Building an Educational Automated Mechatronics-Based Sorting System

Abstract

:1. Introduction

2. Materials and Methods

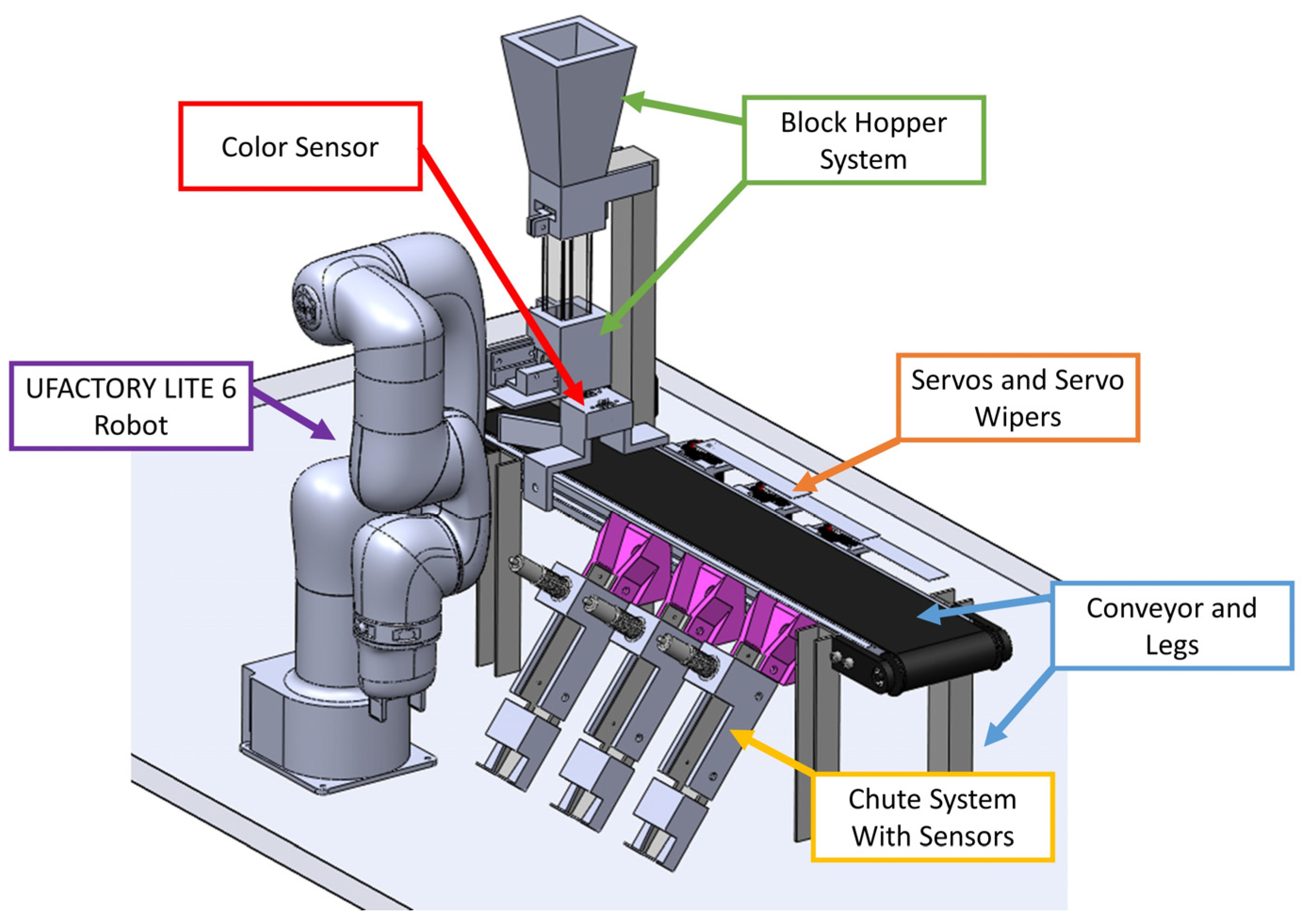

2.1. Mechanical Design

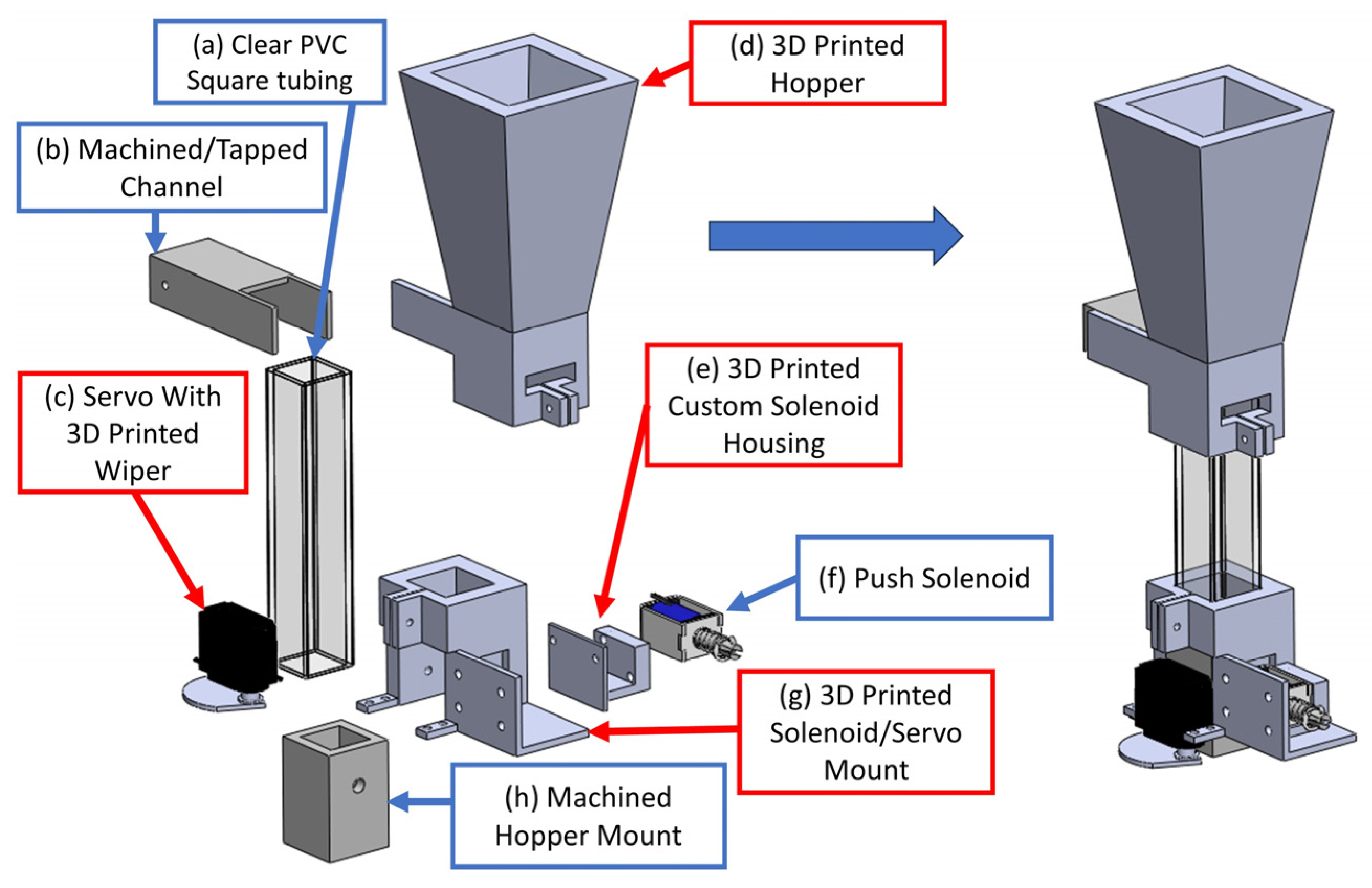

2.1.1. Hopper System Design

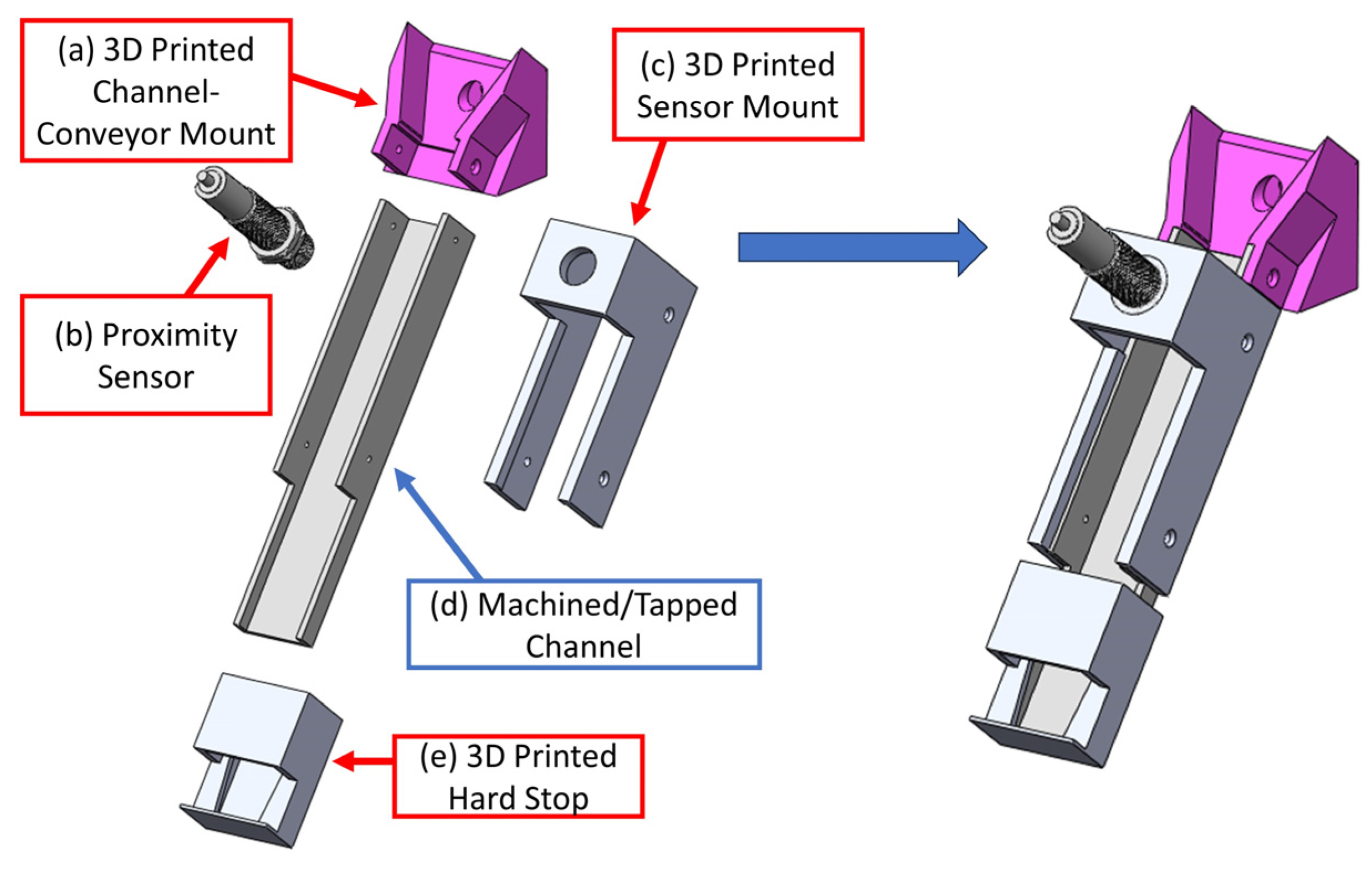

2.1.2. Sorting System Design

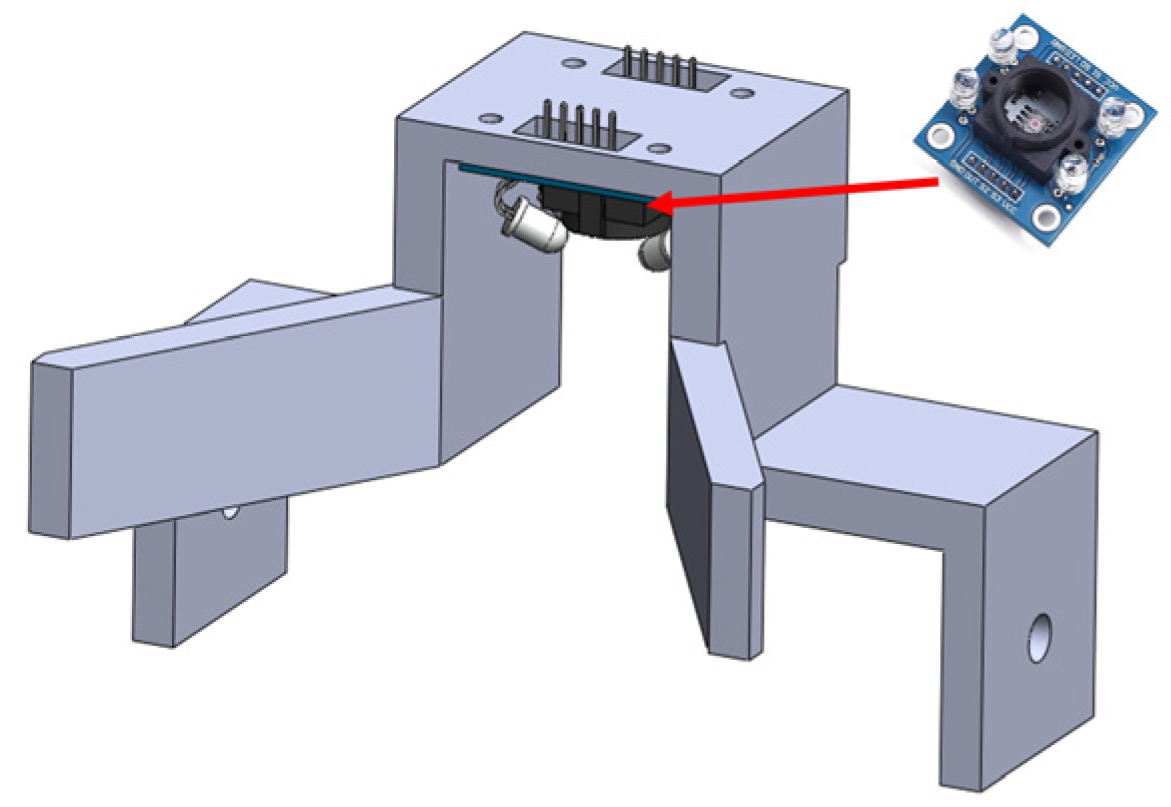

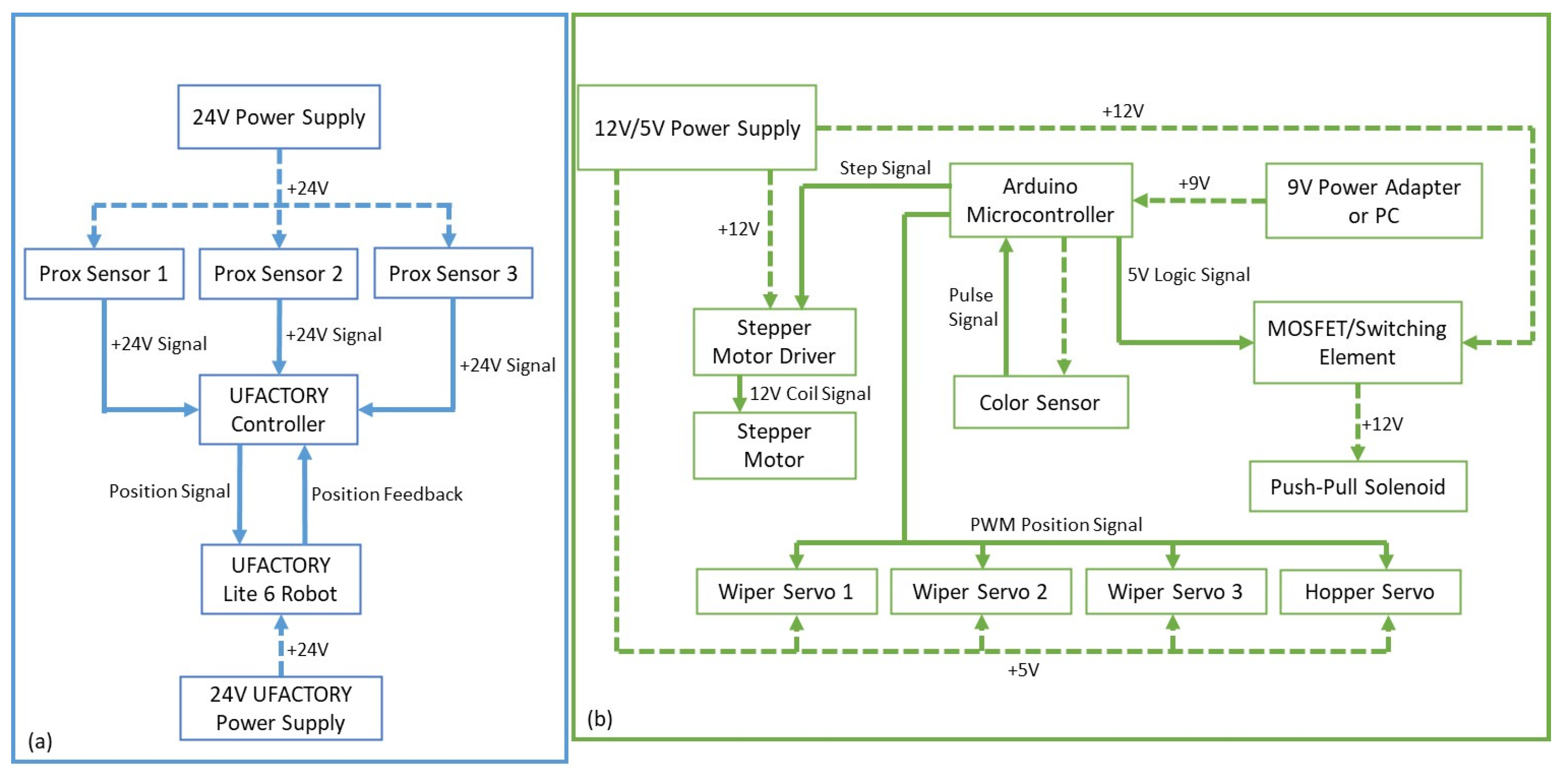

2.2. Electrical Design

2.3. Software Implementation

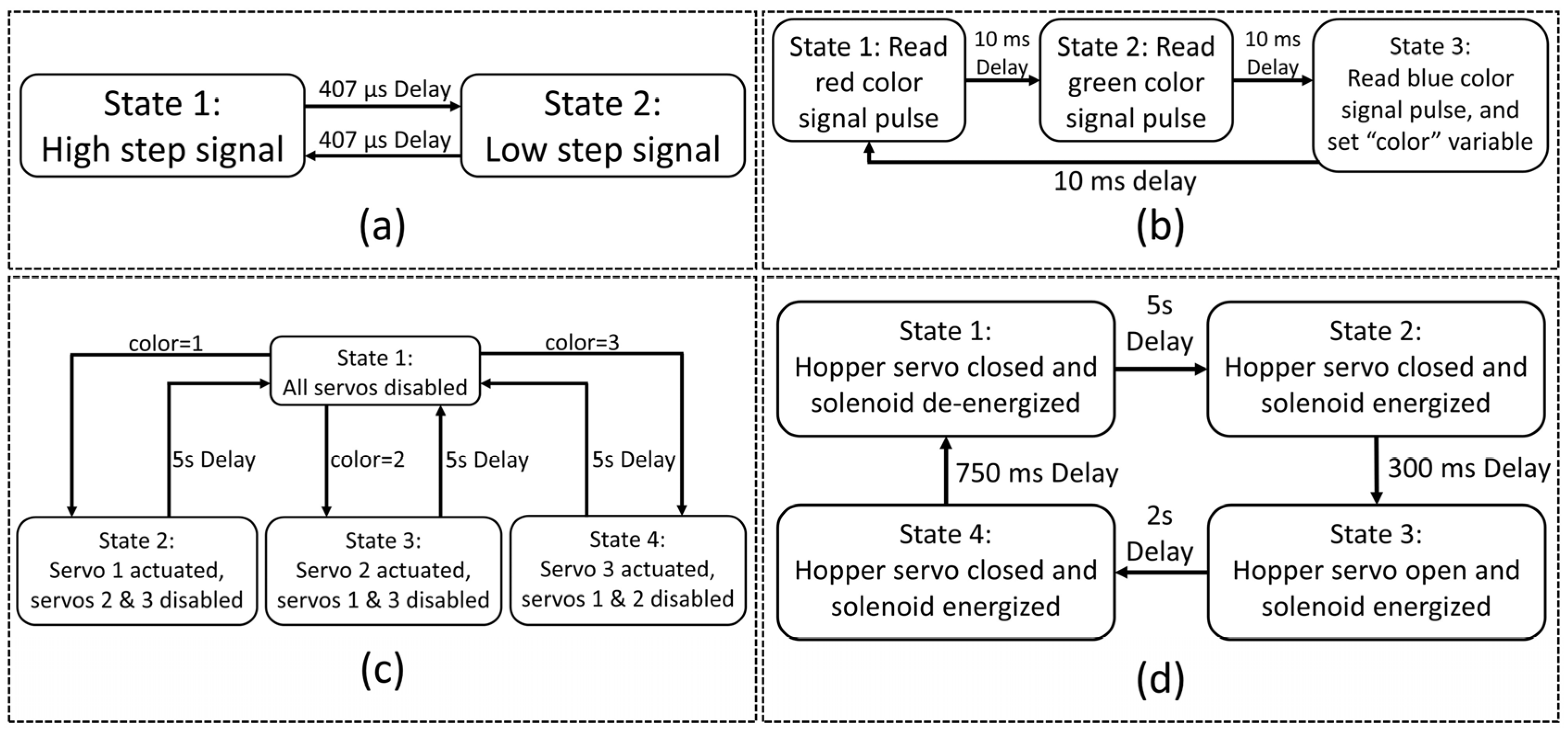

2.3.1. Arduino Code

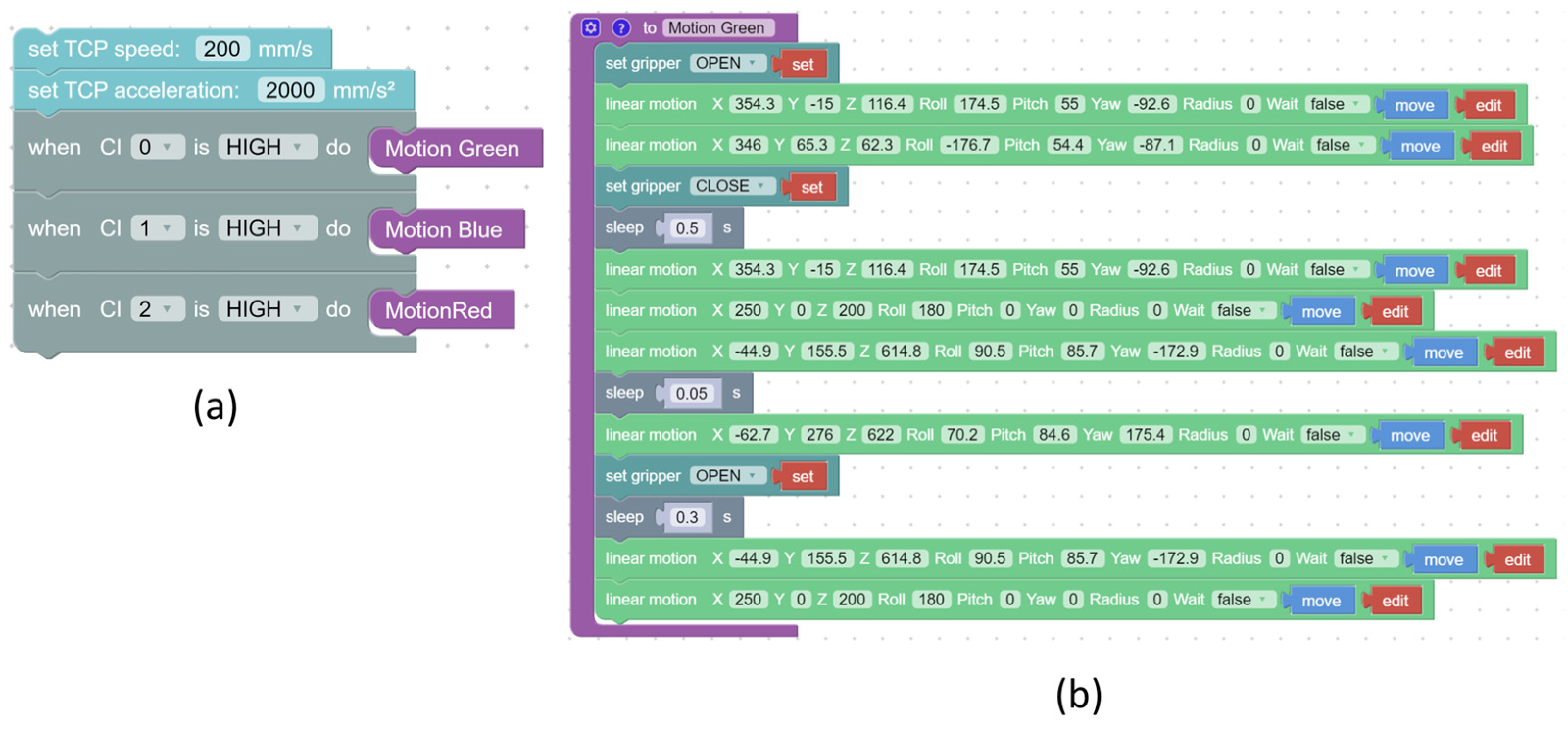

2.3.2. UFACTORY Software/Robot Program

