic-asparagus/ (accessed on 18 March 2024).

- Pennisi, G.; Orsini, F.; Landolfo, M.; Pistillo, A.; Crepaldi, A.; Nicola, S.; Fernández, J.A.; Marcelis, L.F.M.; Gianquinto, G. Optimal Photoperiod for Indoor Cultivation of Leafy Vegetables and Herbs. Eur. J. Hortic. Sci. 2020, 85, 329–338. [Google Scholar] [CrossRef]

- Yan, D.; Ding, K.; He, Y.; Fan, L.; Wang, S.; Jiang, X. Strontium Uptake and Effects in Hydroponically Cultivated Celery. Water Air Soil Pollut. 2020, 231, 279. [Google Scholar] [CrossRef]

- Pennisi, G.; Pistillo, A.; Orsini, F.; Cellini, A.; Spinelli, F.; Nicola, S.; Fernandez, J.A.; Crepaldi, A.; Gianquinto, G.; Marcelis, L.F.M. Optimal Light Intensity for Sustainable Water and Energy Use in Indoor Cultivation of Lettuce and Basil under Red and Blue LEDs. Sci. Hortic. 2020, 272, 109508. [Google Scholar] [CrossRef]

- Karimi, M.; Ahmadi, N.; Ebrahimi, M. Red LED Light Promotes Biomass, Flowering and Secondary Metabolites Accumulation in Hydroponically Grown Hypericum perforatum L. (Cv. Topas). Ind. Crops Prod. 2022, 175, 114239. [Google Scholar] [CrossRef]

- Rahman, A.; Wahjuni, S.; Priandana, K. The Development of Hydroponic Nutrient Solutions Control Using Fuzzy and BPNN for Celery Plant. Int. J. Adv. Sci. Eng. Inf. Technol. 2022, 12, 431–436. [Google Scholar] [CrossRef]

- Hydroponic Gardening—Leeks|Avocados Love Hydroponics. Available online: https://avocado99.wordpress.com/2008/07/02/hydroponic-gardening-leeks/ (accessed on 18 March 2024).

- Growing Leeks Hydroponically—Nutrients, PH, and EC|Agri Farming. Available online: https://www.agrifarming.in/growing-leeks-hydroponically-nutrients-ph-and-ec (accessed on 18 March 2024).

- Stamford, J.D.; Stevens, J.; Mullineaux, P.M.; Lawson, T. LED Lighting: A Grower’s Guide to Light Spectra. HortScience 2023, 58, 180–196. [Google Scholar] [CrossRef]

- IEEE Xplore Full-Text PDF. Available online: https://ieeexplore.ieee.org/stamp/stamp.jsp?tp=&arnumber=10198435 (accessed on 14 July 2024).

- Rahman, M.M.; Field, D.L.; Ahmed, S.M.; Hasan, M.T.; Basher, M.K.; Alameh, K. LED Illumination for High-Quality High-Yield Crop Growth in Protected Cropping Environments. Plants 2021, 10, 2470. [Google Scholar] [CrossRef]

- Rodrigues da Silva, A.A.; Francisco do Nascimento Sousa, P.; Soares de Lima, G.; Soares, L.A.d.A.; Gheyi, H.R.; de Andrade Silva, L.; Lopes Araújo Rocha, J.; Alberto Vieira de Azevedo, C. Salicylic Acid Alleviates the Effects of Salt Stress on the Physiology, Growth, and Production of Hydroponic Okra. Arid. Land Res. Manag. 2023, 37, 602–618. [Google Scholar] [CrossRef]

- Mamledesai, H.; Soriano, M.A.; Ahmad, R. A Qualitative Tool Condition Monitoring Framework Using Convolution Neural Network and Transfer Learning. Appl. Sci. 2020, 10, 7298. [Google Scholar] [CrossRef]

- Ahmed, A.; Zulfiqar, S.; Ghandar, A.; Chen, Y.; Hanai, M.; Theodoropoulos, G. Digital Twin Technology for Aquaponics: Towards Optimizing Food Production with Dynamic Data Driven Application Systems. Commun. Comput. Inf. Sci. 2019, 1094, 3–14. [Google Scholar] [CrossRef]

