Improvement of Stockbridge Damper Design for Cable-Stayed Bridges

Abstract

:1. Introduction

- Determining the mechanical properties of the messenger cable by laboratory measurements, including the bending stiffness and the logarithmic decrement;

- Investigating the effectiveness of damping in a global numerical model, taking into account the position of the damper and the relationship between the eigenfrequency of the damper and the stay cable;

- Investigation of the effect of the design parameters (messenger cable length, counterweight mass, cable diameter) on the natural frequencies of the damper in the local model;

- Establishing the proposed correlation and checking its reliability.

2. Materials and Methods

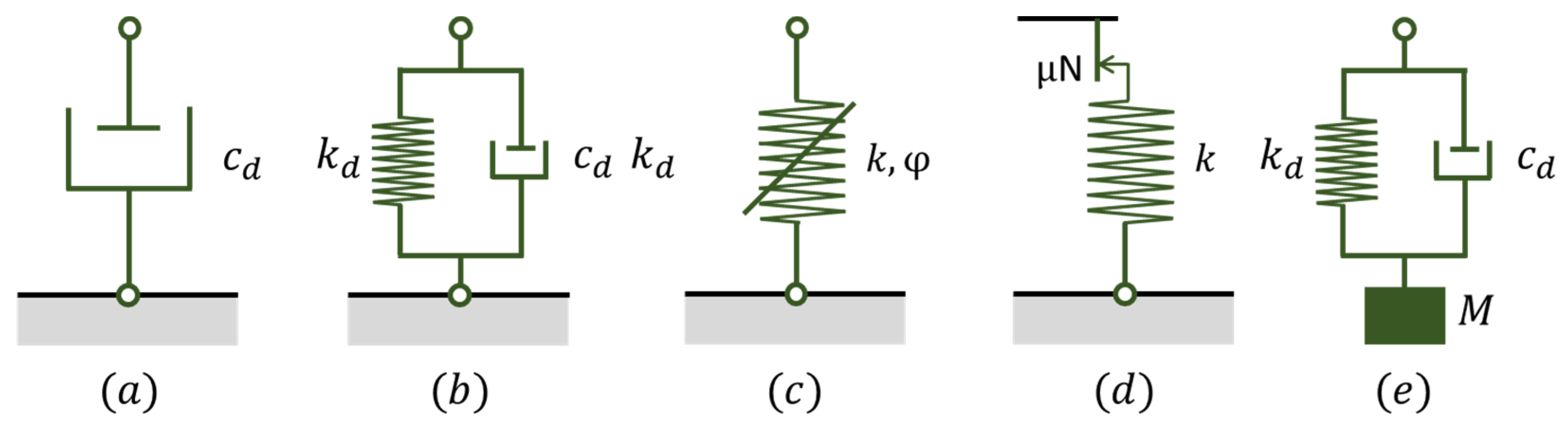

2.1. Types of Cable Dampers

- Viscous damper: This type of damper is the most commonly used for cable vibration control. The device only allows deformation along the damper axis; therefore, damping can be provided in one direction. In cases where both in-plane and out-of-plane vibration mitigation is required, usually, at least two devices are attached to the same point on the cable. Viscous dampers are frequently modelled as a dashpot with one parameter–viscous coefficient as can be seen in Figure 3a. Experimental results have shown that this coefficient factor is not constant in reality but is frequency-dependent. Various authors conducted research in this field, including experimental and analytical investigations [3,4,5]. Chen et al. [6] found that it generally decreases in value as the vibration frequency increases. In 2015, Sun and Chen [7] showed that frequency dependency may be considered using a fractional viscous model.

- Viscous shear damper: A viscous shear damper is a viscoelastic damper which can be modelled by the so-called Kelvin model (Figure 3b). Application of this type of damper is common for cable bridges, see [8,9,10,11]. Chen et al. [12] stated that the stiffness and damping coefficients depend on the amplitude and frequency of the dynamic deformation. In the literature, empirical models have been developed to relate the stiffness and damping coefficients to the viscosity of the viscous fluid, the shearing area and the thickness of the shearing layer [13].

- Friction damper: Friction dampers ideally provide frequency-independent damping. The Coulomb-friction model is widely used to describe the behaviour of the element (Figure 3c). However, time-history responses of a cable-friction damper system, calculated by numerical computation, show larger maximal damping as than in the case of a viscous damper [14]. The explanation might be that this type of element transfers energy to higher vibrational modes, thus dissipating energy more rapidly overall [15,16]. The friction damper is characterised by the stick-slip motion. That means when there is sliding friction between the cable and the damping surface, the vibration of the cable is effectively damped; whereas when the friction surface is stuck, the damping effect is quite small.

- High damping rubber damper: High damping rubber (HDR) dampers are widely used as internal dampers/deviators for cables [17,18]. This type of damper can be modelled using the linear hysteretic damping model, with a complex stiffness coefficient and a loss factor (Figure 3d). Because of the relatively large intrinsic stiffness effects, which mean a small loss factor, the maximal damping provided by HDR dampers to a cable is relatively small. However, HDR dampers can effectively suppress high-frequency and small-amplitude cable vibrations; this has led to them being widely used.

- Tuned mass damper: Tuned mass dampers (TMDs) are widely used to dampen vibration in overhead lines and are now also commonly used on stay cables and/or on pedestrian bridges [19,20,21,22]. Its simplified mechanical model is a mass coupled to a viscous damping element and a spring with a given stiffness, as can be seen in Figure 3e. These elements are simple to install and maintain but are limited in their applicability by the fact that, depending on the design, they can only attenuate with high efficiency at some frequencies and less efficiently at other ones [23]. Further valuable research results on this topic can be found in [24,25,26].

