Systematic and Bibliometric Review of Biomethane Production from Biomass-Based Residues: Technologies, Economics and Environmental Impact

Abstract

1. Introduction

- RQ1: What are the recent advancements in biomass gasification and syngas methanation technologies for biomethane production, and how do these compare with traditional AD methods in terms of efficiency, costs and environmental impacts?

- RQ2: What techno-economic factors influence the viability and scalability of biomethane production from biomass gasification and methanation?

- RQ3: How do LCAs of biomethane production from gasification and methanation compare to other renewable energy alternatives?

- RQ4: What are the emerging feedstock options for biomethane production, and how do they impact overall process sustainability?

2. Materials and Methods

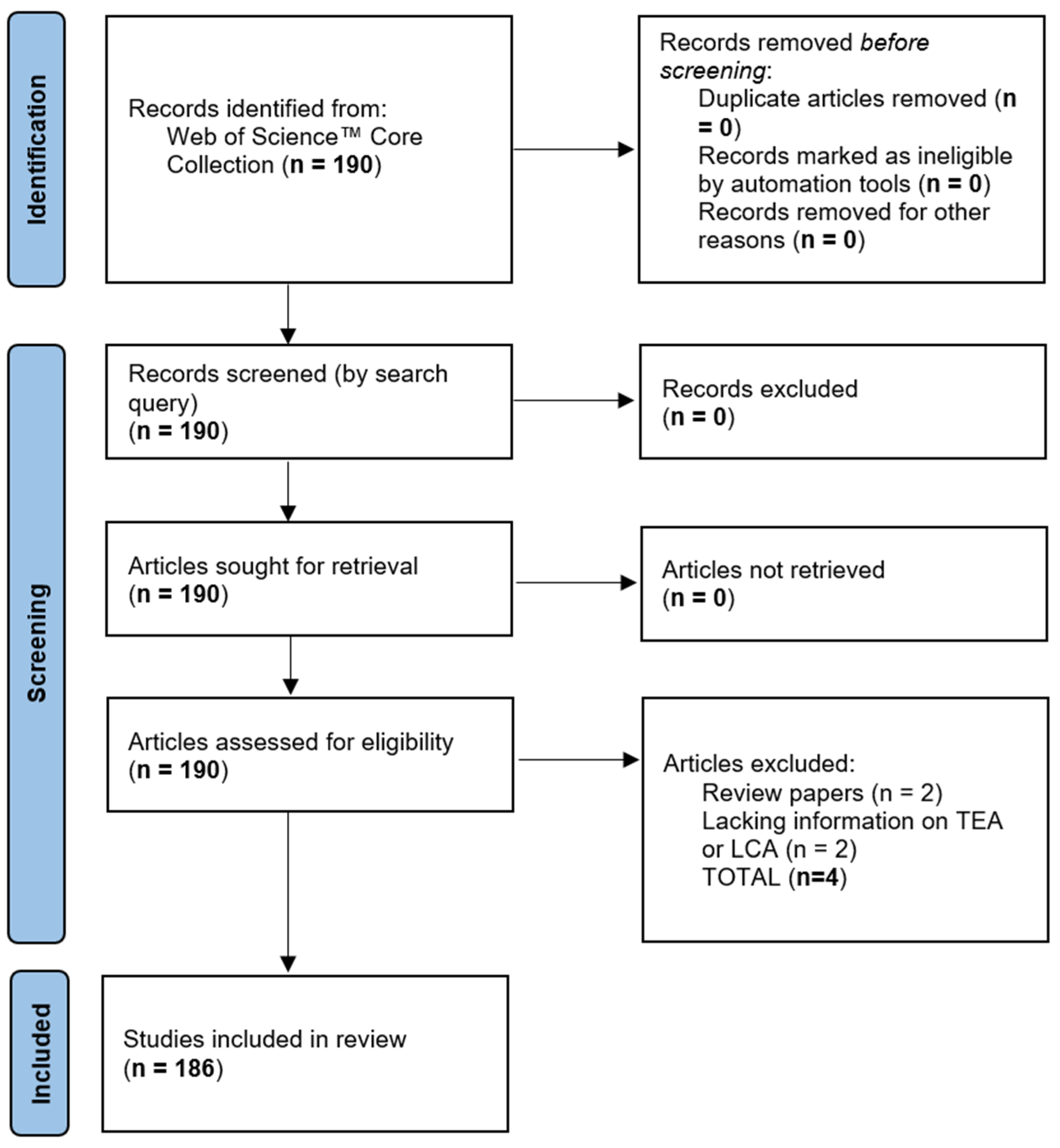

2.1. Systematic Literature Review

- Technological parameters: such as feedstock type, location, technology setup, data source and biomethane production rates.

