Abstract

Asphalt concrete pavements are vulnerable to freeze-thaw cycles. Consecutive cracking and penetration of corrosive agents can expedite the degradation of asphalt pavements and result in weight loss and reduced strength. Fiber reinforcement in flexible bituminous asphalt bridge cracks limits the crack width and enhances the toughness of the composite. Furthermore, steel fibers facilitate asphalt heating during maintenance and repair operations. Electrical resistivity is a vital parameter to measure the efficiency of these operations and to identify the state of degradation in fiber-reinforced asphalt concrete. The significant difference between conductivities of steel fibers and bituminous matrix warrants in-depth investigations of the influence of fiber reinforcement on the measured surface electrical resistivity of placed pavements. Numerical simulations endeavor to predict the resistivity and associated deviations due to randomly distributed fiber reinforcement. Results and discussions reveal the sources and magnitudes of fiber geometry and content adjustments. Outcomes investigate associated errors for practical applications.

1. Introduction

The sustainable development of resilient infrastructure warrants the application of high-performance materials to extend the service life of engineering systems, such as pavements infrastructure, and to minimize input energy and greenhouse gas emissions [1,2,3,4,5]. Extensive resources required to maintain and operate pavement systems signify the importance of planning for sustainability and resilience [6,7,8].

1.1. Durability of Bituminous Asphalt Composites

Asphalt pavements are vulnerable to thermal and chemical environmental conditions. Combinations of volume changes due to freeze–thaw cycles, cracking due to strength loss, and penetration of water and deicing chemicals in asphalt result in progressive weight loss and degradation of structural capacity. Physical and mechanical properties of the aggregate and bituminous matrix and their interaction within the interfacial zone determine materials resistance against these degradations [9,10]. The application of sustainable materials, such as recycled aggregates, is a common practice to enhance the performance and extend the service life of the pavement with adequate resilience against risks [11]. An evaluation of the asphalt performance includes investigating specific material characteristics, such as permeability, porosity, chemical stability, environmental conditions (including the presence of chemicals and salts, water flow, and pressure), and applied cycles of freezing and thawing [12]. Using proper types and gradations of aggregates tends to reduce permeability and limit damages due to the accumulation of water, salt, and chemical agents in mixture voids [12,13,14,15,16].

1.2. Fiber-Reinforced Asphalt

Fiber reinforcement is an established technique to control cracking in composite materials, such as concrete and asphalt pavements [17]. In addition, conductive fibers can facilitate conductive heating as an efficient method to alleviate freezing conditions and enhance healing mechanisms [18,19,20,21,22]. Electrically conductive cementitious or asphalt concrete pavements utilize steel and graphite fibers to achieve required conductivity in critical applications, including airports and bridge decks [23,24,25]. Slender steel fibers are more efficient than graphite powders due to higher conductivity values and the ability to bridge crack widths [26]. However, additives such as graphene and slag are often used to reduce required heating energy without changing the hearing rate [27]. Fibers are placed directly in the hot mix asphalt [28], with proportioning adjustments to increase the bituminous contents [29]. Application of fibers from virgin or recycled sources may also change the air voids and other physical and mechanical properties of the mixture, determining the durability of the pavement [30,31,32,33,34,35,36,37,38,39,40,41].