3. Results and Discussion

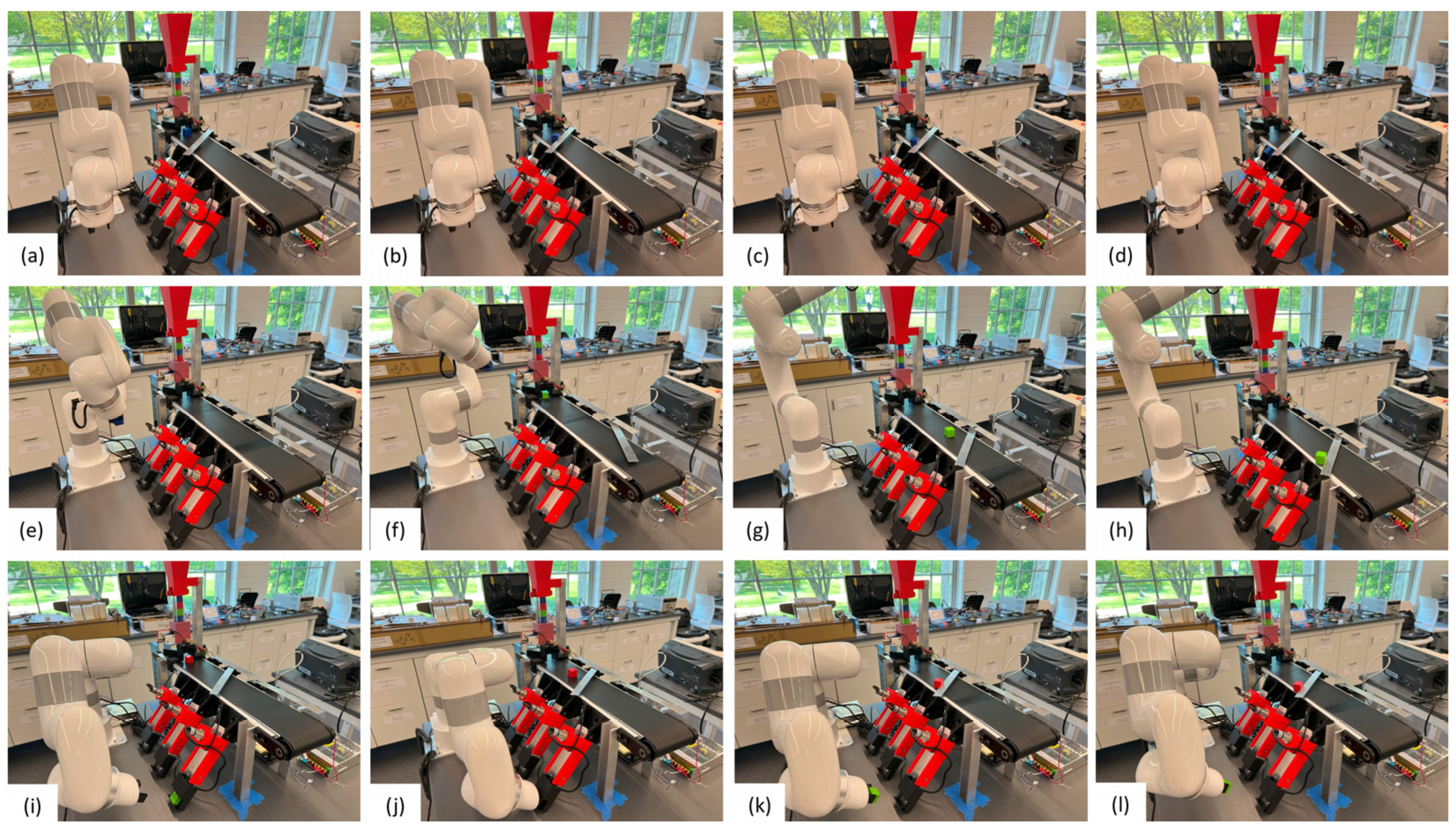

3.1. System Validation

3.2. Block Specimens

3.3. Testing and Results

3.4. Performance Metrics

3.5. Discussion

3.5.1. Physical Design Adjustments

3.5.2. Electronics and Switching Mechanisms

3.5.3. Speed of Robot vs. Dispensing Rate and Conveyer Speed

3.5.4. Two Blocks Back to Back

3.5.5. System Cost

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Almeida, J.M.; Martins, A.; Almeida, C.; Viegas, D.; Ferreira, A.; Matias, B.; Sytnyk, D.; Soares, E.; Pereira, R. Sustainable Exploration and Exploitation of Raw Materials. INESCTEC Sci. Soc. 2023, 1, 92–97. [Google Scholar]

