1. Introduction

In 2020, compared to other sectors, 37% of the global share of energy-related CO

2eq. emissions was attributed to buildings and the construction sector [

1]. So far, efforts have mostly been focused on reducing the operational carbon footprint of buildings by improving their energy efficiency. Global investment in energy efficiency in the building sector rose to an unprecedented 11.4% in 2020 to around USD 184 billion, up from USD 165 billion in 2019, primarily through targeted government support in Europe [

1]. In addition, more recently, awareness has also been raised about embodied carbon: emissions from materials and products must be urgently addressed to ensure sustainable buildings.

In response, countries in Europe are currently accelerating their efforts to comply with climate-change commitments and regulations as pressure grows for the construction sector to reduce its impact rapidly. Some European countries have introduced policies to reduce whole-life carbon emissions from buildings and construction. While a common EU policy on whole-life carbon is still in the making, Denmark, the Netherlands, and France have introduced CO

2eq. limits for a large share of new buildings, while Finland and Sweden have plans to do so. Germany, the UK, and Switzerland have life-cycle assessment (LCA) requirements for certain public buildings; Belgium is planning similar requirements [

2].

To date, the only consistent methodology to assess the carbon emissions of a building is a life-cycle assessment (LCA), a science-based and standardized [

3,

4] methodology for quantifying and reporting environmental impacts. These standards describe the four main steps of an LCA: goal and scope definition, inventory analysis, impact assessment, and interpretation. Amongst several other purposes, LCAs are used to measure and provide insights to reduce the carbon emissions of buildings over their life cycles: before the use of a building, during the use of a building, and at the end of life (EOL) of a building. To improve the effectiveness of the process, an LCA should be performed, when possible, at the earliest stage of a construction project [

5]. In this context, emissions from materials and products have a key role in global emissions and in the decarbonization of buildings; these emissions must be addressed by LCAs to ensure that the buildings being built today are optimized for low-carbon solutions across their entire life cycle. This involves evaluating each design choice using a whole-life-cycle approach seeking to minimize upfront carbon impacts (e.g., low-carbon materials), as well as taking steps to avoid future embodied carbon during the end of life (e.g., circularity).

Low-carbon solutions do not only rely on selecting low-embodied-carbon products and materials, but also on efficient structural design, where engineers and architects play an important role. The definition of the basic structural concept will significantly influence the sustainability performance of the building [

5]: a reduction in the quantity of materials can be achieved by selecting an efficient structural grid, which relates to the materials’ resistance, and by designing with high-strength materials, for example. In addition, the sustainability of buildings can be also achieved by the use of reclaimed elements.