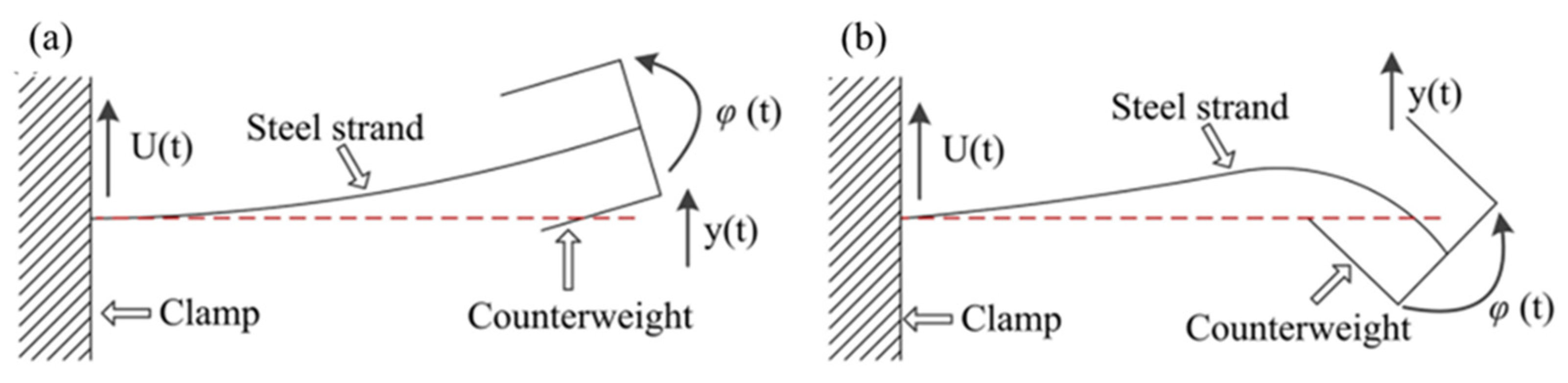

2.2. Mechanical Models of Stockbridge Damper

3. Laboratory Measurements of the Mechanical Properties

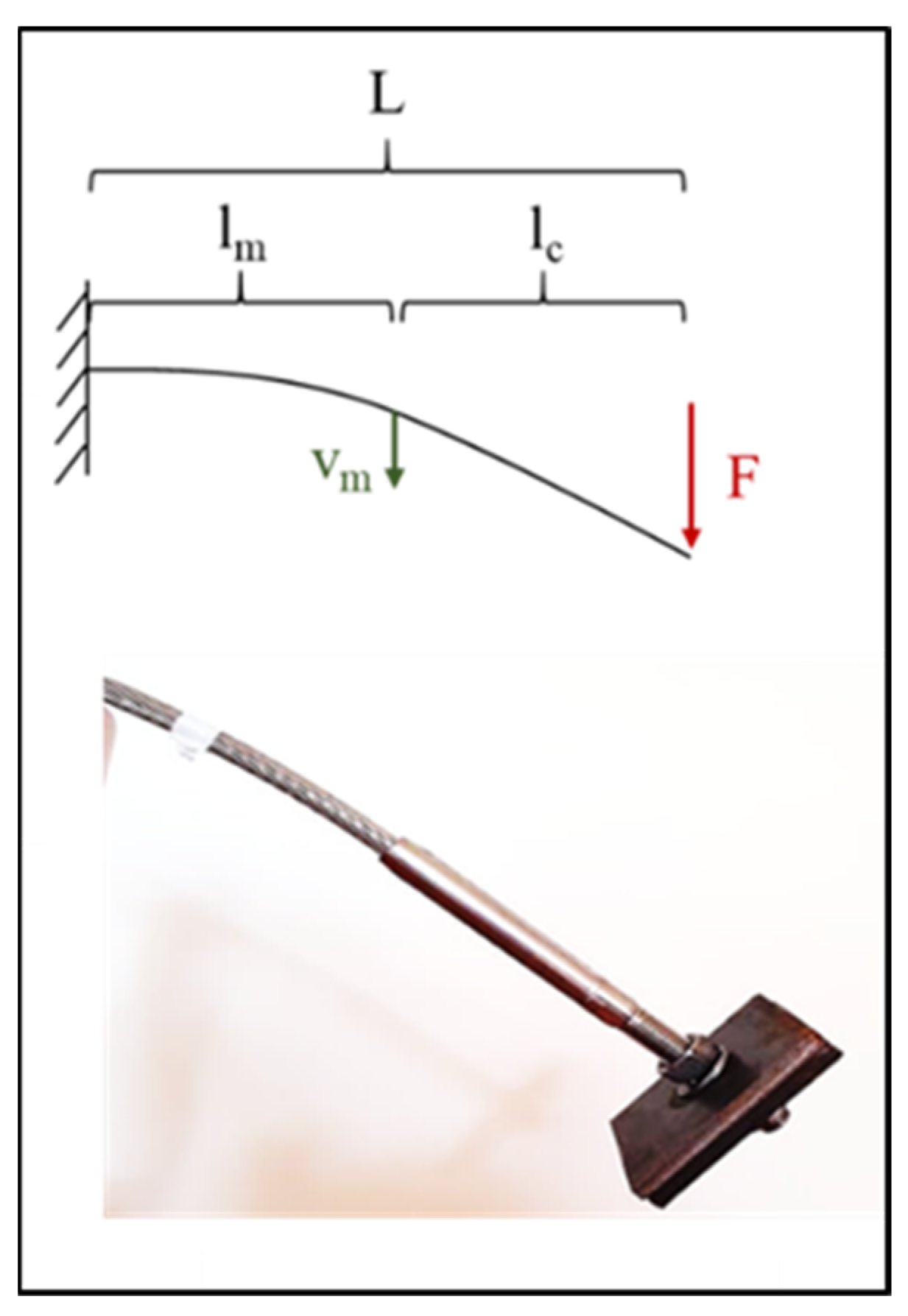

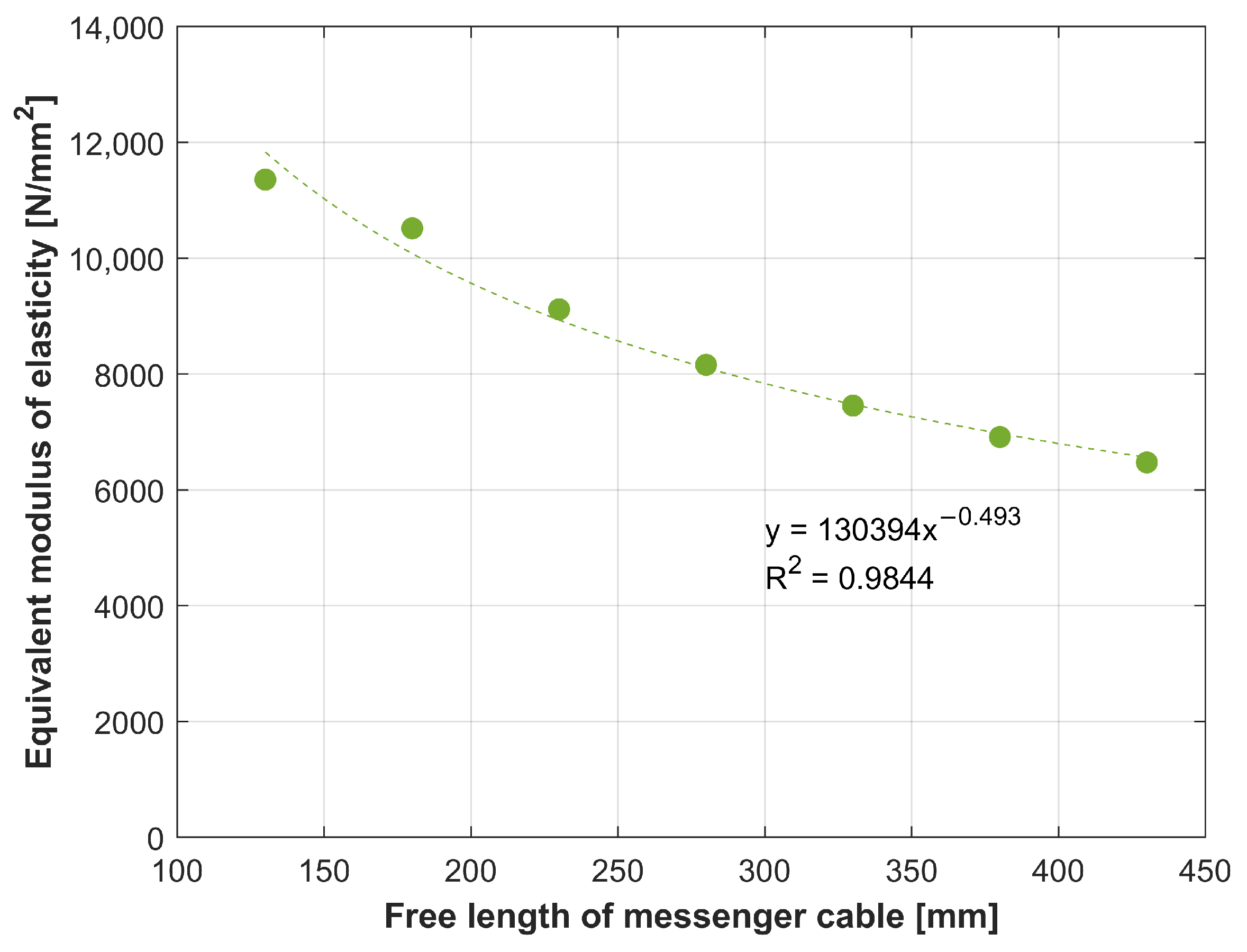

3.1. Determination of Cable Stiffness

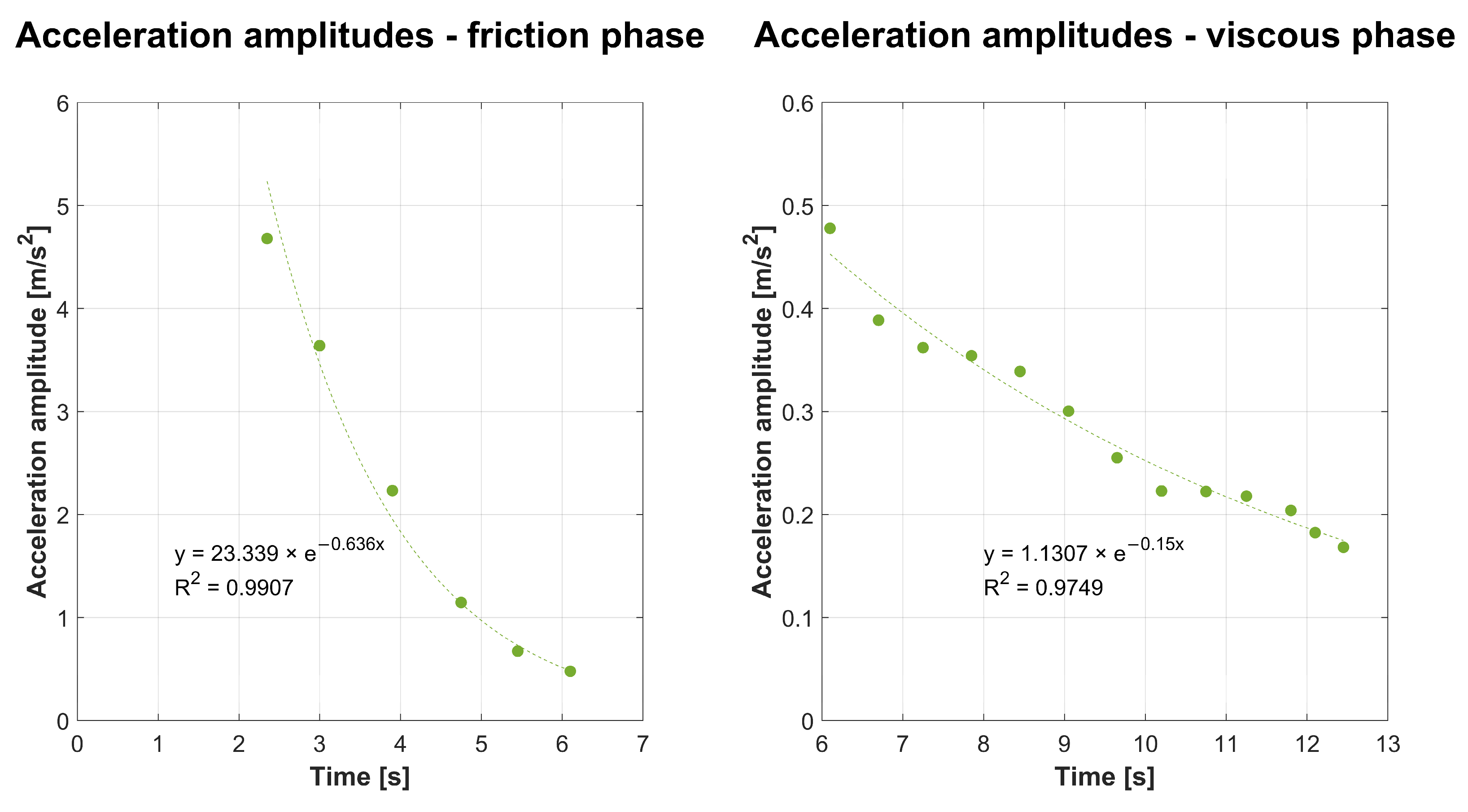

3.2. Determination of the Degree of Damping

4. Global Numerical Model

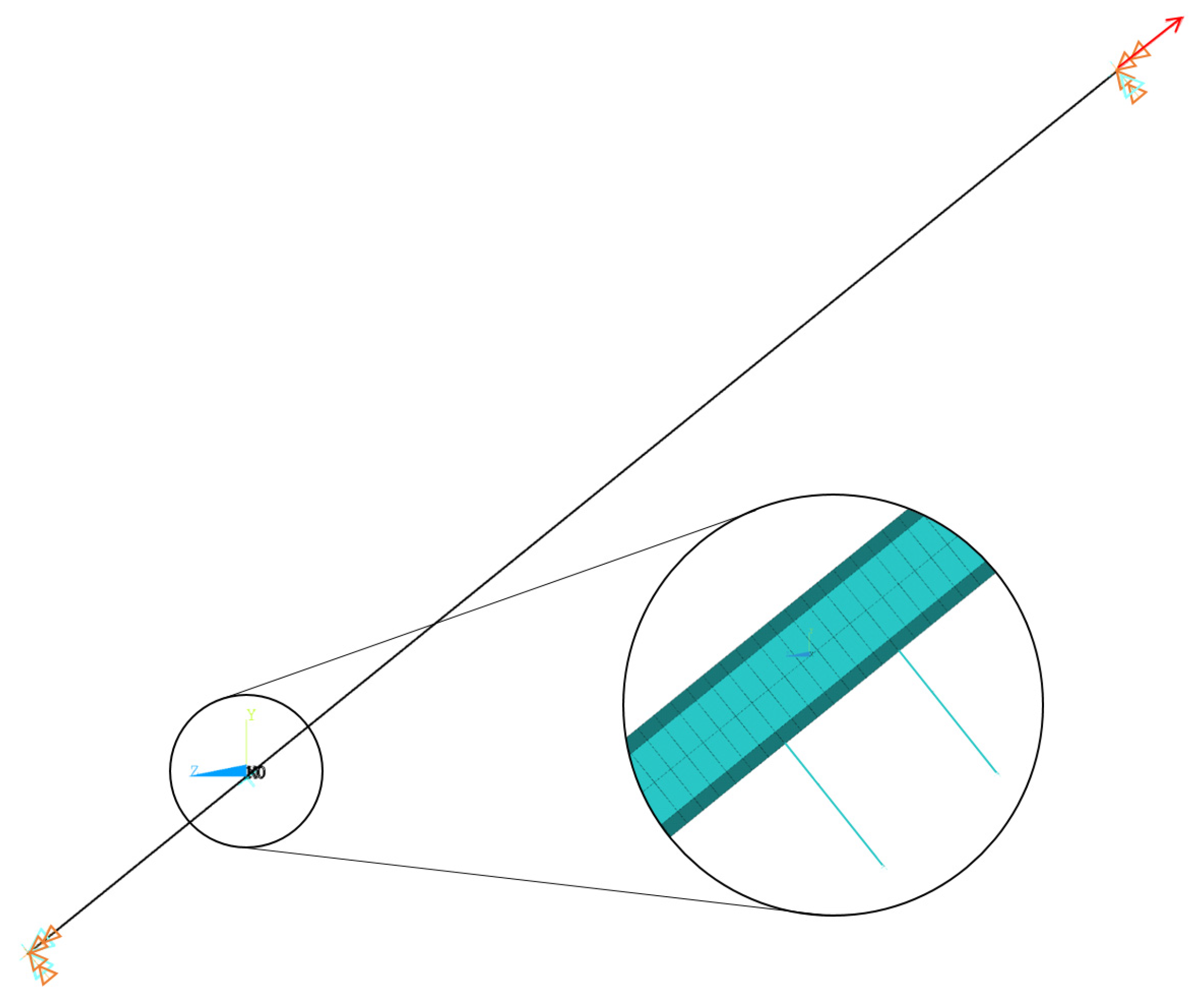

4.1. Structure of the Global Model

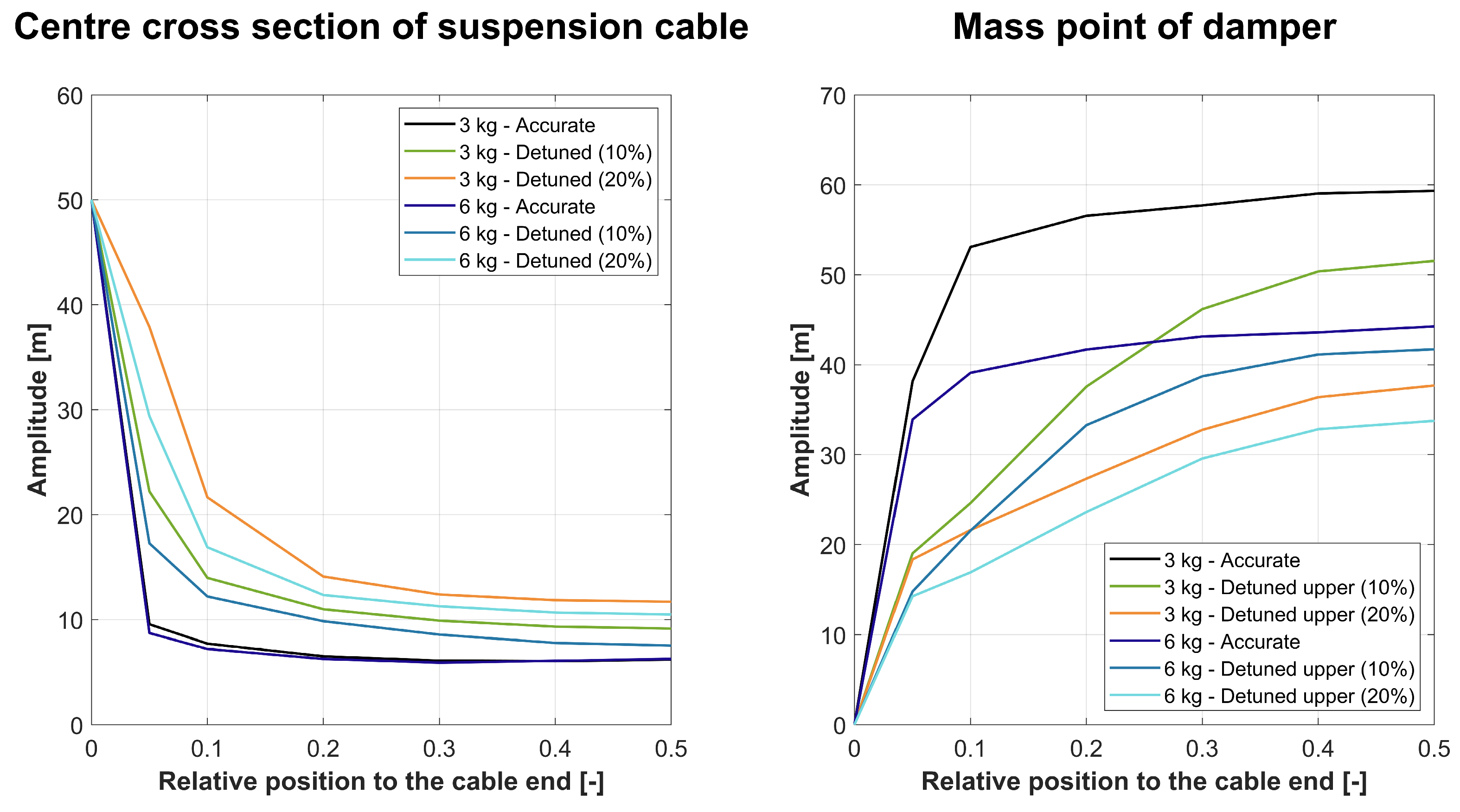

