Impact of N,N-Bis(2-ethoxyethyl) Fatty Acid Amides on the Lubrication Performance of Kerosene Fuel F-34 for Use in CI Engines

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

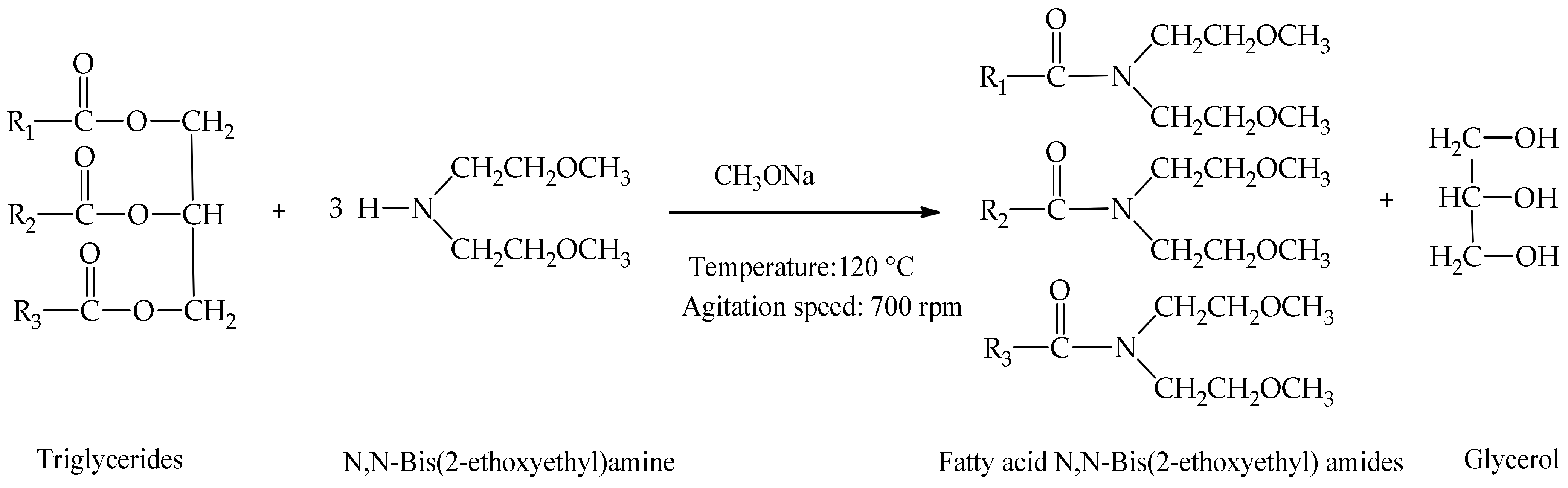

2.2. Synthesis of N,N-Bis(2-ethoxyethyl) Fatty Acid Amides

2.3. Tribological Measurements

3. Results and Discussion

4. Conclusions

- Aviation fuel of kerosene type, when used in land equipment and vehicles of the army in the implementation of the single fuel concept, is a fuel with poor lubrication properties that does not provide the necessary lubricity and may cause serious damage in the fuel pumps of the engines.

