Toward Sustainable Development: Exploring the Value and Benefits of Digital Twins

Abstract

1. Introduction

2. Background

- The hierarchical level at which the Digital Twin is deployed includes six levels (Informational, Component, Product, Process, System, and Multi-system).

- The life-cycle phase in which the Digital Twin is deployed involves six phases (Design, Build, Operate, Maintain, Optimize, and Decommission).

- The use of the Digital Twin refers to seven uses (Digitize, Visualize, Simulate, Emulate, Extract, Orchestrate, and Predict).

- The physical layer, which encompasses the physical entities of the system, environment, and processes;

- The virtual layer, which involves virtual models of the physical entities at different levels of abstraction;

- The interconnection layer, which serves as the bidirectional data proxy between the physical and virtual layers.

3. Methodology

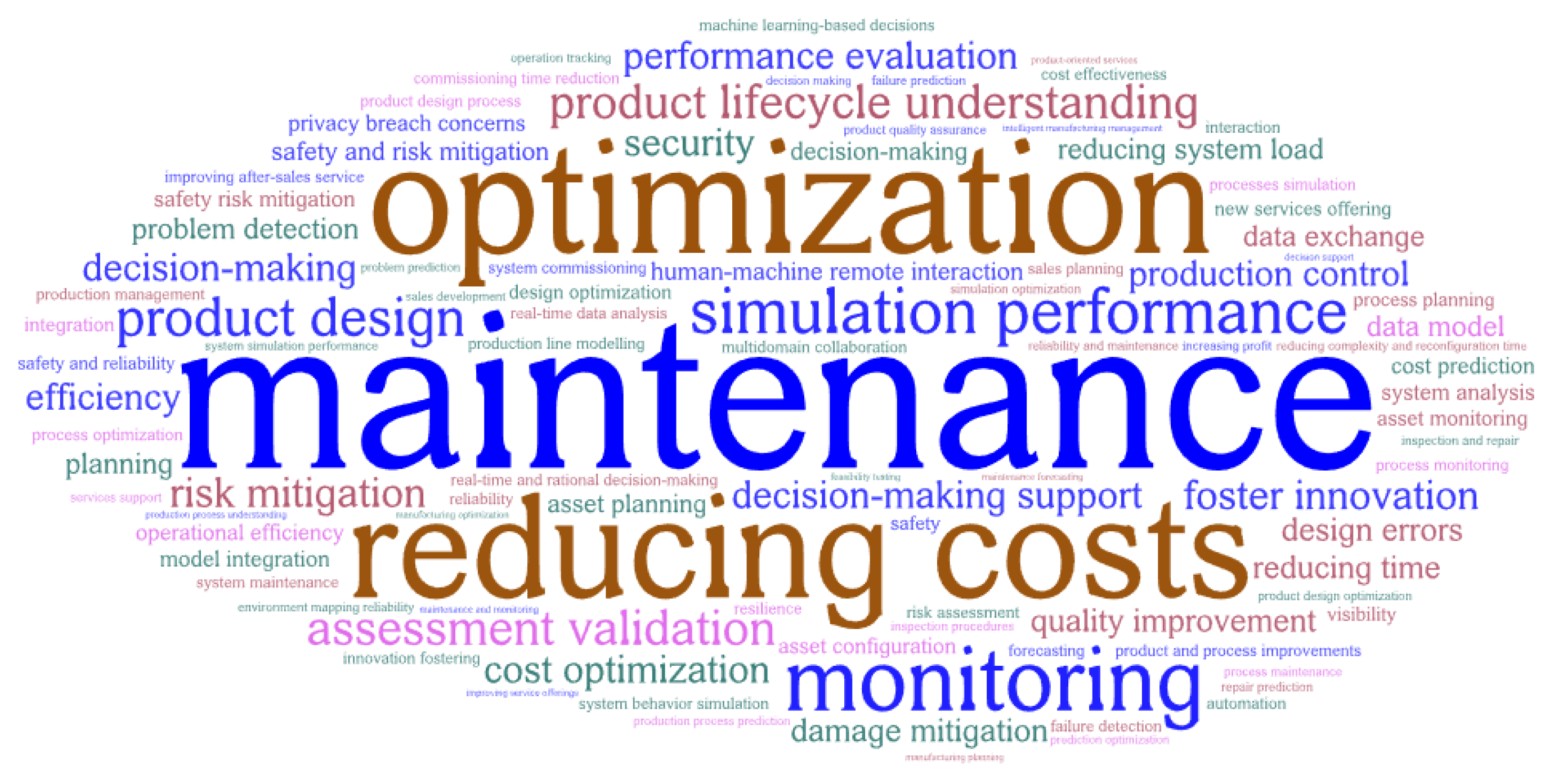

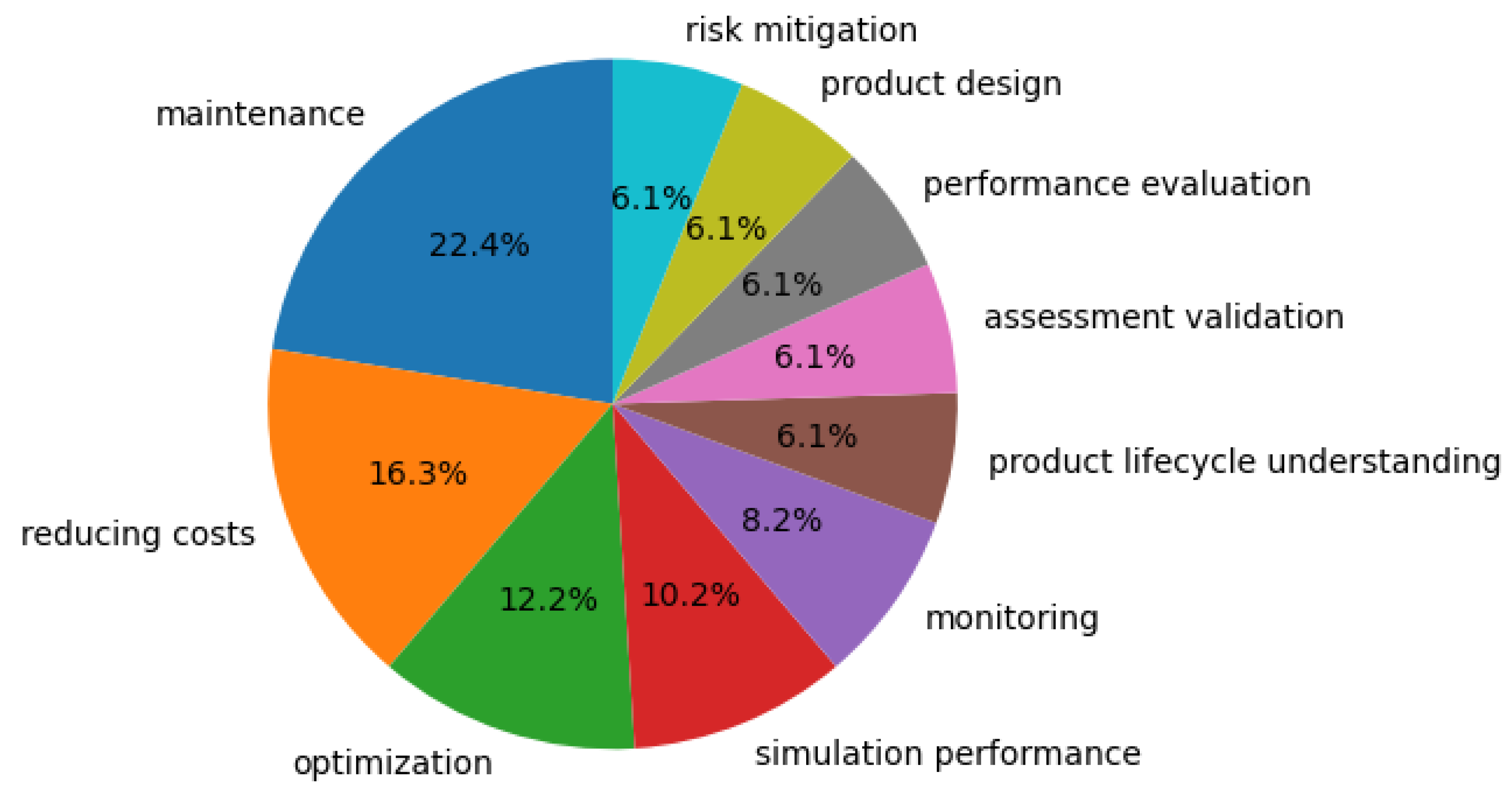

4. Benefits of Digital Twin Deployments

- Maintenance (22.4%)—related to both operational and predictive analysis, enabling stakeholders to better understand the physical systems and actual processes;