4.2. Investigating the Effectiveness of Damping

4.3. Investigating the Position of the Damper

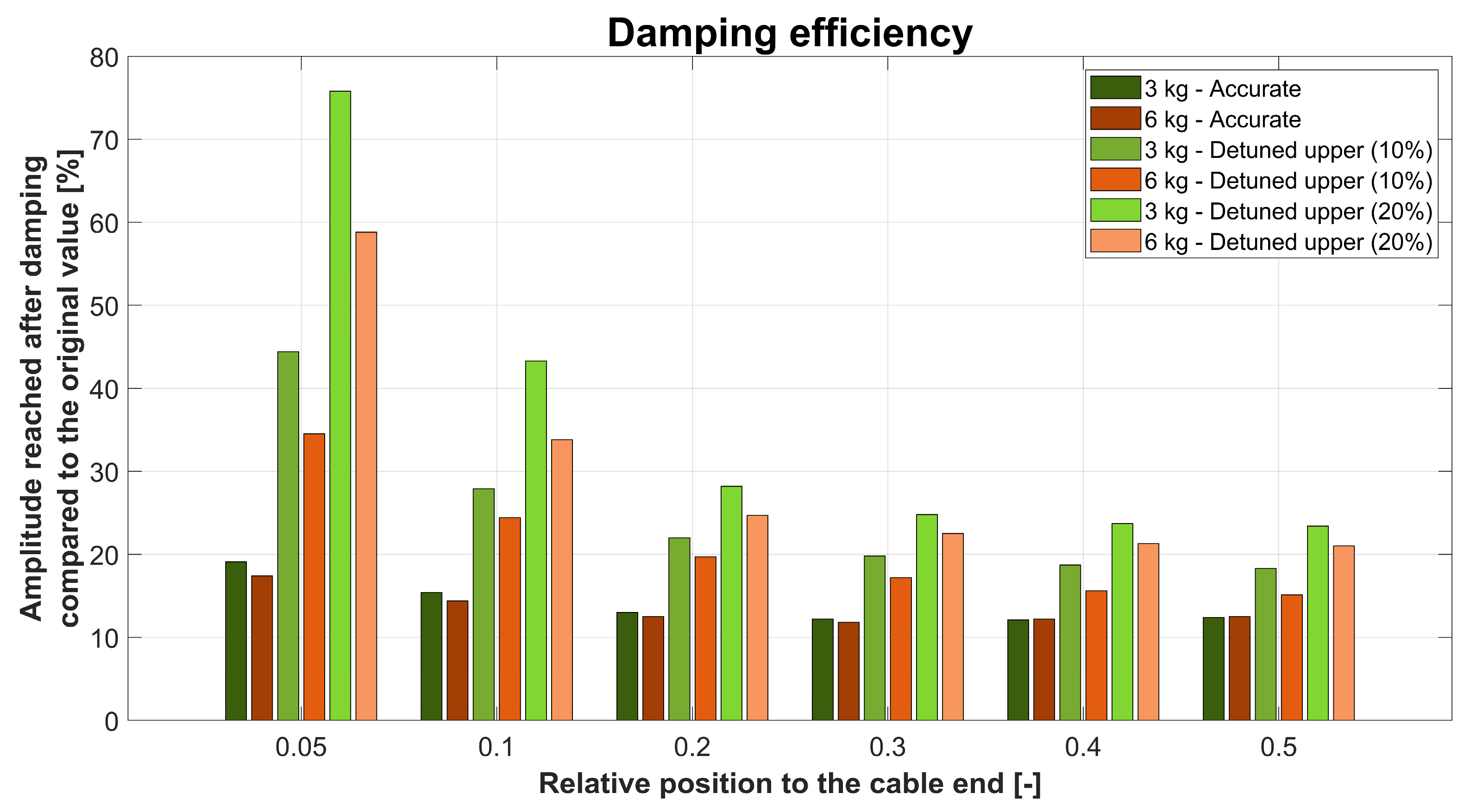

4.4. Effect of Changing the Vibrating Mass

4.5. Suggestions for Effective Damping Design

- In terms of attenuation efficiency, it is preferable to position the attenuator as close as possible to the centre of the cable, but in practice, a positioned element 20% from the cable end can reduce the amplitude to 30%, and this efficiency is not significantly affected by moving the element towards the centre of the cable. Thus, a relative position of ~20% is optimal in terms of attenuation and positioning;

- Due to the fact that the cable forces are not constant in real life, it is advisable to use a certain detuning to maintain the effectiveness of the attenuator. Figure 15 shows that, depending on the amount of detuning, the attenuator efficiency deteriorates at the design’s natural frequency, but the difference between the accurate and detuned elements decreases as the relative position shifts towards the cable centre. Above the proposed ~20% relative position, even at the extreme of 20% detuning, there is only a 4% difference in amplitude between the exact and the detuned elements;

- By increasing the masses at the end of the damper, the damping efficiency is improved, which effect is negligible for precisely tuned elements, but the amount of detuning the effect also increases.