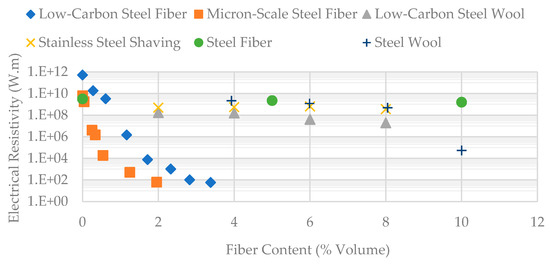

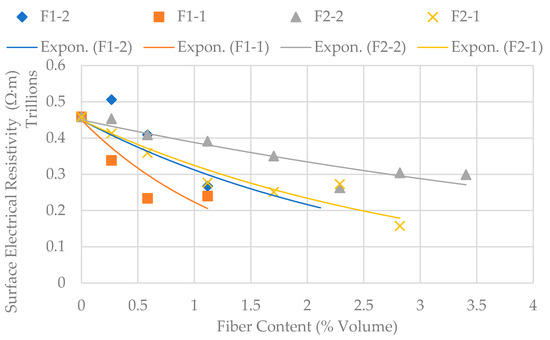

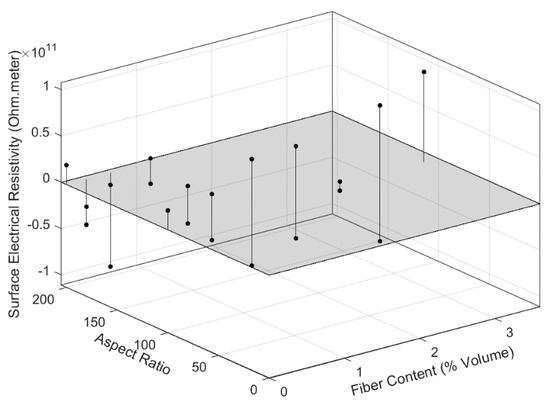

The electrical resistivity of the asphalt is an efficient measure of the conductive heating efficiency of the pavement, which is enhanced by conductive fibers [37,42,43,44]. The surface electrical resistivity is an adaptable method for sensor-based structural health monitoring [45]. The bituminous asphalt is an insulative material with an electrical resistivity of 1011 to 1013 . The electrical resistivity of asphalt concrete is slightly lower than bitumen within the range of 107 to 109 . The addition of steel and carbon fibers can substantially reduce this value in the 101 to 103 . range [44]. The external heating using electromagnetic induction or microwave radiation relies on the electrical resistivity of the pavement to achieve proper temperature and polarization effects [40,46,47,48,49,50,51,52]. The optimum temperature depends on various external conditions, such as time and damage [53,54], as well as internal parameters, such as viscosity and mixture properties [40,47,52,53,54,55,56]. The heating capacity of the bitumen has a substantial impact on the healing properties of the asphalt composite. This capacity, which additives can adjust, influences the level of energy required to begin the healing process in bitumen [34,57,58,59]. Porosity also facilitates the healing and recovery of asphalt mixtures [34,60]. High thermal energy absorption of fibers compared to bituminous matrix and aggregates facilitates this process [52]. However, the practical range of fiber contents is typically 6 to 8 percent by volume to avoid clustering during mixing procedures [61]. Figure 1 displays selected observed data which indicate fiber contents and measured electrical resistivity of the composite bituminous asphalt materials (Table 1). The scattered observations warrant numerical studies in order to understand the trends of electrical resistivity measures concerning fiber type, content, and geometry.

Figure 1.

Selected experimental data on fiber content and electrical resistivity.

Table 1.

Selected experimental studies on the electrical resistivity of fiber-reinforced asphalt.

2. Materials and Methods

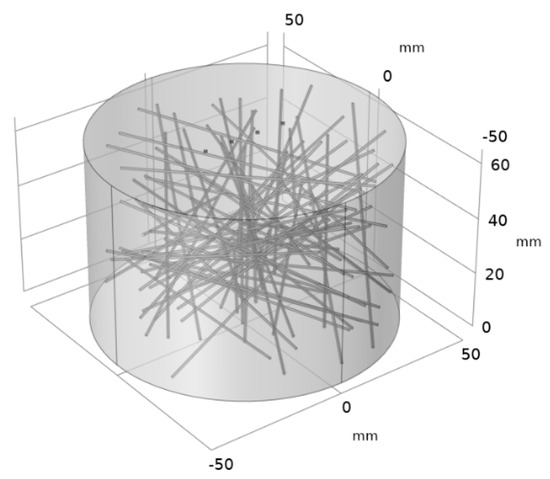

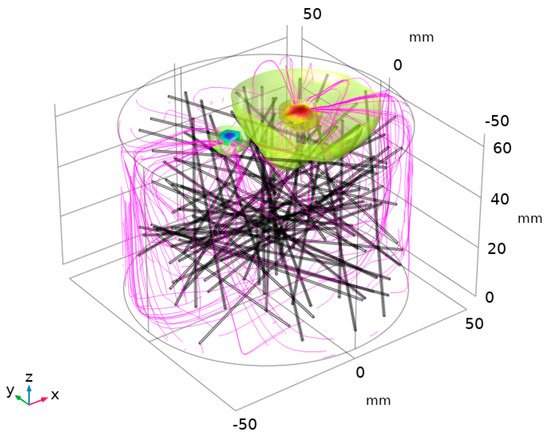

A multi-physics finite element model using COMSOL simulates the numerical solution to the electrical resistivity of asphalt concrete (Figure 2) [63,64,65]. Random distribution of fibers within the asphalt prototype is generated using a pre-processor MATLAB routine [66]. The modeled prototype is a 100 mm-diameter cylinder with a height of 65 mm. The electrical resistivity is 4.5 × 1011 for the homogenized matrix and 2.4 × 10−7 for fibers. Models incorporated two aspect ratio (length to diameter) values of 200 (F1) and 100 (F2) (Table 2). The distribution of fibers in asphalt can be considered random [67]. The finite element model contains nearly 340 solid objects within the modeled cylinder [68]. Figure 3 shows a sample section view of the prototype.