- Khodabandehloo, K. Robotic Handling and Packaging of Poultry Products. Robotica 1990, 8, 285–297. [Google Scholar] [CrossRef]

- Lei, T.; Rong, Y.; Wang, H.; Huang, Y.; Li, M. A Review of Vision-Aided Robotic Welding. Comput. Ind. 2020, 123, 103326. [Google Scholar] [CrossRef]

- Xu, Y.; Wang, Z. Visual Sensing Technologies in Robotic Welding: Recent Research Developments and Future Interests. Sens. Actuators Phys. 2021, 320, 112551. [Google Scholar] [CrossRef]

- Thomas, G.; Chien, M.; Tamar, A.; Ojea, J.A.; Abbeel, P. Learning Robotic Assembly from CAD. In Proceedings of the 2018 IEEE International Conference on Robotics and Automation (ICRA), Brisbane, QLD, Australia, 21–25 May 2018; IEEE: New York, NY, USA, 2018; pp. 3524–3531. [Google Scholar]

- Jiang, J.; Yao, L.; Huang, Z.; Yu, G.; Wang, L.; Bi, Z. The State of the Art of Search Strategies in Robotic Assembly. J. Ind. Inf. Integr. 2022, 26, 100259. [Google Scholar] [CrossRef]

- Harashima, F.; Tomizuka, M.; Fukuda, T. Mechatronics—What Is It, Why and How. IEEE/ASME Trans. Mechatron. 1996, 1, 1–4. [Google Scholar] [CrossRef]

- Chioran, D.; Valean, H. Arduino-based smart home automation system. Int. J. Adv. Comput. Sci. Appl. 2020, 11, 67–73. [Google Scholar] [CrossRef]