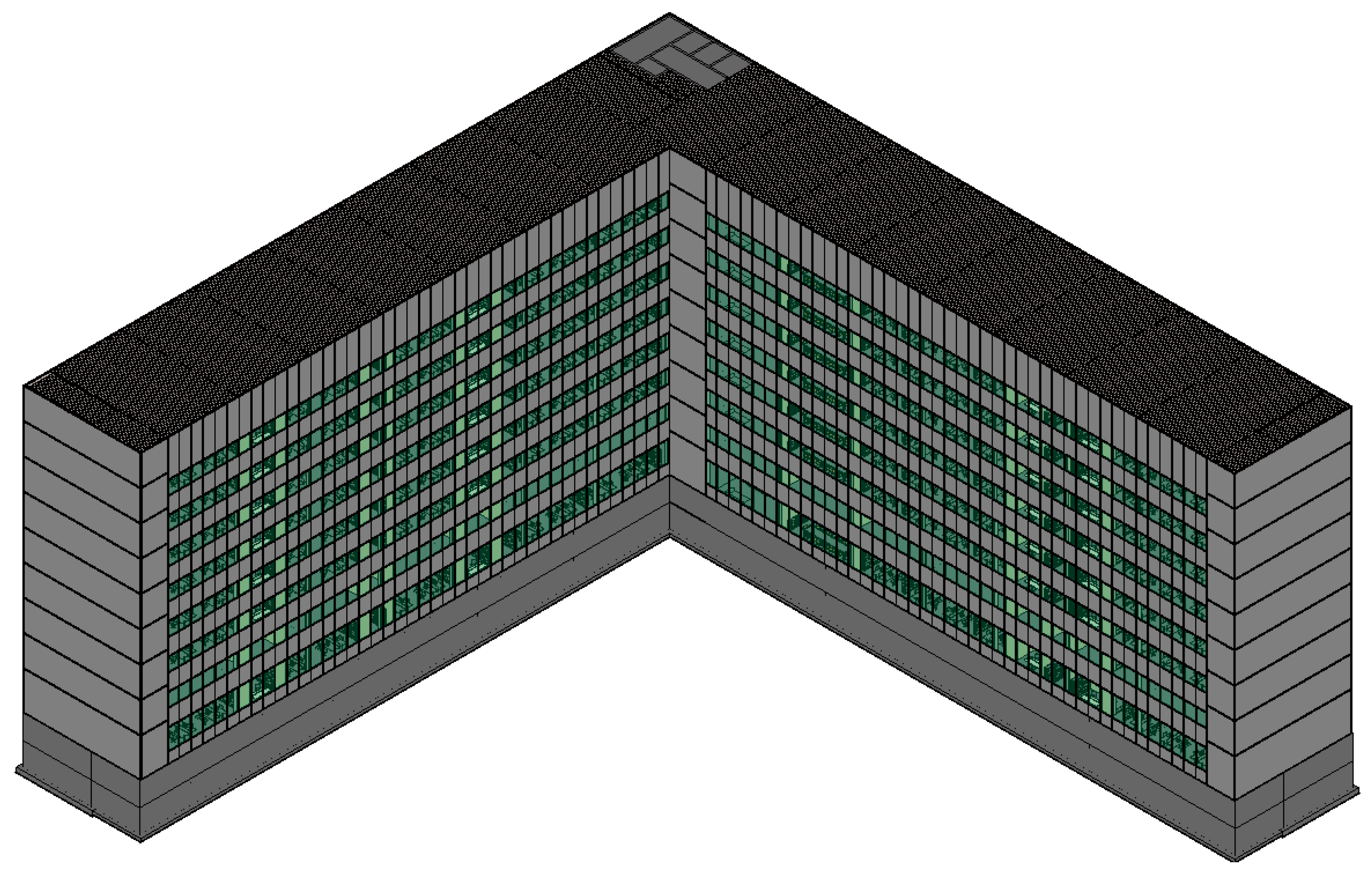

This paper presents the comparative results of a building LCA of a typical nine-story office building located in Luxembourg (2018) (

Figure 1) with 50 years of service life. Three structural systems are compared: a steel–concrete composite frame, a prefabricated reinforced concrete frame, and a timber frame. All the structural options assessed were designed and verified according to the Eurocode’s rules for safety and structural performance by independent design offices. Two grid options were adopted based on the best performance of the different structural options and materials: 8.1 m by 13 m (clear span) for the steel–concrete composite option, 8.1 m by 5 m + 8 m (with intermediate columns) for the prefabricated reinforced concrete option, and finally, 5.4 m by 5 m + 8 m (with intermediate columns) for the timber option.

The building LCA focuses on the product stage (life-cycle stages A1–A3), the construction process (life-cycle stages A4–A5), the end of life (life-cycle stages C3–C4), and the benefits and loads beyond the system boundary (module D) (i.e., cradle to cradle). The life-cycle inventory (LCI) is composed of construction environmental product declarations (EPDs) published according to EN 15804 [

6,

7]. In addition, the Ecoinvent and LIPASTO [

8] databases were used for transport emission factors. All the LCA evaluations were performed using the commercial software One Click LCA.

One Click LCA is a software tool designed to streamline LCA for construction projects. Users input project data, including materials, energy consumption, and transportation, and the software calculates the environmental impact across the project’s life-cycle stages. It offers detailed reports and analysis, enabling users to compare design options and materials for sustainability optimization. Moreover, One Click LCA supports various green building certifications like LEED and BREEAM. Notably, it has been utilized in numerous scientific publications focusing on building LCAs [

9,

10], facilitating rigorous environmental assessment in research.

The aim of this work is, first of all, to evaluate the impact of structural design choices on the overall global warming potential (GWP) of an office building, and secondly, to investigate the influence of critical assumptions, such as end-of-life (EOL) scenarios for timber, on the final result of a comparative Life Cycle Assessment (LCA). The primary objective of this publication is to assist various stakeholders in the construction chain, including engineers, architects, and real estate developers, in their decision-making processes. This is achieved by offering GWP comparisons for equivalent design options that incorporate different structural materials and by highlighting opportunities for enhancing environmental performance, ultimately supporting eco-design initiatives.

2. Literature Review

Several existing studies have researched how the use of different structural materials may impact the GWP of given buildings. Sinha, Rajib et al. [

11] compare the embodied carbon (kg CO

2eq.) of a commercial building in Sweden when the structural frame is made of concrete versus when it is made of timber, focusing on the production stage only (i.e., the life cycle stages A1–A3). In this publication, it is argued that if the use stage of the building (module B), the EOL (module C), and potential benefits outside the system boundaries (module D) are considered, the carbon emissions results would be strongly affected.