Figure 2.

A sample finite element model of fiber-reinforced asphalt concrete prototype.

Table 2.

Dimensions of fibers.

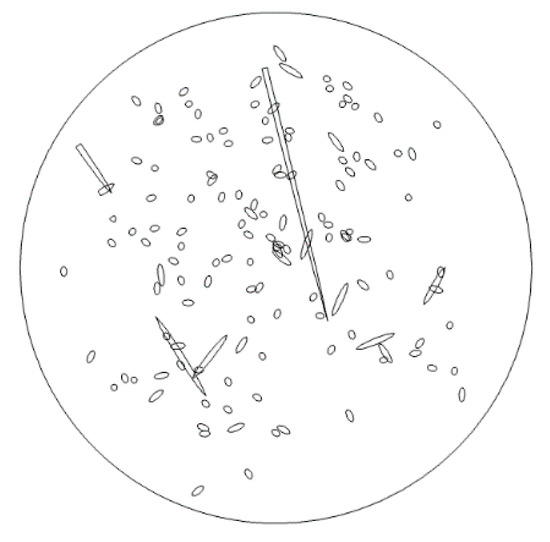

Figure 3.

Simulated fiber dispersion through a section view at a 30 mm height.

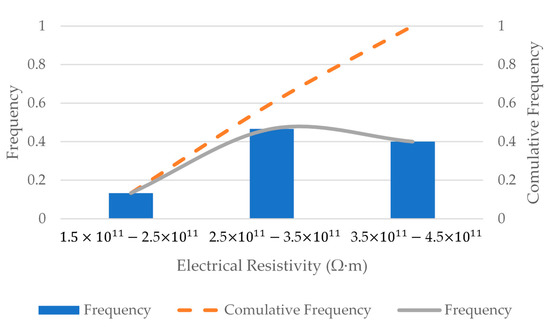

In addition, a series of samples with various fiber dispersion was analyzed to verify the reliability of electrical resistivity results concerning the random distribution of fibers. For this purpose, a total of 15 samples with the same fiber content were examined to assure the normal distribution of fibers within the prototype. Shapiro–Wilk and Kolmogorov–Smirnova rates were 0.861 and 0.148, respectively, which were more significant than 0.05, indicating a normal distribution of numerical analysis results. The values of Kurtosis and Skewness were −0.372 and −0.886, respectively, which were between 2 and −2, confirming the normal distribution of the results (Figure 4). Hence, variations in the random dispersion of fibers do not cause bias, skew, or instability in calculated electrical resistivity measures.

Figure 4.

The normal distribution of electric resistivity values for various fiber dispersions.

The model follows Wenner’s method using four electrodes at an equal spacing in a row as shown with dots in Figure 2, with two external electrodes transmitting the specified current and two internal electrodes measuring the electrical resistance. Equation (1) expresses the surface electrical resistivity in Wenner’s method:

where is the surface electrical resistance, R is the electrical resistance, and s is the distance between electrodes. The model imposed a simulated current of 1 A/m2 at a spacing of 30 mm. The electrical potential formulation follows Poisson’s equation combining the Gauss’ law and continuity equation:

where σ is the electrical conductivity, V is the electric potential, Je is the volume of external current, and Qi is the current at the source.

3. Results

Imposed electrical current is one ampere per square meter at electrodes spaced 10 mm at the top surface of the asphalt porotype (Figure 5). The concentration of the current density in green color is evident at the contact points of electrodes. Purples lines indicate the electric current flow within the body of the prototype, and black lines show fibers.

Figure 5.

Electrical conductivity lines in the simulated model.

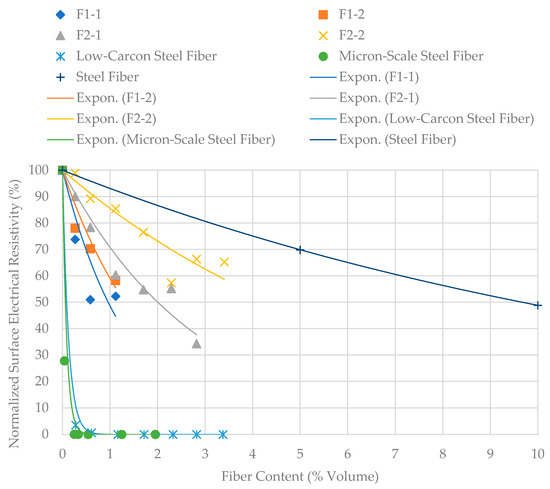

Figure 6 indicates that increasing steel fiber content reduces the surface electrical resistivity. Table 3 provides a summary of reduction rates using exponential regressions. Disregarding a few outliers, it is evident from results that a higher aspect ratio of fibers results in higher rates of reduction in the electrical resistivity. Furthermore, the electrical resistivity is dropped sharper for shorter fibers with the same aspect ratio.

