A Bibliometric Analysis on Artificial Intelligence in the Production Process of Small and Medium Enterprises

Abstract

1. Introduction

- Interoperability: Communication and coordination between machines, computers and people, facilitated by the Industrial Internet of Things (IIoT) [1]. IIoT enables SMEs to seamlessly connect and collaborate with partners across the value chain. Moreover, the collected data are the basis for AI training.

- Virtualization: Generating virtual assets using sensory data to replicate the real world, creating Cyber Physical Systems (CPSs) [2] and Digital Twins (DTs) [3], allowing SMEs to create digital models of products and processes for optimization and simulation. Those systems can be driven by AI to achieve further performance.

- Decentralization: Moving systems to the edge of the enterprise, improving scalability through solutions such as Cloud Computing [4] and empowering SMEs with scalable cloud solutions, reducing IT burdens and boosting agility. AI will be pivotal in that, providing in-depth local data analysis.

- Production flexibility: The ability to quickly respond to variable demand and small production batches, supported by technologies such as additive manufacturing [5] and enabling SMEs to quickly adapt to market changes and offer customized products. AI, with forecasting abilities, can further enhance this characteristic.

- Technical assistance: Using robotics and augmented reality to support customers and employees, improving interoperability and facilitating co-design and training [6]. Equipping SMEs with robotics and augmented reality enhances their efficiency, customer service, and innovation. AI can also provide better insight and suggestions.

- What are the current trends about the publications on the application of AI in the production plants of SMEs?This first question aims to identify the main research trends and topics related to AI in SME production plants. This information can be useful for identifying research gaps and opportunities, as well as for understanding the current state of the art in this field.

- What are the main macro topics and how are they related to each other?The second research question seeks to understand the relationships between different AI topics and how they are applied in SME production plants. This information can be useful for developing a comprehensive framework for understanding the role of AI in SMEs.

- What is the evolution of the topics in time and what are the future research directions?This last research question aims to identify emerging trends and future research directions in the field of AI and SMEs. This information can be useful for researchers who are looking to contribute to this field, as well as for SMEs that are considering adopting AI technologies.