- Cost reduction (16.3%)—refers to the better understanding of the product life-cycle loop, thus recognizing the points of materials and work overhead;

- Optimization (12.2%)—due to the discovery of the best solutions, incorporating the cost-effective resources while maximizing business value;

- Simulation performance (10.2%)—having the capability of handling multiple simultaneous and heterogeneous simulations and aims to model the processes’ evolution by testing different settings of their key behaviors, characteristics, or relationships;

- Monitoring (8.2%)—refers to the regular surveillance over digitized assets, processes, and services over a period of time;

- Product life-cycle understanding (6.1%)—refers to the handling of a good as it moves through the various stages of its lifespan, bringing tangible effects of reducing system load, configuring and planning assets, and checking product feasibility;

- Assessment validation (6.1%)—concerns the quality review of the assessment process, including checking that the assessment tool produces consistent results;

- Performance evaluation (6.1%)—through analyzing, developing, and categorizing a set of alternative scenarios and models before their implementation within the physical system;

- Product design (6.1%)—enabling designers to develop and test more product variations with fewer resources engaged;

- Safety and risk mitigation (6.1%)—relates to the detection, assessment, understanding, and prevention of adverse events, side effects, or any other health-related issues.

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Correction Statement

Abbreviations

| AI | Artificial Intelligence |

| DT | Digital Twin |

| IoT | Internet-of-Things |

| ML | Machine Learning |

| XR | Extended Reality |

Appendix A. An Input for Manual Coding along with the Codes Assigned

| Statements | Assigned Codes |

|---|---|

| “The Digital Twin can move from an interesting and potentially useful concept that aids in understanding the relationship between a physical product and its underlying information to a critical component of an enterprise-wide closed loop product lifecycle. These tasks will both reduce costs and foster innovation in the manufacture of quality products” [71]. | enhance analysis; reducing costs; foster innovation; product life-cycle understanding; quality improvement |

| “In order to gain a better understanding of the impact of external factors on the validity of products throughout their lifecycle, we are proposing to expand the digital thread through a digital framework capable of delivering a rapid impact assessment of product validation. The proposed digital framework can help reduce costs by capitalizing on the knowledge inherent to the product families while recognizing and reusing common association patterns” [113]. | reducing costs; assessment validation; product life-cycle understanding |

| “(…) digital twins are often the best solutions that support remote interaction of humans with physical machines and overcome the challenge of geographical distance” [114]. | human–machine remote interaction |

| “(…) the cloud-based digital twins successfully reduce the system’s overhead and provide an effective CPCM application” [114]. | reducing costs; reducing system load |

| DT “is used to detect privacy concerns and minimize breaches and associated risks to which smart car drivers can be exposed trough connected infotainment applications and services” [115]. | problem detection; privacy breach concerns; safety risk mitigation |

| “The real-time insight into operational driving states provided by the Digital Twin, enables operational efficiency and automated feedback to drivers. (…) The overall outcome should be quicker and more informed decisions on possible privacy vulnerabilities related to operational driving lifecycle” [115]. | real-time and rational decision-making; operational efficiency |

| “(…) Digital Twin is designed with the aim to improve real-world products and processes based on simulated data and ML supported decisions” [115]. | product and process improvements; machine learning-based decisions |

| Digital Twin “can be used to reduce the complexity and time of reconfiguration by early detection of design or process sequence errors of the system with a cross-domain simulation” [73]. | reducing complexity and reconfiguration time; design errors |

| “The Digital Twin is enriched with the developed multi-domain models, which are integrated and semantically referenced together. References between models are achieved by using software tools that allow model integration and data exchange across different domains. This enables a cross-domain simulation of different aspects and the system behavior” [73]. | data exchange; model integration; system behavior simulation |

| “A cross-domain simulation during engineering supports a rising tendency for parallelizing the engineering process, therefore reducing engineering time and supporting multidomain collaboration” [73]. | reducing time; multidomain collaboration |

| “Using this virtual model, sometimes called the “digital twin,” producers can improve their after-sales service, offer a range of new services, and generate insights that can be used to optimize the design of future cars” [116]. | improving after-sales service; new services offering; design optimization |

| “(…) emulation software has become a key tool to create Digital Twins and carry out virtual commissioning of new manufacturing systems, reducing the commissioning time and increasing its final quality” [117]. | efficiency; quality improvement; commissioning time reduction |

| “We envision cognitive digital twins will impact all the stages of the manufacturing systems”, and (…) “we have particularly highlighted the impact of the cognitive digital twin in the product design stage” [117]. | product design process |

| “(…) the asset-related decision-making process can be supported by Digital Twin modeling”, in particular: “Asset configuration—The DT is used for modelling and simulating a production line, to evaluate its systemic Reliability, Availability, Maintainability performance (RAM performance), to finally predict its Total Cost of Ownership (TCO). It allows to assess the choice of the best design solution for the production line” [118]. | maintenance; decision-making; cost optimization; asset configuration; production line modeling; performance evaluation |

| “Asset reconfiguration, (…) the DT is used for modelling and simulating a complex process production plant, to evaluate its systemic RAM performance, to finally predict its TCO. It allows to assess the choice of the best reconfiguration alternative to increase the availability of the plant” [118]. | processes simulation; performance evaluation; decision-making; cost prediction |

| “Asset reconfiguration and planning—The DT is used as semantic data model within a web service-based control system for manufacturing systems. It forms the ground for an open, knowledge-driven Manufacturing Execution System architecture, which allows quick reconfigurations of the system” [118]. | asset planning; production control; production management; system maintenance |

| “Asset commissioning—The DT is used as semantic data model, data analytics and advanced simulation, to make the virtual commissioning of the manufacturing system. Simulation of the system is based on a semantic data model and of a software structure that is able to analyse data in runtime. It allows a quick time to commission the system” [118]. | data model; system analysis; real-time data analysis; system simulation performance; system commissioning |

| “Asset condition monitoring and health assessment—The DT is used for the asset diagnosis, helping to assess its health status based on the monitored condition. The DT provides the data analytics in order to extract the features required for the diagnosis. It allows to limit unreliability situations” [118]. | reliability and maintenance; asset monitoring |

| The primary benefit of using a digital twin, as opposed to a testbed, is that it reliably represents the real industrial environment. In other words, the results of a pen-test conducted on the digital twin genuinely reflect the expected results of conducting the same test in the real environment. [72]. | security; environment mapping reliability |

| “To secure good geometrical quality in the final product, tolerances, locator positions, clamping strategies, welding sequence etc. are optimized during design and pre-production. Faster optimization algorithms, increased computer power and amount of available data, can leverage the area of simulation toward real-time control and optimization of products and production systems—a concept often referred to as a Digital Twin” [119]. | product quality assurance; safety and reliability; product design optimization |

| “The Digital Twin can use data from individuals to perform real-time in-line individual adjustments or data from batches of parts to make adjustment batch wise” [119]. | production control |