Similarly, Sandanayake, Malindu et al. [

12] compares the influence of timber and reinforced concrete on the GWP of commercial and residential buildings in Australia and in the UK. This analysis focuses solely on the emission from materials and products (module A1–3), transportation (module A4), and equipment use (module A5) (i.e., cradle-to-gate analysis). The study mentions that an ideal LCA should consider all life cycle stages so that more conclusive results can be drawn; however, the boundaries can be chosen by the scope and objective of the study.

Morris, Freya et al. [

13] compare the GWP of different structural materials: steel vs. timber when applied to a structure beam element. A whole Life Cycle Assessment was made including the product stage of the building (A1–A3), transportation (A4), EOL (C, with the exception of deconstruction C1), and benefits beyond the system boundaries (module D). In the study, the researchers also performed a sensitivity analysis on the EOL assumptions of timber and their consequences on the resulting GWP.

In her research, Dalia M.A. Morsi et al. [

14] delves into the advantages brought by Building Information Modeling (BIM) to LCA. BIM accomplishes this by reducing the complexity and time needed to conduct an analysis, a critical factor in aiding decision making during the early phases of a project. The publication also provides a comparative LCA perspective on a residential building when considering different structural systems: reinforced concrete solid slab systems, steel structures, and composite structural systems. The LCA boundaries consider the product stage (modules A1–A3), the construction stage (modules A4–A5), the use stage modules B6–B7, the EOL (modules C1–C4), and benefits outside the system boundaries (module D).

Caruso, M.C.et al. [

15] also conducted a comparative analysis of residential building structures employing different building materials. This study explored three alternative material options: reinforced concrete, steel, and wood. A comprehensive cradle-to-cradle analysis was undertaken, and comparisons were made using two LCA methodologies (e.g., IMPACT2002+) and various impact categories. The research findings reveal that there is no single option that consistently delivers the best environmental performance across all impact categories. Therefore, the decision-making process should prioritize specific environmental categories based on the analysis.

Alotaibi, Badr Saad, et al. [

16] conducted a study focused on high-rise residential buildings, examining embodied carbon emissions and decarbonization strategies. Their research introduced and evaluated a LCA method covering construction, operation, and demolition phases. The key takeaway is the critical need to incorporate decarbonization strategies from the early stages of building design. These strategies encompass clever material selection based on durability and recyclability, along with optimizing design choices. The research underscores that implementing decarbonization strategies during the conceptual phase is notably more effective in minimizing carbon emissions for all types of buildings.

When discussing end-of-life (EOL) scenarios and their significance in conducting Life Cycle Assessments (LCA) for buildings, it is crucial to consider construction demolition waste (CDW). In this context, Mesa, Jaime A. et al. [

17] offer a comprehensive review analysis of the literature that consolidates the most pertinent topics and issues within the CDW materials research field and the utilization of LCA over the past two decades. Their study highlights the need for increased research efforts aimed at developing methodologies that offer practical guidelines for considering the entire life cycle of buildings, starting from the early design stages. This approach includes adopting a more circular economy perspective to explore additional alternatives beyond recycling and recovery of C&DW. Furthermore, it advocates for a more comprehensive analysis of globalized supply chains to encompass the entire life cycle impact of raw materials.

Other publications tried to define the state of the art of building LCA. In their work, Fnais, Abdulrahman, et al. [

18] provide a comprehensive review of the state-of-the-art research in Life Cycle Assessment (LCA) as applied to buildings. Their focus is on current research trends while also addressing gaps and outlining future research directions. This paper argues that humans have the potential to reduce and positively manage the environmental impact of their buildings, thus helping to mitigate the effects of climate change. Currently, LCA methodologies and databases lack support for incorporating temporal information necessary to assess impacts related to maintenance, operation, deconstruction, and end-of-life (EOL) considerations.

In a similar vein, Marrone, G. et al. [

19] conduct a thorough review and analysis of the current literature concerning the application of Life Cycle Assessment (LCA) methodology to light-steel lrame (LSF) buildings while also identifying related gaps in research. The publication’s conclusion emphasizes the substantial effort invested in comparative studies. However, these studies often overlook consistent boundary conditions, and, in some cases, crucial information in goal and scope definition is entirely absent. The results obtained in various studies are not directly comparable due to differences in methodologies, geographical locations considered, and variations in data collection. It is essential to note that calculations can vary significantly based on factors such as data collection methods, geographical location, scope, and methodology employed. Consequently, these factors should not be used to compare results between buildings outside of the same defined scope.

