Effect of Geo-Grid Depth in Roads Cross-Section on Reducing Pavement Rutting

Abstract

:1. Introduction

2. Methodology

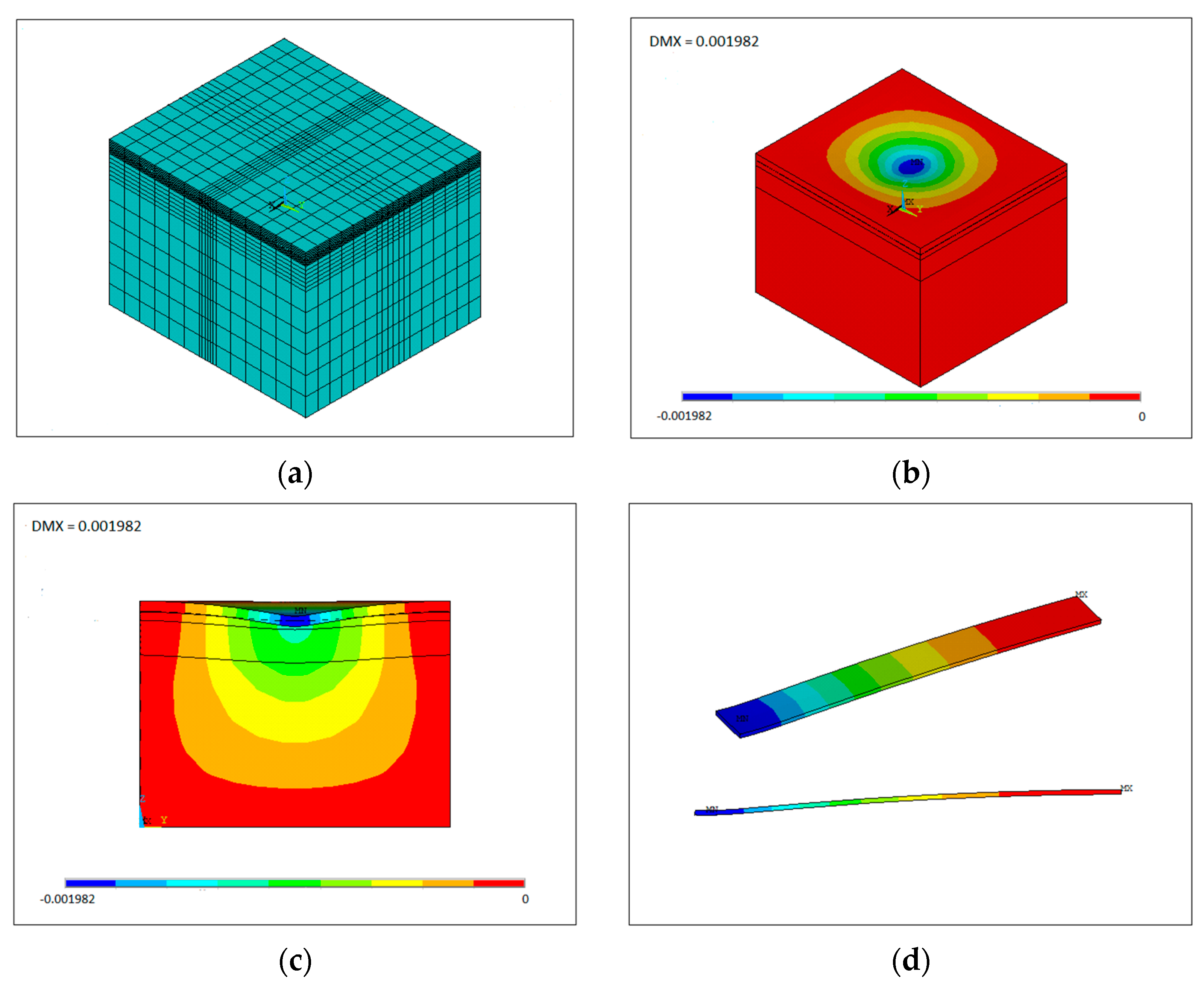

3. Numerical Model

3.1. Geometry and Material Properties Defined in Numerical Model

3.2. Boundary Conditions

- The base of the model was vertically constrained;

- The sides of the model were horizontally constrained corresponding to its axis;

- The top of the model was not constrained; however, it had a load applied to its center.

