1. Introduction

Fibrous materials have gained significant attention in the field of structured catalysts due to their wide-ranging applications in chemical engineering [

1,

2]. These systems offer several advantages, including a high surface-area-to-volume ratio and substantial porosity. Unlike conventional structured materials, such as monoliths or foams, which are typically produced in standardized geometries and materials, fibrous catalysts can be tailored to accommodate various reactor configurations [

3]. Additionally, they are often more cost-effective and provide more favorable conditions for the deposition of thin catalytic layers compared to conventional microreactors [

4]. Fibrous structures such as ceramic paper have shown high efficiency in filtering and oxidizing diesel soot [

5].

Fibers can also be fabricated from a variety of materials, and several methods have been developed for the synthesis of these ceramic fibers, such as electrospinning, stencil printing [

6,

7], molding, biomorphic mineralization, colloidal crystal templating [

7], dry spinning [

8,

9], and centrifugal spinning [

10,

11]. In the context of cleaner production, which emphasizes sustainable resource use and pollution minimization, renewable materials are increasingly employed as precursors. By modifying their properties, these bio-derived materials can replace environmentally detrimental alternatives while adding functional value.

Biological materials inherently possess complex and elegant structures because of long-term evolutionary processes [

12]. Biomorphic mineralization [

7,

13,

14] exploits these natural architectures to fabricate synthetic materials with tailored morphologies and functional properties [

13]. This low-cost, energy-efficient, and environmentally friendly approach has gained substantial interest in recent decades. In biomorphic mineralization, biotemplates—typically plant-based materials such as fibers, rice husks, stems, pollen grains, and wood tissues—are impregnated with metal salt solutions and subsequently calcined [

15]. The process eliminates the organic matrix while retaining its morphology, producing biomorphic ceramic structures. Among the earliest biotemplates employed for this purpose are sisal, jute, and hemp fibers.

Porous metal oxide fibers can be synthesized through the biotemplating route by incubating natural fibers in metal salt solutions and then applying thermal treatment to form crystalline oxides. Among these oxides are those based on Mn–Ce [

16] and Co–Ce [

16], which have been identified as promising alternatives to noble metals in diesel particulate filters, offering cost-effective catalytic performance.

In a previous study [

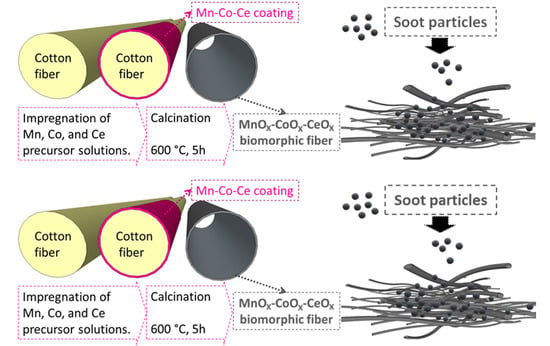

17], biomorphic Co–Ce fibers demonstrated excellent catalytic performance in diesel soot combustion. Given the well-known redox properties of Mn and Ce oxides, this work focuses on the synthesis of Mn–Ce-based biomorphic fibers using cotton as a biotemplate for catalytic soot oxidation. In addition, trimetallic Mn–Co–Ce fibers were prepared to assess the impact of cobalt addition on the morphological and catalytic properties of the resulting materials.

The use of chelating agents such as citric acid [

18,

19], oxalic acid, refs. [

20,

21] formic acid [

22,

23], and polyglycol [

24,

25] has also been investigated in the literature, in order to enhance precursor distribution and metal retention. In addition to Mn–Ce and Co–Ce systems, mixed Mn–Co oxides with spinel-type structures have also been extensively studied for oxidation reactions. These materials have been synthesized by a variety of methods including sol–gel, co-precipitation, and electrospinning, offering high catalytic activity due to their rich redox chemistry and oxygen mobility [

26]. The present work builds on this knowledge by exploring a biomorphic route using cotton as a renewable template to produce Mn–Co–Ce fibers with tunable composition and morphology.