Relatedly, in their work, Lützkendorf, Thomas, et al. [

20] provide in-depth insights, interpretations, and recommendations regarding embodied carbon emissions in buildings. They emphasize that, on average, approximately 50% of the total carbon emissions in new energy-efficient buildings are embodied. While enhancing energy efficiency to reduce operational carbon emissions incurs additional carbon costs, the authors acknowledge a common trade-off between operational and embodied carbon. However, they also point out the potential for optimization on both fronts. Notably, effective design strategies can enable the construction of buildings with low embodied carbon, often without significant extra expenses, that may even yield economic advantages. These economic benefits encompass improved sustainability assessments; enhanced marketing, valuation, and financing opportunities; and favorable insurance conditions.

3. Methodology

3.1. Life Cycle Assessment Framework

A Life Cycle Assessment or LCA is a scientific and quantitative method for determining and assessing environmentally processes or impacts associated with all the life stages from the extraction of the raw material to recycling or final disposal. It was first developed for assessing products, but it is also used today to assess industrial processes, services, behavioral patterns, and complete buildings.

The EN 15978 Sustainability of Construction Works, Assessment of Environmental Performance of Buildings calculation method [

3] defines the steps that are followed for a building LCA:

The purpose and object of assessment;

The boundaries of the analysis;

A life cycle inventory (LCI);

The calculation of the environmental indicators;

The interpretation of results;

The conclusion.

3.2. Purpose and Object of Assessment

The goal of the present building LCA is to quantify the environmental performance of equivalent structural options, composed of different materials, of a given office building located in Luxembourg. This comparative study can support the different construction chain players (e.g., engineers, architects, real estate developers, etc.) in the decision-making process by providing comparisons of the environmental performance of different design options and by indicating the potential for environmental performance improvement (i.e., supporting eco-design).

To define a representative office building for the Luxemburgish construction context, a market analysis was performed by the company TBC. The selected office building type was configured in an “L” shape. Its most significant dimensions are listed in

Table 1.

The layout of a standard floor was devised by the design office ARCADIS based on the findings of the market analysis conducted.

Table 2 presents the functional areas of a typical floor.

The required service life of the building was defined as 50 years, the same as the reference study period (RSP) for the building LCA. For the purposes of analysis, the building was divided into building parts. The building parts that are considered in the scope of the LCA are:

The foundations;

The retaining walls;

The core and bracings;

The framing and floors;

The roof.

3.3. The Structural Options

All the structural options assessed were designed and verified according to Eurocode’s rules for safety and structural performance by independent design offices.

Three grid options were chosen, with a focus on maintaining a balance between the prevailing construction methods and practices in Luxembourg while also taking into account the architectural constraints of the proposed office building. The primary goal was to minimize material consumption while maintaining cost effectiveness. The different structural options and materials were:

Option 1: 8.1 m by 13 m (clear span) for the composite steel–concrete option;

Option 2: 8.1 m by 5 m + 8 m (with intermediate columns) for the prefab reinforced concrete option. Several alternative grid configurations were thoroughly examined, but they resulted in excessively deep beam and floor solutions. This, in turn, significantly increased material consumption and had a notable impact on the overall building height;

Option 3: 5.4 m by 5 m + 8 m (with intermediate columns) for the timber options. Similarly to option 2, other grid configurations were assessed. These alternatives proved to be ineffective in terms of beam and floor compactness, leading to increased material consumption.

Similarly,

Table 3 shows the floor and framing summary of the structural options analyzed.

3.4. Boundaries of the Life Cycle Analysis

The setting of the system boundaries follows the modularity principle (

Figure 5 [

3]) proposed by the EN 15978: Sustainability of Construction Works, Assessment of Environmental Performance of Buildings calculation method [

3].

Depending on the purpose of the building LCA, some stages may be omitted or replaced due to the absence of detailed information or relevancy to the assessment. Since only structural elements were considered in the analysis, the following life-cycle stages were considered:

This comprises resource extraction (A1), transport of the resources (A2), the manufacturing process, and completion of the finished products at the factory gate (A3). The material and product quantities were extracted from construction drawings, bills of quantities, and BIM models as delivered by design engineers. The net quantities were used.

- 2.

Construction Process Stage (A4–A5)

This comprises the transportation of building materials and products from the factory to the construction site (A4) and the actual construction/assembly on-site (A5). Regionally applicable transportation scenarios from One Click LCA were used, representing regional typical transportation distances and methods for product/material types (

Table 4). The wastage impacts were considered and accounted for since net quantities were used in the LCA model. The wastage quantities were estimated using the default values of One Click LCA based on different materials and were accounted for in module A5 (

Table 5). The excavation of the underground levels and foundations was the only construction process/assembly included in the building LCA.