Figure 6.

The electrical resistance for different percentages of fiber content.

Table 3.

Regression results for surface electrical resistivity.

4. Discussion

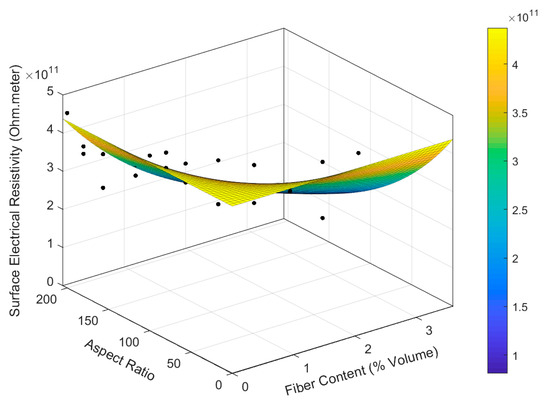

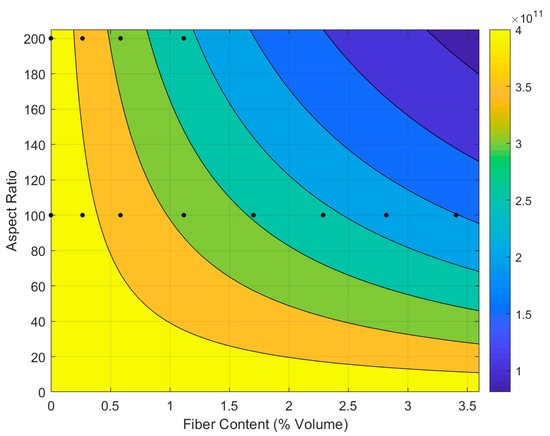

Statistical evaluation of numerical results indicate the best fitting model to follow Equation (3), which is comparable with the outcome of part 1 of this paper for cementitious composites (Figure 7):

where RFRAC and RPAC are the measured electrical resistivity () of fiber-reinforced and plain asphalt concrete, respectively; is the fiber length (mm); d is the fiber diameter (mm); v is the volumetric fiber content (%); and p and q are regression constants. The surface electrical resistivity of the investigated plain asphalt concrete model, RPAC is 4.5 × 1011 , and associated regression parameters p and q are −0.0287 ± 8.56 × 10−2 and −0.00228 ± 7.08 × 10−4 for 95% confidence bounds, respectively. Figure 8 shows that the effect of fiber reinforcement on surface electrical resistivity is negligible for low fiber aspect ratios, say 20. Similarly, the effect of aspect ratio is not significant when the fiber content is lower than 0.5% by volume. Figure 9 exhibits a residuals plot for the proposed model revealing dispersion of results for a few prototypes with the same aspect ratio but different length and diameter values, which are greater than those observed in part 1 of the paper. Furthermore, surface electrical resistance reduction trends with fiber content are similar to experimental cases, validating the proposed methodology (Figure 10, Table 4).

Figure 7.

The electrical resistance for different percentages of fiber content.

Figure 8.

The surface electrical resistance () contour map for the proposed fit.

Figure 9.

The residuals plot of surface electrical resistance () for the proposed fit.

Figure 10.

Comparison of decreasing surface electrical resistance with increasing volumetric percentage of steel fiber in numerical and experimental experiments.

Table 4.

Formulation of experimental and numerical results trends.

5. Conclusions

Fiber reinforcement in bituminous asphalt typically involves shorter and thinner fibers than cementitious concrete. The difference in size implies that the number of fibers in asphalt is more significant than concrete fibers for the same fiber content volume. In addition, the practical content of fiber by volume in asphalt is more than that in concrete. Regardless, the presence of steel fibers reduces the electrical resistivity of the asphalt-like concrete.

Numerical studies indicated that the reduction rate in surface electrical resistivity in asphalt follows the same model as concrete and varies according to fiber content and aspect ratio. Regression parameters of asphalt are close to those observed for concrete; however, the goodness of fit for asphalt shows less fidelity due to the more significant dispersion of results. Hence, further studies are required to broaden the range of parameters and provide empirical verifications.

Author Contributions

Conceptualization, F.M.T.; methodology, F.M.T. and A.M.; software, A.M.; validation, A.M. and R.E.; formal analysis, F.M.T., A.M. and R.E.; investigation, F.M.T. and R.E.; resources, F.M.T., A.M. and R.E.; data curation, A.M.; writing—original draft preparation, F.M.T., A.M. and R.E.; writing—review and editing, F.M.T.; visualization, F.M.T., R.E. and A.M.; supervision, F.M.T.; project administration, F.M.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All generated data are presented in this paper. No other data were created or analyzed in this study. Data sharing is not applicable to this article.