Diesel engine emissions remain a major source of atmospheric pollutants, particularly particulate matter in the form of soot, and carbon monoxide (CO), a toxic gas resulting from incomplete combustion. Soot particles not only contribute to respiratory illnesses and cardiovascular risk but also influence climate forcing due to their light-absorbing properties. CO, meanwhile, poses acute toxicity risks and is a key target for air quality regulations. Despite advances in emission control technologies, cost-effective catalytic systems capable of simultaneously promoting soot combustion and CO oxidation are still needed—especially under low-temperature conditions and with minimal energy input. In this context, developing multifunctional catalysts synthesized via sustainable methods represents an environmentally and technologically relevant approach.

In this context, the present work reports the synthesis of biomorphic fibers composed of Mn–Ce and Mn–Co–Ce oxides, using commercial cotton as a renewable biotemplate via a simple mineralization route. The influence of citric acid as a chelating agent on the structural, morphological, and catalytic properties of the fibers is systematically evaluated. The novelty of this study lies in the use of cotton-derived biomorphic structures to develop trimetallic oxide fibers with enhanced mechanical integrity and competitive catalytic performance in both soot and CO oxidations. By comparing different metal compositions and synthesis conditions, this work provides new insights into the design of sustainable, low-cost catalytic materials for pollution abatement applications. This synthetic route aligns with green chemistry principles by using renewable cotton fibers, aqueous processing without organic solvents, and moderate thermal treatments in air, making it both sustainable and scalable.

2. Materials and Methods

2.1. Synthesis of Biomorphic Fibers

Cotton fibers (Estrella, Avellaneda, Santa Fe, Argentina) were impregnated with 0.3 M aqueous solutions of cobalt, cerium, or manganese nitrates (Sigma-Aldrich®, St. Louis, MO, USA). For bimetallic and trimetallic formulations, the total metal concentration was also maintained at 0.3 M. In all cases, a volume of 15 mL of solution per gram of dry cotton was used.

One gram of cotton was placed in a Büchner funnel and impregnated under vacuum with the corresponding precursors solution. The remnant solution was recovered and reapplied repeatedly until saturation was reached (

Figure 1). When citric acid (CA) (Cicarelli

®, Santa Fe, Argentina) was used as a chelating agent, precursor solutions were prepared with a (Mn + Ce)/CA molar ratio = 1.

The impregnated fibers were dried overnight at 120 °C and calcined at 600 °C (1 °C/min) for 5 h. Catalysts were denoted as MnXCeY(W) or MnXCeY(CA), where X and Y represent the molar percentages of Mn and Ce, and W or CA indicate synthesis with water (W) or citric acid (CA), respectively. Similarly, trimetallic Mn–Co–Ce samples were labeled as MnXCoZCeY(W) or MnXCoZCeY(CA), where Z corresponds to the Co molar percentage, and X, Y, and W are identically defined as binary formulations. In the case of Mn–Co–Ce catalysts, the molar ratio used was (Mn + Ce + Co)/CA = 1.

2.2. Characterization

X-ray diffraction (XRD): Crystalline phases were identified by XRD using a PANalytical Empyrean diffractometer (Malvern-PANalytical, Worcestershire, UK) with Cu Kα radiation, operated at 40 kV and 45 mA, scanning from 20° to 80° at 2°/min.

Scanning electron microscopy (SEM) and energy-dispersive X-ray spectroscopy (EDS): Fiber morphology was examined by SEM using a Carl Zeiss Sigma microscope. EDS (Carl Zeiss AG, Jena, Germany) analysis was employed to assess elemental composition and dispersion.

CO temperature-programmed reduction (CO-TPR): Reducibility was studied in a fixed-bed flow reactor. CO2 evolution was monitored using a Shimadzu GC-2014 chromatograph (Shimadzu Manufacturing Co., Ltd., Kyoto, Japan) with a thermal conductivity detector (TCD). Catalyst samples (50 mg) were heated from 20 °C to 600 °C at 5 °C/min under a flow of 5% CO in He (total flow: 7 mL/min).

CO-TPR and SEM/EDS were primarily conducted for Mn–Co–Ce fibers with and without citric acid. Mn–Ce fibers were characterized only for the non-CA route, as the effect of CA was previously studied in detail on powder systems [

19]. These Mn–Ce fibers are included as reference to assess the influence of cobalt and citric acid under biomorphic synthesis conditions.