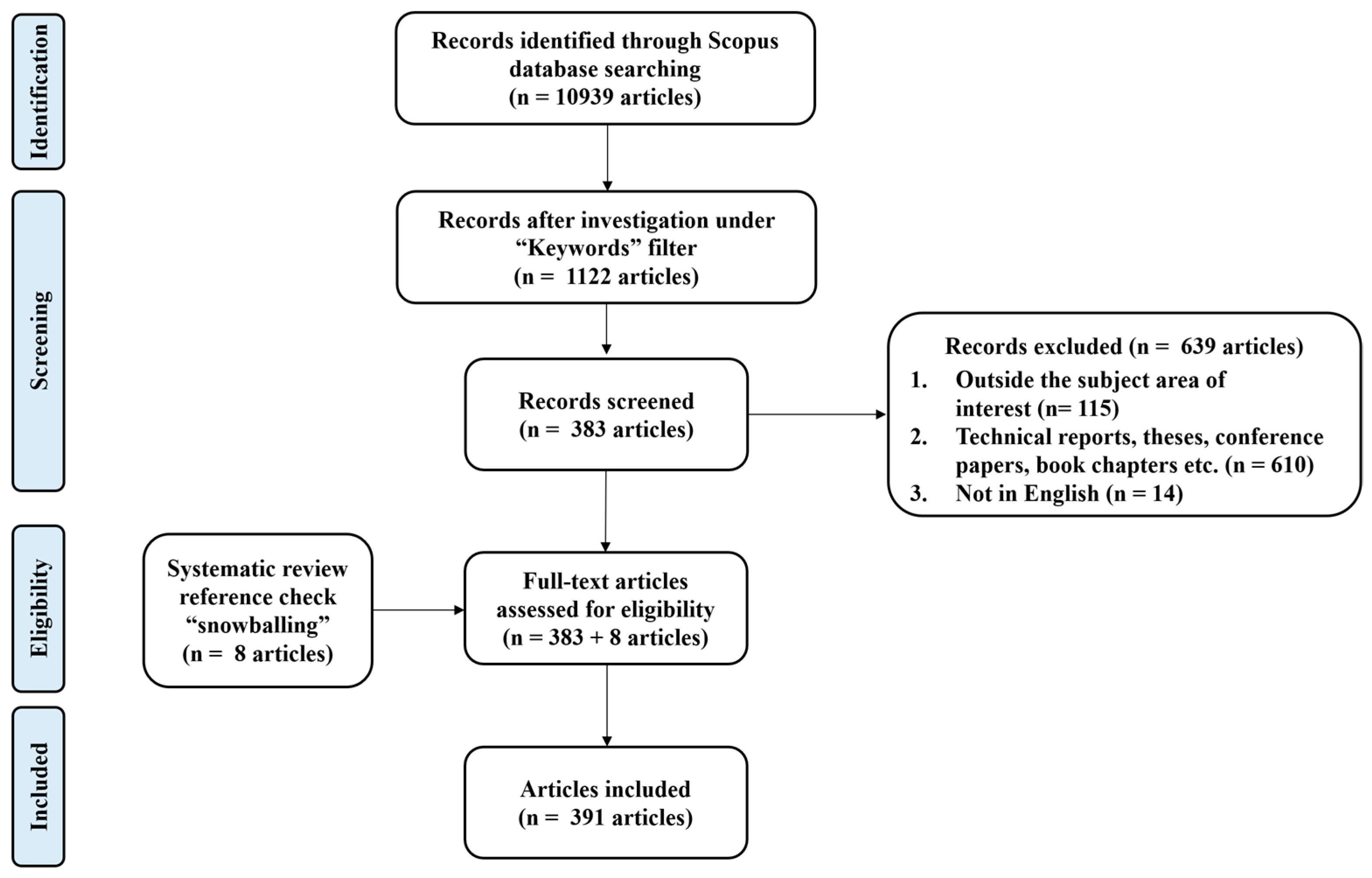

2. Materials and Methods

2.1. Article Selection

2.2. Content Production

3. Bibliometric Analysis and Results from Filters

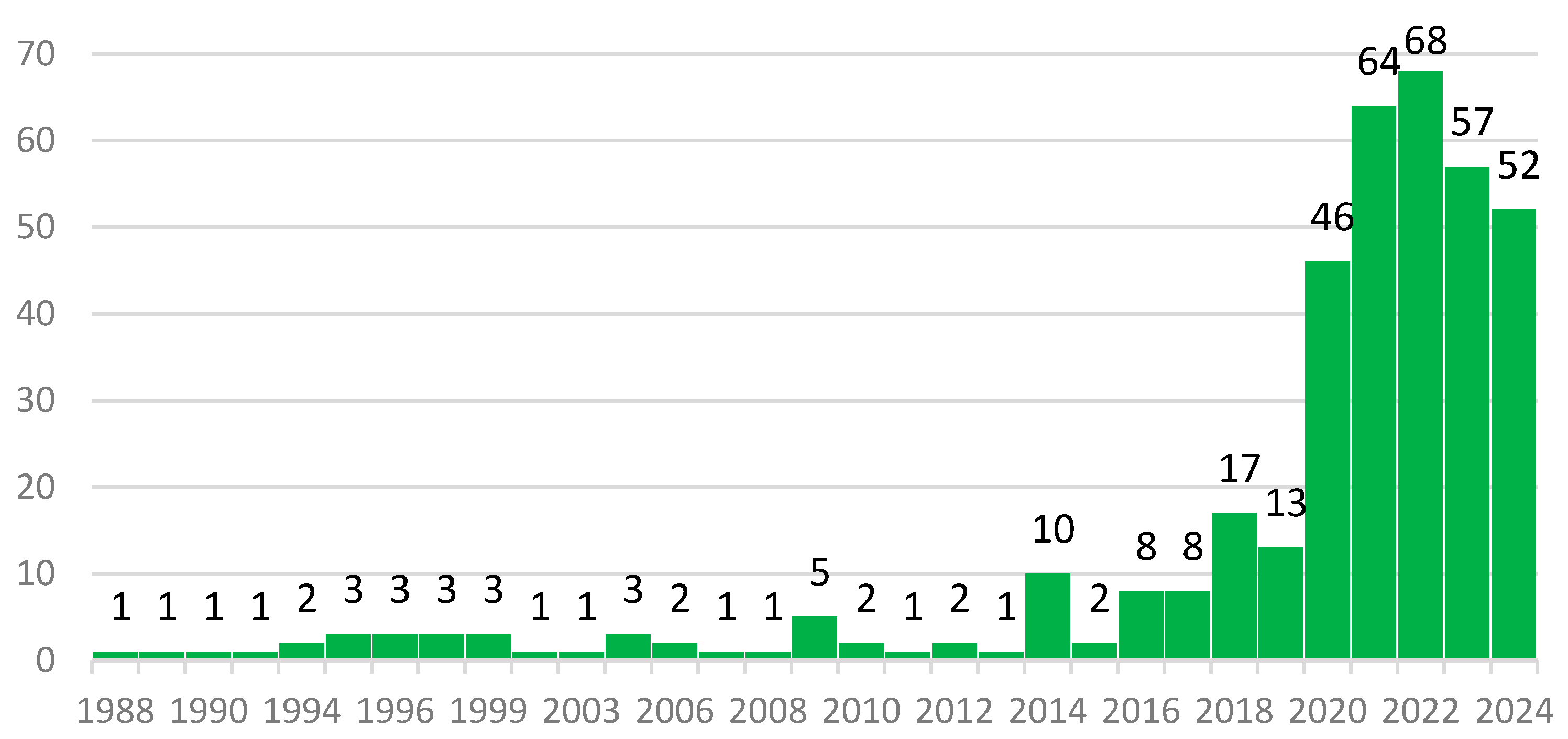

3.1. Year

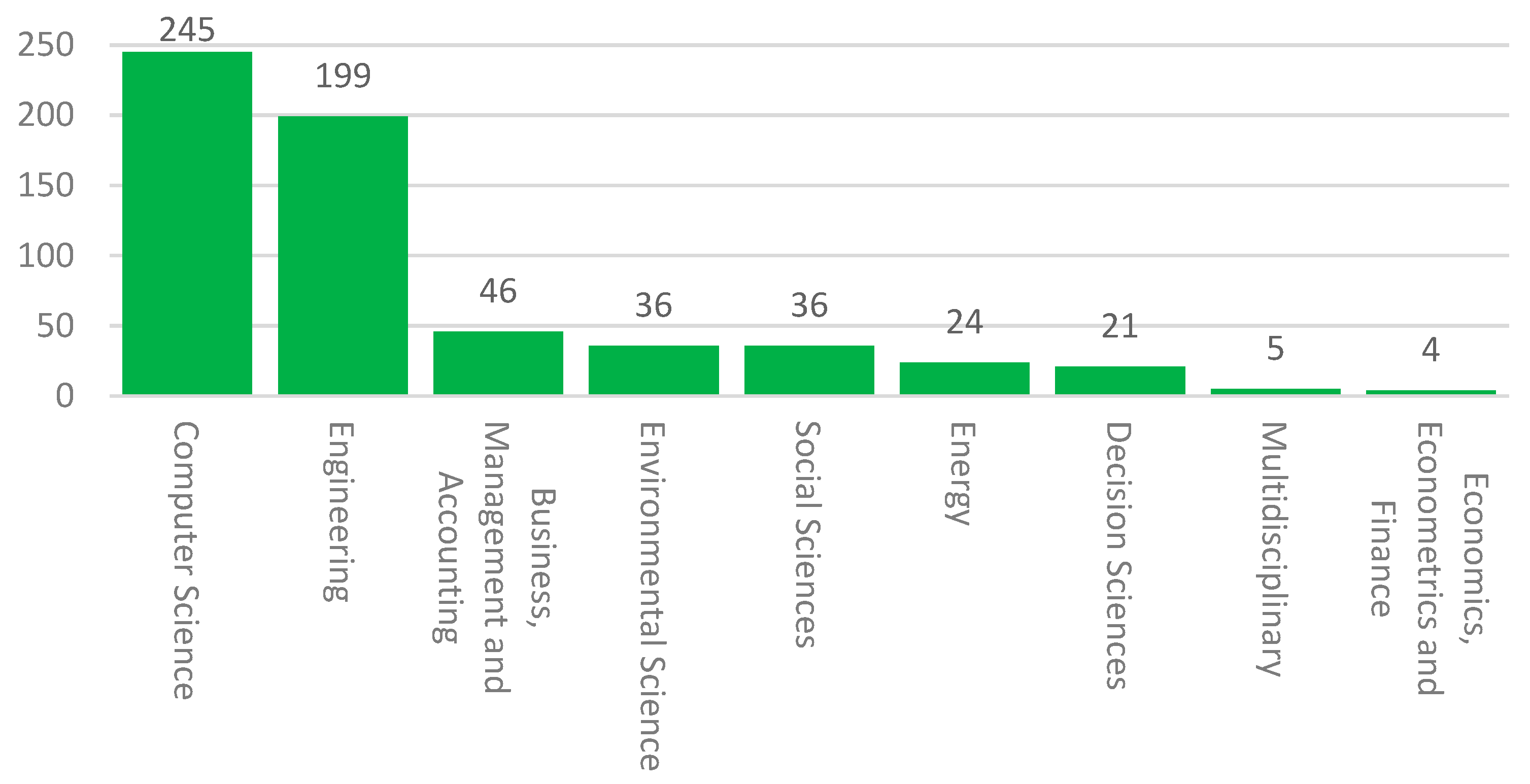

3.2. Subject Area

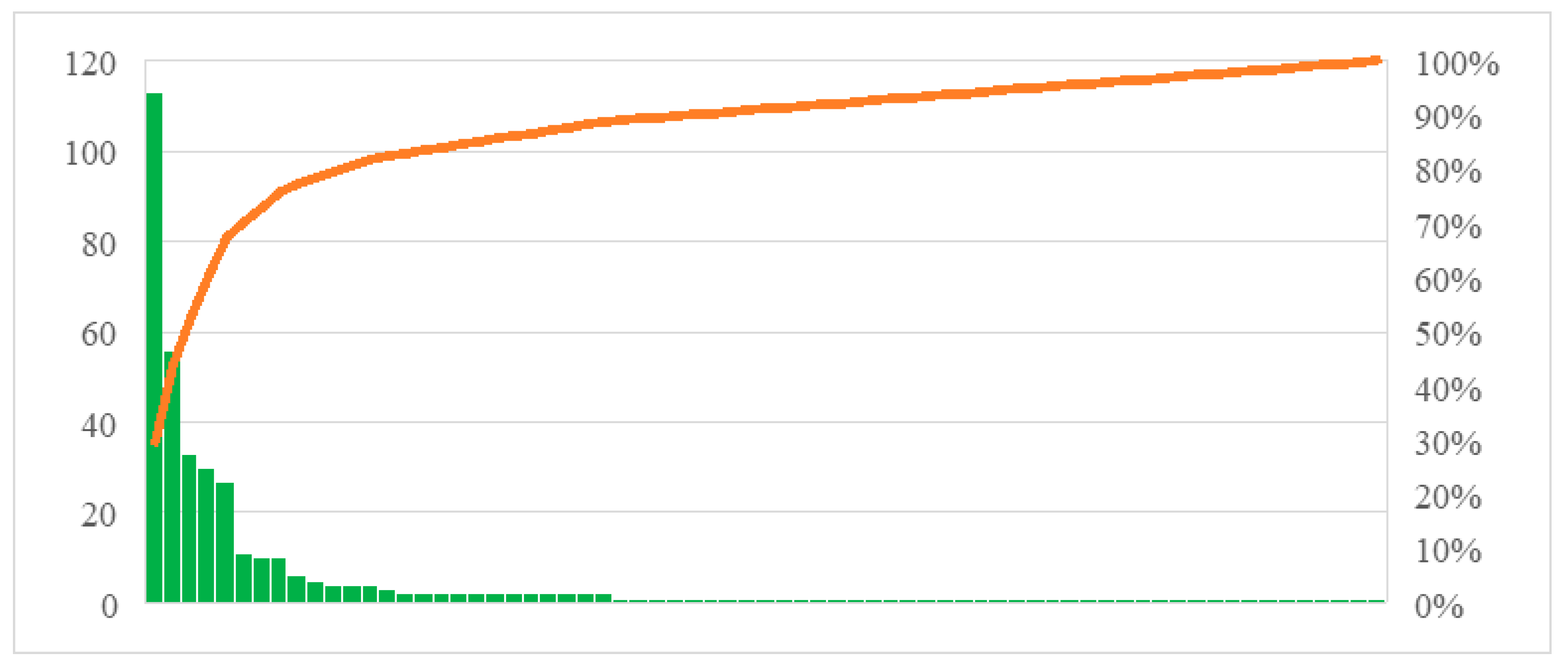

3.3. Publisher

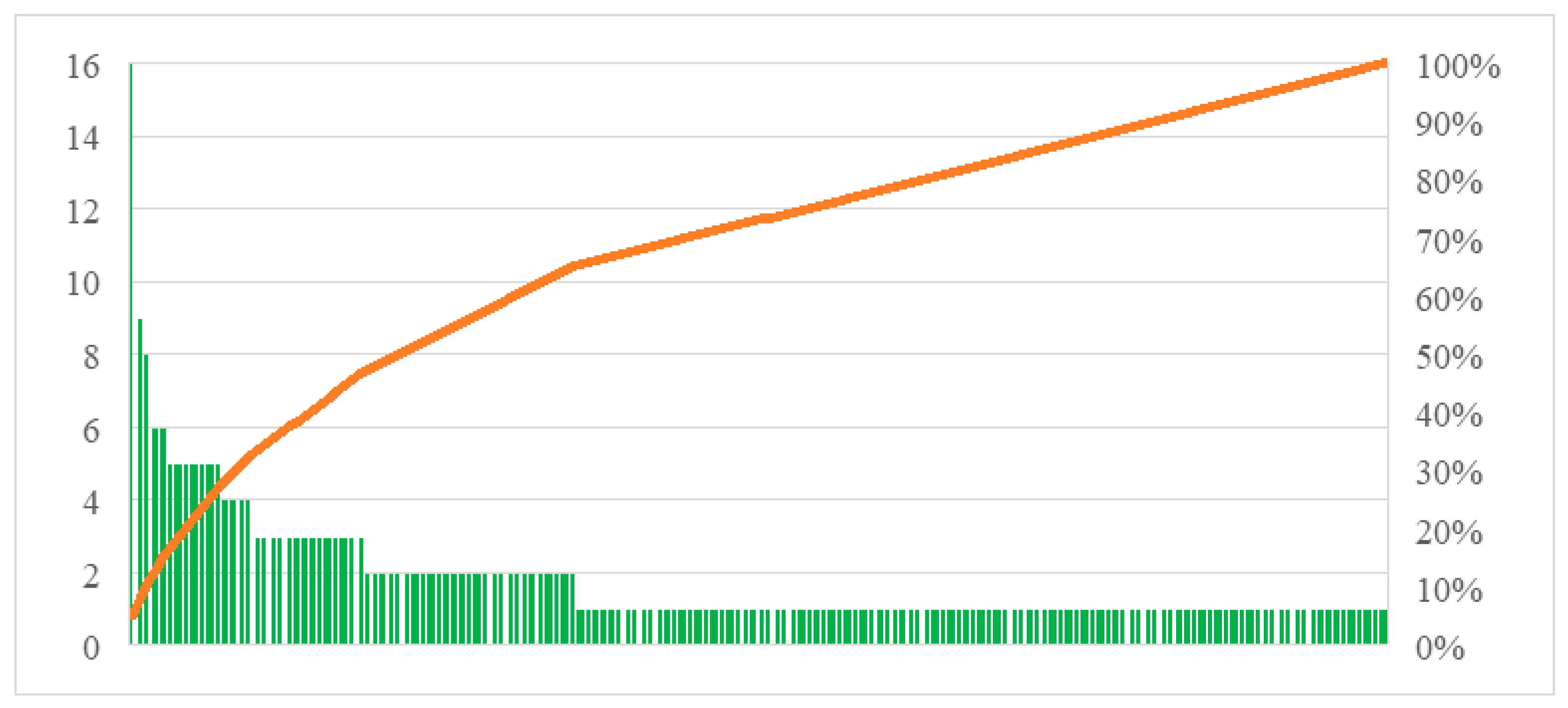

3.4. Journal Distribution

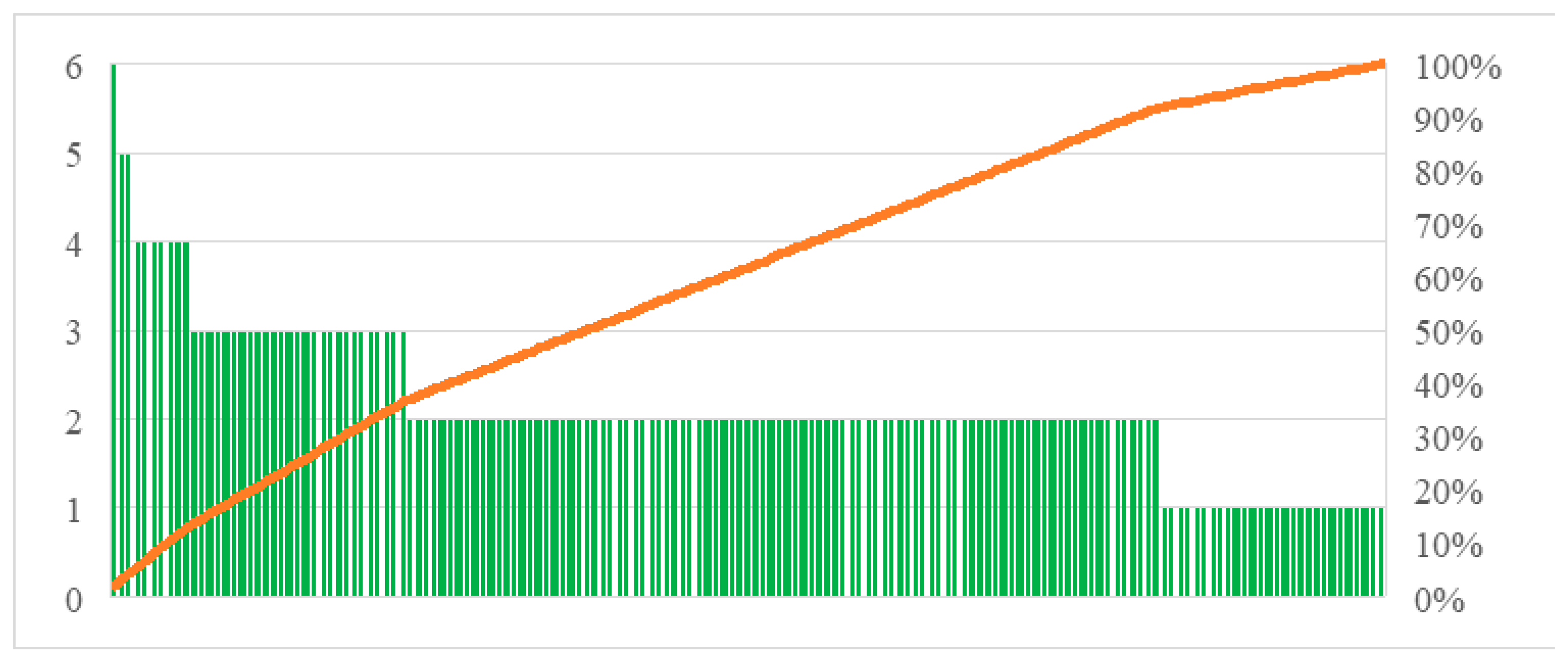

3.5. Affiliation

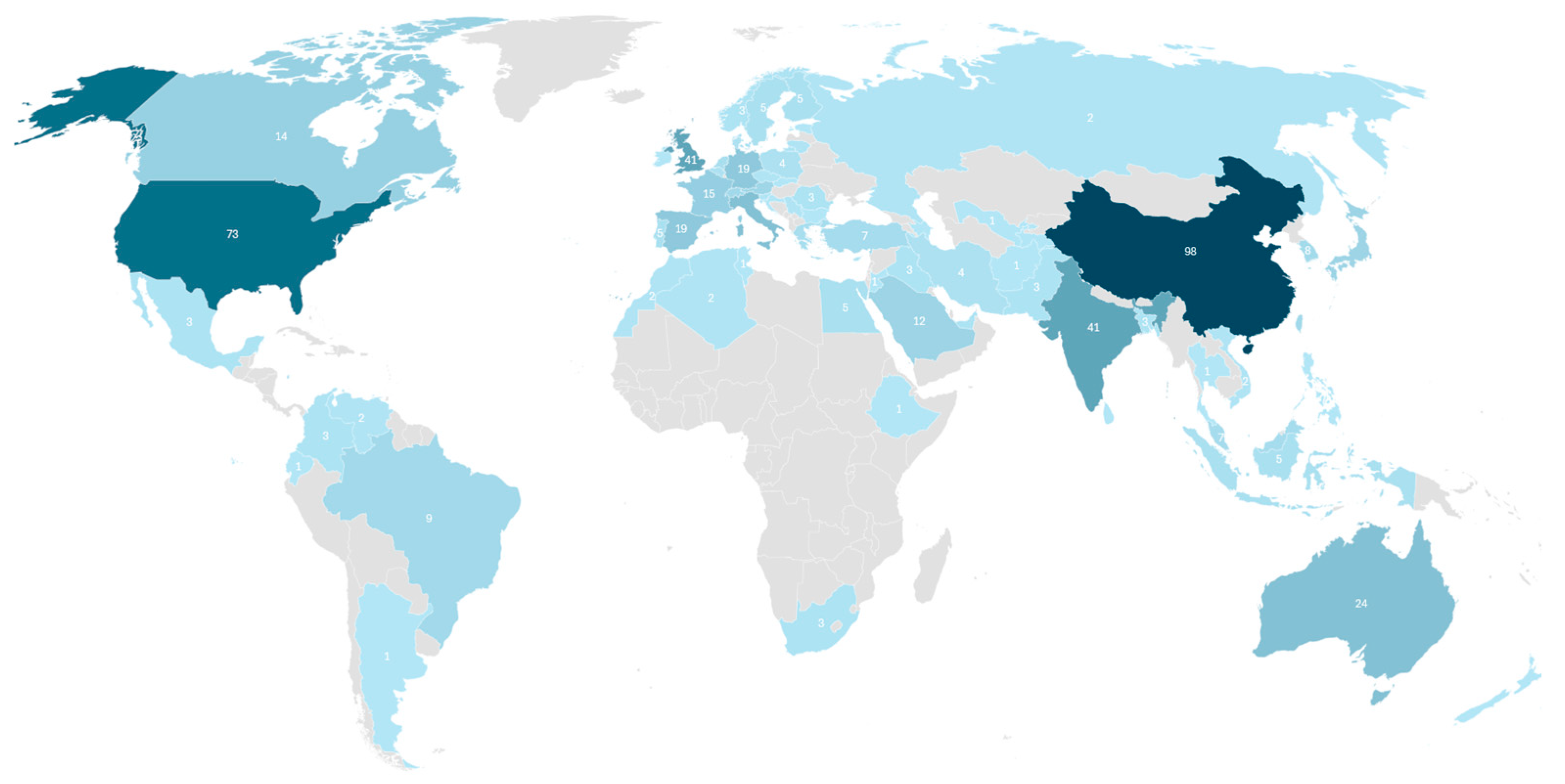

3.6. Country

3.7. Funding Sponsor

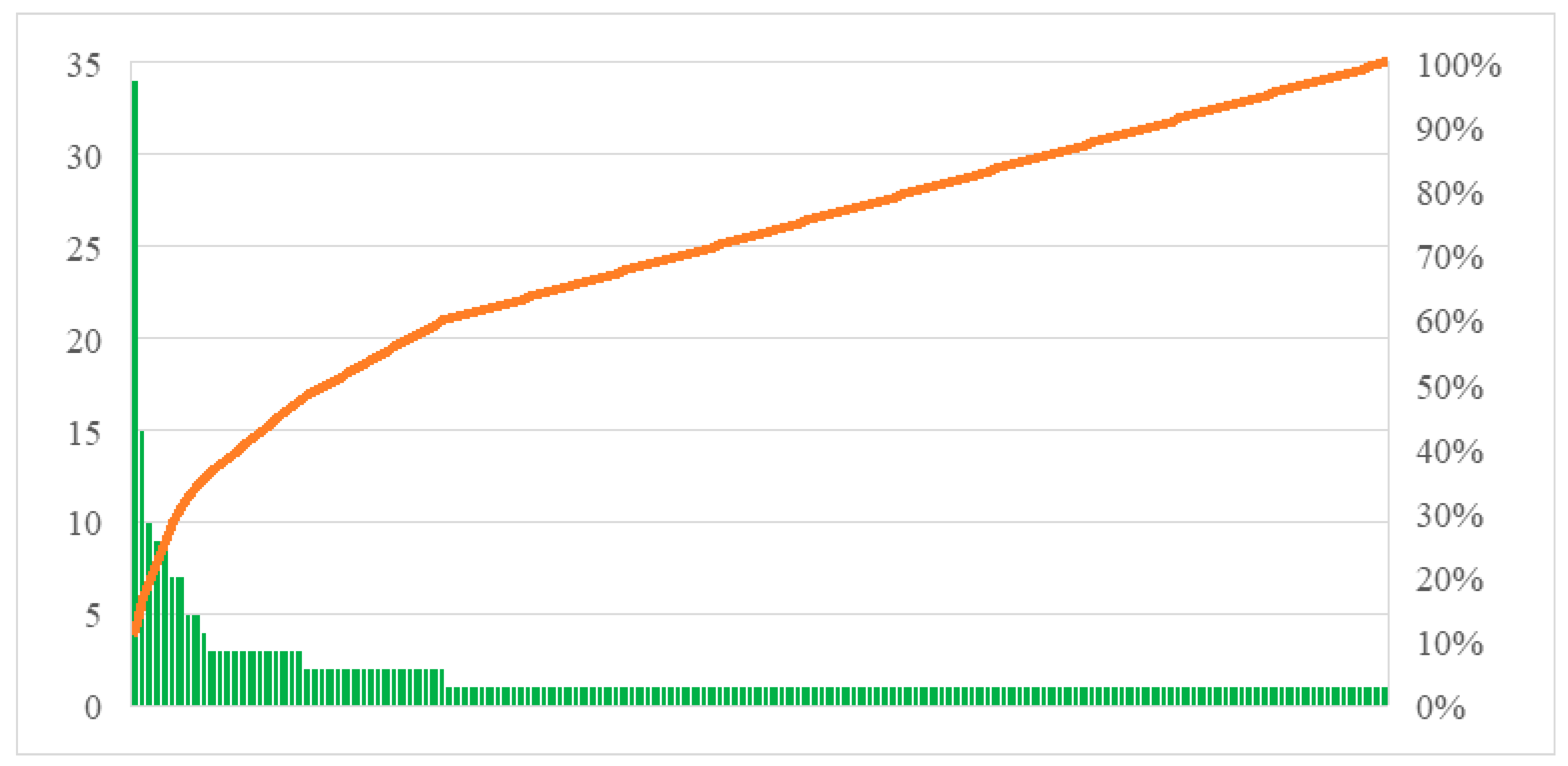

4. Keywords Co-Occurrence

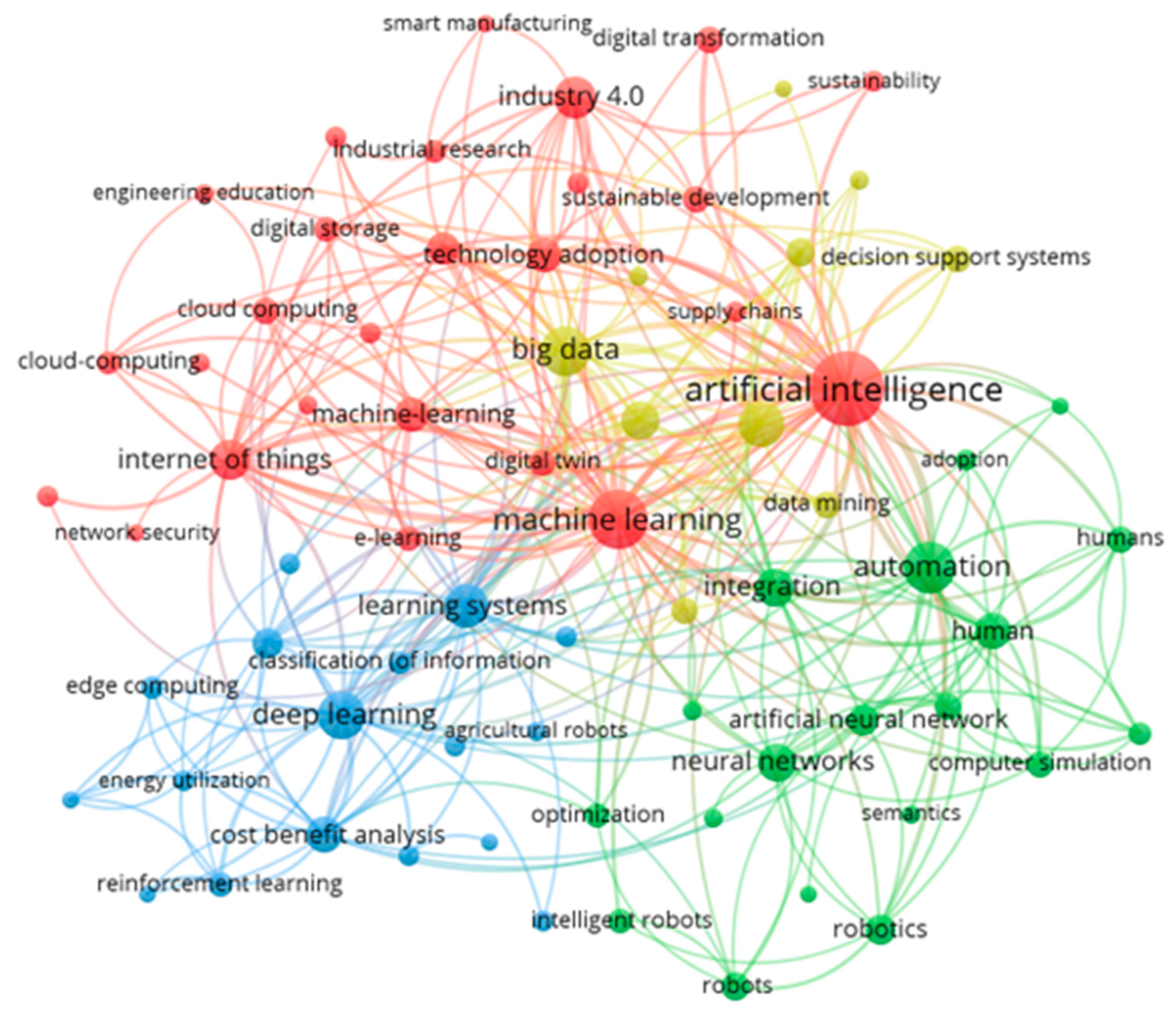

4.1. Clusters

4.1.1. AI in I4.0 Domain (Red)

- On the side, the general I4.0 environment. In fact, there is a group made up of smart manufacturing, Industry 4.0, industrial research, digital transformation, and technology adoption. These generic topics are very strongly connected to AI and machine learning [32].