Acknowledgments

Authors acknowledge computer lab resources provided by their own affiliated institutes.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Tehrani, F.M.; Nelson, D. From Sustainability to Resilience: A Practical Guide to ENVISION®. In Objective Resilience, Book2: Objective Processes; Ettouney, M., Ed.; ASCE Press: Reston, VA, USA, 2022. [Google Scholar]

- Nelson, D.; Tehrani, F.M. Is resilience … sustainable? APWA Rep. 2018, 85, 53–56. [Google Scholar]

- Tehrani, F.M. Deploying and rating sustainable practices for resilient bridge infrastructure. In Proceedings of the Fifth International Conference on Bridges, Tehran, Iran, 17–18 December 2019; AUT: Tehran, Iran, 2019. Paper MS05. [Google Scholar]

- Tehrani, F.M.; Miller, N.M. Tire-derived Aggregate Cementitious Materials: A Review of Mechanical Properties. In Cement-Based Materials; Saleh, H., Ed.; IntechOpen: London, UK, 2018. [Google Scholar]

- Berry, E.; Shadravan, B.; Tehrani, F.M. A Sustainable Approach to Assess the Resilience of Perforated Wood Shear Walls. In Proceedings of the AEI Conference, Oklahoma City, OK, USA, 11–13 April 2017; ASCE: Reston, VA, USA; pp. 506–512. [Google Scholar]

- Tehrani, F.M. Sustainability and resilience through project management. In Proceedings of the 5th International Congress on Civil Engineering, Architecture & Urban Development, Tehran, Iran, 17–18 December 2017; ICSAU: Tehran, Iran, 2017. AB-01440-B. [Google Scholar]

- Tehrani, F.M.; Dadkhah, M. A Case Study on the Analysis of Energy and Emissions for Sustainability Rating. Int. J. Clim. Chang. Impacts Responses 2018, 1, 13–23. [Google Scholar] [CrossRef]

- Tehrani, F.M.; Alexandrou, A.; Mahoney, M.; Adhikari, D.; Raymond, M. Energy inputs and carbon dioxide emissions from construction equipment during construction of a golf course. Int. J. Eng. Res. Innov. 2014, 6, 78–86. [Google Scholar]

- Feng, D.; Yi, J.; Wang, D.; Chen, L. Impact of salt and freeze–Thaw cycles on performance of asphalt mixtures in coastal frozen region of China. Cold Reg. Sci. Technol. 2010, 62, 34–41. [Google Scholar] [CrossRef]

- Guo, M.; Tan, Y.; Wang, L.; Hou, Y. A state-of-the-art review on interfacial behavior between asphalt binder and mineral aggregate. Front. Struct. Civ. Eng. 2018, 12, 248–259. [Google Scholar] [CrossRef]

- Tehrani, F.M. Noise abatement of rubberized hot mix asphalt: A brief review. Int. J. Pavement Res. Technol. 2015, 8, 58. [Google Scholar]

- Ehsani, R.; Miri, A.; Tehrani, F.M. A Quantitative Investigation of the Durability of Asphalt Pavement Materials Using Experimental Freeze-and-Thaw Weathering Data. In Proceedings of the ASCE International Airfield & Highway Pavements Conference: Pavement Design, Construction, and Condition Evaluation, Austin, TX, USA, 8–10 June 2021; Ozer, H., Rushing, J.F., Leng, Z., Eds.; ASCE: Reston, VA, USA, 2021; pp. 169–177. [Google Scholar]

- Amini, B.; Tehrani, S.S. Simultaneous effects of salted water and water flow on asphalt concrete pavement deterioration under freeze–thaw cycles. Int. J. Pavement Eng. 2014, 15, 383–391. [Google Scholar] [CrossRef]

- Gong, Y.; Bi, H.; Liang, C.; Wang, S. Microstructure Analysis of Modified Asphalt Mixtures under Freeze-Thaw Cycles Based on CT Scanning Technology. Appl. Sci. 2018, 8, 2191. [Google Scholar] [CrossRef] [Green Version]

- Lovqvist, L. Towards Frost Damage Prediction in Asphaltic Pavements. Ph.D. Thesis, KTH Royal Institute of Technology, Stockholm, Sweden, 2019. [Google Scholar]

- Hassan, Y.; Abd El Halim, A.O.; Razaqpur, A.G.; Bekheet, W.; Farha, M.H. Effects of runway deicers on pavement materials and mixes: Comparison with road salt. J. Transp. Eng. 2002, 128, 385–391. [Google Scholar] [CrossRef]