| “(…) the digital twin driven smart manufacturing will be made more responsive and predictive and will be beneficial to more reasonable and precise manufacturing management in many aspects. Together they complement each other nicely to help the development of smart manufacturing” [120]. | intelligent manufacturing management |

| “The digital twin is tweeted to be stored, refined and propagated to the process planning for an optimized machining solution” [121]. | process planning; process optimization |

| “A digital twin collects data and monitors the process, has access to past data, and, overall, allows for a better understanding of the production process and better prediction of the behavior and results” [121]. | production process understanding; process monitoring; maintenance; production process prediction |

| The digital twin model allows a shared conceptualization that can be visualized in exactly the same way by an unlimited amount of individuals and by individuals who do not need to share the same location [71]. | innovation fostering |

| “A key ingredient of the DT model is to simulate the inspection and repair of cracked structures in order to plan and implement cost effective inspection and repair procedures. A typical scenario is to determine the time and type of inspections to conduct that minimize cost (…)” [90]. | planning; maintenance; reducing costs; inspection procedures; cost effectiveness |

| “A present-day version of the risk assessment computations for fatigue critical locations was presented that contained the essential components of a probabilistic descriptions of loads, geometry, material properties, probabilistic methods, efficient fracture mechanics, and inspection and repair procedures” [90]. | risk assessment; inspection and repair |

| “The utilisation of in-service data: The implementation of the Digital Twins involves the collection and utilisation of in-service data, such as the pressure of the valves, the amount of fuel consumed by the engines. (…) While some companies use the data for monitoring only, others use it for simulation, prediction and operation optimization” [122]. | monitoring; simulation optimization; process maintenance; prediction optimization |

| “The integration of planning tools: It is possible to connect the data collected and stored in the Digital Twins with planning tools. Before production, it allows the optimization of the manufacturing strategy. During the manufacturing phase, the data stored in the Digital Twin helps to keep track of the operations and optimize planning” [122]. | manufacturing planning; operation tracking; manufacturing optimization |

| “During the utilization phase, some failures or breakdowns can be predicted through the analysis of the data stored in the Digital Twin and affect task scheduling both for the operator and the manufacturer that might have to do some repair” [122]. | repair prediction; maintenance forecasting |

| “The integration of simulation tools: To push the analytics further, it is possible to integrate simulation tools into the Digital Twins. (…) The comparison between in-service data and theoretical data obtained through modelling and simulation allows the assessment of the performance of the physical asset, the detection of failures, the prediction of potential problems and the determination of the next best actions” [122]. | performance evaluation; failure detection; problem prediction |

| “The integration of the product lifecycle steps: A very important characteristic is the level of integration of the different lifecycle steps of the product into the Digital Twin” [122]. | product design; product life-cycle understanding |

| “The creation of simple services: Using Tukker’s service classification, the “simple services” refer to “product-oriented services” (…). These services consist essentially in advice and consultancy using the data stored in the Digital Twin. It can also be some basic real time monitoring features such as asset localization, fuel consumption, etc.” [122]. | maintenance and monitoring; product-oriented services |

| “The creation of advanced services. (…) By using the in-service data of the assets, these services aim at optimizing the operations and predicting failures” [122]. | optimization; failure prediction |

| “The creation of services, enabled by the Digital Twins, allows the manufacturers to develop new selling paradigms. They can build subscription systems for the services, pay per use systems for the product and also base their revenues on the result obtained with the services they provide” [122]. | sales planning; sales development |

| “In particular, the digital twin lends itself to contribute to the value propositions by supporting all of the actors around the product service system, in particular by relieving the pains and increasing the gains of the actors” [123]. | improving service offerings; increasing profit |

| The DT “can be considered a data-driven enabler and support for providing services” [123]. | services support |

| “(…) embedded digital twins are involved in all activities that imply their physical twins—e.g., service set up and optimized configuring, delivery monitoring and update. The main benefits brought by the digital twin concept are: (a) visibility: DTs allow visibility in the operations of resources; (b) prediction: using various modelling techniques (DES—based), the DT model can be used to predict the future state of a service process or resource; (c) interaction with the DES model: simulate conditions that are impractical to create in real life through “what if” analysis; (d) documenting: mechanisms to understand and explain behaviours of individual or interconnected resources; (e) integration: the DT model can be used to connect with backend business applications to co-create value” [124]. | optimization; monitoring; maintenance; visibility; integration; interaction |

| “The Digital Twin is ultra-realistic and may consider one or more important and interdependent vehicle systems, including airframe, propulsion and energy storage, life support, avionics, thermal protection, etc.” [125]. | reliability |

| “(…) the Digital Twin continuously forecasts the health of the vehicle or system, the remaining useful life and the probability of mission success. The Digital Twin can also predict system response to safety critical events and uncover previously unknown issues before they become critical by comparing predicted and actual responses. Finally, the systems on board the Digital Twin are capable of mitigating damage or degradation by activating self-healing mechanisms or by recommending changes in mission profile to decrease loadings thereby increasing both the life span and the probability of mission success” [125]. | forecasting; safety; risk mitigation; damage mitigation |

| (…) a digital twin that fuses the information gained from probabilistic damage diagnosis and prognosis. The digital twin thus supports intelligent decision making (mission planning) using up-to-date information, and quantified uncertainty” [126]. | decision making; resilience |

| “The U. S. Air Force has been investigating the extension of IAT to realize the digital twin concept (…) to fuse multiple heterogeneous sources of information from models and data to support proactive fleet sustainment decisions” [127]. | decision support |

| “The U.S. Air Force is currently investigating this methodology within the Airframe Digital Twin program for demonstration with Air Force legacy aircraft, using full scale experimental tests. The demonstrated P2IAT methodology is expected to be used for both legacy and new aircraft to reduce maintenance cost” [127]. | feasibility testing; reducing costs |

| “With the rapid technological developments of the last several years, it is now possible to simulate complex industrial systems and develop and run digital twins in real-time settings. Digital twins offer an ability to complete off-line ”what-if” analysis in a close-to-reality virtual environment before implementing tested actions in actual operations” [128]. | decision-making; simulation performance |

| “(…) considerable benefits of creating digital twin of a building are as follows: (1) gathering, generating and visualizing the environment of the building, (2) analyzing data irregularities, and (3) optimizing building services” [129]. | simulation performance; optimization; risk mitigation |

| “The digitization of production systems offers the possibility of automated data acquisition”. (…) “Benefits of the proposed new approach for the analysis and modification of production systems can be experienced by participants in practical training sessions, especially continuous data acquisition, automated derivation of optimization measures and capturing of motion data” [130]. | monitoring; optimization |

| “The benefits of DT technology include cost cutting, reduced time-to-market, and predictive maintenance”. (…) “Digital tools and DT technology can increase study motivation, students’ own responsibility for learning, as well as improve learning” [131]. | reducing costs; maintenance; cost optimization |

| “The digital twin is an emerging technology used in intelligent manufacturing that can grasp the state of intelligent manufacturing systems in real-time and predict system failures” (…). “Manufacturing systems can monitor physical processes, create a digital twin in the physical world [132], receive real-time information from the physical world for simulation analysis, and make informed decisions through real-time communication and collaboration with humans” (…). “Using the built-in flexible digital twin helps designers quickly evaluate different designs and find design flaws” [133]. | monitoring; risk mitigation; damage mitigation; simulation performance; assessment validation |

| “The digital twin extends the use of virtual simulation models developed in the design phase of a production system to operations for real-time control, dynamic skill-based tasks allocation between human and robot, sequencing of tasks and developing robot program accordingly.” (…) “Results show that the approach supports the notion of automation while maintaining assembly flexibility” [134]. | maintenance; optimization; automation |

| “The approach proposed prevent complex reverse-engineering processes in setting up a usable digital environment which grow in importance to support and evaluate the impact of increasing engineering and decision-making processes. Stakeholders are being informed about the current machine configuration, status or behaviour or get general information on what machines are present and connected at the moment” [135]. | maintenance; decision-making support; assessment validation |