- Yasin, H.; Zeebaree, S.; Zebari, I. Arduino based automatic irrigation system: Monitoring and SMS controlling. In Proceedings of the 2019 4th Scientific International Conference Najaf (SICN), Al-Najef, Iraq, 29–30 April 2019; IEEE: New York, NY, USA, 2019; pp. 109–114. [Google Scholar]

- Hassan, H.; Saad, F.; Raklan, M. A low-cost automated sorting recycle bin powered by Arduino microcontroller. In Proceedings of the 2018 IEEE Conference on Systems, Process and Control (ICSPC), Melaka, Malaysia, 14–15 December 2018; IEEE: New York, NY, USA, 2018; pp. 182–186. [Google Scholar]

- Hong, W.; Shamsuddin, N.; Abas, E.; Apong, R.; Masri, Z.; Suhaimi, H.; Gödeke, S.; Noh, M. Water Quality Monitoring with Arduino Based Sensors. Environments 2021, 8, 6. [Google Scholar] [CrossRef]

- Tu, X.; Liu, H.; Liu, Q.; Hu, W.; Liu, J.; Yao, D.; Zeng, H. Development and Application of Intelligent Bumper Matching and Sorting System. In Society of Automotive Engineers (SAE)-China Congress; Springer Nature: Singapore, 2023; pp. 1017–1033. [Google Scholar]

- Rapolti, L.; Holonec, R.; Grindei, L.; Viman, O. Automated Sorting of Pharmaceutical Waste Using Machine Vision Technology. In Proceedings of the 7th International Conference on Advancements of Medicine and Health Care through Technology: Proceedings of MEDITECH-2020, Cluj-Napoca, Romania, 13–15 October 2020; Springer International Publishing: Berlin/Heidelberg, Germany, 2022; pp. 409–416. [Google Scholar]

- Rapolti, L.; Rodica, H.; Grindei, L.; Purcar, M.; Dragan, F.; Copîndean, R.; Reman, R. Experimental stand for sorting components dismantled from printed circuit boards. Minerals 2021, 11, 1292. [Google Scholar] [CrossRef]

- Balabanov, P.; Divin, A.; Egorov, A.; Yudaev, V. Mechatronic System for Fruit and Vegetables Sorting. IOP Conf. Ser. Mater. Sci. Eng. 2020, 734, 012128. [Google Scholar] [CrossRef]