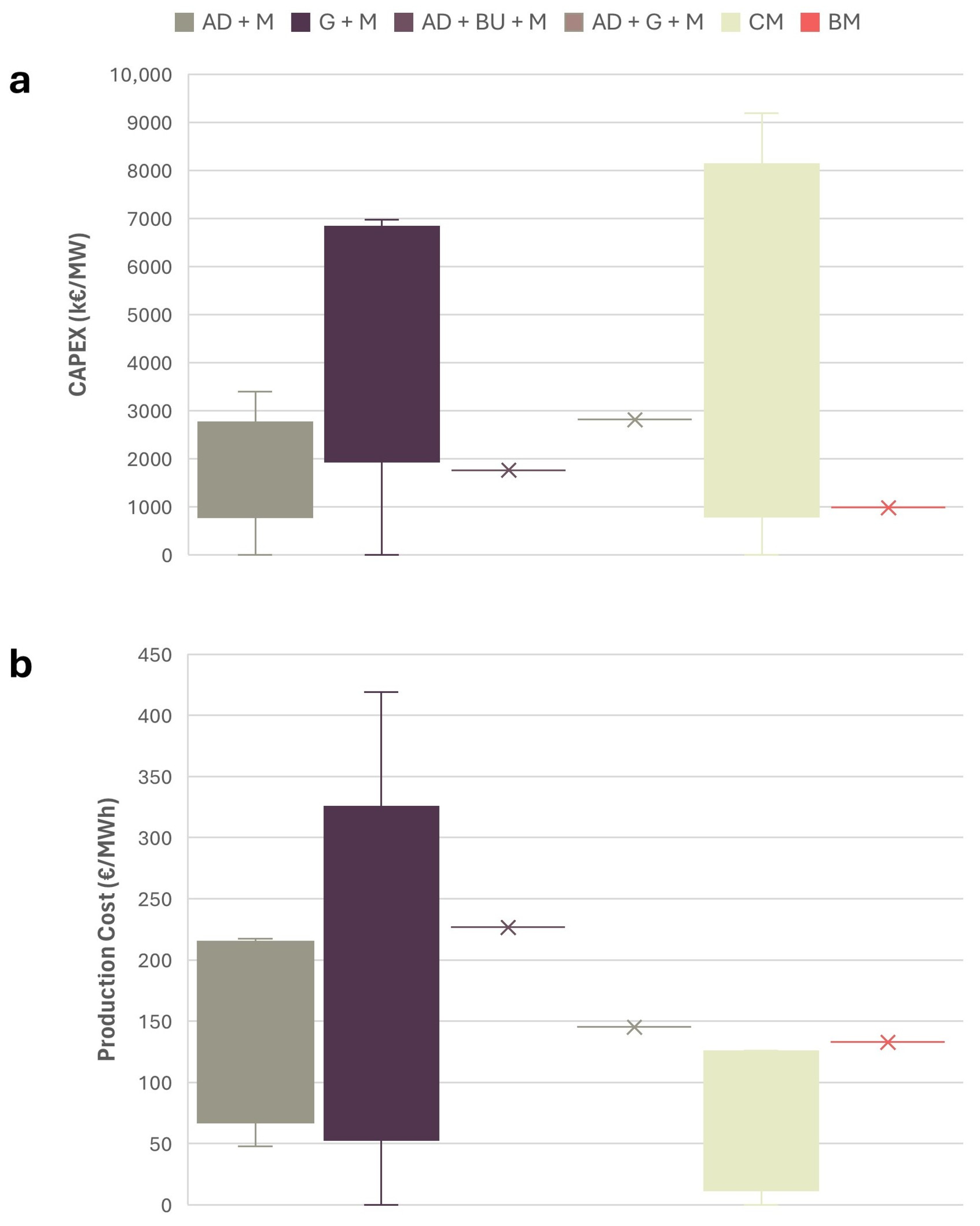

- Economic parameters: including capital (CAPEX) and operational (OPEX) expenditures, minimum selling price of biomethane and production costs; biomethane production costs (in €/MWh) were calculated assuming 7920 h of operation per year, when not specified in the documents. CAPEX was also normalized per biomethane plant capacity (in €/MW).

- Environmental parameters: such as the scope of the assessment, functional unit, software and databases used, life cycle impact assessment methods and environmental impacts.