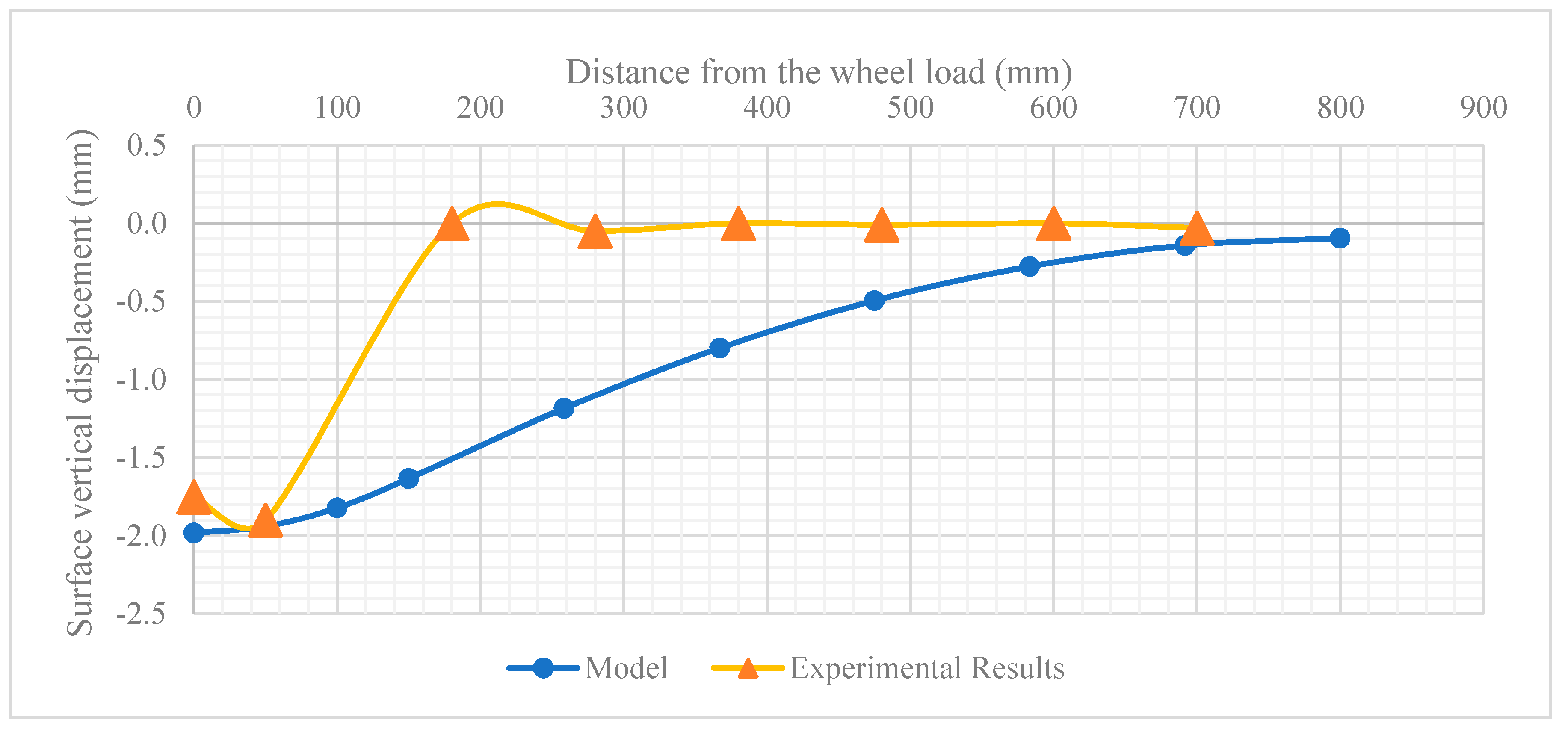

3.3. Validation of Numerical Model

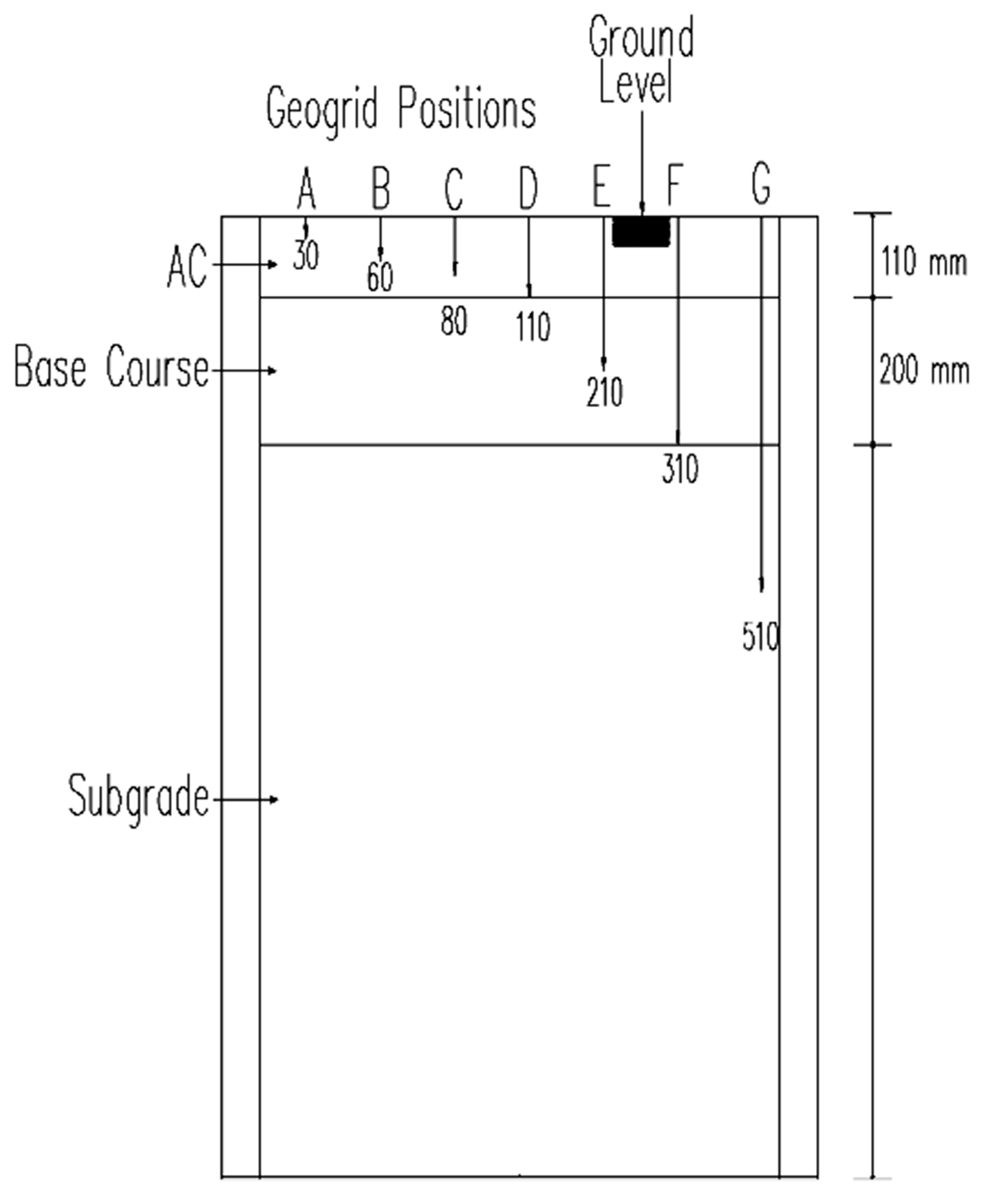

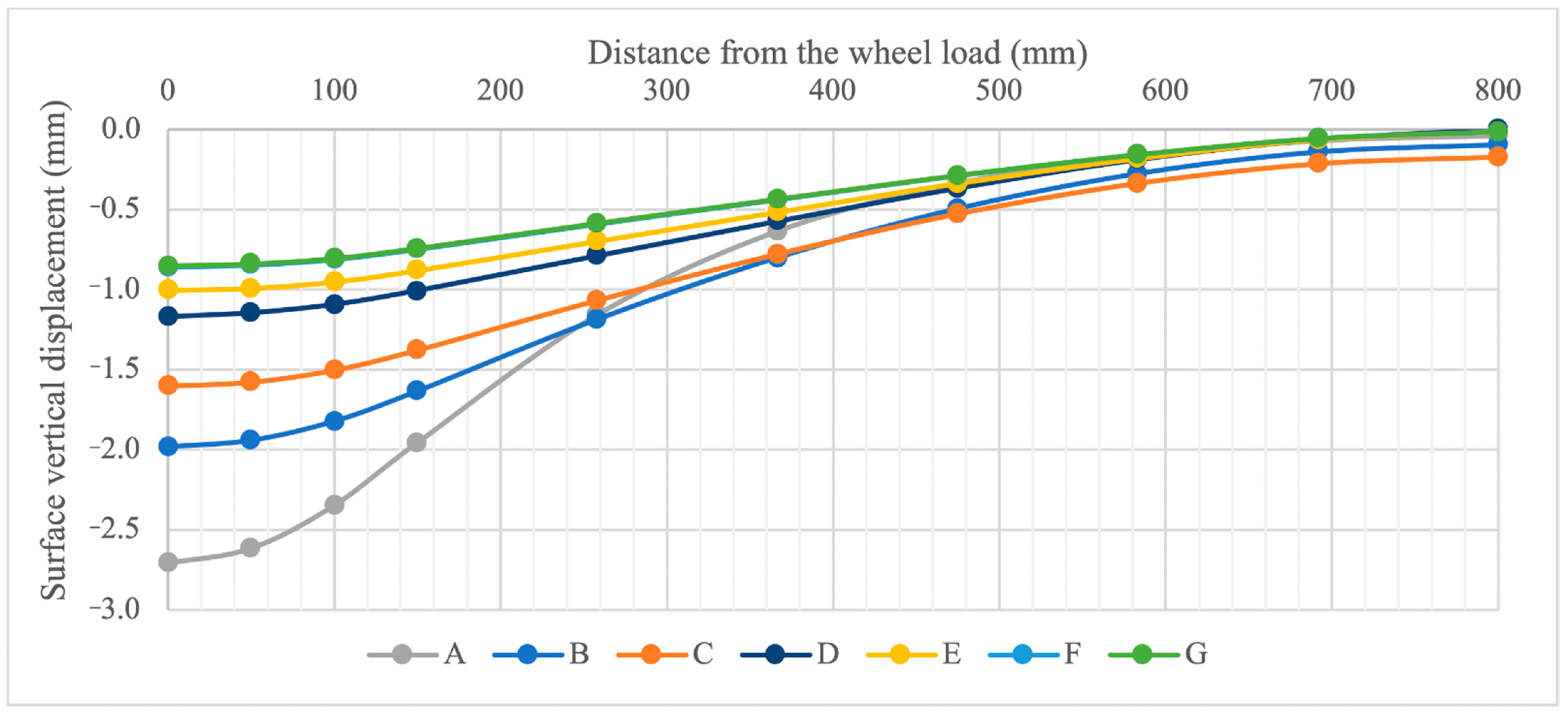

4. Finite Element Geo-Grid Position Effect on Reducing Rutting

5. Conclusions

- A validated 3-D finite elements model is a great tool to assess the performance of a pavement structure and to apply many parametric studies to it. The finite element model was able to show the asphalt surface vertical displacements and vertical stress distributions in pavement layers with acceptable accuracy.

- The model does not show the asphalt upheaval area beside the wheel path that is seen in the experiment, which could be due to using a linear elastic constitutive model.

- Asphalt surface vertical displacement was observed with different geo-grid depth positioning; the deeper the geo-grid is positioned, the more significant the rutting resistance is observed due to stiffness of the geo-grid bearing the tensile force until a certain depth.