| “By establishing cyberphysical connection via decentralized digital twin models, various manufacturing resources can be formed as dynamic autonomous system to co-create personalized products” (…). “It addresses a bi-level online intelligence in proactive decision making for the organization and operation of manufacturing resources”. (…) “Digital twin defines the use of performance metrics to support a manufacturing operation and provides a systems engineering-based approach that enables continuous improvement and strategic adaptability to change. The complexities of mass individualization in the dynamic production flows management are reduced, and the flexibility of WIP for individualized manufacturing demands is improved. Evidenced by a successful case study in board-type product manufacturing system, the proposed prototype can provide manufacturing system with an intelligent optimization engine” [136]. | optimization; product design; decision-making support; maintenance |

| “The dynamic fusion process of digital twin data not only reflects the running conditions of physical elements and virtual models, but also keeps driving and affecting the iterative running processes of both physical production and virtual simulation respectively as well as the co-evolution between these two parts” [137]. | maintenance; simulation performance; product design |

| “Based on the digital twin model, probabilistic roadmap method (PRM) is performed to generate a collision-free path and control the robot to accomplish the assembly mission”. (…) “The experiment results show that the proposed method can quickly plan a collision-free assembly path, and then control the industrial robot to automatically, safely and efficiently complete large-scale components installation” [138]. | simulation performance; safety and risk mitigation; reducing costs |

| “The production plan under the digital twin model is a dynamic model with stronger disturbance resistance. It not only makes the processes (i.e., coking, sintering, iron making, steel making, and steel rolling) and other processes more coordinated and orderly, but also makes energy, power, logistics, equipment maintenance and all kinds of raw materials more balanced. Through capacity requirement planning model and material requirement planning model, the requirements of equipment and material are determined, and the production is arranged according to the scheduling model, and the coordination of man, machines and materials is ensured in time” [139]. | maintenance; reducing costs; decision-making support |

| “This digital twin will have high impact in terms of developing HRI techniques for example facilitating human-robot trust in high stakes scenarios such as emergency response. It will also allow testing of task planning algorithms for cooperative inspection and long-term autonomy, and humanguided supervision and control of the robotic assets from remotely located control stations” [140]. | maintenance; safety and risk mitigation |

References

- Spijkers, O. Intergenerational equity and the sustainable development goals. Sustainability 2018, 10, 3836. [Google Scholar] [CrossRef]

- Sadhukhan, J.; Dugmore, T.I.; Matharu, A.; Martinez-Hernandez, E.; Aburto, J.; Rahman, P.K.; Lynch, J. Perspectives on “game changer” global challenges for sustainable 21st century: Plant-based diet, unavoidable food waste biorefining, and circular economy. Sustainability 2020, 12, 1976. [Google Scholar] [CrossRef]

- Ali, S.M.; Appolloni, A.; Cavallaro, F.; D’Adamo, I.; Di Vaio, A.; Ferella, F.; Gastaldi, M.; Ikram, M.; Kumar, N.M.; Martin, M.A.; et al. Development Goals towards Sustainability. Sustainability 2023, 15, 9443. [Google Scholar] [CrossRef]

- Olawumi, T.O.; Chan, D.W. A scientometric review of global research on sustainability and sustainable development. J. Clean. Prod. 2018, 183, 231–250. [Google Scholar] [CrossRef]

- Elavarasan, R.M.; Shafiullah, G.; Padmanaban, S.; Kumar, N.M.; Annam, A.; Vetrichelvan, A.M.; Mihet-Popa, L.; Holm-Nielsen, J.B. A comprehensive review on renewable energy development, challenges, and policies of leading Indian states with an international perspective. IEEE Access 2020, 8, 74432–74457. [Google Scholar] [CrossRef]

- Pescari, S.; Merea, M.; Pitroacă, A.; Vilceanu, C.B. A Particular Case of Urban Sustainability: Comparison Study of the Efficiency of Multiple Thermal Insulations for Buildings. Sustainability 2022, 14, 16283. [Google Scholar] [CrossRef]

- Lubberink, R.; Blok, V.; Van Ophem, J.; Omta, O. Lessons for responsible innovation in the business context: A systematic literature review of responsible, social and sustainable innovation practices. Sustainability 2017, 9, 721. [Google Scholar] [CrossRef]

- Anacka, H.; Bojanowski, J.; Czyż, P.; Duda, E.; Cecilie, H.; Joudavi, A.; Karaczun, Z.; Konieczny, L.; Kowal, J.; Niemczyk, I.; et al. The Greencoin Project. A Guideline for the Implementation Strategy; Maria Grzegorzewska University Press: Warsaw, Poland, 2024. [Google Scholar]

- Purdy, M.; Eitel-Porter, R.; Krüger, R.; Deblaere, T. How Digital Twins Are Reinventing Innovation. 2020. Available online: https://sloanreview.mit.edu/article/how-digital-twins-are-reinventing-innovation/ (accessed on 21 May 2023).

- Fortune Business Insights. Market Research Report. Digital Twin Market Size. 2021. Available online: https://www.marketsandmarkets.com/Market-Reports/digital-twin-market-225269522.html (accessed on 25 February 2023).

- Alphabet. Google Maps Help. 2023. Available online: https://support.google.com/maps/?hl=en#topic=3092425 (accessed on 21 May 2023).

- Amazon. AWS IoT TwinMaker. 2023. Available online: https://aws.amazon.com/iot-twinmaker/ (accessed on 26 March 2023).

- Microsoft Azure. What Is Azure Digital Twins? 2023. Available online: https://learn.microsoft.com/en-us/azure/digital-twins/overview (accessed on 26 March 2023).

- Hou, L.; Wu, S.; Zhang, G.; Tan, Y.; Wang, X. Literature review of digital twins applications in construction workforce safety. Appl. Sci. 2020, 11, 339. [Google Scholar] [CrossRef]

- Cellina, M.; Cè, M.; Alì, M.; Irmici, G.; Ibba, S.; Caloro, E.; Fazzini, D.; Oliva, G.; Papa, S. Digital Twins: The New Frontier for Personalized Medicine? Appl. Sci. 2023, 13, 7940. [Google Scholar] [CrossRef]

- Ramasubramanian, A.K.; Mathew, R.; Kelly, M.; Hargaden, V.; Papakostas, N. Digital twin for human–robot collaboration in manufacturing: Review and outlook. Appl. Sci. 2022, 12, 4811. [Google Scholar] [CrossRef]

- Lee, D.; Lee, S. Digital twin for supply chain coordination in modular construction. Appl. Sci. 2021, 11, 5909. [Google Scholar] [CrossRef]

- Henrichs, E.; Noack, T.; Pinzon Piedrahita, A.M.; Salem, M.A.; Stolz, J.; Krupitzer, C. Can a byte improve our bite? An analysis of digital twins in the food industry. Sensors 2021, 22, 115. [Google Scholar] [CrossRef] [PubMed]

- Allen, D. Digital Twins and Living Models at NASA. 2021. Available online: https://ntrs.nasa.gov/api/citations/20210023699/downloads/ASME%20Digital%20Twin%20Summit%20Keynote_final.pdf (accessed on 25 February 2023).

- Al Faruque, M.A.; Muthirayan, D.; Yu, S.Y.; Khargonekar, P.P. Cognitive digital twin for manufacturing systems. In Proceedings of the 2021 Design, Automation & Test in Europe Conference & Exhibition (DATE), Grenoble, France, 1–5 February 2021; pp. 440–445. [Google Scholar]

- VanDerHorn, E.; Mahadevan, S. Digital Twin: Generalization, characterization and implementation. Decis. Support Syst. 2021, 145, 113524. [Google Scholar] [CrossRef]

- Lueth, K.L. How the World’s 250 Digital Twins Compare? Same, Same but Different. 2020. Available online: https://iot-analytics.com/how-the-worlds-250-digital-twins-compare/ (accessed on 22 July 2024).