2.2. Bibliometric Analysis Methodology

3. Results and Discussion

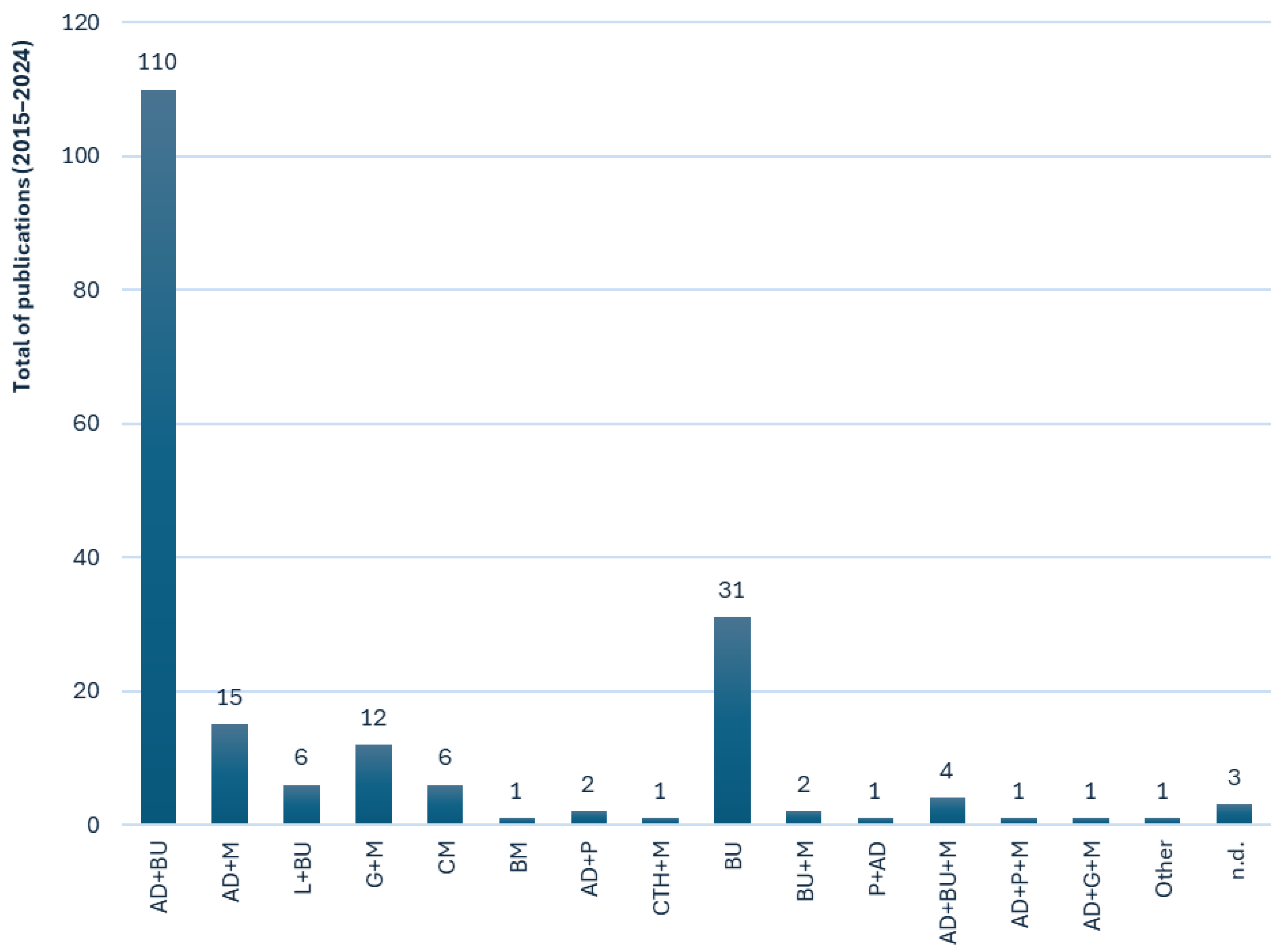

3.1. Overview of Feedstock, Production Technologies and Research Trends in Biomethane Synthesis

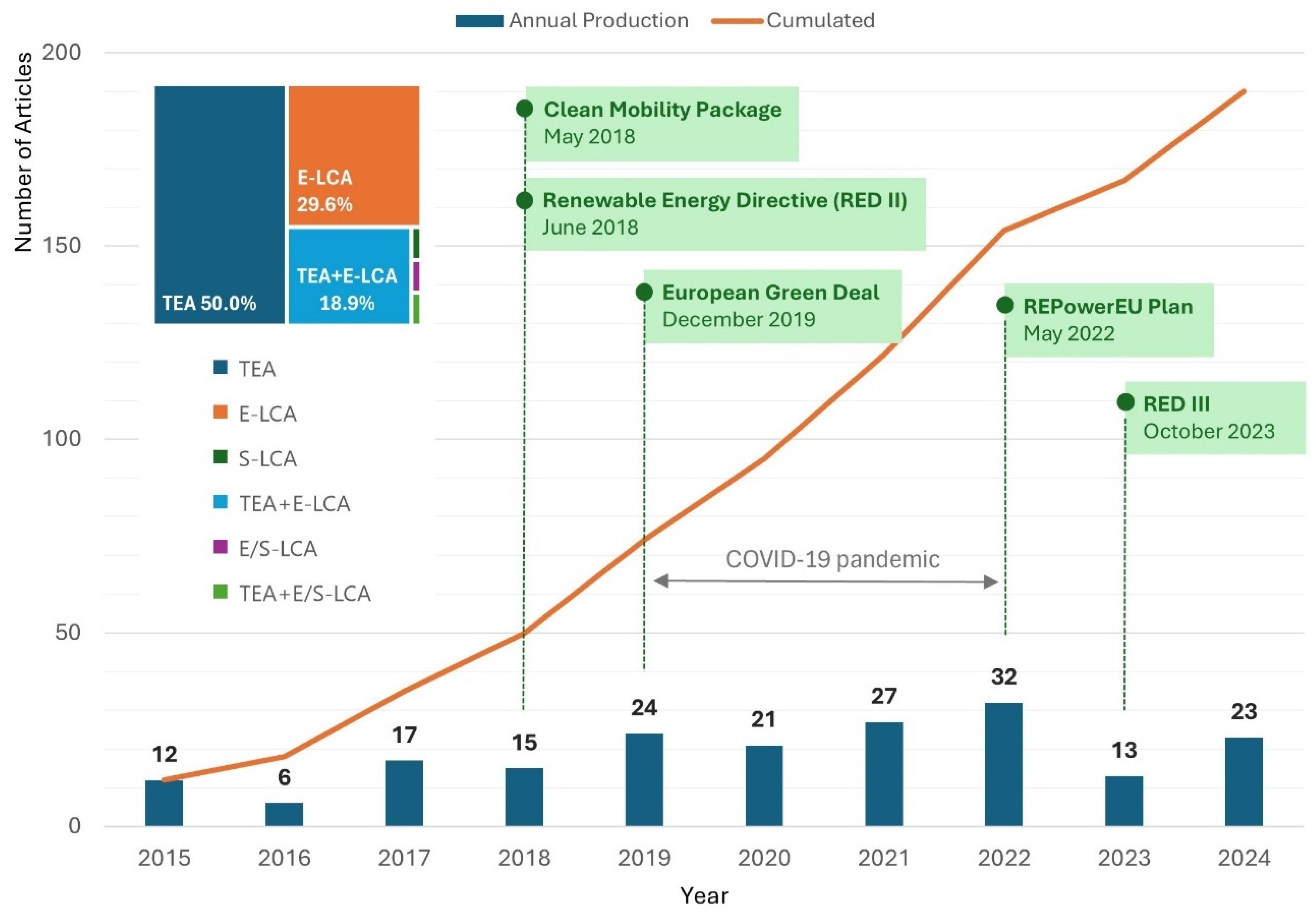

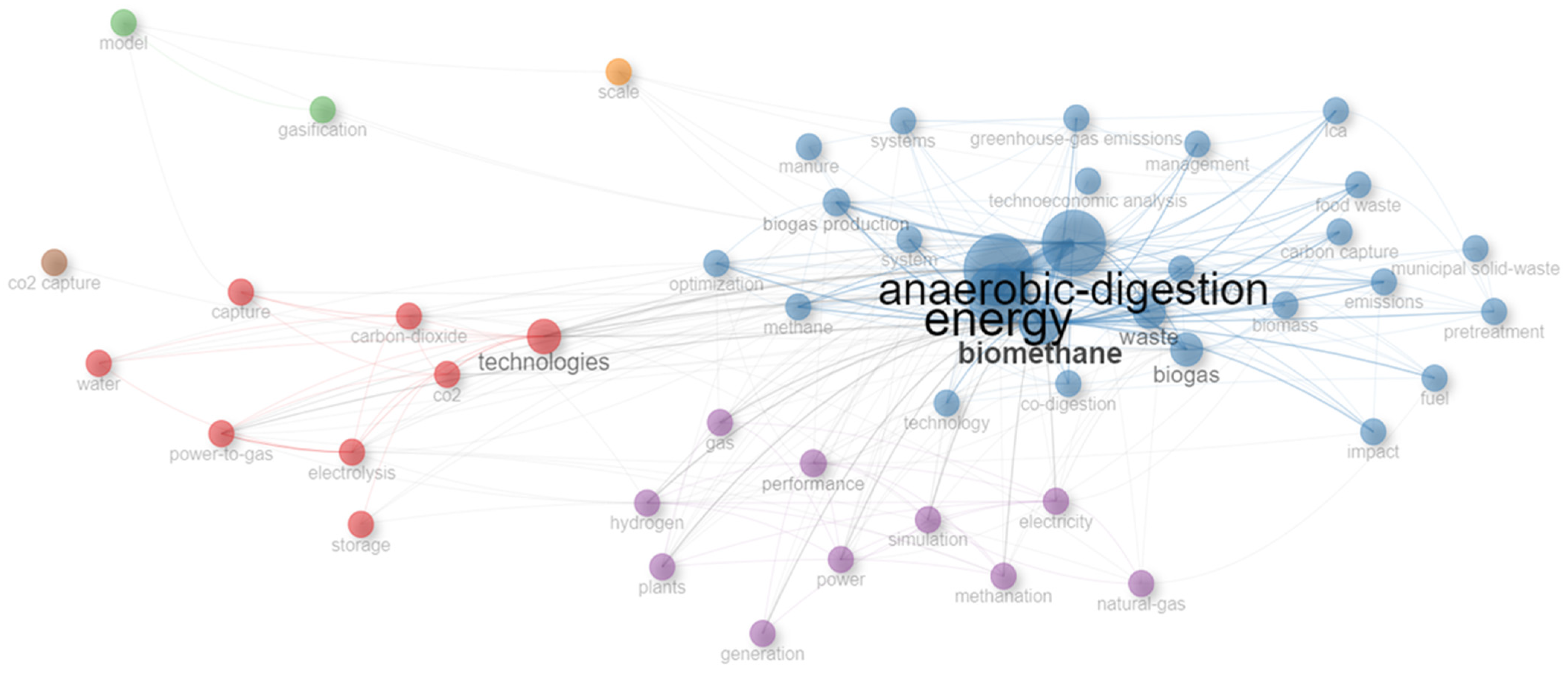

3.2. Bibliometric Analysis

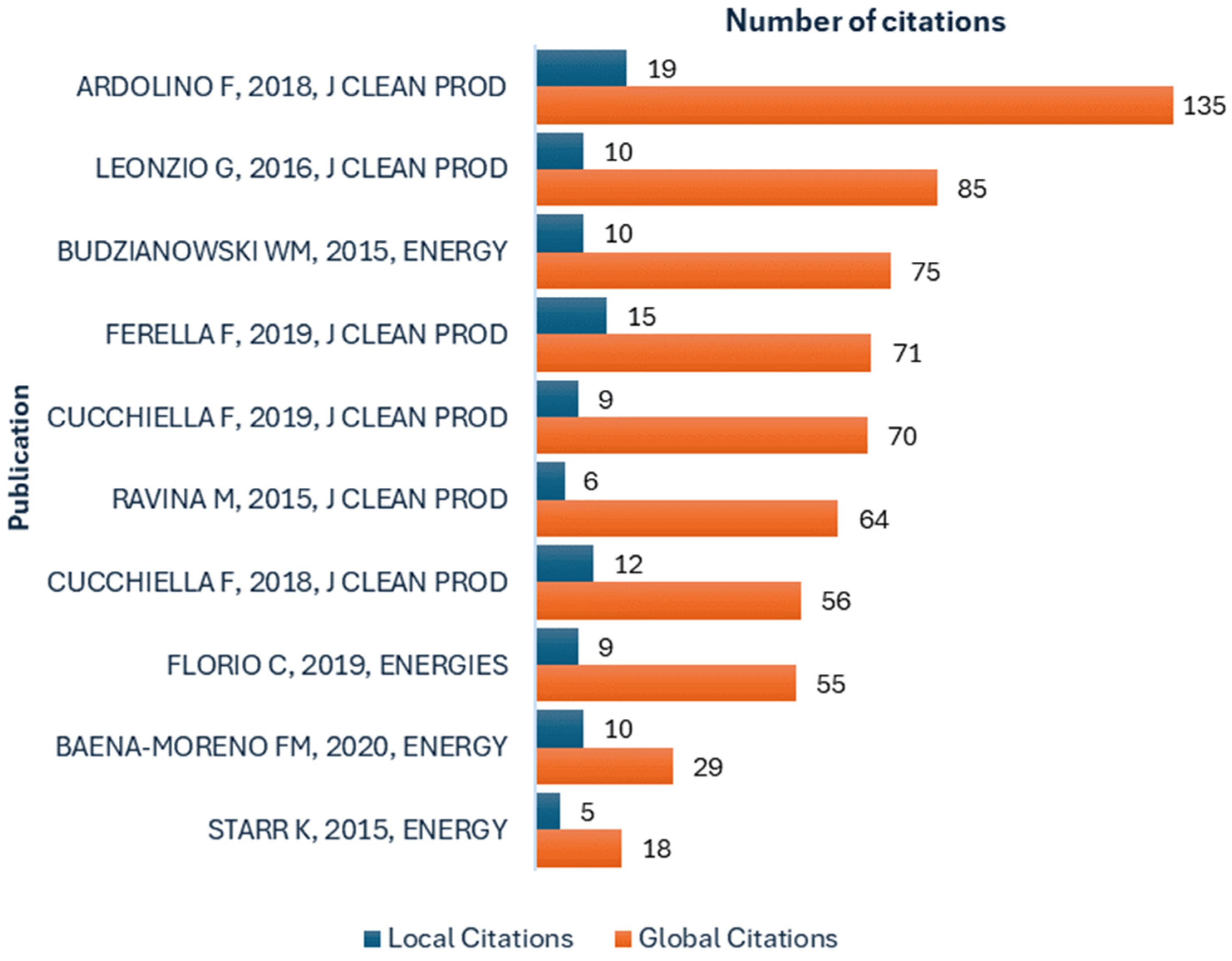

3.2.1. Analysis of the Most Cited Documents

3.2.2. Trend Topics, Authors and Documents

3.3. Advancements in Biomethane Production via Gasification and Methanation

3.3.1. Technical Aspects

3.3.2. Techno-Economic Analysis

| Technology | Feedstock | Location | Plant Capacity (MW) | Production 1 (MWh/Year) | CAPEX (M€) | CAPEX (k€/MW) | Production Cost (€/MWh) | MSP 2 (€/MWh) | Ref. | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Total | G | M | E | |||||||||

| AD + M | Organic waste | Italy | 1 | 7920 | 1.59 | 1592 | - | - | - | 212.37 | - | [29] |

| Manure | Spain | 1 | 8000 | 3.39 | 3391 | - | 840 | 1382 | 86.49 | 116.94 | [67] | |

| Manure (80%) + other biowaste (20%) | Denmark | 4.6 | 38,385 | 5.68 | - | - | - | - | 47.67 | 66.37 | [74] | |

| Grass silage (80%) and dairy manure (20%) | Ireland | 5 | 39,600 | 7.80 | 1560 | - | 938 | - | 217.17 | 143.80 | [73] | |

| Sewage sludge | England | 10.6 | 84,800 | 22.53 | 2125 | - | 761 | 1462 | 148.01 | 185.82 | [69] | |

| AD + BU + M | Grass silage (80%) and dairy manure (20%) | Ireland | 5 | 39,600 | 8.81 | 1762 | - | 938 | - | 226.77 | 150.84 | [73] |

| AD + G + M | Forestry biomass and sludge | Portugal | 0.475 | 3040 | 7.49 | 11,709 | 8661 | 42 | 2659 | 110.22 | 182.30 3 | [70] |

| Sewage sludge | England | 12.8 | 102,080 | 35.93 | 2816 | 277 | 761 | 1462 | 145.20 | 191.43 | [69] | |

| AD + P + M | OFMSW | Sweden | n.d. | 3080 | - | - | - | - | - | 24.17 | 147.82 | [75] |

| G + M | Manure | Spain | 1 | 8000 | 3.87 | 3871 | 608 | 955 | 1663 | 105.58 | 92.86 | [76] |

| Wood chips | Lithuania | 1 | 8000 | 4.25 | 4253 | 295 | 246 | 63 | 418.94 | - | [66] | |

| Crude glycerol | Canada | 16.1 | 128,800 | 6679 | 498 | 899 | 1408 | 231.83 | 147.44 | [72] | ||

