Yield Characteristics of Cemented Paste Backfill

Abstract

:1. Introduction

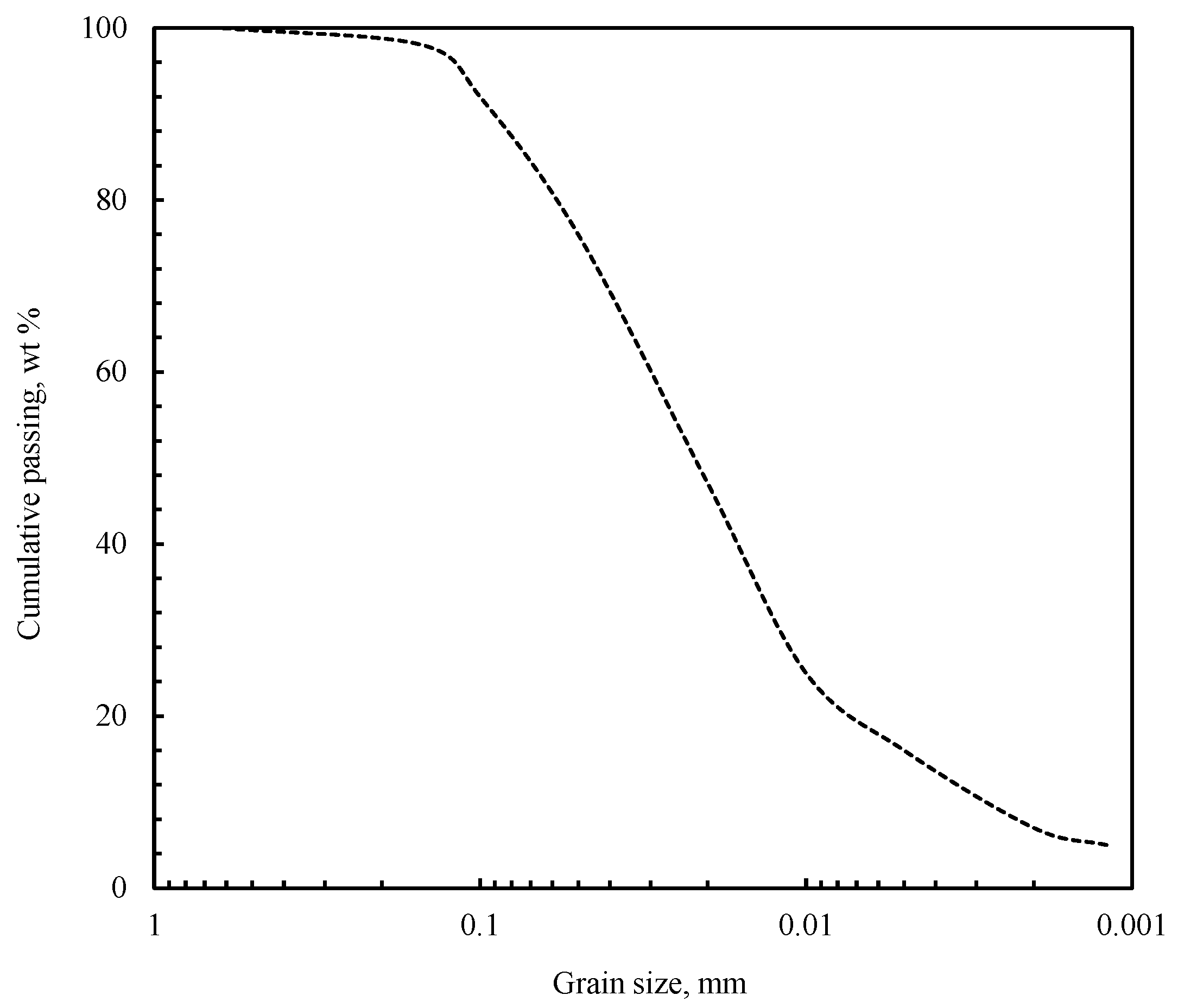