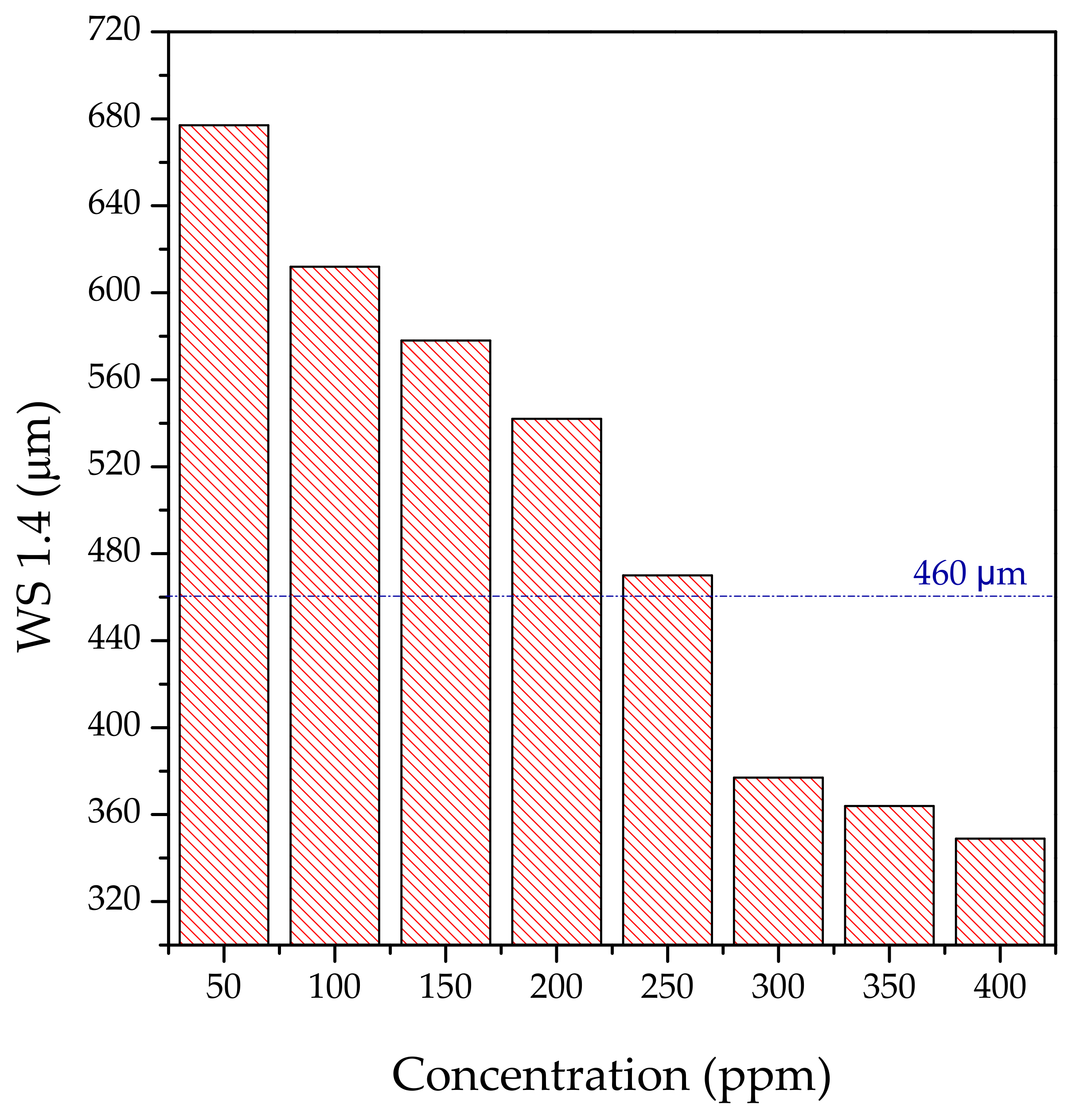

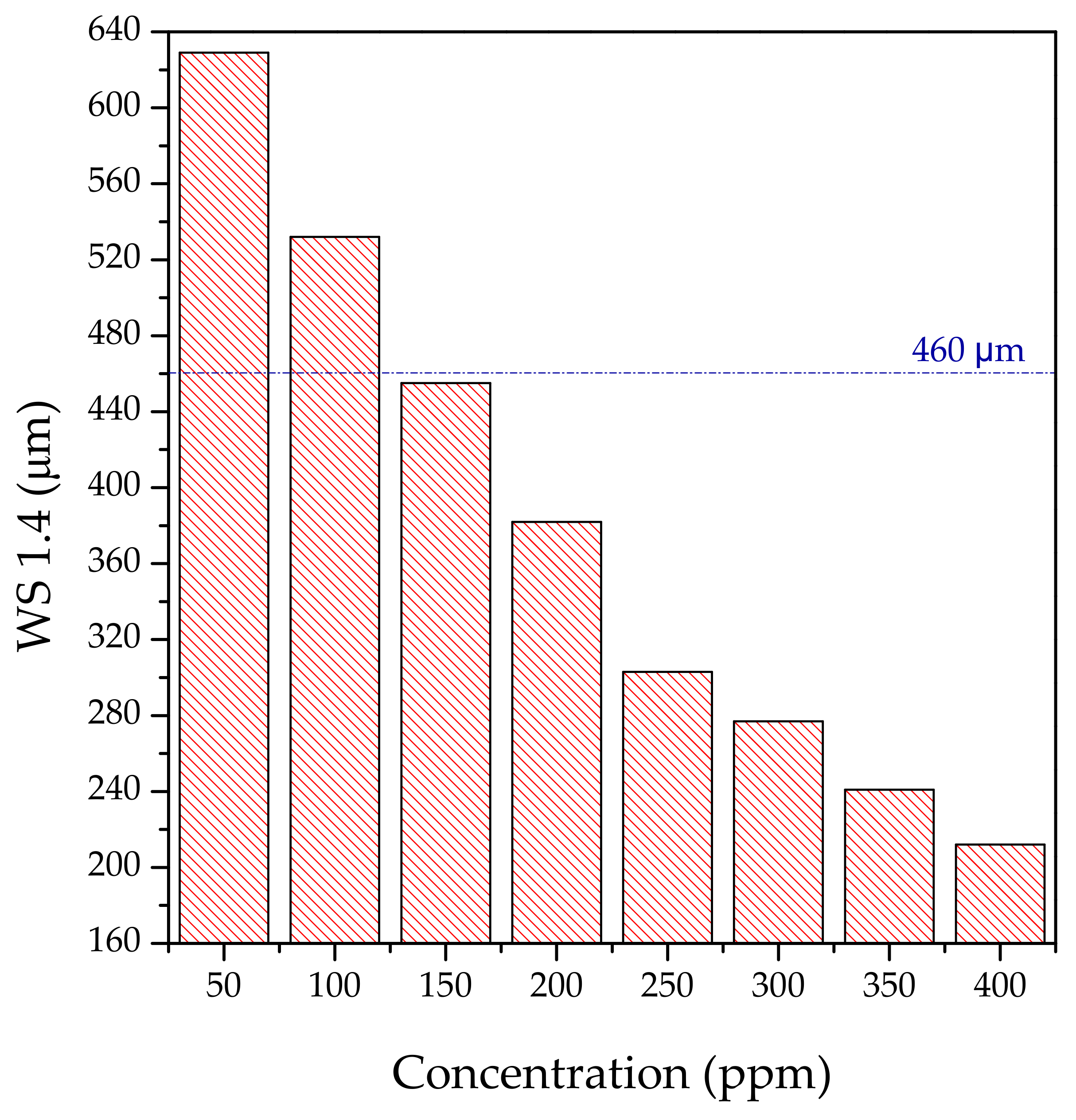

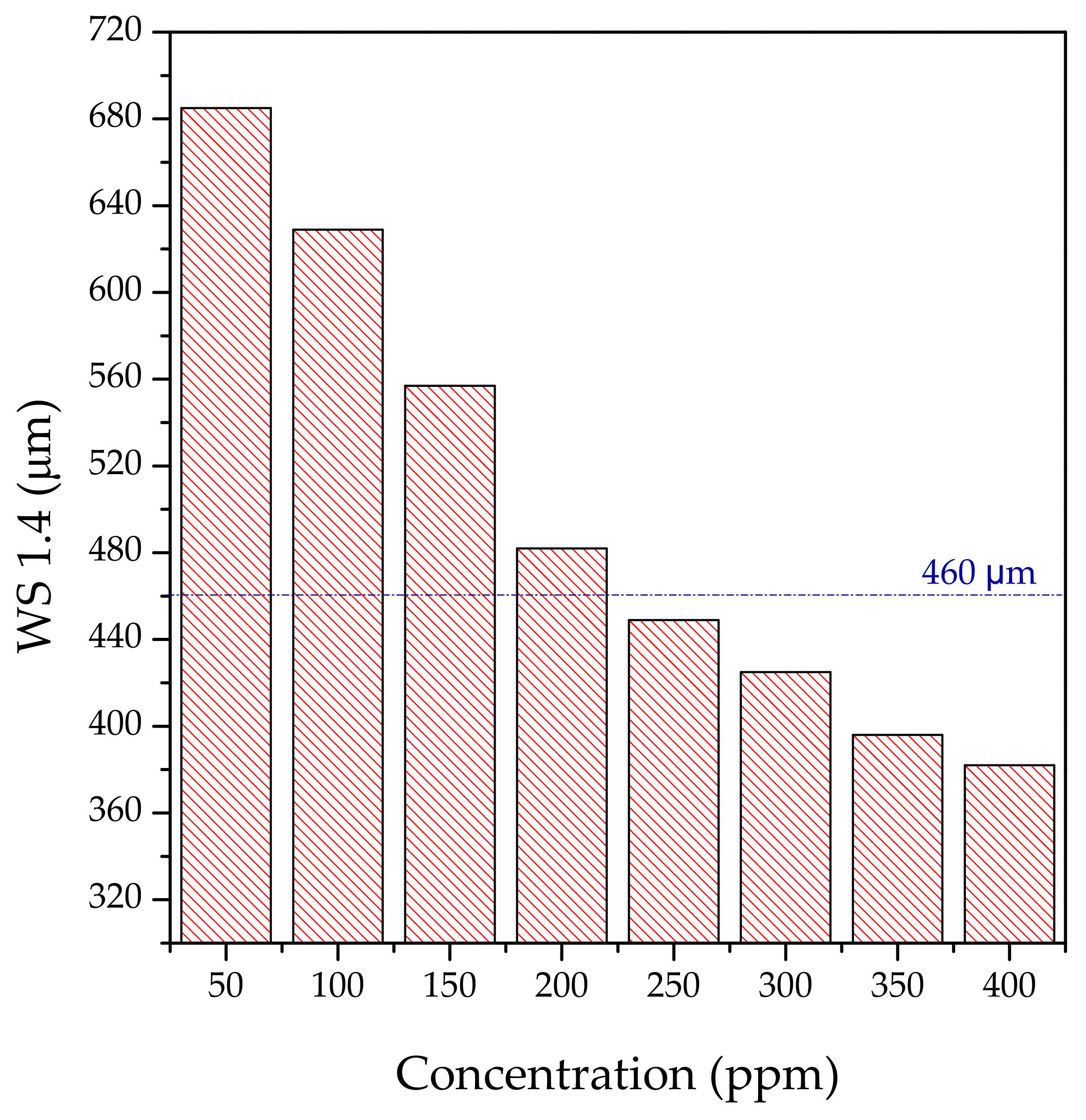

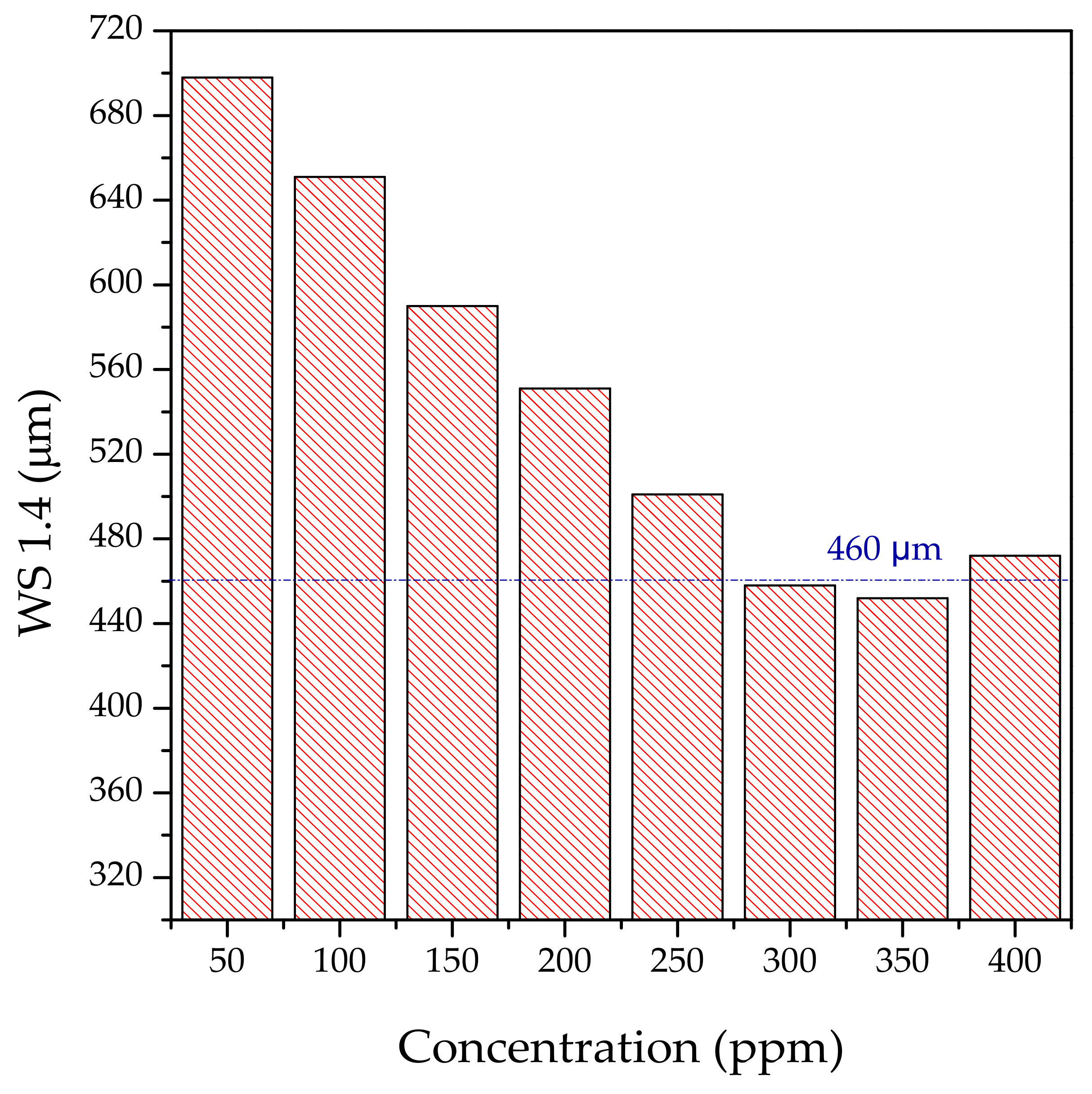

- The necessary dosage levels of the fatty acid N,N-Bis(2-ethoxyethyl) amides, in order to decrease the wear scar diameter below the maximum acceptable limit of 460 μm, were in the range of 150 to 300 ppm. Any further addition of amides did not provide any significant improvement in the lubricity of the base fuel.

- Among the individual types of fatty acid N,N-Bis(2-ethoxyethyl) amides, those derived from non-polyunsaturated oils, such as olive oil and coconut oil appear to be better lubricants.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Arkoudeas, P.; Kalligeros, S.; Zannikos, F.; Anastopoulos, G.; Karonis, D.; Korres, D.; Lois, E. Study of using JP-8 aviation fuel and biodiesel in CI engines. Energy Convers. Manag. 2003, 44, 1013–1102. [Google Scholar] [CrossRef]

- Korres, D.M.; Lois, E.; Karonis, D. Use of J-8 Aviation Fuel and Biodiesel on a Diesel Engine. SAE Tech. Pap. 2004, 1, 3033. [Google Scholar] [CrossRef]

- Schihl, P.; Hoogterp-Decker, L. On the Ignition Behavior of JP-8 in Military Relevant Diesel Engines. SAE Int. J. Engines 2011, 4, 1–13. [Google Scholar] [CrossRef]