| Woody biomass | Sweden | 20 | 160,000 | 139.39 | 6970 | 149 | 98 | - | 60.6 | - | [68] | |

| n.d. | Sweden | 48 | - | - | - | - | - | - | - | 141.12 | [77] | |

| G + P + M | n.d. | Sweden | 170 | 4634 | - | - | - | - | 1000 | - | - | [71] |

| CM | n.d. | Switzerland | 1 | 7920 | 3.16 | 3161 | - | - | - | 126.01 | - | [78] |

| Hungary | 1 | 8000 | 4.98 | 4984 | - | 600 | 1100 | 123.75 | 56.31 | [79] | ||

| Landfill biogas | France | n.d. | 35,665 | - | - | - | - | - | - | 80.00 | [80] | |

| CO2 from flue gases | Spain | 7000 | 58,100,000 | 64.30 | 9186 | - | - | - | 46.82 | - | [81] | |

| BM | Biogas from an anaerobic digester | Denmark | 2.67 | 21,146 | 2.62 | 981 | - | 55 | 752 | 132.83 | 135.34 | [82] |

3.3.3. Life Cycle Assessment

4. Conclusions and Future Prospects

- Gasification and methanation systems exhibit higher CAPEX and OPEX compared to AD and biogas upgrading, primarily due to technical complexity. Economies of scale can mitigate costs, but smaller plants face economic challenges.

- Advanced technologies such as SEG and CLG show promise for cost reduction and carbon efficiency but require further development.

- Environmental assessments highlight higher impacts for gasification and methanation systems compared to AD, attributed to greater energy demands. However, integrating CO2 from flue gases or using wastewater biogas can mitigate some environmental burdens.

- Advancing gasification and methanation processes to improve energy efficiency and lower costs.

- Developing more robust and efficient catalysts for methanation, targeting durability and cost-effectiveness.

- Addressing gaps in LCA studies by evaluating diverse feedstocks, functional units, more impact categories and regional contexts to identify environmental hotspots.

- Assessing policy frameworks and market incentives to promote large-scale adoption, ensuring economic feasibility and alignment with decarbonization goals.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- World Energy Outlook 2022. Available online: https://www.iea.org/reports/world-energy-outlook-2022 (accessed on 17 May 2024).