- Witzel, O.; Wilm, S.; Karimanzira, D.; Baganz, D. Controlling and Regulation of Integrated Aquaponic Production Systems—An Approach for a Management Execution System (MES). Inf. Process. Agric. 2019, 6, 326–334. [Google Scholar] [CrossRef]

- Liakos, K.G.; Busato, P.; Moshou, D.; Pearson, S.; Bochtis, D. Machine Learning in Agriculture: A Review. Sensors 2018, 18, 2674. [Google Scholar] [CrossRef]

- Talaviya, T.; Shah, D.; Patel, N.; Yagnik, H.; Shah, M. Implementation of Artificial Intelligence in Agriculture for Optimisation of Irrigation and Application of Pesticides and Herbicides. Artif. Intell. Agric. 2020, 4, 58–73. [Google Scholar] [CrossRef]

- Xu, X.; Lu, Y.; Vogel-Heuser, B.; Wang, L. Industry 4.0 and Industry 5.0—Inception, Conception and Perception. J. Manuf. Syst. 2021, 61, 530–535. [Google Scholar] [CrossRef]

- Maddikunta, P.K.R.; Pham, Q.V.; Prabadevib, B.; Deepa, N.; Dev, K.; Gadekallu, T.R.; Ruby, R.; Liyanage, M. Industry 5.0: A Survey on Enabling Technologies and Potential Applications. J. Ind. Inf. Integr. 2022, 26, 100257. [Google Scholar] [CrossRef]

| Research Questions |

|

| Search Equations | Preliminary

|

| Analysis Criteria | Inclusion Criteria

Exclusion Criteria

|

| Sr No. | Parameter Description | Units | Linked to | Relative Importance/Significance | Optimal Range | References |

|---|---|---|---|---|---|---|

| 1 | pH | None | Nutrient solution | Highly significant | 5–7.5 | [4,5,15,21,22,34,44,45,46,47,48,49,50,51,52,53,54,55,56,57,58,59,60,61,62,63,64,65,66,67,68,69,70,71,72,73,74,75,76,77,78,79,80,81,82,83,84] |

| 2 | Electrical conductivity (EC) | Millisiemens per centimeter (mScm−1) | Highly significant | 0.8–3.5 | [4,5,7,15,21,22,23,38,41,50,53,54,56,58,63,64,65,66,67,69,70,71,74,75,76,77,78,79,80,85] | |

| 3 | Temperature (nutrient solution) | Degrees centigrade °C | Highly significant | 18–27 | [21,23,26,29,37,41,43,54,57,58,60,62,72,78,85] | |

| 4 | TDS | Parts per million (PPM) | Moderately significant | 500–1800 | [33,53,56] | |

| 5 | Aeration/dissolved oxygen (DO) | Milligram per liter (mg L−1) | significant | 3–10 | [22,33,47,52,54,60,61,67,73,81,83,86] | |

| 6 | Growing media/substrate | Plant growth/nutrient solution | Highly significant | Peat, mineral wool, rock wool, coconut coir etc. | [4,5,22,43,44,51,52,53,57,58,67,69,70,71,72,76,78,79,80,87,88,89,90] | |

| 7 | Lighting/artificial illumination | PPFD (μmol m−2s−1) | Plant growth/overall system | Highly significant | 80–600 | [4,5,22,43,44,51,52,53,57,58,67,69,70,71,72,76,78,79,80,87,88,89,90] |

| 8 | Ambient temperature | Degrees centigrade °C | Overall system | Moderately significant | 18–30 | [13,21,22,23,33,38,39,40,41,43,47,51,54,55,56,57,60,61,63,64,65,67,71,75,78,79,80,82,83,91] |

| 9 | Relative humidity | None (percentage) | Overall system | Moderately significant | 40–80 | [4,13,22,33,38,39,40,41,43,47,51,54,55,57,60,63,65,67,70,71,75,78,79,80,85,91,92] |