- 3.

End-of-life stage (C3–C4)

Waste processing (C3) addresses the environmental impacts associated with the reuse, recycling, or alternative utilization of structural elements and building materials. On the other hand, disposal (C4) focuses on the environmental impacts arising from the need to dispose of or landfill structural elements and building materials. It is worth noting that the analysis did not consider deconstruction (C1) and transportation to disposal (C2) due to the lack of reliable assumptions, primarily concerning building deconstruction practices in Luxembourg. The environmental impacts for both C3 and C4 are contingent upon the end-of-life (EOL) scenarios adopted for each building material.

Table 6 provides an overview of the EOL scenarios applied to different materials:

The EOL assumptions were taken from the considered EPDs and One Click LCA’s database (sources given in

Table 6). They reproduce the current practices for the deconstruction and treatment of construction demolition waste (CDW) of the location where the building is situated. Since the EPD used for timber elements declares several EOL scenarios, two extreme ones were considered here in order to provide a range of plausible results: 100% incineration with energy recovery or 100% landfill.

Regarding biogenic storage in wood-based materials, it was assumed in the present building LCA analysis that the amount of CO

2 absorbed during photosynthesis and stored within the wood during its life cycle is equal to that released at the EOL and thus there is no net impact on emissions. This assumption is commonly adopted for wood-based products in LCA [

13].

- 4.

Benefits and loads beyond the system boundary (D)

Based on decisions taken at the EOL, potential benefits related to the substitution of primary resources were accounted for. Module D was considered in the building LCA analysis, characterizing it as a cradle-to-cradle LCA.

For the end-of-life scenario timber scenario 1, where the energy recovered by incineration is substituted in the energy mix, the District Heat, Luxemburg profile IEA2019 was selected.

3.5. The Environmental Database: Life Cycle Inventory

EPDs provide quantified information on environmental impacts and the aspects of products and services for use in a building LCA. The main EPDs and environmental data used in the building LCA are presented in

Table 7 together with their embodied carbon impacts (A1–A3) in terms of their functional unit (FU).

All the environmental data and EPDs used met the requirements of EN 15804 [

6,

7]; hence, they meet the requirements for data quality of this standard. Due to the unavailability of environmental product declarations (EPDs) from the same manufacturer covering the entire range of concrete classes used in the building, One Click LCA internally verified environmental data were used for concrete. This decision was made to ensure consistent assumptions across all concrete types employed in the project. By using the internally verified data, the analysis maintained a standardized and reliable basis for assessing the environmental impacts of the concrete materials throughout the building’s construction.

The transportation environmental data used were derived from the LCA for European transport based on VTT’s LIPASTO [

8] (One Click LCA 2017), and the considered emission factors are presented in

Table 8.

3.6. Calculation of the Environmental Indicator: GWP

This building LCA analysis focused on the global warming potential (GWP) to describe environmental impact. Other indicators that describe environmental impacts, such as depletion potential of the stratospheric ozone layer (ODP), acidification potential of land and water (AP), eutrophication potential (EP), formation potential of tropospheric ozone photochemical oxidants (POCP), and abiotic resource depletion potential (ADP) are not present in this building LCA evaluation. Similarly, other indicators describing resource use and indicators describing additional environmental information are not included in the present building LCA analysis.

The values for the GWP indicator were calculated for each module in the life cycle stages based on a matrix calculation routine as illustrated in

Figure 6.

For i = to the assessed life cycle stages [A1–A3, A4, A5, C3, C4] and [D]:

The basic principle of this matrix calculation routine consisted of multiplying each product and service quantified in a module of the life cycle of the building with its respective value for any environmental indicator. Equation (1) exemplifies the resulting calculation routine for the quantification of the GWP of stage i:

where:

GWPi is the global warming potential quantified for the module i of the building;

an,i is the gross amount of product or service n used in the module i of the building (n = 1, 2, 3, …, N);

GWPan,i is the global warming potential of product or service n used in the module i of the building (n = 1, 2, 3, …, N).

4. Results

For the office building designed using a composite steel–concrete structural solution, two building LCA analyses were made. The first is referred to as “Steel Composite usual AM’s structural steel” to highlight the environmental results of ArcelorMittal’s electric arc furnace (EAF) process of structural steel making. The second is referred to as “Steel Composite XCarb®” to highlight the benefits achieved using 100% recycled steel (scrap) and 100% renewable energy during the process of steelmaking.