- Davidson, D.J. Exnovating for a Renewable Energy Transition. Nat. Energy 2019, 4, 254–256. [Google Scholar] [CrossRef]

- Kolb, S.; Plankenbühler, T.; Hofmann, K.; Bergerson, J.; Karl, J. Life Cycle Greenhouse Gas Emissions of Renewable Gas Technologies: A Comparative Review. Renew. Sustain. Energy Rev. 2021, 146, 111147. [Google Scholar] [CrossRef]

- Hamelin, L.; Møller, H.B.; Jørgensen, U. Harnessing the Full Potential of Biomethane towards Tomorrow’s Bioeconomy: A National Case Study Coupling Sustainable Agricultural Intensification, Emerging Biogas Technologies and Energy System Analysis. Renew. Sustain. Energy Rev. 2021, 138, 110506. [Google Scholar] [CrossRef]

- Quevedo-Amador, R.A.; Escalera-Velasco, B.P.; Arias, A.M.R.; Reynel-Ávila, H.E.; Moreno-Piraján, J.C.; Giraldo, L.; Bonilla-Petriciolet, A. Application of Waste Biomass for the Production of Biofuels and Catalysts: A Review. Clean Technol. Environ. Policy 2024, 26, 943–997. [Google Scholar] [CrossRef]

- BioGem Express EU Biomethane Production Potential for 2040 Could Cover 30% of Its Current Gas Demand. Available online: https://biogemexpress.com/2024/04/18/eu-biomethane-production-potential-for-2040-could-cover-30-of-its-current-gas-demand/ (accessed on 3 December 2024).

- Verified Market Research Biomethane Market Size And Forecast. Available online: https://www.verifiedmarketresearch.com/product/biomethane-market/ (accessed on 3 December 2024).

- Sulewski, P.; Ignaciuk, W.; Szymańska, M.; Wąs, A. Development of the Biomethane Market in Europe. Energies 2023, 16, 2001. [Google Scholar] [CrossRef]

- Dhull, P.; Lohchab, R.K.; Kumar, S.; Kumari, M.; Shaloo; Bhankhar, A.K. Anaerobic Digestion: Advance Techniques for Enhanced Biomethane/Biogas Production as a Source of Renewable Energy. Bioenergy Res. 2024, 17, 1228–1249. [Google Scholar] [CrossRef]

- Vijin Prabhu, A.; Manimaran, R.; Antony Raja, S.; Jeba, P. Biogas Production from Anaerobic Co-Digestion of Prosopis Juliflora Pods with Water Hyacinth, Dry Leaves, and Cow Manure. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 42, 375–386. [Google Scholar] [CrossRef]

- Emebu, S.; Pecha, J.; Janáčová, D. Review on Anaerobic Digestion Models: Model Classification & Elaboration of Process Phenomena. Renew. Sustain. Energy Rev. 2022, 160, 112288. [Google Scholar] [CrossRef]

- Paniagua, S.; Lebrero, R.; Muñoz, R. Syngas Biomethanation: Current State and Future Perspectives. Bioresour. Technol. 2022, 358, 127436. [Google Scholar] [CrossRef]

- Naveen, S.; Aravind, S.; Yamini, B.; Vasudhareni, R.; Gopinath, K.P.; Arun, J.; Pugazhendhi, A. A Review on Solar Energy Intensified Biomass Valorization and Value-Added Products Production: Practicability, Challenges, Techno Economic and Lifecycle Assessment. J. Clean. Prod. 2023, 405, 137028. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 Statement: An Updated Guideline for Reporting Systematic Reviews. BMJ 2021, 372, 71. [Google Scholar] [CrossRef] [PubMed]

- Haddaway, N.R.; Page, M.J.; Pritchard, C.C.; McGuinness, L.A. PRISMA2020: An R Package and Shiny App for Producing PRISMA 2020-compliant Flow Diagrams, with Interactivity for Optimised Digital Transparency and Open Synthesis. Campbell Syst. Rev. 2022, 18, e1230. [Google Scholar] [CrossRef]

- Aria, M.; Cuccurullo, C. Bibliometrix: An R-Tool for Comprehensive Science Mapping Analysis. J. Informetr. 2017, 11, 959–975. [Google Scholar] [CrossRef]

- European Commission. Europe on the Move: Commission Completes Its Agenda for Safe, Clean and Connected Mobility. Available online: https://ec.europa.eu/commission/presscorner/detail/en/IP_18_3708 (accessed on 23 September 2024).

- European Commission. The European Green Deal-Striving to Be the First Climate-Neutral Continent. Available online: https://commission.europa.eu/strategy-and-policy/priorities-2019-2024/european-green-deal_en (accessed on 23 September 2024).

- European Commission. REPowerEU-Affordable, Secure and Sustainable Energy for Europe. Available online: https://commission.europa.eu/strategy-and-policy/priorities-2019-2024/european-green-deal/repowereu-affordable-secure-and-sustainable-energy-europe_en (accessed on 23 September 2024).

- European Commission. Directive (EU) 2018/2001 of the European Parliament and of the Council of 11 December 2018 on the Promotion of the Use of Energy from Renewable Sources. Off. J. Eur. Union 2018. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32018L2001 (accessed on 18 November 2024).

- European Commission. Directive (EU) 2023/2413 of the European Parliament and of the Council of 18 October 2023 Amending Directive (EU) 2018/2001, Regulation (EU) 2018/1999 and Directive 98/70/EC as Regards the Promotion of Energy from Renewable Sources, and Repealing Council Directive (EU) 2015/652. Off. J. Eur. Union 2023. Available online: https://eur-lex.europa.eu/eli/dir/2023/2413/oj/eng (accessed on 18 November 2024).

- Ardolino, F.; Parrillo, F.; Arena, U. Biowaste-to-Biomethane or Biowaste-to-Energy? An LCA Study on Anaerobic of Organic Waste. J. Clean. Prod. 2018, 174, 462–476. [Google Scholar] [CrossRef]

- Ravina, M.; Genon, G. Global and Local Emissions of a Biogas Plant Considering the production of Biomethane as an Alternative End-Use Solution. J. Clean. Prod. 2015, 102, 115–126. [Google Scholar] [CrossRef]

- Cucchiella, F.; D’Adamo, I.; Gastaldi, M.; Miliacca, M. A Profitability Analysis of Small-Scale Plants for Biomethane injection into the Gas Grid. J. Clean. Prod. 2018, 184, 179–187. [Google Scholar] [CrossRef]

- Baena-Moreno, F.M.; Malico, I.; Rodriguez-Galan, M.; Serrano, A.; Fermoso, F.G.; Navarrete, B. The Importance of Governmental Incentives for Small Biomethane Plants in South Spain. Energy 2020, 206, 118158. [Google Scholar] [CrossRef]

- Starr, K.; Ramirez, A.; Meerman, H.; Vilialba, G.; Gabarrell, X. Explorative Economic Analysis of a Novel Biogas Upgrading Technology Carbon Mineralization. A Case Study for Spain. Energy 2015, 79, 298–309. [Google Scholar] [CrossRef]

- Budzianowski, W.M.; Budzianowska, D.A. Economic Analysis of Biomethane and Bioelectricity Generation from biogas Using Different Support Schemes and Plant Configurations. Energy 2015, 88, 658–666. [Google Scholar] [CrossRef]

- Ferella, F.; Cucchiella, F.; D’Adamo, I.; Gallucci, K. A Techno-Economic Assessment of Biogas Upgrading in a Developed Market. J. Clean. Prod. 2019, 210, 945–957. [Google Scholar] [CrossRef]