- Schihl, P.; Decker-hoogterp, L.; Pence, K.; Leonard, K. On the Premixed Phase Combustion Behavior of JP-8 in a Military Relevant Single Cylinder Diesel Engine. SAE Int. J. Engines 2011, 4, 27–37. [Google Scholar] [CrossRef]

- Walentynowicz, J. Methodology and Results of Testing an Impact of F-34 Fuel on the Engine Reliability. SAE Tech. Pap. 2020, 1, 2133. [Google Scholar] [CrossRef]

- Karczewski, M. Evaluation of the diesel engine feed by unified battlefield fuel F-34/F-35 mixed with biocomponents. Combust. Engines 2019, 178, 240–246. [Google Scholar] [CrossRef]

- Karczewski, M.; Szczęch, L. Influence of the F-34 unified battlefield fuel with bio components on usable parameters of the IC engine. Eksploat. I Niezawodn. Maint. Reliab. 2016, 18, 358–366. [Google Scholar] [CrossRef]

- Hountalas, D.T.; Yfantis, E.; Papagiannakis, R.G.; Kotsiopoulos, P.N. Single Fuel Research Program Comparative Results of the Use of JP-8 Aviation Fuel versus Diesel Fuel on a Direct Injection and Indirect Injection Diesel Engine. SAE Tech. Pap. 2006, 1, 1673. [Google Scholar] [CrossRef]

- European Committee for Standardization (CEN). Specification Automotive Diesel. In Proceedings of the 14th Meeting, Vienna, Austria, 6 February 1997. [Google Scholar]

- EN 590:2013+A1:2017; Automotive fuels—Diesel—Requirements and test methods. European Committee for Standardization: Brussels, Belgium, 2017.

- Anastopoulos, G.; Lois, E.; Serdari, A.; Zanikos, F.; Stournas, S.; Kalligeros, S. Lubrication properties of low-sulfur diesel fuels in the presence of specific types of fatty acid derivates. Energy Fuels 2001, 15, 106–112. [Google Scholar] [CrossRef]

- Geller, D.P.; Goodrum, J.W. Effects of specific fatty acid methyl esters on diesel fuel lubricity. Fuel 2004, 83, 2351–2356. [Google Scholar] [CrossRef]

- Knothe, G.; Steidley, K.R. Lubricity of components of biodiesel and petrodiesel. the origin of biodiesel lubricity. Energy Fuels 2005, 19, 1192–1200. [Google Scholar] [CrossRef]

- Knothe, G. “Designer” biodiesel: Optimizing fatty ester composition to improve fuel properties. Energy Fuels 2008, 22, 1358–1364. [Google Scholar] [CrossRef]

- Sulex, M.W.; Kulczycki, A.; Malysa, A. Assessment of lubricity of compositions of fuel oil with biocomponents derived from rape-seed. Wear 2010, 268, 104–108. [Google Scholar] [CrossRef]

- Sukjit, E.; Dearn, K.D. Enhancing the lubricity of an environmentally friendly Swedish diesel fuel MK1. Wear 2011, 271, 1772–1777. [Google Scholar] [CrossRef]

- Sukjit, E.; Tsolakis, A.; Dearn, K.D. Interrogating the surface: The effect of blended diesel fuels on lubricity. SAE Int. J. Fuel Lubr. Technol. 2012, 5, 154–162. [Google Scholar] [CrossRef]

- Agarwal, S.; Chhibber, V.K.; Bhatnagar, A.K. Tribological behavior of diesel fuels and the effect of anti-wear additives. Fuel 2013, 106, 21–29. [Google Scholar] [CrossRef]

- Loehle, S.; Matta, C.; Minfray, C.; Mogne, T.L.; Martin, J.M.; Iovine, R.; Obara, Y.; Miura, R.; Miyamoto, A. Mixed Lubrication with C18 Fatty Acids: Effect of Unsaturation. Tribol. Lett. 2014, 53, 319–328. [Google Scholar] [CrossRef]

- Chong, W.W.F.; Ng, J.H. An atomic-scale approach for biodiesel boundary lubricity characterization. Int. Biodeter. Biodegr. 2016, 113, 34–43. [Google Scholar] [CrossRef]

- Sundus, F.; Fazal, M.A.; Masjuki, H.H. Tribology with biodiesel: A study on enhancing biodiesel stability and its fuel properties. Renew. Sust. Energ. Rev. 2017, 70, 309–412. [Google Scholar] [CrossRef]

- De Barros Bouchet, M.I.; Martin, J.M.; Forest, C.; le Mogne, T.; Mazarin, M.; Avila, J.; Asensio, M.C.; Fisher, G.L. Tribochemistry of unsaturated fatty acids as friction modifiers in (bio)diesel fuel. RSC Adv. 2017, 7, 33120–33131. [Google Scholar] [CrossRef]

- De Oliveira, J.J.; Mendes de Farias, A.C.; Martins Alves, S. Evaluation of the biodiesel fuels lubricity using vibration signals and multiresolution analysis. Tribol. Int. 2017, 109, 104–113. [Google Scholar] [CrossRef]