- Abisset-Chavanne, E.; Coupaye, T.; Golra, F.R.; Lamy, D.; Piel, A.; Scart, O.; Vicat-Blanc, P. A Digital Twin use cases classification and definition framework based on Industrial feedback. Comput. Ind. 2024, 161, 104113. [Google Scholar] [CrossRef]

- Steindl, G.; Stagl, M.; Kasper, L.; Kastner, W.; Hofmann, R. Generic digital twin architecture for industrial energy systems. Appl. Sci. 2020, 10, 8903. [Google Scholar] [CrossRef]

- Huang, Z.; Shen, Y.; Li, J.; Fey, M.; Brecher, C. A survey on AI-driven digital twins in industry 4.0: Smart manufacturing and advanced robotics. Sensors 2021, 21, 6340. [Google Scholar] [CrossRef]

- Botín-Sanabria, D.M.; Mihaita, A.S.; Peimbert-García, R.E.; Ramírez-Moreno, M.A.; Ramírez-Mendoza, R.A.; Lozoya-Santos, J.d.J. Digital twin technology challenges and applications: A comprehensive review. Remote Sens. 2022, 14, 1335. [Google Scholar] [CrossRef]

- Owoc, M.L.; Sawicka, A.; Weichbroth, P. Artificial intelligence technologies in education: Benefits, challenges and strategies of implementation. In Proceedings of the Artificial Intelligence for Knowledge Management: 7th IFIP WG 12.6 International Workshop, AI4KM 2019, Held at IJCAI 2019, Macao, China, 11 August 2019; Revised Selected Papers. Springer: Cham, Switzerland, 2021; pp. 37–58. [Google Scholar]

- Lv, Z.; Xie, S. Artificial intelligence in the digital twins: State of the art, challenges, and future research topics. Digit. Twin 2022, 1, 12. [Google Scholar] [CrossRef]

- Bartsch, K.; Pettke, A.; Hübert, A.; Lakämper, J.; Lange, F. On the digital twin application and the role of artificial intelligence in additive manufacturing: A systematic review. J. Phys. Mater. 2021, 4, 032005. [Google Scholar] [CrossRef]

- Park, H.A.; Byeon, G.; Son, W.; Jo, H.C.; Kim, J.; Kim, S. Digital twin for operation of microgrid: Optimal scheduling in virtual space of digital twin. Energies 2020, 13, 5504. [Google Scholar] [CrossRef]

- Piltan, F.; Kim, J.M. Bearing anomaly recognition using an intelligent digital twin integrated with machine learning. Appl. Sci. 2021, 11, 4602. [Google Scholar] [CrossRef]

- Fahim, M.; Sharma, V.; Cao, T.V.; Canberk, B.; Duong, T.Q. Machine learning-based digital twin for predictive modeling in wind turbines. IEEE Access 2022, 10, 14184–14194. [Google Scholar] [CrossRef]

- Csányi, G.M.; Vági, R.; Nagy, D.; Üveges, I.; Vadász, J.P.; Megyeri, A.; Orosz, T. Building a Production-Ready Multi-Label Classifier for Legal Documents with Digital-Twin-Distiller. Appl. Sci. 2022, 12, 1470. [Google Scholar] [CrossRef]

- Olszak, C.M.; Mach-Król, M. A conceptual framework for assessing an organization’s readiness to adopt big data. Sustainability 2018, 10, 3734. [Google Scholar] [CrossRef]

- Olszak, C.M.; Zurada, J. Big data in capturing business value. Inf. Syst. Manag. 2020, 37, 240–254. [Google Scholar] [CrossRef]

- Oracle. What Is Big Data? 2023. Available online: https://www.oracle.com/big-data/what-is-big-data/ (accessed on 14 March 2023).

- Perry, J.S. What Is Big Data? More Than Volume, Velocity and Variety. 2017. Available online: https://developer.ibm.com/blogs/what-is-big-data-more-than-volume-velocity-and-variety/ (accessed on 16 March 2023).

- Olszak, C.M.; Zurada, J.; Cetindamar, D. Business intelligence & big data for innovative and sustainable development of organizations. Inf. Syst. Manag. 2021, 38, 268–269. [Google Scholar]

- Kantardzic, M.; Zurada, J. Next Generation of Data-Mining Applications; Wiley-IEEE Press: Hoboken, NJ, USA, 2005. [Google Scholar]

- Kiran, R. Top Big Data Technologies That You Need to Know. 2023. Available online: https://www.edureka.co/blog/top-big-data-technologies/ (accessed on 19 March 2023).

- Kaur, R. The Best Big Data Solutions of 2024. 2023. Available online: https://www.selecthub.com/big-data-analytics/big-data-solutions/ (accessed on 19 March 2023).

- Apache Software Foundation. Apache Hadoop. 2023. Available online: https://hadoop.apache.org/ (accessed on 19 March 2023).

- Apache Software Foundation. Unified Engine for Large-Scale Data Analytics. 2023. Available online: https://spark.apache.org (accessed on 19 March 2023).

- Cloudera. Hortonworks Data Platform. 2023. Available online: https://www.cloudera.com/products/hdp.html (accessed on 19 March 2023).

- Whig, P.; Velu, A.; Nadikattu, R.R. Blockchain Platform to Resolve Security Issues in IoT and Smart Networks. In AI-Enabled Agile Internet of Things for Sustainable FinTech Ecosystems; IGI Global: Hershey, PA, USA, 2022; pp. 46–65. [Google Scholar]

- Wang, J.; Ye, L.; Gao, R.X.; Li, C.; Zhang, L. Digital Twin for rotating machinery fault diagnosis in smart manufacturing. Int. J. Prod. Res. 2019, 57, 3920–3934. [Google Scholar] [CrossRef]

- Jacoby, M.; Usländer, T. Digital twin and internet of things—Current standards landscape. Appl. Sci. 2020, 10, 6519. [Google Scholar] [CrossRef]

- Al-Ali, A.R.; Gupta, R.; Zaman Batool, T.; Landolsi, T.; Aloul, F.; Al Nabulsi, A. Digital twin conceptual model within the context of internet of things. Future Internet 2020, 12, 163. [Google Scholar] [CrossRef]

- Shah, S.F.A.; Iqbal, M.; Aziz, Z.; Rana, T.A.; Khalid, A.; Cheah, Y.N.; Arif, M. The role of machine learning and the internet of things in smart buildings for energy efficiency. Appl. Sci. 2022, 12, 7882. [Google Scholar] [CrossRef]

- Hernes, M. Towards smart enterprises: Supporting the business processes using artificial intelligence. In Proceedings of the Polskie Porozumienie na Rzecz Rozwoju Sztucznej Inteligencji (PP-RAI 2019), Wrocław, Poland, 16–18 October 2019. [Google Scholar]

- Mahir, S.M.; Koch, G.; Herne, J.; Lee, J.J. Data Acquisition Platform for The Energy Management of Smart Factories and Buildings. In Proceedings of the 2023 17th International Conference on Ubiquitous Information Management and Communication (IMCOM), Seoul, Republic of Korea, 3–5 January 2023; pp. 1–7. [Google Scholar]

- Wang, J.; Li, D. Adaptive computing optimization in software-defined network-based industrial internet of things with fog computing. Sensors 2018, 18, 2509. [Google Scholar] [CrossRef] [PubMed]

- Andres, F.; Guitton, A.; Cardoso, J.L., Jr.; Barbin, S.E. Bridging the semantic gap in agriculture early warning. In Proceedings of the 7th International Conference on Management of Computational and Collective Intelligence in Digital EcoSystems, Caraguatatuba, Brazil, 25–29 October 2015; pp. 258–262. [Google Scholar]