- Then, another subcluster focuses on the 4.0 technologies, particularly IoT, Cloud, Digital Twin, embedded systems, data analytics, digital storage, blockchain, network security. This group is strongly connected to AI and machine learning [33]. Moreover, IoT and Cloud are strongly connected (14). DT is connected to IoT (5). Data analytics (14) and digital storage (5) are connected to IoT [34].

- A third one is connected to engineering education and e-learning, which are strongly connected to machine learning (6 the first/13 the second). The first is strongly connected to Cloud (11) and the second with AI (5) [33].

4.1.2. ANN Integration for Optimization (Green)

4.1.3. Deep Learning (Blue)

4.1.4. Big Data for Prediction (Yellow)

4.2. Correlation Among Keywords

4.2.1. AI in I4.0 Domain (Red)

- Industry 4.0 (31), machine learning (25), digital transformation (19), Internet of Things (18), sustainable development (13) in cluster 1.

- Automation (41), integration (22), human/humans (21 + 13), robotics (15), computer simulation (10), intelligent robots (10) in cluster 2.

- Learning systems (15), cost benefits analysis (11) in cluster 3.

- Big Data (26), decision making (21), data integration (21), decision support system (18), information management (12) in cluster 4.

- Artificial intelligence (25), data analytics (17), Internet of Things (16), e-learning (13), Industry 4.0 (10) in cluster 1.

- Automation (22), human (16), integration (11) in cluster 2.

- Learning systems (27), learning algorithms (17) in cluster 3.

- Big Data (28 + 13), data integration (27 + 11) in cluster 4.

4.2.2. ANN Integration for Optimization (Green)

- Artificial intelligence (41), machine learning (22) in cluster 1.

- Neural network (14) in cluster 2.

- Data integration (13) in cluster 4.

- Automation (14) in cluster 2.

4.2.3. Deep Learning (Blue)

- Internet of Things (13) in cluster 1.