- Sukjit, E.; Poapongsakorn, P.; Dearn, K.D.; Lapuerta, M.; Sánchez-Valdepeñas, J. Investigation of the lubrication properties and tribological mechanisms of oxygenated compounds. Wear 2017, 376, 836–842. [Google Scholar] [CrossRef]

- Sukjit, E.; Tongroon, M.; Chollacoop, N.; Yoshimura, Y.; Poapongsakorn, P.; Lapuerta, M.; Dearn, K.D. Improvement of the tribological behaviour of palm biodiesel via partial hydrogenation of unsaturated fatty acid methyl esters. Wear 2019, 426, 813–818. [Google Scholar] [CrossRef]

- Kajdas, C.; Majzner, M. Boundary lubrication of low-sulphur diesel fuel in the presence of fatty acids. Lubr. Sci. 2001, 14, 83–108. [Google Scholar] [CrossRef]

- Weinebeck, A.; Reinertz, O.; Murrenhoff, H. Boundary lubrication of biofuels and similar molecules. SAE Int. J. Fuels Lubr. 2017, 10, 645–651. [Google Scholar] [CrossRef]

- Hu, J.B.; Du, Z.X.; Li, C.X.; Min, E. Study on the lubrication properties of biodiesel as fuel lubricity enhancers. Fuel 2005, 84, 1601–1606. [Google Scholar] [CrossRef]

- Wei, D.; Spikes, H. The Lubricity of Diesel Fuels. Wear 1986, 111, 217–235. [Google Scholar] [CrossRef]

- Patterson, J.; Hassan, M.; Clarke, A.; Shama, G.; Hellgardt, K.; Chen, R. Experimental Study of DI Diesel Engine Performance Using Three Different Biodiesel Fuels. SAE Tech. Pap. 2006, 1, 0234. [Google Scholar] [CrossRef] [Green Version]

- Kotsiopoulos, P.; Papagiannakis, R.; Tsakalou, P.; Gazinou, I.; Yfantis, E. Experimental Investigation Concerning the Effect of the use of Biodiesel and F-34 (JP-8) Aviation Fuel on Performance and Emissions of a DI Diesel Engine. SAE Tech. Pap. 2007, 1, 1450. [Google Scholar] [CrossRef]

- Dagaut, P.; Gaïl, S. Chemical kinetic study of the effect of a biofuel additive on Jet-A1 combustion. J. Phys. Chem. A 2007, 111, 3992–4000. [Google Scholar] [CrossRef]

- Sukjit, E.; Herreros, J.M.; Dearn, K.D.; García-Contreras, R.; Tsolakis, A. The effect of the addition of individual methyl esters on the combustion and emissions of ethanol and butanol -diesel blends. Energy 2012, 42, 364–374. [Google Scholar] [CrossRef]

- Sajjad, H.; Masjuki, H.H.; Varman, M.; Kalam, M.A.; Arbab, M.I.; Imtenan, S.; Ashrafur Rahman, S.M. Engine combustion, performance and emission characteristics of gas to liquid (GTL) fuels and its blends with diesel and bio-diesel. Renew. Sust. Energ. Rev. 2014, 30, 961–986. [Google Scholar] [CrossRef] [Green Version]

- Nautiyal, P.; Subramanian, K.A.; Dastidar, M.G.; Kumar, A. Experimental assessment of performance, combustion and emissions of a compression ignition engine fuelled with Spirulina platensis biodiesel. Energy 2020, 193, 116861. [Google Scholar] [CrossRef]

- Zhang, Z.; Jiaqiang, E.; Deng, Y.; Pham, M.; Zuo, W.; Peng, Q.; Yin, Z. Effects of fatty acid methyl esters proportion on combustion and emission characteristics of a biodiesel fueled marine diesel engine. Energy Convers. Manag. 2018, 159, 244–253. [Google Scholar] [CrossRef]

- Ağbulut, Ü.; Sarıdemir, S.; Albayrak, S. Experimental investigation of combustion, performance and emission characteristics of a diesel engine fuelled with diesel–biodiesel–alcohol blends. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 1–12. [Google Scholar] [CrossRef]

- Dugala, N.S.; Goindi, G.S.; Sharma, A. Experimental investigations on the performance and emissions characteristics of dual biodiesel blends on a varying compression ratio diesel engine. SN Appl. Sci. 2021, 3, 622. [Google Scholar] [CrossRef]

- Chen, H.; Xie, B.; Ma, J.; Chen, Y. NOx emission of biodiesel compared to diesel: Higher or lower? Appl. Therm. Eng. 2018, 137, 584–593. [Google Scholar] [CrossRef]

- ISO 12156-1:2018; Diesel fuel—Assessment of lubricity using the high-frequency reciprocating rig (HFRR)—Part 1: Test method. International Organization for Standardization: Geneva, Switzerland, 2018.