Specific surface area (BET): Surface areas were determined by N2 adsorption at 77 K using a Micromeritics TriStar analyzer (Micromeritics Instrument Corp., Norcross, GA, USA). Samples (100 mg) were outgassed at 26.7 Pa and 623 K for 6 h. BET analysis was used to determine surface area.

Soot oxidation (TPO): Catalytic performance in soot combustion was evaluated under temperature-programmed oxidation conditions. Diesel soot was collected by combustion of YPF diesel (Argentina) [

5,

16,

17]. Catalysts and soot were mixed at a 20:1 mass ratio (loose contact, 2 min manual mixing). The mixture was heated from 25 °C to 600 °C at 5 °C/min under 18% O

2 and 0.1% NO in He (20 mL/min). Gases were analyzed with a Shimadzu GC-2014 (TCD) (Shimadzu Manufacturing Co., Ltd., Kyoto, Japan).

These soot samples were generated by controlled combustion of diesel fuel in a vessel and consisted of primary particles with diameters ranging from 48 nm to 154 nm, and an average size of 102.5 nm, as confirmed by TEM (JEOL, 2100Plus, Tokyo, Japan) and Raman (Horiba-Jobin-Yvon LabRam HR spectrometer, Kyoto, Japan) spectroscopy [

27]. CO oxidation: CO oxidation activity was measured using the same reactor setup. Samples (50 mg) were tested under 1% CO and 2% O

2 in He (30 mL/min) and then heated from room temperature to 500 °C at 5 °C/min. CO conversion was calculated as the ratio of outlet CO

2 to inlet CO concentrations, and T

50 values (temperature for 50% conversion) were extracted. Selected Mn–Ce and Mn–Co–Ce catalysts were tested for this reaction.

For six selected catalysts, CO and soot oxidation experiments were repeated independently to verify reproducibility. The relative standard deviation of the conversion values at representative temperatures ranged between 5.2% and 7.8%, confirming the consistency of the trends. The profiles shown in the figures correspond to representative curves.

3. Results

3.1. XRD Characterization

Figure 2 shows the X-ray diffraction (XRD) patterns of Mn–Ce biomorphic fibers synthesized without (A) and with (B) citric acid, where diffraction peaks corresponding to Mn

2O

3 (JCPDS 001-1061), Mn

3O

4 (JCPDS 002-1062), and CeO

2 (JCPDS 034-0394) are observed, depending on the composition.

For Mn-rich compositions, particularly Mn

100Ce

0(W), patterns of the samples synthesized without citric acid exhibited pronounced reflections associated with Mn

2O

3, while the Mn

3O

4 diffraction peaks were not observed. In contrast, the corresponding sample synthesized with citric acid [Mn

100Ce

0(CA)] displayed all signals corresponding to Mn

3O

4 in addition to those ascribed to Mn

2O

3. This result indicates that citric acid promotes the stabilization or preferential formation of the Mn

3O

4 spinel phase, consistent with previous studies on Mn–Ce oxide systems synthesized via CA-assisted routes [

18,

19].

Patterns of the Ce-rich samples (e.g., Mn10Ce90 and Mn0Ce100) were dominated by the presence of CeO2 signals. These peaks became sharper and more intense in the presence of citric acid, likely due to an improved crystallinity. For intermediate Mn–Ce ratios (Mn25Ce75, Mn50Ce50, Mn75Ce25), both Mn and Ce phases were detected, with proportions dependent on metal content and synthesis conditions.

Overall, while the use of citric acid did not significantly alter the qualitative phase composition, it clearly improved crystallinity and led to the formation of Mn3O4, particularly in Mn-rich samples. This is relevant because the presence of Mn3O4 is often associated with enhanced redox properties and higher catalytic activity.

From

Figure 2, it can be inferred that the incorporation of manganese to CeO

2 widens the main diffraction lines of the ceria fluorite, suggesting a lower crystallinity of Mn-CeO

2 formulations. This is observed both with and without the addition of citric acid during the synthesis of the catalysts. When present, citric acid contributes to the dispersion of manganese precursors, facilitating manganese incorporation into the cerium oxide lattice during calcination, favored by the smaller ionic radius of Mn

3+ relative to Ce

4+, and suppressing phase segregation and crystal growth, as reported elsewhere [

13].