- Leonzio, G. Design and Feasibility Analysis of a Power-to-Gas Plant in Germany. J. Clean. Prod. 2017, 162, 609–623. [Google Scholar] [CrossRef]

- Florio, C.; Fiorentino, G.; Corcelli, F.; Ulgiati, S.; Dumontet, S.; Guesewell, J.; Eltrop, L. A Life Cycle Assessment of Biomethane Production from Waste Feedstock Through Different Upgrading Technologies. Energies 2019, 12, 718. [Google Scholar] [CrossRef]

- Cucchiella, F.; D’Adamo, I.; Gastaldi, M. An Economic Analysis of Biogas-Biomethane Chain from Animal Residues In. J. Clean. Prod. 2019, 230, 888–897. [Google Scholar] [CrossRef]

- Budzianowski, W.M.; Wylock, C.E.; Marciniak, P.A. Power Requirements of Biogas Upgrading by Water Scrubbing and Biomethane Compression: Comparative Analysis of Various Plant Configurations. Energy Convers. Manag. 2017, 141, 2–19. [Google Scholar] [CrossRef]

- Vo, T.T.Q.; Rajendran, K.; Murphy, J.D. Can Power to Methane Systems Be Sustainable and Can They Improve the carbon Intensity of Renewable Methane When Used to Upgrade Biogas from Grass and Slurry? Appl. Energy 2018, 228, 1046–1056. [Google Scholar] [CrossRef]

- IEA Bioenergy-Task 33 Biomass and Waste Gasification for the Production of Synthetic Natural Gas. Available online: https://task33.ieabioenergy.com/biomass-and-waste-gasification-for-the-production-of-synthetic-natural-gas/ (accessed on 3 December 2024).

- Li, H.; Larsson, E.; Thorin, E.; Dahlquist, E.; Yu, X. Feasibility Study on Combining Anaerobic Digestion and Biomass Gasification to Increase the Production of Biomethane. Energy Convers. Manag. 2015, 100, 212–219. [Google Scholar] [CrossRef]

- Li, H.; Mehmood, D.; Thorin, E.; Yu, Z. Biomethane Production Via Anaerobic Digestion and Biomass Gasification. Energy Procedia 2017, 105, 1172–1177. [Google Scholar] [CrossRef]

- Zhang, L.; Yao, D.; Tsui, T.-H.; Loh, K.-C.; Wang, C.-H.; Dai, Y.; Tong, Y.W. Plastic-Containing Food Waste Conversion to Biomethane, Syngas, and Biochar via Anaerobic Digestion and Gasification: Focusing on Reactor Performance, Microbial Community Analysis, and Energy Balance Assessment. J. Environ. Manag. 2022, 306, 114471. [Google Scholar] [CrossRef] [PubMed]

- Safarian, S.; Richter, C.; Unnthorsson, R. Waste Biomass Gasification Simulation Using Aspen Plus: Performance Evaluation of Wood Chips, Sawdust and Mixed Paper Wastes. J. Power Energy Eng. 2019, 7, 12–30. [Google Scholar] [CrossRef]

- Shahrivar, M.; Saeed, M.N.; Surywanshi, G.D.; Mattisson, T.; Soleimanisalim, A.H. Improving Bio Aviation Fuel Yield from Biogenic Carbon Sources through Electrolysis Assisted Chemical Looping Gasification. Fuel 2023, 348, 128525. [Google Scholar] [CrossRef]

- Poluzzi, A.; Guandalini, G.; Guffanti, S.; Martinelli, M.; Moioli, S.; Huttenhuis, P.; Rexwinkel, G.; Palonen, J.; Martelli, E.; Groppi, G.; et al. Flexible Power and Biomass-To-Methanol Plants With Different Gasification Technologies. Front. Energy Res. 2022, 9, 795673. [Google Scholar] [CrossRef]

- Pfeifer, C. 22-Sorption-Enhanced Gasification. In Fluidized Bed Technologies for Near-Zero Emission Combustion and Gasification; Scala, F., Ed.; Woodhead Publishing Series in Energy; Woodhead Publishing: Cambridge, UK, 2013; pp. 971–1001. ISBN 978-0-85709-541-1. [Google Scholar]

- Parvez, A.M.; Hafner, S.; Hornberger, M.; Schmid, M.; Scheffknecht, G. Sorption Enhanced Gasification (SEG) of Biomass for Tailored Syngas Production with in-Situ CO2 Capture: Current Status, Process Scale-up Experiences and Outlook. Renew. Sustain. Energy Rev. 2021, 141, 110756. [Google Scholar] [CrossRef]

- Harb, R.; Rivera-Tinoco, R.; Nemer, M.; Zeghondy, B.; Bouallou, C. Towards Synthetic Fuels Production from Biomass Gasification: Tar Content at Low Temperatures. Biomass Bioenergy 2020, 137, 105540. [Google Scholar] [CrossRef]

- Gaikwad, R.; Villadsen, S.N.B.; Rasmussen, J.P.; Grumsen, F.B.; Nielsen, L.P.; Gildert, G.; Møller, P.; Fosbøl, P.L. Container-Sized CO2 to Methane: Design, Construction and Catalytic Tests Using Raw Biogas to Biomethane. Catalysts 2020, 10, 1428. [Google Scholar] [CrossRef]

- Yun, H.A.H.; Ramírez-Solís, S.; Dupont, V. Bio-CH4 from Palm Empty Fruit Bunch via Pyrolysis-Direct Methanation: Full Plant Model and Experiments with Bio-Oil Surrogate. J. Clean. Prod. 2020, 244, 118737. [Google Scholar] [CrossRef]

- González-Arias, J.; Torres-Sempere, G.; Arroyo-Torralvo, F.; Reina, T.R.; Odriozola, J.A. Optimizing Biogas Methanation over Nickel Supported on Ceria-Alumina Catalyst: Towards CO2-Rich Biomass Utilization for a Negative Emissions Society. Environ. Res. 2024, 242, 117735. [Google Scholar] [CrossRef]

- Lanni, D.; Minutillo, M.; Cigolotti, V.; Perna, A. Biomethane Production through the Power to Gas Concept: A Strategy for Increasing the Renewable Sources Exploitation and Promoting the Green Energy Transition. Energy Convers. Manag. 2023, 293, 117538. [Google Scholar] [CrossRef]

- Atzori, L.; Cutrufello, M.; Meloni, D.; Secci, F.; Cannas, C.; Rombi, E. Soft-Templated NiO–CeO2 Mixed Oxides for Biogas Upgrading by Direct CO2 Methanation. Int. J. Hydrogen Energy 2023, 48, 25031–25043. [Google Scholar] [CrossRef]

- Mhadmhan, S.; Ngamcharussrivichai, C.; Hinchiranan, N.; Kuchonthara, P.; Li, Y.; Wang, S.; Reubroycharoen, P. Direct Biogas Upgrading via CO2 Methanation to High-Quality Biomethane over NiMg/CNT-SiO2 Fiber Catalysts. Fuel 2022, 310, 122289. [Google Scholar] [CrossRef]

- Martins, J.A.; Miguel, C.V.; Rodrigues, A.E.; Madeira, L.M. Novel Adsorption–Reaction Process for Biomethane Purification/Production and Renewable Energy Storage. ACS Sustain. Chem. Eng. 2022, 10, 7833–7851. [Google Scholar] [CrossRef]