- Tehrani, F.M. Performance of Steel Fiber Reinforced Concrete in Beam-Column Connections. Ph.D. Thesis, University of California, Los Angeles, CA, USA, 2008. [Google Scholar]

- Sassani, A.; Ceylan, H.; Kim, S.; Gopalakrishnan, K.; Arabzadeh, A.; Taylor, P. Factorial Study on Electrically Conductive Concrete Mix Design for Heated Pavement Systems. In Proceedings of the Transportation Research Board 96th Annual Meeting, Washington, DC, USA, 8–12 January 2017. [Google Scholar]

- Sassani, A.; Arabzadeh, A.; Ceylan, H.; Kim, S.; Sadati, S.S.; Gopalakrishnan, K.; Abdualla, H. Carbon fiber-based electrically conductive concrete for salt-free deicing of pavements. J. Clean. Prod. 2018, 203, 799–809. [Google Scholar] [CrossRef]

- Sassani, A.; Ceylan, H.; Kim, S.; Arabzadeh, A.; Abdualla, H.; Taylor, P.C.; Gopalakrishnan, K. Designing and Proportioning Electrically Conductive Concrete for Des Moines International Airport Heated Pavement System. In Proceedings of the Transportation Research Board 97th Annual Meeting, Washington, DC, USA, 7–11 January 2018. [Google Scholar]

- Yehia, S.A.A. Conductive Concrete Overlay for Bridge Deck Deicing. Ph.D. Thesis, University of Nebraska-Lincoln, Lincoln, NE, USA, 1999. [Google Scholar]

- Tang, Z.Q.; Li, Z.Q.; Hou, Z.F.; Xu, D.L. Mechanism analyzing on deicing or snow melting of electrical conductive concrete. Concrete 2001, 141, 25–36. [Google Scholar]

- Abtahi, S.M.; Sheikhzadeh, M.; Hejazi, S.M. Fiber-reinforced asphalt-concrete–a review. Constr. Build. Mater. 2010, 24, 871–877. [Google Scholar] [CrossRef]

- García, A.; Norambuena-Contreras, J.; Partl, M.N. A parametric study on the influence of steel wool fibers in dense asphalt concrete. Mater. Struct. 2014, 47, 1559–1571. [Google Scholar] [CrossRef]

- Bressi, S.; Dumont, A.G.; Partl, M.N. An advanced methodology for the mix design optimization of hot mix asphalt. Mater. Des. 2016, 98, 174–185. [Google Scholar] [CrossRef]

- Wang, H.; Yang, J.; Liao, H.; Chen, X. Electrical and mechanical properties of asphalt concrete containing conductive fibers and fillers. Constr. Build. Mater. 2016, 122, 184–190. [Google Scholar] [CrossRef] [Green Version]

- Gulisano, F.; Crucho, J.; Gallego, J.; Picado-Santos, L. Microwave healing performance of asphalt mixture containing electric arc furnace (EAF) slag and graphene nanoplatelets (GNPs). Appl. Sci. 2020, 10, 1428. [Google Scholar] [CrossRef] [Green Version]

- Liu, Q.; Schlangen, E.; Van De Ven, M. Induction healing of porous asphalt. Transp. Res. Rec. 2012, 2305, 95–101. [Google Scholar] [CrossRef]

- Arabzadeh, A.; Notani, M.A.; Zadeh, A.K.; Nahvi, A.; Sassani, A.; Ceylan, H. Electrically conductive asphalt concrete: An alternative for automating the winter maintenance operations of transportation infrastructure. Compos. Part B Eng. 2019, 173, 106985. [Google Scholar] [CrossRef]

- Norambuena-Contreras, J.; Gonzalez, A.; Concha, J.L.; Gonzalez-Torre, I.; Schlangen, E. Effect of metallic waste addition on the electrical, thermophysical and microwave crack-healing properties of asphalt mixtures. Constr. Build. Mater. 2018, 187, 1039–1050. [Google Scholar] [CrossRef] [Green Version]

- Mc Daniel, R.S. Fiber Additives in Asphalt Mixtures. NCHRP Synthesis of Highway Practice 475; AASHTO: Washington, DC, USA, 2015. [Google Scholar]

- Hassan, H.F.; Al-Oraimi, S.; Taha, R. Evaluation of open-graded friction course mixtures containing cellulose fibers and styrene butadiene rubber polymer. J. Mater. Civ. Eng. 2005, 17, 416–422. [Google Scholar] [CrossRef]

- Wu, S.; Ye, Q.; Li, N. Investigation of rheological and fatigue properties of asphalt mixtures containing polyester fibers. Constr. Build. Mater. 2008, 22, 2111–2115. [Google Scholar] [CrossRef]