On the other hand, the Mn

50Ce

50(W) catalyst was also characterized after soot combustion (

Figure S1), and it was observed that the crystalline structure was preserved after the catalytic test.

Figure 3 presents the XRD patterns of Mn–Co–Ce biomorphic fibers synthesized without (A) and with (B) citric acid, where signals corresponding to CeO

2, Mn

2O

3, Mn

3O

4, and Co

3O

4 (JCPDS 009-0418) are observed. Assignment of the Mn and Co spinel phases is challenging due to overlap in their most intense reflections in the 30–40° 2θ region. However, samples synthesized with citric acid generally exhibited sharper and more intense CeO

2 peaks, suggesting that CA promotes oxide crystallization.

3.2. CO-TPR Characterization

Figure 4A displays the CO temperature-programmed reduction (CO-TPR) profiles of Mn–Ce biomorphic fibers synthesized without citric acid. The Mn

100Ce

0(W) sample exhibits two distinct reduction peaks: a sharp peak centered around 340 °C, and a broader peak at 420 °C. These signals correspond to the stepwise reduction of Mn oxides: Mn

2O

3 → Mn

3O

4 (lower temperature peak) and Mn

3O

4 → MnO (second reduction step).

Upon incorporation of cerium, both peaks shift progressively to lower temperatures. For instance, in Mn

75Ce

25(W), the first reduction peak appears near 260 °C. This trend indicates that cerium enhances the reducibility of Mn oxides, likely by increasing the mobility of surface oxygen species [

28]. For samples with Mn/(Mn + Ce) < 0.50 (e.g., Mn

10Ce

90(W), Mn

0Ce

100(W)), well-defined Mn-related peaks are no longer observed. Instead, only broad and weak signals between 300 °C and 500 °C are detected, which can be attributed to the reduction of surface and adsorbed oxygen species on CeO

2 [

29,

30,

31].

CO-TPR profiles of Mn–Ce catalysts synthesized with citric acid revealed similar features, with a slight shift of the reduction peaks toward lower temperatures. This suggests enhanced reducibility and different metal–metal interaction facilitated by the chelating effect of citric acid.

Figure 4B shows the CO-TPR profiles of Mn–Co–Ce catalysts synthesized with and without citric acid. These profiles are more complex due to overlapping reduction events from Mn, Co, and Ce oxides. Co

3O

4 typically undergoes a two-step reduction: first to CoO (225–325 °C), then to metallic Co (325–420 °C), as described by Stegmayer et al. [

19]. These steps may also be accompanied by the Boudouard reaction, generating plateaus in the CO

2 signal. These processes are represented by the following equations:

Due to the overlap with Mn and Ce oxide reductions, it is not possible to unambiguously assign individual contributions. Nonetheless, a general trend is observed: citric acid promotes a shift of the overall reduction profile to lower temperatures, thus indicating improved reducibility. This behavior suggests better oxide dispersion or formation of more labile mixed phases involving solid solutions. Such effects are commonly linked to enhanced redox activity and superior catalytic performance [

19].

3.3. SEM and SEM-EDS Characterization

3.3.1. Morphological Characterization (SEM)

Figure 5 shows SEM images of Mn–Ce and Mn-Co-Ce biomorphic fibers synthesized with and without citric acid. Images A and B correspond to the Mn

10Ce

90 synthesized with citric acid sample, while C to F show Mn

40Co

50Ce

10 synthesized with (C and D) and without (E and F) citric acid, each at different magnifications. In both cases, the fibers preserve the original cotton morphology after calcination [

17].

These fibers exhibit uniform and thin walls, likely resulting from the improved precursor distribution enabled by citric acid. The chelating action of CA promotes homogeneous metal deposition in a sheath-like form over the cotton surface [

16]. Additionally, CA-assisted fibers were easier to handle and more resistant to breakage during mixing with diesel soot compared to their non-CA counterparts.

Figure 5C–F compare SEM micrographs of Mn

40Co

50Ce

10 fibers synthesized with (CA) and without (W) citric acid, respectively. The influence of CA on morphology is evident. The CA-assisted sample (

Figure 5C,D) exhibits compressed, helicoidal, ribbon-like structures with thin walls, typical of cotton-derived biomorphic materials [

32]. In contrast, the sample prepared without CA (

Figure 5E,F) shows thicker, hollow structures with non-helical features.