- Learning systems (18), reinforcement learning (15), cost–benefit analysis (15) in cluster 3.

- Big Data (17), data integration (15) in cluster 4.

4.2.4. Big Data for Prediction (Yellow)

- Machine learning/machine-learning (28 + 13), data analytics (18), Internet of Things (10) in cluster 1.

- Learning systems (17), deep learning (17) in cluster 3.

- Data integration (32), data mining (18), information management (15) in cluster 4.

4.2.5. Others of Interest

- Data integration and data mining (13).

- Data integration and learning systems (12).

- Internet of Things and learning systems (11).

- Decision making and I4.0 (10).

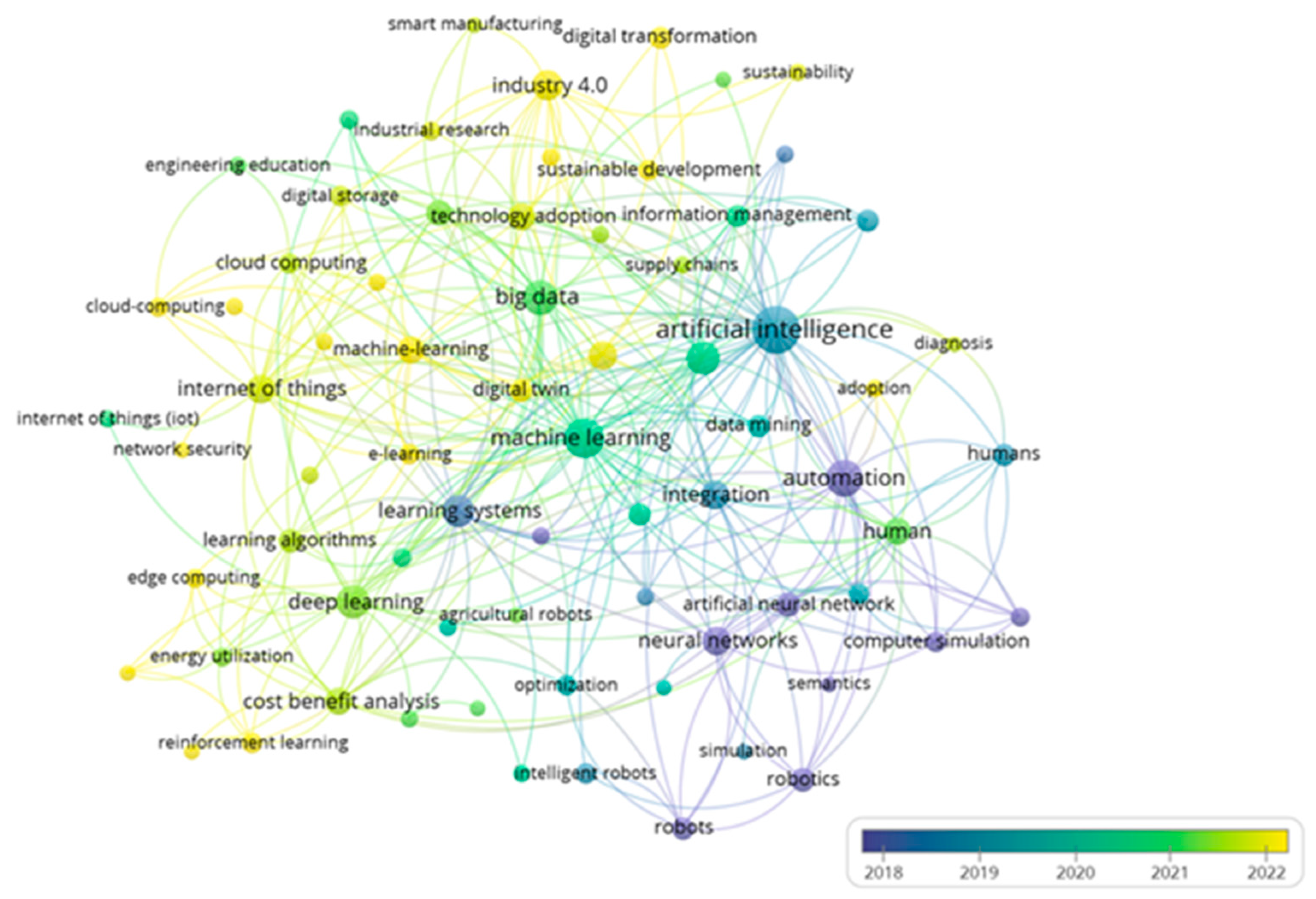

4.3. Temporal Analysis of Keywords

5. Discussions and Future Work Agenda

5.1. Key Findings

5.2. Theoretical Implications

5.3. Practical Implications

6. Conclusions

- Enhanced Automation: AI-powered robots and automated systems can handle repetitive tasks, freeing up human workers for more complex and creative activities.

- Improved Quality Control: AI algorithms can analyze vast amounts of production data to identify defects and anomalies in real time, leading to higher product quality and reduced waste.

- Predictive Maintenance: AI can predict equipment failures before they occur, allowing SMEs to schedule maintenance proactively and avoid costly downtime.

- Optimized Resource Allocation: AI can analyze production data to optimize the use of resources like energy, materials, and personnel, leading to cost savings and improved efficiency.

- Data-Driven Decision Making: AI can analyze data from various sources to provide SMEs with valuable insights for making informed decisions about production planning and inventory management.

- Personalized Customer Experiences: AI-powered chatbots and recommendation systems can help SMEs provide personalized customer service and tailor their products and services to individual customer needs.

- New Product Development: AI can assist in the design and development of new products by analyzing market trends and customer preferences, leading to faster innovation cycles.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ahuett-Garza, H.; Kurfess, T. A brief discussion on the trends of habilitating technologies for Industry 4.0 and Smart manufacturing. Manuf. Lett. 2018, 15, 60–63. [Google Scholar] [CrossRef]

- Leutert, F.; Bohlig, D.; Kempf, F.; Schilling, K.; Mühlbauer, M.; Ayan, B.; Hulin, T.; Stulp, F.; Albu-Schäffer, A.; Kutscher, V.; et al. AI-enabled Cyber–Physical In-Orbit Factory—AI approaches based on digital twin technology for robotic small satellite production. Acta Astronaut. 2024, 217, 1–17. [Google Scholar] [CrossRef]

- Müller-Zhang, Z.; Kuhn, T.; Antonino, P.O. Towards live decision-making for service-based production: Integrated process planning and scheduling with Digital Twins and Deep-Q-Learning. Comput. Ind. 2023, 149, 103933. [Google Scholar] [CrossRef]

- Mousa, K.; Zhang, Z.; Sumarliah, E.; Hamdan, I.K.A. The Impact of Cloud Computing Adoption on Firm Performance Among SMEs in Palestine: A Machine Learning Approach. Int. J. Intell. Inf. Technol. 2024, 20, 1–24. [Google Scholar] [CrossRef]

- Agrawal, R.; Majumdar, A.; Kumar, A.; Luthra, S. Integration of artificial intelligence in sustainable manufacturing: Current status and future opportunities. Oper. Manag. Res. 2023, 16, 1720–1741. [Google Scholar] [CrossRef]

- Chu, Y.; Feng, D.; Liu, Z.; Zhang, L.; Zhao, Z.; Wang, Z.; Feng, Z.; Xia, X.-G. A Fine-Grained Attention Model for High Accuracy Operational Robot Guidance. IEEE Internet Things J. 2023, 10, 1066–1081. [Google Scholar] [CrossRef]

- Ranade, A.; Gómez, J.; de Juan, A.; Chicaiza, W.D.; Ahern, M.; Escaño, J.M.; Hryshchenko, A.; Casey, O.; Cloonan, A.; O’sullivan, D.; et al. Implementing Industry 4.0: An In-Depth Case Study Integrating Digitalisation and Modelling for Decision Support System Applications. Energies 2024, 17, 1818. [Google Scholar] [CrossRef]

- Alieva, J.; Powell, D.J. The significance of employee behaviours and soft management practices to avoid digital waste during a digital transformation. Int. J. Lean Six Sigma 2023, 14, 1–32. [Google Scholar] [CrossRef]

- Briatore, F.; Revetria, R.; Rozhok, A. Literature Review on Applied AI to Public Administration: Insights from Recent Research and Real-Life Examples. In Frontiers in Artificial Intelligence and Applications; IOS Press: Amsterdam, The Netherlands, 2023. [Google Scholar] [CrossRef]

- Briatore, F.; Revetria, R. Artificial intelligence for supporting forecasting in maritime sector. In Proceedings of the Summer School Francesco Turco, Sanremo, Italy, 7–9 September 2022. [Google Scholar]

- Akinsolu, M.O. Applied Artificial Intelligence in Manufacturing and Industrial Production Systems: PEST Considerations for Engineering Managers. IEEE Eng. Manag. Rev. 2023, 51, 52–62. [Google Scholar] [CrossRef]

- Arroyabe, M.F.; Arranz, C.F.; de Arroyabe, I.F.; de Arroyabe, J.C.F. The effect of IT security issues on the implementation of industry 4.0 in SMEs: Barriers and challenges. Technol. Forecast. Soc. Change 2024, 199, 123051. [Google Scholar] [CrossRef]

- Chatterjee, S.; Chaudhuri, R.; Vrontis, D.; Basile, G. Digital transformation and entrepreneurship process in SMEs of India: A moderating role of adoption of AI-CRM capability and strategic planning. J. Strat. Manag. 2022, 15, 416–433. [Google Scholar] [CrossRef]