The results are presented in terms of the total gross floor area (GFA) of the office building.

Figure 7 and

Figure 8 show the GWP results by GFA per life cycle stage for two EOL scenarios: 100% wood incineration with energy recovery and 100% wood landfilling, respectively.

It was observed that independently of the structural option, the product life-cycle stage (A1–A3) contributed the most to the GWP. In terms of CO2eq. emissions, the composite steel–concrete variant outperforms the reinforced concrete variant by reducing by 32% the overall GWP for the usual AM structural steel scenario. A greater reduction was achieved for the XCarb® steel composite scenario, where the overall GWP can be reduced by up to 42%.

The timber frame compared with the usual AM structural steel scenario and the XCarb scenario has a 44% greater impact in terms of GWP for the 100% landfill EOL scenario. When the considered EOL scenario for timber was 100% incineration with energy recovery, the solutions have the same environmental performance.

Similarly,

Figure 9 and

Figure 10 show the results of the GWP via GFA, highlighting the contribution of each structural building part for all the frame options and both timber EOL scenarios.

For all the structural options, it is seen that the building part that contributes the most to the overall GWP is the flooring solution. Steel composite floors outperform prefabricated reinforced concrete hollow core slabs by 37% and 57% for the usual AM structural steel and XCarb® steel composite scenarios, respectively. The work shows that for the timber option, the floors are greatly impacted by the choice of EOL scenarios: 82 kgCO2eq/m2 for the 100% landfill and 45 kgCO2eq/m2 for 100% incineration with energy recovery scenarios.

5. Discussion

The embodied carbon (life-cycle stages A1–A3) is the main component responsible for CO2eq. emissions. The steel-based option benefits from having a high content of recycled steel (scrap), up to 100%. In addition, a greater reduction is achieved for the XCarb® steel composite option since it is produced with 100% renewable energy. The reduction of embodied carbon is paramount for the overall GWP performance of the structural options.

Timber EOL has an important influence on the overall GWP. When the 100% incineration with energy recovery scenario was assumed, the energy created in the combustion process was harnessed for heat generation. In consequence, the life-cycle stage module D represents the benefit of avoiding the use of natural gas for heat production and not the benefit of avoiding raw material extraction (the harvesting of virgin wood) to produce timber structural elements. According to the current practices of wood as a CDW, just a minority (6%) is being incinerated with energy recovery in its EOL [

28].

Wood, when landfilled, being a biodegradable material, decomposes. This decomposition results in the generation of biogenic CO

2, which in this analysis was assumed to be equal to the biogenic storage, and CH

4. Methane is a gas that contributes to the GWP; it causes 25 times more warming over 100 years compared to 1 kg of CO

2, and so methane has a GWP of 25 [

29]. In the 100% landfill scenario, the EPD used in this analysis considers that the landfill is a large modern Type 3 facility with CH

4 collection. It was therefore assumed that the methane uptake partially substituted for natural gas in heat production as a benefit in module D. The non-collected CH

4 was released and accounted for in GWP in module C. This explains the variation in results of the timber frame option between both EOL scenarios. It also explains the reason why the results for timber frame module C, for the 100% landfill EOL assumption, are the highest compared to the other structural options. According to the current practices of wood as a CDW, most of the wood (58%) is being landfilled in its EOL [

28].

Floors were identified as the building part that contributes the most to the overall GWP. For this reason, it is key that floor systems are optimized. Ready-mix concrete is the main component responsible for the impacts related to the floors for the steel and reinforced concrete frames. Steel composite floors are more compact and hence consume less concrete than prefabricated reinforced concrete, leading to lower overall GWP. In the timber structural option, the floors are composed of CLT panels, these being the most timber-intensive building part. This is the reason why the floors are the building part mostly affected by different EOL assumptions (incineration with energy recovery and landfill).

6. Conclusions

The purpose of this building LCA application is two-fold: to quantify the environmental performance of equivalent structural options for a given office building composed of different materials and to support the different construction chain players (e.g., engineers, architects, real estate developers, etc.) in the decision-making process of different structural design options.

In this study, a 9-floor multi-story office building representative of the Luxembourgish market with an RSL of 50 years was analyzed. Three structural systems were considered: a steel frame, a prefabricated reinforced concrete frame, and a timber frame. A cradle-to-cradle building LCA considering the life-cycle stages A1–A3, A4, A5, C3, C4, and D was performed to quantify the overall GWP of each building’s structural system.