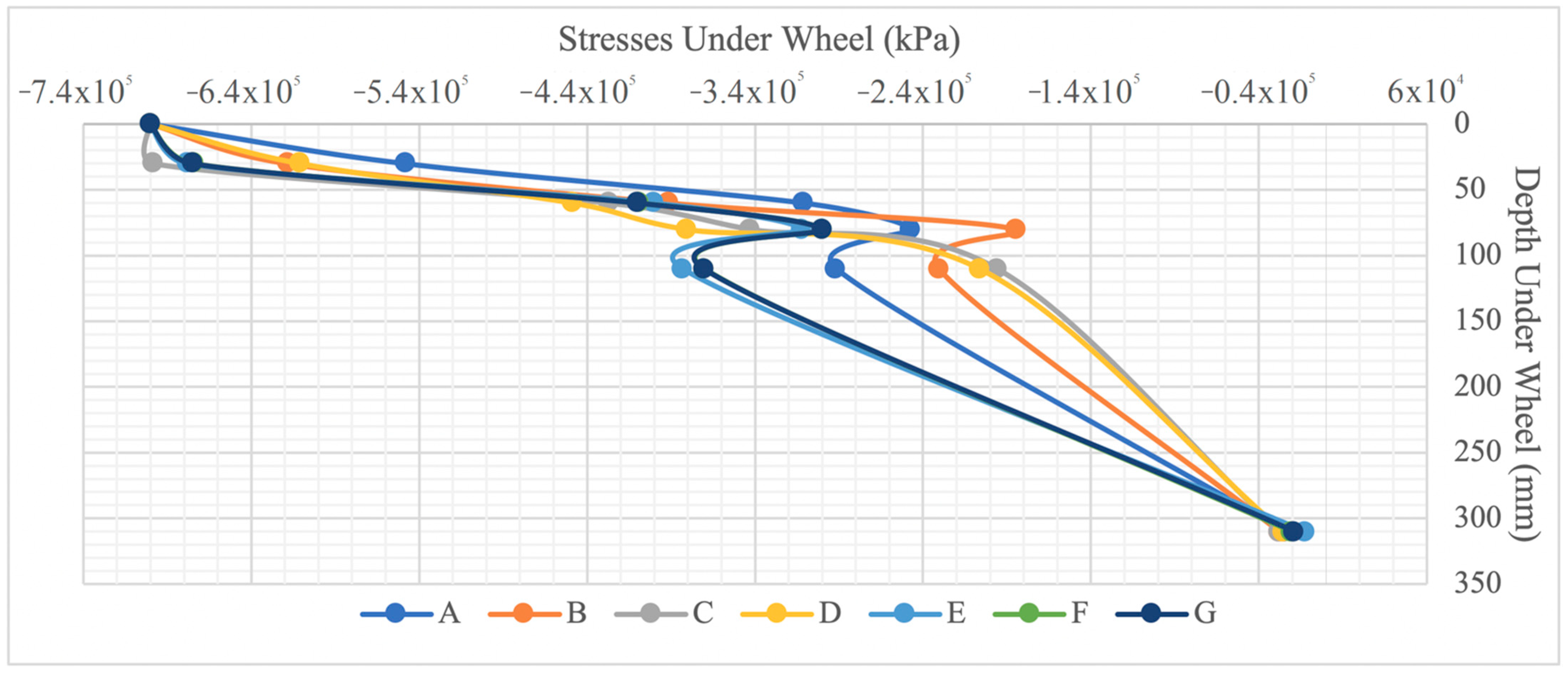

- Vertical compressive stresses under the wheel were also observed with different geo-grid depth positioning and showed noticeable stress reduction by increasing the depth of the geo-grid alone without having to change the geo-grid stiffness.