- Hansen, E.B.; Bøgh, S. Artificial intelligence and internet of things in small and medium-sized enterprises: A survey. J. Manuf. Syst. 2021, 58, 362–372. [Google Scholar] [CrossRef]

- Arranz, C.F.; Arroyabe, M.F.; Arranz, N.; de Arroyabe, J.C.F. Digitalisation dynamics in SMEs: An approach from systems dynamics and artificial intelligence. Technol. Forecast. Soc. Change 2023, 196, 122880. [Google Scholar] [CrossRef]

- Pfeifer, M.R. Development of a smart manufacturing execution system architecture for SMEs: A czech case study. Sustainability 2021, 13, 10181. [Google Scholar] [CrossRef]

- Hemdan, E.E.-D.; El-Shafai, W.; Sayed, A. Integrating Digital Twins with IoT-Based Blockchain: Concept, Architecture, Challenges, and Future Scope. Wirel. Pers. Commun. 2023, 131, 2193–2216. [Google Scholar] [CrossRef]

- Talkhestani, B.A.; Jung, T.; Lindemann, B.; Sahlab, N.; Jazdi, N.; Schloegl, W.; Weyrich, M. An architecture of an Intelligent Digital Twin in a Cyber-Physical Production System. At-Automatisierungstechnik 2019, 67, 762–782. [Google Scholar] [CrossRef]

- Bruneliere, H.; Muttillo, V.; Eramo, R.; Berardinelli, L.; Gómez, A.; Bagnato, A.; Sadovykh, A.; Cicchetti, A. AIDOaRt: AI-augmented Automation for DevOps, a model-based framework for continuous development in Cyber–Physical Systems. Microprocess. Microsyst. 2022, 94, 104672. [Google Scholar] [CrossRef]

- Tang, Y.M.; Kuo, W.T.; Lee, C. Real-time Mixed Reality (MR) and Artificial Intelligence (AI) object recognition integration for digital twin in Industry 4.0. Internet Things 2023, 23, 100753. [Google Scholar] [CrossRef]

- Tian, S.; Zhang, Z.; Xie, X.; Yu, C. A new approach for quality prediction and control of multistage production and manufacturing process based on Big Data analysis and Neural Networks. Adv. Prod. Eng. Manag. 2022, 17, 326–338. [Google Scholar] [CrossRef]

- Yoo, S.-K.; Kim, B.-Y. A Decision-making model for adopting a cloud computing system. Sustainability 2018, 10, 2952. [Google Scholar] [CrossRef]

- Hiran, K.K.; Dadhich, M. Predicting the core determinants of cloud-edge computing adoption (CECA) for sustainable development in the higher education institutions of Africa: A high order SEM-ANN analytical approach. Technol. Forecast. Soc. Change 2024, 199, 122979. [Google Scholar] [CrossRef]

- Fan, L.; Zhang, L. Multi-system fusion based on deep neural network and cloud edge computing and its application in intelligent manufacturing. Neural Comput. Appl. 2022, 34, 3411–3420. [Google Scholar] [CrossRef]

- Poornima, E.; Muthu, B.; Agrawal, R.; Kumar, S.P.; Dhingra, M.; Asaad, R.R.; Jumani, A.K. Fog robotics-based intelligence transportation system using line-of-sight intelligent transportation. Multimed. Tools Appl. 2023, 1–29. [Google Scholar] [CrossRef]

- Barenji, A.V.; Guo, H.; Wang, Y.; Li, Z.; Rong, Y. Toward blockchain and fog computing collaborative design and manufacturing platform: Support customer view. Robot. Comput. Manuf. 2021, 67, 102043. [Google Scholar] [CrossRef]

- Binder, C.; Neureiter, C.; Lüder, A. Towards a domain-specific information architecture enabling the investigation and optimization of flexible production systems by utilizing artificial intelligence. Int. J. Adv. Manuf. Technol. 2022, 123, 49–81. [Google Scholar] [CrossRef]

- Ruiz-Sarmiento, J.-R.; Monroy, J.; Moreno, F.-A.; Galindo, C.; Bonelo, J.-M.; Gonzalez-Jimenez, J. A predictive model for the maintenance of industrial machinery in the context of industry 4.0. Eng. Appl. Artif. Intell. 2020, 87, 103289. [Google Scholar] [CrossRef]

- Roda, I.; Arena, S.; Macchi, M.; Orrù, P.F. Application of Total Cost of Ownership Driven Methodology for Predictive Maintenance Implementation in the Food Industry. In IFIP Advances in Information and Communication Technology; Kim, D.Y., von Cieminski, G., Romero, D., Eds.; Springer: Cham, Switzerland, 2022; pp. 34–40. [Google Scholar] [CrossRef]

- Eldem, B.; Kluczek, A.; Bagiński, J. The COVID-19 Impact on Supply Chain Operations of Automotive Industry: A Case Study of Sustainability 4.0 Based on Sense–Adapt–Transform Framework. Sustainability 2022, 14, 5855. [Google Scholar] [CrossRef]

- Musa, A.A.; Hussaini, A.; Liao, W.; Liang, F.; Yu, W. Deep Neural Networks for Spatial-Temporal Cyber-Physical Systems: A Survey. Future Internet 2023, 15, 199. [Google Scholar] [CrossRef]

- Hu, L.; Miao, Y.; Wu, G.; Hassan, M.M.; Humar, I. iRobot-Factory: An intelligent robot factory based on cognitive manufacturing and edge computing. Future Gener. Comput. Syst. 2019, 90, 569–577. [Google Scholar] [CrossRef]

- Wan, J.; Yang, J.; Wang, Z.; Hua, Q. Artificial intelligence for cloud-assisted smart factory. IEEE Access 2018, 6, 55419–55430. [Google Scholar] [CrossRef]

- Alves, J.M.; Honorio, L.M.; Capretz, M.A.M. ML4IoT: A Framework to Orchestrate Machine Learning Workflows on Internet of Things Data. IEEE Access 2019, 7, 152953–152967. [Google Scholar] [CrossRef]

- Cinar, Z.M.; Abdussalam Nuhu, A.; Zeeshan, Q.; Korhan, O.; Asmael, M.; Safaei, B. Machine learning in predictive maintenance towards sustainable smart manufacturing in Industry 4.0. Sustainability 2020, 12, 8211. [Google Scholar] [CrossRef]

- Briatore, F.; Braggio, M. Resilience and Sustainability plants improvement through Maintenance 4.0: IoT, Digital Twin and CPS framework and implementation roadmap. IFAC-Pap. 2024, 58, 365–370. [Google Scholar] [CrossRef]

- Shahin, M.; Chen, F.F.; Hosseinzadeh, A.; Zand, N. Using machine learning and deep learning algorithms for downtime minimization in manufacturing systems: An early failure detection diagnostic service. Int. J. Adv. Manuf. Technol. 2023, 128, 3857–3883. [Google Scholar] [CrossRef]

- Lee, W.J.; Xia, K.; Denton, N.L.; Ribeiro, B.; Sutherland, J.W. Development of a speed invariant deep learning model with application to condition monitoring of rotating machinery. J. Intell. Manuf. 2021, 32, 393–406. [Google Scholar] [CrossRef]

- Bao, Q.; Zheng, P.; Dai, S. A digital twin-driven dynamic path planning approach for multiple automatic guided vehicles based on deep reinforcement learning. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2024, 238, 488–499. [Google Scholar] [CrossRef]

- Wahid, A.; Breslin, J.G.; Intizar, M.A. Prediction of Machine Failure in Industry 4.0: A Hybrid CNN-LSTM Framework. Appl. Sci. 2022, 12, 4221. [Google Scholar] [CrossRef]

- Alexopoulos, K.; Nikolakis, N.; Chryssolouris, G. Digital twin-driven supervised machine learning for the development of artificial intelligence applications in manufacturing. Int. J. Comput. Integr. Manuf. 2020, 33, 429–439. [Google Scholar] [CrossRef]

- Kaymakci, C.; Wenninger, S.; Pelger, P.; Sauer, A. A Systematic Selection Process of Machine Learning Cloud Services for Manufacturing SMEs. Computers 2022, 11, 14. [Google Scholar] [CrossRef]

- Agarwal, A.; Ojha, R. Prioritising the determinants of Industry-4.0 for implementation in MSME in the post-pandemic period—A quality function deployment analysis. TQM J. 2023, 35, 2181–2202. [Google Scholar] [CrossRef]

- Wang, Q.-J.; Zhang, S.-Y.; Dong, S.-F.; Zhang, G.-C.; Yang, J.; Li, R.; Wang, H.-Q. Pest24: A large-scale very small object data set of agricultural pests for multi-target detection. Comput. Electron. Agric. 2020, 175, 105585. [Google Scholar] [CrossRef]

- Bécue, A.; Praça, I.; Gama, J. Artificial intelligence, cyber-threats and Industry 4.0: Challenges and opportunities. Artif. Intell. Rev. 2021, 54, 3849–3886. [Google Scholar] [CrossRef]

- Wally, B.; Vyskocil, J.; Novak, P.; Huemer, C.; Sšindelář, R.; Kadera, P.; Mazak-Huemer, A.; Wimmer, M. Leveraging Iterative Plan Refinement for Reactive Smart Manufacturing Systems. IEEE Trans. Autom. Sci. Eng. 2021, 18, 230–243. [Google Scholar] [CrossRef]