The whole-life-cycle GWP was calculated for all structural options. The steel composite variant outperforms the reinforced concrete one, reducing by 32% the overall GWP for the usual AM structural steel scenario. For the XCarb® steel frame scenario, the overall GWP can be further reduced by 42%.

The overall GWP of the timber frame is very sensitive to the wood EOL assumptions. When compared to the XCarb

® steel frame scenario, the timber frame with the EOL assumption of 100% incineration with energy recovery performs equivalently concerning the overall GWP. It is worth mentioning that according to EOL practices for wood as CDW, just as much as 6% is being currently incinerated [

28]. On the other hand, when 100% landfilled, the timber frame is outperformed by the XCarb

® steel frame scenario by 43%. Currently, most wood is being landfilled in its EOL [

28].

To conclude, this study shows the benefit of using the steel frame option, which can also benefit from a high-recycled material content, greatly reducing the embodied carbon from steel products. In addition, XCarb® environmental performance is enhanced using 100% renewable energy in steel production, lowering the percentage of embodied carbon even more. Finally, this study shows that the overall GWP of the timber solution is greatly impacted by the EOL assumptions: incineration with energy recovery versus landfill. This office building LCA highlights that the consideration of different design variants in the early stage can bring up to a 30% possible gain in the GWP, which could be further increased to up to 40% if using a low-carbon variant for the steel elements.

Author Contributions

Methodology, J.H.M.d.P.F.; software, J.H.M.d.P.F.; validation, O.V.; data curation, J.H.M.d.P.F.; writing—original draft preparation, J.H.M.d.P.F., M.C. and M.D.; writing—review and editing, J.H.M.d.P.F., M.C. and M.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors José Humberto Matias de Paula Filho, Marion Charlier, Marina, D’Antimo, and Oliver Vassart are employed by the company ArcelorMittal. The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- United Nations. Global Status Report for Buildings and Construction 2021. 2021. Available online: https://globalabc.org/resources/publications/2021-global-status-report-buildings-and-construction (accessed on 18 December 2023).

- One Click LCA Ltd. Construction Carbon Regulations in Europe—Review & Best Practises. 2022. Available online: https://www.oneclicklca.com/construction-carbon-regulations-in-europe/ (accessed on 7 December 2023).

- EN 15978:2012; Sustainability of Construction Works—Assessment of Environmental Performance of Buildings—Calculation Method. European Standards: Brussels, Belgium, 2012.

- ISO 14044; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2006; Volume 14044.

- Hauke, B.; Kuhnhenne, M.; Lawson, M.; Veljkovic, M. Sustainable Steel Buildings: A Practical Guide for Structures and Envelopes, 1st ed.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2016; Available online: www.EngineeringBooksLibrary.com (accessed on 7 December 2023).

- BS EN 15804:2012+A1:2013; Standards Publication Sustainability of Construction Works—Environmental Product Declarations—Core Rules for the Product Category of Construction Products. CEN: Brussels, Belgium, 2013.

- NF EN 15804:2012+A2:2019; Standards Publication Sustainability of Construction Works—Environmental Product Declarations—Core Rules for the Product Category of Construction Products. CEN: Brussels, Belgium, 2019; p. 76.

- Markkanen, J.; Lauhkonen, A.; Eckhardt, J. LIPASTO. 2017. Available online: http://lipasto.vtt.fi/en/index.htm (accessed on 1 July 2022).

- Bhyan, P.; Tyagi, P.; Doddamani, S.; Kumar, N.; Shrivastava, B. Life cycle assessment of lightweight and sustainable materials. In Lightweight and Sustainable Composite Materials; Woodhead Publishing: Jaipur, India, 2023; pp. 117–142. [Google Scholar] [CrossRef]

- Newberry, P.; Harper, P.; Norman, J. Carbon assessment of building shell options for eco self-build community housing through the integration of building energy modelling and life cycle analysis tools. J. Build. Eng. 2023, 70, 106356. [Google Scholar] [CrossRef]

- Sinha, R.; Lennartsson, M.; Frostell, B. Environmental footprint assessment of building structures: A comparative study. Build. Environ. 2016, 104, 162–171. [Google Scholar] [CrossRef]

- Sandanayake, M.; Lokuge, W.; Zhang, G.; Setunge, S.; Thushar, Q. Greenhouse gas emissions during timber and concrete building construction—A scenario based comparative case study. Sustain. Cities Soc. 2018, 38, 91–97. [Google Scholar] [CrossRef]

- Morris, F.; Allen, S.; Hawkins, W. On the embodied carbon of structural timber versus steel, and the influence of LCA methodology. Build. Environ. 2021, 206, 108285. [Google Scholar] [CrossRef]