4.6. Application

5. Local Numerical Model

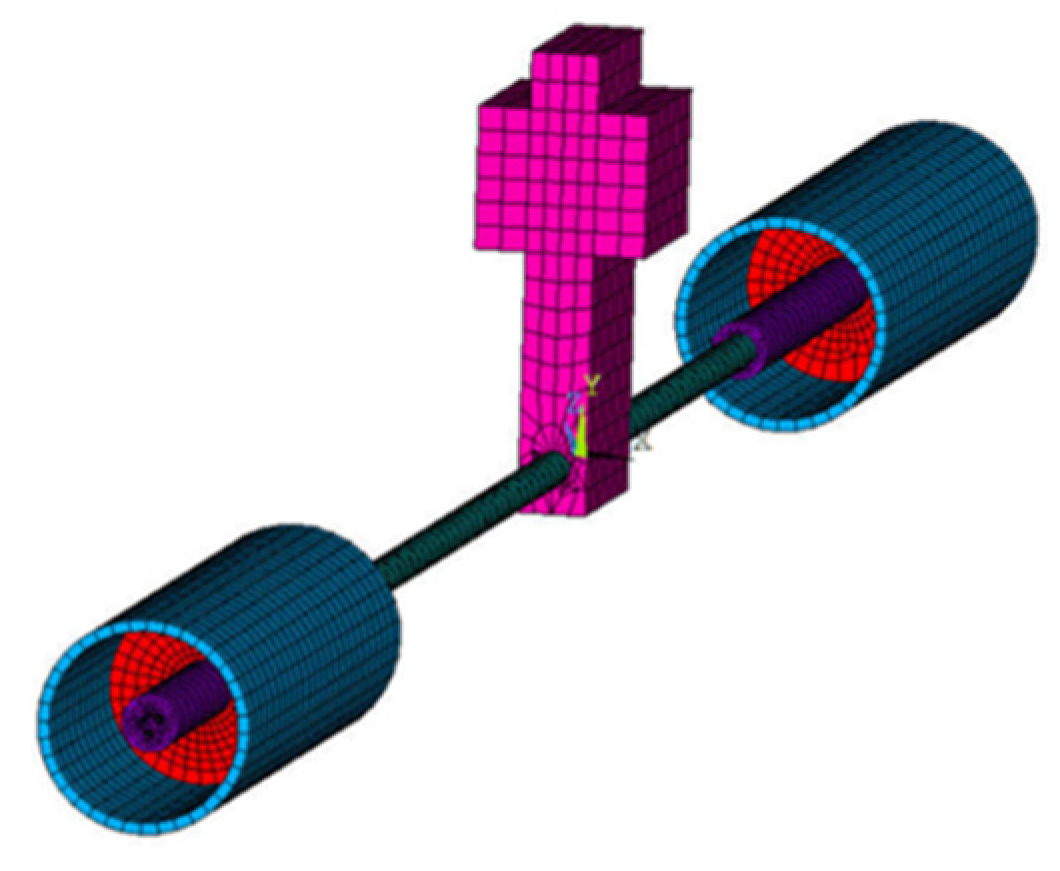

5.1. Presentation of the Numerical Model

5.2. Validation of the Numerical Model

6. Results of the Parametric Study

6.1. Theoretical Background

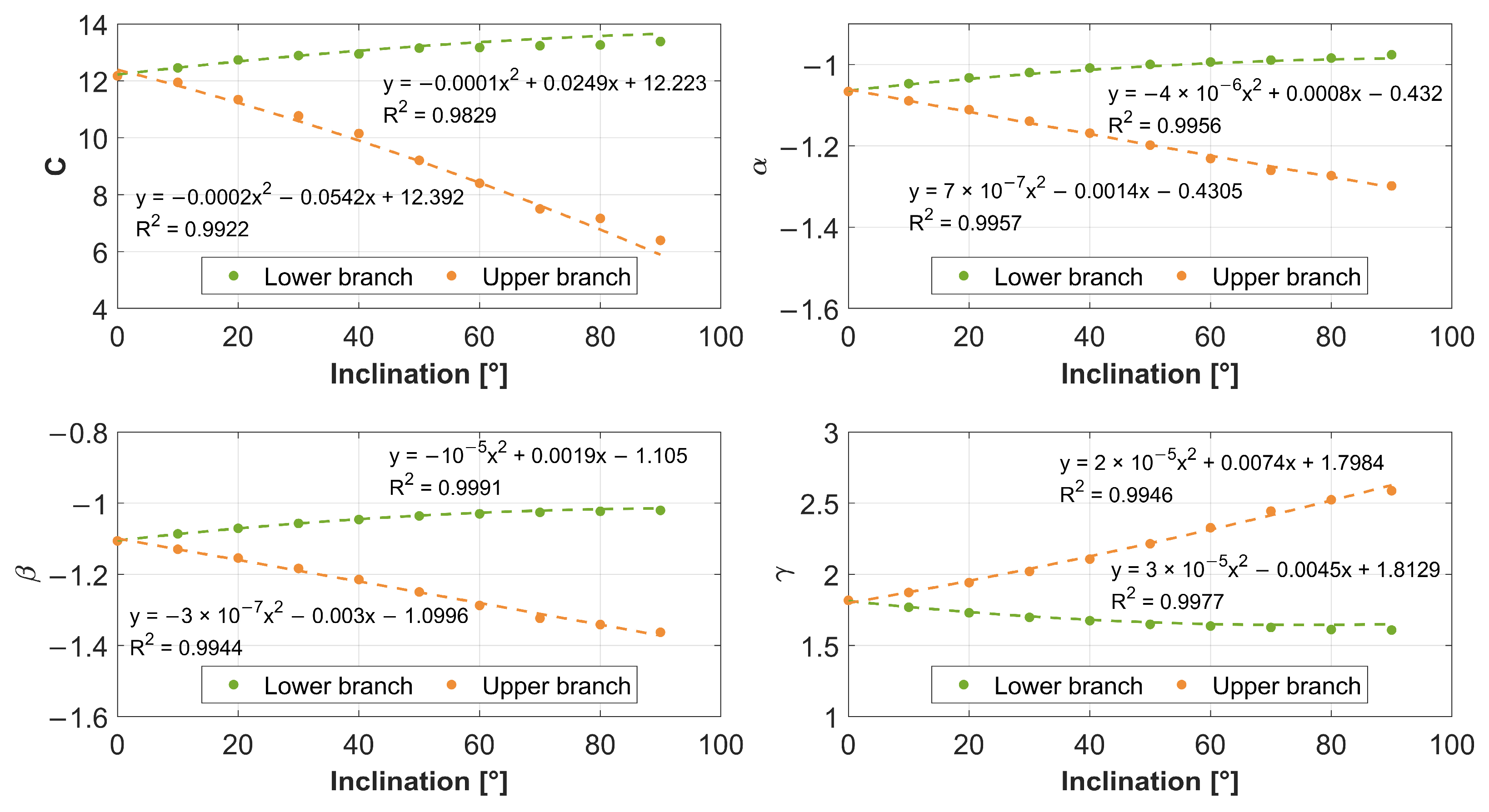

6.2. Results of Parameter Estimation

- In Equation (2), which is effectively “dimensionless”, substitute the parameters (, and ) of the damping element, in order of , and dimensions.