- Leszczyna, R. Cybersecurity in the electricity sector. In Managing Critical Infrastructure; Springer: Gdansk, Poland, 2019. [Google Scholar]

- Gardašević, G.; Katzis, K.; Bajić, D.; Berbakov, L. Emerging wireless sensor networks and Internet of Things technologies—Foundations of smart healthcare. Sensors 2020, 20, 3619. [Google Scholar] [CrossRef] [PubMed]

- Lytras, M.D.; Chui, K.T.; Liu, R.W. Moving towards intelligent transportation via Artificial Intelligence and Internet-of-Things. Sensors 2020, 20, 6945. [Google Scholar] [CrossRef] [PubMed]

- Weichbroth, P. Usability of mobile applications: A systematic literature study. IEEE Access 2020, 8, 55563–55577. [Google Scholar] [CrossRef]

- Aheleroff, S.; Xu, X.; Zhong, R.Y.; Lu, Y. Digital twin as a service (DTaaS) in industry 4.0: An architecture reference model. Adv. Eng. Inform. 2021, 47, 101225. [Google Scholar] [CrossRef]

- Mashaly, M. Connecting the twins: A review on digital twin technology & its networking requirements. Procedia Comput. Sci. 2021, 184, 299–305. [Google Scholar]

- IQS Directory. Data Acquisition Systems. 2023. Available online: https://www.iqsdirectory.com/articles/data-acquisition-system.html (accessed on 19 March 2023).

- Marr, B. The Best Examples of Digital Twins Everyone Should Know About. 2022. Available online: https://www.forbes.com/sites/bernardmarr/2022/06/20/the-best-examples-of-digital-twins-everyone-should-know-about/?sh=56358dc9225f (accessed on 15 March 2023).

- Rowley, J.; Slack, F. Conducting a literature review. Manag. Res. News 2004, 27, 31–39. [Google Scholar] [CrossRef]

- Knopf, J.W. Doing a literature review. PS Political Sci. Politics 2006, 39, 127–132. [Google Scholar] [CrossRef]

- Auraria Library. Research Methods: Literature Reviews. 2023. Available online: https://guides.auraria.edu/researchmethods/literaturereviews (accessed on 1 March 2023).

- Gusenbauer, M. Google Scholar to overshadow them all? Comparing the sizes of 12 academic search engines and bibliographic databases. Scientometrics 2019, 118, 177–214. [Google Scholar] [CrossRef]

- Amodio, P.; Brugnano, L.; Scarselli, F. Implementation of the PaperRank and AuthorRank indices in the Scopus database. J. Informetr. 2021, 15, 101206. [Google Scholar] [CrossRef]

- Yasin, A.; Fatima, R.; Wen, L.; Afzal, W.; Azhar, M.; Torkar, R. On using grey literature and google scholar in systematic literature reviews in software engineering. IEEE Access 2020, 8, 36226–36243. [Google Scholar] [CrossRef]

- Baas, J.; Schotten, M.; Plume, A.; Côté, G.; Karimi, R. Scopus as a curated, high-quality bibliometric data source for academic research in quantitative science studies. Quant. Sci. Stud. 2020, 1, 377–386. [Google Scholar] [CrossRef]

- Arshed, N.; Danson, M. The literature review. In Research Methods for Business and Management: A Guide to Writing Your Dissertation; Goodfellow Publishers Ltd.: Oxford, UK, 2015; pp. 31–49. [Google Scholar]

- Hacking, W. Method: Manual Coding. Memobust Handbook on Methodology of Modern Business Statistics. 2014. Available online: https://bazawiedzy.ue.poznan.pl/info/book/UEP0af092ec2f7b43488fc6f4ba947e5c1b/Memobust++Handbook+on++Methodology+of+Modern+Business+Statistics+title?ps=20&lang=en&pn=1&cid=26470 (accessed on 2 May 2023).

- Grieves, M. Digital twin: Manufacturing excellence through virtual factory replication. White Pap. 2014, 1, 1–7. [Google Scholar]

- Bitton, R.; Gluck, T.; Stan, O.; Inokuchi, M.; Ohta, Y.; Yamada, Y.; Yagyu, T.; Elovici, Y.; Shabtai, A. Deriving a cost-effective digital twin of an ICS to facilitate security evaluation. In Proceedings of the Computer Security: 23rd European Symposium on Research in Computer Security, ESORICS 2018, Proceedings, Part I 23, Barcelona, Spain, 3–7 September 2018; Springer: Berlin/Heidelberg, Germany, 2018; pp. 533–554. [Google Scholar]

- Talkhestani, B.A.; Jazdi, N.; Schloegl, W.; Weyrich, M. Consistency check to synchronize the Digital Twin of manufacturing automation based on anchor points. Procedia CIRP 2018, 72, 159–164. [Google Scholar] [CrossRef]

- Erol, T.; Mendi, A.F.; Doğan, D. The digital twin revolution in healthcare. In Proceedings of the 2020 4th International Symposium on mUltidisciplinary Studies and Innovative Technologies (ISMSIT), Istanbul, Turkey, 22–24 October 2020; pp. 1–7. [Google Scholar]

- Martinez-Velazquez, R.; Gamez, R.; El Saddik, A. Cardio Twin: A Digital Twin of the human heart running on the edge. In Proceedings of the 2019 IEEE International Symposium on Medical Measurements and Applications (MeMeA), Istanbul, Turkey, 26–28 June 2019; pp. 1–6. [Google Scholar]

- Subramanian, K. Digital twin for drug discovery and development—The virtual liver. J. Indian Inst. Sci. 2020, 100, 653–662. [Google Scholar] [CrossRef]

- Feng, Y.; Chen, X.; Zhao, J. Create the individualized digital twin for noninvasive precise pulmonary healthcare. Significances Bioeng. Biosci. 2018, 1, 1–5. [Google Scholar] [CrossRef]

- Hassani, H.; Huang, X.; MacFeely, S. Impactful digital twin in the healthcare revolution. Big Data Cogn. Comput. 2022, 6, 83. [Google Scholar] [CrossRef]

- Sun, T.; He, X.; Li, Z. Digital twin in healthcare: Recent updates and challenges. Digit. Health 2023, 9, 20552076221149651. [Google Scholar] [CrossRef]

- Vallée, A. Digital twin for healthcare systems. Front. Digit. Health 2023, 5, 1253050. [Google Scholar] [CrossRef]

- Bytniewski, A.; Matouk, K.; Rot, A.; Hernes, M.; Kozina, A. Towards industry 4.0: Functional and technological basis for ERP 4.0 systems. Towards Ind. 4.0—Curr. Chall. Inf. Syst. 2020, 3–19. [Google Scholar] [CrossRef]

- Gawlik-Kobylińska, M.; Maciejewski, P.; Lebiedź, J. Mini-Cave Automatic Virtual Environment Application in Security, Safety, and Defence Studies. In Proceedings of the 2021 International Conference on Information Technologies (infoTech), Varna, Bulgaria, 16–17 September 2021; pp. 1–4. [Google Scholar]

- Pu, C.; Ding, X.; Wang, P.; Xie, S.; Chen, J. Semantic Interconnection Scheme for Industrial Wireless Sensor Networks and Industrial Internet with OPC UA Pub/Sub. Sensors 2022, 22, 7762. [Google Scholar] [CrossRef]

- Aheleroff, S.; Huang, H.; Xu, X.; Zhong, R.Y. Toward sustainability and resilience with Industry 4.0 and Industry 5.0. Front. Manuf. Technol. 2022, 2, 951643. [Google Scholar] [CrossRef]

- Khan, L.U.; Han, Z.; Saad, W.; Hossain, E.; Guizani, M.; Hong, C.S. Digital twin of wireless systems: Overview, taxonomy, challenges, and opportunities. IEEE Commun. Surv. Tutor. 2022, 24, 2230–2254. [Google Scholar] [CrossRef]