- Bhuyan, S.; Sundararajan, S.; Yao, L.; Hammond, E.G.; Wang, T. Boundary lubrication properties of lipid-based compounds evaluated using microtribological methods. Tribol. Lett. 2006, 22, 2–11. [Google Scholar] [CrossRef]

- Wadumesthrige, K.; Ara, M.; Salley, S.O.; Simon Ng, K.Y. Investigation of Lubricity Characteristics of Biodiesel in Petroleum and Synthetic Fuel. Energy Fuels 2009, 23, 2229–2234. [Google Scholar] [CrossRef]

- Hong, F.T.; Alghamdi, N.M.; Bailey, A.S.; Khawajah, A.; Sarathy, S.M. Chemical and kinetic insights into fuel lubricity loss of low-sulfur diesel upon the addition of multiple oxygenated compounds. Tribol. Int. 2020, 152, 106559. [Google Scholar] [CrossRef]

- Hu, Z.; Zhang, L.; Li, Y. Investigation of tall oil fatty acid as antiwear agent to improve the lubricity of ultra-low sulfur diesels. Tribol. Int. 2017, 114, 57–64. [Google Scholar] [CrossRef]

| Properties | Sunflower Oil | Soybean Oil | Olive Oil | Cottonseed Oil | Coconut Oil | Used Frying Oil | Tobacco Seed Oil | Test Method |

|---|---|---|---|---|---|---|---|---|

| Kinematic Viscosity at 40 °C (cSt) | 32.6 ± 0.03 | 33.07 ± 0.03 | 29.4 ± 0.02 | 28.4 ± 0.02 | 27.3 ± 0.02 | 40.2 ± 0.03 | 27.7 ± 0.02 | EN ISO 3104 |

| Density at 15 °C (kg/m3) | 921.7 ± 0.08 | 918.6 ± 0.07 | 908.2 ± 0.06 | 914.8 ± 0.08 | 924.0 ± 0.08 | 926.0 ± 0.07 | 917.5 ± 0.06 | EN ISO 12185 |

| Flash Point (°C) | 272 ± 3 | 246 ± 3 | 268 ± 3 | 234 ± 3 | 311 ± 3 | 286 ± 3 | 220 ± 3 | EN 22719 |

| Iodine Number (cg I2/g oil) | 132 ± 4 | 108 ± 3 | 100 ± 3 | 115 ± 3 | 53.5 ± 2 | 108 ± 3 | 135 ± 4 | EN 14111 |

| Acid Value (mg KOH/g) | 0.33 ± 0.03 | 1.02 ± 0.07 | 0.25 ± 0.02 | 0.16 ± 0.02 | 0.22 ± 0.02 | 1.7 ± 0.08 | 0.48 ± 0.03 | EN 14104 |

| Saponification Value (mg KOH/g) | 192.1 ± 0.5 | 170.4 ± 0.4 | 196.2 ± 0.5 | 190 ± 0.5 | 267.6 ± 1.1 | 193.2 ± 0.5 | 193.0 ± 0.5 | AOCS CD3 1993 |

| Water Content (mg/kg) | 347 ± 0.5 | 512 ± 0.8 | 274 ± 0.5 | 578 ± 1.0 | 270 ± 0.5 | 933 ± 1.9 | 754 ± 0.15 | EN ISO 12937 |

| Sulfur Content (mg/kg) | 0.23 ± 0.004 | 3.0 ± 0.04 | 2.6 ± 0.03 | 3.2 ± 0.03 | 2.7 ± 0.04 | 5.7 ± 0.05 | 8.2 ± 0.06 | EN ISO 20846 |

| Carbon Residue (% m/m) | 0.031 ± 0.0004 | 0.056 ± 0.0008 | 0.092 ± 0.001 | 0.073 ± 0.0009 | 0.217 ± 0.02 | 0.181 ± 0.02 | 0.086 ± 0.01 | EN ISO 10370 |

| Fatty Acid | Chemical Structure | Vegetable Oil Type | ||||||

|---|---|---|---|---|---|---|---|---|

| Sunflower Oil | Soybean Oil | Olive Oil | Cottonseed Oil | Coconut Oil | Used Frying Oil | Tobacco Seed Oil | ||

| Lauric (C12) | CH3(CH2)10COOH | 0.0 | 0.1 ± 0.01 | 0.0 | 0.0 | 49.2 ± 0.02 | 2.0 ± 0.01 | 0.0 |

| Myristic (C14) | CH3(CH2)12COOH | 0.0 | 0.1 ± 0.01 | 0.0 | 0.8 ± 0.01 | 18.5 ± 0.02 | 0.3 ± 0.01 | 0.1 ± 0.01 |

| Palmitic (C16) | CH3(CH2)14COOH | 6.2 ± 0.01 | 11.3 ± 0.01 | 11.6 ± 0.01 | 22.2 ± 0.02 | 9.1 ± 0.02 | 15.7 ± 0.02 | 11.0 ± 0.02 |

| Palmitoleic (C16:1) | CH3(CH2)5CH=CH(CH2)7COOH | 0.1 ± 0.01 | 0.0 | 0.9 ± 0.01 | 0.4 ± 0.01 | 0.1 ± 0.01 | 0.3 ± 0.01 | 0.2 ± 0.01 |