- Frankó, A.; Hollósi, G.; Ficzere, D.; Varga, P. Applied Machine Learning for IIoT and Smart Production—Methods to Improve Production Quality, Safety and Sustainability. Sensors 2022, 22, 9148. [Google Scholar] [CrossRef]

- Bahulikar, S.; Chattopadhyay, A.; Hudnurkar, M. Framework for Integrating Lean Thinking with Industry 4.0: Way Ahead for Entrepreneurs in Indian MSME’s. J. Entrep. 2023, 32, 271–306. [Google Scholar] [CrossRef]

- Sader, S.; Husti, I.; Daróczi, M. Industry 4.0 as a key enabler toward successful implementation of total quality management practices. Period. Polytech. Soc. Manag. Sci. 2019, 27, 131–140. [Google Scholar] [CrossRef]

- Abbas, S.; Alsubai, S.; Sampedro, G.A.; Abisado, M.; Almadhor, A.; Kim, T.-H. Privacy preserved and decentralized thermal comfort prediction model for smart buildings using federated learning. PeerJ Comput. Sci. 2024, 10, e1899. [Google Scholar] [CrossRef]

- Gashenko, I.V.; Khakhonova, N.N.; Orobinskaya, I.V.; Zima, Y.S. Competition between human and artificial intellectual capital in production and distribution in Industry 4.0. J. Intellect. Cap. 2020, 21, 531–547. [Google Scholar] [CrossRef]

- Munteanu, I.S.; Ungureanu, L.M.; Străinescu, I.; Stanciu, A. Analysis of the evolution and prospects of introducing robots and artificial intelligence in the activities of the modern competitive society. Int. J. Mechatron. Appl. Mech. 2022, 2022, 210–215. [Google Scholar] [CrossRef]

- Tsai, Y.-T.; Lee, C.-H.; Liu, T.-Y.; Chang, T.-J.; Wang, C.-S.; Pawar, S.; Huang, P.-H.; Huang, J.-H. Utilization of a reinforcement learning algorithm for the accurate alignment of a robotic arm in a complete soft fabric shoe tongues automation process. J. Manuf. Syst. 2020, 56, 501–513. [Google Scholar] [CrossRef]

- Alenizi, F.A.; Abbasi, S.; Hussein Mohammed, A.; Masoud Rahmani, E.A. The artificial intelligence technologies in Industry 4.0: A taxonomy, approaches, and future directions. Comput. Ind. Eng. 2023, 185, 109662. [Google Scholar] [CrossRef]

- Kinkel, S.; Baumgartner, M.; Cherubini, E. Prerequisites for the adoption of AI technologies in manufacturing—Evidence from a worldwide sample of manufacturing companies. Technovation 2022, 110, 102375. [Google Scholar] [CrossRef]

| Technology | Explanation | Application in the Production Process |

|---|---|---|

| IIoT | A system that allows objects to be visible and accessible via the Internet, enabling remote control and monitoring [1]. | Optimizes industrial processes by enabling remote visibility of machines, data processing, feedback control on actuators, and centralized information management via the Cloud [17]. |

| Digital Twin | A Digital Twin is a digital representation of a real-world entity, be it a single object like a machine or an entire business system such as a production line or any process. Its significance lies in the real-time comparison between the actual physical system behavior and its desired state through simulation [3]. | Enables benefits such as real-time monitoring for anomaly detection, predictive maintenance, evaluation of hardware and software improvements, optimization of inventory management, personnel training, lifecycle tracking of products, performance analysis, and simulation of production scenarios to enhance efficiency and productivity [18]. |

| CPS | A technology that combines physical components (machines, sensors) with cyber elements (computing systems, digital models) to create a synchronized system [2]. | Enables predictive maintenance, leveraging real-time data to detect and address issues swiftly and accurately, facilitating virtual simulation, enhancing DT by continuously updating them with high-quality data from IIoT systems [19]. |

| Robot 4.0 | Utilization of autonomous robots to replace human operators in performing repetitive and low-value tasks [6]. | Enhances efficiency and effectiveness in manufacturing activities by performing tasks with high precision and speed, thus improving product quality and overall productivity [5]. |

| Virtual Reality | Three-dimensional visualizations of what is developing, thus avoiding the need to resort to constructing physical prototypes that require significant time and often high costs. | Enhances productivity by providing a safer, cost-effective training method that minimizes learning times and allows for repeated practice until full proficiency is achieved, thereby improving overall operational efficiency. |

| Augmented Reality | A technology that, through devices like smart glasses, helmets, and tablets, allows instructions for operation or diagrams to be displayed directly on the object you are working on, whether it is a product or a machine [20]. | Facilitates remote assistance, assembly guidance, real-time inventory management, and collaborative work among distributed teams, thereby optimizing processes and improving overall productivity. |

| Big Data Analysis | The flow of large volumes of data characterized by high velocity, variety, potential value, and the need for veracity. | Allows for trend analysis, predictive maintenance, quality control enhancement, workforce management improvement, and operational cost optimization in manufacturing processes, thereby enhancing productivity and decision-making [21]. |

| Cloud Computing | A technology that enhances productivity by providing access to shared data over the Internet [4]. | Enhances operational efficiency through shared data management, IT cost reduction, resource scalability based on demand, data security, and agile integration of new technologies and services [22]. |

| Edge Computing | A distributed computing model that decentralizes processing and storage activities closer to devices or data sources, moving away from reliance on remote data centres or centralized Cloud Computing. This approach aims to reduce latency, improve communication efficiency, and provide more immediate responses to connected applications and devices [23]. | Supports real-time data processing, enhances operational efficiency, and enables timely responses critical for connected applications and devices, thereby optimizing production processes and reducing reliance on distant data centres [24]. |

| Fog Computing | A distributed computing model that brings computing and storage resources closer to devices or data sources to reduce latency and improve efficiency, with a broader scope than edge computing, encompassing a diverse range of distributed computing nodes [25]. | Facilitates real-time data processing directly on the production line, alleviating potential data flow bottlenecks and supporting applications sensitive to latency, thereby improving operational efficiency and responsiveness [26]. |

| AI | AI refers to the simulation of human intelligence through various algorithms and techniques, allowing tasks such as learning, reasoning, problem-solving, natural language understanding, and environmental perception to be performed [27]. | Enables intelligent automation and prescriptive maintenance, allowing for mass customization and optimizing processes overall [5]. |

| String | Explanation |

|---|---|

| “industry 4.0” OR “digital transformation” OR “CPS” OR “IOT” OR “digital twin” OR “cyber physical system” OR “Big data” OR “Cloud Computing” OR “IIOT” OR “Edge Computing” OR “Fog Computing” OR “Automation” OR “Robot” | Limit the research to the scope of Industry 4.0 and its technologies, capturing the essence of Industry 4.0 from various angles, ensuring the search doesn’t miss valuable contributions due to terminological variations or specific focuses. |

| “Generative AI” OR “Artificial Intelligence” OR “AI” OR “Machine learning” OR “Deep learning” OR “Neural Network” | Aims to comprehensively cover the field of Artificial Intelligence and its related subfields, ensuring that the research captures a broad range of relevant studies focusing on AI and its algorithms. |

| “Adoption” OR “Integration” OR “Barrier” OR “Benefit” OR “Constrain” | Target research that explores the practical aspects of AI implementation within the context of Industry 4.0, going beyond simply identifying AI applications to focus on the challenges and opportunities associated with their deployment. |

| “sme” OR “Small and Medium Enterprises” OR “Production” OR “Process” OR “Manufacturing” | Explicitly targets research focused on the adoption of Industry 4.0 technologies, including AI, specifically within SMEs and within their production processes. |

| Year | N° of Art. | % on Tot Art. | Cumulative % |

|---|---|---|---|

| 2024 | 52 | 13.58% | 13.58% |

| 2023 | 57 | 14.88% | 28.46% |

| 2022 | 68 | 17.75% | 46.21% |

| 2021 | 64 | 16.71% | 62.92% |

| 2020 | 46 | 12.01% | 74.93% |

| 2019 | 13 | 3.39% | 78.33% |

| 2018 | 17 | 4.44% | 82.77% |

| 2017 and before | 24 | 17.23% | 100.00% |

| Subject Area | N° of Art. | % on Tot Art. | Cumul. % on Art. | Cumul. % on SA |