- García, A.; Norambuena-Contreras, J.; Bueno, M.; Partl, M.N. Single and multiple healing of porous and dense asphalt concrete. J. Intell. Mater. Syst. Struct. 2015, 26, 425–433. [Google Scholar] [CrossRef]

- Putman, B.J.; Amirkhanian, S.N. Utilization of waste fibers in stone matrix asphalt mixtures. Resour. Conserv. Recycl. 2004, 42, 265–274. [Google Scholar] [CrossRef]

- Lee, S.J.; Rust, J.P.; Hamouda, H.; Kim, Y.R.; Borden, R.H. Fatigue cracking resistance of fiber-reinforced asphalt concrete. Text. Res. J. 2005, 75, 123–128. [Google Scholar] [CrossRef]

- Wu, S.; Pan, P.; Chen, M.; Zhang, Y. Analysis of characteristics of electrically conductive asphalt concrete prepared by multiplex conductive materials. J. Mater. Civ. Eng. 2013, 25, 871–879. [Google Scholar] [CrossRef]

- Liu, X.; Wu, S.; Ye, Q.; Qiu, J.; Li, B. Properties evaluation of asphalt-based composites with graphite and mine powders. Constr. Build. Mater. 2008, 22, 121–126. [Google Scholar] [CrossRef]

- Liu, X.; Wu, S. Study on the graphite and carbon fiber modified asphalt concrete. Constr. Build. Mater. 2011, 25, 1807–1811. [Google Scholar] [CrossRef]

- García, A.; Bueno, M.; Norambuena-Contreras, J.; Partl, M.N. Induction healing of dense asphalt concrete. Constr. Build. Mater. 2013, 49, 1–7. [Google Scholar] [CrossRef]

- Menozzi, A.; Garcia, A.; Partl, M.N.; Tebaldi, G.; Schuetz, P. Induction healing of fatigue damage in asphalt test samples. Constr. Build. Mater. 2015, 74, 162–168. [Google Scholar] [CrossRef]

- Liu, Q.; Schlangen, E.; García, Á.; van de Ven, M. Induction heating of electrically conductive porous asphalt concrete. Constr. Build. Mater. 2010, 24, 1207–1213. [Google Scholar] [CrossRef]

- Arabzadeh, A.; Ceylan, H.; Kim, S.; Sassani, A.; Gopalakrishnan, K. Investigating the heat generation efficiency of electrically-conductive asphalt mastic using infrared thermal imaging. In Proceedings of the International Conference on Transportation and Development 2018: Airfield and Highway Pavements, Pittsburgh, PA, USA, 15–18 July 2018; pp. 206–214. [Google Scholar]

- Wu, S.-P.; Mo, L.-T.; Shui, Z.-H.; Xuan, D.-X.; Xue, Y.-J.; Yang, W.-F. An improvement in electrical properties of asphalt concrete. J. Wuhan Univ. Technol.-Mater. 2002, 17, 69–72. [Google Scholar]

- Maraveas, C.; Bartzanas, T. Sensors for Structural Health Monitoring of Agricultural Structures. Sensors 2021, 21, 314. [Google Scholar] [CrossRef] [PubMed]

- Gallego, J.; del Val, M.A.; Contreras, V.; Páez, A. Heating asphalt mixtures with microwaves to promote self-healing. Constr. Build. Mater. 2013, 42, 1–4. [Google Scholar] [CrossRef]

- Norambuena-Contreras, J.; Garcia, A. Self-healing of asphalt mixture by microwave and induction heating. Mater. Des. 2016, 106, 404–414. [Google Scholar] [CrossRef]

- González, A.; Norambuena-Contreras, J.; Storey, L.; Schlangen, E. Effect of RAP and fibers addition on asphalt mixtures with self-healing properties gained by microwave radiation heating. Constr. Build. Mater. 2018, 159, 164–174. [Google Scholar] [CrossRef]

- Norambuena-Contreras, J.; Gonzalez-Torre, I. Influence of the microwave heating time on the self-healing properties of asphalt mixtures. Appl. Sci. 2017, 7, 1076. [Google Scholar] [CrossRef] [Green Version]

- García, Á.; Schlangen, E.; van de Ven, M.; Liu, Q. Electrical conductivity of asphalt mortar containing conductive fibers and fillers. Constr. Build. Mater. 2009, 23, 3175–3181. [Google Scholar] [CrossRef]

- Sun, Y.; Wu, S.; Liu, Q.; Zeng, W.; Chen, Z.; Ye, Q.; Pan, P. Self-healing performance of asphalt mixtures through heating fibers or aggregate. Constr. Build. Mater. 2017, 150, 673–680. [Google Scholar] [CrossRef]