- Zhou, H.; Wang, M.; Wang, F. Oxygen-Vacancy-Mediated Catalytic Methanation of Lignocellulose at Temperatures below 200 °C. Joule 2021, 5, 3031–3044. [Google Scholar] [CrossRef]

- Andreides, D.; Bautista Quispe, J.I.; Bartackova, J.; Pokorna, D.; Zabranska, J. A Novel Two-Stage Process for Biological Conversion of Syngas to Biomethane. Bioresour. Technol. 2021, 327, 124811. [Google Scholar] [CrossRef] [PubMed]

- Asimakopoulos, K.; Kaufmann-Elfang, M.; Lundholm-Høffner, C.; Rasmussen, N.B.K.; Grimalt-Alemany, A.; Gavala, H.N.; Skiadas, I.V. Scale up Study of a Thermophilic Trickle Bed Reactor Performing Syngas Biomethanation. Appl. Energy 2021, 290, 116771. [Google Scholar] [CrossRef]

- Okoro-Shekwaga, C.K.; Ross, A.B.; Camargo-Valero, M.A. Enhanced In-Situ Biomethanation of Food Waste by Sequential Inoculum Acclimation: Energy Efficiency and Carbon Savings Analysis. Waste Manag. 2021, 130, 12–22. [Google Scholar] [CrossRef] [PubMed]

- Thapa, A.; Park, J.-G.; Jun, H.-B. Enhanced Ex-Situ Biomethanation of Hydrogen and Carbon Dioxide in a Trickling Filter Bed Reactor. Biochem. Eng. J. 2022, 179, 108311. [Google Scholar] [CrossRef]

- Gantenbein, A.; Witte, J.; Biollaz, S.M.A.; Kröcher, O.; Schildhauer, T.J. Flexible Application of Biogas Upgrading Membranes for Hydrogen Recycle in Power-to-Methane Processes. Chem. Eng. Sci. 2021, 229, 116012. [Google Scholar] [CrossRef]

- Canu, P.; Pagin, M. Biogas Upgrading by 2-Steps Methanation of Its CO2–Thermodynamics Analysis. J. CO2 Util. 2022, 63, 102123. [Google Scholar] [CrossRef]

- Molino, A.; Braccio, G. Synthetic Natural Gas SNG Production from Biomass Gasification—Thermodynamics and Processing Aspects. Fuel 2015, 139, 425–429. [Google Scholar] [CrossRef]

- Ahlström, J.M.; Zetterholm, J.; Pettersson, K.; Harvey, S.; Wetterlund, E. Economic Potential for Substitution of Fossil Fuels with Liquefied Biomethane in Swedish Iron and Steel Industry—Synergy and Competition with Other Sectors. Energy Convers. Manag. 2020, 209, 112641. [Google Scholar] [CrossRef]

- Ren, J.; Liu, Y.-L.; Zhao, X.-Y.; Cao, J.-P. Methanation of Syngas from Biomass Gasification: An Overview. Int. J. Hydrogen Energy 2020, 45, 4223–4243. [Google Scholar] [CrossRef]

- Bartik, A.; Benedikt, F.; Lunzer, A.; Walcher, C.; Müller, S.; Hofbauer, H. Thermodynamic Investigation of SNG Production Based on Dual Fluidized Bed Gasification of Biogenic Residues. Biomass Convers. Biorefinery 2021, 11, 95–110. [Google Scholar] [CrossRef]

- Akbari, M.; Kumar, A. The Development of Data-Intensive Techno-Economic Models for the Comparison of Renewable Natural Gas Production from Six Different Biomass Feedstocks for the Decarbonization of Energy Demand Sectors. Fuel 2024, 358, 130107. [Google Scholar] [CrossRef]

- Wicaksono, F.D.; Arshad, Y.B.; Sihombing, H. Monte Carlo Net Present Value for Techno-Economic Analysis of Oil and Gas Production Sharing Contract. Int. J. Technol. 2019, 10, 291–319. [Google Scholar] [CrossRef]

- Aldersey-Williams, J.; Rubert, T. Levelised Cost of Energy—A Theoretical Justification and Critical Assessment. Energy Policy 2019, 124, 169–179. [Google Scholar] [CrossRef]

- Biomethane Industrial Partnership. Insights into the Current Cost of Biomethane: From Real Industry Data. 2023. Available online: https://bip-europe.eu/wp-content/uploads/2023/10/BIP_TF4-study_Full-slidedeck_Oct2023.pdf (accessed on 18 November 2024).

- Striugas, N.; Zakarauskas, K.; Paulauskas, R.; Lisauskas, A.; Jancauskas, A. Syngas Methanation over a Metal Hydride Catalyst: Technology, Efficiency and Economic Profitability. Energy Convers. Manag. 2023, 291, 117322. [Google Scholar] [CrossRef]

- Skorek-Osikowska, A.; Martin-Gamboa, M.; Iribarren, D.; Garcia-Gusano, D.; Dufour, J. Thermodynamic, Economic and Environmental Assessment of Energy Systems the Use of Gas from Manure Fermentation in the Context of the Spanish Potential. Energy 2020, 200, 117452. [Google Scholar] [CrossRef]

- Thunman, H.; Gustavsson, C.; Larsson, A.; Gunnarsson, I.; Tengberg, F. Economic Assessment of Advanced Biofuel Production via Gasification Cost Data from the GoBiGas Plant. Energy Sci. Eng. 2019, 7, 217–229. [Google Scholar] [CrossRef]

- Michailos, S.; Walker, M.; Moody, A.; Poggio, D.; Pourkashanian, M. Biomethane Production Using an Integrated Anaerobic Digestion, Gasification and CO2 Biomethanation Process in a Real Waste Treatment Plant: A Techno-Economic Assessment. Energy Convers. Manag. 2020, 209, 112663. [Google Scholar] [CrossRef]

- Carmo-Calado, L.; Mota-Panizio, R.; Assis, A.C.; Nobre, C.; Alves, O.; Lourinho, G.; Brito, P. Pre-Feasibility Study of a Multi-Product Biorefinery for the Production of Essential Oils and Biomethane. C 2022, 9, 2. [Google Scholar] [CrossRef]

- Chen, H.; Dahlquist, E.; Kyprianidis, K. Retrofitting Biomass Combined Heat and Power Plant for Biofuel Production—A Detailed Techno-Economic Analysis. Energies 2024, 17, 522. [Google Scholar] [CrossRef]

- Okolie, J.A.; Tabat, M.E.; Gunes, B.; Epelle, I.E.; Mukherjee, A.; Nanda, S.; Dalai, A.K. A Techno-Economic Assessment of Biomethane and Bioethanol production from Crude Glycerol through Integrated Hydrothermal Gasification, Syngas and Biomethanation. Energy Convers. Manag.-X 2021, 12, 100131. [Google Scholar] [CrossRef]

- Vo, T.T.; Wall, D.M.; Ring, D.; Rajendran, K.; Murphy, J.D. Techno-Economic Analysis of Biogas Upgrading via Amine Scrubber, Carbon and Ex-Situ Methanation. Appl. Energy 2018, 212, 1191–1202. [Google Scholar] [CrossRef]

- Lawson, N.; Alvarado-Morales, M.; Tsapekos, P.; Angelidaki, I. Techno-Economic Assessment of Biological Biogas Upgrading Based on Danish Biogas Plants. Energies 2021, 14, 8252. [Google Scholar] [CrossRef]