- For pavement structures constructed over weak subgrade layers, the geo-grid should be placed in the layers above the subgrade to reduce the stresses before they reach the weak subgrade layers.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Du, Y.; Chen, J.; Han, Z.; Liu, W. A review on solutions for improving rutting resistance of asphalt pavement and test methods. Constr. Build. Mater. 2018, 168, 893–905. [Google Scholar] [CrossRef]

- Hammoum, F.; Chabot, A.; St-Laurent, D.; Chollet, H.; Vulturescu, B. Effects of accelerating and decelerating tramway loads on bituminous pavement. Mater. Struct. 2009, 43, 1257–1269. [Google Scholar] [CrossRef]

- Shukla, P.K.; Das, A. A re-visit to the development of fatigue and rutting equations used for asphalt pavement design. Int. J. Pavement Eng. 2008, 9, 355–364. [Google Scholar] [CrossRef]

- Faruk, A.N.; Lee, S.I.; Zhang, J.; Naik, B.; Walubita, L.F. Measurement of HMA shear resistance potential in the lab: The Simple Punching Shear Test. Constr. Build. Mater. 2015, 99, 62–72. [Google Scholar] [CrossRef]

- Norouzi, A.; Kim, D.; Kim, Y.R. Numerical evaluation of pavement design parameters for the fatigue cracking and rutting performance of asphalt pavements. Mater. Struct. 2015, 49, 3619–3634. [Google Scholar] [CrossRef]

- Domingos, M.I.; Faxina, A.L. Susceptibility of Asphalt Binders to Rutting: Literature Review. J. Mater. Civ. Eng. 2016, 28, 04015134. [Google Scholar] [CrossRef]

- Wang, H.; Al-Qadi, I.L. Evaluation of Surface-Related Pavement Damage due to Tire Braking. Road Mater. Pavement Des. 2010, 11, 101–121. [Google Scholar] [CrossRef]

- Li, L.; Huang, X.; Wang, L.; Li, C. Integrated Experimental and Numerical Study on Permanent Deformation of Asphalt Pavement at Intersections. J. Mater. Civ. Eng. 2013, 25, 907–912. [Google Scholar] [CrossRef]

- Morea, F.; Agnusdei, J.O.; Zerbino, R. The use of asphalt low shear viscosity to predict permanent deformation performance of asphalt concrete. Mater. Struct. 2010, 44, 1241–1248. [Google Scholar] [CrossRef]

- Bildik, S.; Laman, M. Effect of geogrid reinforcement on soil-structure–pipe interaction in terms of bearing capacity, settlement and stress distribution. Geotext. Geomembr. 2020, 48, 844–853. [Google Scholar] [CrossRef]

- Qadir, A.; Gazder, U.; Choudhary, K.-U. Statistical analysis for comparing and predicting rutting resistance of asphalt pavements with rigid and flexible geogrid layers. Constr. Build. Mater. 2021, 302, 124136. [Google Scholar] [CrossRef]

- Siriwardane, H.; Gondle, R.; Kutuk, B. Analysis of Flexible Pavements Reinforced with Geogrids. Geotech. Geol. Eng. 2008, 28, 287–297. [Google Scholar] [CrossRef]

- Sharbaf, M.; Ghafoori, N. Laboratory evaluation of geogrid-reinforced flexible pavements. Transp. Eng. 2021, 4, 100070. [Google Scholar] [CrossRef]

- Mittal, A.; Shalinee, S. Effect of Geogrid Reinforcement on Strength, Thickness and Cost of Low-volume Rural Roads. Jordan J. Civ. Eng. 2020, 14, 587–597. [Google Scholar]

- Baadiga, R.; Balunaini, U.; Saride, S.; Madhav, M.R. Influence of Geogrid Properties on Rutting and Stress Distribution in Reinforced Flexible Pavements under Repetitive Wheel Loading. J. Mater. Civ. Eng. 2021, 33, 04021338. [Google Scholar] [CrossRef]

- Larrain, M.M.M.; Tarefder, R.A. Weibull Model for Rutting Prediction of Warm-Mix Asphalt Agents: Using Hamburg Wheel-Tracking Device Results. Transp. Res. Rec. J. Transp. Res. Board 2016, 2575, 206–212. [Google Scholar] [CrossRef]

- Mitchell, M.R.; Link, R.E.; Hong, F.; Chen, D.-H. Calibrating Mechanistic-Empirical Design Guide Permanent Deformation Models Based on Accelerated Pavement Testing. J. Test. Eval. 2009, 37, 31–39. [Google Scholar] [CrossRef]