- Norambuena-Contreras, J.; Aguilar, V.G.; Gonzalez-Torre, I. Physical and mechanical behaviour of a fibre-reinforced rubber membrane with self-healing purposes via microwave heating. Constr. Build. Mater. 2015, 94, 45–56. [Google Scholar] [CrossRef]

- Xiang, H.; He, Z.; Chen, L.; Zhu, H.; Wang, Z. Key factors and optimal conditions for self-healing of bituminous binder. J. Mater. Civ. Eng. 2019, 31, 04019172. [Google Scholar] [CrossRef]

- Zhu, X.; Cai, Y.; Zhong, S.; Zhu, J.; Zhao, H. Self-healing efficiency of ferrite-filled asphalt mixture after microwave irradiation. Constr. Build. Mater. 2017, 141, 12–22. [Google Scholar] [CrossRef]

- Zhu, X.; Ye, F.; Cai, Y.; Birgisson, B.; Lee, K. Self-healing properties of ferrite-filled open-graded friction course (OGFC) asphalt mixture after moisture damage. J. Clean. Prod. 2019, 232, 518–530. [Google Scholar] [CrossRef]

- Liu, Q.; Wu, S.; Schlangen, E. Induction heating of asphalt mastic for crack control. Constr. Build. Mater. 2013, 41, 345–351. [Google Scholar] [CrossRef]

- Sun, D.; Sun, G.; Zhu, X.; Guarin, A.; Li, B.; Dai, Z.; Ling, J. A comprehensive review on self-healing of asphalt materials: Mechanism, model, characterization and enhancement. Adv. Colloid Interface Sci. 2018, 256, 65–93. [Google Scholar] [CrossRef]

- Kim, Y.R.; Little, D.N.; Benson, F.C. Chemical and mechanical evaluation on healing mechanism of asphalt concrete (with discussion). J. Assoc. Asph. Paving Technol. 1990, 59, 240–275. [Google Scholar]

- Sun, D.; Yu, F.; Li, L.; Lin, T.; Zhu, X.Y. Effect of chemical composition and structure of asphalt binders on self-healing. Constr. Build. Mater. 2017, 133, 495–501. [Google Scholar] [CrossRef]

- Ayar, P.; Moreno-Navarro, F.; Rubio-Gámez, M.C. The healing capability of asphalt pavements: A state of the art review. J. Clean. Prod. 2016, 113, 28–40. [Google Scholar] [CrossRef]

- García, A.; Norambuena-Contreras, J.; Bueno, M.; Partl, M.N. Influence of steel wool fibers on the mechanical, thermal, and healing properties of dense asphalt concrete. J. Test. Eval. 2014, 42, 1107–1118. [Google Scholar] [CrossRef]

- Huang, B.; Chen, X.; Shu, X. Effects of electrically conductive additives on laboratory-measured properties of asphalt mixtures. J. Mater. Civ. Eng. 2009, 21, 612–617. [Google Scholar] [CrossRef]

- Butler, S.L.; Sinha, G. Forward modeling of applied geophysics methods using COMSOL and comparison with analytical and laboratory analog models. Comput. Geosci. 2012, 42, 168–176. [Google Scholar] [CrossRef]

- Clement, R.; Bergeron, M.; Moreau, S. COMSOL: Multiphysics modelling for measurement device of electrical resistivity in laboratory test cell. In Proceedings of the 2011 COMSOL Conference, Stuttgart, Germany, 26–28 October 2011; COMSOL, Inc.: Burlington, MA, USA, 2011. [Google Scholar]

- COMSOL. COMSOL Multiphysics 5.5 (Build: 359); COMSOL, Inc.: Burlington, MA, USA, 2019. [Google Scholar]

- MATLAB. MATLAB and Statistics Toolbox Release 2021a; The MathWorks, Inc.: Natick, MA, USA, 2021. [Google Scholar]

- Gao, H.; Zhang, L.; Zhang, D.; Ji, T.; Song, J. Mechanical properties of fiber-reinforced asphalt concrete: Finite element simulation and experimental study. e-Polymers 2021, 21, 533–548. [Google Scholar] [CrossRef]

- Miri, A.; Ehsani, R.; Tehrani, F.M. A Numerical Simulation of the Electrical Resistivity of Concrete Pavements Containing Steel Fibers. In Proceedings of the ASCE International Airfield & Highway Pavements Conference: Pavement Design, Construction, and Condition Evaluation, Austin, TX, USA, 8–10 June 2021; Ozer, H., Rushing, J.F., Leng, Z., Eds.; ASCE: Reston, VA, USA, 2021; pp. 356–364. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).