| Stearic (C18) | CH3(CH2)16COOH | 3.7 ± 0.01 | 4.1 ± 0.01 | 3.1 ± 0.01 | 2.2 ± 0.01 | 2.7 ± 0.01 | 3.1 ± 0.01 | 3.3 ± 0.01 |

| Oleic (C18:1) | CH3(CH2)7CH=CH(CH2)7COOH | 25.2 ± 0.02 | 22.7 ± 0.02 | 75.0 ± 0.03 | 17.7 ± 0.02 | 6.5 ± 0.01 | 48.7 ± 0.02 | 15.5 ± 0.02 |

| Linoleic (C18:2) | CH3(CH2)3(CH2CH=CH)2(CH2)7COOH | 63.1 ± 0.02 | 52.6 ± 0.02 | 7.8 ± 0.02 | 55.8 ± 0.02 | 1.7 ± 0.01 | 22.4 ± 0.02 | 69.5 ± 0.02 |

| Linolenic (C18:3) | CH3(CH2CH=CH)3(CH2)7COOH | 0.3 ± 0.01 | 7.4 ± 0.02 | 0.6 ± 0.01 | 0.1 ± 0.01 | 0.0 | 1.0 ± 0.01 | 0.7 ± 0.01 |

| Eicosenoic (C20) | CH3(CH2)8CH=CH(CH2)8COOH | 0.2 ± 0.01 | 0.5 ± 0.01 | 0.0 | 0.2 ± 0.01 | 0.1 ± 0.01 | 0.1 ± 0.01 | 0.3 ± 0.01 |

| Behenic (C22) | CH3(CH2)20COOH | 0.7 ± 0.01 | 0.5 ± 0.01 | 0.1 ± 0.01 | 0.0 | 0.1 ± 0.01 | 0.2 ± 0.01 | 0.1 ± 0.01 |

| Erucic (C22:1) | CH3(CH2)7CH=CH(CH2)11COOH | 0.1 ± 0.01 | 0.2 ± 0.01 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| Lignoceric (C24) | CH3(CH2)22COOH | 0.2 ± 0.01 | 0.2 ± 0.01 | 0.5 ± 0.01 | 0.0 | 0.0 | 0.3 ± 0.01 | 0.0 |

| Properties | JP-8 | Method |

|---|---|---|

| Density (kg/m3, 15 °C) | 795.0 ± 0.1 | ASTM D 1298 |

| Kinematic Viscosity (cSt, −20 °C) | 3.87 ± 0.005 | ASTM D 445 |

| Flash Point (°C) | 41 ± 0.5 | ASTM D 93 |

| Conductivity (pS/m) | 375 ± 5 | ASTM D 2624 |

| Sulfur wt% | 0.23 + 0.007 | ASTM D 4294 |

| Aromatics vol% | 15.3 ± 0.6 | ASTM D 1319 |

| Olefins vol% | 0.3 ± 0.1 | ASTM D 1319 |

| Lubricity | ISO 12156-1 | |

| Initial measurement, μm | 754 ± 2 | |

| Repeated measurement, μm | 758 ± 2 | |

| Distillation (°C) | ASTM D 86 | |

| IBP | 145 ± 2 | |

| 10% | 174 ± 1 | |

| 20% | 181 ± 1 | |

| 50% | 200 ± 1 | |

| 90% | 233 ± 1 | |

| FBP | 250 ± 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Anastopoulos, G.; Schinas, P.; Zannikou, Y.; Komiotou, M.; Zannikos, F.; Karonis, D. Impact of N,N-Bis(2-ethoxyethyl) Fatty Acid Amides on the Lubrication Performance of Kerosene Fuel F-34 for Use in CI Engines. Fuels 2023, 4, 19-32. https://doi.org/10.3390/fuels4010002

Anastopoulos G, Schinas P, Zannikou Y, Komiotou M, Zannikos F, Karonis D. Impact of N,N-Bis(2-ethoxyethyl) Fatty Acid Amides on the Lubrication Performance of Kerosene Fuel F-34 for Use in CI Engines. Fuels. 2023; 4(1):19-32. https://doi.org/10.3390/fuels4010002

Chicago/Turabian StyleAnastopoulos, George, Petros Schinas, Ypatia Zannikou, Maria Komiotou, Fanourios Zannikos, and Dimitrios Karonis. 2023. "Impact of N,N-Bis(2-ethoxyethyl) Fatty Acid Amides on the Lubrication Performance of Kerosene Fuel F-34 for Use in CI Engines" Fuels 4, no. 1: 19-32. https://doi.org/10.3390/fuels4010002

APA StyleAnastopoulos, G., Schinas, P., Zannikou, Y., Komiotou, M., Zannikos, F., & Karonis, D. (2023). Impact of N,N-Bis(2-ethoxyethyl) Fatty Acid Amides on the Lubrication Performance of Kerosene Fuel F-34 for Use in CI Engines. Fuels, 4(1), 19-32. https://doi.org/10.3390/fuels4010002