- Wang, S.; Wen, Y.; Shi, Z.; Zaini, I.N.; Jonsson, P.G.; Yang, W. Novel Carbon-Negative Methane Production via Integrating Anaerobic and Pyrolysis of Organic Fraction of Municipal Solid Waste. Energy Convers. Manag. 2022, 252, 115042. [Google Scholar] [CrossRef]

- Skorek-Osikowska, A.; Martín-Gamboa, M.; Dufour, J. Thermodynamic, Economic and Environmental Assessment of Renewable Natural Gas Production Systems. Energy Convers. Manag. X 2020, 7, 100046. [Google Scholar] [CrossRef]

- Salman, C.A.; Naqvi, M.; Thorin, E.; Yan, J. Impact of Retrofitting Existing Combined Heat and Power Plant with polygeneration of Biomethane: A Comparative Techno-Economic Analysis of integrating Different Gasifiers. Energy Convers. Manag. 2017, 152, 250–265. [Google Scholar] [CrossRef]

- Gantenbein, A.; Kröcher, O.; Biollaz, S.M.A.; Schildhauer, T.J. Techno-Economic Evaluation of Biological and Fluidised-Bed Based Methanation Process Chains for Grid-Ready Biomethane Production. Front. Energy Res. 2022, 9, 775259. [Google Scholar] [CrossRef]

- Bai, A.; Balogh, P.; Nagy, A.; Csedő, Z.; Sinóros-Szabó, B.; Pintér, G.; Prajapati, S.K.; Singh, A.; Gabnai, Z. Economic Evaluation of a 1 MWel Capacity Power-to-Biomethane System. Energies 2023, 16, 8009. [Google Scholar] [CrossRef]

- Ghafoori, M.S.; Loubar, K.; Marin-Gallego, M.; Tazerout, M. Techno-Economic and Sensitivity Analysis of Biomethane Production via landfill Biogas Upgrading and Power-to-Gas Technology. Energy 2022, 239, 122086. [Google Scholar] [CrossRef]

- Chirone, R.; Paulillo, A.; Coppola, A.; Scala, F. Carbon Capture and Utilization via Calcium Looping, Sorption Enhanced and Green Hydrogen: A Techno-Economic Analysis and Life Assessment Study. Fuel 2022, 328, 125255. [Google Scholar] [CrossRef]

- Sieborg, M.U.; Engelbrecht, N.; Ottosen, L.D.M.; Kofoed, M.V.W. Sunshine-to-Fuel: Demonstration of Coupled Photovoltaic-Driven Biomethanation Operation, Process, and Techno-Economical Evaluation. Energy Convers. Manag. 2024, 299, 117767. [Google Scholar] [CrossRef]

- Lorenzi, G.; Gorgoroni, M.; Silva, C.; Santarelli, M. Life Cycle Assessment of Biogas Upgrading Routes. Energy Procedia 2019, 158, 2012–2018. [Google Scholar] [CrossRef]

- Vinardell, S.; Fenske, C.F.; Heimann, A.; Cortina, J.L.; Valderrama, C.; Koch, K. Exploring the Potential of Biological Methanation for Future Scenarios: Techno-Economic and Environmental Evaluation. Energy Convers. Manag. 2024, 307, 118339. [Google Scholar] [CrossRef]

- Tasca, A.L.; di Capaci, R.B.; Tognotti, L.; Puccini, M. Biomethane from Short Rotation Forestry and Microalgal Open Ponds: System Modeling and Life Cycle Assessment. Bioresour. Technol. 2019, 273, 468–477. [Google Scholar] [CrossRef] [PubMed]

- Lopes Silva, D.A.; Nunes, A.O.; Piekarski, C.M.; da Silva Moris, V.A.; de Souza, L.S.M.; Rodrigues, T.O. Why Using Different Life Cycle Assessment Software Tools Can Generate Different Results for the Same Product System? A Cause–Effect Analysis of the Problem. Sustain. Prod. Consum. 2019, 20, 304–315. [Google Scholar] [CrossRef]

| Technology | Anaerobic Digestion + Methanation | Gasification + Methanation | Methanation | |||

|---|---|---|---|---|---|---|

| Feedstock | Manure | Pig manure (66.7%wt) and green waste (33.3%wt) | Biogas from a WWTP | Manure | Wood chips | CO2 from flue gases |

| Functional Unit (FU) | 1 MWh biomethane | 1 m3 biomethane | 1 kWh biomethane | 1 MWh biomethane | 1 MJ biomethane | 1 kg biomethane |

| Database | Ecoinvent v3 | Ecoinvent v3 | Ecoinvent | Ecoinvent v3 | n.d. | Ecoinvent v3.5 |

| Software | SimaPro | SimaPro | OpenLCA v1.10.2 | SimaPro | SimaPro 8.3 | n.d. |

| Method | CML | ReCiPe Midpoint (H) | ReCiPe 2016 Midpoint (H) | CML | ReCiPe Midpoint (H) v1.13 | EF 2.0 |

| Scope | Cradle-to-gate | |||||

| Ref. | [67] | [83] | [84] | [67] | [85] | [81] |

| Impacts normalized to 1 MWh of biomethane | ||||||

| GWP (kgCO2, e) | 98.4 a | 484.0 | 3.3 c | 47.1 b | 446.4 | 17.0 |

| AP (SO2, e) | 0.0718 a | 2.10 | 0.13 c | 0.15 b | 2.52 | 0.0086 |

| FE (kg Pe) | 0.2210 a | 0.1140 | 0.0210 c | 0.0281 b | 0.0468 | 5.66 × 10−5 |

| ME (kg Ne) | - | - | - | - | 0.11 | 157.86 |

| SOD (kg CFC-11e) | - | 1.35 × 10−4 | 1.40 × 10−5 c | - | 3.17 × 10−5 | 2.44 × 10−7 |

| IR (kg U-235e) | - | - | - | - | 36 | 1.23 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tiago, G.A.O.; Rodrigo, N.P.B.; Lourinho, G.; Lopes, T.F.; Gírio, F. Systematic and Bibliometric Review of Biomethane Production from Biomass-Based Residues: Technologies, Economics and Environmental Impact. Fuels 2025, 6, 8. https://doi.org/10.3390/fuels6010008

Tiago GAO, Rodrigo NPB, Lourinho G, Lopes TF, Gírio F. Systematic and Bibliometric Review of Biomethane Production from Biomass-Based Residues: Technologies, Economics and Environmental Impact. Fuels. 2025; 6(1):8. https://doi.org/10.3390/fuels6010008

Chicago/Turabian StyleTiago, Gonçalo A. O., Naresh P. B. Rodrigo, Gonçalo Lourinho, Tiago F. Lopes, and Francisco Gírio. 2025. "Systematic and Bibliometric Review of Biomethane Production from Biomass-Based Residues: Technologies, Economics and Environmental Impact" Fuels 6, no. 1: 8. https://doi.org/10.3390/fuels6010008

APA StyleTiago, G. A. O., Rodrigo, N. P. B., Lourinho, G., Lopes, T. F., & Gírio, F. (2025). Systematic and Bibliometric Review of Biomethane Production from Biomass-Based Residues: Technologies, Economics and Environmental Impact. Fuels, 6(1), 8. https://doi.org/10.3390/fuels6010008