- Opoku, D.G.J.; Perera, S.; Osei-Kyei, R.; Rashidi, M. Digital twin application in the construction industry: A literature review. J. Build. Eng. 2021, 40, 102726. [Google Scholar] [CrossRef]

- Shahzad, M.; Shafiq, M.T.; Douglas, D.; Kassem, M. Digital twins in built environments: An investigation of the characteristics, applications, and challenges. Buildings 2022, 12, 120. [Google Scholar] [CrossRef]

- Ibrion, M.; Paltrinieri, N.; Nejad, A.R. On risk of digital twin implementation in marine industry: Learning from aviation industry. In Proceedings of the Journal of Physics: Conference Series; IOP Publishing: Bristol, UK, 2019; Volume 1357, p. 012009. [Google Scholar]

- Liezina, A.; Andriushchenko, K.; Rozhko, O.; Datsii, O.; Mishchenko, L.; Cherniaieva, O. Resource planning for risk diversification in the formation of a digital twin enterprise. Accounting 2020, 6, 1337–1344. [Google Scholar] [CrossRef]

- Millwater, H.; Ocampo, J.; Crosby, N. Probabilistic methods for risk assessment of airframe digital twin structures. Eng. Fract. Mech. 2019, 221, 106674. [Google Scholar] [CrossRef]

- Attaran, M.; Celik, B.G. Digital Twin: Benefits, use cases, challenges, and opportunities. Decis. Anal. J. 2023, 100165. [Google Scholar] [CrossRef]

- Attaran, M. The internet of things: Limitless opportunities for business and society. J. Strateg. Innov. Sustain. Vol. 2017, 12, 11. [Google Scholar]

- Lo, C.; Chen, C.; Zhong, R.Y. A review of digital twin in product design and development. Adv. Eng. Inform. 2021, 48, 101297. [Google Scholar] [CrossRef]

- Groshev, M.; Guimarães, C.; Martín-Pérez, J.; de la Oliva, A. Toward intelligent cyber-physical systems: Digital twin meets artificial intelligence. IEEE Commun. Mag. 2021, 59, 14–20. [Google Scholar] [CrossRef]

- Alizadehsalehi, S.; Yitmen, I. Digital twin-based progress monitoring management model through reality capture to extended reality technologies (DRX). Smart Sustain. Built Environ. 2023, 12, 200–236. [Google Scholar] [CrossRef]

- Tahmasebinia, F.; Lin, L.; Wu, S.; Kang, Y.; Sepasgozar, S. Exploring the benefits and limitations of digital twin technology in building energy. Appl. Sci. 2023, 13, 8814. [Google Scholar] [CrossRef]

- Madubuike, O.C.; Anumba, C.J.; Khallaf, R. A review of digital twin applications in construction. J. Inf. Technol. Constr. 2022, 27, 145–172. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, H.; Liu, A.; Nee, A.Y. Digital twin in industry: State-of-the-art. IEEE Trans. Ind. Inform. 2018, 15, 2405–2415. [Google Scholar] [CrossRef]

- Jelisic, E.; Jankovic, M.; Ivezic, N.; Kulvatunyou, B.; Kehagias, D.; Marjanovic, Z. Business context-based approach for Digital Twin services integration. In Proceedings of the 12th International Conference on Information Society and Technology, Kopaonik, Serbia, 13–16 March 2022. [Google Scholar]

- Xiang, F.; Zhou, P.; Zuo, Y.; Tao, F.; Zhang, D. Manufacturing service network of digital twin systems under cloud computing environment. Procedia CIRP 2022, 109, 460–465. [Google Scholar] [CrossRef]

- Marche, C.; Nitti, M. An Evaluation of Service Discovery Mechanisms for a Network of Social Digital Twins. In Proceedings of the GLOBECOM 2023-2023 IEEE Global Communications Conference, Kuala Lumpur, Malaysia, 4–8 December 2023; pp. 3215–3221. [Google Scholar]

- Dong, R.; She, C.; Hardjawana, W.; Li, Y.; Vucetic, B. Deep learning for hybrid 5G services in mobile edge computing systems: Learn from a digital twin. IEEE Trans. Wirel. Commun. 2019, 18, 4692–4707. [Google Scholar] [CrossRef]

- Wang, Z.; Gupta, R.; Han, K.; Wang, H.; Ganlath, A.; Ammar, N.; Tiwari, P. Mobility digital twin: Concept, architecture, case study, and future challenges. IEEE Internet Things J. 2022, 9, 17452–17467. [Google Scholar] [CrossRef]

- Zhang, Q.; Xiao, R.; Liu, Z.; Duan, J.; Qin, J. Process simulation and optimization of arc welding robot workstation based on digital twin. Machines 2023, 11, 53. [Google Scholar] [CrossRef]

- Zhang, L.; Yang, C.; Yan, Y.; Cai, Z.; Hu, Y. Automated guided vehicle dispatching and routing integration via digital twin with deep reinforcement learning. J. Manuf. Syst. 2024, 72, 492–503. [Google Scholar] [CrossRef]

- Deponti, A. Why the Digital Twin Is Not about Technology. 2020. Available online: https://blogs.sw.siemens.com/simcenter/digital-twin-is-not-about-technology (accessed on 22 July 2024).

- Carayannis, E.G.; Morawska, J. Digital and green twins of Industry & Society 5.0: The role of universities. In The Elgar Companion to Digital Transformation, Artificial Intelligence and Innovation in the Economy, Society and Democracy; Edward Elgar Publishing: Cheltenham, UK, 2023; pp. 166–202. [Google Scholar]

- Nalini, M.; Bharathkumar, M.; Keerthivasan, R.; Nithyashree, N.; Dhanashree, V. Impact of internet of things and digital twin on manufacturing era. In Digital Twin for Smart Manufacturing; Elsevier: Amsterdam, The Netherlands, 2023; pp. 185–202. [Google Scholar]

- Khan, S.; Farnsworth, M.; McWilliam, R.; Erkoyuncu, J. On the requirements of digital twin-driven autonomous maintenance. Annu. Rev. Control 2020, 50, 13–28. [Google Scholar] [CrossRef]

- Hajjem, E.; Benderbal, H.H.; Hamani, N.; Dolgui, A. Digital twin framework for reconfigurable manufacturing systems: Challenges and requirements. In Proceedings of the IFIP International Conference on Advances in Production Management Systems, Nantes, France, 5–9 September 2021; Springer: Berlin/Heidelberg, Germany, 2021; pp. 553–562. [Google Scholar]

- Gitnux Market Data. Google Maps Usage Statistics 2023: The Most Important Facts. 2023. Available online: https://gitnux.org/google-maps-usage-statistics/ (accessed on 25 July 2023).

- OpenAI. ChatGPT. 2023. Available online: https://chat.openai.com (accessed on 25 March 2023).