- The values of the coefficients and C as a function of the cable inclination angle can be taken from the graphs in Figure 20.

- Knowing these, the natural frequency can be calculated from the given equation.

6.3. Proposed Formula Reliability Check

7. Conclusions

- In terms of attenuation efficiency, it is preferable to position the attenuator as close as possible to the centre of the cable, but in practice, a positioned element 20% from the cable end can reduce the amplitude to 30%, and this efficiency is not significantly affected by moving the element towards the centre of the cable. Thus, a relative position of ~20% is optimal in terms of attenuation and positioning;

- Due to the fact that the cable forces are not constant in real life, it is advisable to use a certain detuning to maintain the effectiveness of the attenuator. Figure 15 shows that, depending on the amount of detuning, the attenuator efficiency deteriorates at the design’s natural frequency, but the difference between the accurate and detuned elements decreases as the relative position shifts towards the cable centre. Above the proposed ~20% relative position, even at the extreme of 20% detuning, there is only a 4% difference in amplitude between the exact and the detuned elements;

- By increasing the masses at the end of the damper, the damping efficiency is improved, which effect is negligible for precisely tuned elements, but the amount of detuning the effect also increases.

- The natural frequency of the damper can be estimated using the following formula:

- In the equation given above, which is effectively “dimensionless”, substitute the parameters (, and ) of the damping element, in order of , and dimensions.

- The values of the coefficients and C as a function of the cable inclination angle can be taken from the graphs in Figure 20.

- Knowing these, the natural frequency can be calculated from the given equation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sun, L.; Chen, L.; Huang, H. Stay cable vibration mittigation: A review. Adv. Struct. Eng. 2022, 25, 3368–3404. [Google Scholar] [CrossRef]

- SPECIÁLTERV. The Robinson Bridge. 2022. Available online: https://www.specialterv.hu/projects/bridges/robinsonbridge (accessed on 15 April 2024).

- Zhou, H.; Sun, L.; Xing, F. Damping of full-scale stay cable with viscous damper: Experiment and analysis. Adv. Struct. Eng. 2016, 17, 265–274. [Google Scholar] [CrossRef]

- Zhou, H.; Xiang, N.; Huang, X.; Sun, L.; Xing, F.; Zhou, R. Full-scale test of dampers for stay cable vibration mitigation and improvement measures. Struct. Monit. Maint. 2018, 5, 489–506. [Google Scholar] [CrossRef]

- Chen, L.; Sun, L. Laboratory-scale experimental setup for studying cable dampers. J. Eng. Mech. 2014, 141, 04014159. [Google Scholar] [CrossRef]

- Chen, L.; Sun, L.; Xu, Y.; Di, F.; Xu, Y.; Wang, L. A comparative study of multi-mode cable vibration control using viscous and viscoelastic dampers through field tests on the Sutong Bridge. Eng. Struct. 2020, 224, 111226. [Google Scholar] [CrossRef]

- Sun, L.; Chen, L. Free vibrations of a taut cable with a general viscoelastic damper modeled by fractional derivatives. J. Sound Vib. 2015, 335, 19–33. [Google Scholar] [CrossRef]

- Zhao, Y.; Huang, P.; Long, G.; Yuan, Y.; Sun, Y. Influence of Fluid Viscous Damper on the Dynamic Response of Suspension Bridge under Random Traffic Load. Adv. Civ. Eng. 2020, 2020, 1857378. [Google Scholar] [CrossRef]

- Liang, L.; Feng, Z.; Xu, Y.; Chen, Z.; Liang, L. Parallel Scheme of Friction Dampers and Viscous Dampers for Girder-End Longitudinal Displacement Control of a Long-Span Suspension Bridge under Operational and Seismic Conditions. Buildings 2023, 13, 412. [Google Scholar] [CrossRef]

- Wu, C.; Jing, H.; Feng, Z.; Song, J.; Wan, T.; Chen, Z. Control of longitudinal movement response of suspension bridges induced by passing trains using low-exponent fluid viscous dampers. Structures 2024, 62, 106330. [Google Scholar] [CrossRef]

- Wu, C.; He, X.; He, L.; Zhao, X.; Wang, Y.; Li, C.; Yang, Y.; Zhang, X. Improving cable-stayed bridge longitudinal aseismic capability via fluid viscous damper parametric optimization and experimental investigation. Structures 2023, 57, 105199. [Google Scholar] [CrossRef]

- Chen, L.; Di, F.; Xu, Y.; Sun, L.; Xu, Y.; Wang, L. Multimode cable vibration control using a viscous-shear damper: Case studies on the Sutong Bridge. Struct. Control Health Monit. 2020, 27, e2536. [Google Scholar] [CrossRef]

- Yoneda, M.; Maeda, K. A study on practical estimation method for structural damping of stay cable with damper. In Proceedings of the Canada-Japan Workshop on Bridge Aerodynamics, Ottawa, ON, Canada, 25–27 September 1989; pp. 119–128. [Google Scholar]

- Weber, F.; Høgsberg, J.; Krenk, S. Optimal tuning of amplitude proportional coulomb friction damper for maximum cable damping. J. Struct. Eng. 2010, 136, 123–134. [Google Scholar] [CrossRef]

- Chen, L.; Sun, L. Calibration of nonlinear damper for shallow cable based on forced vibration analysis. In Proceedings of the EASEC-15, Xi’an, China, 11–13 October 2017; pp. 1852–1859. [Google Scholar]

- Chen, L.; Sun, L. Steady-state analysis of cable with nonlinear damper via harmonic balance method for maximizing damping. J. Struct. Eng. 2017, 143, 04016172. [Google Scholar] [CrossRef]