2. Materials and Methods

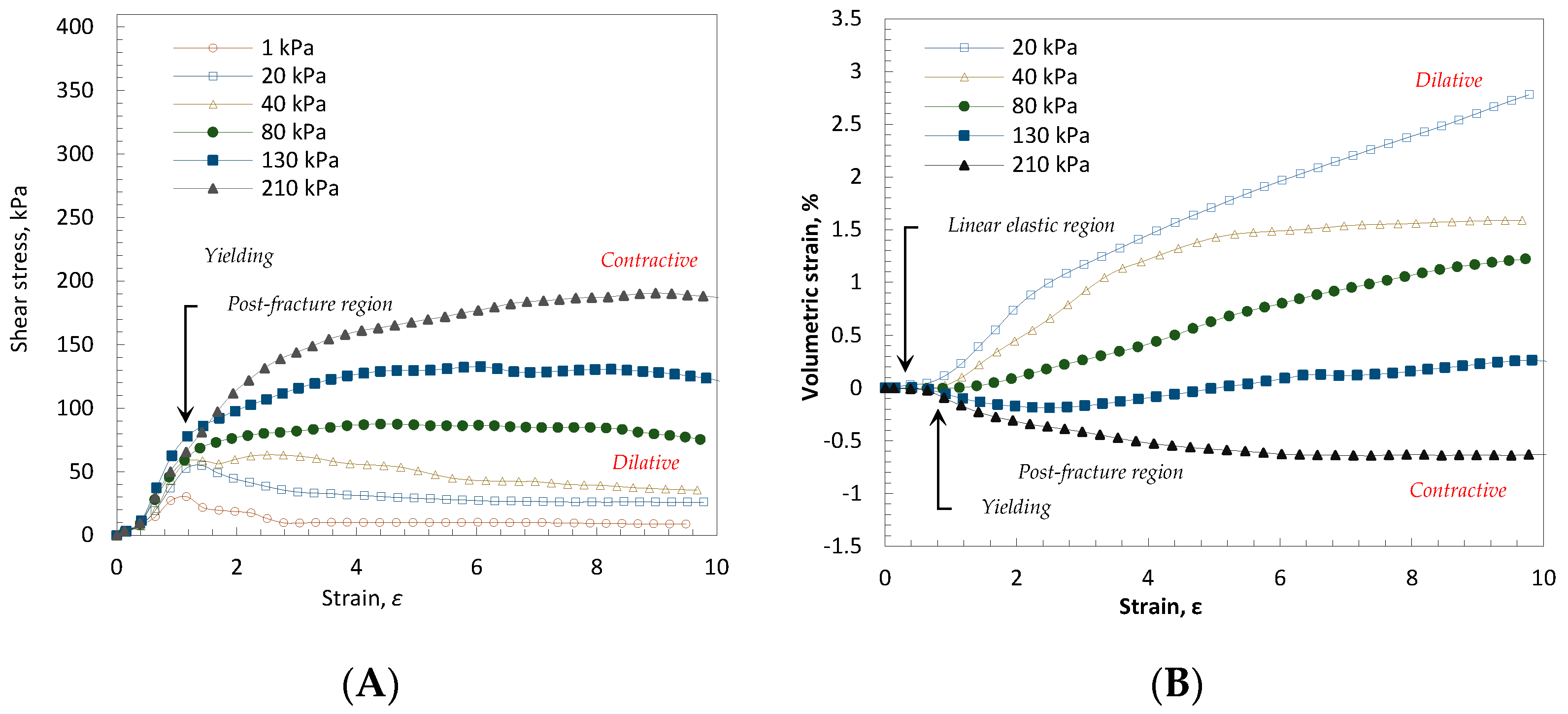

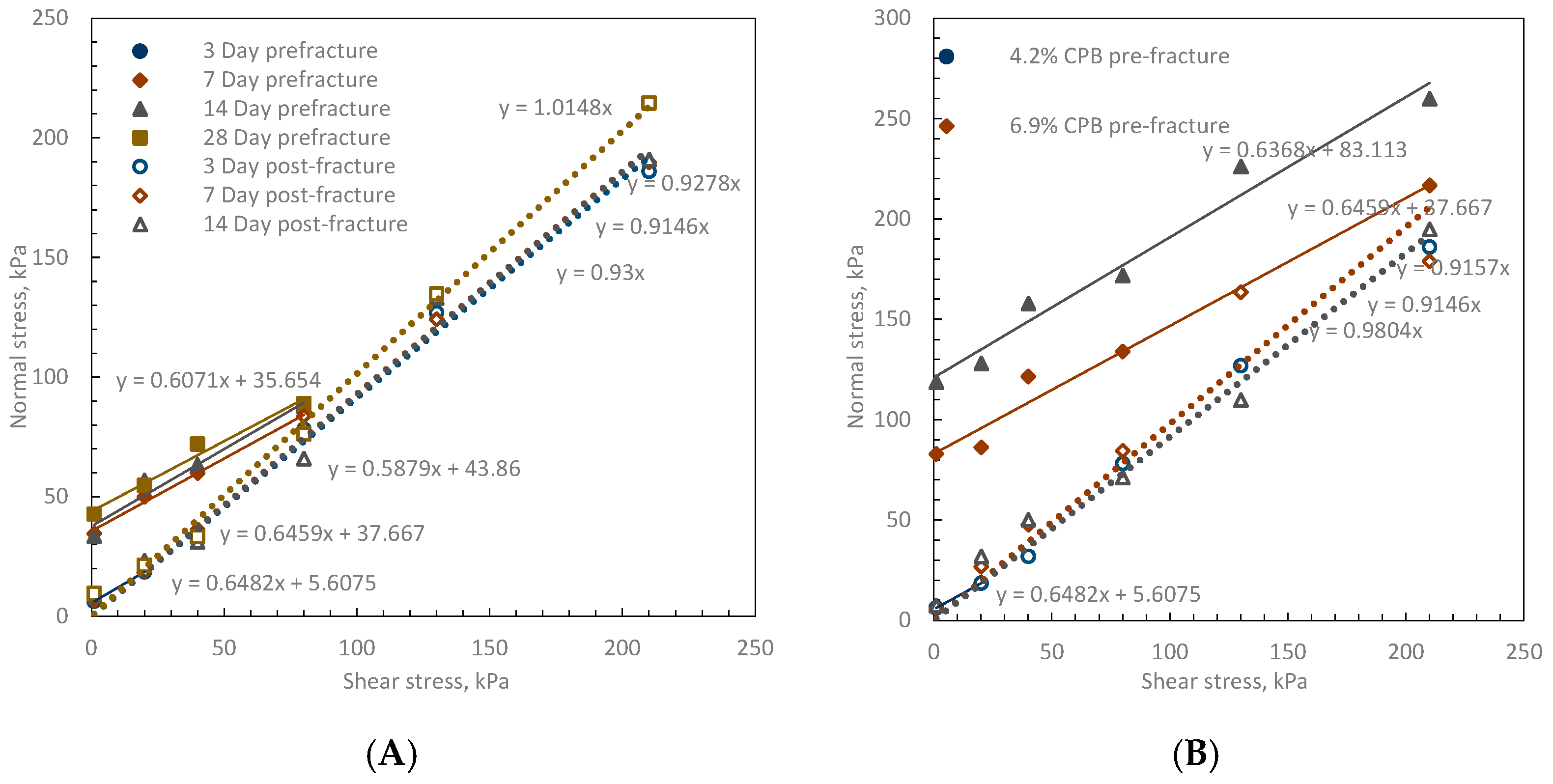