Figure 5D shows a detailed cross-section with a central cavity and porous wall, while

Figure 5F confirms a wall thickness of ~21 µm. These features are consistent with previous reports on biomorphic oxides derived from cotton [

33,

34], and they are likely related to rapid gas release during template decomposition.

Figure S2 presents SEM images of Mn

33Co

33Ce

33 fibers synthesized with and without citric acid. As observed in previous cases, CA-assisted fibers retain a well-defined helicoidal morphology with continuous walls (

Figure S2C,D). In contrast, fibers synthesized without CA (

Figure S2A,B) exhibit non-uniform, thicker walls and some degree of agglomeration.

Notably, cobalt incorporation improved the mechanical integrity of the fibers, enhancing resistance to handling regardless of the synthesis route. Citric acid may also chemically modify cotton surfaces by forming ester bonds with cellulose hydroxyl groups during the low-temperature treatment [

35,

36]. As a tricarboxylic acid, it retains unreacted carboxyl groups that can coordinate with metal cations. This dual functionality—covalent anchoring and metal chelation—is likely responsible for the improved precursor distribution and structural stability observed in CA-assisted samples [

37]. This mechanism has been previously described in studies on cellulose modification with organic acids, where citric acid acts both as a grafting agent and as a metal-binding moiety [

37]. By anchoring to the cotton template and simultaneously retaining free –COOH groups, citric acid establishes a chemically integrated interface between the biotemplate and the metal precursors. This promotes uniform distribution, reduces metal loss during processing, and contributes to the formation of adherent oxide coatings upon calcination.

3.3.2. Compositional Analysis (SEM–EDS)

SEM–EDS analyses were conducted to assess elemental composition and the distribution of individual elements on the biomorphic fibers.

Figure 6 shows elemental mappings of Mn

10Ce

90(CA) and Mn

75Ce

25(CA), revealing a homogeneous distribution of Mn, Ce, and O across the fiber. Measured atomic ratios (

Table 1) are consistent with the nominal compositions, confirming an effective incorporation and uniform dispersion of the metal precursors.

Figure 7 presents SEM–EDS results for Mn

40Co

50Ce

10 fibers synthesized with and without citric acid.

Figure 7A shows a cross-section view of a fiber prepared without CA, with uniform elemental distribution confirmed by EDS mapping, while

Figure 7B corresponds to the CA-assisted sample, where area mappings show homogeneous surface composition of Mn, Co, and Ce.

For Mn

33Co

33Ce

33 samples, representative EDS analyses were performed, and the atomic compositions are summarized in

Table 1. These results, together with morphological observations, highlight the effectiveness of biomorphic synthesis in achieving uniform elemental distribution and structured architectures. The use of citric acid further improves structural fidelity and precursor retention.

These SEM–EDS results, together with the morphological observations, demonstrate the effectiveness of the biomorphic synthesis approach in controlling both structure and elemental distribution. The influence of citric acid is particularly evident in enhancing fiber uniformity and precursor retention.

3.4. Specific Surface Area

The specific surface areas of the biomorphic fibers were determined by nitrogen adsorption at 77 K using the BET method. The results are summarized in

Table 2.

In Mn-based catalysts, the incorporation of citric acid during synthesis led to an increase in surface area compared to fibers prepared without it. This trend was observed the most in Mn–Ce and Mn–Co–Ce compositions, except for Mn25Ce75(CA), which showed no significant improvement. It can also be observed that increasing the amount of cerium increases the surface area.

Compared with previously reported Co–Ce biomorphic fibers prepared by similar methods [

17], the Mn–Ce-based catalysts—particularly those with high cerium content and synthesized with citric acid—exhibited significantly higher surface areas. This is a key feature in catalytic applications, as oxidation efficiency is closely related to the availability of active sites and effective contact area with soot particles.

Furthermore, in comparison to pure cerium oxide biomorphic fibers (13 m

2/g) reported in previous studies [

17], the incorporation of manganese and cobalt notably increased the specific surface area of the resulting materials.