- Morsi, D.M.A.; Ismaeel, W.S.E.; Ehab, A.; Othman, A.A.E. BIM-based life cycle assessment for different structural system scenarios of a residential building. Ain Shams Eng. J. 2022, 13, 101802. [Google Scholar] [CrossRef]

- Caruso, M.C.; Menna, C.; Asprone, D.; Prota, A. LCA-Based Comparison of the Environmental Impact of Different Structural Systems. IOP Conf. Ser. Mater. Sci. Eng. 2018, 442, 012010. [Google Scholar] [CrossRef]

- Alotaibi, B.S.; Khan, S.A.; Abuhussain, M.A.; Al-Tamimi, N.; Elnaklah, R.; Kamal, M.A. Life Cycle Assessment of Embodied Carbon and Strategies for Decarbonization of a High-Rise Residential Building. Buildings 2022, 12, 1203. [Google Scholar] [CrossRef]

- Mesa, J.A.; Fúquene-Retamoso, C.; Maury-Ramírez, A. Life Cycle Assessment on Construction and Demolition Waste: A Systematic Literature Review. Sustainability 2021, 13, 7676. [Google Scholar] [CrossRef]

- Fnais, A.; Rezgui, Y.; Petri, I.; Beach, T.; Yeung, J.; Ghoroghi, A.; Kubicki, S. The application of life cycle assessment in buildings: Challenges, and directions for future research. Int. J. Life Cycle Assess. 2022, 27, 627–654. [Google Scholar] [CrossRef]

- Marrone, G.; Imperadori, M.; Sesana, M.M. Life-cycle assessment of light steel frame buildings: A systematic literature review. In Life-Cycle of Structures and Infrastructure Systems; CRC Press: London, UK, 2023; pp. 2405–2412. ISBN 9781003323020. [Google Scholar]

- Lützkendorf, T.; Balouktsi, M. Embodied carbon emissions in buildings: Explanations, interpretations, recommendations. Build. Cities 2022, 3, 964–973. [Google Scholar] [CrossRef]

- ArcelorMittal Europe. XCarbTM Recycled and Renewably Produced Structural Steel Sections and Merchant Bars. Institut Bauen und Umwelt e.V. (IBU). 2021. Available online: https://epd-online.com/EmbeddedEpdList/Download/14498 (accessed on 7 December 2023).

- ArcelorMittal Europe. Long Products, Structural Steel Sections in HISTAR® Grades; Institut Bauen und Umwelt e.V. (IBU): Berlin, Germany, 2017. [Google Scholar]

- ArcelorMittal Europe—Flat Products. XCarb® Recycled and Renewably Produced Hot Dip Galvanized Steel with Magnelis® Coating. Institut Bauen und Umwelt e.V. (IBU). 2022, pp. 1–8. Available online: https://epd-online.com/EmbeddedEpdList/Download?id=16309 (accessed on 7 December 2023).

- ArcelorMittal Europe. XCarb® Recycled and Renewably Produced Reinforcing Steel in Bars. Institut Bauen und Umwelt e.V. (IBU). 2021. Available online: https://epd-online.com/EmbeddedEpdList/Download/14755 (accessed on 7 December 2023).

- ArcelorMittal Europe. Reinforcing Steel in Bars; Institut Bauen und Umwelt e.V. (IBU): Berlin, Germany, 2016. [Google Scholar]

- Studiengemeinschaft Holzleimbau e.V. Cross-laminated timber (X-Lam). Institut Bauen und Umwelt e.V. (IBU). 2017. Available online: https://www.studiengemeinschaft-holzleimbau.de/publish/binarydata/Brettsperrholz/downloads/cross-laminated-timber-x-lam-01.pdf (accessed on 7 December 2023).

- Binderholz GmbH. BSH GluLam; Institut Bauen und Umwelt e.V. (IBU): Berlin, Germany, 2019. [Google Scholar]

- BCSA, Steel for Life, and SCI. SCI Steel and the Circular Economy. Available online: https://steelconstruction.info/Steel_and_the_circular_economy (accessed on 14 October 2022).

- Hartmann, D.L.; Klein Tank, A.M.G.; Rusticucci, M.; Alexander, L.V.; Brönnimann, S.; Charabi, Y.A.R.; Dentener, F.J.; Dlugokencky, E.J.; Easterling, D.R.; Kaplan, A.; et al. Observations: Atmosphere and surface. In Climate Change 2013 the Physical Science Basis: Working Group I Contribution to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK, 2013; Volume 9781107057, pp. 159–254. [Google Scholar]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).