| 10 | CO2 dosing | Parts per million (PPM) | Plant growth | Optional supplementation | 450–1200 | [4,13,22,33,38,39,40,54,55,57,62,63,64,78,80,82,91,92] |

| Plant Species | pH | EC (Milli Siemens cm−1) | Temperature (Nutrient Solution) (°C) | Growing Media/ Substrate | Lighting Intensity PPFD (µmol m−2s−1) | Photoperiod Hours (h) (Light/Dark) | Ambient Temperature (°C) | Relative Humidity (% Age) | References |

|---|---|---|---|---|---|---|---|---|---|

| Asparagus | 6–6.8 | 1.4–1.8 | 20–28 | Peat, mineral wool, perlite, rock wool, coconut coir etc. | 150–200 | 8/16 | 18–30 | 45–80 | [5,15,23,88] |

| Arugula | 5.5–6.0 | 1.5–1.8 | 18–25 | 150–200 | 16/8 | 18–30 | 45–80 | [1,7,23,67,91] | |

| Basil | 5.5–6.5 | 1.1–1.6 | 18–24 | 80–250 | 16/8 | 18–30 | 50–85 | [1,4,5,7,15,21,50,58,61,64,65,69,71,89,96,97] | |

| Celery | 5.5–6.5 | 1.8–3 | 18–25 | 150 | 16/8 | 18–30 | 50–85 | [5,15,23,90,93] | |

| Kale | 6–6.5 | 1.2–1.8 | 18–25 | 150–250 | 16/8 | 18–30 | 50–80 | [7,60] | |

| Leek | 6.5–7 | 1.4–1.8 | 18–23 | 150–250 | (12–14)/ (12–10) | 18–30 | 60 | [5,15,94,95] | |

| Lettuce | 5–7 | 1.5–2.5 | 18–25 | 150–250 | 14–17 | 18–27 | 45–80 | [1,4,5,15,23,64,65,70,80,91,93,96] | |

| Parsley | 6.0–6.5 | 1.8–2.2 | 18–25 | 150–200 | 16/8 or 14/8 | 18–30 | 45–80 | [5,15,23] | |

| Peppers | 5.5–6 | 0.8–1.8 | - | 50–200 | 16/8 | 20–35 | 50–80 | [1,5,15,23,65,77] | |

| Strawberry | 6.0 | 1.8–2.2 | 18–30 | 115–350 | 12–16 | 18–30 | 40–80 | [1,5,7,15,23,64,84] | |

| Spinach | 6–6.5 | 1.8–2.2 | 20–30 | 100–150 | 13/11 | 20–35 | 20–30 | [1,5,15,23,56,65,72,96,98] | |

| Tomato | 5.5–6.5 | 2–4 | - | 50–200 | 15/9 | - | - | [1,5,7,15,23,77,93] | |

| Okra | 5.5–6.5 | 2–2.4 | - | - | - | 20–35 | 50–80 | [5,15,99] | |

| Rhubarb | 5.5–6.0 | 1.6–2.0 | - | - | - | - | - | [5,15] | |

| Rose | 5.5–6.0 | 1.5–2.5 | - | - | - | - | - | [5,15] | |

| Sage | 5.5–6.5 | 1.0–1.6 | - | - | - | - | - | [5,15] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shareef, U.; Rehman, A.U.; Ahmad, R. A Systematic Literature Review on Parameters Optimization for Smart Hydroponic Systems. AI 2024, 5, 1517-1533. https://doi.org/10.3390/ai5030073

Shareef U, Rehman AU, Ahmad R. A Systematic Literature Review on Parameters Optimization for Smart Hydroponic Systems. AI. 2024; 5(3):1517-1533. https://doi.org/10.3390/ai5030073

Chicago/Turabian StyleShareef, Umar, Ateeq Ur Rehman, and Rafiq Ahmad. 2024. "A Systematic Literature Review on Parameters Optimization for Smart Hydroponic Systems" AI 5, no. 3: 1517-1533. https://doi.org/10.3390/ai5030073