3.5. Catalytic Performance

3.5.1. Soot Oxidation

Temperature-programmed oxidation (TPO) profiles for diesel soot combustion of Mn–Ce biomorphic fibers are shown in

Figure 8A,B, with the corresponding T

M summarized in

Table 3.

Among the Mn–Ce catalysts synthesized without citric acid, Mn

100Ce

0(W) exhibited the best activity, with a broad oxidation peak centered around 400 °C. This curve can be deconvoluted into two peaks at approximately 320 °C and 400 °C. The low-temperature contribution is particularly significant, as Mn

3O

4 is known to be more active in oxidation reactions than Mn

2O

3 [

38]. Bimetallic Mn–Ce catalysts showed improved activity compared to pure CeO

2, and some of them (e.g., Mn

75Ce

25 and Mn

50Ce

50) approached the performance of pure Mn-based fibers.

For samples synthesized with citric acid (

Figure 8B), the TPO profiles were sharper and shifted to lower temperatures. This indicates enhanced redox properties, attributable to improved Mn–Ce interaction and metal dispersion promoted by citric acid. As reflected in

Table 2, T

M values for Mn

50Ce

50(CA) and Mn

75Ce

25(CA) slightly decreased to 421 °C and 428 °C, respectively, compared to 432–429 °C for the corresponding non-CA samples.

Soot conversion curves as a function of temperature are shown in

Figure 9A,B. They confirm that CA-assisted Mn–Ce catalysts not only initiate oxidation at lower temperatures but also achieve total conversion below 450 °C.

Figure 8C,D and

Figure 9C,D present the TPO and conversion curves for Mn–Co–Ce catalysts. All trimetallic systems exhibited good catalytic activity under loose contact conditions, with T

M values between 420 °C and 440 °C (see

Table 3). The effect of citric acid was less pronounced in this group of catalysts. For example, Mn

40Co

50Ce

10(CA) and Mn

33Co

33Ce

33(CA) showed slightly lower T

M values than their W counterparts, but differences remained within ~5 °C. This suggests a compensation effect: enhanced oxide interaction from citric acid versus the mechanical stability observed without its addition in the synthesis process.

Table 3 also includes the T

M values of monometallic Co and Ce fibers for comparison purposes. Pure CeO

2 fibers showed limited catalytic activity, with T

M values of 469 °C (W) and 457 °C (CA). Co

100(W) performed better (≈370 °C) but remained less active than the Mn-containing formulations. Notably, the addition of Co to Mn–Ce systems did not significantly enhance activity beyond what was already achieved by Mn and CA effects alone.

Importantly, all catalysts achieved near-complete soot conversion between 430 and 470 °C, well below the non-catalyzed combustion temperature (>600 °C), confirming their high activity and effectiveness under loose contact conditions.

In addition, mechanical integrity also differed across formulations. While Mn–Ce fibers required CA to maintain structure during handling, Mn–Co–Ce fibers remained robust regardless of the synthesis route. This suggests a structural stabilizing effect of cobalt in the fiber framework, which is beneficial for practical applications in diesel particulate filters.

The structural integrity of the catalysts after reaction can be reasonably inferred from previous studies involving Mn–Ce and Co–Ce biomorphic fibers synthesized under identical conditions—including the use of cotton as a biotemplate, equivalent metal compositions, and calcination at 600 °C. In those works, X-ray diffraction analyses performed after soot combustion tests confirmed the retention of the fluorite-and spinel-type crystalline phases, without evidence of structural degradation or phase transformation [

17,

19]. Given the high reproducibility of the synthesis route and the similarity in reaction conditions employed here, comparable structural stability is expected for the present catalysts. This was confirmed by XRD, as previously described in

Section 3.1.

3.5.2. CO Oxidation

The catalytic activity of the biomorphic fibers in CO oxidation was assessed under temperature-programmed reaction conditions. CO conversion profiles as a function of temperature are shown in

Figure 10A,B for Mn–Ce and Mn–Co–Ce catalysts, respectively. The corresponding T

50 values (temperature at which 50% CO conversion is reached) are indicated in the figure.

Among the Mn–Ce systems, Mn

75Ce

25(W) exhibited the highest activity, achieving a T

50 of 259 °C, followed by Mn

50Ce

50(W) with T

50 at 275 °C. These values align with the CO-TPR data (

Figure 4A), where Mn-rich compositions showed reduction peaks at lower temperatures, indicating higher oxygen mobility and redox activity. In contrast, Ce-rich formulations such as Mn

10Ce

90(W) displayed a T

50 of 293 °C.