|---|---|---|---|---|

| Computer Science | 245 | 28.99% | 28.99% | 4.35% |

| Engineering | 199 | 23.55% | 52.54% | 8.70% |

| Business, Management and Accounting | 46 | 5.44% | 57.99% | 13.04% |

| Mathematics | 38 | 4.50% | 62.49% | 17.39% |

| Environmental Science | 36 | 4.26% | 66.75% | 21.74% |

| Social Sciences | 36 | 4.26% | 71.01% | 26.09% |

| Materials Science | 33 | 3.91% | 74.91% | 30.43% |

| Physics and Astronomy | 27 | 3.20% | 78.11% | 34.78% |

| Medicine | 25 | 2.96% | 81.07% | 39.13% |

| Biochemistry, Genetics and Molecular Biology | 24 | 2.84% | 83.91% | 43.48% |

| Energy | 24 | 2.84% | 86.75% | 47.83% |

| Decision Sciences | 21 | 2.49% | 89.23% | 52.17% |

| Chemistry | 20 | 2.37% | 91.60% | 56.52% |

| Neuroscience | 13 | 1.54% | 93.14% | 60.87% |

| Psychology | 13 | 1.54% | 94.67% | 65.22% |

| Agricultural and Biological Sciences | 11 | 1.30% | 95.98% | 69.57% |

| Chemical Engineering | 9 | 1.07% | 97.04% | 73.91% |

| Earth and Planetary Sciences | 8 | 0.95% | 97.99% | 78.26% |

| Health Professions | 6 | 0.71% | 98.70% | 82.61% |

| Others | 5 | 1.30% | 100.00% | 100.00% |

| Chemical Engineering | 9 | 1.07% | 97.04% | 73.91% |

| Earth and Planetary Sciences | 8 | 0.95% | 97.99% | 78.26% |

| Health Professions | 6 | 0.71% | 98.70% | 82.61% |

| Others | 5 | 1.30% | 100.00% | 100.00% |

| Publisher | N° of Art. | % on Tot Art. | Cumul. % on Art. | Cumul. % on Pub. |

|---|---|---|---|---|

| Elsevier | 113 | 29.50% | 29.50% | 1.05% |

| IEEE | 56 | 14.62% | 44.13% | 2.11% |

| Springer | 33 | 8.62% | 52.74% | 3.16% |

| MDPI AG | 30 | 7.83% | 60.57% | 4.21% |

| Taylor and Francis Ltd. | 11 | 2.87% | 63.45% | 5.26% |

| Hindawi Limited | 10 | 2.61% | 66.06% | 6.32% |

| Emerald Publishing | 10 | 2.61% | 68.67% | 7.37% |

| IGI Global | 6 | 1.57% | 70.23% | 8.42% |

| Association for Computing Machinery | 5 | 1.31% | 71.54% | 9.47% |

| Inderscience Publishers | 4 | 1.04% | 72.58% | 10.53% |

| John Wiley and Sons Ltd. | 4 | 1.04% | 73.63% | 11.58% |

| John Wiley and Sons Inc. | 4 | 1.04% | 74.67% | 12.63% |

| Routledge | 3 | 0.78% | 75.46% | 13.68% |

| Publishers with 2 articles | 24 | 6.26% | 81.72% | 26.32% |

| Publishers with 1 article | 43 | 11.22% | 92.95% | 71.58% |

| Publisher unknow | 27 | 7.05% | 100.00% | 100.00% |

| Source Title | N° of Art. | % on Tot Art. | Cumul. % on Art. | Cumul. % on Jour. |

|---|---|---|---|---|

| IEEE Access | 16 | 5.42% | 5.42% | 0.63% |

| Technological Forecasting And Social Change | 9 | 3.05% | 8.47% | 1.25% |

| Sensors | 8 | 2.71% | 11.19% | 1.88% |

| IEEE Internet Of Things Journal | 6 | 2.03% | 13.22% | 2.50% |

| Sustainability Switzerland | 6 | 2.03% | 15.25% | 3.13% |

| Computers And Electronics In Agriculture | 5 | 1.69% | 16.95% | 3.75% |

| IEEE Transactions On Industrial Informatics | 5 | 1.69% | 18.64% | 4.38% |

| Journal Of Cleaner Production | 5 | 1.69% | 20.34% | 5.00% |

| Journal Of Industrial Information Integration | 5 | 1.69% | 22.03% | 5.63% |

| Journal Of Manufacturing Systems | 5 | 1.69% | 23.73% | 6.25% |

| Multimedia Tools And Applications | 5 | 1.69% | 25.42% | 6.88% |

| Sensors Switzerland | 5 | 1.69% | 27.12% | 7.50% |

| Engineering Applications Of Artificial Intelligence | 4 | 1.36% | 28.47% | 8.13% |

| Expert Systems With Applications | 4 | 1.36% | 29.83% | 8.75% |

| Neural Computing And Applications | 4 | 1.36% | 31.19% | 9.38% |

| Neural Networks | 4 | 1.36% | 32.54% | 10.00% |

| Journal with 3 Articles | 42 | 14.24% | 46.78% | 18.75% |

| Journal with 2 Articles | 54 | 18.31% | 65.09% | 35.65% |

| Journal with 1 Article | 103 | 34.91% | 100.00% | 100.00% |

| Affiliation | Country | N° of Art. | Cumul. % on Art. | Cumul. % on Aff. |

|---|---|---|---|---|

| Chinese Academy of Sciences | China | 6 | 1.76% | 1.76% |

| Pennsylvania State University | USA | 5 | 1.47% | 3.23% |

| Ministry of Education of the People’s Republic of China | China | 5 | 1.47% | 4.69% |

| Swansea University | UK | 4 | 1.17% | 5.87% |

| La Trobe University | Australia | 4 | 1.17% | 7.04% |

| University of Leeds | UK | 4 | 1.17% | 8.21% |

| University of Science and Technology Beijing | China | 4 | 1.17% | 9.38% |

| Xi’an Jiaotong University | China | 4 | 1.17% | 10.56% |

| Hunan University | China | 4 | 1.17% | 11.73% |

| Penn State College of Engineering | USA | 4 | 1.17% | 12.90% |

| Affiliations with 3 Articles | / | 81 | 23.75% | 36.65% |

| Affiliations with 2 Articles | / | 186 | 54.55% | 91.20% |

| Affiliations with 1 Article | / | 30 | 8.80% | 100.00% |

| Country | N° of Art. | % on Tot Art. | Cumul. % on Art. | Cumul. % on Country |

|---|---|---|---|---|

| China | 98 | 16.61% | 16.61% | 1.39% |

| United States | 73 | 12.37% | 28.98% | 2.78% |

| India | 41 | 6.95% | 35.93% | 4.17% |

| United Kingdom | 41 | 6.95% | 42.88% | 5.56% |

| Australia | 24 | 4.07% | 46.95% | 6.94% |

| Italy | 24 | 4.07% | 51.02% | 8.33% |

| Germany | 19 | 3.22% | 54.24% | 9.72% |

| Spain | 19 | 3.22% | 57.46% | 11.11% |

| France | 15 | 2.54% | 60.00% | 12.50% |

| Canada | 14 | 2.37% | 62.37% | 13.89% |

| Japan | 12 | 2.03% | 64.41% | 15.28% |

| Saudi Arabia | 12 | 2.03% | 66.44% | 16.67% |

| Austria | 11 | 1.86% | 68.31% | 18.06% |

| Brazil | 9 | 1.53% | 69.83% | 19.44% |

| Switzerland | 9 | 1.53% | 71.36% | 20.83% |

| Taiwan | 9 | 1.53% | 72.88% | 22.22% |

| South Korea | 8 | 1.36% | 74.24% | 23.61% |

| Malaysia | 7 | 1.19% | 75.42% | 25.00% |

| Turkey | 7 | 1.19% | 76.61% | 26.39% |

| Greece | 6 | 1.02% | 77.63% | 27.78% |

| Hong Kong | 6 | 1.02% | 78.64% | 29.17% |

| Netherlands | 6 | 1.02% | 79.66% | 30.56% |

| Countries with <6 Articles or Undefined | 50 | 20.34% | 100.00% | 100.00% |

| Funding Sponsor | N° of Art. | % on Tot Art. | Cumul. % on Art. | Cumul. % on FS |

|---|---|---|---|---|

| National Natural Science Foundation of China | 34 | 6.68% | 6.68% | 0.63% |

| National Science Foundation | 15 | 2.95% | 9.63% | 1.25% |

| National Key Research and Development Program of China | 10 | 1.96% | 11.59% | 1.88% |

| European Commission | 9 | 1.77% | 13.36% | 2.50% |

| Horizon 2020 Framework Programme | 9 | 1.77% | 15.13% | 3.13% |

| Engineering and Physical Sciences Research Council | 7 | 1.38% | 16.50% | 3.75% |

| European Regional Development Fund | 7 | 1.38% | 17.88% | 4.38% |

| Fundamental Research Funds for the Central Universities | 5 | 0.98% | 18.86% | 5.00% |

| National Research Foundation of Korea | 5 | 0.98% | 19.84% | 5.63% |

| Japan Society for the Promotion of Science | 4 | 0.79% | 20.63% | 6.25% |

| Funding Sponsor with 3 Articles | 36 | 7.07% | 27.70% | 13.75% |

| Funding Sponsor with 2 Articles | 36 | 7.07% | 34.77% | 25.00% |

| Funding Sponsor with 1 Article | 119 | 23.38% | 58.15% | 99.37% |

| Funding Sponsor Undefined | 213 | 41.85% | 100.00% | 100.00% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Briatore, F.; Mosca, M.T.; Mosca, R.N.; Braggio, M. A Bibliometric Analysis on Artificial Intelligence in the Production Process of Small and Medium Enterprises. AI 2025, 6, 54. https://doi.org/10.3390/ai6030054

Briatore F, Mosca MT, Mosca RN, Braggio M. A Bibliometric Analysis on Artificial Intelligence in the Production Process of Small and Medium Enterprises. AI. 2025; 6(3):54. https://doi.org/10.3390/ai6030054

Chicago/Turabian StyleBriatore, Federico, Marco Tullio Mosca, Roberto Nicola Mosca, and Mattia Braggio. 2025. "A Bibliometric Analysis on Artificial Intelligence in the Production Process of Small and Medium Enterprises" AI 6, no. 3: 54. https://doi.org/10.3390/ai6030054

APA StyleBriatore, F., Mosca, M. T., Mosca, R. N., & Braggio, M. (2025). A Bibliometric Analysis on Artificial Intelligence in the Production Process of Small and Medium Enterprises. AI, 6(3), 54. https://doi.org/10.3390/ai6030054