- Wahab, D.; Hussain, A.; Scavino, E.; Mustafa, M.; Basri, H. Development of a Prototype Automated Sorting System for Plastic Recycling. Am. J. Appl. Sci. 2006, 3, 1924–1928. [Google Scholar] [CrossRef]

- Konstantinidis, F.; Sifnaios, S.; Tsimiklis, G.; Mouroutsos, S.; Amditis, A.; Gasteratos, A. Multi-sensor cyber-physical sorting system (cpss) based on industry 4.0 principles: A multi-functional approach. Procedia Comput. Sci. 2023, 217, 227–237. [Google Scholar] [CrossRef]

- Jouaneh, M. Fundamentals of Mechatronics; Cengage Learning: Stamford, CT, USA, 2013. [Google Scholar]

| Test | Observed Fault | Number of Faults | Total Faults | Percent Failure |

|---|---|---|---|---|

| Full functional test 1, 15 min, 75 sorted blocks | Stuck to gripper | 1 | 6 | 8% |

| Block fell out of chute | 1 | |||

| Block stuck in hopper | 1 | |||

| Color sensor failed to sort | 1 red | |||

| Misalignment at the bottom of the chute | 2 | |||

| Full functional test 2, 15 min, 75 sorted blocks | Color sensor failed to sort | 1 red, 1 blue, 1 green | 4 | 5% |

| Block fell out of chute | 1 |

| Observed Fault | Reasons | Possible Solutions |

|---|---|---|

| Stuck to gripper | Humidity, adhesiveness from paint | Slight sanding on block surfaces, fewer coats of paint |

| Block fell out of chute | Steep chute angle, lack of smooth entry to the chute | Reduction in chute angle |

| Block stuck in hopper | Flat face of the block not parallel to the ground | Change in cone design for hopper, making sure the blocks are dropped square with respect to the ground |

| Color sensor failed to sort | Poor sensor calibration, poor surface finish on block | Tighter block size tolerances and finishing, recalibration of sensor |

| Misalignment at the bottom of the chute | Steep chute angle | Reduction in chute angle, better block damping by stopper redesign |

| Parameter | Value |

|---|---|

| Color sensing accuracy | 97% |

| Block processing rate | 5 per minute |

| Fault rate | 6.7% |

| Part | Quantity | Specifications/Desc. | Unit Cost (USD) | Total Cost (USD) |

|---|---|---|---|---|

| UFACTORY Lite 6 Kit Top3dshop.com, Bakersfield, CA, USA | 1 | Robot arm | 3639.00 | 3639.00 |

| Heschen M18 Capacitive Proximity Sensor Heschen, Amazon.com, USA | 3 | 10–30 VDC 200 mA NPN NC 3-wire proximity sensor | 8.99 | 26.97 |

| Fielect DC 12 V 25 N Solenoid Push Pull Fielect, Amazon.com, USA | 1 | 12 V coil, 0.4 A current rating, 10 mm stroke | 12.99 | 12.99 |

| DOBOT Conveyor Belt Kits the Simplest Production Line Dobot, Amazon.com, USA | 1 | Conveyor belt kit | 500.00 | 500.00 |

| Hitec 31311S HS-311 Servo Standard Universal Hitec RCD, Amazon.com, USA | 4 | Standard 4.8–6.0 V servo | 17.22 | 68.88 |

| Arcity 5 V 12 V 24 V Output Switching Power Supply Unit Arcity, Amazon.com, USA | 1 | 24/12/5 V power supply adapter | 23.99 | 23.99 |

| ALITOVE DC 24 V 15 A 360 W Power Supply Universal Alitove, Amazon.com, USA | 1 | 24 V power adapter | 23.99 | 23.99 |

| STR2 DC Powered Advanced Microstep Drive Applied Motion Products, Morgan Hill, CA, USA | 1 | Stepper motor drive 0.3–2.2 A/phase | 117.00 | 117.00 |

| GY-31 TCS3200 TCS230 Color Sensor Module Teyleten, Amazon.com, USA | 1 | Color sensor | 13.99 | 13.99 |

| Arduino UNO Rev3 Arduino, Amazon.com, USA | 1 | Microcontroller | 27.90 | 27.90 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jackvony, B.; Jouaneh, M. Building an Educational Automated Mechatronics-Based Sorting System. Automation 2024, 5, 297-309. https://doi.org/10.3390/automation5030018

Jackvony B, Jouaneh M. Building an Educational Automated Mechatronics-Based Sorting System. Automation. 2024; 5(3):297-309. https://doi.org/10.3390/automation5030018

Chicago/Turabian StyleJackvony, Benjamin, and Musa Jouaneh. 2024. "Building an Educational Automated Mechatronics-Based Sorting System" Automation 5, no. 3: 297-309. https://doi.org/10.3390/automation5030018

APA StyleJackvony, B., & Jouaneh, M. (2024). Building an Educational Automated Mechatronics-Based Sorting System. Automation, 5(3), 297-309. https://doi.org/10.3390/automation5030018