Trimetallic Mn–Co–Ce catalysts showed comparable or even improved activity. Notably, Mn33Co33Ce33(CA) exhibited the best overall performance, with a T50 of 254 °C, significantly lower than its non-CA counterpart (320 °C). This suggests that citric acid enhances oxide interaction and dispersion, leading to more efficient redox behavior, as stated above.

Other Mn–Co–Ce samples synthesized without CA also showed moderate activity: Mn

40Co

50Ce

10(W) and Mn

50Co

50(W) reached T

50 values of ~270 °C and 290 °C, respectively (curves not included in

Figure 10 for clarity). These results are consistent with previous findings [

13] for Co–Ce electrospun fibers, which reported T

50 values between 150 and 325 °C depending on composition and synthesis method.

Compared to these benchmarks, the Mn–Co–Ce biomorphic catalysts developed in this work offer comparable activity, despite being synthesized via a simpler and more sustainable route using cotton templates. The presence of manganese not only improves surface area and structural integrity but also maintains high catalytic efficiency.

These trends reinforce the correlation between redox properties (as seen in CO-TPR) and CO oxidation performance. Thus, the best-performing catalysts in CO oxidation were those that had balanced metal compositions and were synthesized by citric acid assistance.

The catalytic performance of the Mn

33Co

33Ce

33(CA) sample in CO oxidation (T

50 ≈ 254 °C) is in line with values reported for Co–Ce nanofibers synthesized via electrospinning [

17], and is similar to those observed for other Co–Ce catalysts evaluated under comparable conditions [

39]. In soot combustion, T

M values between 350 and 370 °C are also consistent with those reported for Mn–Ce and Co–Ce catalysts supported on ceramic filters or structured as nanofiber mats [

5,

40]. Importantly, the present materials were synthesized via a straightforward and scalable route, using cotton as a renewable template and conventional thermal treatment, without the need for organic polymers, surfactants, or controlled-atmosphere processing. This confers a clear advantage on them in terms of cost, sustainability, and practical applicability.

In order to study the long-term applicability of the prepared catalysts, the Mn

75Ce

25(W) catalyst was treated at 900 °C for 2 h as an accelerated process of aging. This aged catalyst was tested both for soot combustion and CO oxidation reactions. In the first case, the TPO profile for soot oxidation was compared to that of the fresh sample, and both profiles are shown in

Figure S3, where it can be observed that the aged catalyst maintains practically the same activity as that of the fresh catalyst. On the other hand, when the aged catalyst was used for CO oxidation, no differences in T

50 values were observed (T

50 = 260 °C) between the fresh and the aged catalysts, although a slight deactivation occurs above 300 °C, likely ascribed to a change in the reaction mechanism.

4. Conclusions

A series of Mn–Ce and Mn–Co–Ce biomorphic fibers were successfully synthesized, using commercial cotton as a renewable template, through a simple aqueous-based method and moderate thermal treatment. The incorporation of citric acid significantly modified the morphology of the fibers, making them more compact and resistant, especially in Mn-rich formulations. As a tricarboxylic acid, citric acid bonds to terminal OH groups of cellulose, enhancing the anchoring of metallic ions and the subsequent metal distribution after calcination.

Among all samples, Mn75Ce25(CA) and Mn33Co33Ce33(CA) achieved the best performance. In soot combustion under tight contact, both reached T50 values between 350 °C and 370 °C, while in CO oxidation, Mn33Co33Ce33(CA) displayed a T50 of ~254 °C and an over 90% conversion at 300 °C. These results are comparable to or better than values reported for benchmark Mn–Ce and Co–Ce catalysts in similar applications.

The addition of cobalt enhanced the mechanical robustness of the fibers, facilitating handling and post-synthesis processing, although its impact on catalytic activity was more pronounced for CO oxidation than for soot combustion.

The proposed synthesis method combines catalytic performance with environmental compatibility, relying on renewable templates, solvent-free processing, and moderate thermal treatment in air, thus offering a sustainable and practical alternative for the preparation of multifunctional oxidation catalysts.