- Nakamura, A.; Kasuga, A.; Arai, H. The effects of mechanical dampers on stay cables with high-damping rubber. Const. Build. Mat. 1998, 12, 115–123. [Google Scholar] [CrossRef]

- Takano, H.; Ogasawara, M.; Ito, N.; Shimosato, T.; Takeda, K.; Murakami, T. Vibrational damper for cables of the Tsurumi Tsubasa Bridge. J. Wind Eng. Ind. Aerodyn. 1997, 69–71, 807–818. [Google Scholar] [CrossRef]

- Su, X.; Kang, H.; Guo, T. Modelling and energy transfer in the coupled nonlinear response of a 1:1 internally resonant cable system with a tuned mass damper. Mech. Syst. Signal Process. 2022, 162, 108058. [Google Scholar] [CrossRef]

- Gu, M.; Xiang, H.F.; Chen, A.R. A practical method of passive TMD for suppressing wind-induced vertical buffeting of long-span cable-stayed bridges and its application. J. Wind Eng. Ind. Aerodyn. 1994, 51, 203–213. [Google Scholar] [CrossRef]

- Di, F.; Sun, L.; Chen, L. Suppression of vortex-induced high-mode vibrations of a cable-damper system by an additional damper. Eng. Struct. 2021, 242, 112495. [Google Scholar] [CrossRef]

- Kaczmarczyk, S.; Iwankiewicz, R. Nonlinear Vibrations of a Cable System with a Tuned Mass Damper under Deterministic and Stochastic Base Excitation. Procedia Eng. 2017, 199, 675–680. [Google Scholar] [CrossRef]

- Cu, V.H.; Han, B.; Pham, D.H. Tuned mass-high damping rubber damper on a taut cable. KSCE J. Civ. Eng. 2017, 21, 928–936. [Google Scholar] [CrossRef]

- Javidan, M.M.; Assefa, J.D.; Kim, J. Seismic retrofit of low-rise structures using rotational viscoelastic dampers. Structures 2023, 58, 105403. [Google Scholar] [CrossRef]

- Javidan, M.M.; Kim, J. Steel hexagonal damper-brace system for efficient seismic protection of structures. Steel Compos. Struct. 2022, 45, 683–695. [Google Scholar] [CrossRef]

- Javidan, M.M.; Kim, J. A ductile steel damper-brace for low-damage framed structures. Steel Compos. Struct. 2022, 44, 325–337. [Google Scholar] [CrossRef]

- Markiewicz, M. Optimum dynamic characteristics of Stockbridge dampers for dead-end spans. J. Sound Vib. 1995, 188, 243–256. [Google Scholar] [CrossRef]

- Vecchiarelli, J.; Currie, I.G.; Havard, D.G. Computational analysis of aeolian conductor vibration with a Stockbridge-type damper. J. Fluids Struct. 2000, 14, 489–509. [Google Scholar] [CrossRef]

- Liu, X.; Yang, Y.; Sun, Y.; Zhong, Y.; Zhou, L.; Li, S.; Wu, C. Tuned-mass-damper-inerter performance evaluation and optimal design for transmission line under harmonic excitation. Buildings 2022, 12, 435. [Google Scholar] [CrossRef]

- Barry, O.R. Vibration Modelling and Analysis of a Single Conductor with Stockbridge Dampers. Ph.D. Thesis, University of Toronto, Toronto, ON, Canada, 2014. [Google Scholar]

- Golebiowska, I.; Dutkiewicz, M. Experimental analysis of efficiency of mass dampers. In Proceedings of the 23rd International Conference Engineering Mechanics, Svratka, Czech Republic, 15–18 May 2017. [Google Scholar]

- Wagner, H.; Ramamurti, V.; Sastry, R.; Hartman, K. Dynamic of Stockbridge Dampers. J. Sound Vib. 1973, 30, 207–220. [Google Scholar] [CrossRef]

- Yin, Q.; Zhao, J.; Liu, Y.; Zhang, Y. The approximate calculation of the natural frequancies of a Stockbridge type vibration damper and analysis of natual frequencies sensitivity to the structural parameters. Mech. Sci. 2021, 12, 863–873. [Google Scholar] [CrossRef]

- Barbieri, N.; Marchi, M.; Mannala, M.; Barbieri, R.; Barbieri, L.; Barbieri, G. Nonlinear dynamic analysis of a Stockbridge damper. Can. J. Civ. Eng. 2018, 46, 828–835. [Google Scholar] [CrossRef]

- Foti, F.; Martinelli, L. Hysteretic Behaviour of Stockbridge dampers: Modelling and parameter identification. Math. Probl. Eng. 2018, 2018, 8925121. [Google Scholar] [CrossRef]

- ANSYS®, version 19.1; Ansys: Canonsburg, PA, USA, 2018.

- MATLAB, version R2023a; MathWorks: Natick, MA, USA, 2023.

| Natural Frequency [Hz] | Relative Deviation [%] | |||||

|---|---|---|---|---|---|---|

| Lower Branch | Upper Branch | |||||

| Damper Parameters | Analytical | Numerical | Analytical | Numerical | Lower b. | Upper b. |

| 1.292 | 1.258 | 1.114 | 1.100 | 2.72 | 1.23 | |

| 2.123 | 2.021 | 1.754 | 1.768 | 5.09 | 0.77 | |

| 2.249 | 2.155 | 1.831 | 1.836 | 4.34 | 0.25 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Olosz, A.; Kövesdi, B.; Hegyi, P.; Dunai, L. Improvement of Stockbridge Damper Design for Cable-Stayed Bridges. Appl. Mech. 2024, 5, 818-838. https://doi.org/10.3390/applmech5040046

Olosz A, Kövesdi B, Hegyi P, Dunai L. Improvement of Stockbridge Damper Design for Cable-Stayed Bridges. Applied Mechanics. 2024; 5(4):818-838. https://doi.org/10.3390/applmech5040046

Chicago/Turabian StyleOlosz, Adél, Balázs Kövesdi, Péter Hegyi, and László Dunai. 2024. "Improvement of Stockbridge Damper Design for Cable-Stayed Bridges" Applied Mechanics 5, no. 4: 818-838. https://doi.org/10.3390/applmech5040046

APA StyleOlosz, A., Kövesdi, B., Hegyi, P., & Dunai, L. (2024). Improvement of Stockbridge Damper Design for Cable-Stayed Bridges. Applied Mechanics, 5(4), 818-838. https://doi.org/10.3390/applmech5040046