- Ben Miled, Z.; French, M.O. Towards a reasoning framework for digital clones using the digital thread. In Proceedings of the 55th AIAA Aerospace Sciences Meeting, Grapevine, TX, USA, 9–13 January 2017; p. 0873. [Google Scholar]

- Hu, L.; Nguyen, N.T.; Tao, W.; Leu, M.C.; Liu, X.F.; Shahriar, M.R.; Al Sunny, S.N. Modeling of cloud-based digital twins for smart manufacturing with MT connect. Procedia Manuf. 2018, 26, 1193–1203. [Google Scholar] [CrossRef]

- Damjanovic-Behrendt, V. A digital twin-based privacy enhancement mechanism for the automotive industry. In Proceedings of the 2018 International Conference on Intelligent Systems (IS), Funchal, Portugal, 25–27 September 2018; pp. 272–279. [Google Scholar]

- Rüßmann, M.; Lorenz, M.; Gerbert, P.; Waldner, M.; Justus, J.; Engel, P.; Harnisch, M. Industry 4.0: The future of productivity and growth in manufacturing industries. Boston Consult. Group 2015, 9, 54–89. [Google Scholar]

- Ayani, M.; Ganebäck, M.; Ng, A.H. Digital Twin: Applying emulation for machine reconditioning. Procedia CIRP 2018, 72, 243–248. [Google Scholar] [CrossRef]

- Macchi, M.; Roda, I.; Negri, E.; Fumagalli, L. Exploring the role of digital twin for asset lifecycle management. IFAC-PapersOnLine 2018, 51, 790–795. [Google Scholar] [CrossRef]

- Söderberg, R.; Wärmefjord, K.; Carlson, J.S.; Lindkvist, L. Toward a Digital Twin for real-time geometry assurance in individualized production. CIRP Ann. 2017, 66, 137–140. [Google Scholar] [CrossRef]

- Qi, Q.; Tao, F. Digital twin and big data towards smart manufacturing and industry 4.0: 360 degree comparison. IEEE Access 2018, 6, 3585–3593. [Google Scholar] [CrossRef]

- Botkina, D.; Hedlind, M.; Olsson, B.; Henser, J.; Lundholm, T. Digital twin of a cutting tool. Procedia CIRP 2018, 72, 215–218. [Google Scholar] [CrossRef]

- Martinez Hernandez, V.; Neely, A.; Ouyang, A.; Burstall, C.; Bisessar, D. Service Business Model Innovation: The Digital Twin Technology. 2019. Available online: https://api.repository.cam.ac.uk/server/api/core/bitstreams/97d296d5-ef54-486f-a2d8-ed64133acf67/content (accessed on 25 July 2023).

- Meierhofer, J.; West, S.; Rapaccini, M.; Barbieri, C. The digital twin as a service enabler: From the service ecosystem to the simulation model. In Proceedings of the Exploring Service Science: 10th International Conference, IESS 2020, Proceedings 10, Porto, Portugal, 5–7 February 2020; Springer: Berling/Heidelberg, Germany, 2020; pp. 347–359. [Google Scholar]

- Borangiu, T.; Oltean, E.V.; Răileanu, S.; Iacob, I.; Anton, S.; Anton, F. Modelling service processes as discrete event systems with ARTI-Type holonic control architecture. In Proceedings of the Exploring Service Science: 10th International Conference, IESS 2020, Proceedings 10, Porto, Portugal, 5–7 February 2020; Springer: Berling/Heidelberg, Germany, 2020; pp. 377–390. [Google Scholar]

- Glaessgen, E.; Stargel, D. The digital twin paradigm for future NASA and US Air Force vehicles. In Proceedings of the 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference 20th AIAA/ASME/AHS Adaptive Structures Conference 14th AIAA, Honolulu, HI, USA, 23–26 April 2012; p. 1818. [Google Scholar]

- Karve, P.M.; Guo, Y.; Kapusuzoglu, B.; Mahadevan, S.; Haile, M.A. Digital twin approach for damage-tolerant mission planning under uncertainty. Eng. Fract. Mech. 2020, 225, 106766. [Google Scholar] [CrossRef]

- Li, C.; Mahadevan, S.; Ling, Y.; Choze, S.; Wang, L. Dynamic Bayesian network for aircraft wing health monitoring digital twin. AIAA J. 2017, 55, 930–941. [Google Scholar] [CrossRef]

- Zhou, C.; Xu, J.; Miller-Hooks, E.; Zhou, W.; Chen, C.H.; Lee, L.H.; Chew, E.P.; Li, H. Analytics with digital-twinning: A decision support system for maintaining a resilient port. Decis. Support Syst. 2021, 143, 113496. [Google Scholar] [CrossRef]

- Khajavi, S.H.; Motlagh, N.H.; Jaribion, A.; Werner, L.C.; Holmström, J. Digital twin: Vision, benefits, boundaries, and creation for buildings. IEEE Access 2019, 7, 147406–147419. [Google Scholar] [CrossRef]

- Uhlemann, T.H.J.; Schock, C.; Lehmann, C.; Freiberger, S.; Steinhilper, R. The digital twin: Demonstrating the potential of real time data acquisition in production systems. Procedia Manuf. 2017, 9, 113–120. [Google Scholar] [CrossRef]

- Liljaniemi, A.; Paavilainen, H. Using digital twin technology in engineering education–course concept to explore benefits and barriers. Open Eng. 2020, 10, 377–385. [Google Scholar] [CrossRef]

- Wang, S.; Wan, J.; Zhang, D.; Li, D.; Zhang, C. Towards smart factory for industry 4.0: A self-organized multi-agent system with big data based feedback and coordination. Comput. Netw. 2016, 101, 158–168. [Google Scholar] [CrossRef]

- He, B.; Bai, K.J. Digital twin-based sustainable intelligent manufacturing: A review. Adv. Manuf. 2021, 9, 1–21. [Google Scholar] [CrossRef]

- Bilberg, A.; Malik, A.A. Digital twin driven human–robot collaborative assembly. CIRP Ann. 2019, 68, 499–502. [Google Scholar] [CrossRef]

- Um, J.; Weyer, S.; Quint, F. Plug-and-Simulate within Modular Assembly Line enabled by Digital Twins and the use of AutomationML. IFAC-PapersOnLine 2017, 50, 15904–15909. [Google Scholar] [CrossRef]

- Leng, J.; Zhang, H.; Yan, D.; Liu, Q.; Chen, X.; Zhang, D. Digital twin-driven manufacturing cyber-physical system for parallel controlling of smart workshop. J. Ambient. Intell. Humaniz. Comput. 2019, 10, 1155–1166. [Google Scholar] [CrossRef]

- Cheng, Y.; Zhang, Y.; Ji, P.; Xu, W.; Zhou, Z.; Tao, F. Cyber-physical integration for moving digital factories forward towards smart manufacturing: A survey. Int. J. Adv. Manuf. Technol. 2018, 97, 1209–1221. [Google Scholar] [CrossRef]

- Meng, S.; Tang, S.; Zhu, Y.; Chen, C. Digital twin-driven control method for robotic automatic assembly system. In Proceedings of the IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; Volume 493, p. 012128. [Google Scholar]

- Xiang, F.; Zhi, Z.; Jiang, G. Digital twins technolgy and its data fusion in iron and steel product life cycle. In Proceedings of the 2018 IEEE 15th International Conference on Networking, Sensing and Control (ICNSC), Zhuhai, China, 27–29 March 2018; pp. 1–5. [Google Scholar]

- Pairet, È.; Ardón, P.; Liu, X.; Lopes, J.; Hastie, H.; Lohan, K.S. A digital twin for human-robot interaction. In Proceedings of the 2019 14th ACM/IEEE International Conference on Human-Robot Interaction (HRI), Daegu, Republic of Korea, 11–14 March 2019; p. 372. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Weichbroth, P.; Jandy, K.; Zurada, J. Toward Sustainable Development: Exploring the Value and Benefits of Digital Twins. Telecom 2024, 5, 774-791. https://doi.org/10.3390/telecom5030039

Weichbroth P, Jandy K, Zurada J. Toward Sustainable Development: Exploring the Value and Benefits of Digital Twins. Telecom. 2024; 5(3):774-791. https://doi.org/10.3390/telecom5030039

Chicago/Turabian StyleWeichbroth, Paweł, Krystian Jandy, and Jozef Zurada. 2024. "Toward Sustainable Development: Exploring the Value and Benefits of Digital Twins" Telecom 5, no. 3: 774-791. https://doi.org/10.3390/telecom5030039

APA StyleWeichbroth, P., Jandy, K., & Zurada, J. (2024). Toward Sustainable Development: Exploring the Value and Benefits of Digital Twins. Telecom, 5(3), 774-791. https://doi.org/10.3390/telecom5030039