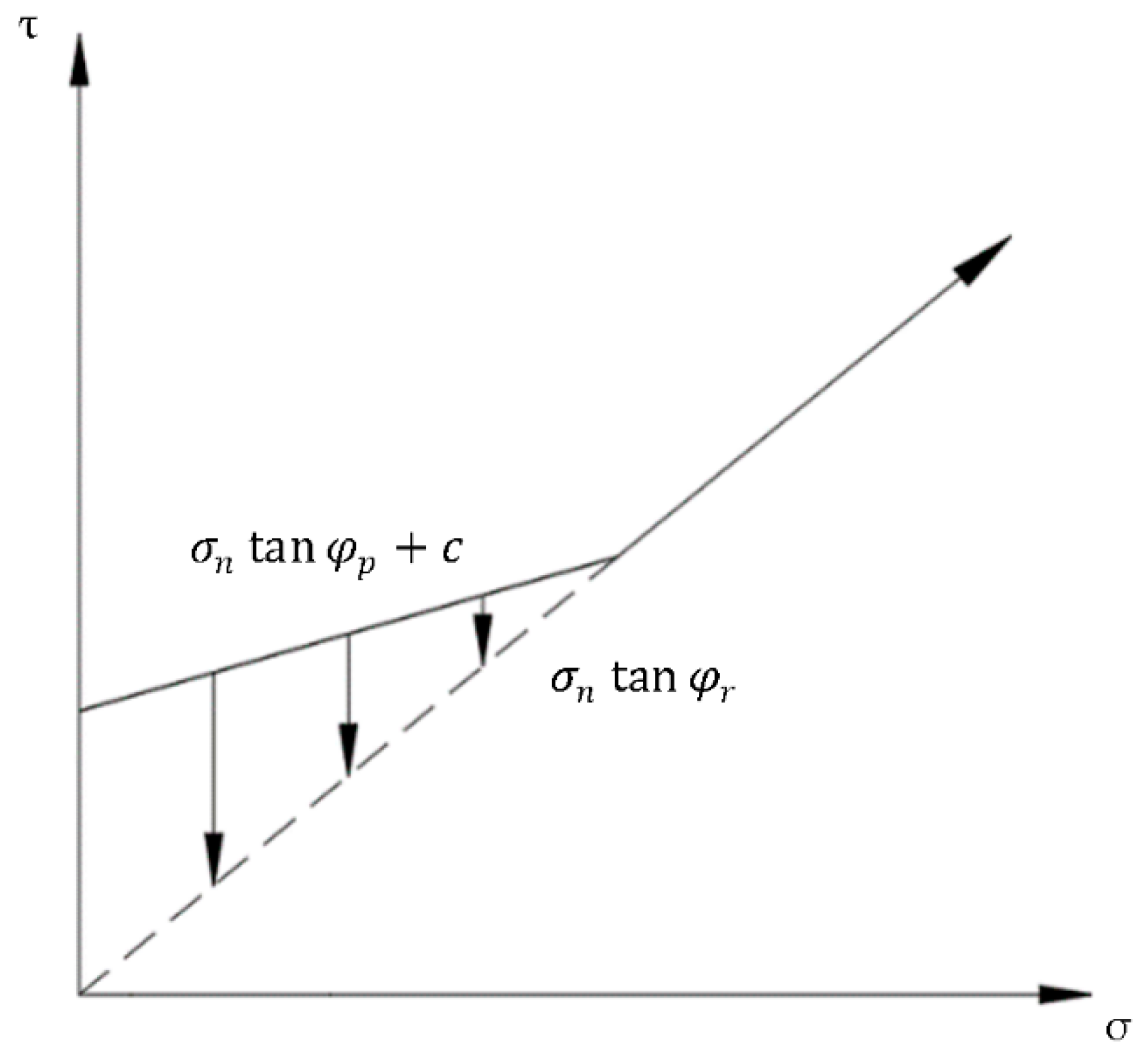

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mitchell, R.J.; Olsen, R.S.; Smith, J.D. Model studies on cemented tailings used in mine backfill. Can. Geotech. J. 1982, 19, 14–28. [Google Scholar] [CrossRef]