- Ji, X.; Zheng, N.; Hou, Y.; Niu, S. Application of asphalt mixture shear strength to evaluate pavement rutting with accelerated loading facility (ALF). Constr. Build. Mater. 2013, 41, 1–8. [Google Scholar] [CrossRef]

- Pandey, S.; Rao, K.R.; Tiwari, D. Effect of geogrid reinforcement on critical responses of bituminous pavements. In Proceedings of the 25th ARRB Conference, Perth, Australia, 23–26 September 2012. [Google Scholar]

- Faheem, H.; Hassan, A.M. 2D plaxis finite element modeling of asphalt-concrete pavement reinforced with geogrid. JES J. Eng. Sci. 2014, 42, 1336–1348. [Google Scholar] [CrossRef]

- Taherkhani, H.; Jalali, M. Investigating the performance of geosynthetic-reinforced asphaltic pavement under various axle loads using finite-element method. Road Mater. Pavement Des. 2016, 18, 1200–1217. [Google Scholar] [CrossRef]

- Al-Jumaili, M.A. Finite element modelling of asphalt concrete pavement reinforced with geogrid by using 3-D plaxis software. Int. J. Mater. Chem. Phys. 2016, 3, 62–70. [Google Scholar]

- Correia, N.S.; Esquivel, E.R.; Zornberg, J.G. Finite-Element Evaluations of Geogrid-Reinforced Asphalt Overlays over Flexible Pavements. J. Transp. Eng. Part. B Pavements 2018, 144, 04018020. [Google Scholar] [CrossRef]

- Correia, N.S. Performance of Flexible Pavements Enhanced Using Geogrid-Reinforced Asphalt Overlays. Doctoral Dissertation, Sao Carlos School of Engineering of the University of Sao Paulo, Sao Carlos, Brazil, 2014. [Google Scholar] [CrossRef] [Green Version]

- Kohnke, P. ANSYS Theory Reference; ANSYS, Inc.: Canonsburg, PA, USA, 1999. [Google Scholar]

| Material | Subgrade | Base Course | Bottom Asphalt | Top Asphalt |

|---|---|---|---|---|

| Thickness | 1000 mm | 200 mm | 50 mm | 60 mm |

| Unit Weight | 18 kN/m3 | 22 kN/m3 | 25 kN/m3 | 25 kN/m3 |

| Cohesion | 46 kPa | 0.01 kPa | - | - |

| Friction Angle | 26° | 45° | - | - |

| Poisson’s Ratio | 0.40 | 0.30 | 0.35 | 0.35 |

| Young’s Modulus | 10 MPa | 100 MPa | 2500 MPa | 2500 MPa |

| Constitutive Model | Linear Elastic | Linear Elastic | Linear Elastic | Linear Elastic |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alharbi, F.; Almoshaigeh, A.; Almoshaogeh, M.; Elragi, A.; Elkholy, S. Effect of Geo-Grid Depth in Roads Cross-Section on Reducing Pavement Rutting. Eng 2022, 3, 1-8. https://doi.org/10.3390/eng3010001

Alharbi F, Almoshaigeh A, Almoshaogeh M, Elragi A, Elkholy S. Effect of Geo-Grid Depth in Roads Cross-Section on Reducing Pavement Rutting. Eng. 2022; 3(1):1-8. https://doi.org/10.3390/eng3010001

Chicago/Turabian StyleAlharbi, Fawaz, Ahmed Almoshaigeh, Meshal Almoshaogeh, Ahmed Elragi, and Sherif Elkholy. 2022. "Effect of Geo-Grid Depth in Roads Cross-Section on Reducing Pavement Rutting" Eng 3, no. 1: 1-8. https://doi.org/10.3390/eng3010001

APA StyleAlharbi, F., Almoshaigeh, A., Almoshaogeh, M., Elragi, A., & Elkholy, S. (2022). Effect of Geo-Grid Depth in Roads Cross-Section on Reducing Pavement Rutting. Eng, 3(1), 1-8. https://doi.org/10.3390/eng3010001