- Hassani, F.; Archibald, J. Mine Backfill; Canadian Institute of Mining, Metallurgy and Petroleum: Montreal, QC, Canada, 1998. [Google Scholar]

- Paterson & Cooke Canada Inc. Mine Backfill Design & Operation Course; Patterson & Cooke: Sudbury, ON, Canada, 2019. [Google Scholar]

- Mitchell, R.J. Sill mat evaluation using centrifuge models. Min. Sci. Technol. 1991, 13, 301–313. [Google Scholar] [CrossRef]

- Grabinsky, M. In situ monitoring for ground truthing paste backfill designs. In Paste 2010: Proceedings of the Thirteenth International Seminar on Paste and Thickened Tailings; Jewell, R., Fourie, A.B., Eds.; Australian Centre for Geomechanics: Perth, Australia, 2010; pp. 85–98. [Google Scholar] [CrossRef] [Green Version]

- Pakalnis, R.; Caceres, C.; Clapp, K.; Morin, M.; Brady, T.; Williams, T.; Blake, W.; MacLaughlin, M. Design Spans—Underhand Cut and Fill Mining. In Proceedings of the 107th Canadian Institute of Mining Annual General Meeting, Toronto, ON, Canada, 1–9 April 2005. [Google Scholar]

- De Souza, E.; Archibald, J.F.; Dirige, A.P. Underground Backfill Practices in Canadian Mines. In Proceedings of the 6th North America Rock Mechanics Symposium (NARMS), Houston, TX, USA, 5–9 June 2004. [Google Scholar]

- Keita, A.M.T.; Jahanbakhshzadeh, A.; Li, L. Numerical analysis of the failure mechanisms of sill mats made of cemented backfill. Int. J. Geotech. Eng. 2021, 16, 802–814. [Google Scholar] [CrossRef]

- Grabinsky, M.; Jafari, M.; Pan, A. Cemented Paste Backfill (CPB) Material Properties for Undercut Analysis. Mining 2022, 2, 7. [Google Scholar] [CrossRef]

- le Roux, K.; Bawden, W.F.; Grabinsky, M. Field properties of cemented paste backfill at the Golden Giant mine. Min. Technol. 2005, 114, 65–80. [Google Scholar] [CrossRef]

- Koupouli, N.J.; Belem, T.; Rivard, P.; Effenguet, H. Direct shear tests on cemented paste backfill–rock wall and cemented paste backfill–backfill interfaces. JRMGE 2016, 8, 472–479. [Google Scholar] [CrossRef] [Green Version]

- Fall, M.; Belem, T.; Samb, S.; Benzaazoua, M. Experimental characterization of the stress–strain behaviour. J. Mater. Sci. 2007, 42, 3914–3922. [Google Scholar] [CrossRef]

- Grabinsky, M.; Pan, A. Cemented paste backfill failure envelope at low confining stress. In Proceedings of the 13th International Symposium on Mining with Backfill, Katowice, Poland, 25–27 May 2021. [Google Scholar]

- Pan, A.; Grabinsky, M. Tensile Strength of Cemented Paste Backfill. Geotech. Test. J. 2021, 44, 1886–1897. [Google Scholar] [CrossRef]

- Pan, A.; Grabinsky, M.; Guo, L. Shear Properties of Cemented Paste Backfill under Low Confining Stress. Adv. Civ. Eng. 2021, 2021, 7561977. [Google Scholar] [CrossRef]

- Nasir, O.; Fall, M. Shear behaviour of cemented pastefill-rock interfaces. Eng. Geol. 2008, 101, 146–153. [Google Scholar] [CrossRef]

- Veenstra, R.L. A Design Procedure for Determining the In Situ Stresses of Early Age Cemented Paste Backfill. Ph.D. Thesis, University of Toronto, Toronto, ON, Canada, 2013. Available online: tspace.library.utoronto.ca/bitstream/1807/36027/1/Veenstra_Ryan_L_201306_PhD_thesis.pdf (accessed on 10 October 2022).

- Grabinsky, M.; Bawden, W.; Simon, D.; Thompson, R.; Veenstra, R. In Situ Properties of Cemented Paste Backfill from Three Mines. In Proceedings of the 66th Canadian Geotechnical Conference, Montreal, QC, Canada, 29 September–3 October 2013. [Google Scholar]

- Roscoe Postle Associates. Technical Report on the Hemlo Mine; Barrick Gold Corporation: Marathon, ON, Canada, 2017. [Google Scholar]

- Jafari, M. Experimental Study of Physical and Mechanical Properties of a Cemented Mine Tailings. Ph.D. Thesis, University of Toronto, Toronto, ON, Canada, 2020. Available online: tspace.library.utoronto.ca/handle/1807/101293 (accessed on 10 October 2022).

- ASTM D3080-04; Standard Test Method for Direct Shear Test of Soils Under Consolidated Drained Conditions. ASTM Standard; ASTM International: West Conshohocken, PA, USA, 2020.

- Casagrande, A. Characteristics of Cohesionless Soils Affecting the Stability of Slopes and Earth Fills. J. Boston Soc. Civ. Eng. 1936, 23, 13–32. [Google Scholar]

- Knappett, J.A.; Graig, R.F. Graig’s Soil Mechanics, 8th ed.; Taylor & Francis: New York, NY, USA, 2012. [Google Scholar]

- Roscoe, K.H.; Schofield, A.N.; Wroth, C.P. On the Yielding of Soils. Géotechnique 1958, 8, 22–53. [Google Scholar] [CrossRef]

- Quiroga, A.J.; Thompson, Z.M.; Muraleetharan, K.K.; Miller, G.A.; Cerato, A.B. Stress–strain behavior of cement-improved clays: Testing and modeling. Acta Geotech. 2017, 12, 1003–1020. [Google Scholar] [CrossRef]

| Chemical composition | CaO | SiO2 | SO3 | Al2O3 | MgO | Fe2O3 | K2O | Na2O | |||

| Mill tailings (wt.%) | 64.2 | 20.0 | 4.1 | 3.9 | 3.1 | 3.0 | 0.5 | 0.2 | |||

| Chemical composition | SiO2 | Al2O3 | CaO | MgO | K2O | Na2O | Fe2O3 | S | TiO2 | P2O5 | Ba |

| Binder (wt.%) | 59.8 | 12.2 | 3.6 | 3.5 | 3.4 | 3.2 | 2.4 | 0.6 | 0.4 | 0.2 | 0.1 |

| Binder Content, (wt.%) | Curing Time, Days | Stress Intervals, kPa | Number of Samples |

|---|---|---|---|

| 4.2 | 3, 7, 14, 28 | 1, 20, 40, 80, 130, 210 | 24 |

| 6.9 | 3, 7, 14, 28 | 1, 20, 40, 80, 130, 210 | 24 |

| 9.7 | 3, 7, 14, 28 | 1, 20, 40, 80, 130, 210 | 24 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, A.; Grabinsky, M. Yield Characteristics of Cemented Paste Backfill. CivilEng 2022, 3, 1053-1060. https://doi.org/10.3390/civileng3040059

Pan A, Grabinsky M. Yield Characteristics of Cemented Paste Backfill. CivilEng. 2022; 3(4):1053-1060. https://doi.org/10.3390/civileng3040059

Chicago/Turabian StylePan, Andrew, and Murray Grabinsky. 2022. "Yield Characteristics of Cemented Paste Backfill" CivilEng 3, no. 4: 1053-1060. https://doi.org/10.3390/civileng3040059

APA StylePan, A., & Grabinsky, M. (2022). Yield Characteristics of Cemented Paste Backfill. CivilEng, 3(4), 1053-1060. https://doi.org/10.3390/civileng3040059